Crystal Plasticity Finite Element Analyses on the Formability of AA6061 Aluminum Alloy with Different Ageing Treatments

Abstract

:1. Introduction

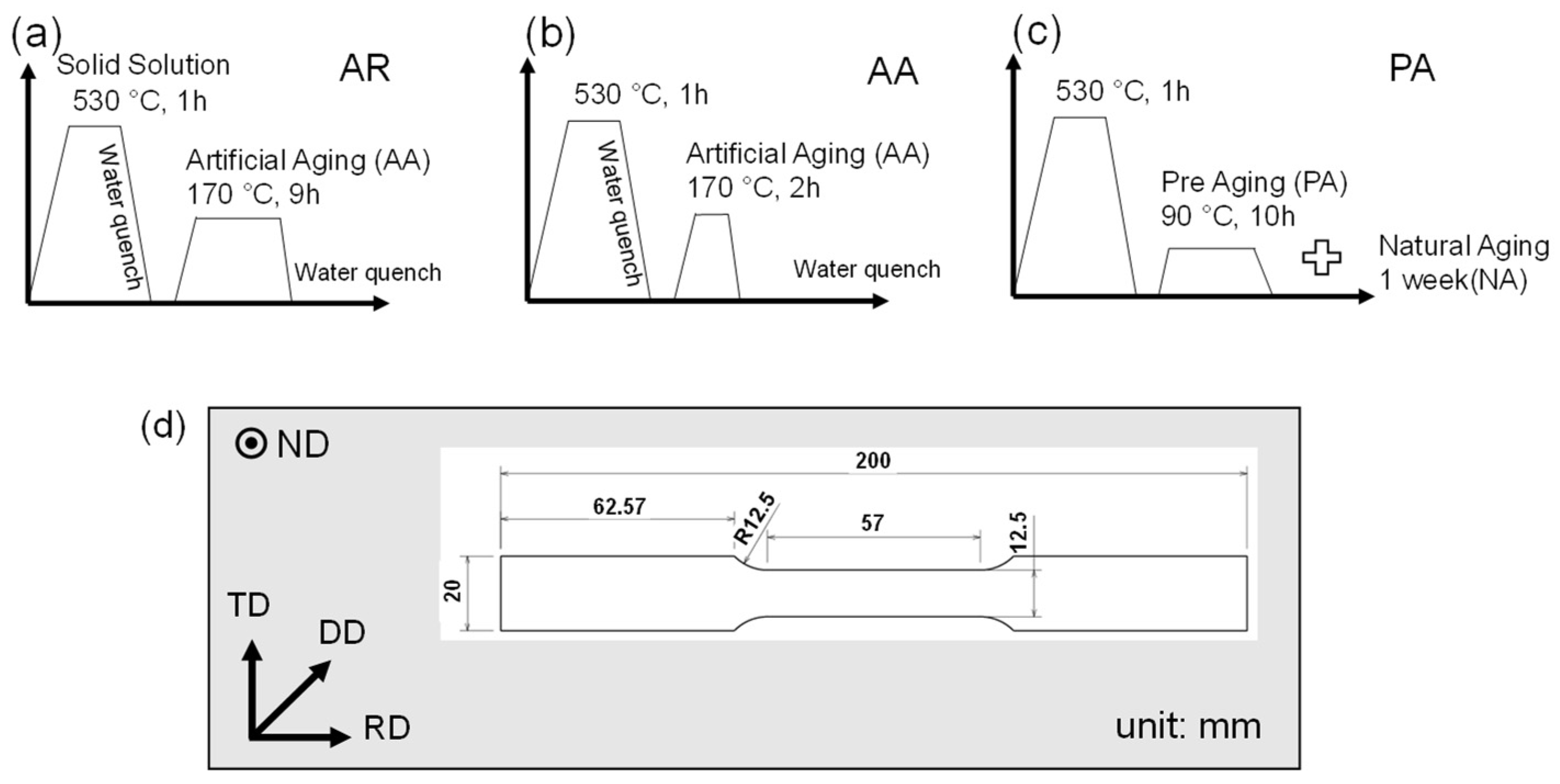

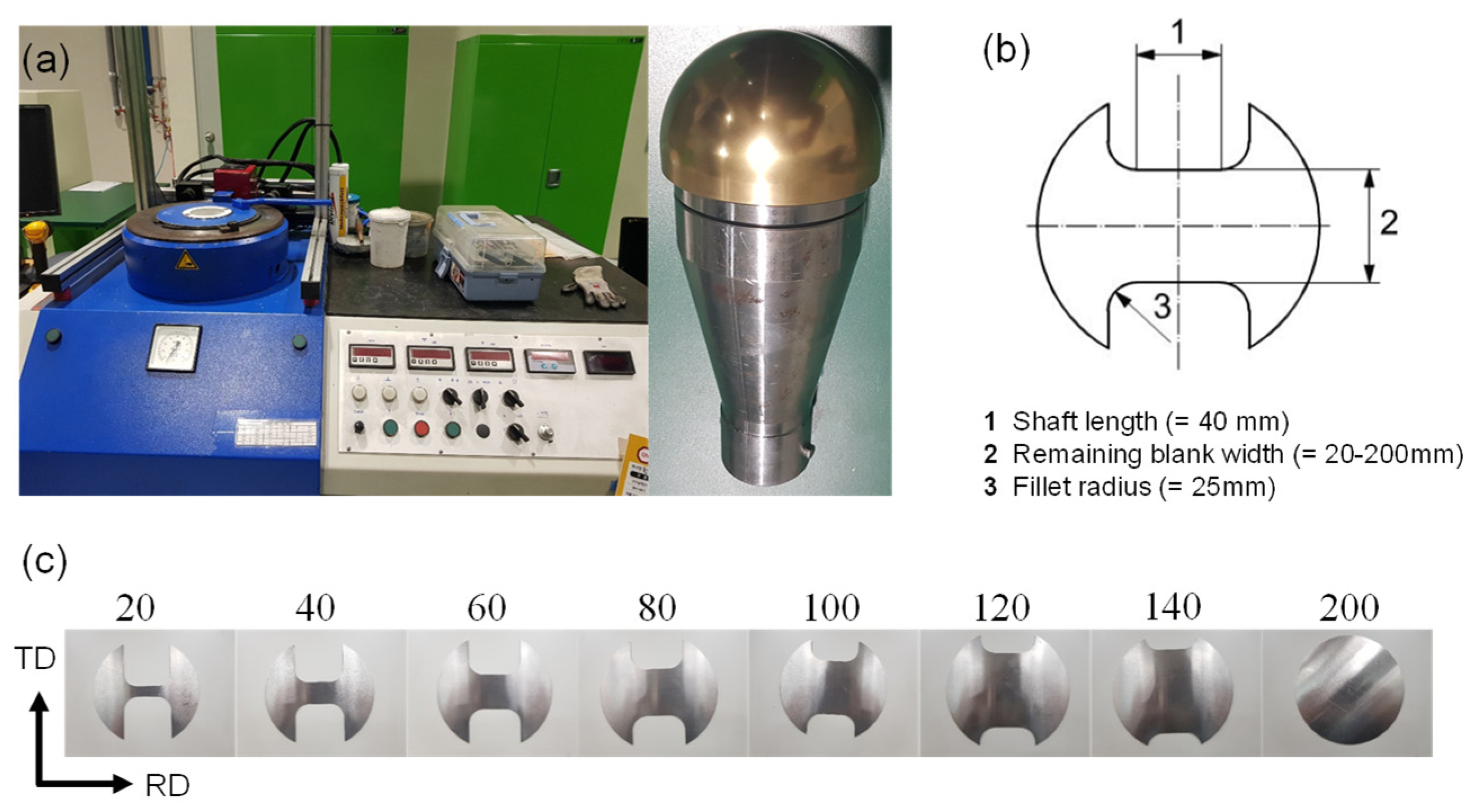

2. Experimental Procedure

3. Numerical Modeling

3.1. Crystal Plasticity Model

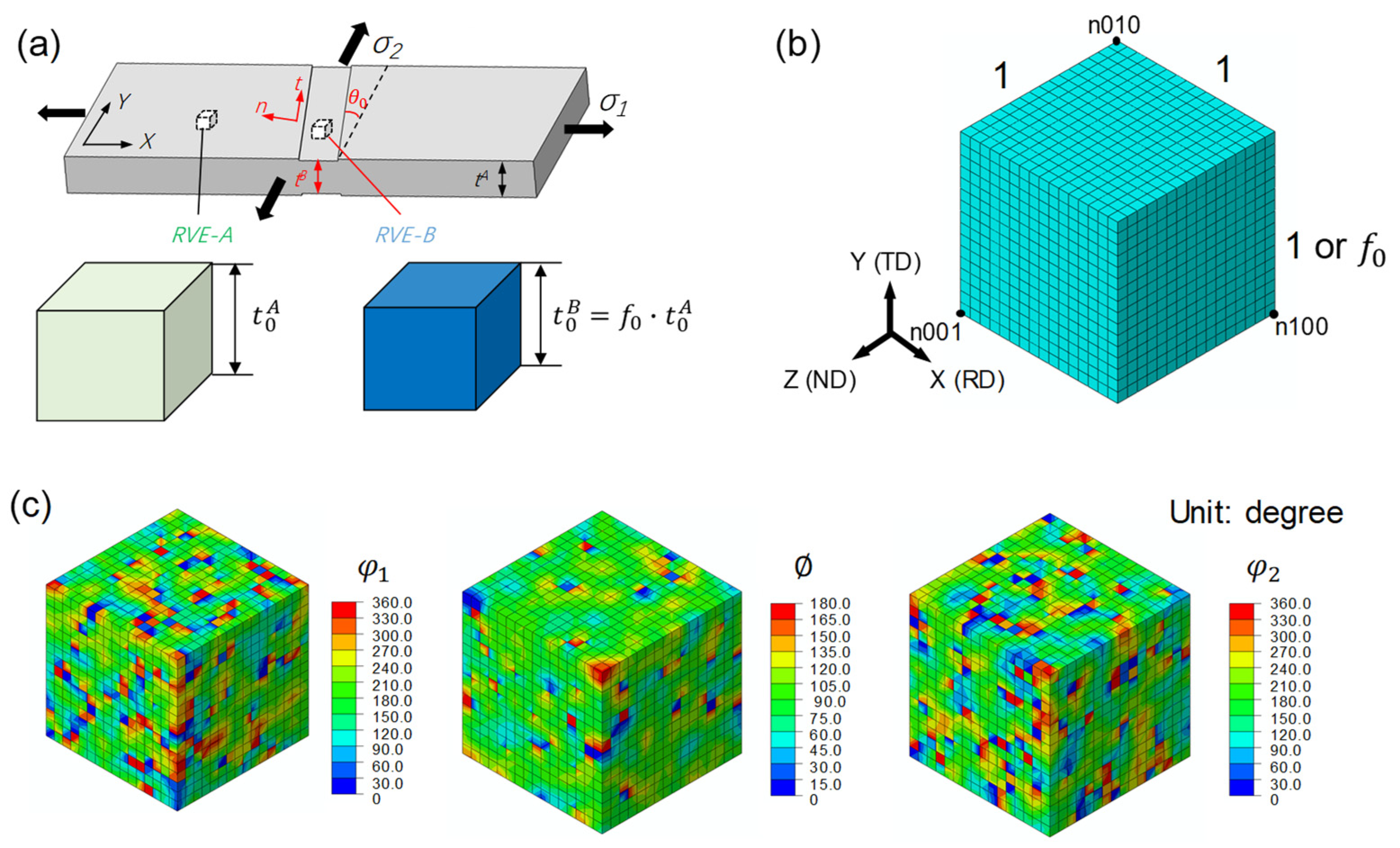

3.2. Implementation of the M-K Approach

3.3. Finite Element Model

