New Insights into the Ingot Breakdown Mechanism of Near-β Titanium Alloy: An Orientation-Driven Perspective

Abstract

1. Introduction

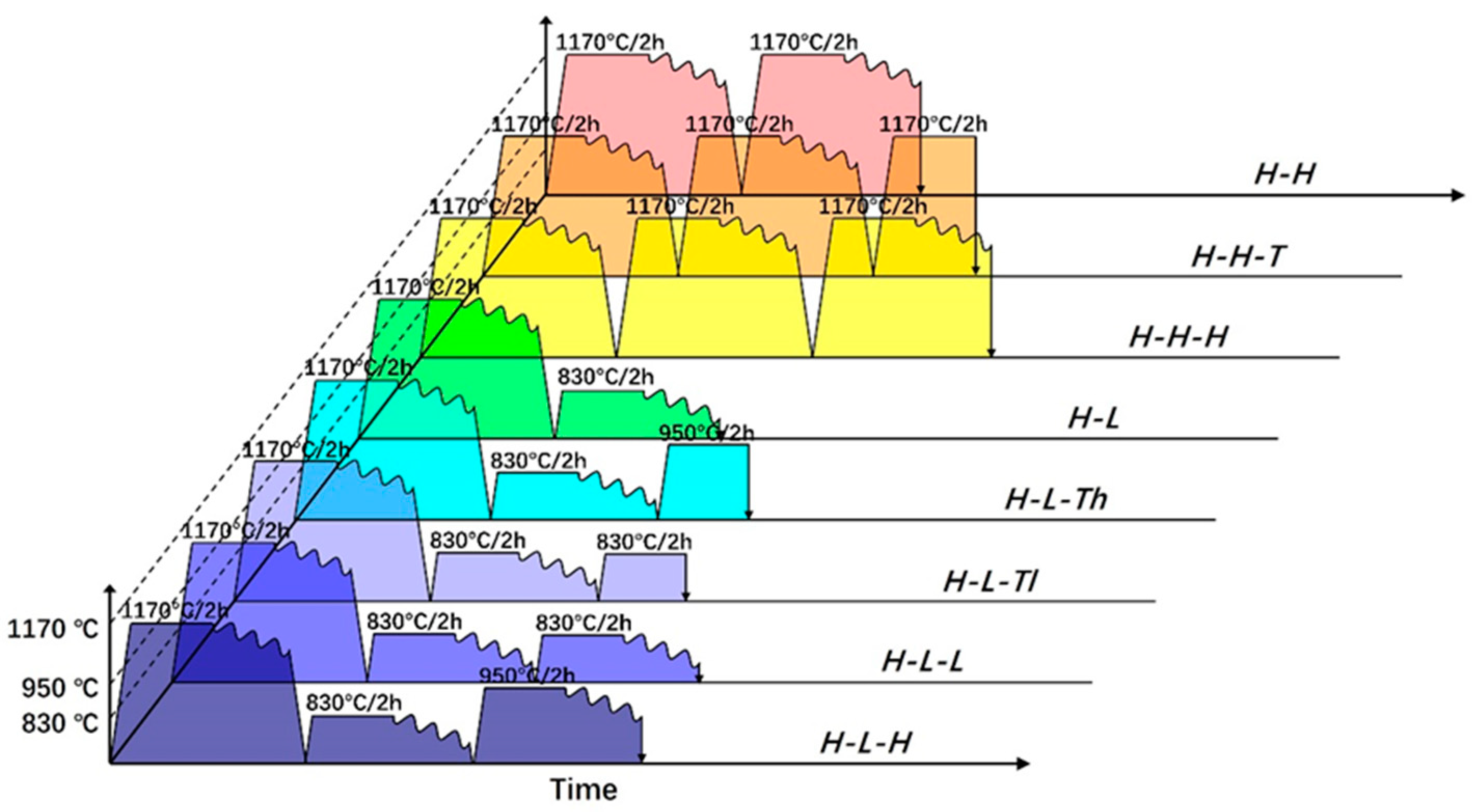

2. Materials and Methods

3. Results

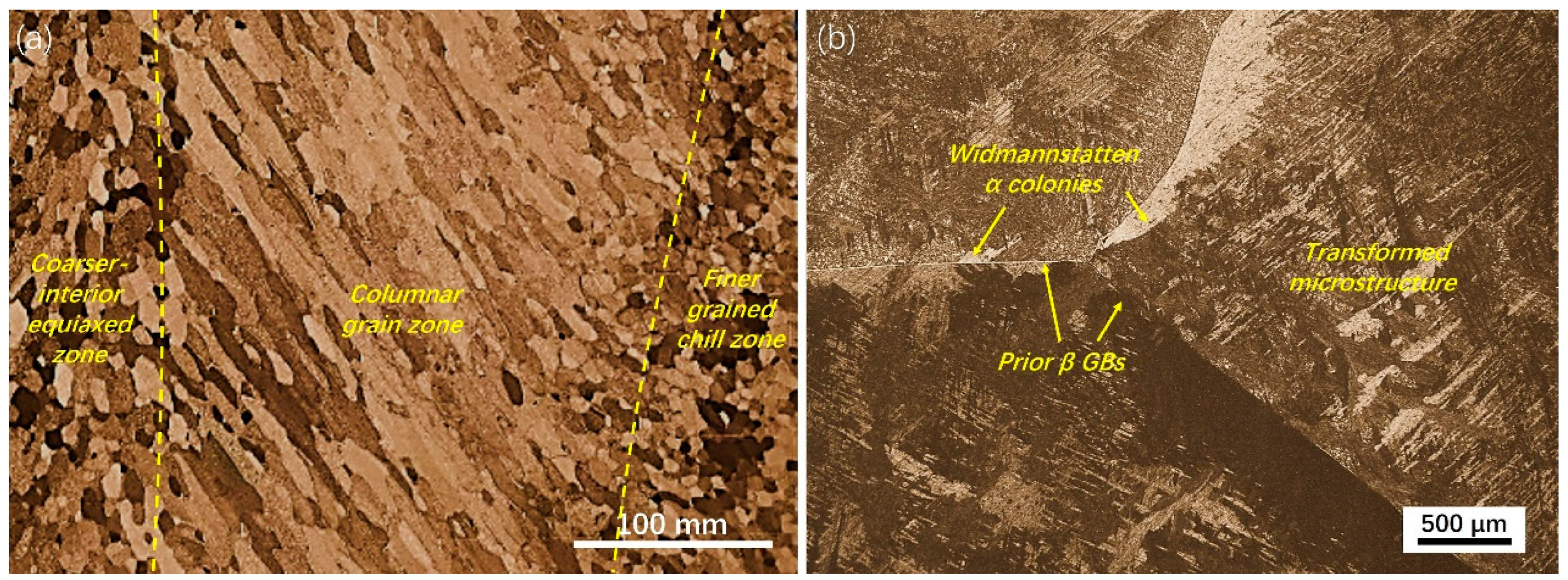

3.1. As-Cast Material

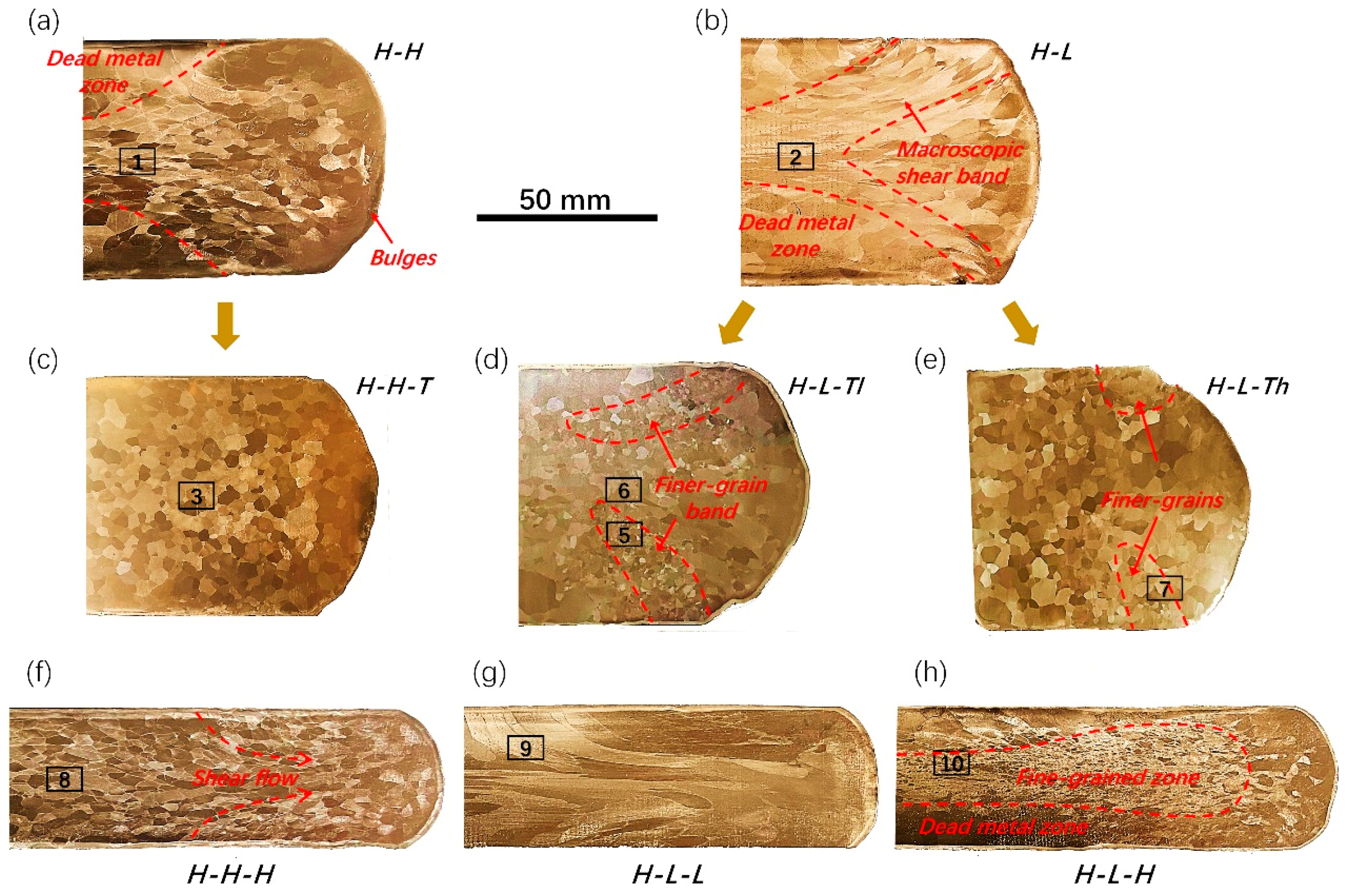

3.2. Apparent Macrostructure Characterization

3.2.1. Two-Pass Upsetting

3.2.2. Post-Deformation Annealing

3.2.3. Three-Pass Upsetting

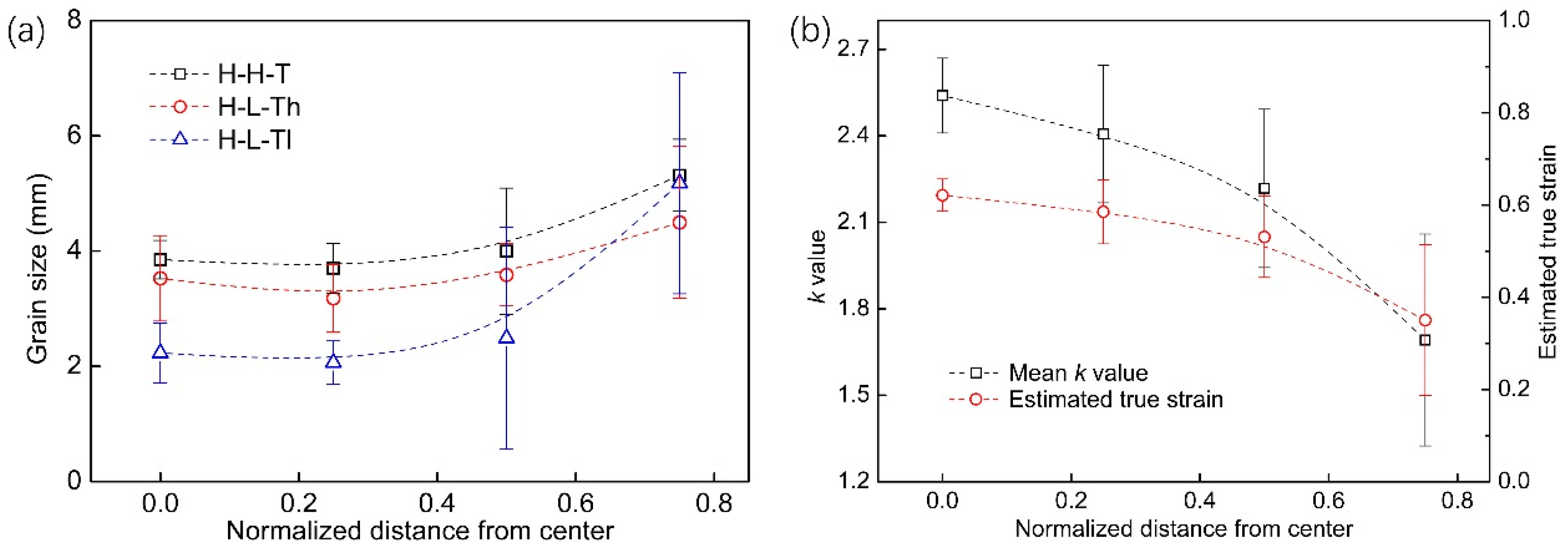

3.3. Microstructural Evolution

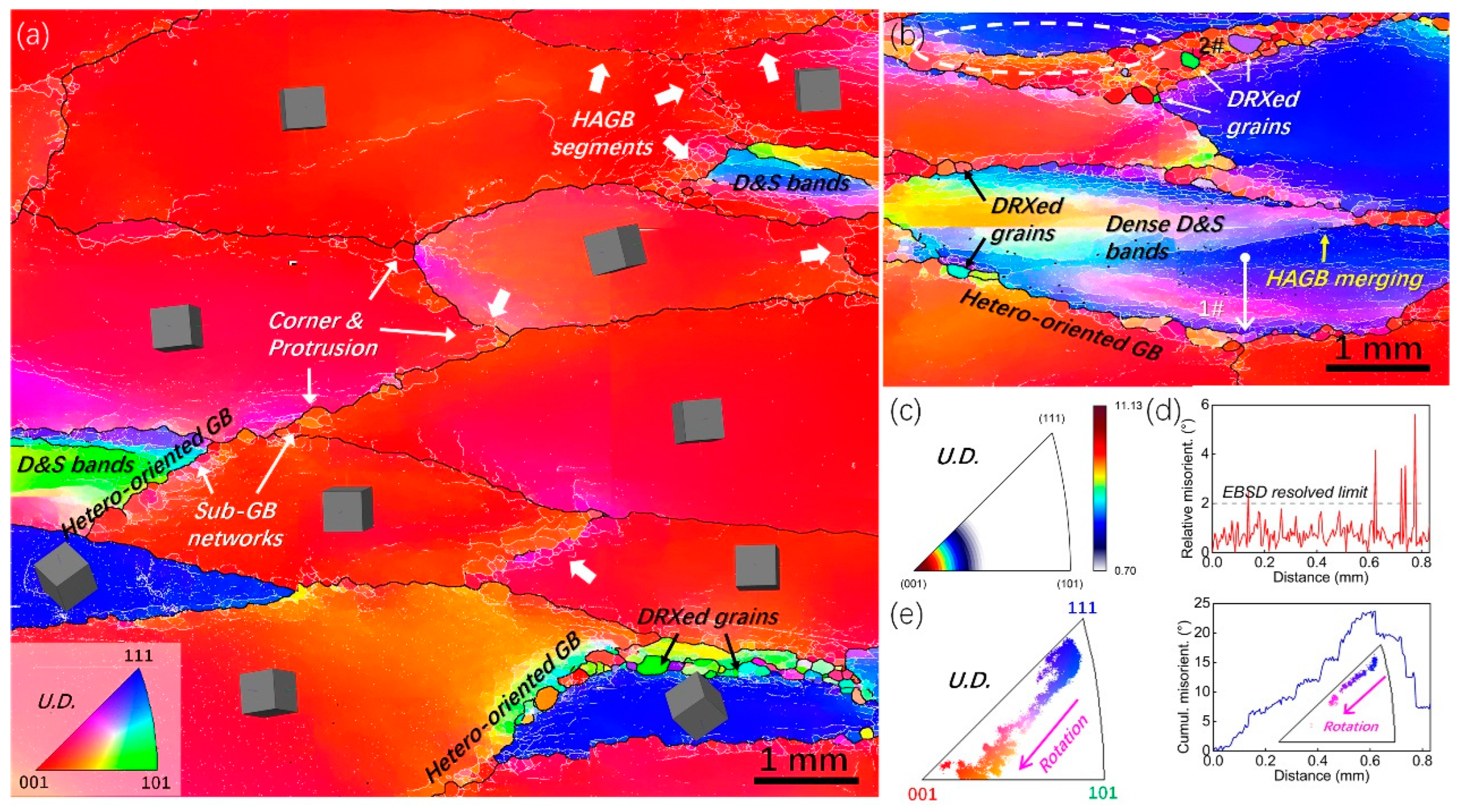

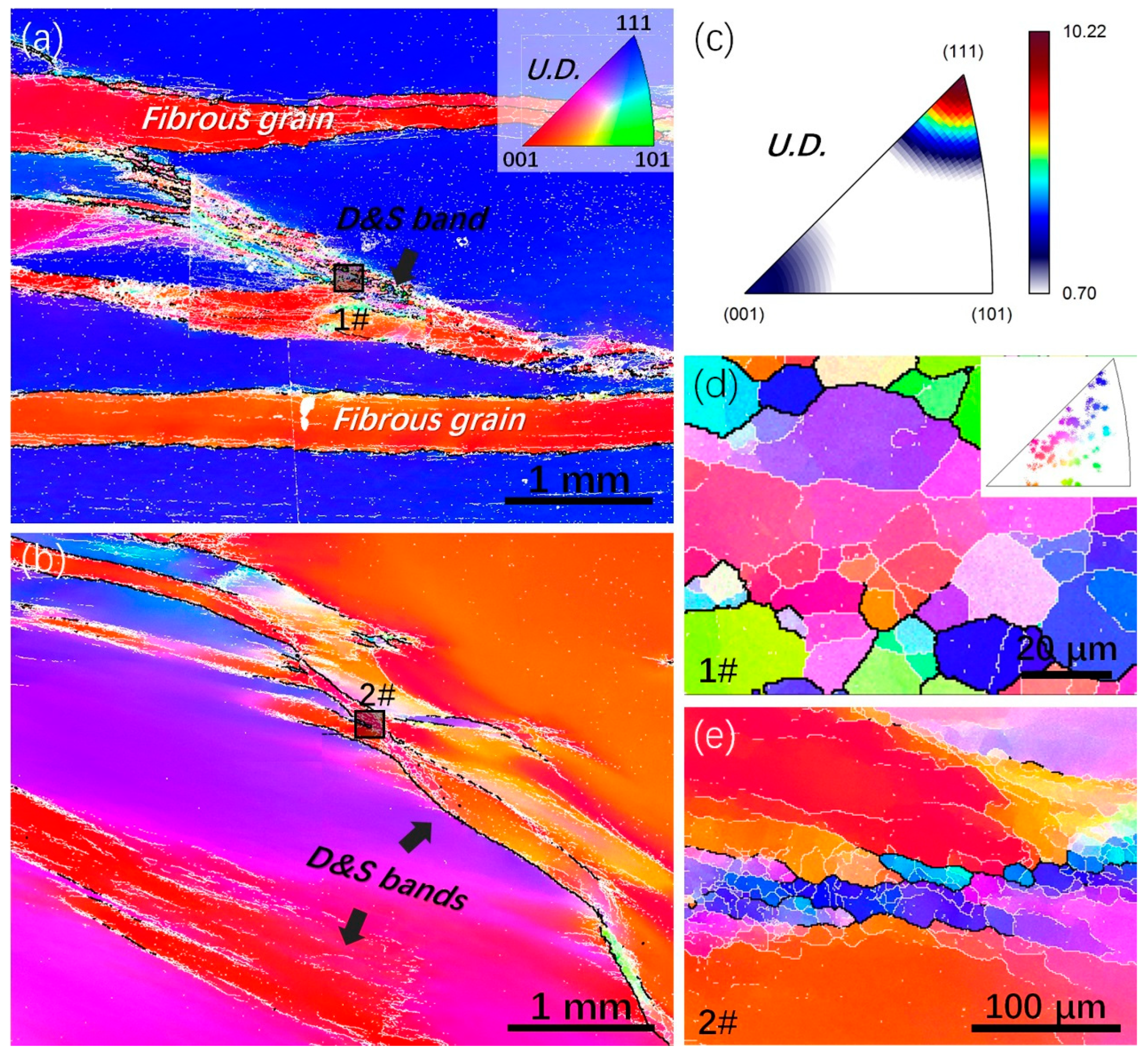

3.3.1. β-Working

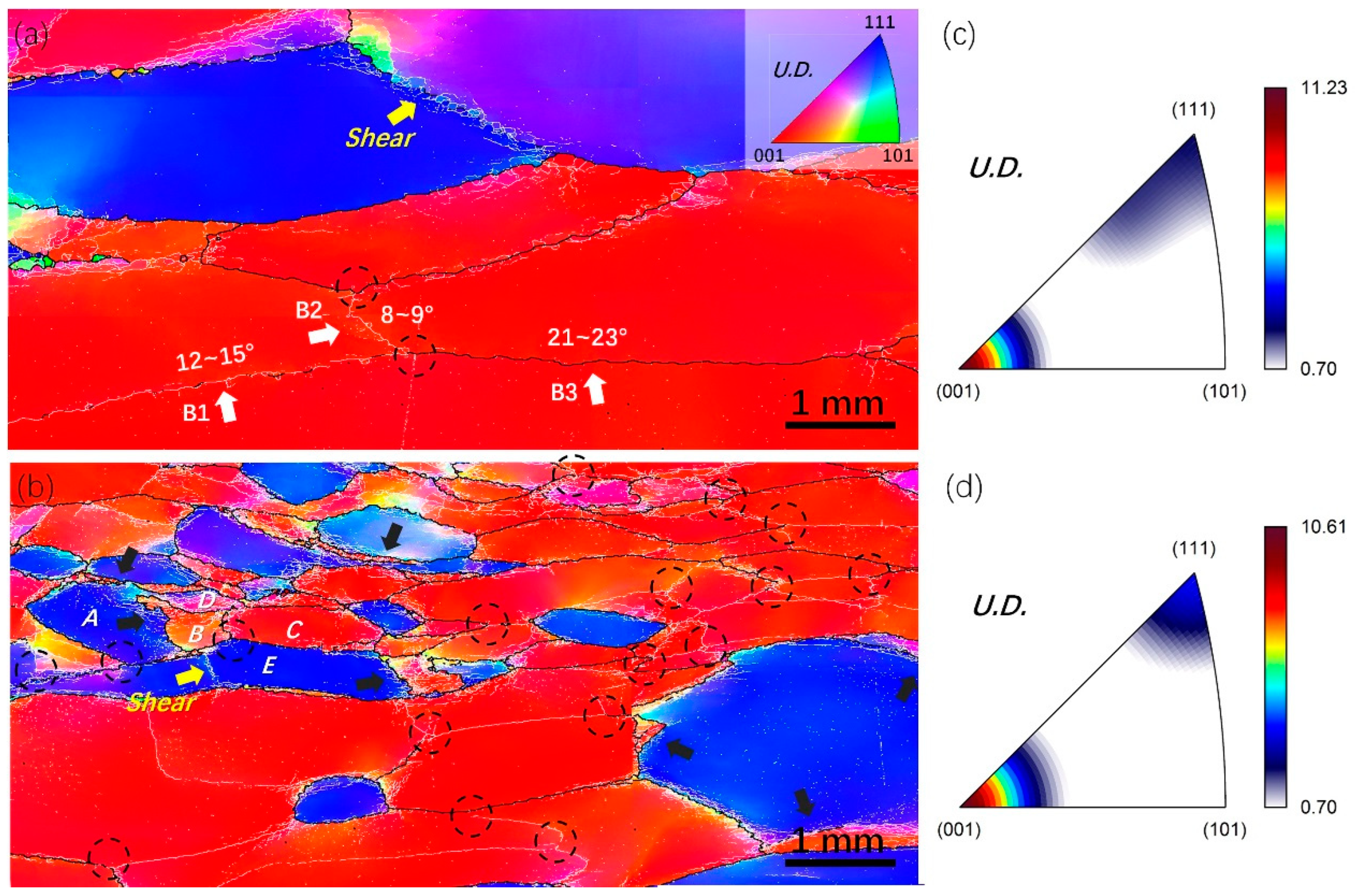

3.3.2. α/β-Working

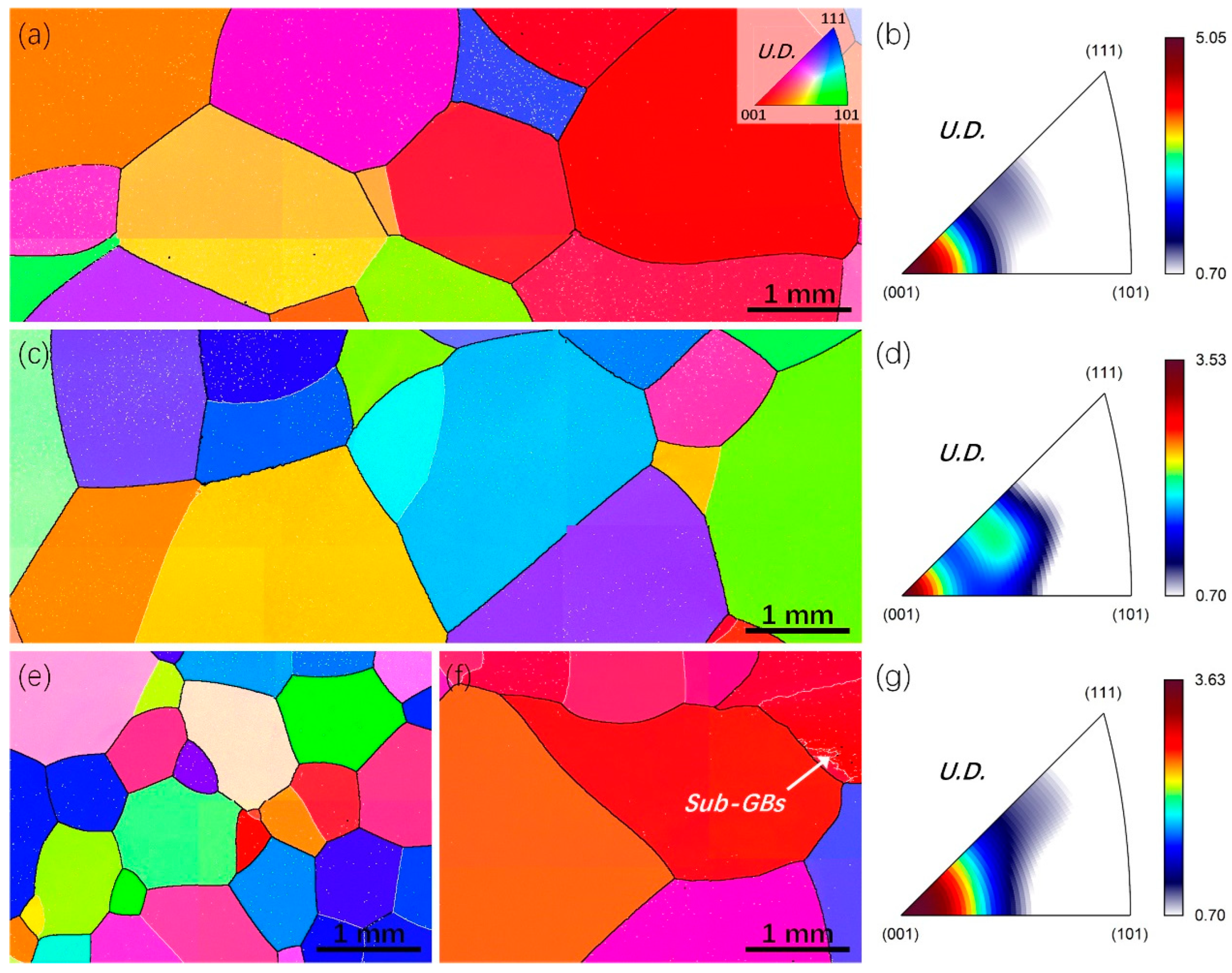

3.3.3. Post-Deformation Annealing

