Micro-WEDM of Ti-29Nb-13Ta-4.6Zr Alloy for Antibacterial Properties: Experimental Investigation and Optimization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Desing of Experiments

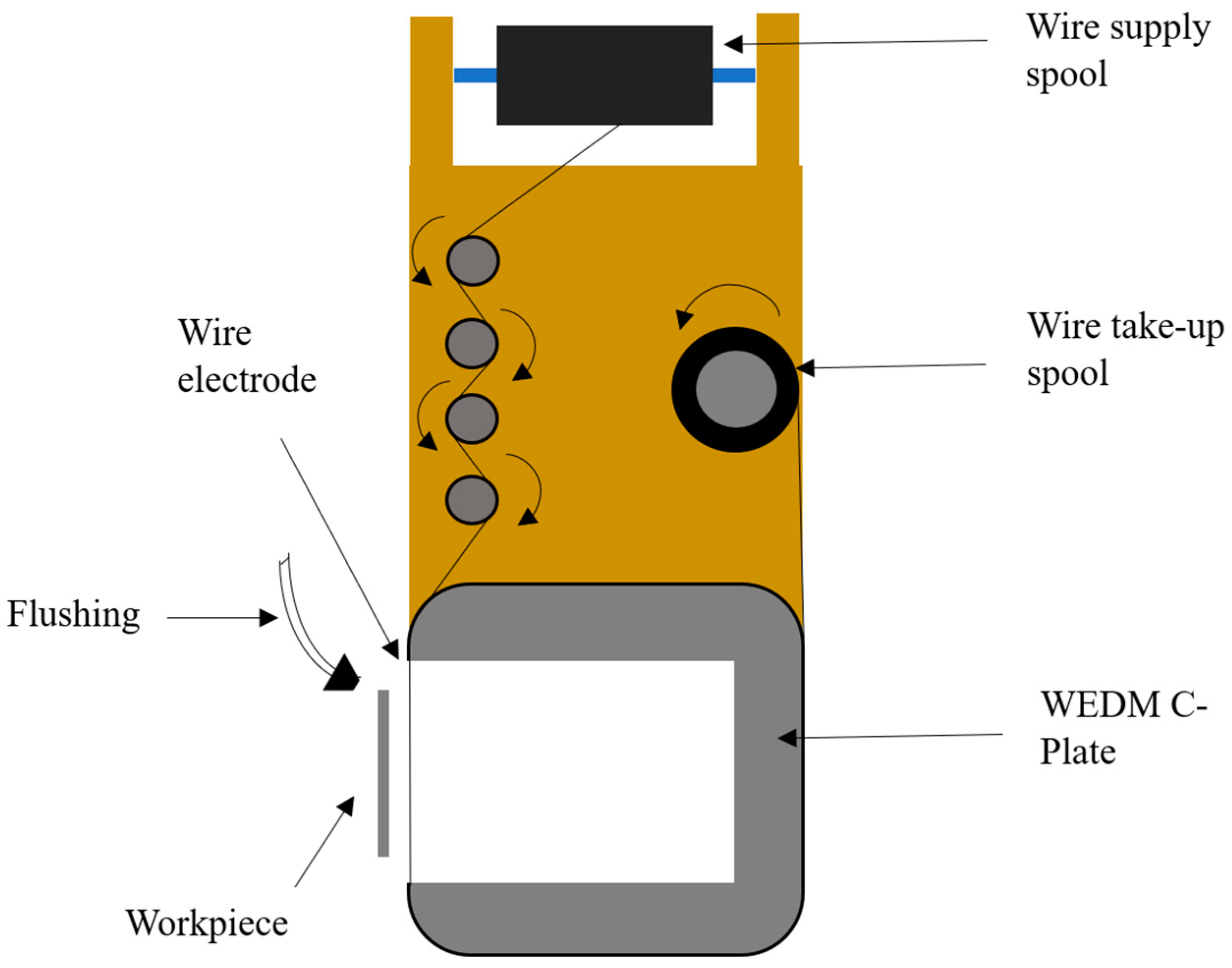

2.3. Analysis of Kerf Width (KW)

2.4. Material Removal Rate (MRR)

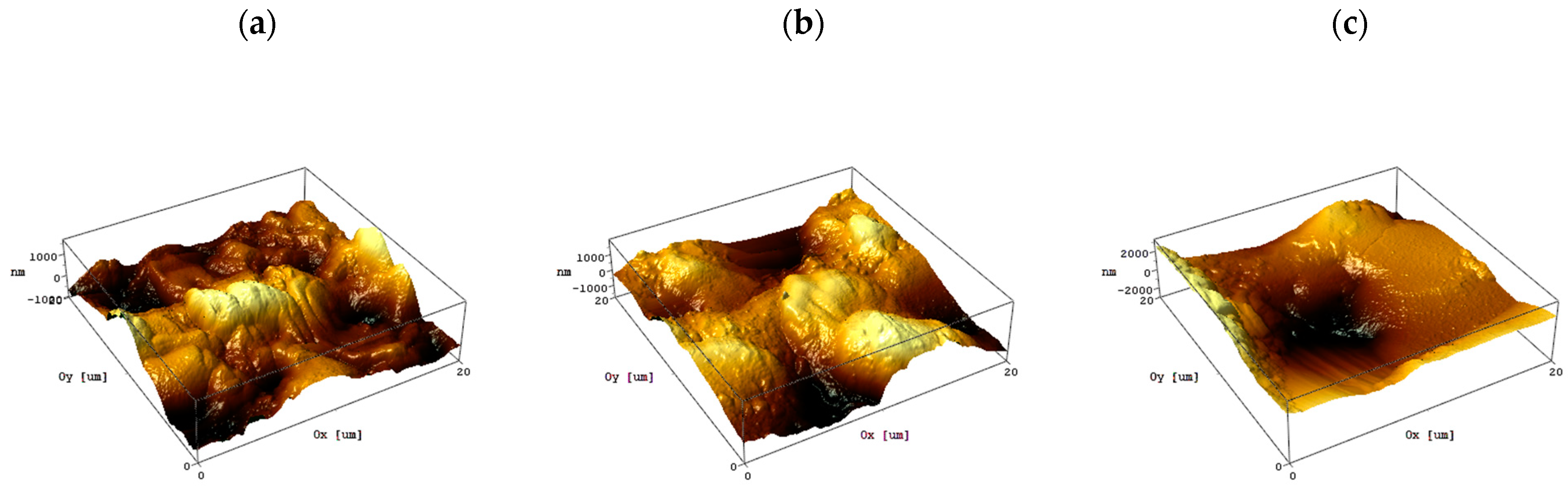

2.5. Crater Area (CA), Microhardness and Average Surface Roughness (SR)

2.6. Regression Model

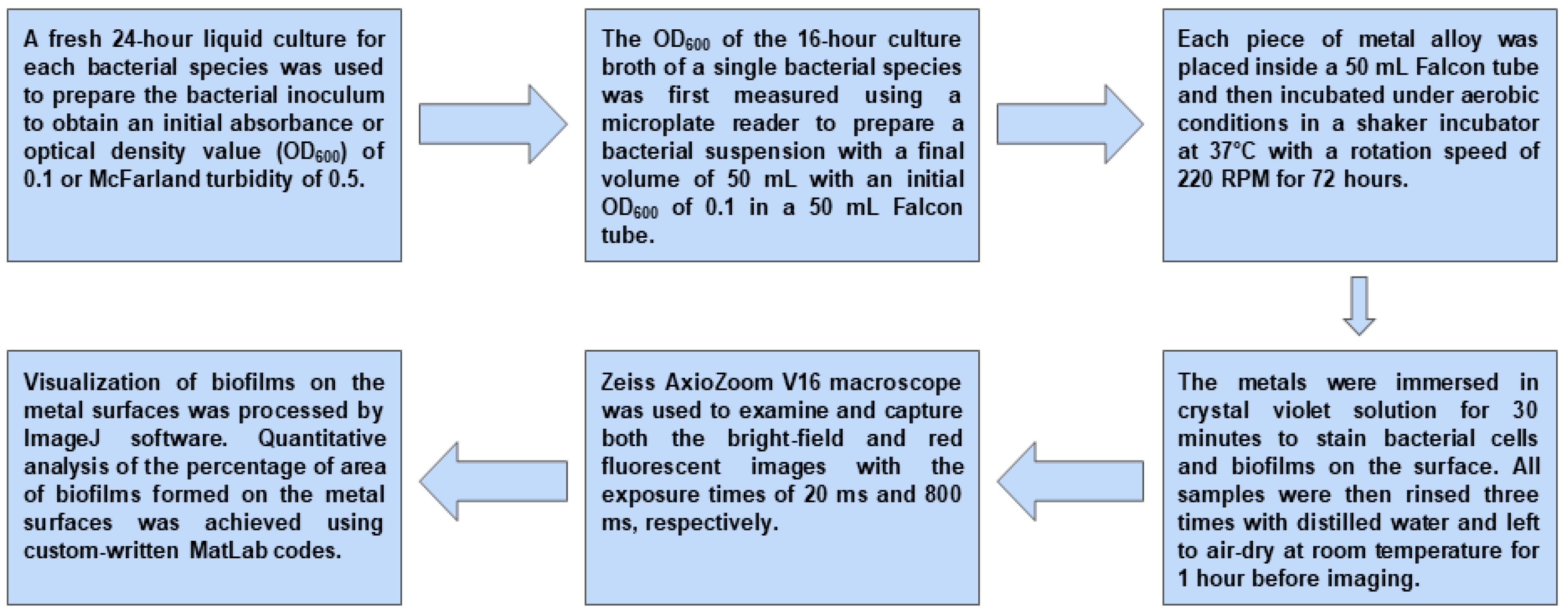

2.7. Antibacterial Test

3. Results and Discussion

3.1. Taguchi’s Orthogonal Array

3.2. ANOVA

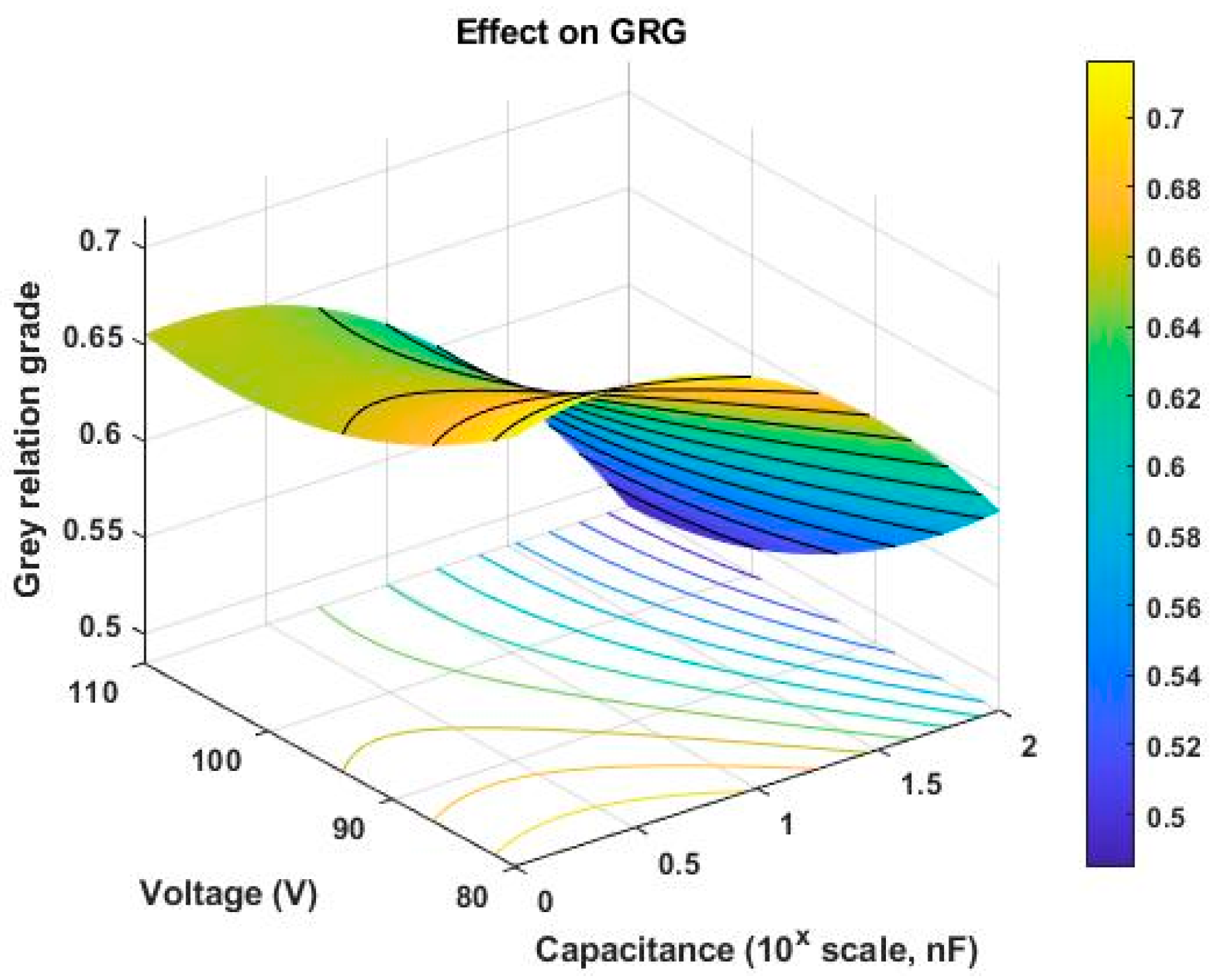

3.3. Grey Relation Analysis

