Effect of Bi on the Tensile and Viscoplastic Behavior of Sn-Ag-Cu-Bi Alloys Used for Microelectronics Applications

Abstract

1. Introduction

2. Materials and Methods

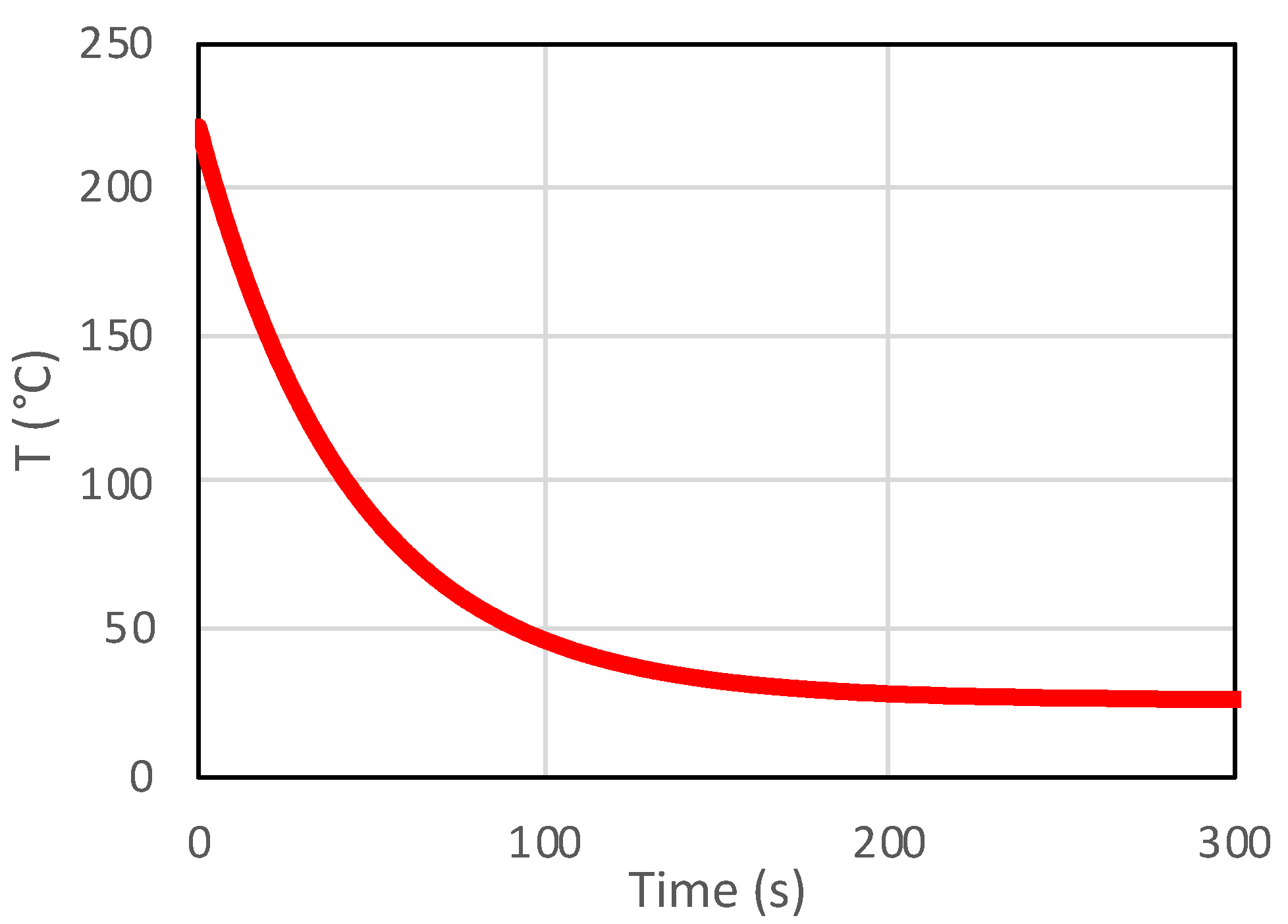

2.1. Sample Preparation

2.2. Aging Experiment

2.3. Tensile Testing

2.4. Calculation of Anand Parameters

2.5. Microstructural Investigation

3. Results

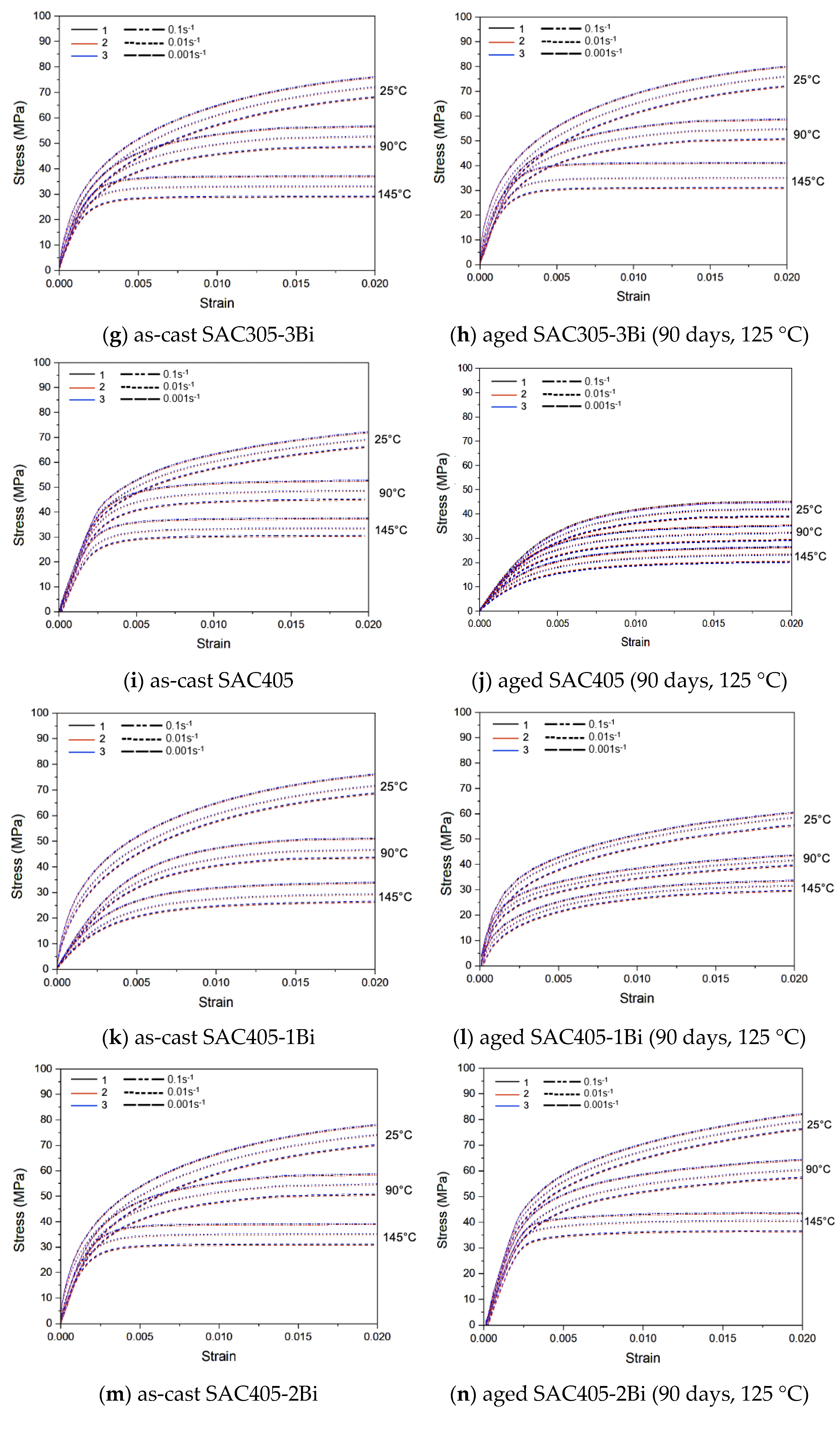

3.1. Tensile and Viscoplastic Behavior

3.2. Anand Parameters

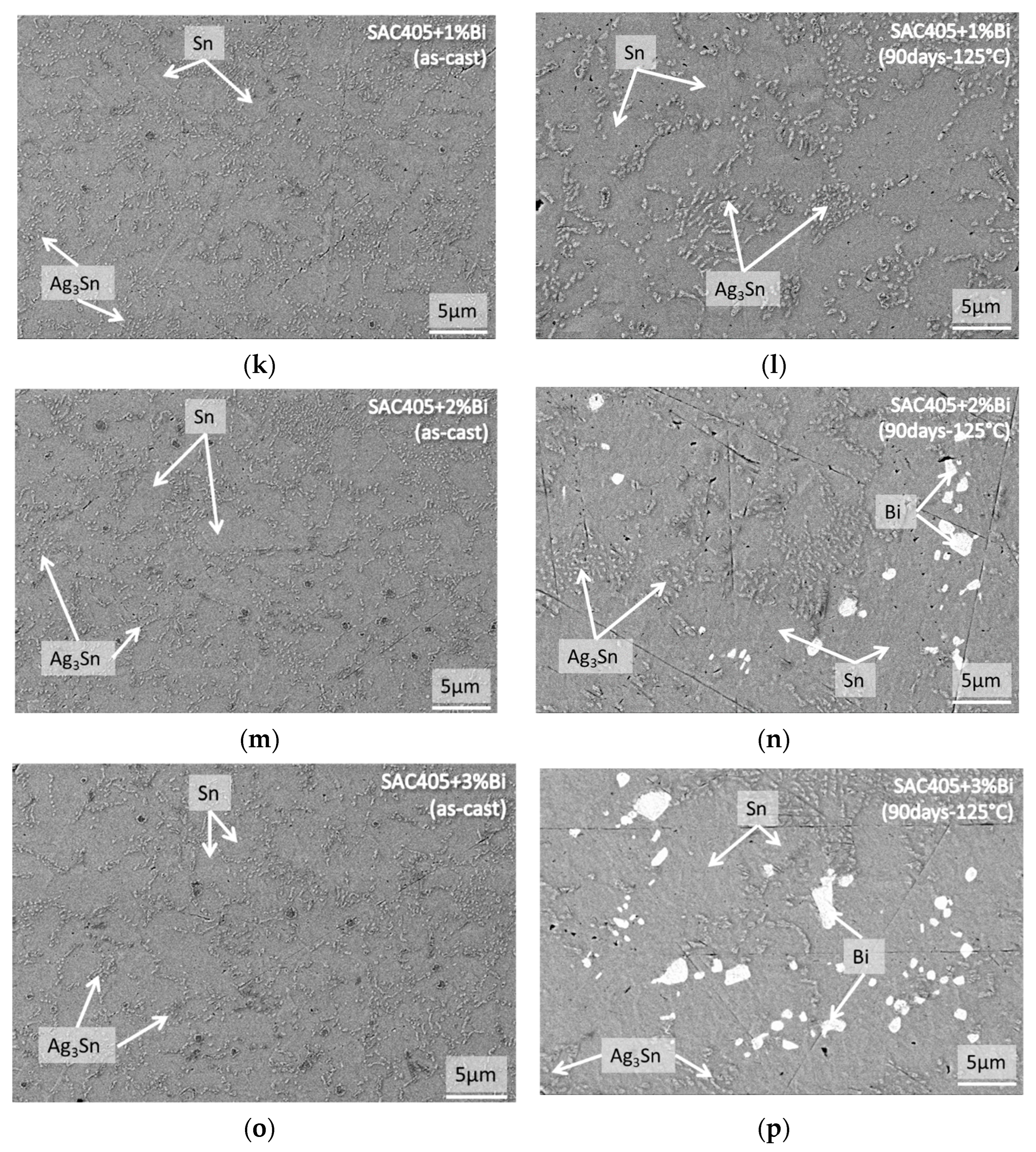

3.3. Microstructure

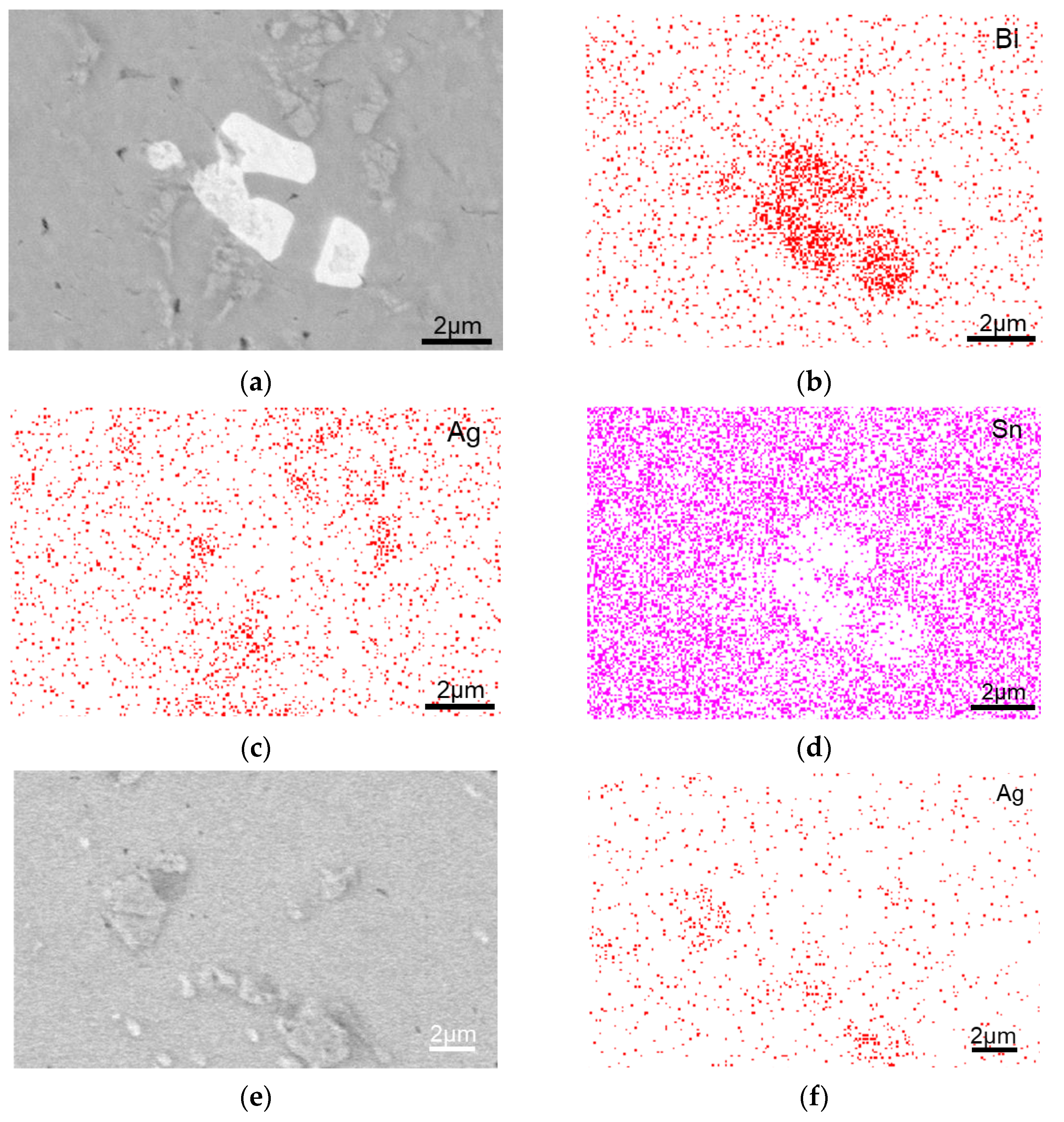

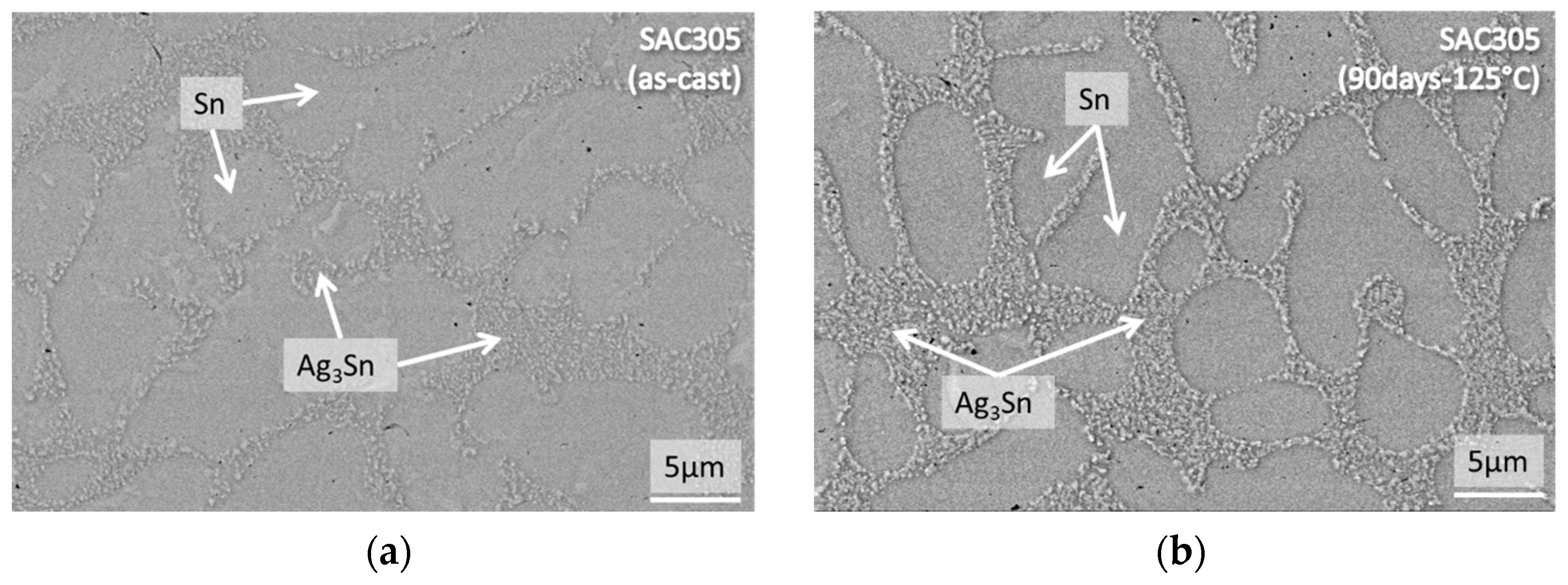

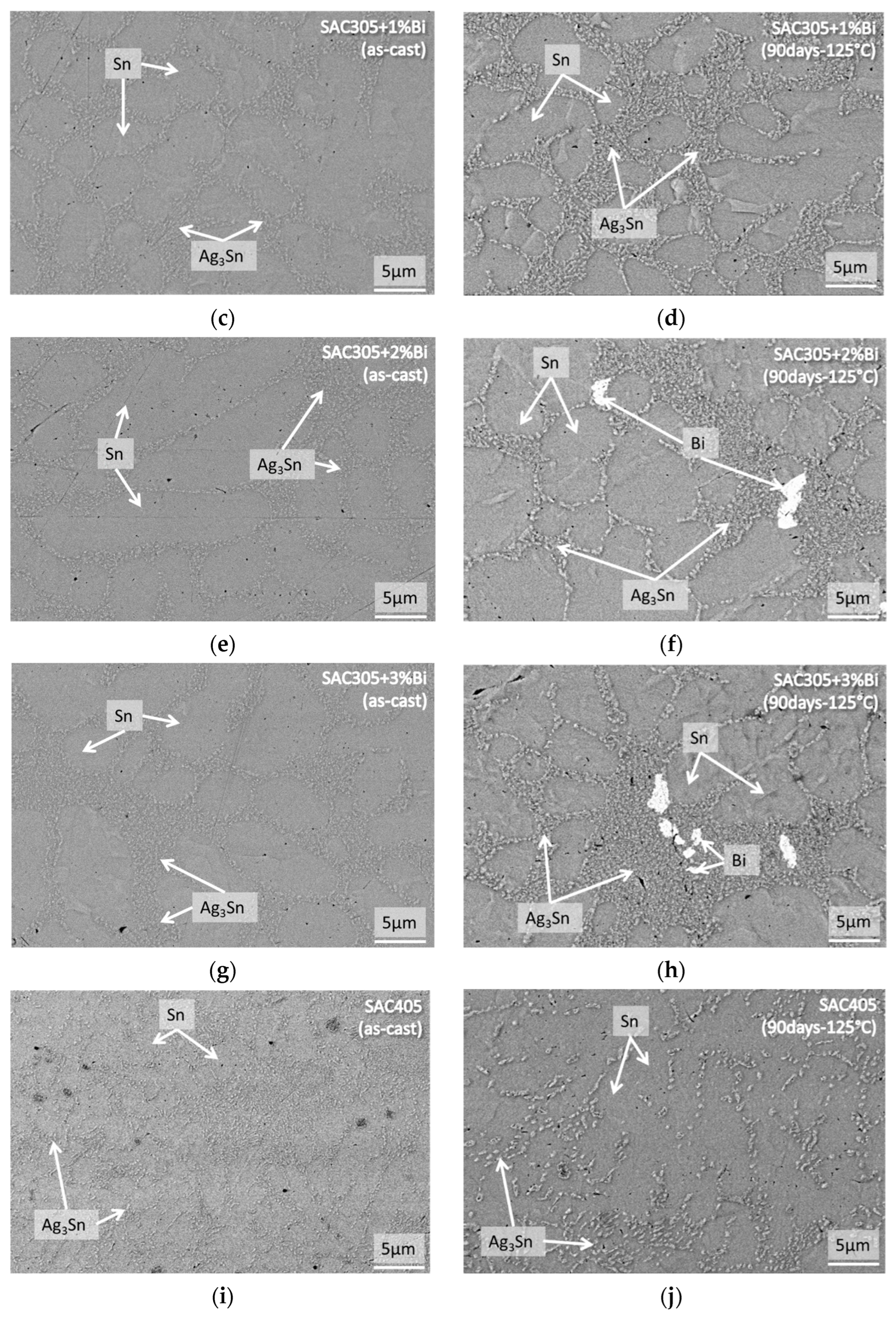

4. Discussion

5. Conclusions

