Influence of the Material Production Route on the Material Properties and the Machinability of the Lead-Free Copper-Zinc-Alloy CuZn40 (CW509L)

Abstract

:1. Introduction

2. Materials and Methods

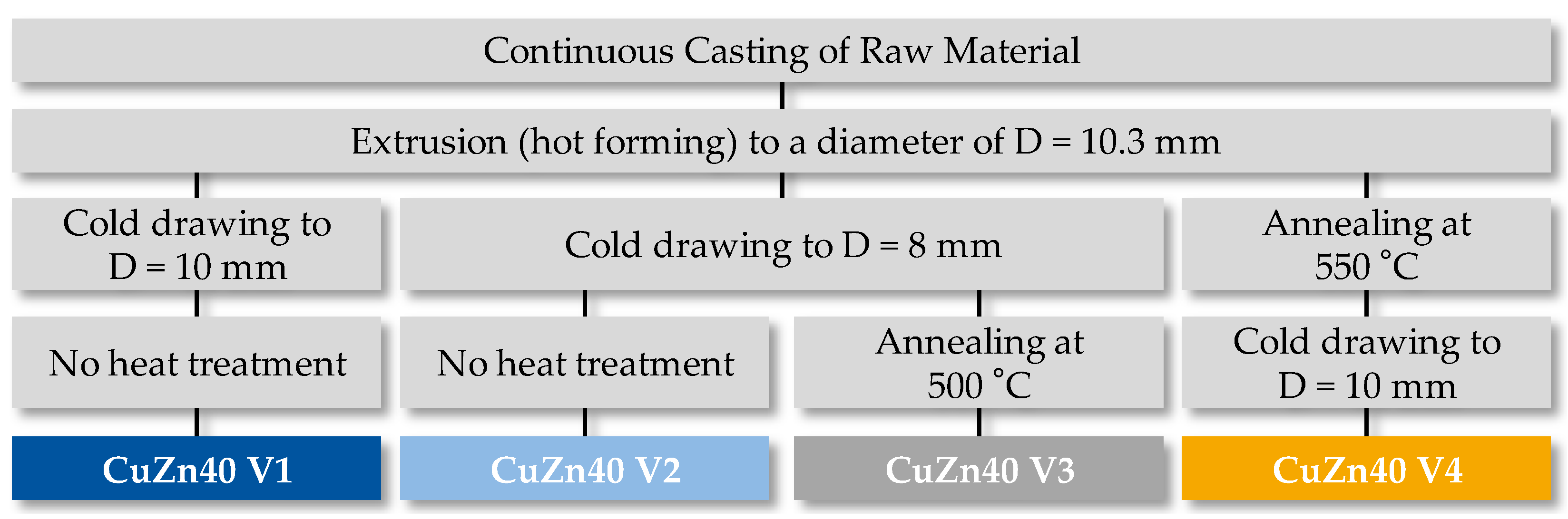

2.1. Investigated Materials

2.1.1. Chemical Composition

2.1.2. Mechanical Material Properties

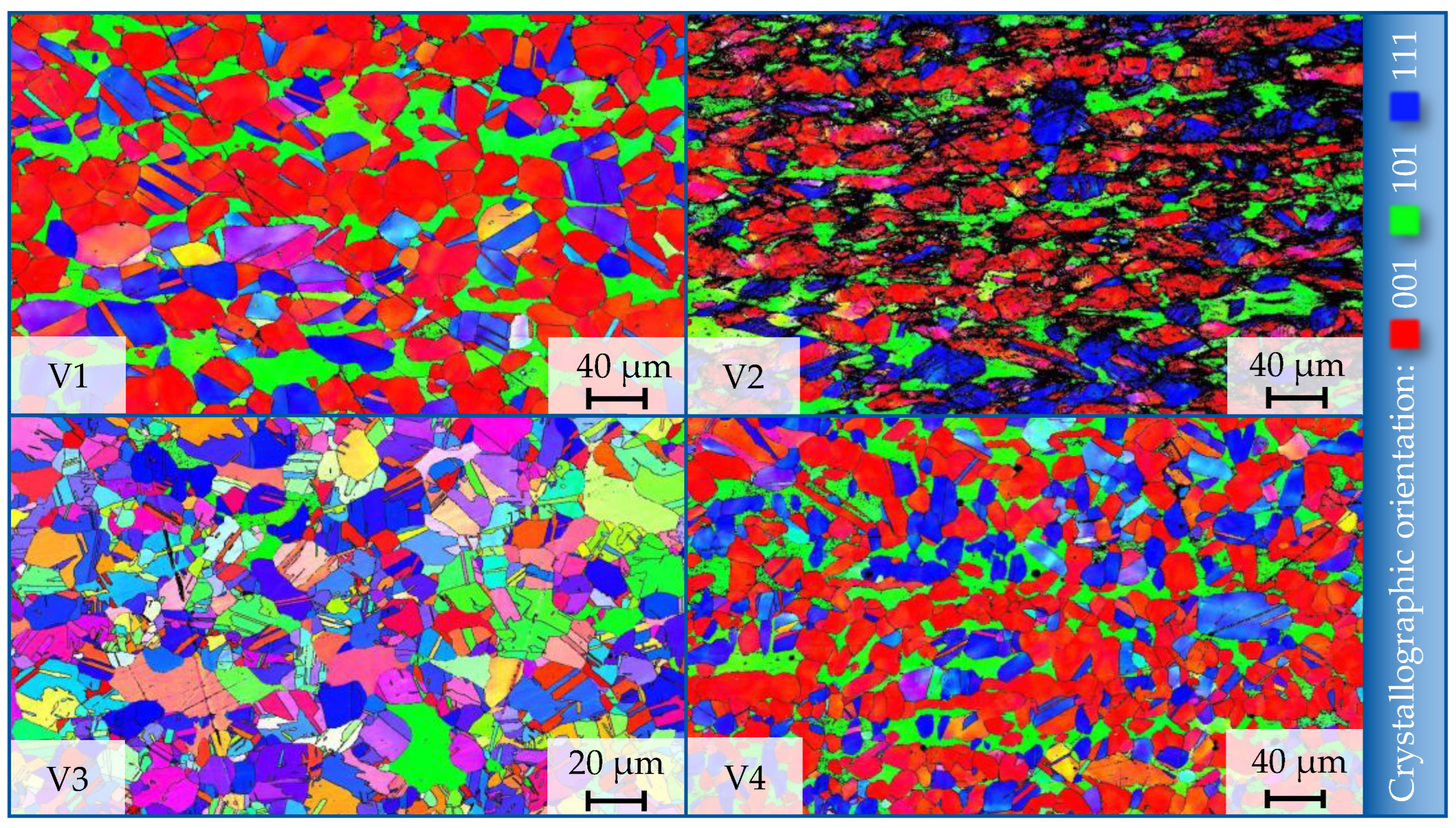

2.1.3. Characteristics of the Material Microstructure

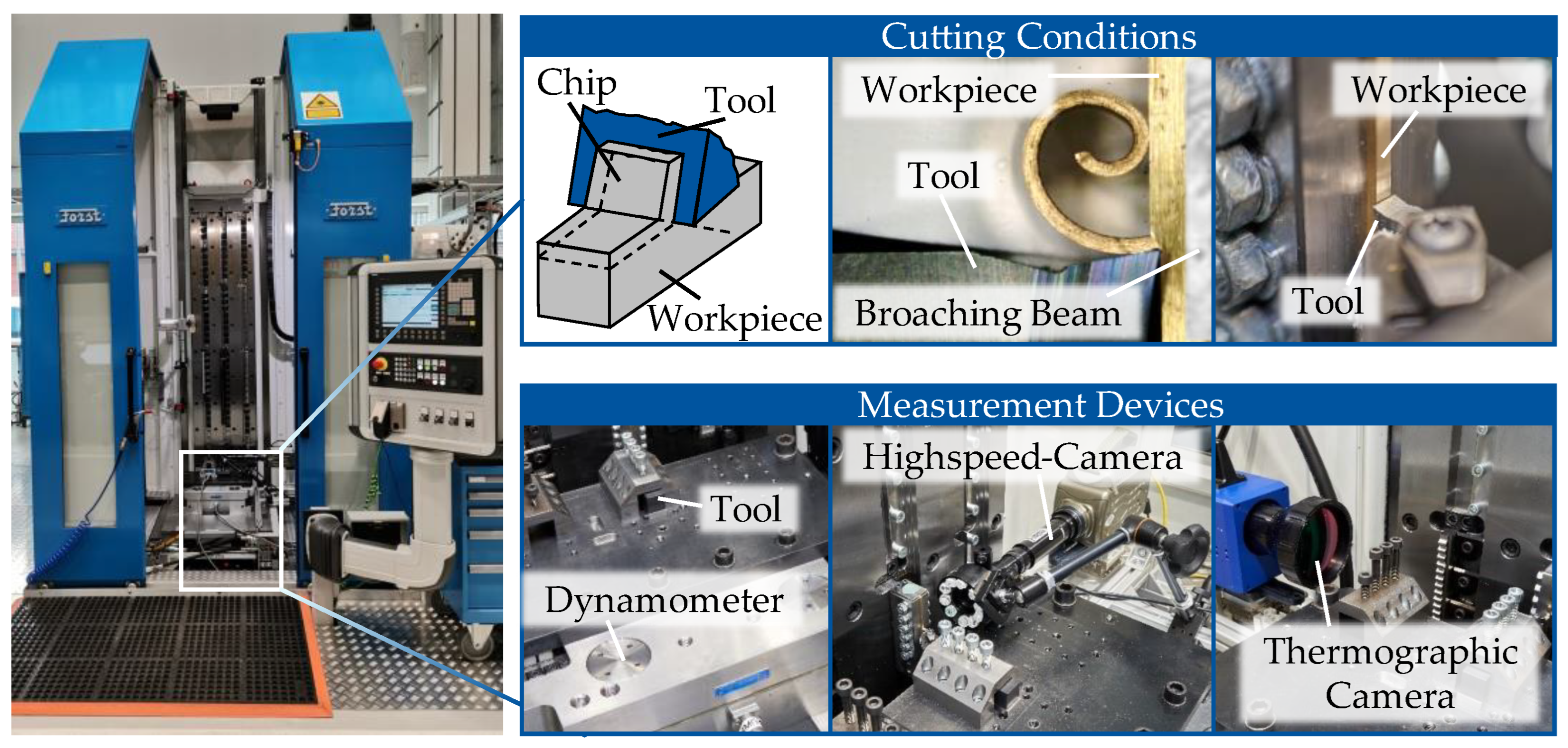

2.2. Experimental Setup

2.3. Experimental Design

3. Results and Discussion