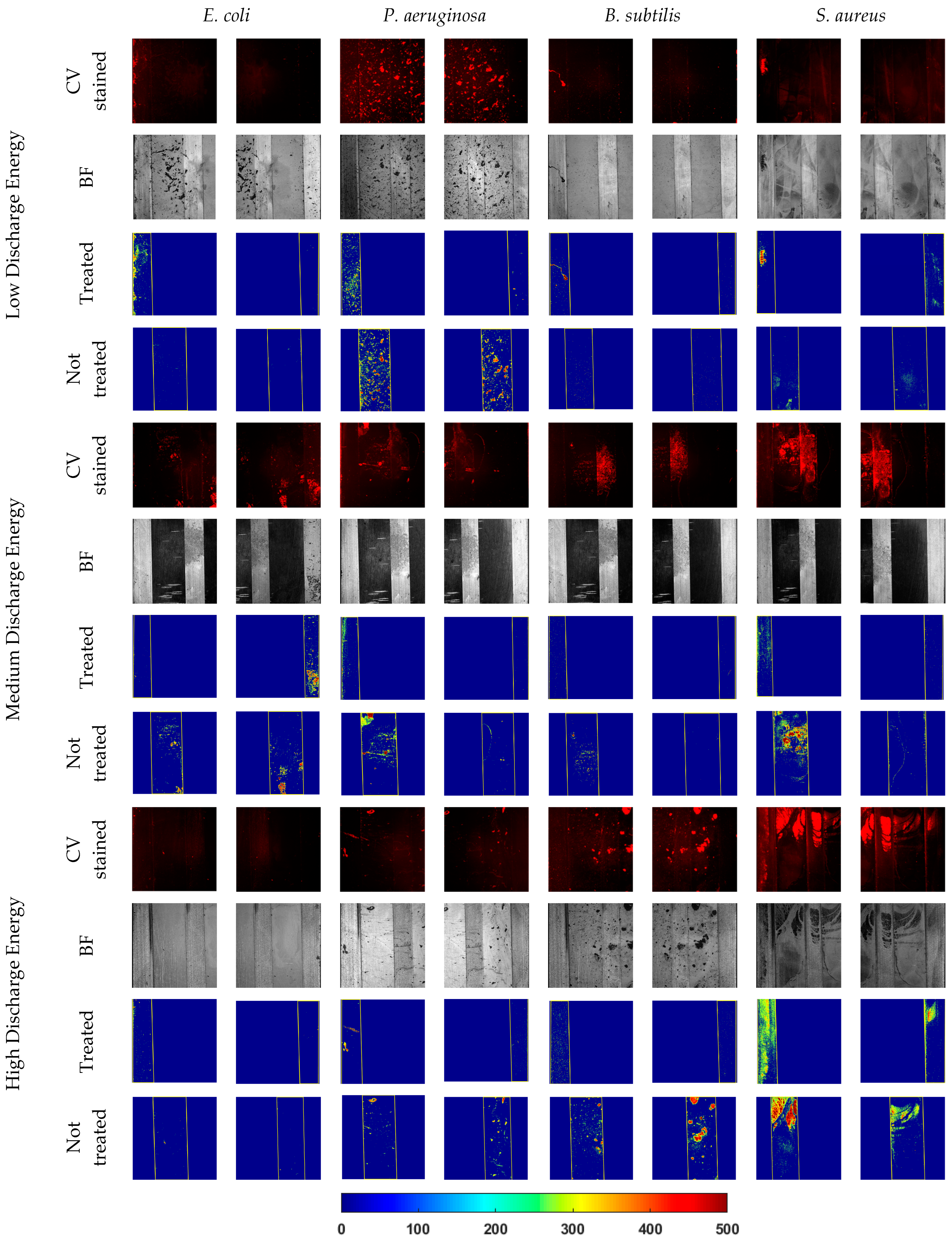

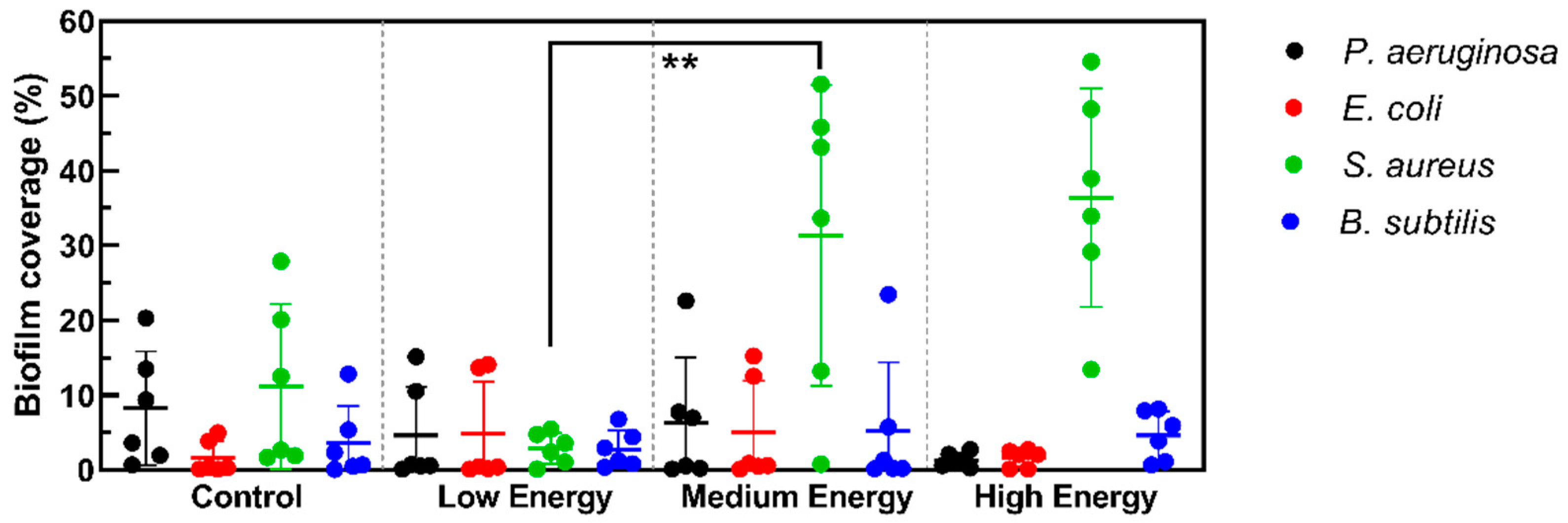

3.4. Antibacterial Response

4. Conclusions

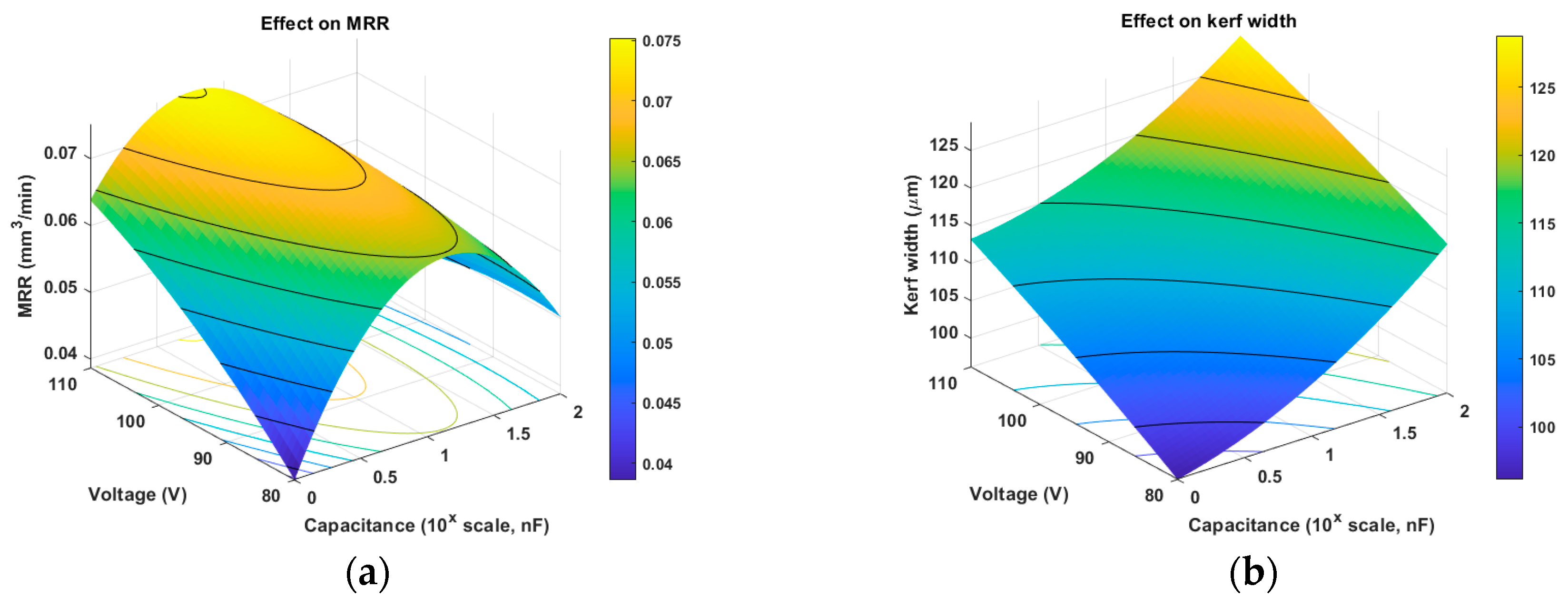

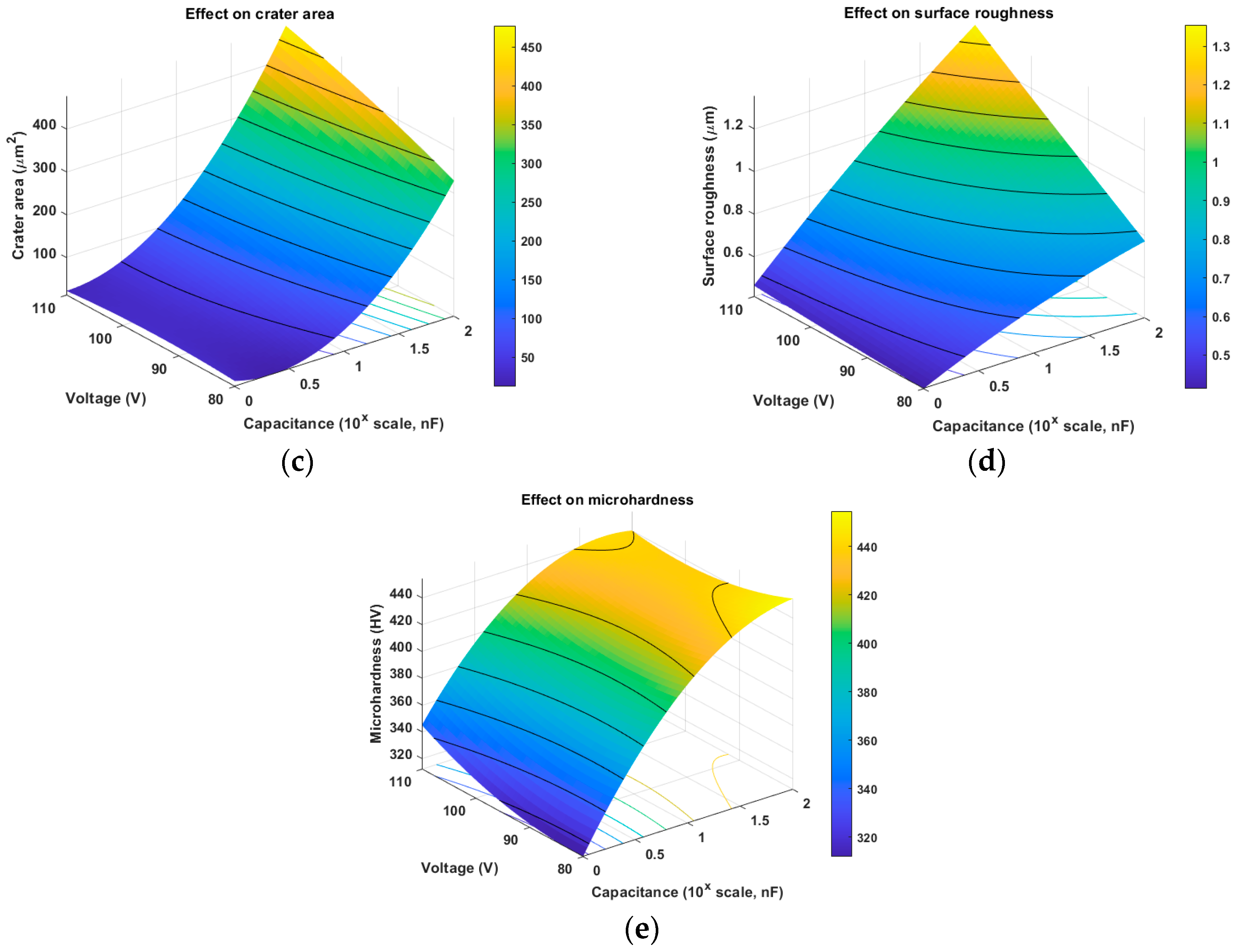

- Kerf width, crater size, surface roughness and microhardness increased with discharge energy through capacitance and gap voltage. Capacitance had a significant effect for all outputs, gap voltage was significant for kerf width, crater size and surface roughness and their interactions were significant for crater area and surface roughness.

- MRR had an increase from capacitance level 1 to level 2 following a drop at level 3. Meanwhile, increase in gap voltage contributed to a minor increase in MRR. Despite that, capacitance and the interaction of capacitance and gap voltage had a significant effect, while gap voltage was insignificant. The increase in discharge energy can benefit the amount of material removed per spark; however, insufficient debris removal results in poor machinability.

- According to Taguchi optimization, 10 nF and 110 V resulted in MRR (0.0637 mm3/min). The optimal parameters were 1 nF and 80 V for kerf width (93.0 μm), crater area (21.8 μm2) and surface roughness (0.348 μm). Microhardness was highest at 100 nF and 110 V and equal to 442 HV.

- The rank of output parameters of R2 were as follows: crater area (99.6%), surface roughness (89.60%), microhardness (85.99%), kerf width (83.55%) and MRR (72.44%). Crater area, having R2 equal to 99.6%, is strongly affected by capacitance and gap voltage, while MRR, with 72.44% of R2, might have other parameters influencing the results than capacitance and gap voltage.

- GRA estimated the most optimal conditions for multiple output parameters. Given the same priority values for every output parameter, the most optimal conditions were at 1 nF and 80 V. Comparing GRG from the middle level parameters (10 nF and 95 V) to optimal (1 nF and 80 V), the total improvement was equal to 11.9%.