- When up to 1 wt.% Bi was added to SAC alloys, it existed as solute atoms in the alloy matrix. As aging progressed, SAC305, SAC305 + 1 wt.%Bi, SAC405, and SAC405 + 1 wt.%Bi alloys experienced a reduction in strength. The reduction was less pronounced in SAC305 + 1 wt.%Bi and SAC405 + 1 wt.%Bi because of solution strengthening by Bi solutes. However, the effect from solid solution strengthening was not sufficient to counteract the reduction in strength by 21 to 43% due to aging-induced coarsening of the IMCs.

- When 2 to 3 wt.% Bi was added to SAC alloys, the Bi exceeded the alloy’s solubility, and precipitates formed progressively with aging. The strength of SAC305 + 2 wt.%Bi, SAC305 + 3 wt.%Bi, SAC405 + 2 wt.%Bi, and SAC405 + 3 wt.%Bi increased after aging by around 6 to 10%, attributed to the formation of Bi precipitates.

- Anand viscoplastic parameters for all eight alloys in both the as-cast and nine aging conditions were obtained, which will enable the modeling of these SAC-Bi alloys as solder joints for advanced packaging applications.

- The results reveal the important role of Bi in aging-induced changes in microstructure and mechanical properties. The new findings of this study include revealing the evolution of SAC-Bi microstructures, particularly the precipitation of Bi with aging in SAC doped with 2 to 3% Bi, and the calculation of Anand parameters of SAC-Bi alloys in various aging durations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shnawah, D.; Sabri, M.; Badruddin, I. A review on thermal cycling and drop impact reliability of SAC solder joint in portable electronic products. Microelectron. Reliab. 2012, 52, 90–99. [Google Scholar] [CrossRef]

- Char, M.; Chakraborty, A.; Bhattacharya, A.; Kar, A. A Comparative Study on the Influence of SAC305 Lead-Free Solder Sandwiched by Sn on the Micromechanical and Electrical Properties of the Joints. Adv. Eng. Mater. 2022, 24, 2100679. [Google Scholar] [CrossRef]

- Chowdhury, M.M.R.; Hoque, M.A.; Fahim, A.; Suhling, J.C.; Hamasha, S.; Lall, P. Microstructural Evolution in SAC305 and SAC-Bi Solders Subjected to Mechanical Cycling. In Proceedings of the ASME 2018 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, San Francisco, CA, USA, 27–30 August 2018; p. V001T03A007. [Google Scholar] [CrossRef]

