Effect of Annealing Temperature on Microstructure and Properties of DH Steel and Optimization of Hole Expansion Property

Abstract

1. Introduction

2. Materials and Methods

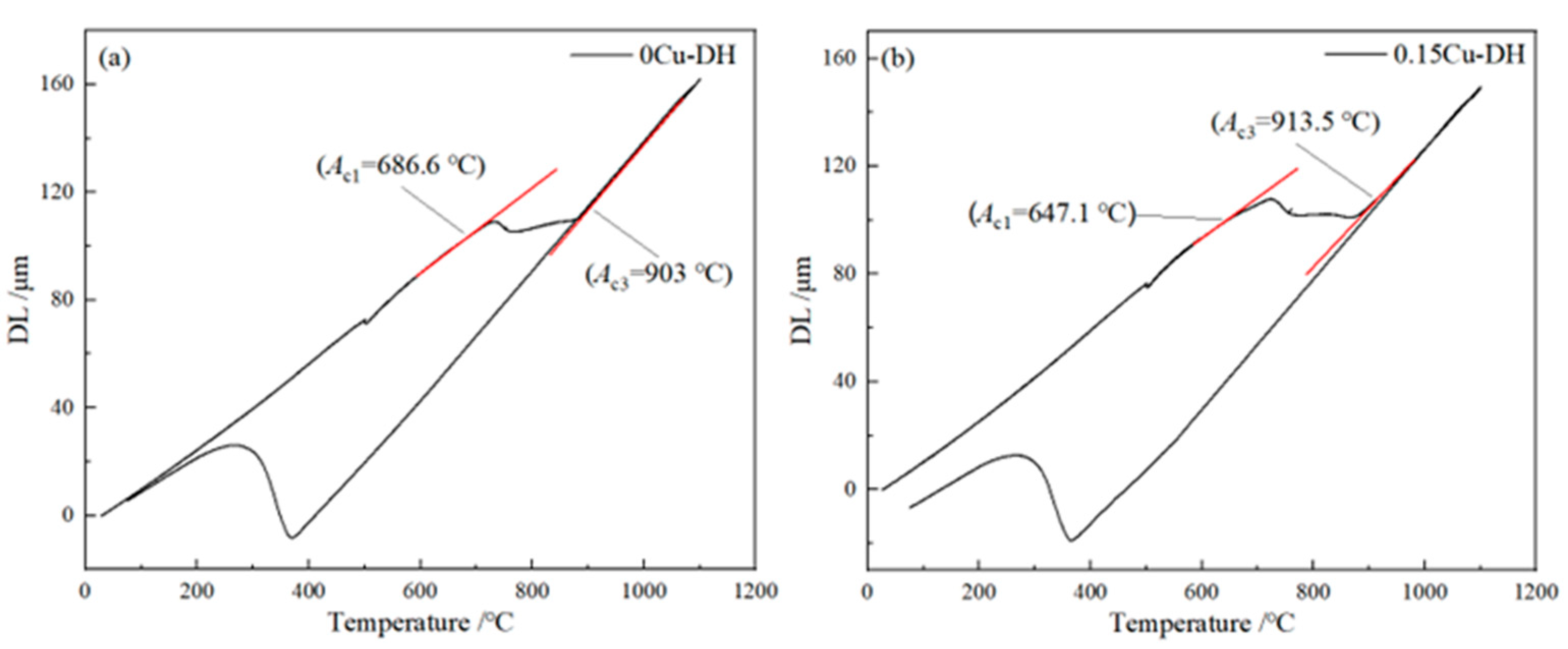

2.1. Law of Phase Transformation

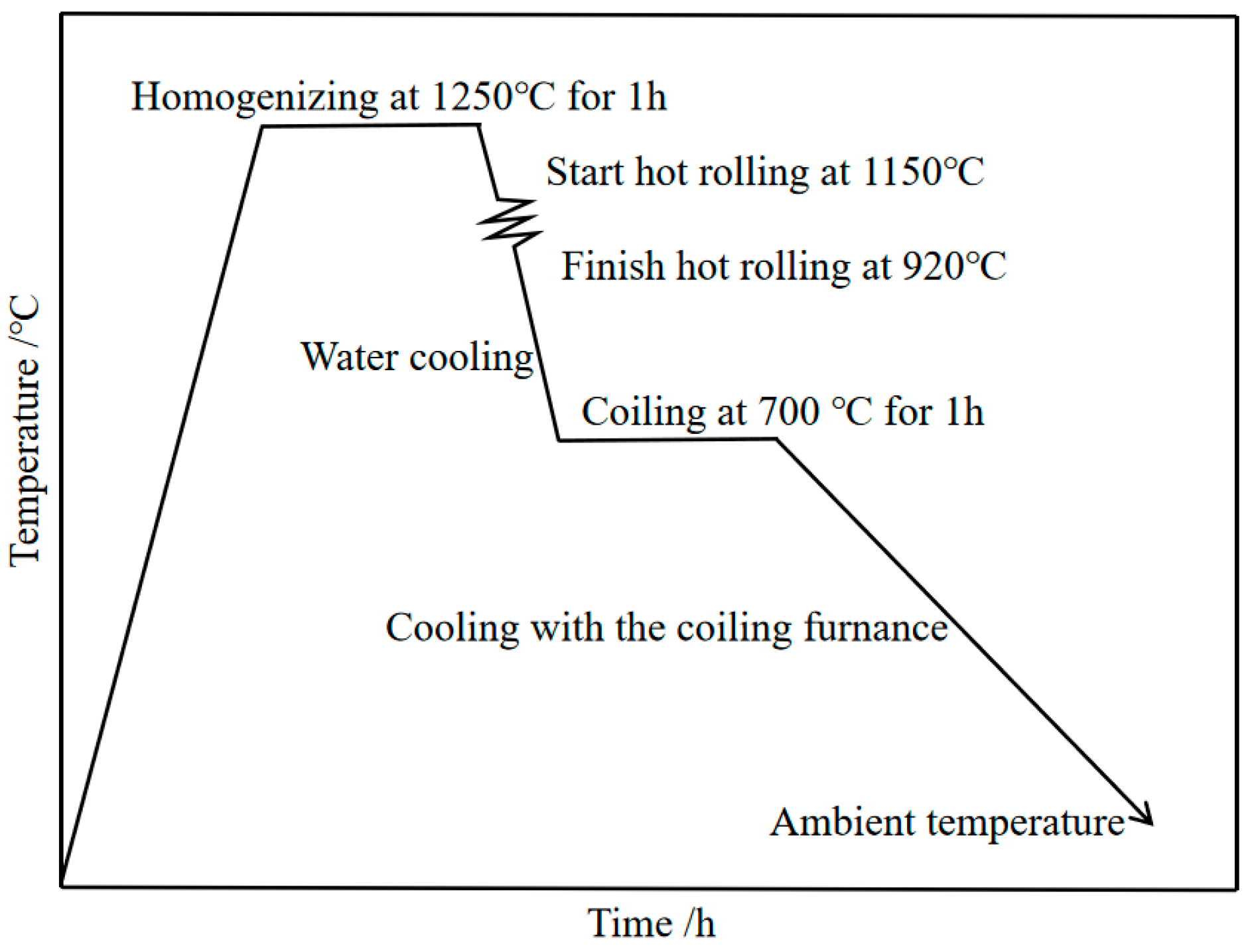

2.2. Preparation of Test Steel and Research Methods

3. Results and Discussion

