Temperature-Dependent Mechanical Behaviors and Deformation Mechanisms in a Si-Added Medium-Entropy Superalloy with L12 Precipitation

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Alloy Preparation

2.2. Tensile Testing

2.3. Microstructural Characterization

3. Results and Discussion

3.1. Initial Microstructure

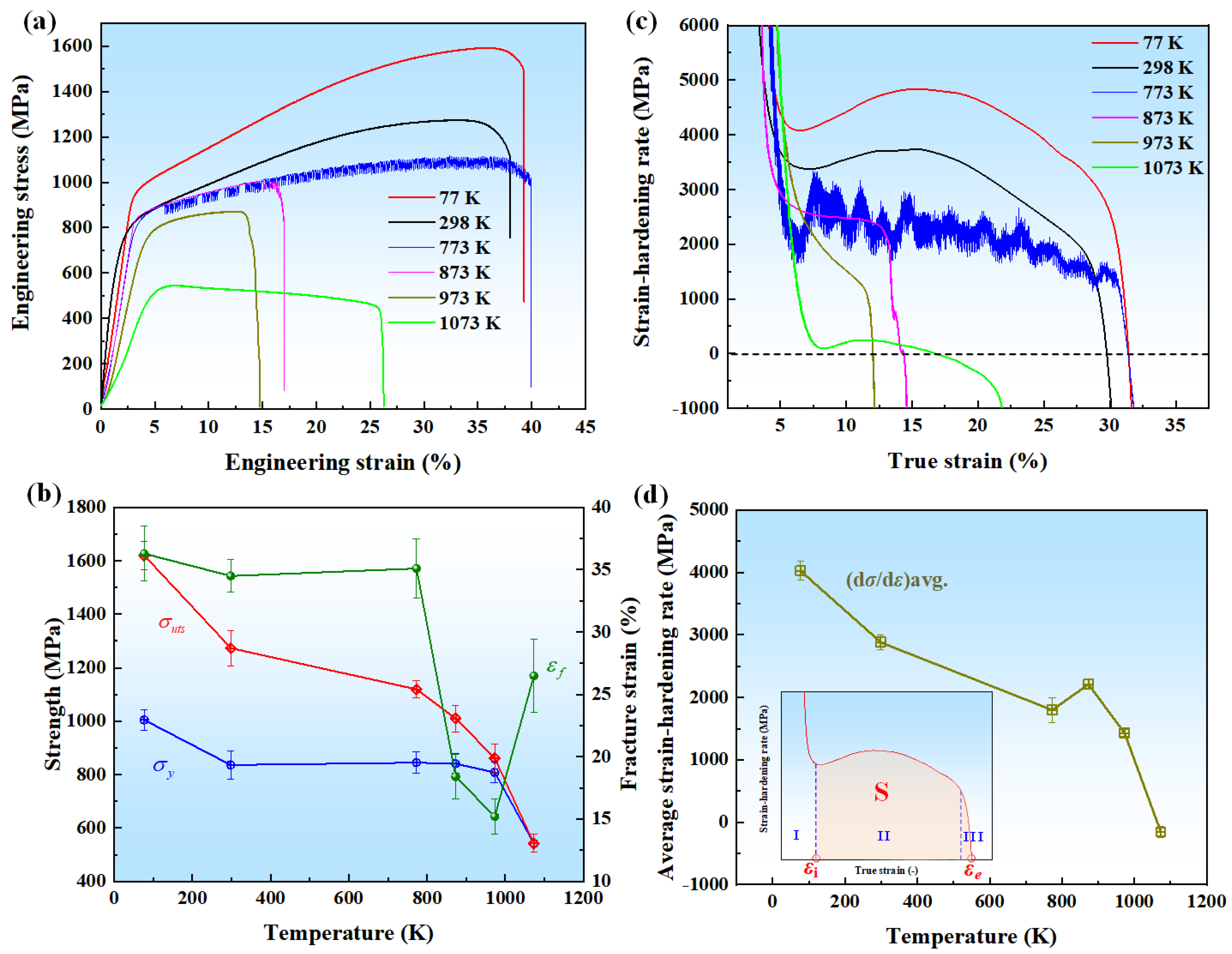