- Chauhan, P.; Mukherjee, S.; Osterman, M.; Dasgupta, A.; Pecht, M. Effect of Isothermal Aging on Microstructure and Creep Properties of SAC305 Solder: A Micromechanics Approach. In Proceedings of the ASME 2013 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, Burlingame, CA, USA, 16–18 July 2013; Volume 1, p. V001T07A009. [Google Scholar] [CrossRef]

- Abdullah, I.; Zulkifli, M.N.; Jalar, A.; Ismail, R.; Ambak, M.A. Relationship of Mechanical and Micromechanical Properties with Microstructural Evolution of Sn-3.0Ag-0.5Cu (SAC305) Solder Wire Under Varied Tensile Strain Rates and Temperatures. J. Electron. Mater. 2019, 48, 2826–2839. [Google Scholar] [CrossRef]

- Depiver, J.A.; Mallik, S.; Amalu, E. Comparing and Benchmarking Fatigue Behaviours of Various SAC Solders under Thermo-Mechanical Loading. In Proceedings of the 2020 IEEE 8th Electronics System-Integration Technology Conference (ESTC), Tønsberg, Norway, 15–18 September 2020; pp. 1–11. [Google Scholar] [CrossRef]

- Pal, M.K.; Gergely, G.; Horváth, D.K.; Gácsi, Z. Microstructural Investigations and Mechanical Properties of Pure Lead-Free (Sn-3.0Ag-0.5Cu and Sn-4.0Ag-0.5Cu) Solder Alloy. Metall. Mater. Eng. 2018, 24, 27–36. [Google Scholar] [CrossRef]

- Jian, M.; Hamasha, S.; Alahmer, A.; Hamasha, M.; Wei, X.; Belhadi, M.E.A.; Hamasha, K. Analysis and Modeling of Aged SAC-Bi Solder Joints Subjected to Varying Stress Cycling Conditions. Materials 2023, 16, 750. [Google Scholar] [CrossRef]

- Cai, C.; Xu, J.; Wang, H.; Park, S.B. A comparative study of thermal fatigue life of Eutectic Sn-Bi, Hybrid Sn-Bi/SAC and SAC solder alloy BGAs. Microelectron. Reliab. 2021, 119, 114065. [Google Scholar] [CrossRef]

- Haq, M.A.; Hoque, M.A.; Suhling, J.C.; Lall, P. Effect of Bismuth Content on the Mechanical Cyclic Properties of SAC+Bi Lead Free Solders. In Proceedings of the 2021 IEEE 71st Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 1 June–4 July 2021; 1797-1804. [Google Scholar] [CrossRef]

- Lall, P.; Mehta, V.; Suhling, J.; Blecker, K. Mechanical Properties of Doped Solder SAC-Q for High Strain Rate Testing at Extreme Surrounding Temperatures for 6 Months of Isothermal Aging. J. Electron. Packag. 2024, 146, 031006. [Google Scholar] [CrossRef]

- Belhadi, M.E.A.; Akkara, F.J.; Athamenh, R.; Abueed, M.; Hamasha, S.; Ali, H.; Suhling, J.; Lall, P. The Effect of Bi on the Mechanical Properties of Aged SAC Solder Joint. In Proceedings of the 2020 19th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 21–23 July 2020; pp. 1100–1105. [Google Scholar] [CrossRef]

- Shukla, V.; Ayers, N.; Moreno, A.; Crutchfield, N.; Lyons, D.; Ahmed, O.; Su, P.; Glasauer, B. The Effects of Bi Doping and Aging on Viscoplasticity of Sn-Ag-Cu-Bi alloys. In Proceedings of the 2022 IEEE 72nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 31 May–3 June 2022; pp. 1687–1694. [Google Scholar] [CrossRef]

- Shukla, V.; Ahmed, O.; Jalilvand, G.; Mehta, A.; Su, P.; Jiang, T. Effects of Aging on Microstructure and Mechanical Properties of Sn-Ag-Cu-Bi Solder Alloys. In Proceedings of the 2021 IEEE 71st Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 1 June–4 July 2021; pp. 667–672. [Google Scholar] [CrossRef]

- Ahsan, M.A.; Hasan, S.M.K.; Fahim, A.; Suhling, J.C.; Lall, P. Mechanical Property Evolution in SAC+Bi Lead Free Solders Subjected to Various Thermal Exposures. In Proceedings of the 2021 20th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm), San Diego, CA, USA, 1–4 June 2021; pp. 700–7007. [Google Scholar] [CrossRef]

- Maalekian, M.; Xu, Y.; Seelig, K. Effect of Bi content on properties of low silver SAC solders. In Proceedings of the SMTA International, Rosemont, IL, USA, 27 September–1 October 2015; pp. 191–198. [Google Scholar]

- Yang, T.; Chen, Y.; You, K.; Dong, Z.; Jia, Y.; Wang, G.; Peng, J.; Cai, S.; Luo, X.; Liu, C.; et al. Effect of Bi, Sb, and Ti on Microstructure and Mechanical Properties of SAC105 Alloys. Materials 2022, 15, 4727. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.; Lin, T.; Kao, C.; Huang, F.; Tsai, Y.; Hsiao, S.; Kuo, J. Effects of bismuth additions on mechanical property and microstructure of SAC-Bi solder joint under current stressing. Microelectron. Reliab. 2021, 117, 114041. [Google Scholar] [CrossRef]

- Syed, A.; Lin, W.; Sohn, E.; Cha, S. Plastic Deformation and Life Prediction of Solder Joints for Mechanical Shock and Drop/Impact Loading Conditions. In Proceedings of the 57th Electronic Components and Technology Conference, Sparks, NV, USA, 29 May–1 June 2007; pp. 507–514. [Google Scholar] [CrossRef]

- Nguyen, T.; Park, S. Characterization of elasto-plastic behavior of actual SAC solder joints for drop test modeling. Microelectron. Reliab. 2011, 51, 1385–1392. [Google Scholar] [CrossRef]

- Ahmed, S.; Basit, M.; Suhling, J.; Lall, P. Characterization of Doped SAC Solder Materials and Determination of Anand Parameters. In Proceedings of the ASME 2015 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems collocated with the ASME 2015 13th International Conference on Nanochannels, Microchannels, and Minichannels, San Francisco, CA, USA, 6–9 July 2015; Volume 2, p. V002T01A003. [Google Scholar] [CrossRef]

