The Influence of Aging Precipitates on the Mechanical Properties of Al–Li Alloys and Microstructural Analysis

Abstract

1. Introduction

2. Methods

2.1. Experimental Methods

2.2. Computational Methods

3. Results and Discussion

3.1. Aging Hardening Curves for Binary Al–Li Alloys

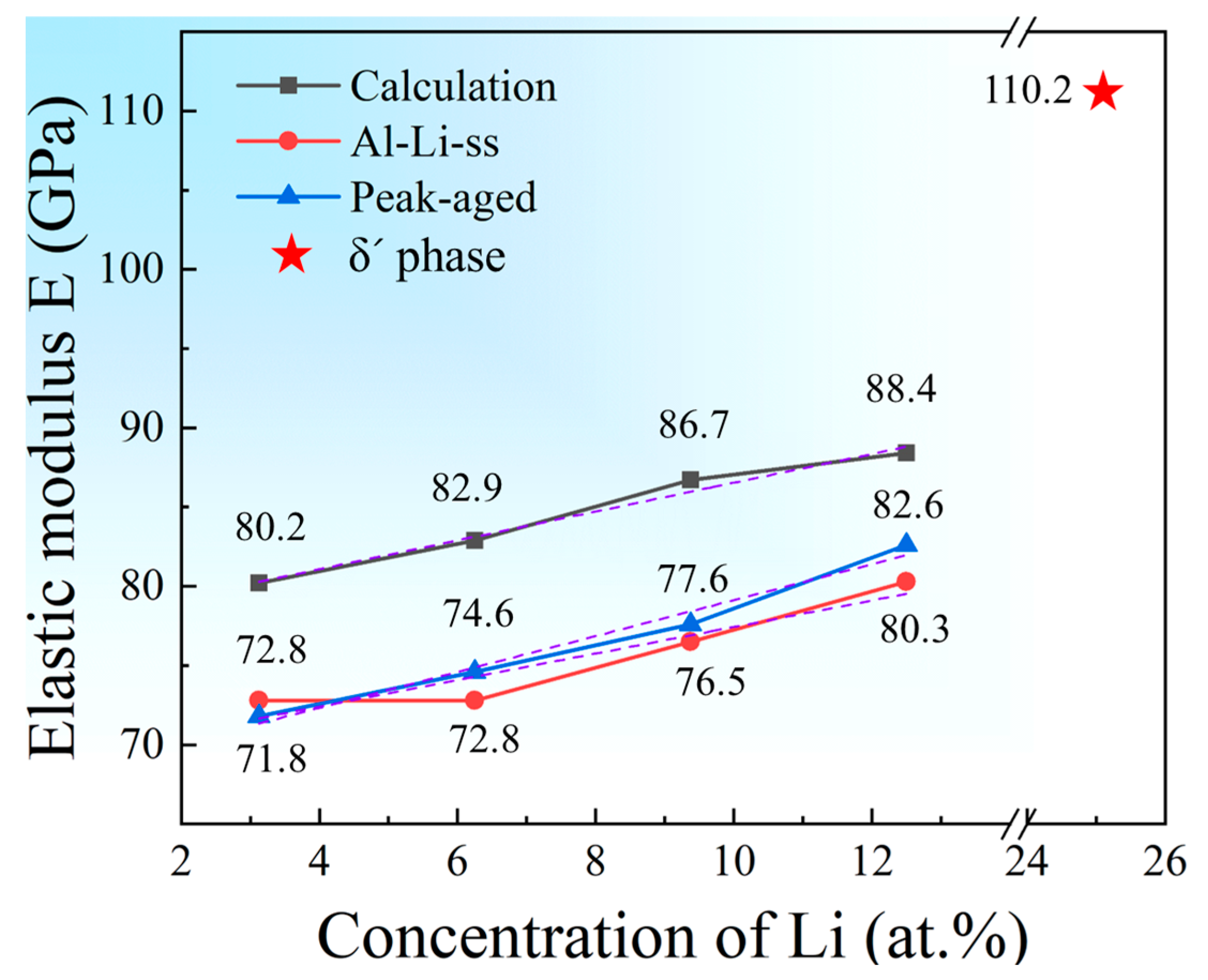

3.2. Determination of Density and Modulus of Binary Al–Li Alloys

3.3. Tensile Properties of Binary Al–Li Alloys

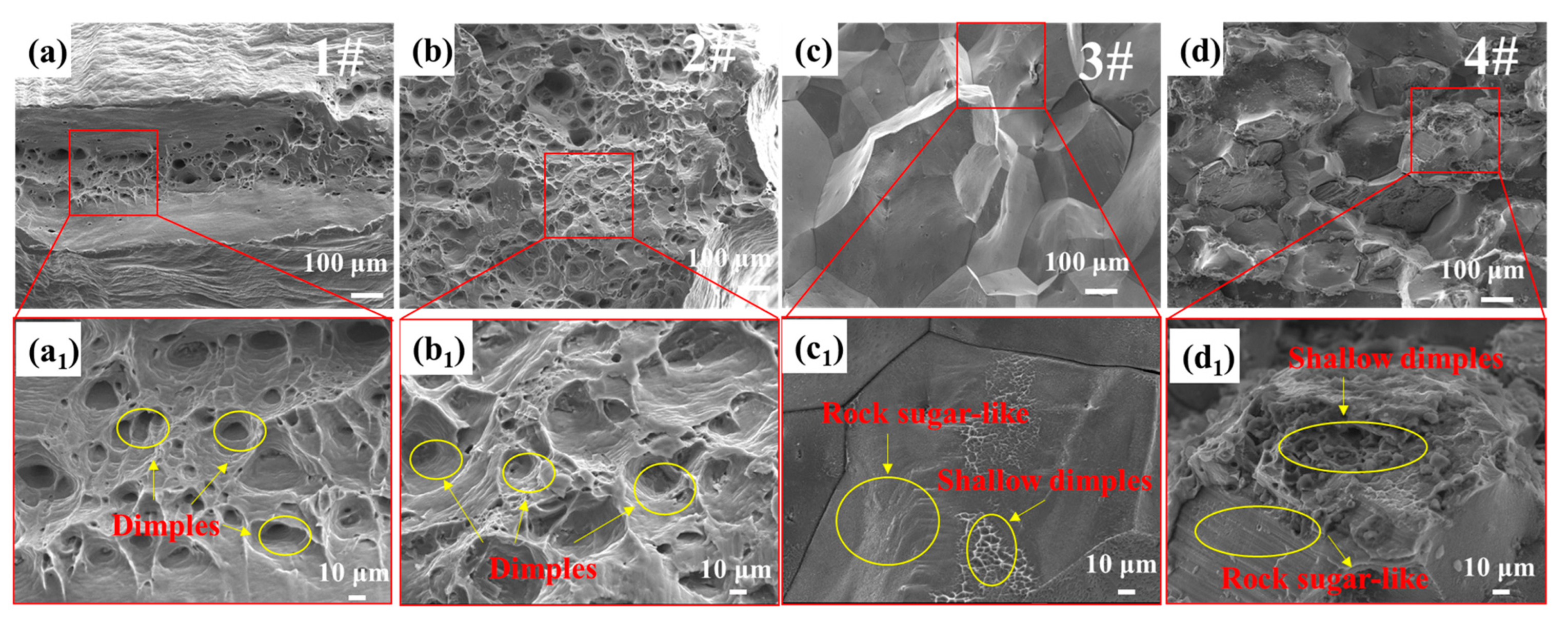

3.4. Fracture Surface Observation of Peak-Aged Alloys

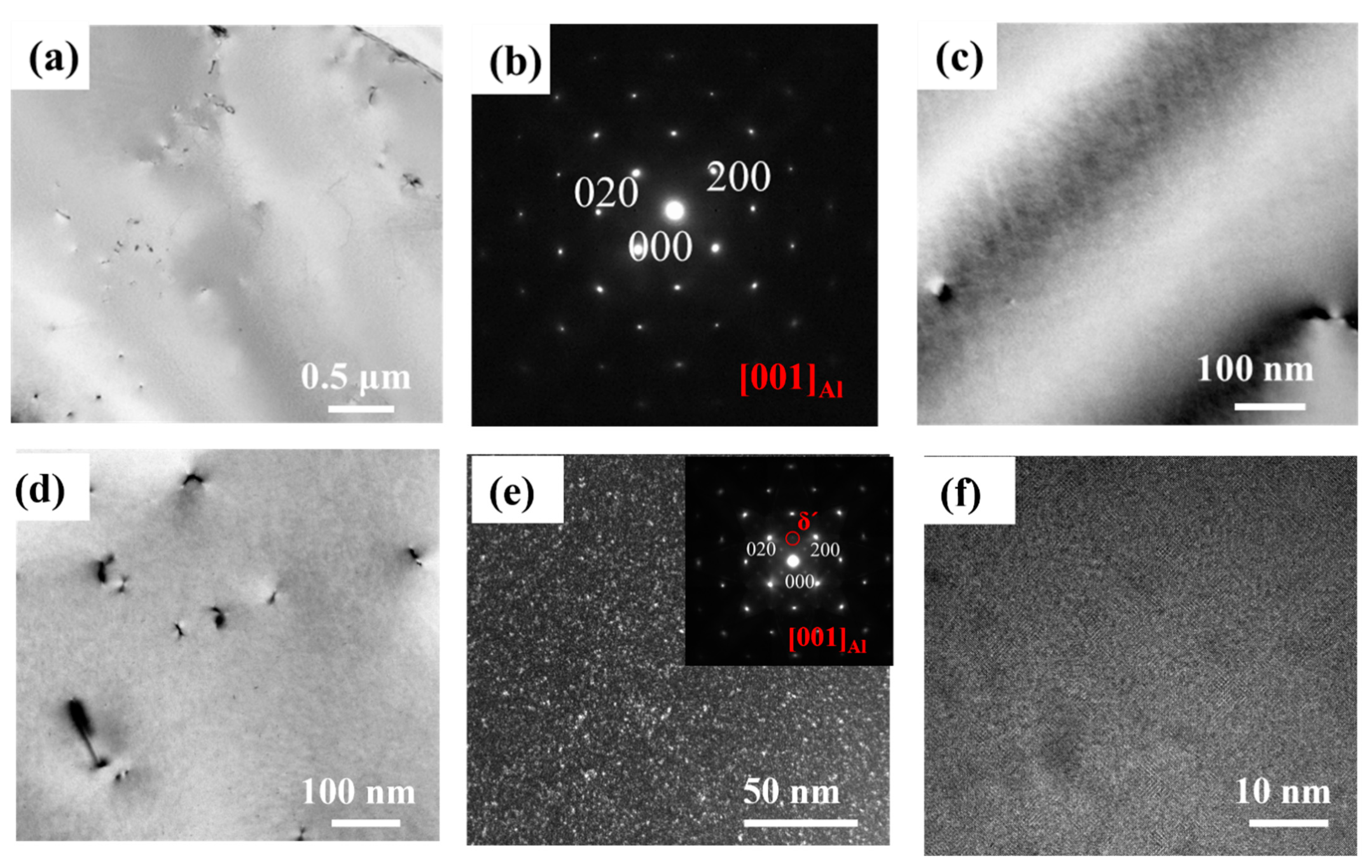

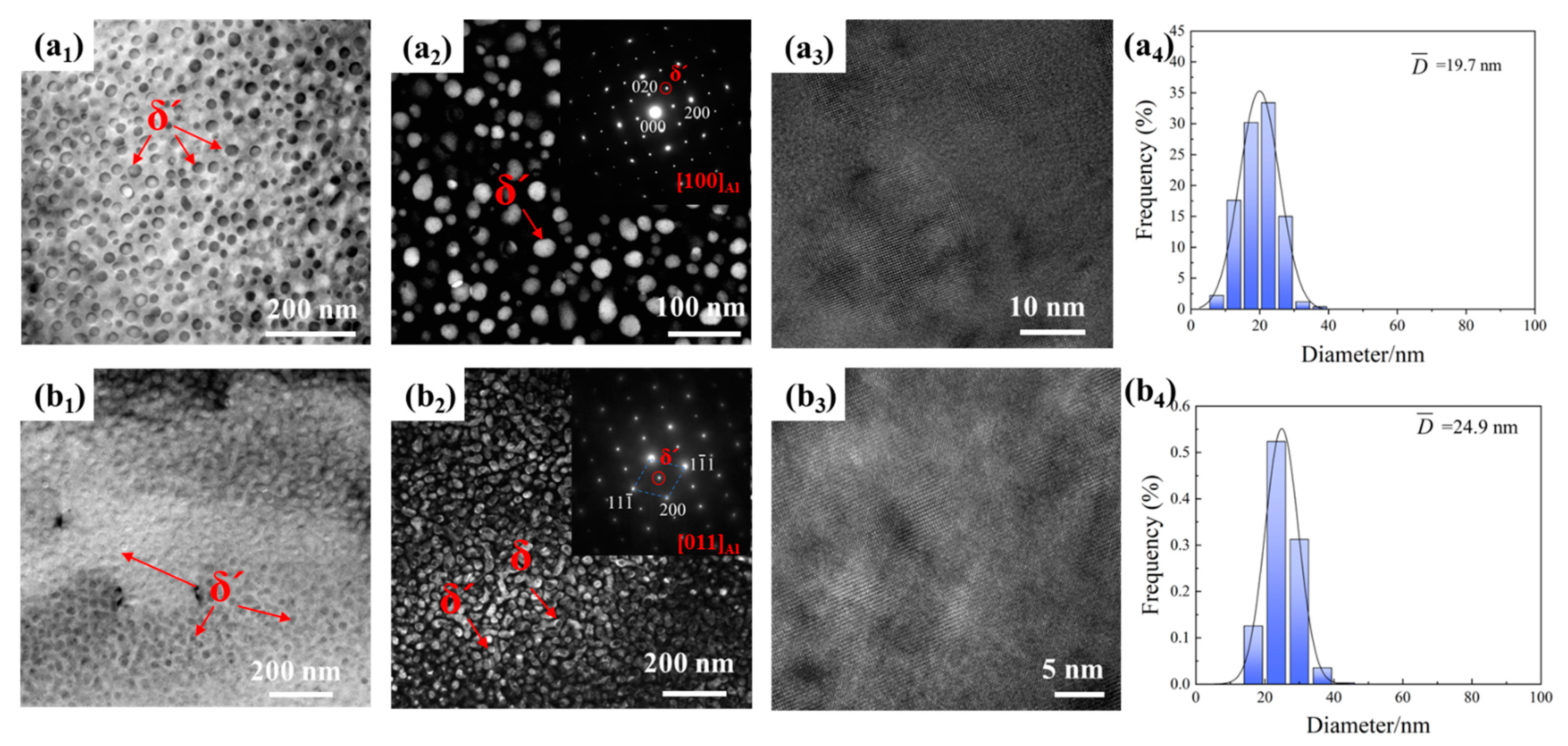

3.5. Microstructure Analysis of Peak-Aged Alloys

4. Conclusions

- (1)