4. Discussion

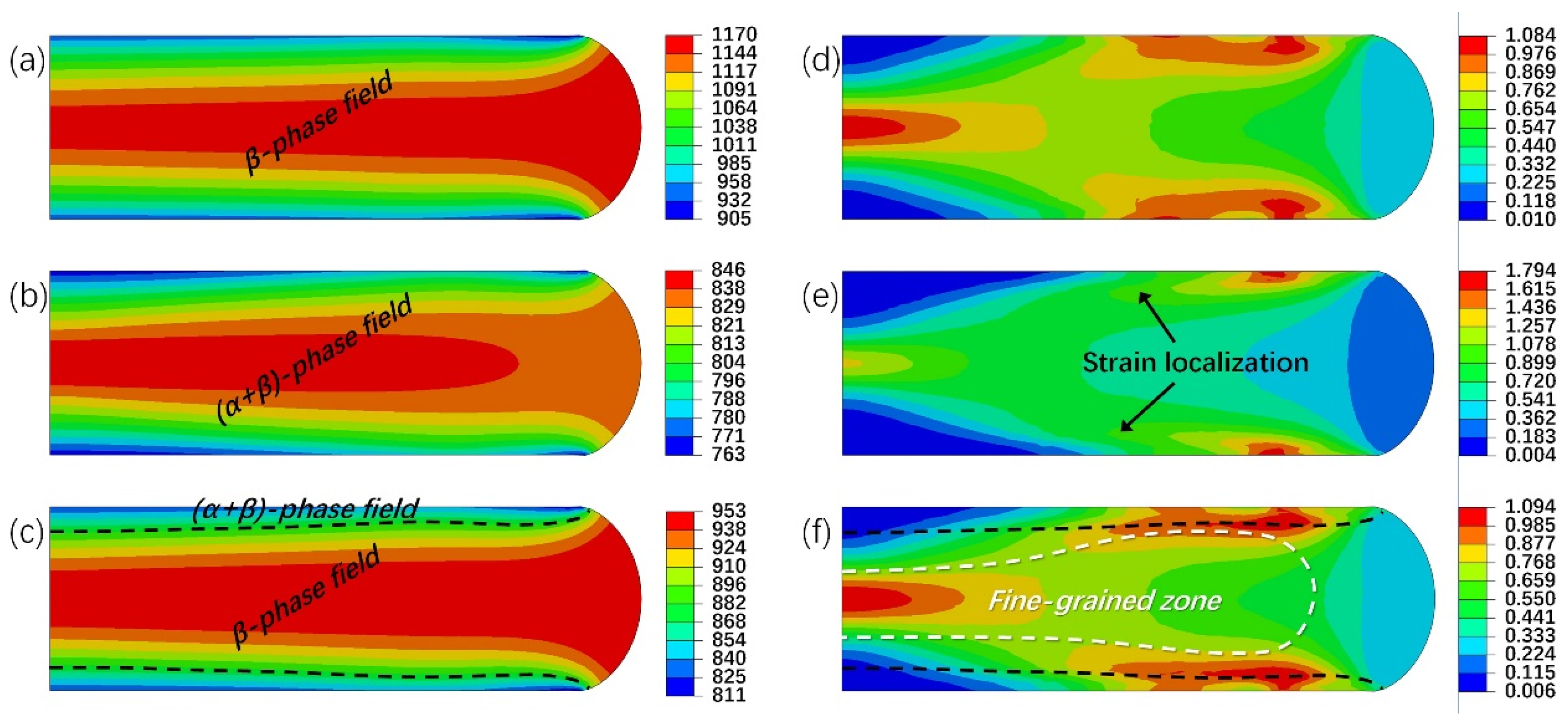

4.1. Deformation Nonuniformity

4.2. Microstructural Conversion Mechanism

4.3. Implications for Efficient Ingot Breakdown

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

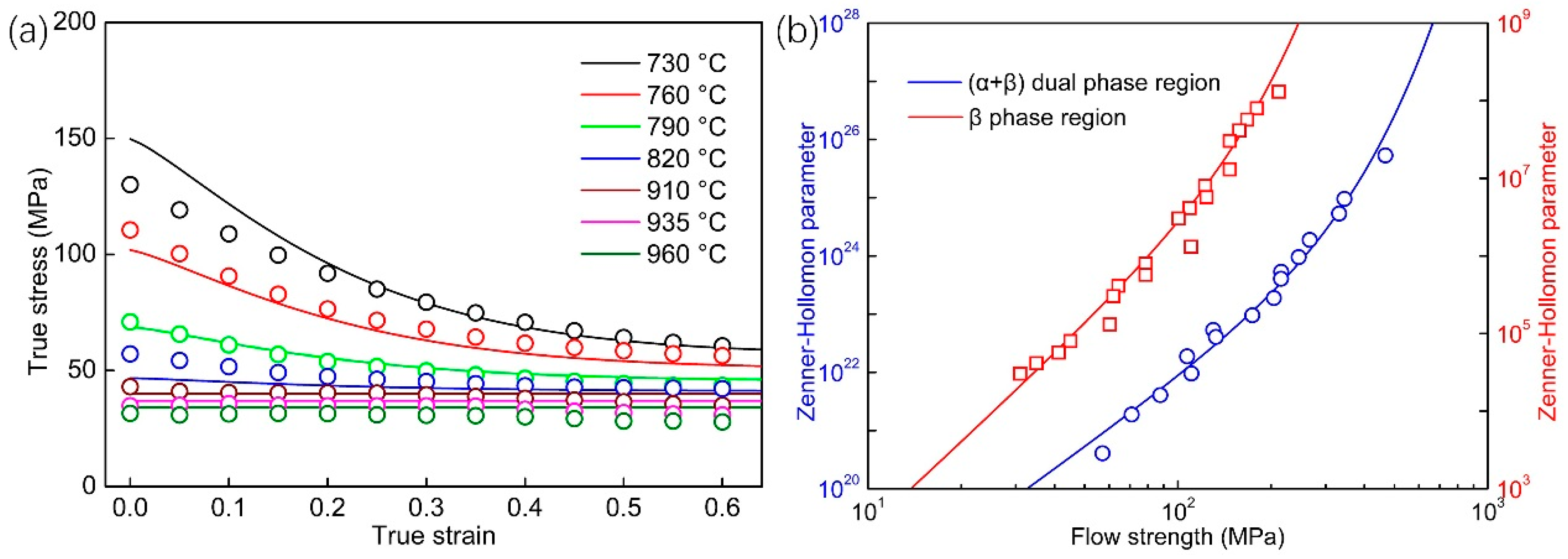

Appendix A

| σ | Current Flow Stress |

| σP | Peak stress when deformed in dual-phase region |

| σS | Steady-state flow stress when deformed in dual-phase region |

| X | Flow softening fraction when deformed in dual-phase region (a) |

| Zs | Zenner–Hollomon parameter for steady-state flow stress (b) |

| ZP | Zenner–Hollomon parameter for peak stress in dual-phase field |

| ε | True strain |

| True strain rate |

References