4. Results and Discussion

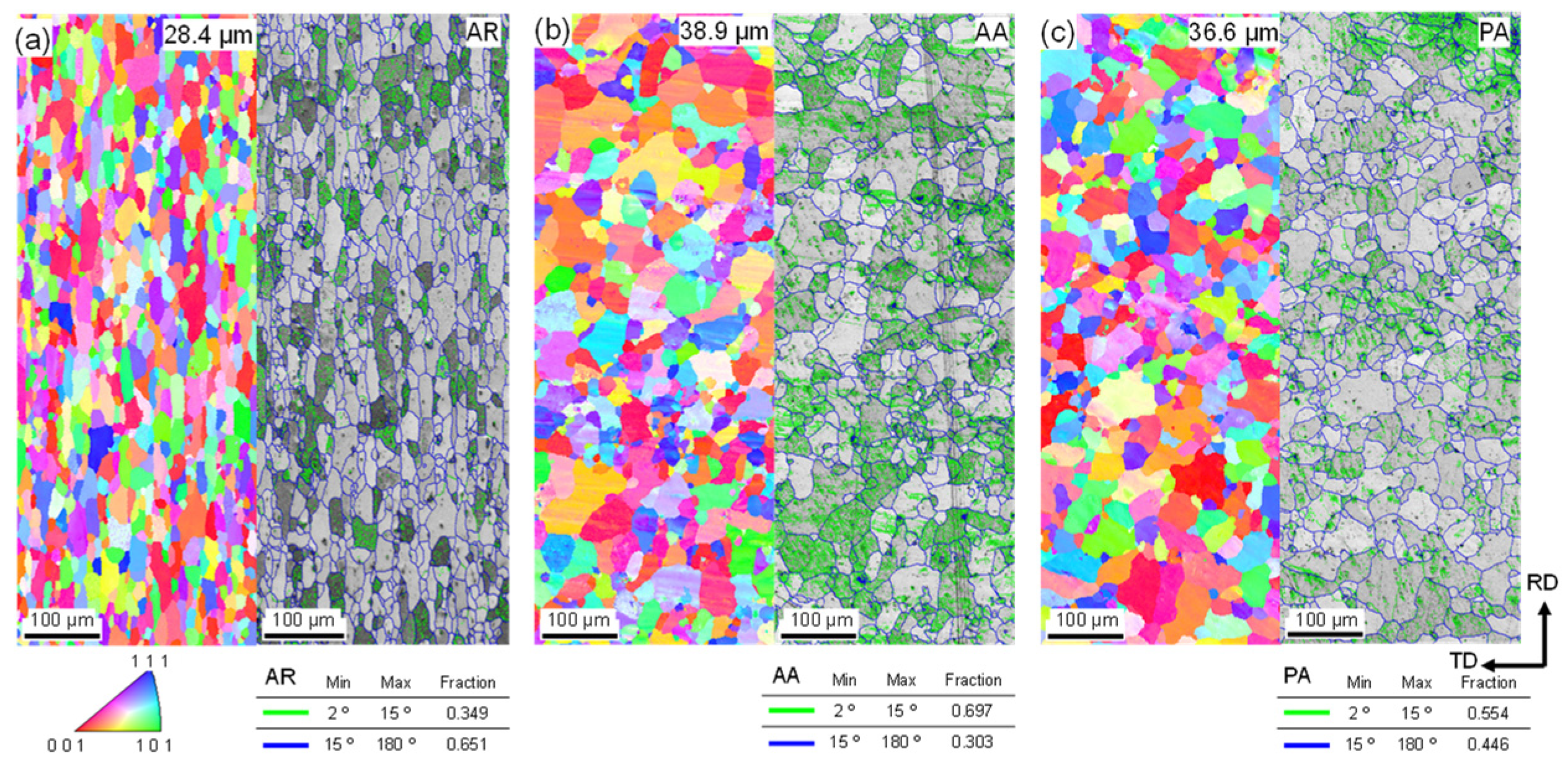

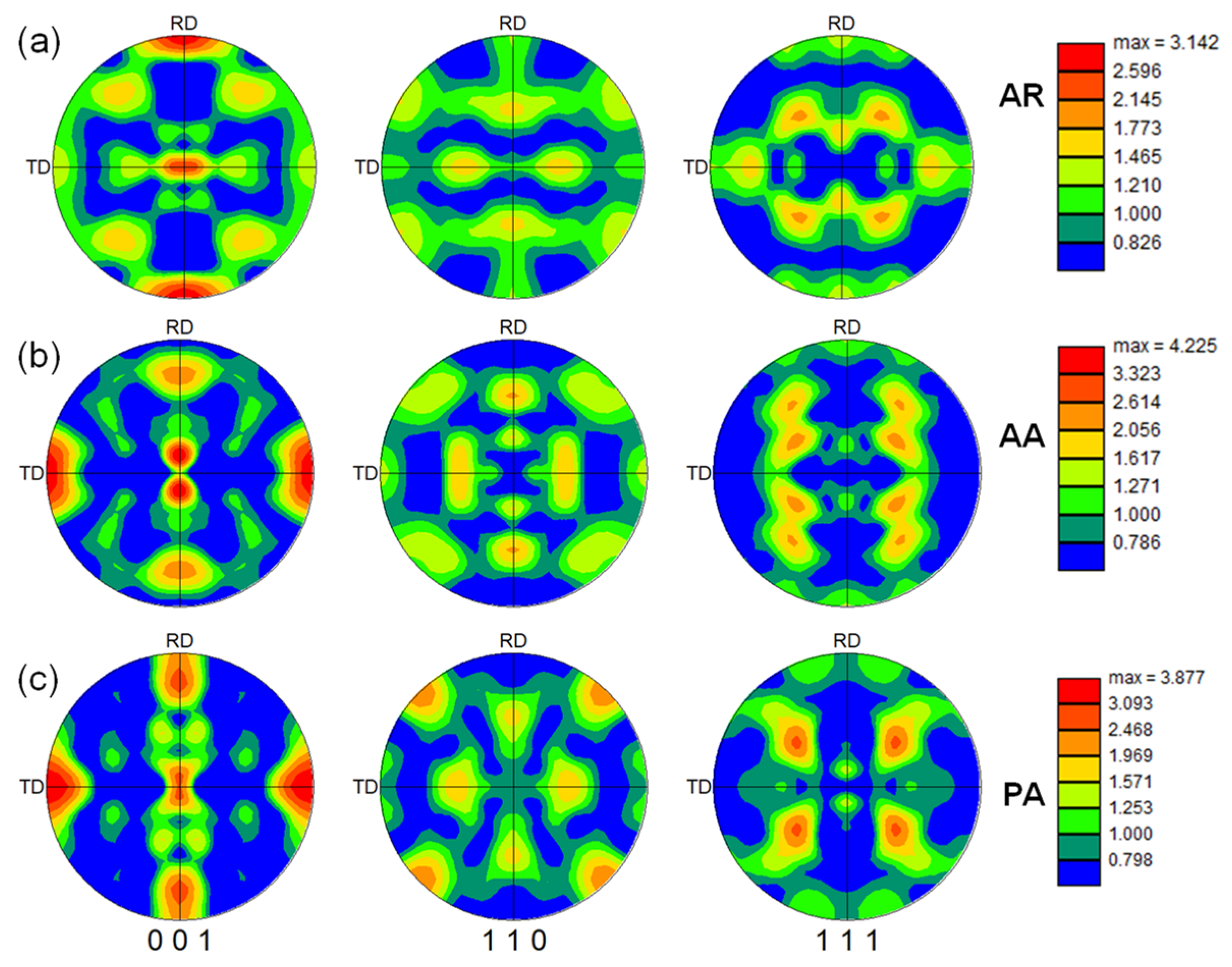

4.1. Initial Microstructure and Crystallographic Texture

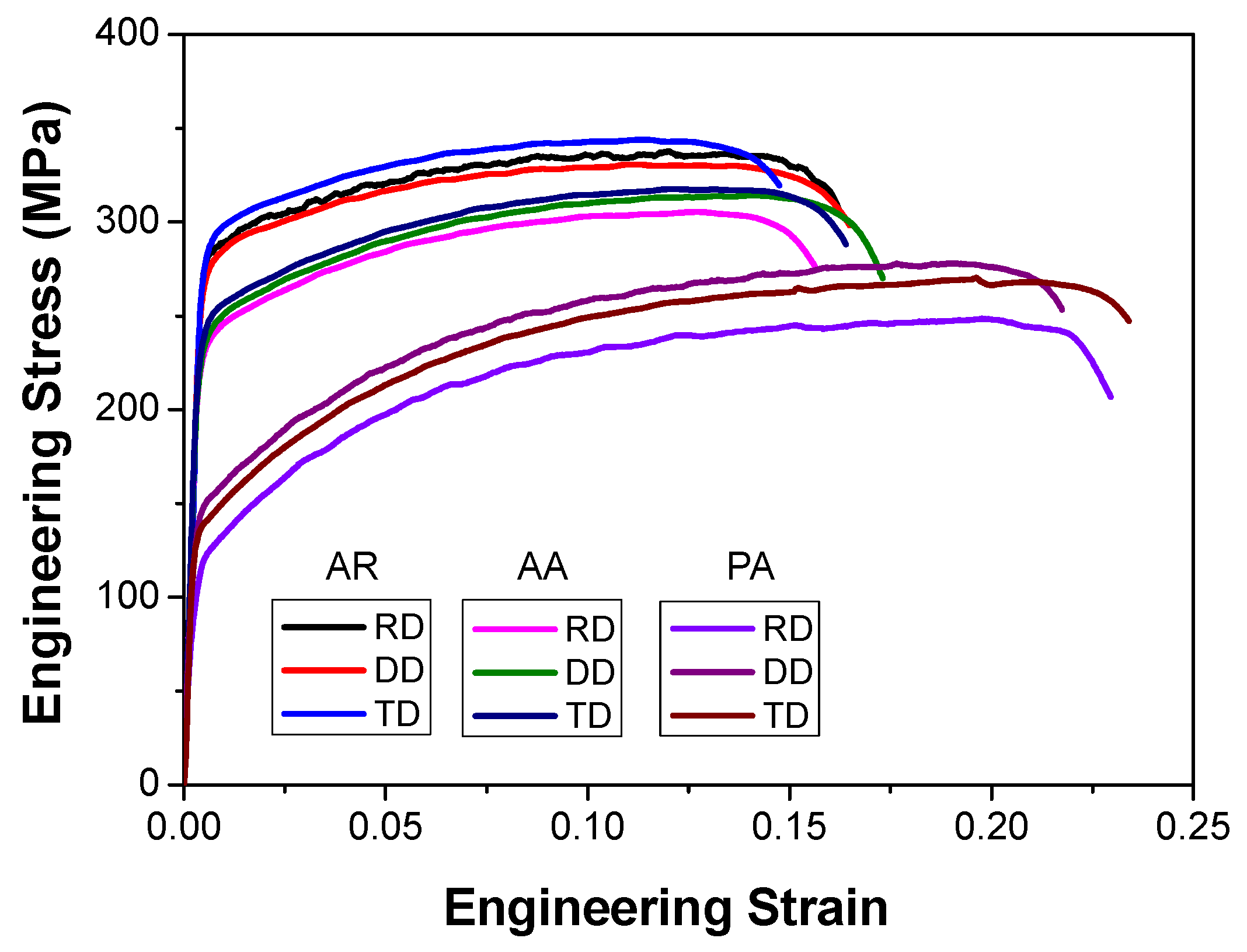

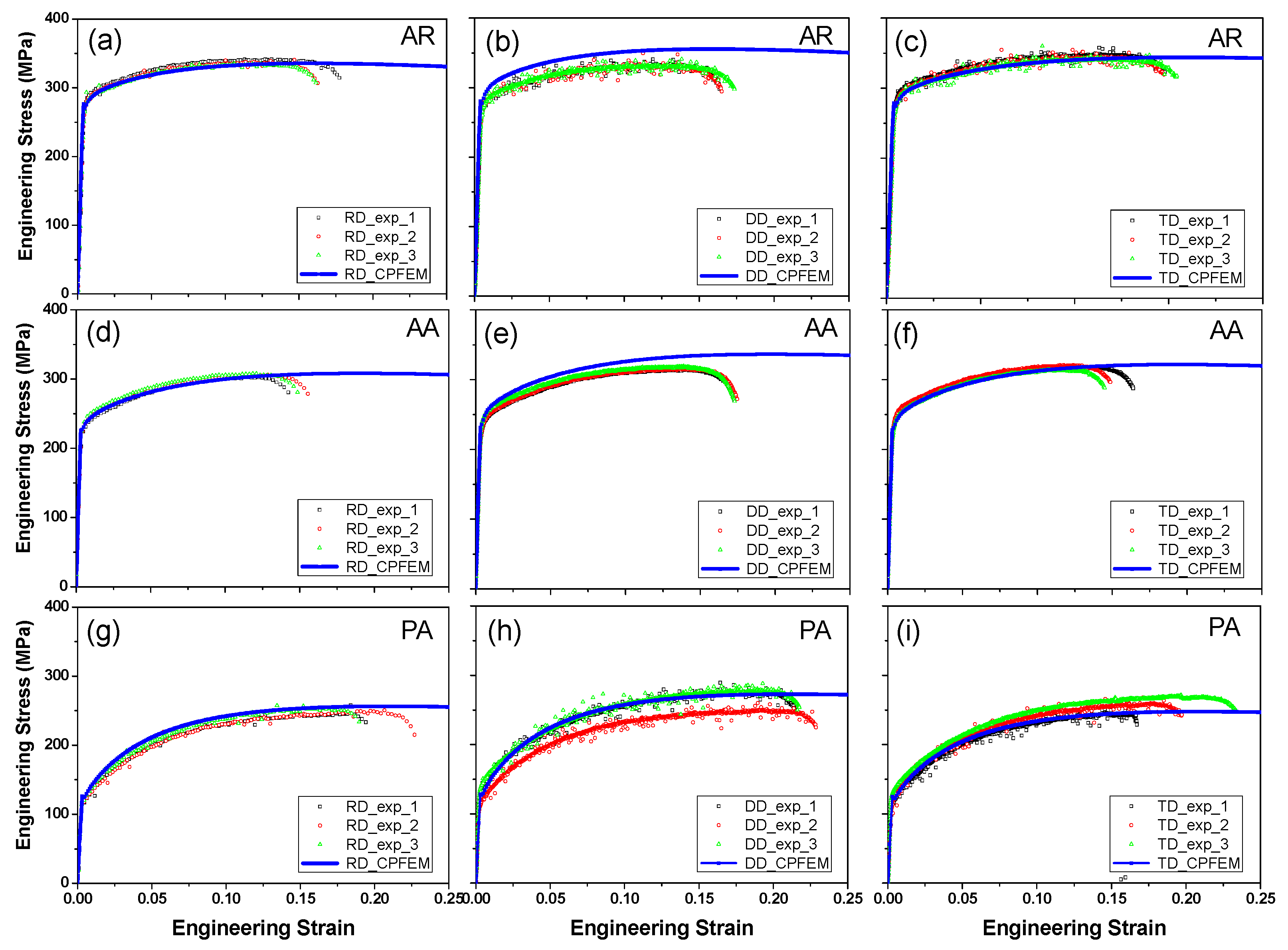

4.2. Stress–Strain Behavior and Parameter Calibration

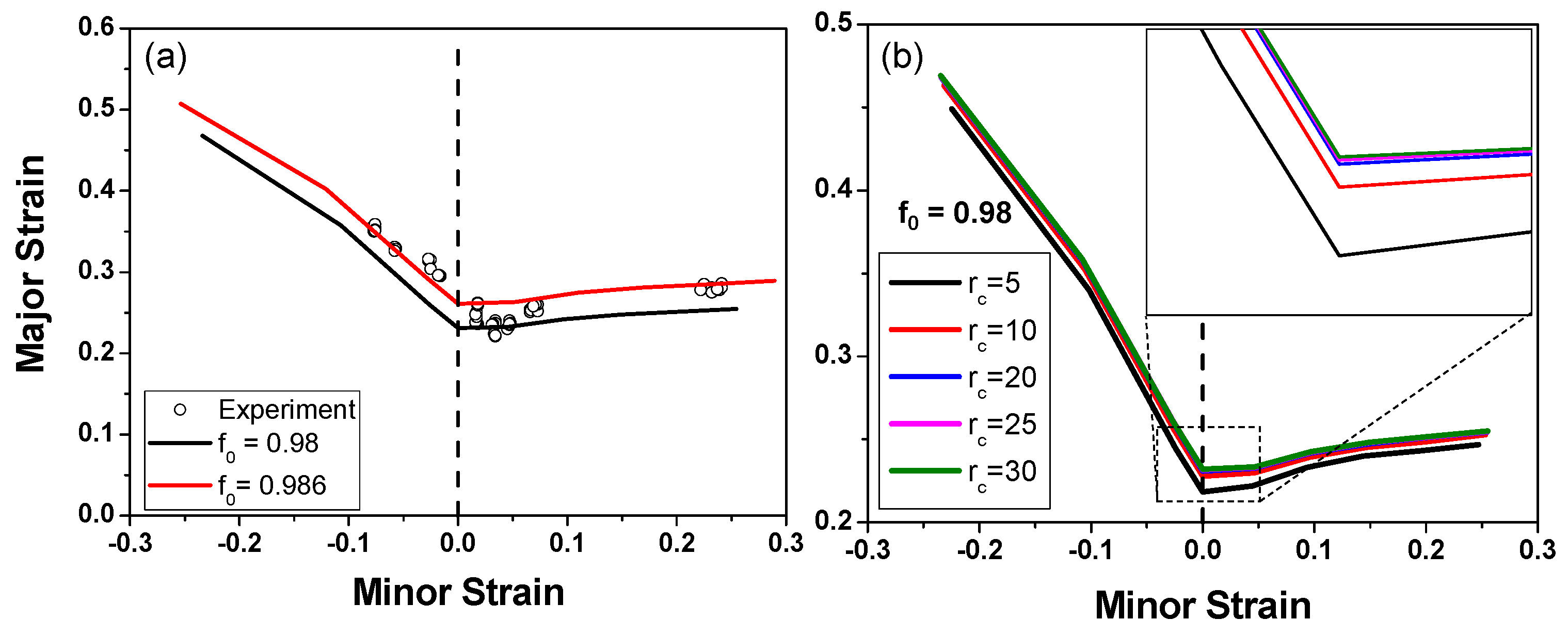

4.3. FLC Prediction

4.4. Effect of Heat Treatment and Initial Texture

5. Conclusions

- (1)

- The microstructures of the differently heat-treated alloys exhibit fully recrystallized equi-axis grain morphology, and the grain size of the PA and AA alloys is slightly higher than that of the AR alloy. When compared to the AR alloy, which has a dominant cubic texture component and S component, the texture of the PA and AA alloys is also slightly modified due to the solution heat treatment process.

- (2)

- Due to the different aging treatment processes, the AR alloy has the highest yield strength (290 MPa along the TD) and moderate elongation (0.152 along the DD), and the PA alloy shows a good ductility (0.21 along the RD and TD) with a low yield strength (149 MPa along the DD) and high work hardening. The AA alloy is in the mediate between the other two.

- (3)