- Both in the solution-treated and peak-aged states, the elastic modulus of binary Al–Li alloys showed an approximately linear increase with increasing Li content, consistent with trends predicted via DFT calculations. Under peak-aged conditions, the elastic modulus of the alloys increased from 71.8 GPa for alloy 1# to 82.6 GPa for alloy 4#. Due to the presence of precipitates, the modulus of higher—Li-concentration alloys in the peak-aged state increased by approximately 1.4–2.5% compared with that of alloys in the solution-treated state.

- (2)

- Increasing Li content significantly enhances the tensile strength and yield strength of an alloy but decreases its ductility, leading to a transition in the fracture mode from ductile to brittle, as evidenced by the microscopic analysis of fracture surfaces. Under peak-aged conditions (175 °C/48 h), alloy 4#, with the highest Li content, exhibited the maximum tensile strength of 341 MPa and a yield strength of 296 MPa, while its elongation was the lowest at 2.1%.

- (3)

- No δ′ phase was observed in alloy 1# during peak aging, indicating mainly solid solution strengthening. However, alloys 2#, 3#, and 4# all exhibited the presence of the δ′ phase as observed through TEM, accompanied by an increase in the elastic modulus, suggesting that these three alloys were primarily strengthened by precipitation hardening. Alloys 3# and 4# exhibited significant age-hardening and strengthening effects, with hardness increasing notably with aging time and stabilizing in later stages. At peak aging (175 °C/48 h), the hardness of alloy 3# stabilized at approximately 110 HV, while alloy 4# reached a hardness of around 141 HV.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, X.; Wang, M.; Zhang, C.; Xue, C.; Guo, Y.; Liu, X. Achieving high strength and ductility of Al-Cu-Li alloy via creep aging treatment with different pre-strain levels. Mater. Today Commun. 2021, 29, 102898–102910. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, C.; Li, X.; Wang, J. Heterophase interface dominated deformation and mechanical properties in Al-Cu-Li Alloys. Adv. Theory Simul. 2021, 4, 2100059–2100070. [Google Scholar] [CrossRef]