- Fanning, J.; Boyer, R.; Lutjering, G.; Albrecht, J. (Eds.) Titanium 2003: Science and Technology; Wiley-VCH: Hamburg, Germany, 2003; Volume 4, pp. 2643–2650. [Google Scholar]

- Wang, J.; Zhao, Y.; Zhao, Q.; Lei, C.; Zhou, W.; Zeng, W. Comparison on impact toughness of high-strength metastable β titanium alloy with bimodal and lamellar microstructures. Metals 2022, 12, 271. [Google Scholar] [CrossRef]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Zhang, X.; Li, J.; Tao, M.; Wan, J.; Chen, B. Electron Beam Welding and Post Heat Treatment of a New Near-Beta High-Strength Ti-4Al-5Mo-5V-5Cr-1Nb Alloy. Metals 2022, 12, 1396. [Google Scholar] [CrossRef]

- Guo, L.G.; Fan, X.G.; Yu, G.F.; Yang, H. Microstructure control techniques in primary hot working of titanium alloy bars: A review. Chin. J. Aeronaut. 2016, 29, 30–40. [Google Scholar] [CrossRef]

- Zhao, Q.Y.; Sun, Q.Y.; Xin, S.W.; Chen, Y.N.; Wu, C.; Wang, H.; Xu, J.W.; Wan, M.P.; Zeng, W.D.; Zhao, Y.Q. High-strength titanium alloys for aerospace engineering applications: A review on melting-forging process. Mater. Sci. Eng. A 2022, 845, 143260. [Google Scholar] [CrossRef]

- Semiatin, S.L. An Overview of the thermomechanical processing of α/β titanium alloys: Current status and future research opportunities. Metall. Mater. Trans. A 2020, 51, 2593–2625. [Google Scholar] [CrossRef]

- Shi, S.X.; Ge, J.Y.; Lin, Y.C.; Zhang, X.Y.; Zhou, K.C. High-temperature deformation behavior and recrystallization mechanism of a near beta titanium alloy Ti-55511 in β phase region. Mater. Sci. Eng. A 2022, 847, 143335. [Google Scholar] [CrossRef]