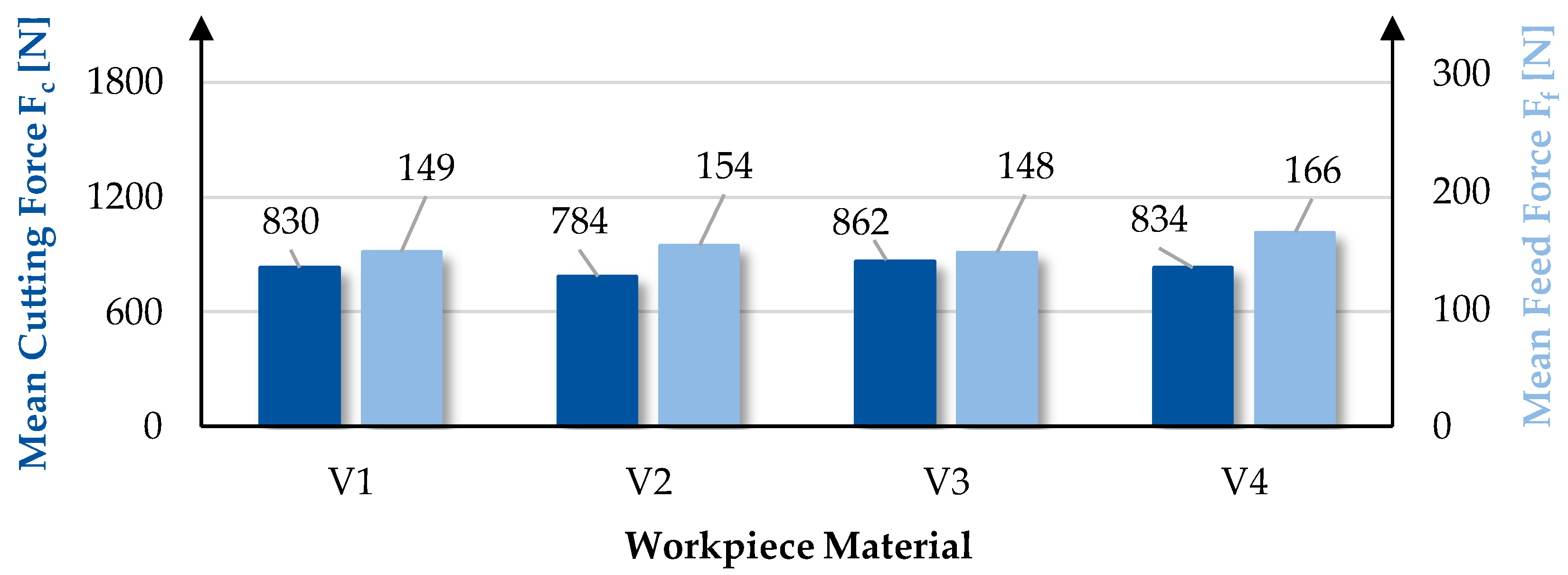

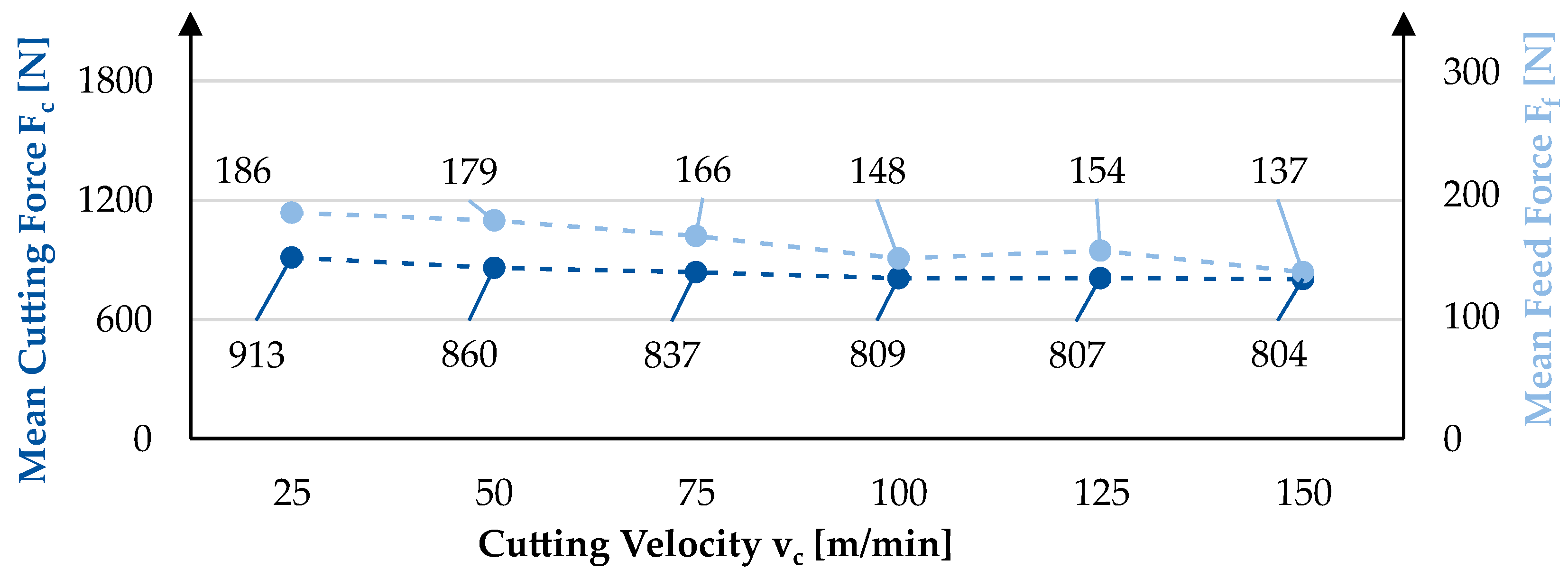

3.1. Cutting Force Components

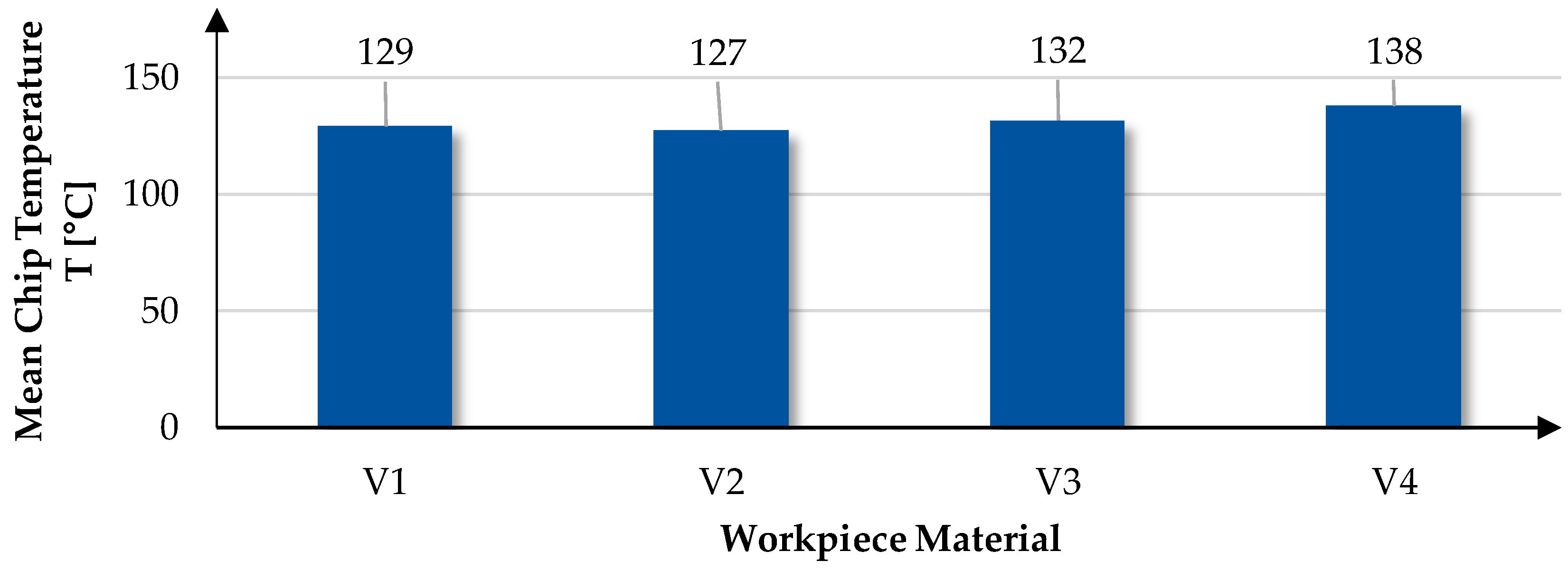

3.2. Cutting Temperature

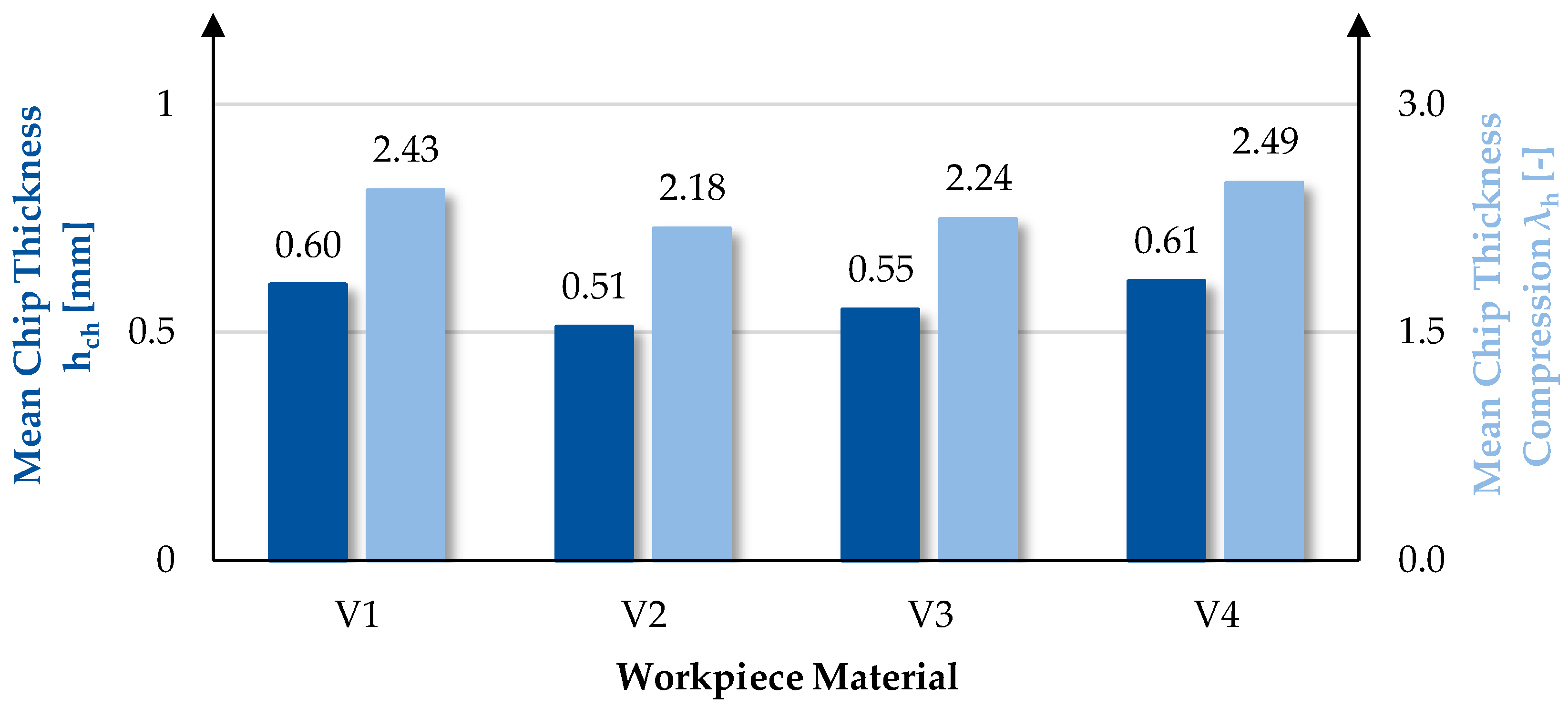

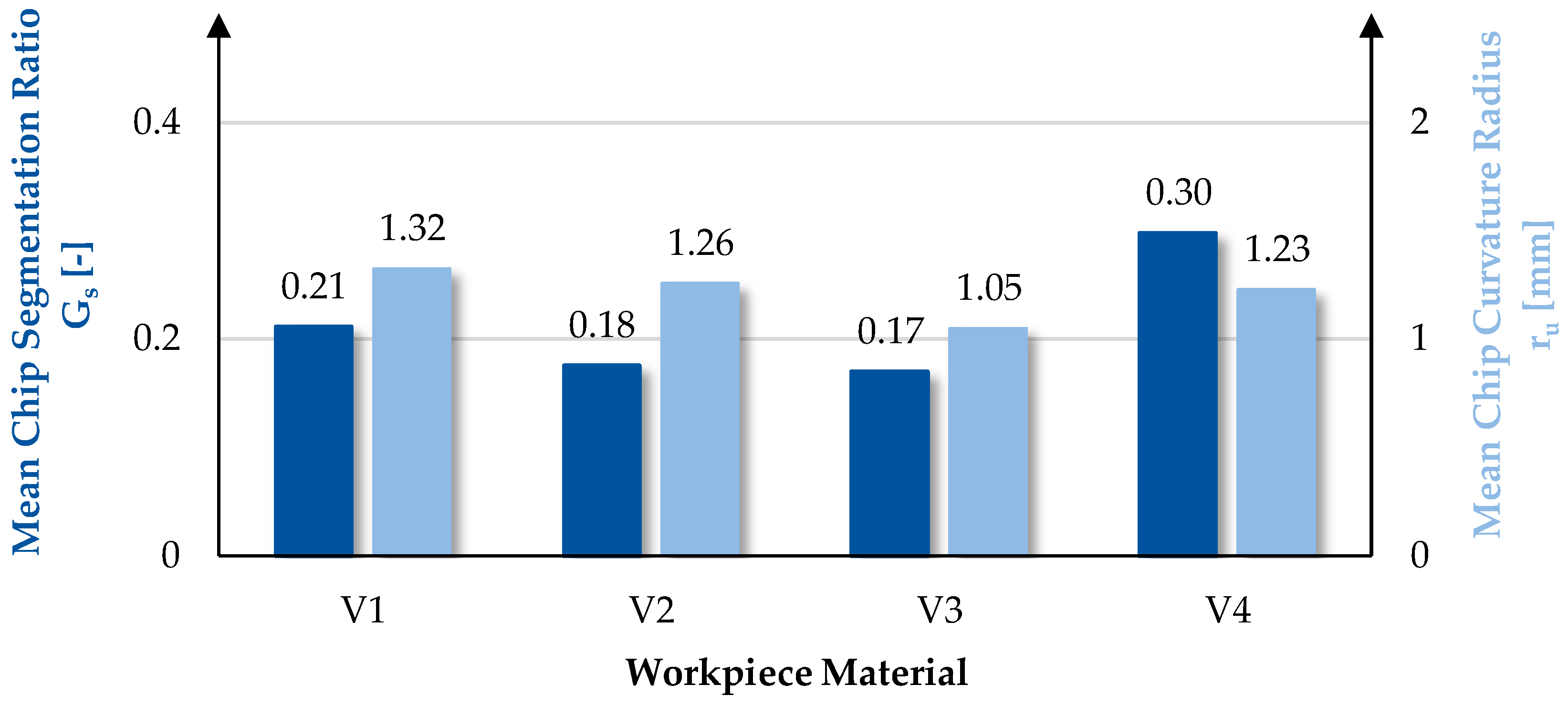

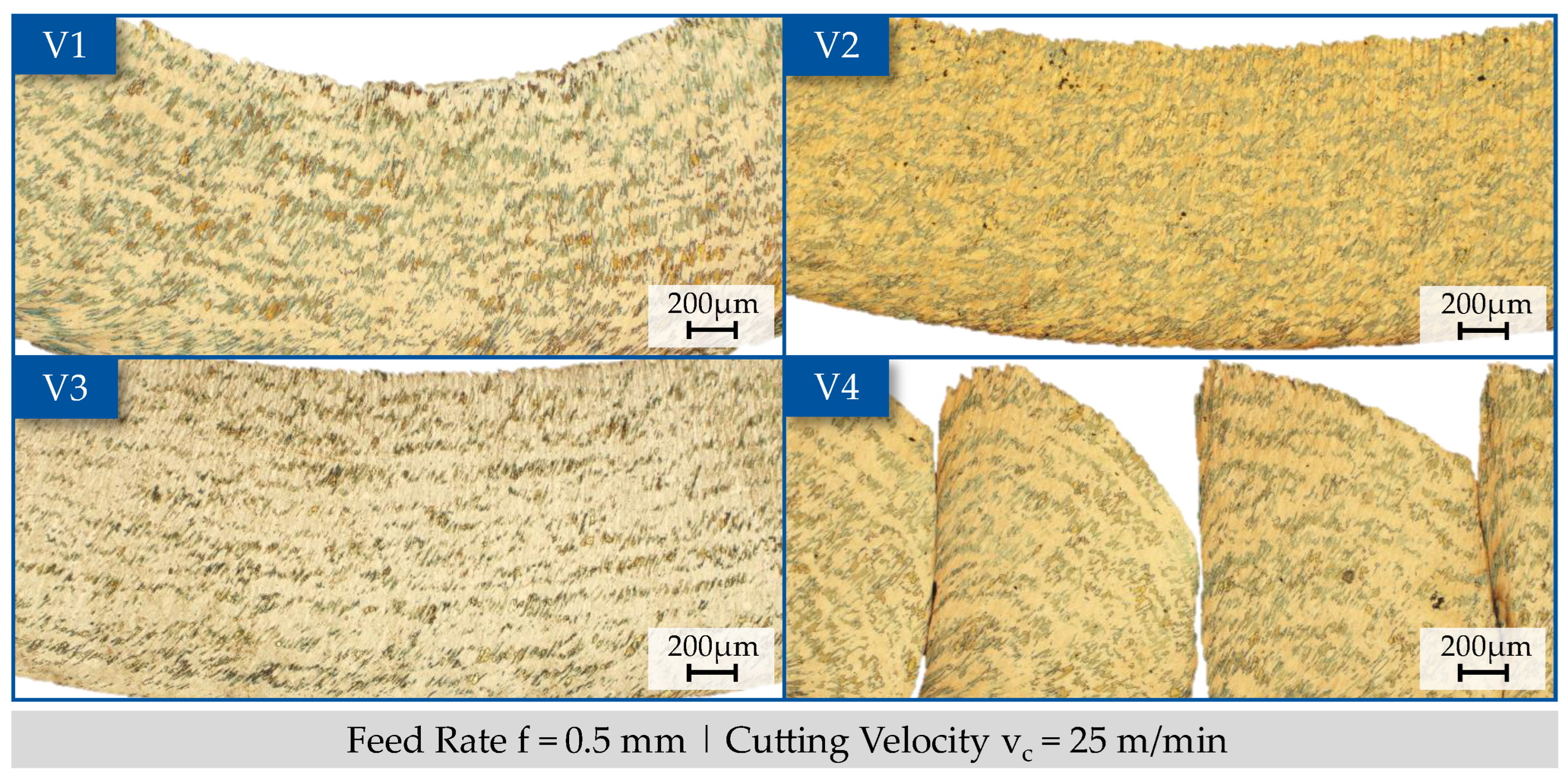

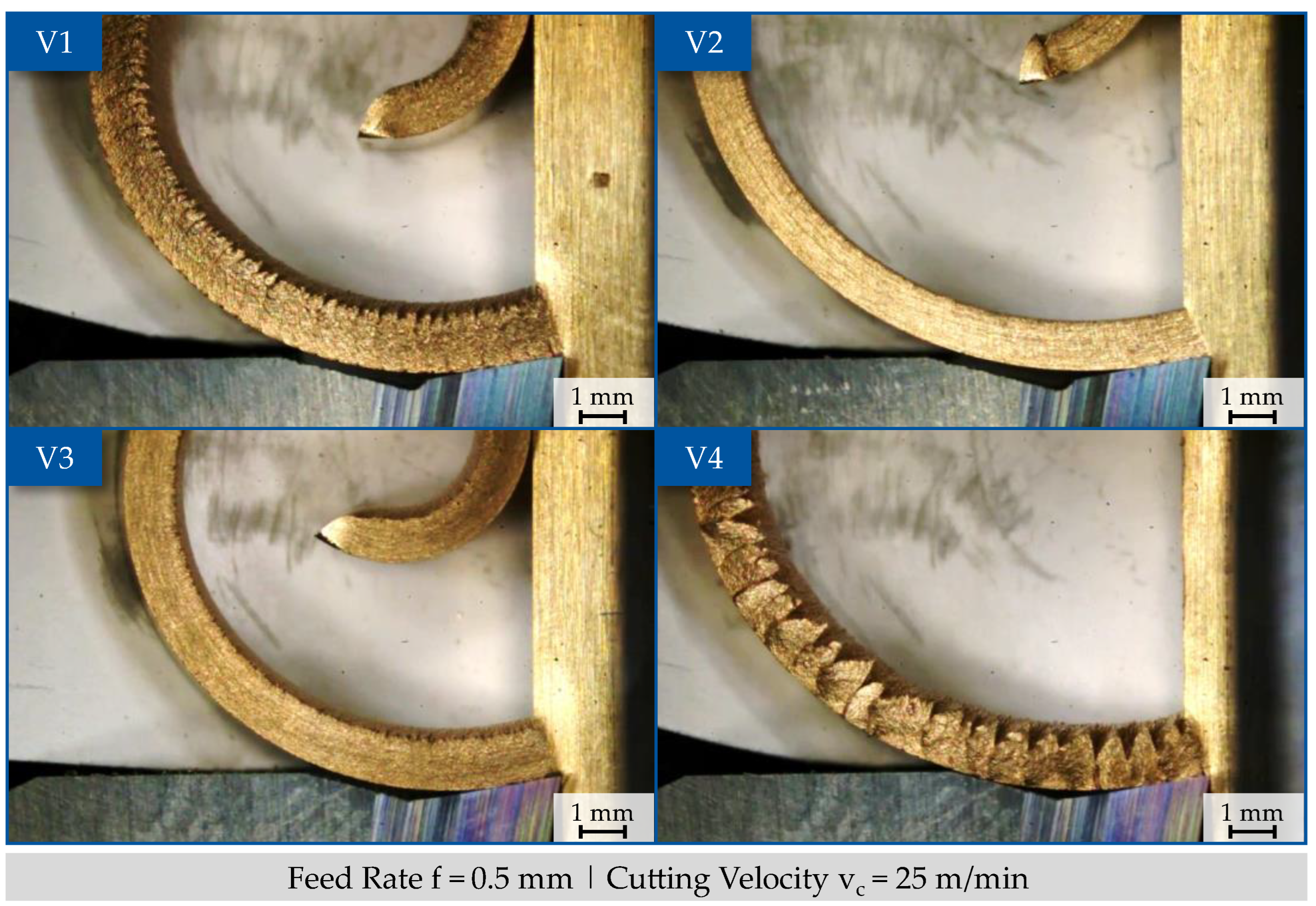

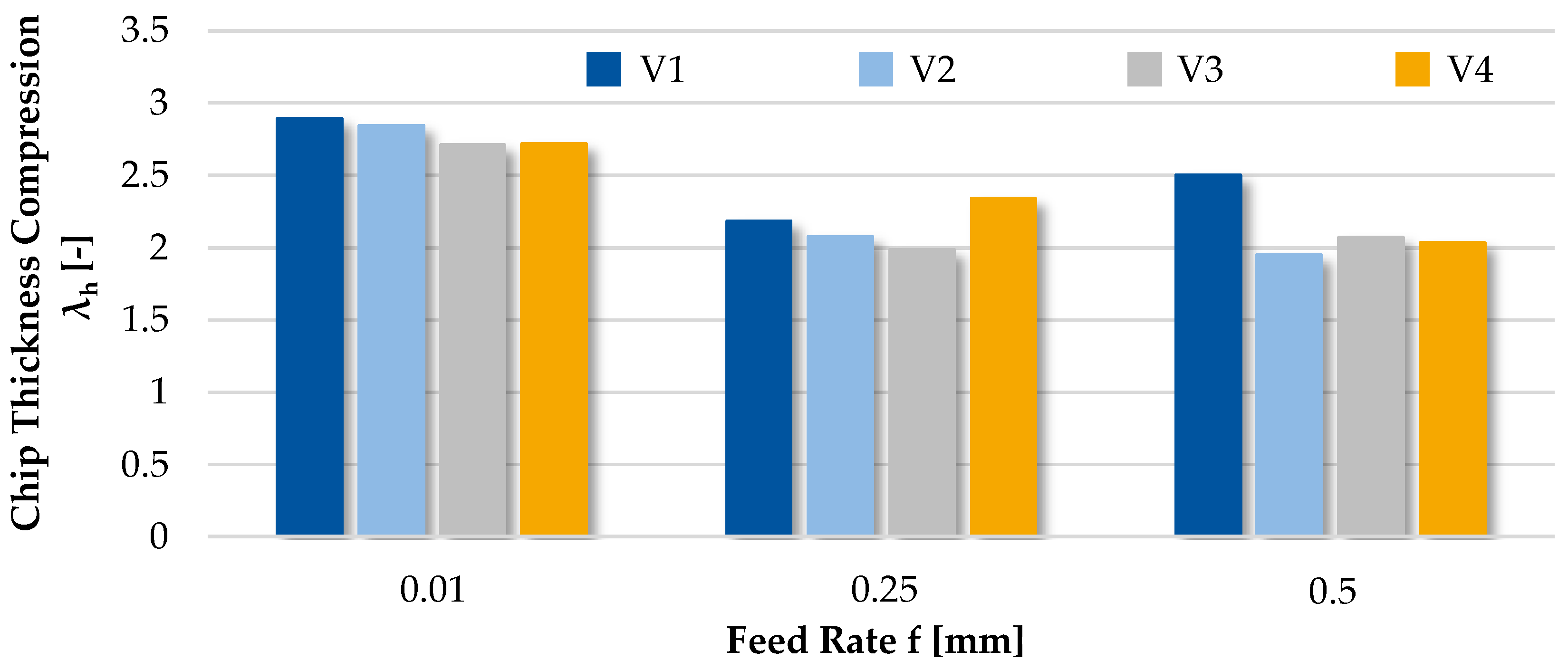

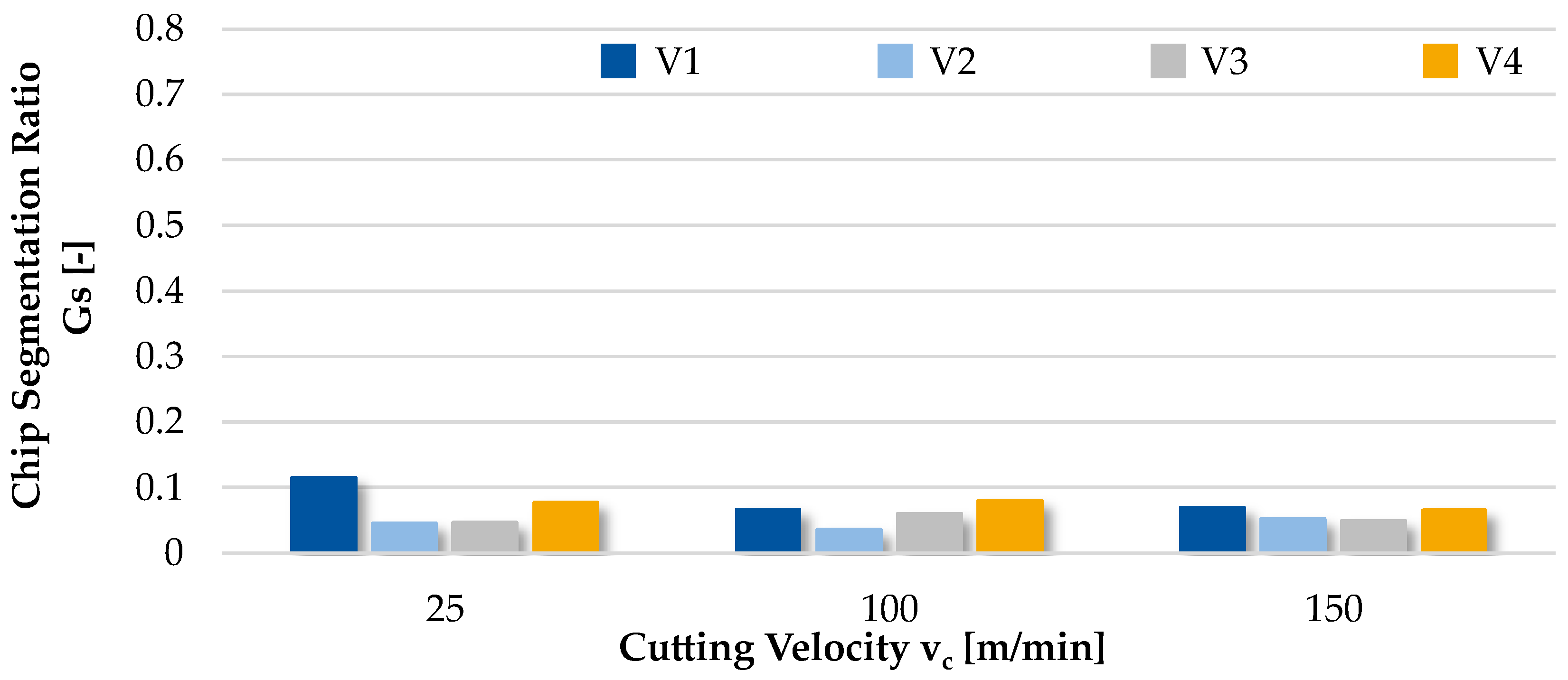

3.3. Chip Formation and Resulting Chip Form

4. Conclusions

- ▪