- Ahmed, S.; Suhling, J.; Lall, P. The anand parameters of aging resistant doped solder alloys. In Proceedings of the 2017 16th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 30 May–2 June 2017; pp. 1416–1424. [Google Scholar] [CrossRef]

- Wang, G.Z.; Cheng, Z.N.; Becker, K.; Wilde, J. Applying Anand Model to Represent the Viscoplastic Deformation Behavior of Solder Alloys. ASME J. Electron. Packag. 2001, 123, 247–253. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Yu, J. Anand constitutive model of lead-free solder joints in 3D IC device. J. Phys. Conf. Ser. 2016, 738, 012050. [Google Scholar] [CrossRef]

- Motalab, M.; Cai, Z.; Suhling, J.; Lall, P. Determination of Anand constants for SAC solders using stress-strain or creep data. In Proceedings of the 13th InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, San Diego, CA, USA, 30 May–1 June 2012; pp. 910–922. [Google Scholar] [CrossRef]

- Basit, M.; Ahmed, S.; Motalab, M.; Roberts, J.; Suhling, J.; Lall, P. The Anand parameters for SAC solders after extreme aging. In Proceedings of the 2016 15th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 31 May–3 June 2016; pp. 440–447. [Google Scholar] [CrossRef]

- Hassan, K.; Wu, J.; Alam, M.; Suhling, J.; Lall, P. The Effect of Bismuth Content on Mechanical Properties of SAC+Bi Lead Free Solder Materials and Determination of Anand Parameters. In Proceedings of the 2021 20th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm), San Diego, CA, USA, 1–4 June 2021; pp. 933–940. [Google Scholar] [CrossRef]

- Motalab, M.; Mustafa, M.; Suhling, J.; Lall, P. Improved predictions of cyclic stress-strain curves for lead free solders using the Anand viscoplastic constitutive model. In Proceedings of the 2016 15th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 31 May–3 June 2016; pp. 471–480. [Google Scholar]

- Yule, L.; Harris, N.; Hill, M.; Zaghari, B.; Grundy, J. Temperature Hotspot Detection on Printed Circuit Boards (PCBs) Using Ultrasonic Guided Waves—A Machine Learning Approach. Sensors 2024, 24, 1081. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.N.; Wang, G.Z.; Chen, L.; Wilde, J.; Becker, K. Viscoplastic Anand model for solder alloys and its application. Solder. Surf. Mt. Technol. 2000, 12, 31–36. [Google Scholar] [CrossRef]

- Gain, A.; Zhang, L. Temperature and humidity effects on microstructure and mechanical properties of an environmentally friendly Sn–Ag–Cu material. J. Mater. Sci. 2019, 54, 12863–12874. [Google Scholar] [CrossRef]

- Karakaya, I.; Thompson, W.T. The Ag-Sn (Silver-Tin) system. Bull. Alloy Phase Diagr. 1987, 8, 340–347. [Google Scholar] [CrossRef]

- Wang, F.; Huang, Y.; Zhang, Z.; Yan, C. Interfacial Reaction and Mechanical Properties of Sn-Bi Solder joints. Materials 2017, 10, 920. [Google Scholar] [CrossRef] [PubMed]

- Kaushik, R.K.; Batra, U.; Sharma, J.D. Structural, Thermal and Wetting Characteristics of Novel Low Bi-Low Ag Containing Sn–x.Ag–0.7Cu–1.0Bi (x = 0.5 to 1.5) Alloys for Electronic Application. Met. Mater. Int 2021, 27, 4550–4563. [Google Scholar] [CrossRef]

- Wang, S.; Yao, Y.; Long, X. Critical Review of Size Effects on Microstructure and Mechanical Properties of Solder Joints for Electronic Packaging. Appl. Sci. 2019, 9, 227. [Google Scholar] [CrossRef]

- Belhadi, M.; Hamasha, S.; Alahmer, A.; Zhao, R.; Prorok, B.; Soroosh, A. The Impact of Bi Content on the Coarsening Kinetics of IMC Particles and Creep Deformation Under Thermal Cycling. J. Electron. Mater. 2024, 53, 380–393. [Google Scholar] [CrossRef]

- Shnawah, D.; Sabri, M.; Badruddin, I.; Said, S.; Ariga, T.; Che, F. Effect of Ag Content and the Minor Alloying Element Fe on the Mechanical Properties and Microstructural Stability of Sn-Ag-Cu Solder Alloy Under High-Temperature Annealing. J. Electron. Mater. 2013, 42, 470–484. [Google Scholar] [CrossRef]

- JEDEC Solid State Technology Association. Moisture/Reflow Sensitivity Classification for Non-Hermitic Surface Mount Devices (SMDS) 2022, J-STD-020F. Available online: https://www.jedec.org/standards-documents/docs/j-std-020e (accessed on 12 May 2024).

- Çengel, Y.A.; Ghajar, A.J. Heat and Mass Transfer: Fundamentals & Applications; McGraw Hill Education: Singapore, 2015. [Google Scholar]

- Jorge, K.; Muneer, T.; Thomas, G. Heat Transfer: A Problem Solving Approach; CRC Press: London, UK, 2012. [Google Scholar]

- Li, Y.; Long, W.; Hu, X.; Fu, Y. Interfacial Reaction and IMC Growth of an Ultrasonically Soldered Cu/SAC305/Cu Structure during Isothermal Aging. Materials 2018, 11, 84. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Troparevsky, M.; Gao, Y.; Morris, J.; Stocks, G.; Bei, H. Phase stability, physical properties and strengthening mechanisms of concentrated solid solution alloys. Curr. Opin. Solid State Mater. Sci. 2017, 21, 267–284. [Google Scholar] [CrossRef]

- Belyakov, S.A.; Xian, J.; Zeng, G.; Sweatman, K.; Nishimura, T.; Akaiwa, T.; Gourlay, C.M. Precipitation and coarsening of bismuth plates in Sn–Ag–Cu–Bi and Sn–Cu–Ni–Bi solder joints. J. Mater. Sci. Mater. Electron. 2019, 30, 378–390. [Google Scholar] [CrossRef]