- Li, M.; Huang, L.; Zhao, M.J.; Guo, S.Q.; Li, J.J. Hot deformation behavior and mechanism of a new metastable β titanium alloy Ti–6Cr–5Mo–5V–4Al in single phase region. Mater. Sci. Eng. A 2021, 814, 141231. [Google Scholar] [CrossRef]

- Lin, Y.C.; Huang, J.; He, D.G.; Zhang, X.Y.; Wu, Q.; Wang, L.H.; Chen, C.; Zhou, K.C. Phase transformation and dynamic recrystallization behaviors in a Ti55511 titanium alloy during hot compression. J. Alloys Compd. 2019, 795, 471–482. [Google Scholar] [CrossRef]

- Pallot, L.; Piot, D.; Desrayaud, C.; Montheillet, F.; Bénéteau, A. Traitement Thermomécanique de L’alliage Ti-17 Dans le Domaine Bêta. Matériaux 2010, Nantes, France, DVD Publication: 2010.

- Fan, X.G.; Zhang, Y.; Gao, P.F.; Lei, Z.N.; Zhan, M. Deformation behavior and microstructure evolution during hot working of a coarse-grained Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy in beta phase field. Mater. Sci. Eng. A 2017, 694, 24–32. [Google Scholar] [CrossRef]

- Callegari, B.; Oliveira, J.P.; Coelho, R.S.; Brito, P.P.; Schell, N.; Soldera, F.A.; Mücklich, F.; Sadik, M.I.; García, J.L.; Pinto, H.C. New insights into the microstructural evolution of Ti-5Al-5Mo-5V-3Cr alloy during hot working. Mater. Charact. 2020, 162, 110180. [Google Scholar] [CrossRef]

- Wang, H.D.; Ge, J.Y.; Zhang, X.Y.; Chen, C.; Zhou, K.C. Investigation of the dynamic recovery and recrystallization of near-β titanium alloy Ti-55511 during two-pass hot compression. Metals 2021, 11, 359. [Google Scholar] [CrossRef]

- Balachandran, S.; Kumar, S.; Banerjee, D. On recrystallization of the α and β phases in titanium alloys. Acta Mater. 2017, 131, 423–434. [Google Scholar] [CrossRef]

- Li, L.; Luo, J.; Yan, J.J.; Li, M.Q. Dynamic globularization and restoration mechanism of Ti–5Al–2Sn–2Zr–4Mo–4Cr alloy during isothermal compression. J. Alloys Compd. 2015, 622, 174–183. [Google Scholar] [CrossRef]

- Guo, B.Q.; Jonas, J.J. Dynamic transformation during the high temperature deformation of titanium alloys. J. Alloys Compd. 2021, 884, 161179. [Google Scholar] [CrossRef]

- Flower, H.M. Microstructural development in relation to hot working of titanium alloys. Mater. Sci. Technol. 1990, 6, 1082–1092. [Google Scholar] [CrossRef]