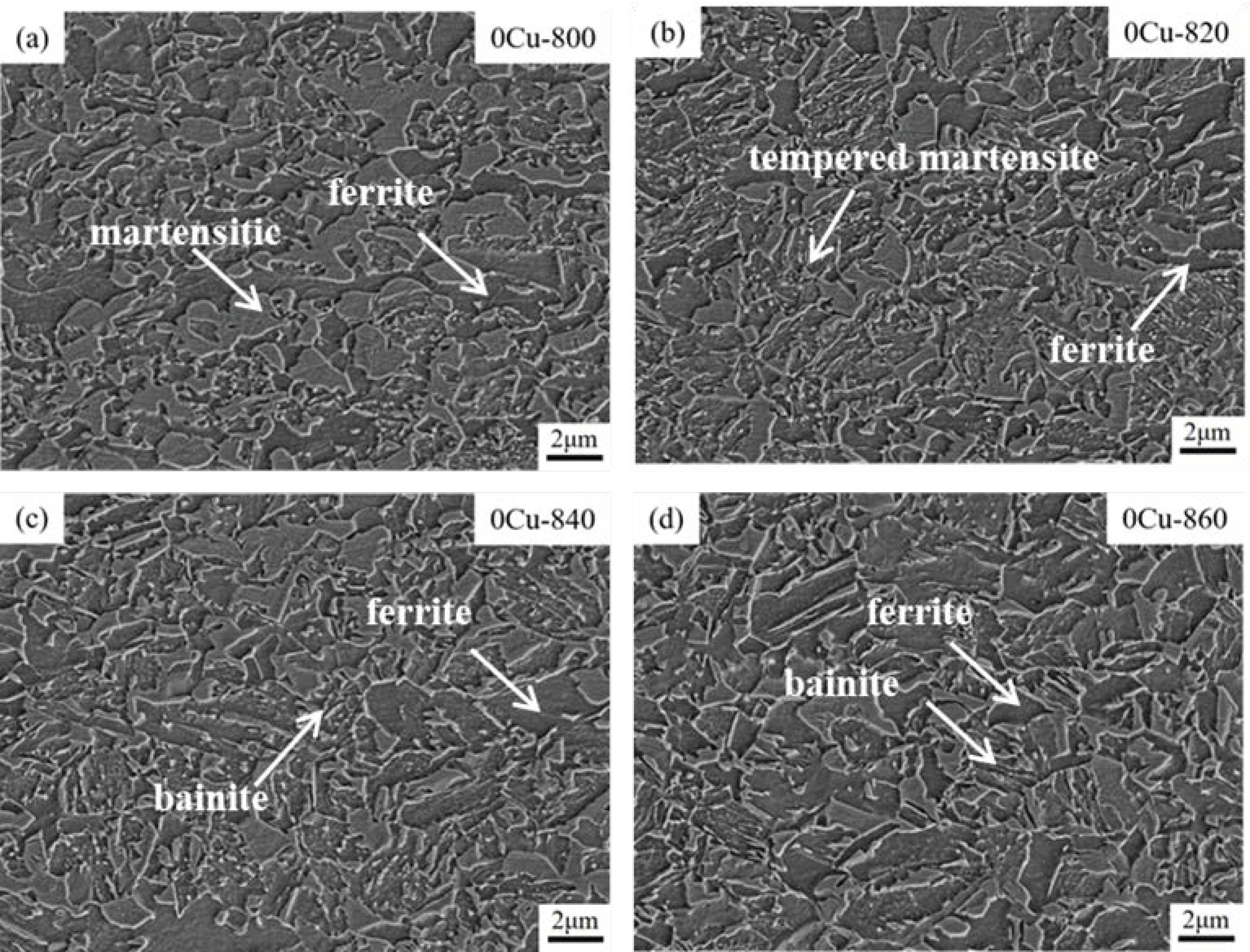

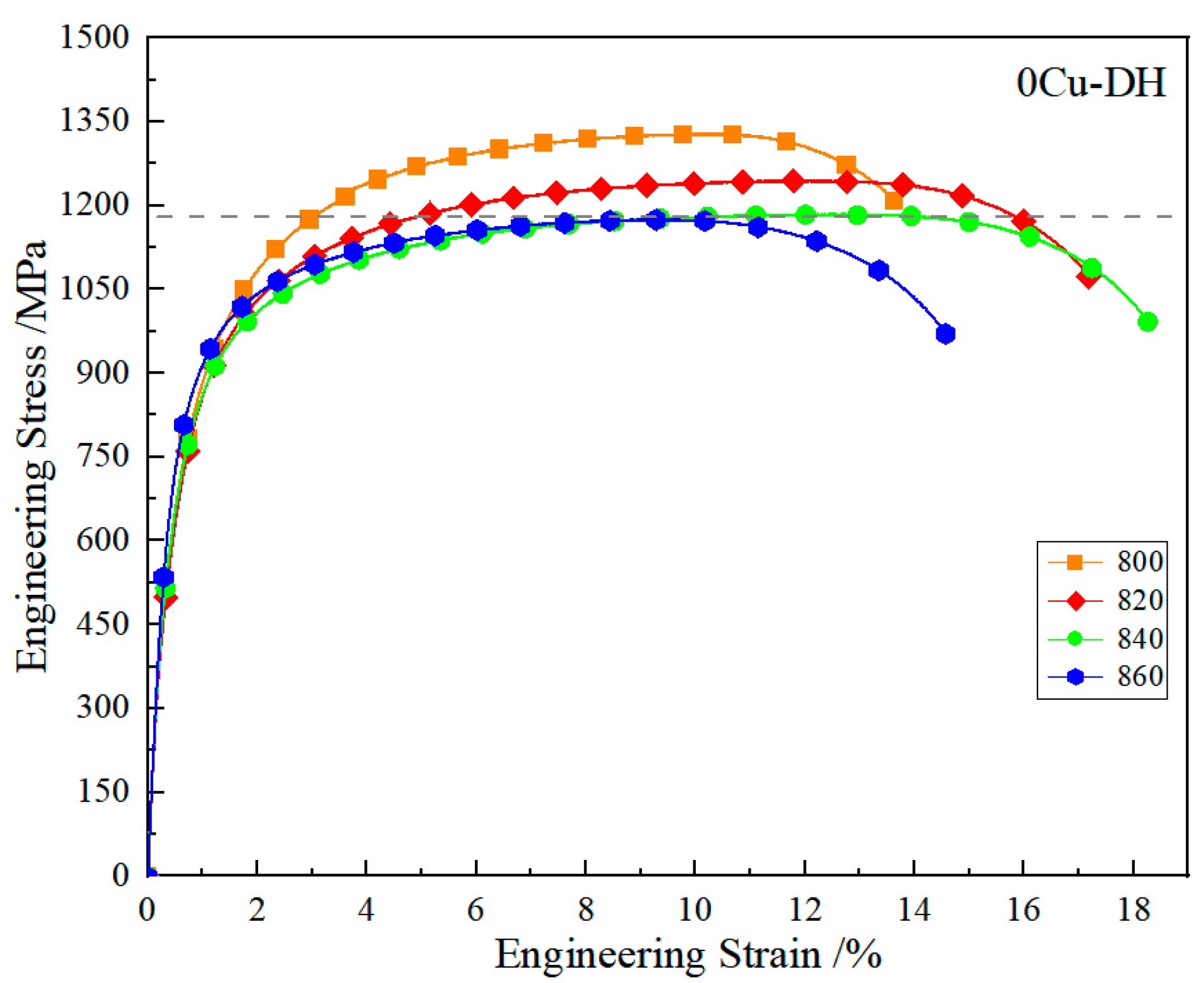

3.1. Microstructure and Properties of 0Cu-DH Steel at Different Annealing Temperatures

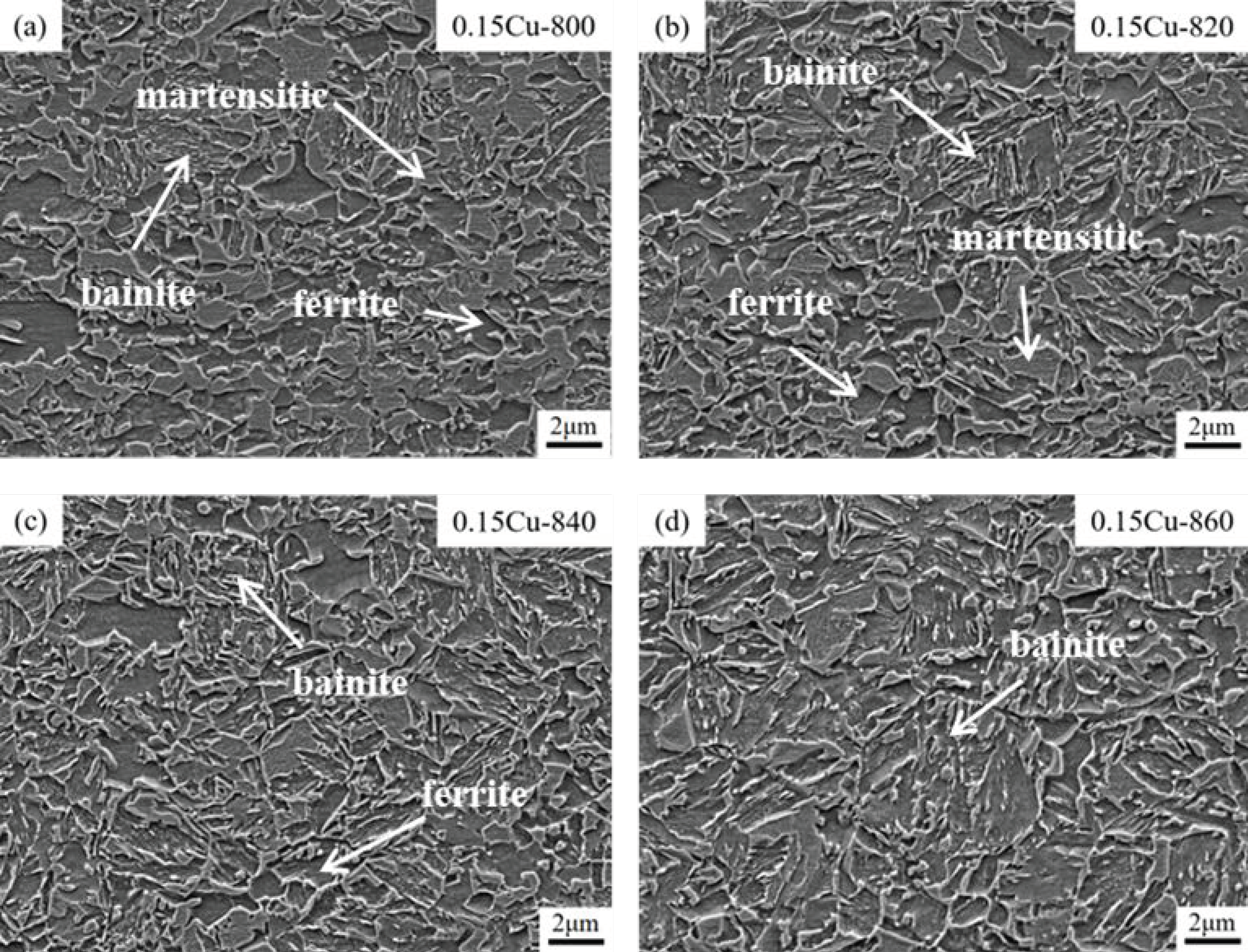

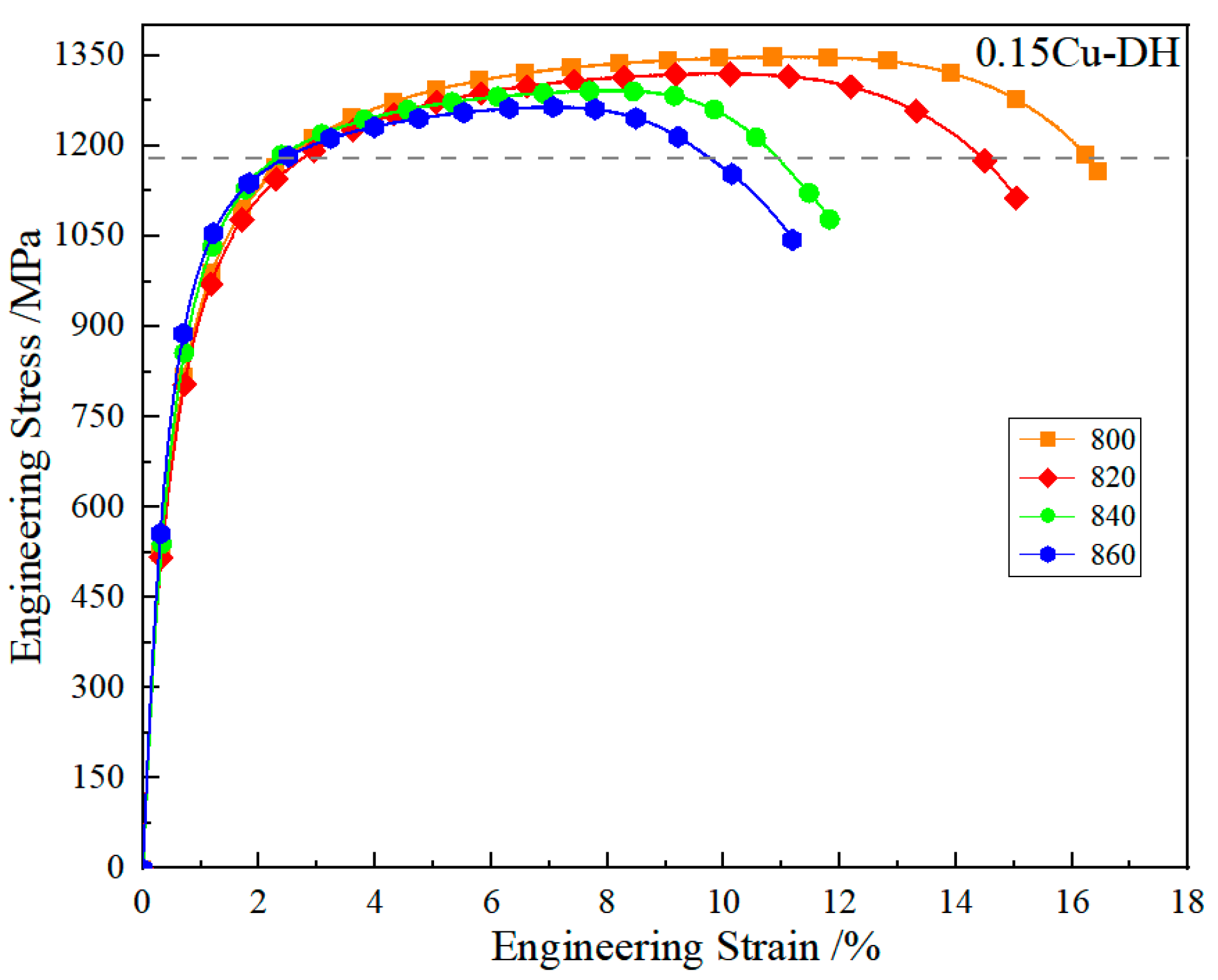

3.2. Microstructure and Properties of 0.15Cu-DH Steel at Different Annealing Temperatures

3.3. Characterization and Optimization of Hole Expansion Property of Test Steel