- Ma, J.; Liu, X.; Yan, D.; Rong, L. A novel GP-Li precursor and the correlated precipitation behaviors in Al-Cu-Li alloys with different Cu/Li Ratio. Acta Mater. 2023, 243, 118442–118458. [Google Scholar] [CrossRef]

- Xue, C.; Zhang, Y.; Mao, P.; Liu, C.; Guo, Y.; Qian, F.; Zhang, C.; Liu, K.; Zhang, M.; Tang, S.; et al. Improving Mechanical Properties of Wire Arc Additively Manufactured AA2196 Al–Li Alloy by Controlling Solidification Defects. Addit. Manuf. 2021, 43, 102019. [Google Scholar] [CrossRef]

- Rioja, R.J.; Liu, J. The Evolution of Al-Li Base Products for Aerospace and Space Applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Elagin, V.I.; Zakharov, V.V. Modern Al-Li Alloys and Prospects of Their Development. Met. Sci. Heat Treat. 2013, 55, 184–190. [Google Scholar] [CrossRef]

- Decreus, B.; Deschamps, A.; De Geuser, F.; Donnadieu, P.; Sigli, C.; Weyland, M. The Influence of Cu/Li Ratio on Precipitation in Al–Cu–Li–x Alloys. Acta Mater. 2013, 61, 2207–2218. [Google Scholar] [CrossRef]

- Duan, S.; Guo, F.; Wu, D.; Wang, T.; Tsuchiya, T.; Matsuda, K.; Zou, Y. Influences of Pre-Rolling Deformation on Aging Precipitates and Mechanical Properties for a Novel Al–Cu–Li Alloy. J. Mater. Res. Technol. 2021, 15, 2379–2392. [Google Scholar] [CrossRef]

- Rodgers, B.I.; Prangnell, P.B. Quantification of the Influence of Increased Pre-Stretching on Microstructure-Strength Relationships in the Al–Cu–Li Alloy AA2195. Acta Mater. 2016, 108, 55–67. [Google Scholar] [CrossRef]

- Noble, B.; Harris, S.J.; Dinsdale, K. The elastic modulus of aluminum-lithium alloys. J. Mater. Sci. 1982, 17, 461–468. [Google Scholar] [CrossRef]

- Xue, C.; Zhang, Y.; Wang, S.; Tian, G.; Yang, X.; Ke, Y.; Xie, Z.; Wang, J. Achieving Highest Young’s Modulus in Al-Li by Tracing the Size and Bonding Evolution of Li-Rich Precipitates. J. Mater. Sci. Technol. 2023, 145, 125–135. [Google Scholar] [CrossRef]

- Gao, Y.J.; Mo, Q.F.; Chen, H.N.; Huang, C.G.; Zhang, L.N. Atomic Bonding and Mechanical Properties of Al–Li–Zr Alloy. Mater. Sci. Eng. A 2009, 499, 299–303. [Google Scholar] [CrossRef]

- Starke, E.A.; Sanders, T.H. New Approaches to Alloy Development in the AI-Li System. J. Met. 1981, 33, 24–33. [Google Scholar]

- Jeon, S.M.; Kim, J.D.; Park, J.K.; Lee, S.S. Quantitative Analysis of Elastic Property of Al-Li Alloys Using Ultrasonic Velocity Measurement and Tem. In Review of Progress in Quantitative Nondestructive Evaluation; Springer: Berlin/Heidelberg, Germany, 1993. [Google Scholar]

- Zhang, X.; Zhang, L.; Wu, G.; Liu, W.; Shi, C.; Tao, J.; Sun, J. Microstructural Evolution and Mechanical Properties of Cast Al-2Li-2Cu-0.5Mg-0.2Zr Alloy during Heat Treatment. Mater. Charact. 2017, 132, 312–319. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Yan, B.; Zou, C.; Wei, Z. The Effect of Grain Refinement and Precipitation Strengthening Induced by Sc or Er Alloying on the Mechanical Properties of Cast Al-Li-Cu-Mg Alloys at Elevated Temperatures. Mater. Sci. Eng. A 2021, 822, 141641. [Google Scholar] [CrossRef]