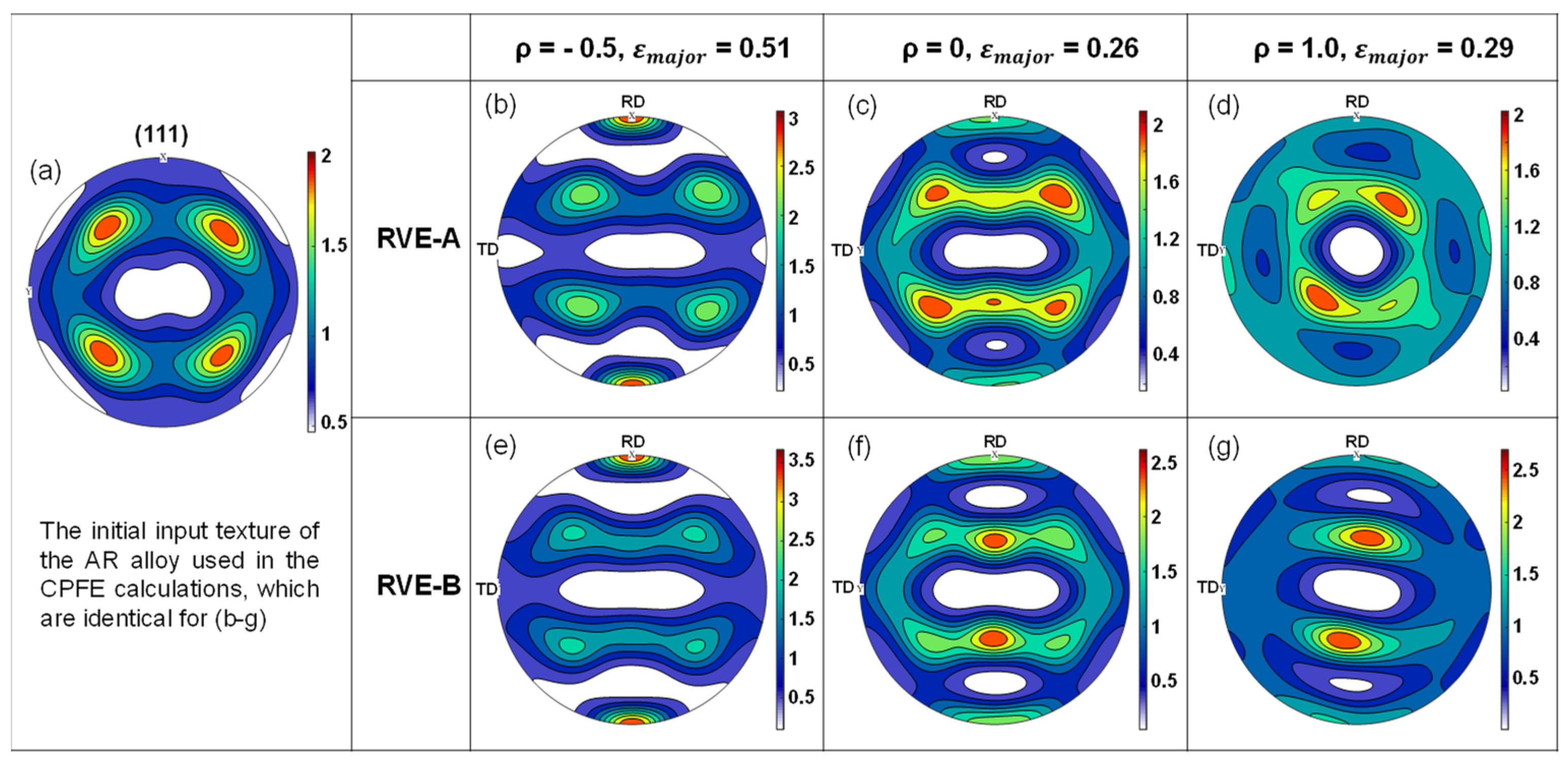

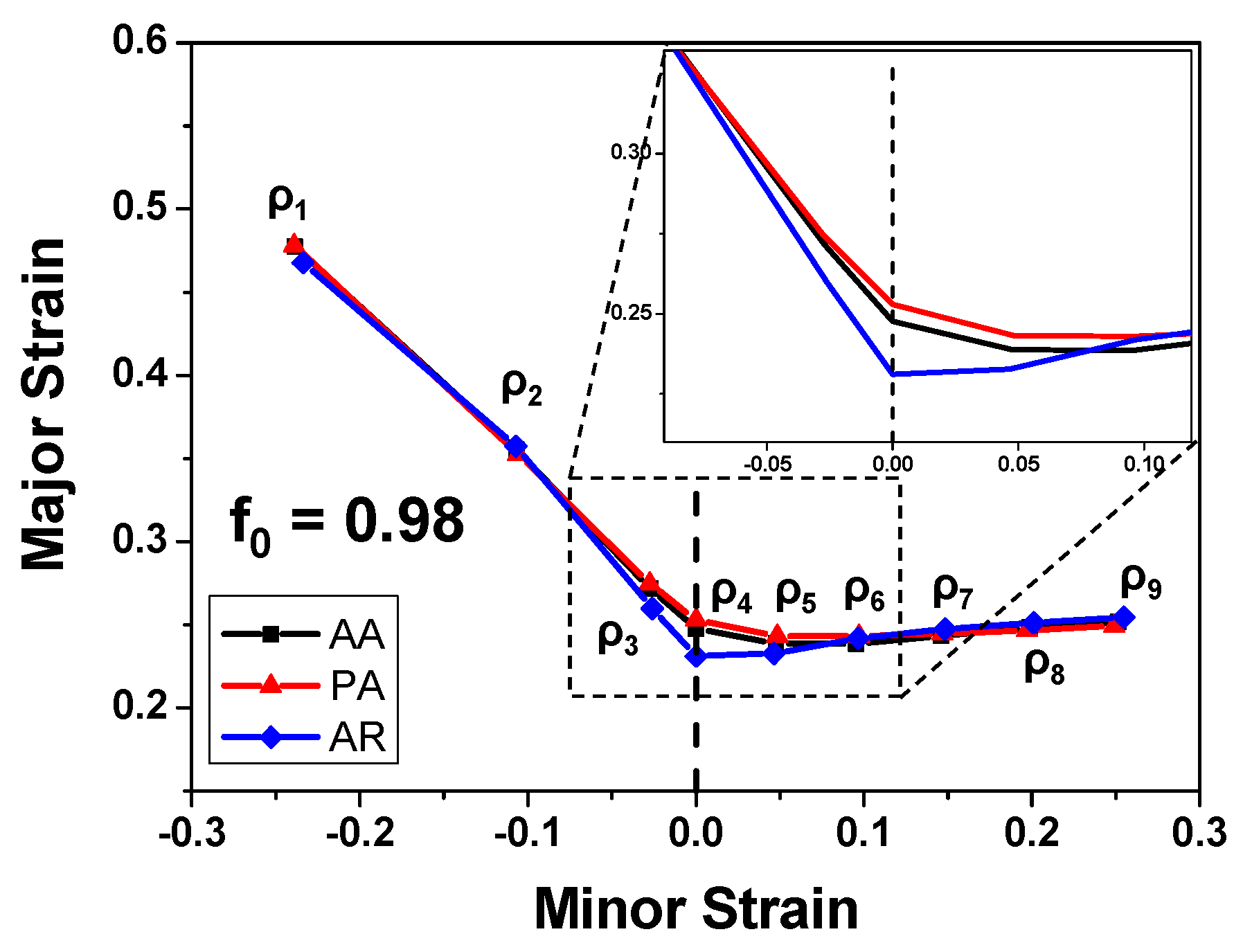

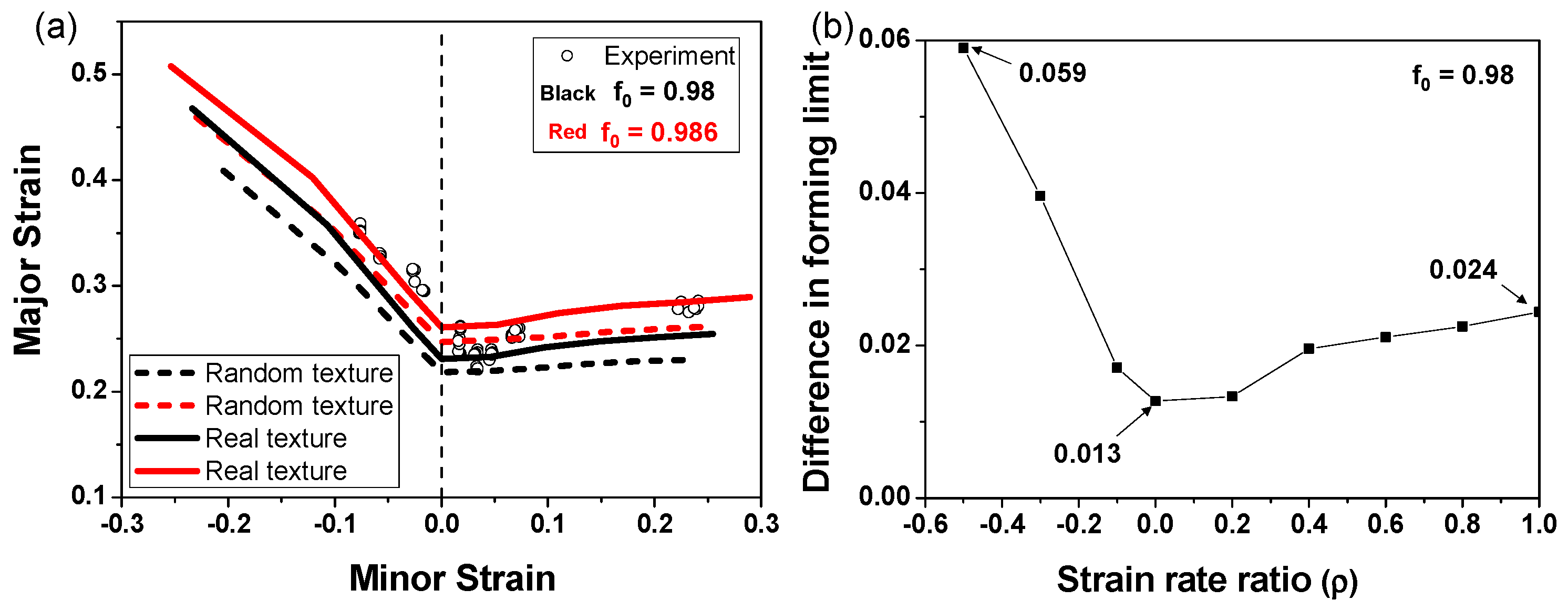

- A CPFE model was successfully combined with the M-K approach, which can precisely predict the stress–strain behavior and the forming limits of the alloys using only a small set of modeling parameters. It is revealed that a slight change in the imperfection factor could lead to a large discrepancy in the predicted FLC of the material, and the deformed textures of the RVE-A and the RVE-B are similar in uniaxial tension and balanced biaxial tension, but are quite different in plane strain tension.