3.2. Mechanical Properties

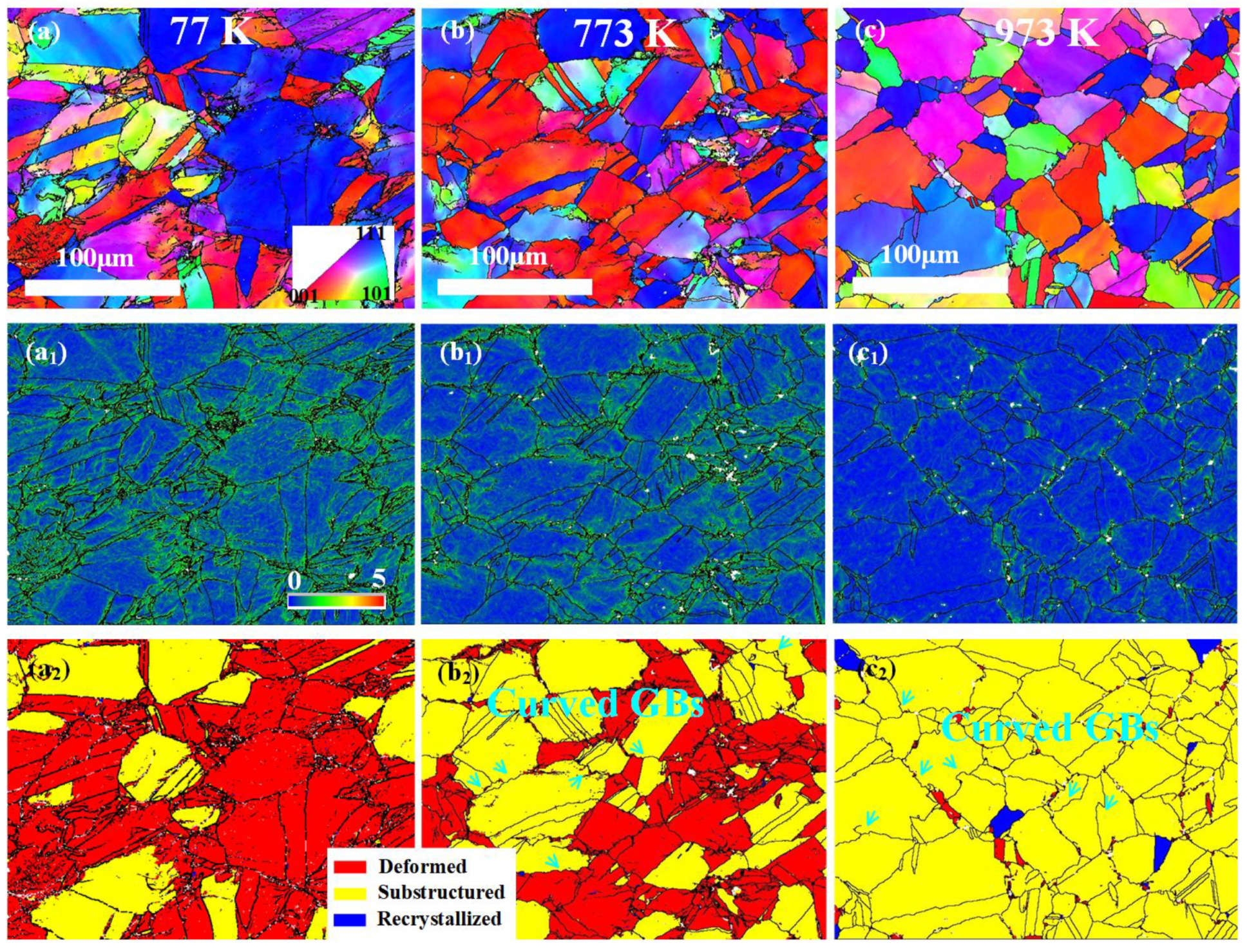

3.3. EBSD Analysis at a Wide Range of Temperatures

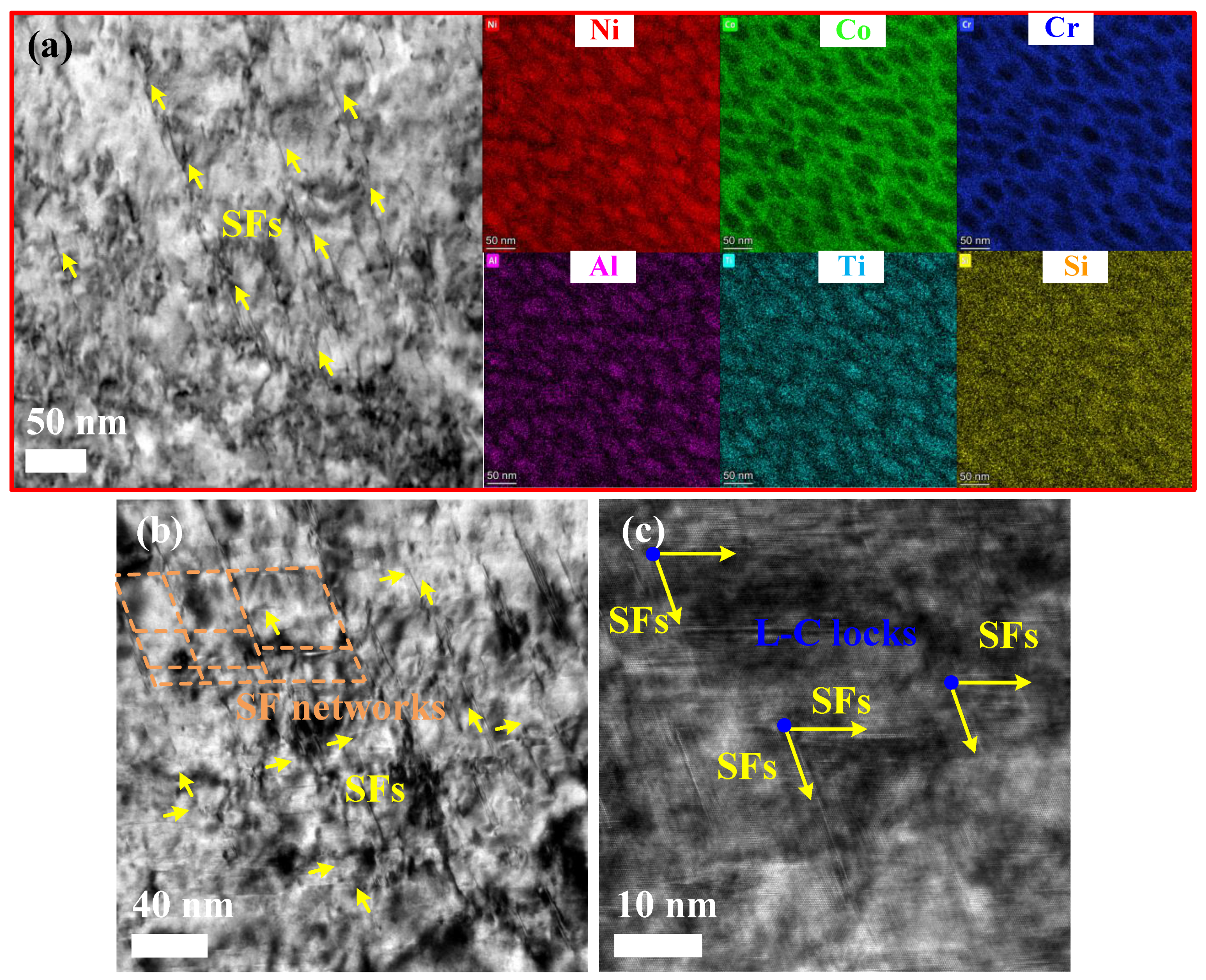

3.4. Low-Temperature Deformation Mechanisms at 298 K and 77 K

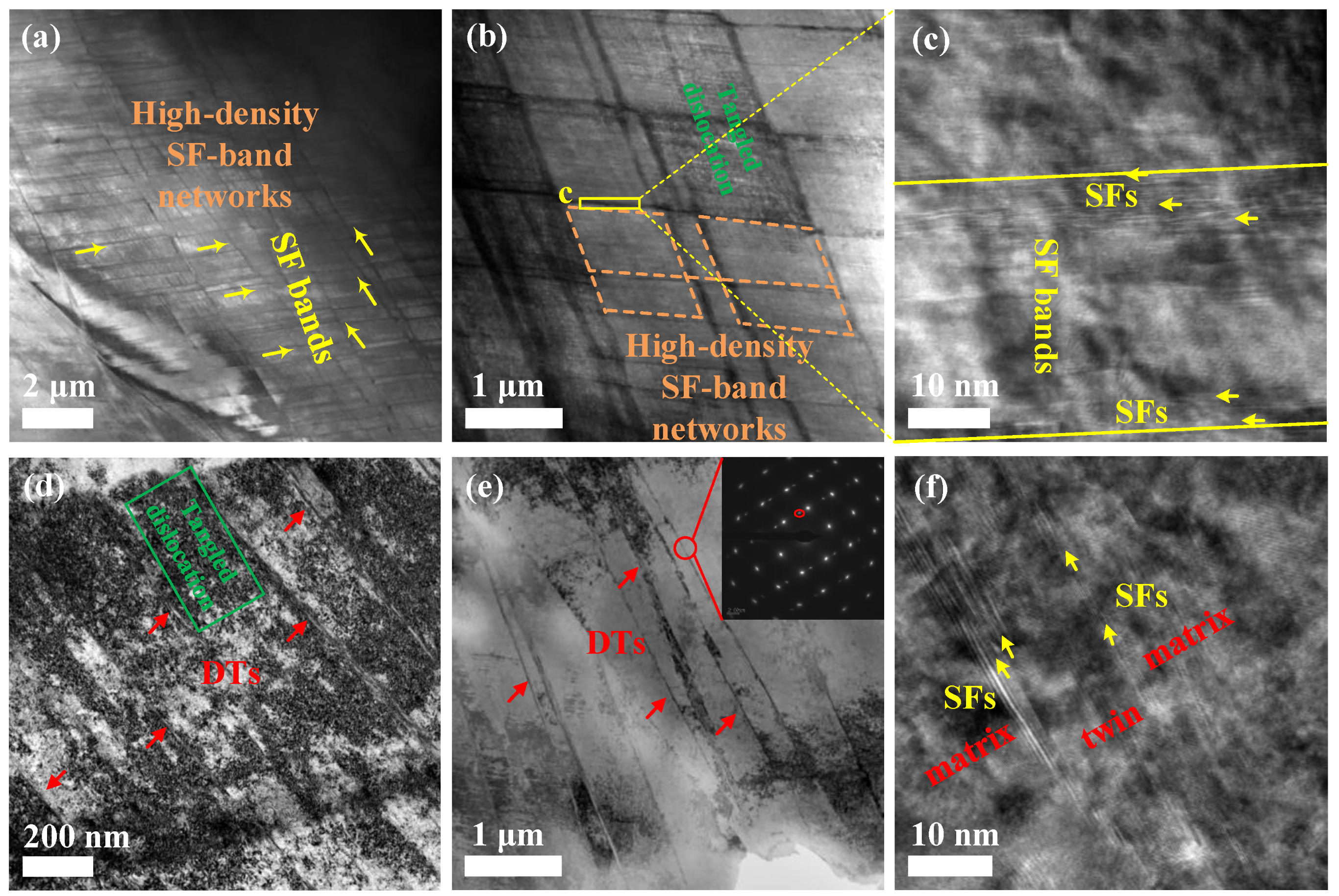

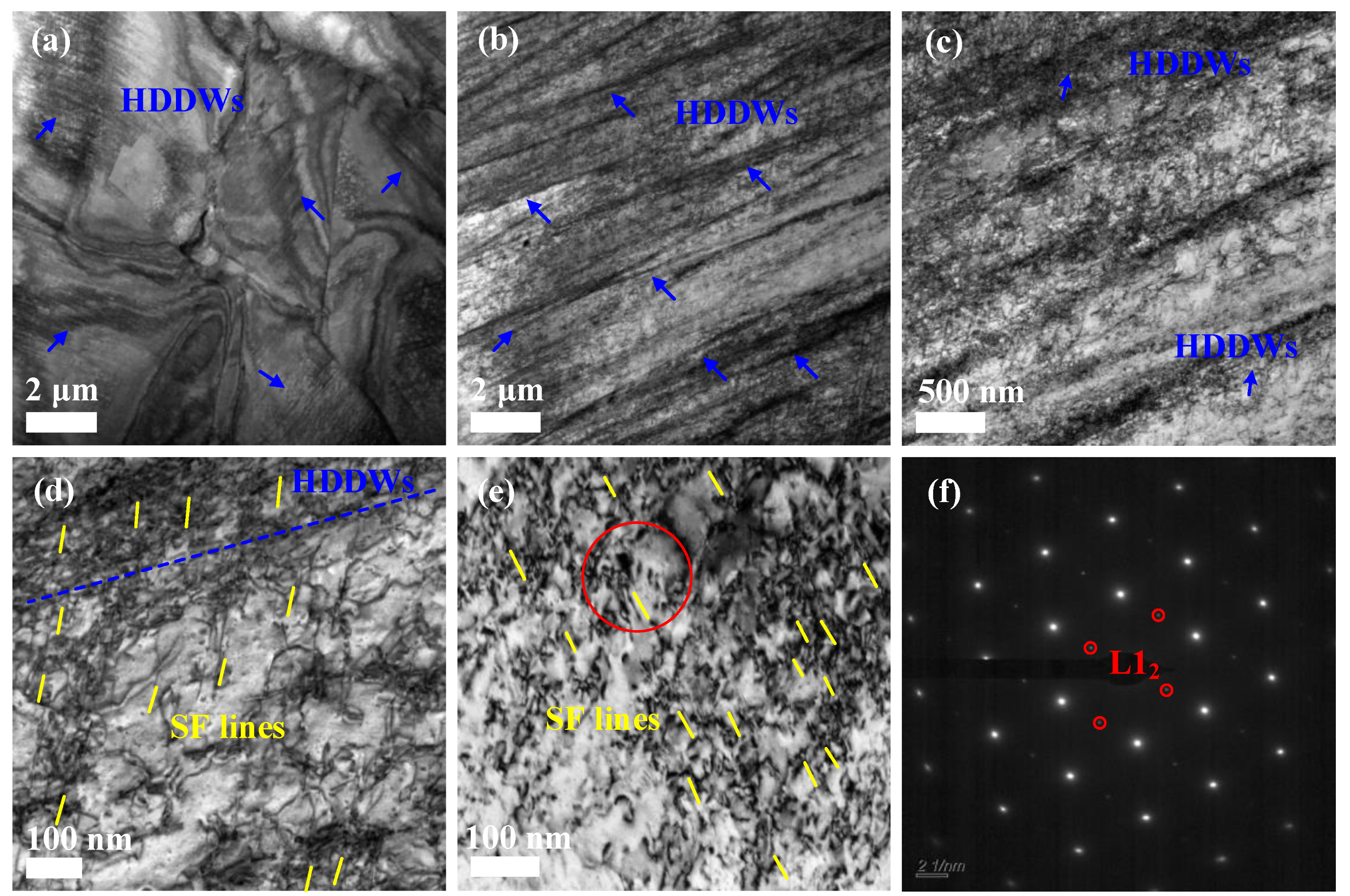

3.5. Intermediate-Temperature Deformation Mechanisms at 773 K and 973 K

3.6. Temperature-Dependent Correlation between Tensile Properties and Mechanisms

4. Conclusions

- The alloy consists of equiaxed grains with precipitates present inside the grains and at the grain boundaries (GBs). More specifically, spherical precipitates are evenly dispersed within the grains, while tapered-rod precipitates are situated close to the GBs.

- A nearly constant yield strength of approximately 800 MPa is achieved within the temperature range of 298 K to 973 K. The alloy exhibits notable strain-hardening capabilities, with strengths of 2.5 GPa, 3.7 GPa, and 4.8 GPa observed at temperatures of 873 K, 298 K, and 77 K, respectively.