3.4. Discussion

3.4.1. Effect of Annealing Temperature on Microstructure and Properties of Test Steel

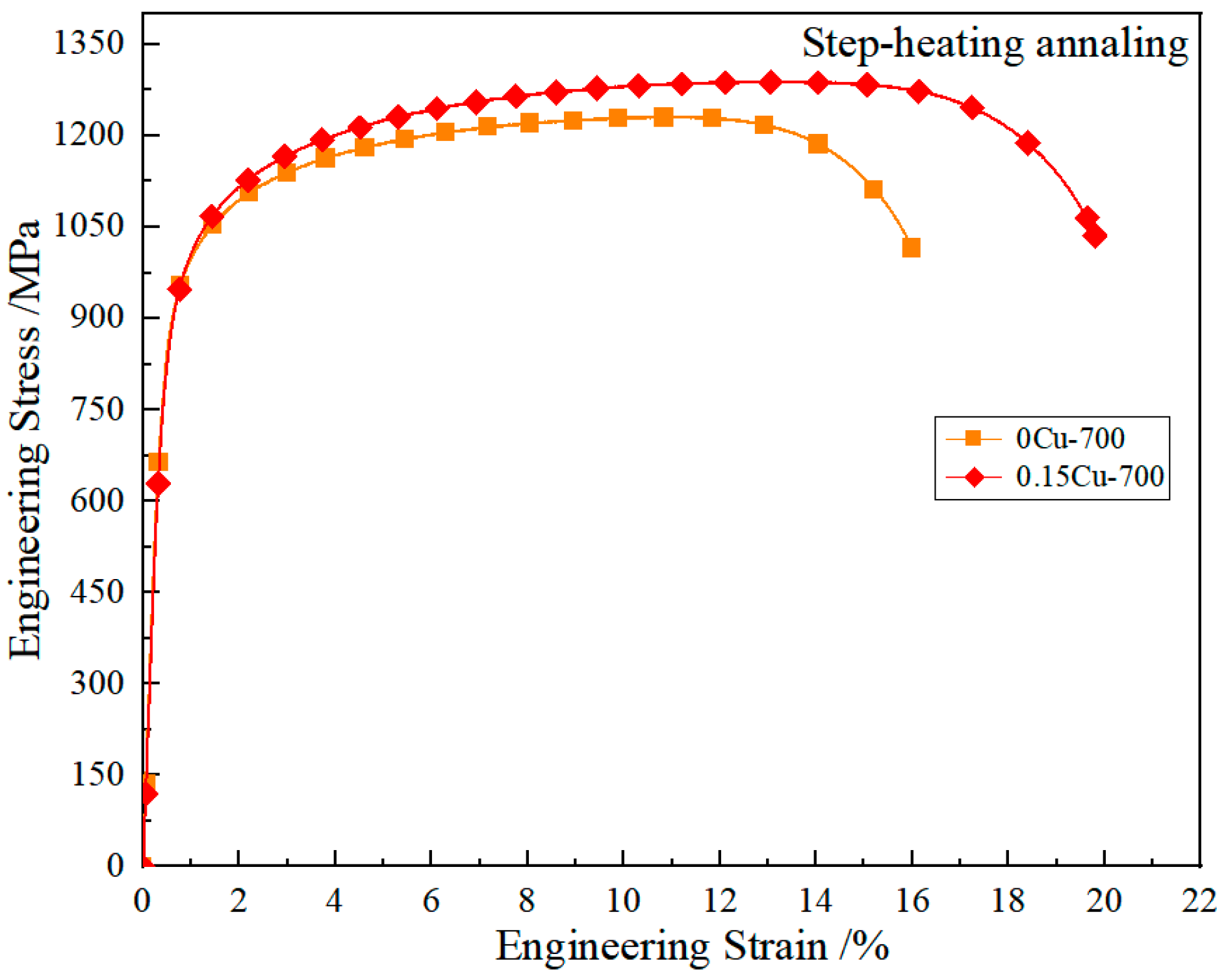

3.4.2. Optimization of Step Heating Annealing on Hole Expanding Property of Test Steel

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qiao, Y.; Wang, G. Recent Status of Production, Administration