- (4)

- The ageing treatment effect on the FLC exhibits a clear dependency on the loading paths. The highest difference in the forming limit strain is observed to happen in the case of plane strain tension, where the PA alloy exhibits better formability than the other two, owing to its high work hardening. The random texture is found to yield lower forming limits than the real texture, which is dominated by the cubic texture component in the AR alloy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Burger, G.B.; Gupta, A.K.; Jeffrey, P.W.; Lloyd, D.J. Microstructural Control of Aluminum Sheet Used in Automotive Applications. Mater. Charact. 1995, 35, 23–39. [Google Scholar] [CrossRef]

- Polmear, I.; StJohn, D.; Nie, J.-F.; Qian, M. (Eds.) 4—Wrought Aluminium Alloys. In Light Alloys, 5th ed.; Butterworth-Heinemann: Boston, MA, USA, 2017; pp. 157–263. ISBN 978-0-08-099431-4. [Google Scholar]

- Andersen, S.J.; Marioara, C.D.; Friis, J.; Wenner, S.; Holmestad, R. Precipitates in Aluminium Alloys. Adv. Phys. X 2018, 3, 1479984. [Google Scholar] [CrossRef]

- Robson, J.D.; Engler, O.; Sigli, C.; Deschamps, A.; Poole, W.J. Advances in Microstructural Understanding of Wrought Aluminum Alloys. Metall. Mater. Trans. A 2020, 51, 4377–4389. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Zandbergen, H.W.; Holmestad, R. The Influence of Alloy Composition on Precipitates of the Al-Mg-Si System. Metall. Mater. Trans. A 2005, 36, 691–702. [Google Scholar] [CrossRef]

- Liu, L.; Hou, Y.; Ye, T.; Zhang, L.; Huang, X.; Gong, Y.; Liu, C.; Wu, Y.; Duan, S. Effects of Aging Treatments on the Age Hardening Behavior and Microstructures in an Al-Mg-Si-Cu Alloy. Metals 2024, 14, 238. [Google Scholar] [CrossRef]

- Remøe, M.S.; Marthinsen, K.; Westermann, I.; Pedersen, K.; Røyset, J.; Marioara, C. The Effect of Alloying Elements on the Ductility of Al–Mg–Si Alloys. Mater. Sci. Eng. A 2017, 693, 60–72. [Google Scholar] [CrossRef]

- Zhu, S.; Shih, H.-C.; Cui, X.; Yu, C.-Y.; Ringer, S.P. Design of Solute Clustering during Thermomechanical Processing of AA6016 Al–Mg–Si Alloy. Acta Mater. 2021, 203, 116455. [Google Scholar] [CrossRef]

- Ozturk, F.; Sisman, A.; Toros, S.; Kilic, S.; Picu, R.C. Influence of Aging Treatment on Mechanical Properties of 6061 Aluminum Alloy. Mater. Des. 2010, 31, 972–975. [Google Scholar] [CrossRef]

- Engler, O.; Marioara, C.D.; Aruga, Y.; Kozuka, M.; Myhr, O.R. Effect of Natural Ageing or Pre-Ageing on the Evolution of Precipitate Structure and Strength during Age Hardening of Al–Mg–Si Alloy AA 6016. Mater. Sci. Eng. A 2019, 759, 520–529. [Google Scholar] [CrossRef]

- Birol, Y. Pre-Aging to Improve Bake Hardening in a Twin-Roll Cast Al–Mg–Si Alloy. Mater. Sci. Eng. A 2005, 391, 175–180. [Google Scholar] [CrossRef]

- Österreicher, J.A.; Nebeling, D.; Grabner, F.; Cerny, A.; Zickler, G.A.; Eriksson, J.; Wikström, G.; Suppan, W.; Schlögl, C.M. Secondary Ageing and Formability of an Al–Cu–Mg Alloy (2024) in W and under-Aged Tempers. Mater. Des. 2023, 226, 111634. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, H.; Chen, X.; Gault, B.; Brechet, Y.; Hutchinson, C. The Effect of Shearable Clusters and Precipitates on Dynamic Recovery of Al Alloys. Acta Mater. 2024, 265, 119643. [Google Scholar] [CrossRef]

- Zhong, H.; Rometsch, P.A.; Wu, X.; Cao, L.; Estrin, Y. Influence of Pre-Ageing on the Stretch Formability of Al–Mg–Si Automotive Sheet Alloys. Mater. Sci. Eng. A 2017, 697, 79–85. [Google Scholar] [CrossRef]

- Hodžić, E.; Domitner, J.; Thum, A.; Sabet, A.S.; Müllner, N.; Fragner, W.; Sommitsch, C. Influence of Natural Aging on the Formability of Al–Mg–Si Alloy Blanks. J. Manuf. Process. 2023, 94, 228–239. [Google Scholar] [CrossRef]

- Wang, X.; Guo, M.; Moliar, O.; Peng, W.; Xie, C.; Chen, J.; Wang, Y. Enhanced Grain Refinement and Texture Weakening in Al–Mg–Si Alloy through a Novel Thermomechanical Processing. J. Alloys Compd. 2022, 925, 166654. [Google Scholar] [CrossRef]

- Keeler, S.P.; Backofen, W.A. Plastic Instability and Fracture in Sheets Stretched over Rigid Punches. ASM Trans. Q. 1963, 56, 25–48. [Google Scholar]

- Goodwin, G.M. Application of Strain Analysis to Sheet Metal Forming Problems in the Press Shop; SAE International: Warrendale, PA, USA, 1968. [Google Scholar]

- Banabic, D.; Barlat, F.; Cazacu, O.; Kuwabara, T. Advances in Anisotropy of Plastic Behaviour and Formability of Sheet Metals. Int. J. Mater. Form. 2020, 13, 749–787. [Google Scholar] [CrossRef]

- Marciniak, Z.; Kuczyński, K. Limit Strains in the Processes of Stretch-Forming Sheet Metal. Int. J. Mech. Sci. 1967, 9, 609–620. [Google Scholar] [CrossRef]