- Lungen, S.; Tiedje, T.; Meier, K.; Nieweglowski, K.; Bock, K. Reliability of 3D additive manufactured packages. In Proceedings of the 2018 7th Electronic System-Integration Technology Conference (ESTC), Dresden, Germany, 18–21 September 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Zhang, Z.; Yuan, X. Applications and Future of Automated and Additive Manufacturing for Power Electronics Components and Converters. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 4509–4525. [Google Scholar] [CrossRef]

| Temp./Time | 0 Day (As-Cast) | 30 Days | 60 Days | 90 Days |

|---|---|---|---|---|

| 25 °C | X | X | X | X |

| 75 °C | X | X | X | |

| 125 °C | X | X | X |

| Temp./Strain Rate | 0.1/s | 0.01/s | 0.001/s |

|---|---|---|---|

| 25 °C | X | X | X |

| 90 °C | X | X | X |

| 145 °C | X | X | X |

| SAC305 | Sample 1 | Sample 2 | Sample 3 | Average | S | RSD |

|---|---|---|---|---|---|---|

| s0 | 32.85 | 32.69 | 32.78 | 32.77 | 0.08 | 0.24 |

| Q/R | 9068.00 | 9050.00 | 9046.00 | 9054.67 | 11.72 | 0.13 |

| A | 2995.10 | 2947.00 | 2965.30 | 2969.13 | 24.28 | 0.82 |

| ξ | 4.00 | 4.00 | 4.00 | 4.00 | 0.00 | 0.00 |

| m | 0.29 | 0.29 | 0.28 | 0.29 | 0.01 | 2.01 |

| h0 | 183,010.00 | 183,010.00 | 182,980.00 | 183,000.00 | 17.32 | 0.01 |

| 40.80 | 40.20 | 41.00 | 40.67 | 0.42 | 1.02 | |

| n | 0.01 | 0.01 | 0.01 | 0.01 | 0.00 | 2.14 |

| a | 1.75 | 1.75 | 1.74 | 1.75 | 0.01 | 0.33 |

| SAC305 | As-Cast | 30 d, 25 °C | 30 d, 75 °C | 30 d, 125 °C | 60 d, 25 °C | 60 d, 75 °C | 60 d, 125 °C | 90 d, 25 °C | 90 d, 75 °C | 90 d, 125 °C |

|---|---|---|---|---|---|---|---|---|---|---|

| s0 | 32.77 | 30.11 | 27.35 | 24.22 | 24.87 | 23.21 | 19.78 | 21.12 | 18.18 | 14.56 |

| Q/R | 9055 | 9017 | 9042 | 9030 | 9050 | 9022 | 9028 | 9072 | 9015 | 9030 |

| A | 2969.1 | 3055.1 | 3274.5 | 3502.3 | 3287.4 | 3465.7 | 3847.3 | 3596.5 | 3943.6 | 4175.2 |

| ξ | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| m | 0.29 | 0.28 | 0.25 | 0.24 | 0.21 | 0.20 | 0.18 | 0.16 | 0.15 | 0.12 |

| h0 | 183,000 | 181,150 | 180,000 | 173,000 | 163,100 | 179,200 | 145,100 | 100,050 | 80,000 | 71,100 |

| 40.7 | 39.3 | 38.9 | 37.6 | 33.5 | 32.1 | 28.2 | 26.4 | 23.4 | 21.3 | |

| n | 0.01 | 0.01 | 0.0085 | 0.0081 | 0.007 | 0.0059 | 0.0048 | 0.0019 | 0.0014 | 0.0009 |

| a | 1.75 | 1.76 | 1.79 | 1.82 | 1.83 | 1.87 | 1.91 | 1.92 | 1.94 | 1.97 |

| SAC305 + 1 wt.%Bi | As-Cast | 30 d, 25 °C | 30 d, 75 °C | 30 d, 125 °C | 60 d, 25 °C | 60 d, 75 °C | 60 d, 125 °C | 90 d, 25 °C | 90 d, 75 °C | 90 d, 125 °C |

|---|---|---|---|---|---|---|---|---|---|---|

| s0 | 22.81 | 22.74 | 22.70 | 22.67 | 22.63 | 22.48 | 22.32 | 22.20 | 22.10 | 22.0 |

| Q/R | 9640 | 9644 | 9657 | 9648 | 9650 | 9649 | 9663 | 9648 | 9654 | 9650 |

| A | 3851.2 | 3864.1 | 3871.0 | 3873.7 | 3886.2 | 3896.4 | 3911.0 | 3942.5 | 3976.1 | 3997.8 |

| ξ | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| m | 0.34 | 0.34 | 0.34 | 0.34 | 0.33 | 0.32 | 0.32 | 0.32 | 0.31 | 0.30 |

| h0 | 155,100 | 154,450 | 154,375 | 154,360 | 152,910 | 152,050 | 151,275 | 148,750 | 148,000 | 147,760 |

| 38.1 | 38.0 | 37.8 | 37.7 | 37.2 | 37.1 | 36.8 | 36.3 | 36.2 | 36.0 | |

| n | 0.0085 | 0.0085 | 0.0083 | 0.0083 | 0.0081 | 0.008 | 0.008 | 0.0075 | 0.0074 | 0.0073 |

| a | 1.82 | 1.83 | 1.83 | 1.84 | 1.83 | 1.84 | 1.84 | 1.85 | 1.85 | 1.85 |

| SAC305 + 2 wt.%Bi | As-Cast | 30 d, 25 °C | 30 d, 75 °C | 30 d, 125 °C | 60 d, 25 °C | 60 d, 75 °C | 60 d, 125 °C | 90 d, 25 °C | 90 d, 75 °C | 90 d, 125 °C |

|---|---|---|---|---|---|---|---|---|---|---|

| s0 | 27.31 | 27.33 | 27.66 | 28.1 | 28.1 | 28.2 | 28.6 | 28.7 | 28.9 | 29.1 |

| Q/R | 10,450 | 10,452 | 10,463 | 10,466 | 10,481 | 10,487 | 10,457 | 10,459 | 10,455 | 10,450 |

| A | 5021.6 | 5008.7 | 5010.5 | 4989.5 | 4985.1 | 4967.2 | 4957.5 | 4934.5 | 4928.5 | 4914.6 |

| ξ | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| m | 0.38 | 0.41 | 0.42 | 0.44 | 0.45 | 0.47 | 0.47 | 0.48 | 0.49 | 0.5 |