- Analysis on biofilm formation of B. subtilis, E. coli, P. aeruginosa and S. aureus on treated surfaces observed improvement in antibacterial properties compared to untreated surfaces; however, specific observations also investigated a decrease of the antibacterial properties of a treated surface compared to untreated. It is suggested that the surface of Ti-29Nb-13Ta-4.6Zr can be treated by μ-WEDM with different discharge energy levels to adjust antibacterial properties accordingly against a specific bacterial strain. However, the least amount of total biofilm formation was achieved at the lowest surface roughness value equal to 0.348 μm obtained at 1 nF and 80 V.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Filipović, U.; Dahmane, R.G.; Ghannouchi, S.; Zore, A.; Bohinc, K. Bacterial adhesion on orthopedic implants. Adv. Colloid Interface Sci. 2020, 283, 102228. [Google Scholar] [CrossRef] [PubMed]

- Tsakiris, V.; Tardei, C.; Clicinschi, F.M. Biodegradable Mg alloys for orthopedic implants—A review. J. Magnes. Alloys 2021, 9, 1884–1905. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, R.; Wang, C.T.; He, Y.; He, Y.; Ma, Y.; Hu, X. Compressive Mechanical Properties and Shock-Induced Reaction Behavior of a Ti–29Nb–13Ta–4.6Zr Alloy. Met. Mater. Int. 2020, 26, 1498–1505. [Google Scholar] [CrossRef]

- Carlos, O.; Alejandro, D. Titanium as a Biomaterial for Implants. In Recent Advances in Arthroplasty; Samo, K.F., Ed.; IntechOpen: Rijeka, Croatia, 2012; Chapter 9. [Google Scholar]

- Gain, A.K.; Zhang, L.; Lim, S. Tribological behavior of Ti–6Al–4V alloy: Subsurface structure, damage mechanism and mechanical properties. Wear 2021, 464–465, 203551. [Google Scholar] [CrossRef]

- Lee, Y.T.; Welsch, G. Young’s modulus and damping of Ti-6Al-4V alloy as a function of heat treatment and oxygen concentration. Mater. Sci. Eng. A 1990, 128, 77–89. [Google Scholar] [CrossRef]

- Sidhu, S.S.; Singh, H.; Gepreel, M.A.-H. A review on alloy design, biological response, and strengthening of β-titanium alloys as biomaterials. Mater. Sci. Eng. C 2021, 121, 111661. [Google Scholar] [CrossRef]

- Bocchetta, P.; Chen, L.-Y.; Tardelli, J.D.; Reis, A.C.; Almeraya-Calderón, F.; Leo, P. Passive Layers and Corrosion Resistance of Biomedical Ti-6Al-4V and β-Ti Alloys. Coatings 2021, 11, 487. [Google Scholar] [CrossRef]

- Omarov, S.; Nauryz, N.; Talamona, D.; Perveen, A. Surface Modification Techniques for Metallic Biomedical Alloys: A Concise Review. Metals 2023, 13, 82. [Google Scholar] [CrossRef]

- Senopati, G.; Rahman Rashid, R.A.; Kartika, I.; Palanisamy, S. Recent Development of Low-Cost β-Ti Alloys for Biomedical Applications: A Review. Metals 2023, 13, 194. [Google Scholar] [CrossRef]

- Pesode, P.; Barve, S. A review—Metastable β titanium alloy for biomedical applications. J. Eng. Appl. Sci. 2023, 70, 25. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

- Koizumi, H.; Ishii, T.; Okazaki, T.; Kaketani, M.; Matsumura, H.; Yoneyama, T. Castability and mechanical properties of Ti-15Mo-5Zr-3Al alloy in dental casting. J. Oral Sci. 2018, 60, 285–292. [Google Scholar] [CrossRef] [PubMed]

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef] [PubMed]

- Bolzoni, L.; Ruiz-Navas, E.M.; Gordo, E. Investigation of the factors influencing the tensile behaviour of PM Ti–3Al–2.5V alloy. Mater. Sci. Eng. A 2014, 609, 266–272. [Google Scholar] [CrossRef]

- Canumalla, R.; Jayaraman, T.V. Decision Science-Driven Assessment of Ti Alloys for Aircraft Landing Gear Beams. Aerospace 2024, 11, 51. [Google Scholar] [CrossRef]

- Xu, Y.F.; Yi, D.Q.; Liu, H.Q.; Wu, X.Y.; Wang, B.; Yang, F.L. Effects of cold deformation on microstructure, texture evolution and mechanical properties of Ti–Nb–Ta–Zr–Fe alloy for biomedical applications. Mater. Sci. Eng. A 2012, 547, 64–71. [Google Scholar] [CrossRef]

- Niinomi, M.; Hattori, T.; Morikawa, K.; Kasuga, T.; Suzuki, A.; Fukui, H.; Niwa, S. Development of Low Rigidity β-type Titanium Alloy for Biomedical Applications. Mater. Trans. 2002, 43, 2970–2977. [Google Scholar] [CrossRef]

- Niinomi, M.; Liu, Y.; Nakai, M.; Liu, H.; Li, H. Biomedical titanium alloys with Young’s moduli close to that of cortical bone. Regen. Biomater. 2016, 3, 173–185. [Google Scholar] [CrossRef]

- Niinomi, M. Fatigue performance and cyto-toxicity of low rigidity titanium alloy, Ti–29Nb–13Ta–4.6Zr. Biomaterials 2003, 24, 2673–2683. [Google Scholar] [CrossRef]

- Sotniczuk, A.; Kuczyńska-Zemła, D.; Kwaśniak, P.; Thomas, M.; Garbacz, H. Corrosion behavior of Ti-29Nb-13Ta-4.6Zr and commercially pure Ti under simulated inflammatory conditions–comparative effect of grain refinement and non-toxic β phase stabilizers. Electrochim. Acta 2019, 312, 369–379. [Google Scholar] [CrossRef]

- Rajabi, F.; Zarei Hanzaki, A.; Abedi, H.R.; Farghadany, E. Corrosion behavior of thermo-mechanically processed biomedical Ti-29Nb-13Ta-4.6Zr. J. Alloys Compd. 2017, 725, 23–31. [Google Scholar] [CrossRef]

- Gunawarman; Giatmana, D.D.; Ilhamdi; Affi, J.; Fonna, S.; Niinomi, M.; Nakai, M. Corrosion resistance of new beta type titanium alloy, Ti-29Nb-13Ta-4.6Zr in artificial saliva solution. IOP Conf. Ser. Mater. Sci. Eng. 2018, 352, 012008. [Google Scholar] [CrossRef]

- Li, S.J.; Yang, R.; Li, S.; Hao, Y.L.; Cui, Y.Y.; Niinomi, M.; Guo, Z.X. Wear characteristics of Ti–Nb–Ta–Zr and Ti–6Al–4V alloys for biomedical applications. Wear 2004, 257, 869–876. [Google Scholar] [CrossRef]

- Matos, G.R.M. Surface Roughness of Dental Implant and Osseointegration. J. Maxillofac. Oral Surg. 2021, 20, 1–4. [Google Scholar] [CrossRef]

- Ghimire, A.; Song, J. Anti-Periprosthetic Infection Strategies: From Implant Surface Topographical Engineering to Smart Drug-Releasing Coatings. ACS Appl. Mater. Interfaces 2021, 13, 20921–20937. [Google Scholar] [CrossRef]

- Liu, Y.; Rath, B.; Tingart, M.; Eschweiler, J. Role of implants surface modification in osseointegration: A systematic review. J. Biomed. Mater. Res. Part A 2020, 108, 470–484. [Google Scholar] [CrossRef] [PubMed]