- Hirosawa, S.; Sato, T.; Kamio, A. Effects of Mg Addition on the Kinetics of Low-Temperature Precipitation in Al–Li–Cu–Ag–Zr Alloys. Mater. Sci. Eng. A 1998, 242, 195–201. [Google Scholar] [CrossRef]

- Joh, C.-H.; Yamada, K.; Miura, Y. Effect of Sc-Addition on the Coarsening Behavior of Al3Li Precipitates in Al-Li Alloys. Mater. Trans. JIM 1999, 40, 439–442. [Google Scholar] [CrossRef]

- Deschamps, A.; Garcia, M.; Chevy, J.; Davo, B.; De Geuser, F. Influence of Mg and Li Content on the Microstructure Evolution of Al-Cu-Li Alloys during Long-Term Ageing. Acta Mater. 2017, 122, 32–46. [Google Scholar] [CrossRef]

- Katsikis, S.; Noble, B.; Harris, S.J. Microstructural Stability during Low Temperature Exposure of Alloys within the Al–Li–Cu–Mg System. Mater. Sci. Eng. A 2008, 485, 613–620. [Google Scholar] [CrossRef]

- Chai, Z.; Meng, C. Small-Angle X-ray Scattering Study of the Interfacial Characteristics Between δ′ Phase and Matrix in Al–2.70 mass% Li Alloy. J. Appl. Crystallogr. 1998, 31, 7–9. [Google Scholar] [CrossRef]

- Xie, B.; Huang, L.; Xu, J.; Su, H.; Zhang, H.; Xu, Y.; Li, J.; Wang, Y. Effect of the Aging Process and Pre-Deformation on the Precipitated Phase and Mechanical Properties of 2195 Al–Li Alloy. Mater. Sci. Eng. A 2022, 832, 142394. [Google Scholar] [CrossRef]

- Balducci, E.; Ceschini, L.; Messieri, S.; Wenner, S.; Holmestad, R. Effects of Overaging on Microstructure and Tensile Properties of the 2055 Al-Cu-Li-Ag Alloy. Mater. Sci. Eng. A 2017, 707, 221–231. [Google Scholar] [CrossRef]

- Yan, S.; Wang, R.; Peng, C.; Cai, Z.; Peng, X.; Lv, P.; Li, X. Microstructural evolution and mechanical properties of the rapidly-solidified and hot-extruded 2196 Al-Li alloy. J. Alloys Compd. 2024, 988, 174285. [Google Scholar] [CrossRef]

- Li, H.; Li, X.; Li, Y.; Xiao, W.; Wen, K.; Li, Z.; Zhang, Y.; Xiong, B. Machine learning assisted design of aluminum-lithium alloy with high specific modulus and specific strength. Mater. Des. 2023, 225, 111483. [Google Scholar] [CrossRef]

- Kresse, G.; Joubert, D. From Ultrasoft Pseudopotentials to the Projector Augmented-Wave Method. Phys. Rev. B 1999, 59, 1758–1775. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficiency of Ab-Initio Total Energy Calculations for Metals and Semiconductors Using a Plane-Wave Basis Set. Comput. Mater. Sci. 1996, 6, 15–50. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef]

- Zunger, A.; Wei, S.-H.; Ferreira, L.G.; Bernard, J.E. Special quasirandom structures. Phys. Rev. Lett. 1990, 65, 4. [Google Scholar] [CrossRef] [PubMed]

- Van, D.; Asta, M.; Ceder, G. The Alloy Theoretic Automated Toolkit: A User Guide. Calphad 2002, 26, 539–553. [Google Scholar]

- Jiang, S.; Wang, H.; Wu, Y.; Liu, X.; Chen, H.; Yao, M.; Gault, B.; Ponge, D.; Raabe, D.; Hirata, A.; et al. Ultrastrong Steel via Minimal Lattice Misfit and High-Density Nanoprecipitation. Nature 2017, 544, 460–464. [Google Scholar] [CrossRef]

- Sumitomo, T.; Cáceres, C.H.; Veidt, M. The Elastic Modulus of Cast Mg–Al–Zn Alloys. J. Light Met. 2002, 2, 49–56. [Google Scholar] [CrossRef]

- Matsumuro, A.; Murata, K.; Sakai, K.; Senoo, M. Elastic and Superconducting Properties of Supersaturated Al-Si and Al-Ge Solid-Solution Alloys Treated under a 5.4 GPa Pressure. J. Mater. Sci. 1993, 28, 5836–5842. [Google Scholar] [CrossRef]