- Yu, K.; Li, Q.; Wu, Y.; Guo, M.; Li, D.; Liu, C.; Zhuang, L.; Wu, P. An Improved Marciniak-Kuczynski Approach for Predicting Sheet Metal Formability. Int. J. Mech. Sci. 2022, 221, 107200. [Google Scholar] [CrossRef]

- Banabic, D.; Kami, A.; Comsa, D.-S.; Eyckens, P. Developments of the Marciniak-Kuczynski Model for Sheet Metal Formability: A Review. J. Mater. Process. Technol. 2021, 287, 116446. [Google Scholar] [CrossRef]

- Butuc, M.C.; Teodosiu, C.; Barlat, F.; Gracio, J.J. Analysis of Sheet Metal Formability through Isotropic and Kinematic Hardening Models. Eur. J. Mech.-A/Solids 2011, 30, 532–546. [Google Scholar] [CrossRef]

- Nagra, J.S.; Brahme, A.; Mishra, R.; Lebensohn, R.A.; Inal, K. An Efficient Full-Field Crystal Plasticity-Based M–K Framework to Study the Effect of 3D Microstructural Features on the Formability of Polycrystalline Materials. Model. Simul. Mater. Sci. Eng. 2018, 26, 075002. [Google Scholar] [CrossRef]

- Jeong, Y.; Pham, M.-S.; Iadicola, M.; Creuziger, A.; Foecke, T. Forming Limit Prediction Using a Self-Consistent Crystal Plasticity Framework: A Case Study for Body-Centered Cubic Materials. Model. Simul. Mater. Sci. Eng. 2016, 24, 055005. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Lee, M.-G.; Kang, J.-H.; Oh, C.-S.; Barlat, F. Crystal Plasticity Finite Element Analysis of Ferritic Stainless Steel for Sheet Formability Prediction. Int. J. Plast. 2017, 93, 26–45. [Google Scholar] [CrossRef]

- Bong, H.J.; Lee, J. Crystal Plasticity Finite Element–Marciniak-Kuczynski Approach with Surface Roughening Effect in Predicting Formability of Ultra-Thin Ferritic Stainless Steel Sheets. Int. J. Mech. Sci. 2021, 191, 106066. [Google Scholar] [CrossRef]

- Tran, M.T.; Wang, H.; Lee, H.W.; Kim, D.-K. Crystal Plasticity Finite Element Analysis of Size Effect on the Formability of Ultra-Thin Ferritic Stainless Steel Sheet for Fuel Cell Bipolar Plate. Int. J. Plast. 2022, 154, 103298. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, G.; Li, D.; Jain, M.K.; Peng, Y.; Wu, P. Forming Limits of Magnesium Alloy AZ31B Sheet at Elevated Temperatures. Int. J. Plast. 2020, 135, 102822. [Google Scholar] [CrossRef]

- Signorelli, J.W.; Bertinetti, M.A.; Roatta, A. A Review of Recent Investigations Using the Marciniak-Kuczynski Technique in Conjunction with Crystal Plasticity Models. J. Mater. Process. Technol. 2021, 287, 116517. [Google Scholar] [CrossRef]

- Rice, J.R. Inelastic Constitutive Relations for Solids: An Internal-Variable Theory and Its Application to Metal Plasticity. J. Mech. Phys. Solids 1971, 19, 433–455. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. Material Rate Dependence and Localized Deformation in Crystalline Solids. Acta Metall. 1983, 31, 1951–1976. [Google Scholar] [CrossRef]

- ASTM E8/E8M-16a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- ISO/DIS 12004-2:2008; Metallic Materials—Sheet and Strip—Determination of Forming Limit Curves—Part 2: Determination of Forming Limit Curves in the Laboratory. International Organization for Standardization: Geneva, Switzerland, 2008.

- Brown, S.; Kim, K.; Anand, L. An Internal Variable Constitutive Model for Hot Working of Metals. Int. J. Plast. 1989, 5, 95–130. [Google Scholar] [CrossRef]

- Khadyko, M.; Myhr, O.R.; Hopperstad, O.S. Work Hardening and Plastic Anisotropy of Naturally and Artificially Aged Aluminium Alloy AA6063. Mech. Mater. 2019, 136, 103069. [Google Scholar] [CrossRef]

- Mecking, H.; Kocks, U.F. Kinetics of Flow and Strain-Hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Hu, P.; Liu, Y.; Zhu, Y.; Ying, L. Crystal Plasticity Extended Models Based on Thermal Mechanism and Damage Functions: Application to Multiscale Modeling of Aluminum Alloy Tensile Behavior. Int. J. Plast. 2016, 86, 1–25. [Google Scholar] [CrossRef]

- Yoshida, K.; Ishizaka, T.; Kuroda, M.; Ikawa, S. The Effects of Texture on Formability of Aluminum Alloy Sheets. Acta Mater. 2007, 55, 4499–4506. [Google Scholar] [CrossRef]

| AR | AA | PA | |||||||

|---|---|---|---|---|---|---|---|---|---|

| YS | UTS | YS | UTS | YS | UTS | ||||

| RD | 285 | 383 | 0.15 | 233 | 345 | 0.145 | 115 | 298 | 0.207 |

| DD | 277 | 376 | 0.152 | 237 | 359 | 0.16 | 149 | 332 | 0.197 |

| TD | 290 | 386 | 0.137 | 244 | 362 | 0.152 | 139 | 325 | 0.21 |

| (MPa) | (MPa) | (MPa) | q | ||

|---|---|---|---|---|---|

| AR | 1500 | 115 | 199 | 2.6 | 1.4 |

| AA | 1000 | 98 | 185 | 2.1 | 1.4 |

| PA | 1400 | 50 | 150 | 2.4 | 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Lee, H.-W.; Kang, S.-H.; Kim, D.-K. Crystal Plasticity Finite Element Analyses on the Formability of AA6061 Aluminum Alloy with Different Ageing Treatments. Metals 2024, 14, 503. https://doi.org/10.3390/met14050503

Wang H, Lee H-W, Kang S-H, Kim D-K. Crystal Plasticity Finite Element Analyses on the Formability of AA6061 Aluminum Alloy with Different Ageing Treatments. Metals. 2024; 14(5):503. https://doi.org/10.3390/met14050503

Chicago/Turabian StyleWang, Huai, Ho-Won Lee, Seong-Hoon Kang, and Dong-Kyu Kim. 2024. "Crystal Plasticity Finite Element Analyses on the Formability of AA6061 Aluminum Alloy with Different Ageing Treatments" Metals 14, no. 5: 503. https://doi.org/10.3390/met14050503

APA StyleWang, H., Lee, H.-W., Kang, S.-H., & Kim, D.-K. (2024). Crystal Plasticity Finite Element Analyses on the Formability of AA6061 Aluminum Alloy with Different Ageing Treatments. Metals, 14(5), 503. https://doi.org/10.3390/met14050503