- The different material properties, which were introduced by varying the material production route, resulted in changes in the cutting force components. The change in cutting force between the materials investigated was ΔFc,material = 10%, and the change in feed force was ΔFf,material = 11.89%. In particular, a higher coefficient of friction as a result of heat treatment led to an increase in the cutting force.

- ▪

- The variation in the material production route had a small influence of ΔTChip,material = 7.8% on the chip temperature. The reduced coefficient of friction and increased strength resulting from high work hardening and the absence of heat treatment resulted in low chip temperatures TChip in the machining process due to reduced deformations in the primary shear zone.

- ▪

- The adjustment of the material production route had the highest effect on the underlying chip formation mechanisms and the resulting chip shape.

- ▪

- On average, a lower work hardening and the use of a heat treatment lead to a higher chip thickness compression ratio, but the underlying mechanisms of action are feed rate-dependent and a different behavior can be observed at very small or very high feed rates.

- ▪

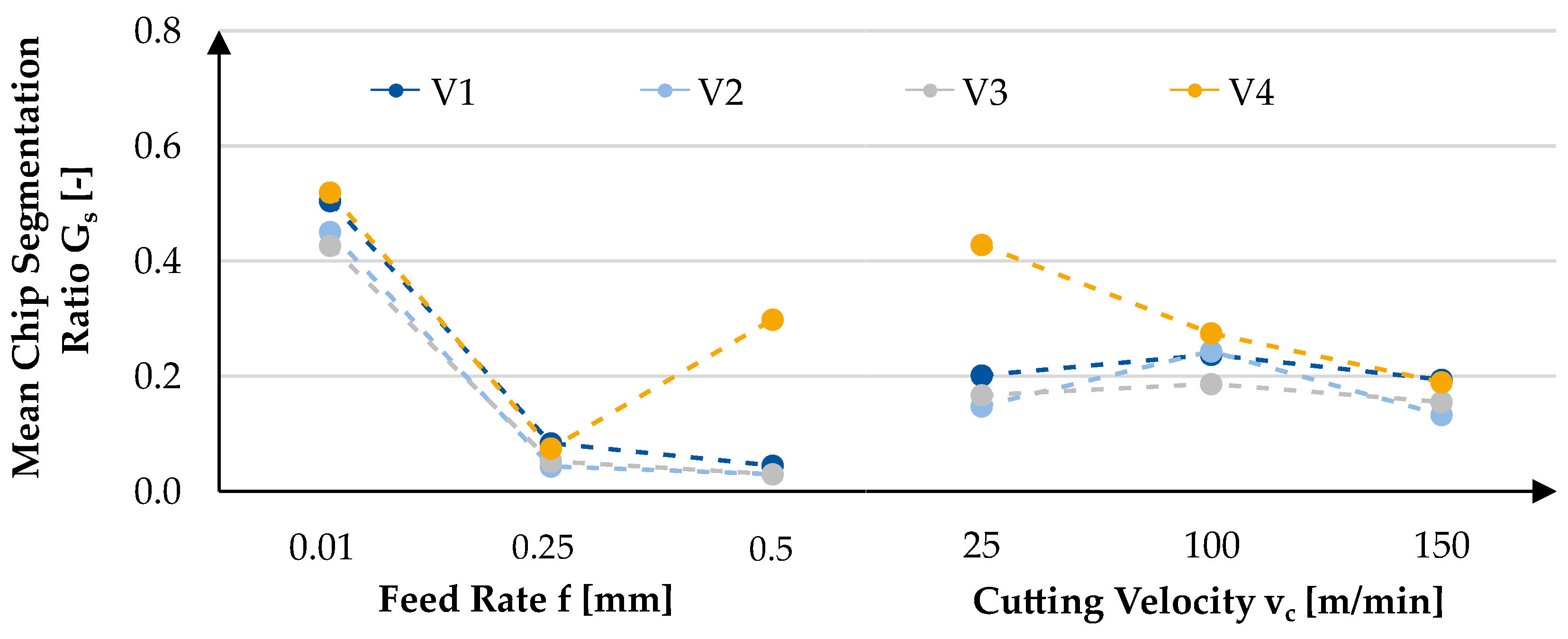

- In general, the chip segmentation Gs increased with a decrease in work hardening. Furthermore, the heat treatment caused an increase in the degree of chip segmentation. Nevertheless, process parameter-dependent changes in the chip formation mechanism led to different behavior when using small feed rates of f = 0.01 mm.

- ▪

- At lower feed rates (f = 0.01 mm) a size effect was recognized: the chip segmentation was significantly higher and the influence of the material production route was different in comparison to the other process parameter settings. Due to the low chip thickness of 20.6 µm ≤ hch ≤ 28.91 µm, there were areas in the chip where the ß-phase extended over the entire chip thickness. This resulted in significantly increased segmentation in these areas. For small chip thicknesses, the distribution and size of the ß-phase areas are therefore particularly relevant for the chip formation mechanisms and the resulting chip segmentation. Due to a larger proportion of ß-phase in the microstructure, this behavior was more pronounced in material variant V2.