- Al-Amin, M.; Abdul Rani, A.M.; Abdu Aliyu, A.A.; Abdul Razak, M.A.H.; Hastuty, S.; Bryant, M.G. Powder mixed-EDM for potential biomedical applications: A critical review. Mater. Manuf. Process. 2020, 35, 1789–1811. [Google Scholar] [CrossRef]

- Mughal, M.P.; Farooq, M.U.; Mumtaz, J.; Mia, M.; Shareef, M.; Javed, M.; Jamil, M.; Pruncu, C.I. Surface modification for osseointegration of Ti6Al4V ELI using powder mixed sinking EDM. J. Mech. Behav. Biomed. Mater. 2021, 113, 104145. [Google Scholar] [CrossRef] [PubMed]

- Bharat, N.; Bose, P.S.C. An overview on machinability of hard to cut materials using laser assisted machining. Mater. Today: Proc. 2021, 43, 665–672. [Google Scholar] [CrossRef]

- Alkahlan, B.; Tabbakh, T.; Kurdi, A.; Pramanik, A.; Basak, A.K. Formation and Characterization of the Recast Layer Formed on Inconel 718 during Wire Electro Discharge Machining. Materials 2023, 16, 930. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Cui, Y.-W.; Zhang, L.-C. Recent Development in Beta Titanium Alloys for Biomedical Applications. Metals 2020, 10, 1139. [Google Scholar] [CrossRef]

- Öpöz, T.T.; Yaşar, H.; Murphy, M.F.; Ekmekci, N.; Ekmekci, B. Ti6Al4V Surface Modification by Hydroxyapatite Powder Mixed Electrical Discharge Machining for Medical Applications. In Proceedings of the 18th International Conference on Machine Design and Production, Eskişehir, Turkey, 3–6 July 2018; pp. 787–802. [Google Scholar]

- Büssemaker, H.; Meinshausen, A.-K.; Bui, V.D.; Döring, J.; Voropai, V.; Buchholz, A.; Mueller, A.J.; Harnisch, K.; Martin, A.; Berger, T.; et al. Silver-integrated EDM processing of TiAl6V4 implant material has antibacterial capacity while optimizing osseointegration. Bioact. Mater. 2024, 31, 497–508. [Google Scholar] [CrossRef] [PubMed]

- Jayakumar, K.; Suresh, T. Effect of wire materials on performance during WEDM of SS304. Mater. Today Proc. 2022, 62, 606–610. [Google Scholar] [CrossRef]

- Suresh, T.; Jayakumar, K.; Selvakumar, G.; Ramprakash, S. Experimental investigation on improvement of machinability of SS 304 through multipass cutting in WEDM. Arab. J. Sci. Eng. 2023, 48, 11577–11590. [Google Scholar] [CrossRef]

- Manoj, I.V.; Narendranath, S. Wire electric discharge machining at different slant angles during slant type taper profiling of microfer 4722 superalloy. J. Mater. Eng. Perform. 2022, 31, 697–708. [Google Scholar] [CrossRef]

- Zhang, T.; Xiao, H.; Zhang, Z.; Yao, B.; Yang, F. Effect of Y2O3 addition on microstructural characteristics and microhardness of laser-cladded Ti-6Al-4V alloy coating. J. Mater. Eng. Perform. 2020, 29, 8221–8235. [Google Scholar] [CrossRef]

- Naydenkin, E.V.; Mishin, I.P.; Ratochka, I.V.; Lykova, O.N.; Zabudchenko, O.V. The effect of alpha-case formation on plastic deformation and fracture of near β titanium alloy. Mater. Sci. Eng. A 2020, 769, 138495. [Google Scholar] [CrossRef]

- Guo, Z.; Huang, Y.; Sun, C.; He, Z.; Li, Y.; Qiu, H.; Yuan, D.; Zhang, J.; Chu, C.; Shen, B. Preparation and characterization of metastable β-type titanium alloys with favorable properties for orthopedic applications. J. Alloys Compd. 2023, 949, 169839. [Google Scholar] [CrossRef]

- Elius, M.; Richard, S.; Boyle, K.; Chang, W.S.; Moisander, P.H.; Ling, H. Impact of gas bubbles on bacterial adhesion on super-hydrophobic aluminum surfaces. Results Surf. Interfaces 2024, 15, 100211. [Google Scholar] [CrossRef]

- Knapic, D.; Minenkov, A.; Luczak, W.; Zrinski, I.; Kleber, C.; Hild, S.; Weth, A.; Hassel, A.W.; Mardare, A.I. Hindrance of osteoblast cell adhesion on titanium by surface nanostructuring. Surf. Interfaces 2024, 46, 103990. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, L.; Wang, Z. Experimental study on EDM of network microstructure titanium matrix composites. Mater. Manuf. Process. 2024, 1–13. [Google Scholar] [CrossRef]

- Somashekhar, K.P.; Mathew, J.; Ramachandran, N. Multi-objective optimization of micro wire electric discharge machining parameters using grey relational analysis with Taguchi method. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2011, 225, 1742–1753. [Google Scholar] [CrossRef]

- Kuriachen, B.; Somashekhar, K.P.; Mathew, J. Multiresponse optimization of micro-wire electrical discharge machining process. Int. J. Adv. Manuf. Technol. 2015, 76, 91–104. [Google Scholar] [CrossRef]

- Ali, M.Y.; Banu, A.; Al Hazza, M.H. Analysis of kerf accuracy in dry micro-wire EDM. Int. J. Adv. Manuf. Technol. 2020, 111, 597–608. [Google Scholar] [CrossRef]

- Zhou, M.; Mu, X.; He, L.; Ye, Q. Improving EDM performance by adapting gap servo-voltage to machining state. J. Manuf. Process. 2019, 37, 101–113. [Google Scholar] [CrossRef]

- Jeswani, M.L. Roughness and wear characteristics of spark-eroded surfaces. Wear 1978, 51, 227–236. [Google Scholar] [CrossRef]

- Jahan, M.P.; Alavi, F.; Kirwin, R.; Mahbub, R. Micro-EDM induced surface modification of titanium alloy for biocompatibility. Int. J. Mach. Mach. Mater. 2018, 20, 274–298. [Google Scholar]

- Wang, X.; Li, C.; Guo, H.; Yi, S.; Kong, L.; Ding, S. Alternating Energy Electrical Discharge Machining of Titanium Alloy Using a WC-PCD Electrode. J. Manuf. Process. 2020, 60, 37–47. [Google Scholar] [CrossRef]