- Ravi, C.; Wolverton, C.; Ozoliņš, V. Predicting Metastable Phase Boundaries in Al–Cu Alloys from First-Principles Calculations of Free Energies: The Role of Atomic Vibrations. Europhys. Lett. 2006, 73, 719–725. [Google Scholar] [CrossRef]

- Amirkhanlou, S.; Ji, S. A Review on High Stiffness Aluminum-Based Composites and Bimetallics. Crit. Rev. Solid State Mater. Sci. 2020, 45, 1–21. [Google Scholar] [CrossRef]

- Tsubakino, H.; Nozato, R.; Sakurai, T.; Hasegawa, Y.; Hayashi, Y. Precipitation of metastable δ′ in AI-1.9Li-2.5Mg alloy. Mater. Sci. Technol. 1994, 10, 222–226. [Google Scholar] [CrossRef]

- Huang, X.; Guan, B.; Wang, B.; Zang, Y. Hot tensile deformation behavior, fracture mechanism and microstructural evolution of 2195 Al-Li alloy. J. Alloys Compd. 2023, 946, 169426. [Google Scholar] [CrossRef]

- Guo, X.; Wen, S.H.; Jiao, H.; Wu, S. Effect of aging treatment on microstructure and mechanical properties of TIG welded joints of 2195-T8 Al-Li alloy. Mater. Charact. 2023, 196, 112576. [Google Scholar] [CrossRef]

- Xu, X.; Wu, G.; Zhang, L.; Tong, X.; Zhang, X.; Sun, J.; Li, L.; Xiong, X. Effects of heat treatment and pre-stretching on the mechanical properties and microstructure evolution of extruded 2050 Al–Cu–Li alloy. Mater. Sci. Eng. A 2022, 845, 143236. [Google Scholar] [CrossRef]

- Noble, B.; Bray, S.E. On the α(Al)/δ′(Al3Li) Metastable Solvus in Aluminium–Lithium Alloys. Acta Mater. 1998, 46, 6163–6171. [Google Scholar] [CrossRef]

- Tang, J.; Yi, Y.; He, H.; Huang, S.; Wang, H.; Zhang, J. Effect of forging pretreatment on the microstructures and mechanical properties of the Al-Cu-Li alloy. J. Alloys Compd. 2023, 965, 171379. [Google Scholar] [CrossRef]

| Alloy No. | Nominal Elemental-Content (wt.%) | |

|---|---|---|

| Li | Al | |

| 1# | 0.91 | Bal. |

| 2# | 1.59 | Bal. |

| 3# | 2.44 | Bal. |

| 4# | 3.98 | Bal. |

| Alloy No. | Homogenization Regimes |

|---|---|

| 1# | - |

| 2# | - |

| 3# | 525 °C/24 h |

| 4# | 525 °C/24 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Xiao, W.; Li, X.; Wen, K.; Gao, G.; Yan, L.; Li, Y.; Yan, H.; Zhang, Y.; Wang, X.; et al. The Influence of Aging Precipitates on the Mechanical Properties of Al–Li Alloys and Microstructural Analysis. Metals 2024, 14, 506. https://doi.org/10.3390/met14050506

Li G, Xiao W, Li X, Wen K, Gao G, Yan L, Li Y, Yan H, Zhang Y, Wang X, et al. The Influence of Aging Precipitates on the Mechanical Properties of Al–Li Alloys and Microstructural Analysis. Metals. 2024; 14(5):506. https://doi.org/10.3390/met14050506

Chicago/Turabian StyleLi, Ganghui, Wei Xiao, Xiwu Li, Kai Wen, Guanjun Gao, Lizhen Yan, Yanan Li, Hongwei Yan, Yongan Zhang, Xingquan Wang, and et al. 2024. "The Influence of Aging Precipitates on the Mechanical Properties of Al–Li Alloys and Microstructural Analysis" Metals 14, no. 5: 506. https://doi.org/10.3390/met14050506

APA StyleLi, G., Xiao, W., Li, X., Wen, K., Gao, G., Yan, L., Li, Y., Yan, H., Zhang, Y., Wang, X., & Xiong, B. (2024). The Influence of Aging Precipitates on the Mechanical Properties of Al–Li Alloys and Microstructural Analysis. Metals, 14(5), 506. https://doi.org/10.3390/met14050506