- High Si content (7.5 at.%) is primarily dissolved into the matrix, resulting in a decrease in the stacking fault energy (SFE) within the matrix. Stacking faults (SFs) evolve into multilayer SFs, SF bands, and SF networks rather than twins. Those SF-related microstructures can effectively store a significant amount of dislocations and impede dislocation movement, thereby enhancing the work-hardening capability of the alloy at both room and cryogenic temperatures.

- At 773 K, significant quantities of dislocation entanglements and dislocation walls form, effectively impeding dislocation movement and storing dislocations, leading to increased work hardening and plasticity. As the temperature rises to 973 K, the typical APB shearing mechanism (in the form of dislocation pairs), SF lines, and microtwins (resulting from atomic rearrangement) also contribute significantly to the high levels of work hardening observed at 973 K.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Praveen, S.; Kim, H.S. High-Entropy Alloys: Potential Candidates for High-Temperature Applications—An Overview. Adv. Eng. Mater. 2018, 20, 1700645. [Google Scholar] [CrossRef]

- Chen, Y.-T.; Chang, Y.-J.; Murakami, H.; Gorsse, S.; Yeh, A.-C. Designing High Entropy Superalloys for Elevated Temperature Application. Scripta Mater. 2020, 187, 177–182. [Google Scholar] [CrossRef]

- Li, W.D.; Xie, D.; Li, D.Y.; Zhang, Y.; Gao, Y.F.; Liaw, P.K. Mechanical behavior of high-entropy alloys. Prog. Mater. Sci. 2021, 118, 100777. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- George, E.P.; Curtin, W.A.; Tasan, C.C. High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Mater. 2020, 188, 435–474. [Google Scholar] [CrossRef]

- Feng, R.; Feng, B.J.; Gao, M.C.; Zhang, C.; Neuefeind, J.C.; Poplawsky, J.D.; Ren, Y.; An, K.; Widom, M.; Liaw, P.K. Superior High-Temperature Strength in a Supersaturated Refractory High-Entropy Alloy. Adv. Mater. 2021, 33, 2102401. [Google Scholar] [CrossRef]

- Huang, H.L.; Wu, Y.; He, J.Y.; Wang, H.; Liu, X.J.; An, K.; Wu, W.; Lu, Z.P. Phase-Transformation Ductilization of Brittle High-Entropy Alloys via Metastability Engineering. Adv. Mater. 2017, 29, 1701678.1–1701678.7. [Google Scholar] [CrossRef]

- Wang, S.B.; Shu, D.; Shi, P.Y.; Zhang, X.B.; Mao, B.; Wang, D.H.; Liaw, P.K.; Sun, B.D. TiZrHfNb refractory high-entropy alloys with twinning-induced plasticity. J. Mater. Sci. Technol. 2024, 187, 72–85. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J.; et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Chen, H.W.; Lu, Z.P.; Nieh, T.G. Thermal stability and coarsening of coherent particles in a precipitation-hardened (NiCoFeCr)94Ti2Al4 high-entropy alloy. Acta Mater. 2018, 147, 184–194. [Google Scholar] [CrossRef]

- Liang, Y.J.; Wang, L.J.; Wen, Y.R.; Cheng, B.Y.; Wu, Q.L.; Cao, T.Q.; Xiao, Q.; Xue, Y.F.; Sha, G.; Wang, Y.D.; et al. High-Content Ductile Coherent Nanoprecipitates Achieve Ultrastrong High-Entropy Alloys. Nat. Commun. 2018, 9, 4063. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Yu, Q.; Tang, Y.T.; Xu, M.J.; Wang, H.R.; Zhu, C.Y.; Ell, J.; Zhao, S.T.; MacDonald, B.E.; Cao, P.H.; et al. Strong and Ductile Fenicoal-Based High-Entropy Alloys for Cryogenic to Elevated Temperature Multifunctional Applications. Acta Mater. 2023, 242, 118449. [Google Scholar] [CrossRef]

- Du, X.H.; Li, W.P.; Chang, H.T.; Yang, T.; Duan, G.S.; Wu, B.L.; Huang, J.C.; Chen, F.R.; Liu, C.T.; Chuang, W.S.; et al. Dual heterogeneous structures lead to ultrahigh strength and uniform ductility in a Co-Cr-Ni medium-entropy alloy. Nat. Commun. 2020, 11, 2390. [Google Scholar] [CrossRef] [PubMed]

- He, J.Y.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. High-temperature plastic flow of a precipitation-hardened FeCoNiCr high entropy alloy. Mater. Sci. Eng. A 2017, 686, 34–40. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Yang, T.; Li, Y.R.; Fan, L.; Han, B.; Jiao, Z.B.; Chen, D.; Liu, C.T.; Kai, J.J. Superior high-temperature properties and deformation-induced planar faults in a novel L12-strengthened high-entropy alloy. Acta Mater. 2020, 188, 517–527. [Google Scholar] [CrossRef]

- Gao, L.; Wu, Y.D.; An, N.; Chen, J.Y.; Liu, X.L.; Bai, R.; Hui, X.D. Nanoscale L12 phase precipitation induced superb ambient and high temperature mechanical properties in Ni–Co–Cr–Al system high-entropy superalloys. Mater. Sci. Eng. A 2024, 898, 145995. [Google Scholar] [CrossRef]