Policies, and Low-Carbon Technology Development of China’s Steel Industry. Metals 2024, 14, 480. [Google Scholar] [CrossRef]

- Yao, T.L.; Wu, W.; Yang, Y.; He, Q.; Meng, H.D.; Lin, T.C. Analysis on low-carbon development of China’s steel industry under dual-carbon goal. J. Iron Steel Res. 2022, 34, 505–513. [Google Scholar] [CrossRef]

- Liu, X.L.; Huang, G. Analysis of Factors for the Flange Cracking of Dual Phase Steel. Eng. Technol. Res. 2021, 6, 13–14. [Google Scholar] [CrossRef]

- Silva, R.C.; Silva, F.; Gouveia, M.R. Investigations on the edge crack defect in Dual Phase steel stamping process. Procedia Manuf. 2018, 17, 737–17745. [Google Scholar] [CrossRef]

- Yu, L.; Liu, J.; Ge, R.; Wei, X.; Peng, Z.; Chen, M.; Liu, D. Fracture characteristics and mechanism of DP780 duplex steel under different strains. Forg. Technol. 2022, 47, 48–55. [Google Scholar]

- Feng, Y.; Wan, X.M.; Zhou, J.; Xu, W.; Gao, X.; Fang, G.; Yu, C.L.; Zhang, J.P.; Shen, J.; Huang, L.; et al. Research Progress on Fracture Properties of Advanced High-Strength Steel Sheet for Automobiles. Chin. J. Automot. Eng. 2023, 13, 273–297. [Google Scholar]