- Yang, K.; Shi, J.; Wang, L.; Chen, Y.; Liang, C.; Yang, L.; Wang, L.-N. Bacterial anti-adhesion surface design: Surface patterning, roughness and wettability: A review. J. Mater. Sci. Technol. 2022, 99, 82–100. [Google Scholar] [CrossRef]

| Material | Alloy Type | UTS (MPa) | Elastic Modulus (GPa) | Refs. |

|---|---|---|---|---|

| Cortical bone | - | 119.4–150.6 | 14–21.8 | [9,10] |

| CP Ti | α | 240–500 | 100–115 | [9,11] |

| Ti-6Al-4V (annealed) | α+β | 895–930 | 110–114 | [9,10,12] |

| Ti-6Al-7Nb | α+β | 900–1050 | 105–114 | [9,11,12,13] |

| Ti-5Al-2.5Fe | α+β | 1020–1033 | 110–112 | [9,11,12,14] |

| Ti-3Al-2.5V | α+β | 620–690 | 100–107 | [9,11,15] |

| Ti-6.5Al-3.3Mo-0.3Si | α+β | 911 | 65 | [16] |

| Ti-15V-3Cr-3Al-3Sn | β | 1248 | 82 | [16] |

| Ti-10V-2Fe-3Al | β | 965–1193 | 109.6 | [16] |

| Ti-29Nb-13Ta-4.6Zr | β | 911 | 65 | [11] |

| Ti-35Nb-5Ta-7Zr | β | 590–597 | 55 | [9,11,17] |

| Ti-15Mo | β | 874–921 | 78–84 | [9,10,11] |

| Ti-13Nb-13Zr | β | 970–1040 | 77–84 | [9,11] |

| Ti-12Mo-6Zr-2Fe | β | 1060–1100 | 74–85 | [11] |

| Ti-15Mo-5Zr-3Al | β | 880–980 | 75–88 | [9,11] |

| Surface Condition | Ti (wt%) | Nb (wt%) | Ta (wt%) | Zr (wt%) | Si (wt%) | O (wt%) | C (wt%) | W (wt%) |

|---|---|---|---|---|---|---|---|---|

| Pure TNTZ * | 52.22 | 30.52 | 12.49 | 4.77 | - | - | - | - |

| Not treated | 42.19 | 24.43 | 10.19 | 3.81 | 2.47 | 8.89 | 8.03 | - |

| Low-energy treated | 33.60 | 27.80 | 13.50 | 3.67 | 0.56 | 2.35 | 16.10 | 2.42 |

| Medium-energy treated | 35.79 | 27.52 | 12.89 | 4.07 | 0.53 | 1.79 | 15.65 | 1.76 |

| High-energy treated | 39.66 | 26.91 | 12.47 | 4.30 | 0.36 | 1.54 | 13.02 | 1.74 |

| Parameter | Value | Unit |

|---|---|---|

| Gap voltage | 80, 95, and 110 | V |

| Capacitance | 1, 10, and 100 | nF |

| Wire speed | 0.8377 | mm/s |

| Feed rate | 1.5 | μm/s |

| Wire tension | 8.25 | g-wt |

| Depth of cut | 50 | μm |

| Wire diameter | 50 | μm |

| Workpiece polarity | Positive |

| Parameters | Factor | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|

| Capacitance (nF) | A | 1 | 10 | 100 |

| Gap Voltage (V) | B | 80 | 95 | 110 |

| Exp. No. | Factors | MRR (mm3/min) | Kerf Width (μm) | Crater Size (μm2) | Average Surface Roughness (μm) | Microhardness (HV) | |