- Chang, H.; Zhang, T.W.; Ma, S.G.; Zhao, D.; Xiong, R.L.; Wang, T.; Li, Z.Q.; Wang, Z.H. Novel Si-added CrCoNi medium entropy alloys achieving the breakthrough of strength-ductility trade-off. Mater. Des. 2021, 197, 109202. [Google Scholar] [CrossRef]

- Luo, S.H.; Zhang, T.W.; Chang, H.; Du, S.Y.; Jiao, Z.M.; Xiong, R.L.; Kim, H.S.; Wang, Z.H. Ultra-high work hardening mediated by three-level precipitation in a Ni2CoCr0.5Si0.3Al0.2Ti0.2 medium entropy alloy. J. Mater. Res. Technol. 2023, 25, 3093–3103. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Yang, T.; Tong, Y.; Wang, J.; Luan, J.H.; Jiao, Z.B.; Chen, D.; Yang, Y.; Hu, A.; Liu, C.T.; et al. Heterogeneous precipitation behavior and stacking-fault-mediated deformation in a CoCrNi-based medium-entropy alloy. Acta Mater. 2017, 138, 72–82. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.L.; Fan, L.; Wei, J.; Luan, J.H.; Liu, W.H.; Wang, C.; Jiao, Z.B.; Kai, J.J.; Liu, C.T. Control of nanoscale precipitation and elimination of intermediate-temperature embrittlement in multicomponent high-entropy alloys. Acta Mater. 2020, 189, 47–59. [Google Scholar] [CrossRef]

- Du, S.Y.; Zhang, T.W.; Jiao, Z.M.; Zhao, D.; Wang, J.J.; Xiong, R.L.; Kim, H.S.; Wang, Z.H. Strength-ductility synergy and grain refinement mechanisms in a Co-Cr-Ni medium-entropy alloy with novel analogous harmonic structure. Scr. Mater. 2023, 235, 115635. [Google Scholar] [CrossRef]

- Li, Z.Z.; Zhao, S.T.; Ritchie, R.O.; Meyers, M.A. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater. Sci. 2019, 102, 296–345. [Google Scholar] [CrossRef]

- Vitek, V.; Pope, D.P.; Bassani, J.L. Anomalous Yield Behaviour of Compounds with L12 Structure. In L12 Ordered Alloys; Nabarro, F.R.N., Duesbery, M.S., Eds.; Elsevier Science B.V.: Amsterdam, The Netherlands, 1996; pp. 137–185. [Google Scholar]

- Senkov, O.N.; Miracle, D.B.; Chaput, K.J.; Couzinie, J.P. Development and exploration of refractory high entropy alloys—A review. J. Mater. Res. 2018, 33, 3092–3128. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Brechtl, J.; Chen, S.Y.; Xie, X.; Ren, Y.; Qiao, J.W.; Liaw, P.K.; Zinkle, S.J. Towards a greater understanding of serrated flows in an Al-containing high-entropy-based alloy. Int. J. Plast. 2019, 115, 71–92. [Google Scholar] [CrossRef]

- Zhang, R.P.; Zhao, S.T.; Ding, J.; Chong, Y.; Jia, T.; Ophus, C.; Asta, M.; Ritchie, R.O.; Minor, A.M. Short-range order and its impact on the CrCoNi medium-entropy alloy. Nature 2020, 581, 283–287. [Google Scholar] [CrossRef]

- Zhang, T.W.; Ma, S.G.; Zhao, D.; Wu, Y.C.; Zhang, Y.; Wang, Z.H.; Qiao, J.W. Simultaneous enhancement of strength and ductility in a NiCoCrFe high-entropy alloy upon dynamic tension: Micromechanism and constitutive modeling. Int. J. Plast. 2020, 124, 226–246. [Google Scholar] [CrossRef]

- Zhi, H.H.; Zhang, C.; Antonov, S.; Yu, H.Y.; Guo, T.; Su, Y.J. Investigations of dislocation-type evolution and strain hardening during mechanical twinning in Fe-22Mn-0.6C twinning-induced plasticity steel. Acta Mater. 2020, 195, 371–382. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Tang, Y.T.; Karamched, P.; Liu, J.; Haley, J.C.; Reed, R.C.; Wilkinson, A.J. Grain boundary serration in nickel alloy inconel 600: Quantification and mechanisms. Acta Mater. 2019, 181, 352–366. [Google Scholar] [CrossRef]

- Wu, S.W.; Yang, T.; Cao, B.X.; Luan, J.H.; Jia, Y.F.; Xu, L.; Mu, Y.K.; Zhang, T.L.; Kong, H.J.; Tong, X.; et al. Multicomponent Ni-rich high-entropy alloy toughened with irregular-shaped precipitates and serrated grain boundaries. Scr. Mater. 2021, 204, 114066. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, Z.H.; Zhang, L.; Wang, H.; Li, J.B.; Li, Z.; Yu, J.X.; Wu, B.L. Enhancing the strength-ductility trade-off in a NiCoCr-based medium-entropy alloy with the synergetic effect of ultra fine precipitates, stacking faults, dislocation locks and twins. Scr. Mater. 2022, 211, 114497. [Google Scholar] [CrossRef]