- Tasan, C.C.; Diehl, M.; Yan, D.; Bechtold, M.; Roters, F.; Schemmann, L.; Zheng, C.; Peranio, N.; Ponge, D.; Koyama, D.; et al. An Overview of Dual-Phase Steels: Advances in Microstructure-Oriented Processing and Micromechanically Guided Design. Annu. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- Zhang, W.; Li, C.G.; Lin, X.M.; Yang, J.W.; Liu, L.X.; Liu, H.S. Analysis of Energy Absorption Characteristics of Dual Phase Steel with High Formability Based on Drop Test. In Proceedings of the 12th CSM steel Congress of the Conference, Beijing, China, 15 October 2019. [Google Scholar] [CrossRef]

- Kim, S.; Lee, G.C.; Lee, T.; Oh, C. Effects of Copper Addition on Mechanical Properties of 0.15C-1.5Mn-1.5Si TRIP-aided Multiphase Cold-rolled Steel Sheets. ISIJ Int. 2002, 42, 1452–1456. [Google Scholar] [CrossRef]

- Li, H.; Tian, X.; Ren, X. Fatigue fracture behavior and organization analysis of cold-rolled duplex steel. J. Plast. Eng. 2023, 30, 151–158. [Google Scholar]

- Hou, X.; Wang, J.; Ding, M.; Liu, W.; Sun, W.; Kang, H. Influence of matrix organization on the strength-plasticity mechanism of 800 MPa-grade duplex steels. Met. Heat Treat. 2022, 47, 222–227. [Google Scholar]

- Wang, P.; Zhang, Y.; Cai, N.; Fu, C.; Yi, R.; Ju, J.; Chen, W.; Yu, Y. Effect of martensite content on the organization and properties of resistance spot welded joints of alloyed hot-dip galvanized duplex steel. Precis. Molding Eng. 2023, 15, 160–167. [Google Scholar]

- E, H.; Zheng, X.; Li, Y.; Han, L. Prediction of forming limits of DP780 duplex steel based on different instability theories. Mech. Eng. Mater. 2022, 46, 82–87, 94. [Google Scholar]

- Zheng, X.; Tang, D.; Xiao, Y.; Cui, L.; Zhan, H. Influence of annealing process on the reaming properties of 780 MPa Nb-Ti microalloyed duplex steel. Jiangxi Metall. 2022, 42, 7–11. [Google Scholar]

- Lu, H.Z.; Ma, M.T.; Guo, A.M. Development of Automotive EVI Technologies. Automot. Technol. Mater. 2022, 1-9+79. [Google Scholar] [CrossRef]

- Li, H.; Dai, J.; Xian, L.; Liu, X.; Ren, J.; Gao, Y. Effect of annealing temperature on phase transformation and organization of DP590 cold-rolled duplex steel. Eng. Technol. Res. 2020, 5, 1–4. [Google Scholar]

- Wu, X.; Song, Z.; He, J.; Feng, H.; Zheng, W.; Zhu, Y. Effect of N content on the secondary austenite precipitation behavior in S32750 duplex stainless steel. Spec. Steel 2024, 45, 18–22. [Google Scholar]

- Ma, C.; Zhang, D.; Gong, Z.; Liu, X.; Song, H.; Li, D. Study on fracture criterion parameters for toughness of high-strength duplex steel plates. Mech. Strength 2023, 45, 1474–1482. [Google Scholar]

- Cu, S.; Mao, B.; Hu, G. Microstructure modulation and toughening mechanism of advanced high-strength cold-rolled duplex steels for automotive applications. J. Met. 2022, 58, 551–566. [Google Scholar]

- Liu, L.X. Effect of Pre-strain on Microstructure and Mechanical Properties of High Strength Steel DH780. Hot Work. Technol. 2022, 51, 97–101. [Google Scholar] [CrossRef]

- Luo, R.; Hu, W.; Wang, F.; Tu, J.; Tao, Y.; Shen, W. Effect of aging on the evolution of precipitated phases in super duplex stainless steel. Spec. Steel 2024, 45, 77–81. [Google Scholar]

- Ma, C.; Gao, X.; Xing, L.; Wang, H.; Hu, Z.; Zhai, T. Analysis of stress-strain inhomogeneity during tensile deformation of ferritic/martensitic duplex steels. Mater. Guide 2023, 37, 178–181. [Google Scholar]

- Liu, H.; Yang, S.Y.; Gao, P. Solution to Cracking Problem of 780DH Rear Shock Absorber Support. Automob. Ind. 2022, 36–38. [Google Scholar]

- Li, Q.; Ying, C.; Meng, H.; He, L.; Jiang, F. Effects of coiling temperature and cooling rate on microstructure and tensile properties of hot rolled duplex steel containing niobium. Mech. Eng. Mater. 2023, 47, 45–49+96. [Google Scholar] [CrossRef]