|---|---|---|---|---|---|---|---|

| A | B | ||||||

| 1 | 1 | 1 | 0.0266 | 89.6 | 19 | 0.457 | 343 |

| 2 | 1 | 1 | 0.0345 | 94.8 | 22 | 0.276 | 270 |

| 3 | 1 | 1 | 0.0305 | 95.6 | 24 | 0.311 | 313 |

| 4 | 1 | 2 | 0.0636 | 116.6 | 23 | 0.635 | 312 |

| 5 | 1 | 2 | 0.0582 | 104.8 | 33 | 0.324 | 315 |

| 6 | 1 | 2 | 0.0546 | 104.8 | 24 | 0.399 | 349 |

| 7 | 1 | 3 | 0.0665 | 113.2 | 28 | 0.504 | 326 |

| 8 | 1 | 3 | 0.0671 | 113.2 | 31 | 0.567 | 316 |

| 9 | 1 | 3 | 0.0663 | 110.7 | 34 | 0.468 | 385 |

| 10 | 2 | 1 | 0.0921 | 112.4 | 95 | 0.611 | 409 |

| 11 | 2 | 1 | 0.0689 | 95.6 | 74 | 0.820 | 436 |

| 12 | 2 | 1 | 0.0670 | 106.5 | 66 | 0.720 | 409 |

| 13 | 2 | 2 | 0.0635 | 111.5 | 115 | 0.778 | 363 |

| 14 | 2 | 2 | 0.0749 | 111.5 | 89 | 0.761 | 441 |

| 15 | 2 | 2 | 0.0721 | 112.4 | 93 | 0.921 | 423 |

| 16 | 2 | 3 | 0.0421 | 119.9 | 123 | 0.931 | 419 |

| 17 | 2 | 3 | 0.0846 | 119.1 | 128 | 0.661 | 433 |

| 18 | 2 | 3 | 0.0645 | 108.2 | 133 | 0.832 | 425 |

| 19 | 3 | 1 | 0.0410 | 118.3 | 328 | 0.908 | 446 |

| 20 | 3 | 1 | 0.0394 | 115.7 | 313 | 0.496 | 463 |

| 21 | 3 | 1 | 0.0593 | 117.5 | 308 | 0.831 | 459 |

| 22 | 3 | 2 | 0.0550 | 120.1 | 434 | 1.142 | 456 |

| 23 | 3 | 2 | 0.0416 | 117.5 | 451 | 0.991 | 432 |

| 24 | 3 | 2 | 0.0411 | 118.3 | 392 | 0.876 | 416 |

| 25 | 3 | 3 | 0.0469 | 135.0 | 476 | 1.339 | 429 |

| 26 | 3 | 3 | 0.0509 | 121.6 | 473 | 1.421 | 463 |

| 27 | 3 | 3 | 0.0578 | 139.2 | 480 | 1.561 | 435 |

| Source | DF | SS (×10−3) | MS (×10−3) | F | p | Contribution |

|---|---|---|---|---|---|---|

| A | 2 | 2.45 | 1.22 | 11.81 | 0.00 | 36.17% |

| B | 2 | 0.46 | 0.23 | 2.21 | 0.14 | 6.78% |

| A × B | 4 | 2.00 | 0.50 | 4.82 | 0.01 | 29.49% |

| Error | 18 | 1.86 | 0.10 | 27.56% | ||

| Total | 26 | 6.77 | 100% | |||

| R2 = 72.44% | R2 (adj) = 60.19% |

| Source | DF | SS | MS | F | p | Contribution |

|---|---|---|---|---|---|---|

| A | 2 | 1468 | 734.10 | 25.17 | 0.00 | 46.01% |

| B | 2 | 1004 | 502.10 | 17.21 | 0.00 | 31.47% |

| A × B | 4 | 194 | 48.40 | 1.66 | 0.20 | 6.07% |

| Error | 18 | 525 | 29.20 | 16.45% | ||

| Total | 26 | 3191 | 100% | |||

| R2 = 83.55% | R2 (adj) = 76.23% |

| Source | DF | SS | MS | F | p | Contribution |

|---|---|---|---|---|---|---|

| A | 2 | 727.40 | 363.69 | 2137.96 | 0.00 | 93.92% |

| B | 2 | 24.40 | 12.19 | 71.64 | 0.00 | 3.15% |

| A × B | 4 | 19.70 | 4.92 | 28.93 | 0.00 | 2.54% |

| Error | 18 | 3.10 | 0.17 | 0.40% | ||

| Total | 26 | 774.50 | 100% | |||

| R2 = 99.60% | R2 (adj) = 99.43% |

| Source | DF | SS | MS | F | p | Contribution |

|---|---|---|---|---|---|---|

| A | 2 | 1.76 | 0.88 | 51.60 | 0.00 | 61.37% |

| B | 2 | 0.45 | 0.23 | 13.25 | 0.00 | 15.76% |

| A × B | 4 | 0.35 | 0.09 | 5.12 | 0.01 | 12.17% |

| Error | 18 | 0.31 | 0.02 | 10.70% | ||

| Total | 26 | 2.87 | 100% | |||

| R2 = 89.30% | R2 (adj) = 84.54% |

| Source | DF | SS (×103) | MS (×103) | F | p | Contribution |

|---|---|---|---|---|---|---|

| A | 2 | 70.01 | 35.00 | 53.10 | 0.00 | 82.66% |

| B | 2 | 0.89 | 0.44 | 0.67 | 0.52 | 1.05% |

| A × B | 4 | 1.93 | 0.48 | 0.73 | 0.58 | 2.28% |

| Error | 18 | 11.87 | 0.66 | 14.01% | ||

| Total | 26 | 84.69 | 100% | |||

| R2 = 85.99% | R2 (adj) = 79.76% |

| No. Exp. | Grey Relation Coefficient | Grey Relation Grade | Average Grey Relation Grade | ||||

|---|---|---|---|---|---|---|---|

| MRR | Kerf Width | Crater Area | Average Surface Roughness | Microhardness | |||

| 1 | 0.333 | 1.000 | 1.000 | 0.827 | 0.446 | 0.721 | 0.707 |

| 2 | 0.362 | 0.827 | 0.988 | 1.000 | 0.333 | 0.702 | |

| 3 | 0.347 | 0.805 | 0.980 | 0.961 | 0.391 | 0.697 | |

| 4 | 0.534 | 0.479 | 0.984 | 0.707 | 0.390 | 0.619 | 0.659 |

| 5 | 0.491 | 0.619 | 0.946 | 0.947 | 0.395 | 0.680 | |

| 6 | 0.466 | 0.619 | 0.979 | 0.875 | 0.458 | 0.680 | |

| 7 | 0.561 | 0.512 | 0.965 | 0.791 | 0.413 | 0.649 | 0.655 |

| 8 | 0.567 | 0.512 | 0.951 | 0.748 | 0.396 | 0.635 | |

| 9 | 0.559 | 0.540 | 0.942 | 0.818 | 0.553 | 0.682 | |

| 10 | 1.000 | 0.521 | 0.752 | 0.721 | 0.641 | 0.727 | 0.702 |

| 11 | 0.585 | 0.805 | 0.809 | 0.614 | 0.781 | 0.719 | |

| 12 | 0.566 | 0.594 | 0.831 | 0.661 | 0.641 | 0.659 | |

| 13 | 0.533 | 0.531 | 0.707 | 0.633 | 0.491 | 0.579 | 0.632 |

| 14 | 0.655 | 0.531 | 0.767 | 0.641 | 0.814 | 0.681 | |

| 15 | 0.621 | 0.521 | 0.758 | 0.573 | 0.707 | 0.636 | |

| 16 | 0.396 | 0.450 | 0.690 | 0.569 | 0.687 | 0.558 | 0.620 |

| 17 | 0.813 | 0.457 | 0.679 | 0.692 | 0.763 | 0.681 | |

| 18 | 0.542 | 0.572 | 0.670 | 0.609 | 0.717 | 0.622 | |

| 19 | 0.390 | 0.464 | 0.428 | 0.578 | 0.850 | 0.542 | 0.587 |

| 20 | 0.383 | 0.487 | 0.440 | 0.797 | 1.000 | 0.621 | |

| 21 | 0.499 | 0.471 | 0.444 | 0.609 | 0.960 | 0.597 | |

| 22 | 0.468 | 0.449 | 0.357 | 0.500 | 0.932 | 0.541 | 0.515 |

| 23 | 0.393 | 0.471 | 0.348 | 0.547 | 0.757 | 0.503 | |

| 24 | 0.391 | 0.464 | 0.382 | 0.590 | 0.672 | 0.500 | |

| 25 | 0.420 | 0.353 | 0.335 | 0.449 | 0.739 | 0.459 | 0.485 |

| 26 | 0.442 | 0.437 | 0.337 | 0.430 | 1.000 | 0.529 | |

| 27 | 0.488 | 0.333 | 0.333 | 0.402 | 0.775 | 0.466 |

| Source | DF | SS (×10−3) | MS (×10−3) | F | p | Contribution |

|---|---|---|---|---|---|---|

| A | 2 | 109.50 | 54.77 | 36.70 | 0.00 | 64.72% |

| B | 2 | 30.80 | 15.42 | 10.33 | 0.00 | 18.22% |

| A × B | 4 | 2.00 | 0.50 | 0.33 | 0.85 | 1.18% |

| Error | 18 | 26.90 | 1.49 | 15.87% | ||

| Total | 26 | 169.30 | 100% | |||

| R2 = 84.13% | R2 (adj) = 77.07% |

| Parameters | Level 1 | Level 2 | Level 3 | Delta | Rank |

|---|---|---|---|---|---|

| Capacitance | 0.674 | 0.651 | 0.529 | 0.145 | 1 |

| Gap Voltage | 0.665 | 0.602 | 0.587 | 0.078 | 2 |

| Total mean value of GRG | 0.618 |

| Initial Parameters | Taguchi Optimization | GRA Optimization | Initial Parameters | |

|---|---|---|---|---|

| Levels | ||||

| Levels | A2B2 | A1B1 | ||

| MRR (mm3/min) | 0.0702 * | A2B3 | 0.0637 | 0.03056 |

| Kerf width (μm) | 111.8 * | A1B1 | 93.0 | 93.0 |

| Crater size (μm2) | 99.1 * | A1B1 | 21.8 | 21.8 |

| Average surface roughness (μm) | 0.820 * | A1B1 | 0.348 | 0.348 |

| Microhardness (HV) | 409 * | A3B3 | 442 | 309 |

| GRG | 0.632 * | A1B1 | 0.707 | 0.707 |

| Improvement in GRG = 0.075 or 11.9% | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, S.; Omarov, S.; Utebayeva, A.; Pham, T.T.; Talamona, D.; Perveen, A. Micro-WEDM of Ti-29Nb-13Ta-4.6Zr Alloy for Antibacterial Properties: Experimental Investigation and Optimization. Metals 2024, 14, 714. https://doi.org/10.3390/met14060714

Ali S, Omarov S, Utebayeva A, Pham TT, Talamona D, Perveen A. Micro-WEDM of Ti-29Nb-13Ta-4.6Zr Alloy for Antibacterial Properties: Experimental Investigation and Optimization. Metals. 2024; 14(6):714. https://doi.org/10.3390/met14060714

Chicago/Turabian StyleAli, Shahid, Salikh Omarov, Altynay Utebayeva, Tri Thanh Pham, Didier Talamona, and Asma Perveen. 2024. "Micro-WEDM of Ti-29Nb-13Ta-4.6Zr Alloy for Antibacterial Properties: Experimental Investigation and Optimization" Metals 14, no. 6: 714. https://doi.org/10.3390/met14060714