- Zhang, Z.; Mao, M.M.; Wang, J.; Gludovatz, B.; Zhang, Z.; Mao, S.X.; George, E.P.; Yu, Q.; Ritchie, R.O. Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 2015, 6, 10143. [Google Scholar] [CrossRef]

- Song, W.; Wang, X.G.; Li, J.G.; Meng, J.; Yang, Y.H.; Liu, J.L.; Liu, J.D.; Zhou, Y.Z.; Sun, X.F. Effect of Ru on tensile behavior and deformation mechanism of a nickel-based single crystal superalloy. Mater. Sci. Eng. A 2021, 802, 140430. [Google Scholar] [CrossRef]

- Hou, K.L.; Wang, M.; Zhao, P.; Ou, M.Q.; Li, H.Z.; Ma, Y.C.; Liu, K. Temperature-dependent yield strength and deformation mechanism of a casting Ni-based superalloy containing low volume-fraction gamma’ phase. J. Alloys Compd. 2022, 905, 164–187. [Google Scholar] [CrossRef]

- Bai, J.M.; Zhang, H.P.; Liu, J.T.; Zhang, M.D.; Liu, C.S.; Zhang, Y.W. Temperature dependence of tensile deformation mechanisms in a powder metallurgy Ni–Co–Cr based superalloy with Ta addition. Mater. Sci. Eng. A 2022, 856, 143965. [Google Scholar] [CrossRef]

- Ding, Q.Q.; Bei, H.B.; Yao, X.; Zhao, X.B.; Wei, X.; Wang, J.; Zhang, Z. Temperature effects on deformation substructures and mechanisms of a Ni-based single crystal superalloy. Appl. Mater. Today 2021, 23, 101061. [Google Scholar] [CrossRef]

- Kovarik, L.; Unocic, R.R.; Li, J.; Sarosi, P.; Shen, C.; Wang, Y.; Mills, M.J. Microtwinning and other shearing mechanisms at intermediate temperatures in Ni-based superalloys. Prog. Mater. Sci. 2009, 54, 839–873. [Google Scholar] [CrossRef]

- Tian, C.G.; Han, G.M.; Cui, C.Y.; Sun, X.F. Effects of stacking fault energy on the creep behaviors of Ni-base superalloy. Mater. Des. 2014, 64, 316–323. [Google Scholar] [CrossRef]

- Yu, S.X.; Wang, Q.; Deng, X.T.; Wang, Z.D. Collaboratively enhancing the strength and ductility of GH3600 Nickel-Based Ultra-Thin strips via the Pre-Precipitation process. Mater. Des. 2023, 234, 112322. [Google Scholar] [CrossRef]

- Qi, D.Q.; Fu, B.D.; Du, K.; Yao, T.T.; Cui, C.Y.; Zhang, J.X.; Ye, H.Q. Temperature effects on the transition from Lomer-Cottrell locks to deformation twinning in a Ni-Co-based superalloy. Scr. Mater. 2016, 125, 24–28. [Google Scholar] [CrossRef]

- Xu, G.S.; Zhang, C.L. Analysis of dislocation nucleation from a crystal surface based on the Peierls–Nabarro dislocation model. J. Mech. Phys. Solids 2003, 51, 1371–1394. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Langdon, T.G. Deformation mechanisms in ultrafine-grained metals with an emphasis on the Hall–Petch relationship and strain rate sensitivity. J. Mater. Res. Technol. 2021, 14, 137–159. [Google Scholar] [CrossRef]

- Li, W.G.; Ma, J.Z.; Kou, H.B.; Shao, J.X.; Zhang, X.Y.; Deng, Y.; Tao, Y.; Fang, D.N. Modeling the effect of temperature on the yield strength of precipitation strengthening Ni-base superalloys. Int. J. Plast. 2019, 116, 143–158. [Google Scholar] [CrossRef]

- Yuan, K.B.; Guo, W.G.; Li, D.W.; Li, P.H.; Zhang, Y.; Wang, P.C. Influence of heat treatments on plastic flow of laser deposited Inconel 718: Testing and microstructural based constitutive modeling. Int. J. Plast. 2021, 136, 102865. [Google Scholar] [CrossRef]

- Liebig, J.P.; Krauß, S.; Göken, M.; Merle, B. Influence of stacking fault energy and dislocation character on slip transfer at coherent twin boundaries studied by micropillar compression. Acta Mater. 2018, 154, 261–272. [Google Scholar] [CrossRef]

- Sang, L.J.; Lu, J.X.; Wang, J.; Ullah, R.; Sun, X.C.; Zhang, Y.F.; Zhang, Z. In-Situ Sem Study of Temperature-Dependent Tensile Behavior of Inconel 718 Superalloy. J. Mater. Sci. 2021, 56, 16097–16112. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. A general mechanism of martensitic nucleation: Part I. General concepts and the FCC HCP transformation. Metall. Trans. A 1976, 7, 1897–1904. [Google Scholar]

- Achmad, T.L.; Fu, W.; Chen, H.; Zhang, C.; Yang, Z.-G. Computational thermodynamic and first-principles calculation of stacking fault energy on ternary Co-based alloys. Comput. Mater. Sci. 2018, 143, 112–117. [Google Scholar] [CrossRef]