- Cao, L.; Zheng, B.Q.; Wang, Y.C.; Zhou, C.; Yang, Z.M. Influence of acicular ferrite on yielding behavior of HRB400 reinforcing steel bars containing niobium. China Metall. 2016, 26, 28–32. [Google Scholar] [CrossRef]

- Yang, C.; Xiao, Z.; Feng, Q.; Luo, Z. Study on continuous annealing and organizational properties of high-strength automotive duplex steels. Precis. Molding Eng. 2023, 15, 168–176. [Google Scholar]

- Wang, L.; Fan, L.; Hu, Y.; Zhou, P. Influence of heat treatment process on the organization and properties of S31803 duplex stainless steel. J. Heat Treat. Mater. 2023, 44, 108–116. [Google Scholar]

- Han, L.S.; Ye, S.W.; Zheng, X.B.; Han, Y.; Chen, H.S. Experimental study on hole expansion performance for ultra-high strength dual-phase steel. Forg. Stamp. Technol. 2020, 45, 187–192. [Google Scholar] [CrossRef]

- Shen, G. Computational Simulation of Organization Evolution during Continuous Annealing of Duplex Steel. Ph.D. Thesis, Shanghai Jiaotong University, Shanghai, China, 2018. [Google Scholar]

- Pan, L.; Zuo, Z.; Zhou, W.; Zhu, H. Analysis of forming and fracture limit properties of duplex steels. Forg. Technol. 2021, 46, 185–189. [Google Scholar]

| Test Steel | C | Si+Al | Mn | Cr | Cu | Nb |

|---|---|---|---|---|---|---|

| 0Cu-DH | 0.17–0.22 | 1.05–1.55 | 2.05–2.85 | 0.15–0.35 | 0.00 | 0.01–0.05 |

| 0.15Cu-DH | 0.17–0.22 | 1.05–1.55 | 2.05–2.85 | 0.15–0.35 | 0.15 | 0.01–0.05 |

| Annealing Temperature/°C | Yield Strength/MPa | Tensile Strength/MPa | Total Elongation/% | Product of Strength and Plasticity/GPa·% |

|---|---|---|---|---|

| 800 | 672 | 1328 | 13.6 | 18.1 |

| 820 | 628 | 1245 | 17.2 | 21.4 |

| 840 | 655 | 1184 | 18.3 | 21.7 |

| 860 | 749 | 1175 | 14.6 | 17.2 |

| Annealing Temperature/°C | Yield Strength/MPa | Tensile Strength/MPa | Total Elongation/% | Product of Strength and Plasticity/GPa·% |

|---|---|---|---|---|

| 800 | 706 | 1348 | 16.5 | 22.2 |

| 820 | 686 | 1321 | 15.0 | 19.8 |

| 840 | 784 | 1293 | 11.8 | 15.3 |

| 860 | 822 | 1265 | 11.2 | 14.2 |

| Test Steel | Tensile Strength/MPa | Total Elongation/% | Time between Punching and Expanding/h | Hole Expansion Rate/% | Loss of Hole Expansion Rate/% |

|---|---|---|---|---|---|

| 0Cu-DH | 1184 | 18.3 | 0 | 18.3 | 55.2 |

| 72 | 8.2 | ||||

| 0.15Cu- DH | 1293 | 11.8 | 0 | 16.0 | 76.2 |

| 72 | 3.8 |

| Test Steel | Tensile Strength/MPa | Total Elongation/% | Time between Punching and Expanding/h | Hole Expansion Rate/% | Loss of Hole Expansion Rate/% |

|---|---|---|---|---|---|

| 0Cu-DH | 1231 | 16.0 | 0 | 19.5 | 21.5 |

| 72 | 15.3 | ||||

| 0.15Cu- DH | 1289 | 19.8 | 0 | 21.9 | 10.0 |

| 72 | 19.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Ma, X.; Lu, H.; Zhao, Z. Effect of Annealing Temperature on Microstructure and Properties of DH Steel and Optimization of Hole Expansion Property. Metals 2024, 14, 791. https://doi.org/10.3390/met14070791

Yang Y, Ma X, Lu H, Zhao Z. Effect of Annealing Temperature on Microstructure and Properties of DH Steel and Optimization of Hole Expansion Property. Metals. 2024; 14(7):791. https://doi.org/10.3390/met14070791

Chicago/Turabian StyleYang, Yuhuan, Xiaoyue Ma, Hongzhou Lu, and Zhengzhi Zhao. 2024. "Effect of Annealing Temperature on Microstructure and Properties of DH Steel and Optimization of Hole Expansion Property" Metals 14, no. 7: 791. https://doi.org/10.3390/met14070791

APA StyleYang, Y., Ma, X., Lu, H., & Zhao, Z. (2024). Effect of Annealing Temperature on Microstructure and Properties of DH Steel and Optimization of Hole Expansion Property. Metals, 14(7), 791. https://doi.org/10.3390/met14070791