- ▪

- For the material variant V4, which was heat-treated before work hardening, strong differences in chip formation were identified for high feed rates of f = 0.5 mm and low cutting speeds of vc = 25 m/min, which suggests an interaction between material properties and process parameters, as this phenomenon only occurs with V4. With the material-process parameter combination described, a discontinuous chip formation process occurs, resulting in a highly segmented chip. The cause is assumed to be the finer distribution of the ß-phase at V4, which causes the acyclic sliding of the chip over the rake face under the given boundary conditions. To investigate this hypothesis, the chip formation of the material should be analyzed under similar boundary conditions in chip root investigations.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Johansson, J.; Alm, P.; M’Saoubi, R.; Malmberg, P.; Stahl, J.-E.; Bushlya, V. On the function of lead (Pb) in machining brass alloys. Int. J. Adv. Manuf. Technol. 2022, 120, 7263–7275. [Google Scholar] [CrossRef]

- Nobel, C.; Klocke, F.; Lung, D.; Wolf, S. Machinability Enhancement of Lead-free Brass Alloys. Procedia CIRP 2014, 14, 95–100. [Google Scholar] [CrossRef]

- Schultheiss, F. Machinability of CuZn21Si3P brass. Mater. Sci. Technol. 2016, 32, 1744–1750. [Google Scholar] [CrossRef]

- Zachert, C.; Brans, K.; Schraknepper, D.; Bergs, T. Assessment and Comparison of the Machinability of Innovative Copper Alloys. In Proceedings of the Copper Alloys 2022, Düsseldorf, Germany, 22–23 November 2022; Volume 1, pp. 56–59. [Google Scholar]

- Müller, M.S. Machinability of Low-Lead and Lead-Free Brass Alloys. Ph.D. Dissertation, NTNU, Trondheim, Norway, 2024. [Google Scholar]

- Nobel, C.; Klocke, F.; Veselovac, D. Influence of tool material and coating on the machinability of low-leaded brass alloys in turning. Mater. Manuf. Process. 2016, 31, 1895–1903. [Google Scholar] [CrossRef]

- Müller, M.S.; Brans, K.; Meurer, M.; Sørby, K.; Bergs, T. The effect of high-pressure cutting fluid supply on the chip breakability of lead-free brass alloys. Int. J. Adv. Manuf. Technol. 2023, 129, 4317–4333. [Google Scholar] [CrossRef]

- Müller, M.S.; Sørby, K. The Influence of the Rake Angle on the Cutting of Low-Lead and Lead-Free Brass Alloys. In Manufacturing Driving Circular Economy; Kohl, H., Seliger, G., Dietrich, F., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 219–227. ISBN 978-3-031-28838-8. [Google Scholar]

- Laakso, S.V.A.; Hokka, M.; Niemi, E.; Kuokkala, V.-T. Investigation of the effect of different cutting parameters on chip formation of low-lead brass with experiments and simulations. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 1620–1634. [Google Scholar] [CrossRef]

- Nobel, C.; Hofmann, U.; Klocke, F.; Veselovac, D. Experimental investigation of chip formation, flow, and breakage 5 in free orthogonal cutting of copper-zinc alloys. Int. J. Adv. Manuf. Technol. 2015, 84, 1127–1140. [Google Scholar] [CrossRef]

- Stavroulakis, P.; Toulfatzis, A.I.; Pantazopoulos, G.A.; Paipetis, A.S. Machinable Leaded and Eco-Friendly Brass Alloys for High Performance Manufacturing Processes: A Critical Review. Metals 2022, 12, 246. [Google Scholar] [CrossRef]

- Brans, K.; Baier, S.; Schraknepper, D.; Bergs, T. Empirical Studies on the Influence of Tool and Process Parameters on the Machinability in Plunge Milling of Lead-Free CuZn-Alloys. Procedia CIRP 2022, 115, 113–118. [Google Scholar] [CrossRef]

- Baier, S. Tool Geometry Analysis for Plunge Milling of Lead-Free CuZn-Alloys. In Proceedings of the 24th International Conference on Material Forming, Online, 14–16 April 2021. [Google Scholar]

- Baier, S.; Brans, K.; Schraknepper, D.; Bergs, T. Experimental optimization of tool geometry and lubricoolant supply in plunge milling of lead-free Brass. In Proceedings of the Copper Alloys 2022, Düsseldorf, Germany, 22–23 November 2022; Volume 1, pp. 4–7. [Google Scholar]

- Twarog, D.L. Modified Red Brass With Bismuth and Selenium: Research Result. AFS Trans. 1995, 103, 451–461. [Google Scholar]

- Imai, H.; Shufeng, L.; Atsumi, H.; Kosaka, Y.; Kojima, A.; Kondoh, K. Development of Lead-Free Machinable Brass with Bismuth and Graphite Particles by Powder Metallurgy Process. Mater. Trans. 2010, 51, 855–859. [Google Scholar] [CrossRef]

- Saigal, A. Machinability of Cast Lead-Free Yellow Brass Containing Graphite Particles. AFS Trans. 1996, 104, 225–228. [Google Scholar]

- Imai, H. Characteristics of Lead-Free P/M Cu60-Zn40 Brass Alloys with Graphite. Trans. JWRI 2008, 37, 51–55. [Google Scholar]

- Taha, M.A.; El-Mahallawy, N.A.; Hammouda, R.M.; Moussa, T.M.; Gheith, M.H. Machinability characteristics of lead free-silicon brass alloys as correlated with microstructure and mechanical properties. Ain Shams Eng. J. 2012, 3, 383–392. [Google Scholar] [CrossRef]

- Yang, C. High-strength and free-cutting silicon brasses designed via the zinc equivalent rule. Mater. Sci. Eng. A 2018, 723, 296–305. [Google Scholar] [CrossRef]

- Schultheiss, F.; Johansson, D.; Bushlya, V.; Zhou, J.; Nilsson, K.; Ståhl, J.-E. Comparative study on the machinability of lead-free brass. J. Clean. Prod. 2017, 149, 366–377. [Google Scholar] [CrossRef]

- Toulfatzis, A.; Pantazopoulos, G.; David, C.; Sagris, D.; Paipetis, A. Final Heat Treatment as a Possible Solution for the Improvement of Machinability of Pb-Free Brass Alloys. Metals 2018, 8, 575. [Google Scholar] [CrossRef]

- Toulfatzis, A.I.; Pantazopoulos, G.A.; Paipetis, A.S. Microstructure and properties of lead-free brasses using post-processing heat treatment. Mater. Sci. Technol. 2016, 32, 1771–1781. [Google Scholar] [CrossRef]

- Toulfatzis, A.I.; Besseris, G.J.; Pantazopoulos, G.A.; Stergiou, C. Characterization and comparative machinability investigation of extruded and drawn copper alloys using non-parametric multi-response optimization and orthogonal arrays. Int. J. Adv. Manuf. Technol. 2011, 57, 811–826. [Google Scholar] [CrossRef]

- Vilarinho, C. Influence of the chemical composition on the machinability of brasses. J. Mater. Process. Technol. 2005, 170, 441–447. [Google Scholar] [CrossRef]

- Vazdirvanidis, A.; Rikos, A.; Toulfatzis, A.I.; Pantazopoulos, G.A. Electron Backscatter Diffraction (EBSD) Analysis of Machinable Lead-Free Brass Alloys: Connecting Texture with Fracture. Metals 2022, 12, 569. [Google Scholar] [CrossRef]

- Stavroulakis, P.; Toulfatzis, A.I.; Pantazopoulos, G.; Paipetis, A.S. A Review of Industrial Brass Alloys towards High Productivity Machining Processes. In Proceedings of the 8th International Conference of the Hellenic Metallurgical Society, Patras, Greece, 14–16 December 2022. [Google Scholar]

- Hofmann, U. Über den Einfluss von Werkstoffkennwerten auf das Spanbruchverhalten von bleiarmem Messing. Materialwiss. Werkstofftech. 2018, 49, 753–768. [Google Scholar] [CrossRef]

- Chaskis, S.; Maritsa, S.; Stavroulakis, P.; Papadopoulou, S.; Goodall, R.; Papaefthymiou, S. Compositional Design and Thermal Processing of a Novel Lead-free Cu–Zn–Al–Sn Medium Entropy Brass Alloy. Metals 2024, 14, 620. [Google Scholar] [CrossRef]

- DIN Deutsches Institut für Normung e.V. Zugversuch: Teil 1: Prüfvwerfahren bei Raumtemperatur; Beuth Verlag GmbH: Berlin, Germany, 2020; 77.040.10 (6892-1). [Google Scholar]

- DIN Deutsches Institut für Normung e.V. Prüfung Metallischer Werkstoffe–Druckversuch bei Raumtemperatur; Beuth Verlag GmbH: Berlin, Germany, 2023; 77.040.10 (50106). [Google Scholar]

- ISO 6507-1:2023; Metallic Materials—Vickers Hardness Test-Part 1: Test Method. ISO: Geneva, Switzerland, 2023.