- Tian, X.; Zhang, Y. Effect of Si content on the stacking fault energy in γ-Fe–Mn–Si–C alloys: Part II. Thermodynamic estimation. Mater. Sci. Eng. A 2009, 516, 78–83. [Google Scholar] [CrossRef]

- Xiong, R.; Peng, H.; Si, H.; Zhang, W.; Wen, Y. Thermodynamic calculation of stacking fault energy of the Fe–Mn–Si–C high manganese steels. Mater. Sci. Eng. A 2014, 598, 376–386. [Google Scholar] [CrossRef]

- Lee, S.-M.; Lee, S.-J.; Lee, S.; Nam, J.-H.; Lee, Y.-K. Tensile properties and deformation mode of Si-added Fe-18Mn-0.6C steels. Acta Mater. 2018, 144, 738–747. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Choi, C. Driving force for γ→ε martensitic transformation and stacking fault energy of γ in Fe-Mn binary system. Metall. Mater. Trans. A 2000, 31, 355–360. [Google Scholar] [CrossRef]

- Xiong, R.; Liu, Y.; Si, H.; Peng, H.; Wang, S.; Sun, B.; Chen, H.; Kim, H.S.; Wen, Y. Effects of Si on the Microstructure and Work Hardening Behavior of Fe–17Mn–1.1C–xSi High Manganese Steels. Met. Mater. Int. 2020, 27, 3891–3904. [Google Scholar] [CrossRef]

- Dinsdale, A.T. SGTE data for pure elements. Calphad 1991, 15, 317–425. [Google Scholar] [CrossRef]

- Yang, S.; Jiang, M.; Li, H.; Liu, Y.; Wang, L. Assessment of Co-Cr-Ni ternary system by CALPHAD technique. Rare Met. 2012, 31, 75–80. [Google Scholar] [CrossRef]

- Oikawa, K.; Qin, G.-W.; Ikeshoji, T.; Kainuma, R.; Ishida, K. Direct evidence of magnetically induced phase separation in the fcc phase and thermodynamic calculations of phase equilibria of the Co–Cr system. Acta Mater. 2002, 50, 2223–2232. [Google Scholar] [CrossRef]

| Elements | Ni | Co | Cr | Si | Al | Ti |

|---|---|---|---|---|---|---|

| Nominal composition | 50 | 25 | 12.5 | 7.5 | 2.5 | 2.5 |

| Actual composition | 47.77 | 25.31 | 12.29 | 8.70 | 3.11 | 2.83 |

| Temp. (K) | Tensile Properties | |||

|---|---|---|---|---|

| σy (MPa) | σuts (MPa) | εf (%) | (dσ/dε)avg. (MPa) | |

| 77 | 1005 ± 38 | 1620 ± 53 | 36.3 ± 2.2 | 4025 ± 153 |

| 298 | 836 ± 52 | 1274 ± 66 | 34.5 ± 1.3 | 2884 ± 120 |

| 773 | 835 ± 40 | 1120 ± 32 | 35.1 ± 2.4 | 1800 ± 200 |

| 873 | 841 ± 37 | 1010 ± 49 | 18.4 ± 1.8 | 2212 ± 85 |

| 973 | 808 ± 38 | 862 ± 53 | 15.2 ± 1.4 | 1430 ± 53 |

| 1073 | 542 ± 34 | 542 ± 34 | 26.5 ± 2.9 | −155 ± 95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Bai, T.; Xiong, R.; Luo, S.; Chang, H.; Du, S.; Ma, J.; Jiao, Z.; Ma, S.; Wang, J.; et al. Temperature-Dependent Mechanical Behaviors and Deformation Mechanisms in a Si-Added Medium-Entropy Superalloy with L12 Precipitation. Metals 2024, 14, 749. https://doi.org/10.3390/met14070749

Zhang T, Bai T, Xiong R, Luo S, Chang H, Du S, Ma J, Jiao Z, Ma S, Wang J, et al. Temperature-Dependent Mechanical Behaviors and Deformation Mechanisms in a Si-Added Medium-Entropy Superalloy with L12 Precipitation. Metals. 2024; 14(7):749. https://doi.org/10.3390/met14070749

Chicago/Turabian StyleZhang, Tuanwei, Tianxiang Bai, Renlong Xiong, Shunhui Luo, Hui Chang, Shiyu Du, Jinyao Ma, Zhiming Jiao, Shengguo Ma, Jianjun Wang, and et al. 2024. "Temperature-Dependent Mechanical Behaviors and Deformation Mechanisms in a Si-Added Medium-Entropy Superalloy with L12 Precipitation" Metals 14, no. 7: 749. https://doi.org/10.3390/met14070749

APA StyleZhang, T., Bai, T., Xiong, R., Luo, S., Chang, H., Du, S., Ma, J., Jiao, Z., Ma, S., Wang, J., & Wang, Z. (2024). Temperature-Dependent Mechanical Behaviors and Deformation Mechanisms in a Si-Added Medium-Entropy Superalloy with L12 Precipitation. Metals, 14(7), 749. https://doi.org/10.3390/met14070749