- CPark, H.; Kim, J.H.; Hyun, Y.T.; Yeom, J.T.; Reddy, N.S. The origins of flow softening during high-temperature deformation of a Ti–6Al–4V alloy with a lamellar microstructure. J. Alloys Compd. 2014, 582, 126–129. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. Hot workability of titanium and titanium aluminide alloys—An overview. Mater. Sci. Eng. A 1998, 243, 1–24. [Google Scholar] [CrossRef]

- Li, L.; Li, M.Q.; Luo, J. Mechanism in the β phase evolution during hot deformation of Ti–5Al–2Sn–2Zr–4Mo–4Cr with a transformed microstructure. Acta Mater. 2015, 94, 36–45. [Google Scholar] [CrossRef]

- Fan, X.G.; Yang, H.; Gao, P.F.; Zuo, R.; Lei, P.H. The role of dynamic and post dynamic recrystallization on microstructure refinement in primary working of a coarse grained two-phase titanium alloy. J. Am. Acad. Dermatol. 2016, 234, 290–299. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Meng, L.; Kitashima, T.; Tsuchiyama, T.; Watanabe, M. β-texture evolution of a near-β titanium alloy during cooling after forging in the β single-phase and (α+β) dual-phase regions. Metall. Mater. Trans. A 2021, 52, 303–315. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, S.J.; Yang, G.; Kou, H.C.; Li, J.S. Hot tensile behavior of a TiAl alloy with a (β0+γ) microduplex microstructure prepared simply by heat treatments. J. Alloys Compd. 2021, 875, 160039. [Google Scholar] [CrossRef]

- Li, K.; Yang, P. The formation of strong {100} texture by dynamic strain-induced boundary migration in hot compressed Ti-5Al-5Mo-5V-1Cr-1Fe alloy. Metals 2017, 7, 412. [Google Scholar] [CrossRef]

- Rosenberg, J.M.; Piehler, H.R. Calculation of the Taylor factor and lattice rotations for bcc metals deforming by pencil glide. Metall. Trans. 1971, 2, 257–259. [Google Scholar] [CrossRef]

- Cheng, L.; Zhu, B.; Yang, G.; Qiang, F.M.; Li, J.S. Insights into the abnormal flow softening of lamellar γ-TiAl alloys during hot-working: Experimental analysis and numerical simulation. Mater. Sci. Eng. A 2022, 852, 143695. [Google Scholar] [CrossRef]

- Cheng, L.; Qiang, F.M.; Li, J.S.; Bouzy, E. Quantitative evaluation of the lamellar kinking&rotation on the flow softening of γ-TiAl-based alloys at elevated temperatures. Mater. Lett. 2021, 290, 129458. [Google Scholar]

- Masuda, H.; Sato, E. Diffusional and dislocation accommodation mechanisms in superplastic materials. Acta Mater. 2020, 197, 235–252. [Google Scholar] [CrossRef]

- Raabe, D.; Lücke, K. Rolling and annealing textures of BCC metals. Mater. Sci. Forum 1994, 157–162, 597–610. [Google Scholar] [CrossRef]

- Laasraoui, A.; Jonas, J.J. Prediction of steel flow stresses at high temperatures and strain rates. Metall. Trans. A 1991, 22, 1545–1558. [Google Scholar] [CrossRef]

- Bambach, M.; Sizova, I.; Bolz, S.; Weiß, S. Devising strain hardening models using Kocks–Mecking plots—A comparison of model development for titanium aluminides and case hardening steel. Metals 2016, 6, 204. [Google Scholar] [CrossRef]

- Chen, T. The Study of Hot Deformation Behaviour and Numerical Simulation of Heat Treatment of TC18 Titanium Alloy. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2013. [Google Scholar]

- Gottstein, G. Physical Foundations of Materials Science; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Doherty, R.D.; Hughes, D.A.; Humphreys, F.J.; Jonas, J.J.; Jensen, D.J.; Kassner, M.E.; King, W.E.; McNelley, T.R.; McQueen, H.J.; Rollett, A.D. Current issues in recrystallization: A review. Mater. Sci. Eng. A 1997, 238, 219–274. [Google Scholar] [CrossRef]

| Ti | Al | Mo | V | Cr | Fe | Zr | Si | C | H | O | N | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Top | Bal. | 5.29 | 5.03 | 5.12 | 1.120 | 0.945 | <0.01 | 0.014 | 0.008 | <0.001 | 0.113 | 0.014 |

| Middle | Bal. | 5.3 | 5.03 | 5.13 | 1.100 | 0.996 | - | - | - | - | - | - |

| Bottom | Bal. | 5.27 | 5.05 | 5.12 | 1.130 | 0.987 | <0.01 | 0.014 | 0.008 | - | 0.11 | 0.014 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wang, T.; Ren, X.; Fu, J.; Cheng, L.; Zhu, B.; Wang, K. New Insights into the Ingot Breakdown Mechanism of Near-β Titanium Alloy: An Orientation-Driven Perspective. Metals 2024, 14, 792. https://doi.org/10.3390/met14070792

Liu X, Wang T, Ren X, Fu J, Cheng L, Zhu B, Wang K. New Insights into the Ingot Breakdown Mechanism of Near-β Titanium Alloy: An Orientation-Driven Perspective. Metals. 2024; 14(7):792. https://doi.org/10.3390/met14070792

Chicago/Turabian StyleLiu, Xianghong, Tao Wang, Xiaolong Ren, Jie Fu, Liang Cheng, Bin Zhu, and Kaixuan Wang. 2024. "New Insights into the Ingot Breakdown Mechanism of Near-β Titanium Alloy: An Orientation-Driven Perspective" Metals 14, no. 7: 792. https://doi.org/10.3390/met14070792

APA StyleLiu, X., Wang, T., Ren, X., Fu, J., Cheng, L., Zhu, B., & Wang, K. (2024). New Insights into the Ingot Breakdown Mechanism of Near-β Titanium Alloy: An Orientation-Driven Perspective. Metals, 14(7), 792. https://doi.org/10.3390/met14070792