- ISO 14577-1; Metallic Materials-Instrumented Indentation Test for Hardness and Materials Parameters-Part 1: Test Method. ISO: Geneva, Switzerland, 2015.

- DIN Deutsches Institut für Normung e.V. Metallische Werkstoffe-Kerbschlagbiegeversuch nach Charpy: Teil 1: Prüfverfahren; Beuth Verlag GmbH: Berlin, Germany, 2017; 77.040.10 (148-1). [Google Scholar]

- Puls, H.; Klocke, F.; Lung, D. Experimental investigation on friction under metal cutting conditions. Wear 2014, 310, 63–71. [Google Scholar] [CrossRef]

- Puls, H. Mehrskalenmodellierung Thermo-Elastischer Werkstückdeformationen beim Trockendrehen. Ph.D. Dissertation, Rheinisch-Westfälischen Technischen Hochschule Aachen, Aachen, Germany, 2015. [Google Scholar]

- Nobel, C. Application of a new, severe-condition friction test method to understand the machining characteristics of Cu–Zn alloys using coated cutting tools. Wear 2015, 344, 58–68. [Google Scholar] [CrossRef]

- Nobel, C. Drehbearbeitung von Bleiarmen Kupfer-Zink-Legierungen. Ph.D. Dissertation, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2016. [Google Scholar]

- Albrecht, P. New Developments in the Theory of the Metal-Cutting Process: Part I. The Ploughing Process in Metal Cutting. J. Eng. Ind. 1960, 82, 348–357. [Google Scholar] [CrossRef]

- Laakso, S.V.A.; Niemi, E. Modified Johnson–Cook flow stress model with thermal softening damping for finite element modeling of cutting. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 230, 241–253. [Google Scholar] [CrossRef]

| Cu | Zn | Fe | Sn | Si | Pb | Ni | Zr | P | Ag | S | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 66.610 | 38.957 | 0.159 | 0.140 | 0.101 | 0.024 | 0.003 | 0.002 | 0.002 | 0.001 | 0.001 | 0.001 |

| Mechanical Material Property | V1 | V2 | V3 | V4 |

|---|---|---|---|---|

| Tensile Strength 1—Rm [MPa] | 455.5 | 617 | 432.5 | 447 |

| Yield Strength 1—Rp0.2 [MPa] | 323 | 585 | 200.5 | 315 |

| Elongation at Break 1—A [%] | 32.05 | 13.15 | 46.05 | 33.2 |

| Compressive Strength 2—Rdb[MPa] | 1197.5 | 1249 | 1160.5 | 1134.5 |

| Macro-hardness (rim-zone) 3—[HV] | 145 | 185 | 105 | 140 |

| Macro-hardness (core) 3—[HV] | 118 | 180 | 103 | 117 |

| Micro-hardness (α-Phase) 4—[HVe] | 148 | 217 | 163 | 169 |

| Micro-hardness (β-Phase) 4—[HVe] | 196 | 258 | 208 | 231 |

| Notched Impact Strength 5—ak [J/cm2] | 12.6 * | 8 | 14.4 | 9 * |

| Friction coefficient at vrel = 50 m/min 6—µ [-] | 0.42 | 0.28 | 0.50 | 0.41 |

| Friction coefficient at vrel = 75 m/min 6—µ [-] | 0.39 | 0.25 | 0.44 | 0.38 |

| Friction coefficient at vrel = 100 m/min 6—µ [-] | 0.35 | 0.23 | 0.40 | 0.35 |

| Friction coefficient at vrel = 125 m/min 6—µ [-] | 0.32 | 0.23 | 0.38 | 0.33 |

| Friction coefficient at vrel = 150 m/min 6—µ [-] | 0.30 | 0.21 | 0.36 | 0.29 |

| Microstructural Material Property | V1 | V2 | V3 | V4 |

|---|---|---|---|---|

| α-Phase Fraction—φα [%] | 81 | 72 | 88 | 82 |

| β-Phase Fraction—φβ [%] | 19 | 28 | 12 | 18 |

| Average Grain Area (α-Phase)—ak,α [μm2] | 337.6 | 143.6 | 123.4 | 228.3 |

| Average Grain Area (β-Phase)—ak,β [μm2] | 255.4 | 143 | 119.5 | 176.6 |

| Average Grain Diameter (α-Phase)—dα [μm] | 18.2 | 12.8 | 11 | 15.7 |

| Average Grain Diameter (β-Phase)—dβ [μm] | 16 | 12.6 | 10.7 | 14.1 |

| Grain aspect ratio (α-Phase)—b/h [-] | 1.9 | 2.6 | 1.8 | 2 |

| Grain aspect ratio (β-Phase)—b/h [-] | 2.7 | 2.7 | 2.4 | 2.6 |

| 1 Feed Variation | 2 Cutting Speed Variation | 3 Min. and Max. Variation | |

|---|---|---|---|

| Process | Orthogonal Cutting | ||

| Machine | Broaching Machine Type Forst RASX 8 × 2200 × 600 M/CNC | ||

| Tool Holder | Kennametal NSL2525M3 | ||

| Tool | Kennametal N3BL (adjusted) | ||

| Cutting Tool Material | Carbide K313 | ||

| Face Rake Angle γ [°] | 10 | ||

| Face Flank Angle α [°] | 10 | ||

| Cutting Edge Angle κr [°] | 90 | ||

| Cutting Edge Radius rβ [µm] | 2 µm < rβ < 8 µm | ||

| Feed Rate f/mm | 0.01; 0.05; 0.1; 0.15; 0.2; 0.25; 0.3; 0.35; 0.4; 0.45; 0.5 | 0.25 | 0.01; 0.5 |

| Cutting Velocity vc [m/min] | 100 | 25; 50; 75; 100; 125; 150 | 25; 150 |

| Workpiece Material | CuZn40 V1, CuZn40 V2, CuZn40 V3, CuZn40 V4 | ||

| Cooling Lubricant | Dry | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brans, K.; Kind, S.; Meurer, M.; Bergs, T. Influence of the Material Production Route on the Material Properties and the Machinability of the Lead-Free Copper-Zinc-Alloy CuZn40 (CW509L). Metals 2024, 14, 747. https://doi.org/10.3390/met14070747

Brans K, Kind S, Meurer M, Bergs T. Influence of the Material Production Route on the Material Properties and the Machinability of the Lead-Free Copper-Zinc-Alloy CuZn40 (CW509L). Metals. 2024; 14(7):747. https://doi.org/10.3390/met14070747

Chicago/Turabian StyleBrans, Kilian, Stefan Kind, Markus Meurer, and Thomas Bergs. 2024. "Influence of the Material Production Route on the Material Properties and the Machinability of the Lead-Free Copper-Zinc-Alloy CuZn40 (CW509L)" Metals 14, no. 7: 747. https://doi.org/10.3390/met14070747

APA StyleBrans, K., Kind, S., Meurer, M., & Bergs, T. (2024). Influence of the Material Production Route on the Material Properties and the Machinability of the Lead-Free Copper-Zinc-Alloy CuZn40 (CW509L). Metals, 14(7), 747. https://doi.org/10.3390/met14070747