| h0 | 110,000 | 112,150 | 11,325 | 114,520 | 114,750 | 115,000 | 116,400 | 117,100 | 117,900 | 120,000 |

| 32.5 | 32.7 | 32.8 | 33.2 | 33.3 | 33.5 | 33.7 | 34.0 | 34.4 | 35.0 | |

| n | 0.007 | 0.008 | 0.008 | 0.009 | 0.01 | 0.011 | 0.012 | 0.013 | 0.014 | 0.015 |

| a | 1.88 | 1.87 | 1.86 | 1.85 | 1.86 | 1.85 | 1.83 | 1.82 | 1.81 | 1.80 |

| SAC305 + 3 wt.%Bi | As-Cast | 30 d, 25 °C | 30 d, 75 °C | 30 d, 125 °C | 60 d, 25 °C | 60 d, 75 °C | 60 d, 125 °C | 90 d, 25 °C | 90 d, 75 °C | 90 d, 125 °C |

|---|---|---|---|---|---|---|---|---|---|---|

| s0 | 18.33 | 18.55 | 18.45 | 18.71 | 18.62 | 18.81 | 18.88 | 18.91 | 19.10 | 19.15 |

| Q/R | 11,520 | 11,520 | 11,520 | 11,548 | 11,565 | 11,538 | 11,544 | 11,530 | 11,548 | 11,540 |

| A | 6521.4 | 6515.2 | 6512.3 | 6507.2 | 6500.2 | 6498.3 | 6488.3 | 6475.6 | 6466.7 | 6450.1 |

| ξ | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| m | 0.40 | 0.41 | 0.42 | 0.43 | 0.43 | 0.47 | 0.48 | 0.49 | 0.53 | 0.55 |

| h0 | 75,000 | 76,125 | 76,875 | 77,654 | 78,450 | 79,350 | 80,100 | 80,760 | 81,520 | 82,525 |

| 33.8 | 33.8 | 33.9 | 33.8 | 34.4 | 34.6 | 34.8 | 35.1 | 35.4 | 35.6 | |

| n | 0.005 | 0.006 | 0.006 | 0.006 | 0.007 | 0.007 | 0.008 | 0.009 | 0.009 | 0.01 |

| a | 2 | 1.98 | 1.97 | 1.96 | 1.96 | 1.95 | 1.94 | 1.93 | 1.92 | 1.91 |

| SAC405 | As-Cast | 30 d, 25 °C | 30 d, 75 °C | 30 d, 125 °C | 60 d, 25 °C | 60 d, 75 °C | 60 d, 125 °C | 90 d, 25 °C | 90 d, 75 °C | 90 d, 125 °C |

|---|---|---|---|---|---|---|---|---|---|---|

| s0 | 34.43 | 30.20 | 28.40 | 25.60 | 25.20 | 23.59 | 20.15 | 21.20 | 18.85 | 15.33 |

| Q/R | 9265 | 9258 | 9277 | 9282 | 9259 | 9260 | 9268 | 9272 | 9266 | 9263 |

| A | 2879.1 | 2990.5 | 3210.4 | 3455.5 | 3215.5 | 3392.4 | 3789.1 | 3522.5 | 3886.6 | 4110.5 |

| ξ | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| m | 0.3 | 0.28 | 0.26 | 0.25 | 0.23 | 0.2 | 0.19 | 0.18 | 0.16 | 0.14 |

| h0 | 190,150 | 188,100 | 186,000 | 175,100 | 164,000 | 182,000 | 150,200 | 110,000 | 82,000 | 76,000 |

| 41.9 | 40.1 | 39.8 | 38.2 | 34.5 | 33.6 | 29.4 | 27.7 | 24.4 | 22.2 | |

| n | 0.012 | 0.011 | 0.0094 | 0.0085 | 0.0075 | 0.0066 | 0.0054 | 0.0028 | 0.0019 | 0.001 |

| a | 1.72 | 1.75 | 1.78 | 1.81 | 1.82 | 1.86 | 1.89 | 1.90 | 1.93 | 1.96 |

| SAC405 + 1 wt.%Bi | As-Cast | 30 d, 25 °C | 30 d, 75 °C | 30 d, 125 °C | 60 d, 25 °C | 60 d, 75 °C | 60 d, 125 °C | 90 d, 25 °C | 90 d, 75 °C | 90 d, 125 °C |

|---|---|---|---|---|---|---|---|---|---|---|

| s0 | 24.21 | 24.18 | 24.15 | 24.10 | 24.05 | 23.95 | 23.83 | 23.78 | 23.62 | 23.50 |

| Q/R | 9750 | 9743 | 9758 | 9746 | 9745 | 9754 | 9756 | 9749 | 9742 | 9746 |

| A | 3746.3 | 3753.7 | 3768.4 | 3780.1 | 3797.2 | 3823.5 | 3842.3 | 3868.4 | 3883.5 | 3915.1 |

| ξ | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| m | 0.36 | 0.36 | 0.35 | 0.35 | 0.34 | 0.33 | 0.32 | 0.32 | 0.31 | 0.31 |

| h0 | 165,050 | 164,250 | 164,110 | 163,250 | 160,000 | 158,550 | 157,300 | 155,000 | 154,000 | 153,400 |

| 39.6 | 39.5 | 39.3 | 39.3 | 39.3 | 39.1 | 38.8 | 38.6 | 38.4 | 38.3 | |

| n | 0.0095 | 0.0094 | 0.0093 | 0.0092 | 0.009 | 0.0088 | 0.0085 | 0.0083 | 0.008 | 0.0079 |

| a | 1.78 | 1.8 | 1.81 | 1.82 | 1.82 | 1.83 | 1.85 | 1.85 | 1.87 | 1.89 |

| SAC405 + 2 wt.%Bi | As-Cast | 30 d, 25 °C | 30 d, 75 °C | 30 d, 125 °C | 60 d, 25 °C | 60 d, 75 °C | 60 d, 125 °C | 90 d, 25 °C | 90 d, 75 °C | 90 d, 125 °C |

|---|---|---|---|---|---|---|---|---|---|---|

| s0 | 27.30 | 27.30 | 27.60 | 28.00 | 28.20 | 28.40 | 28.60 | 28.70 | 28.90 | 29.00 |

| Q/R | 10,425 | 10,450 | 10,460 | 10,460 | 10,471 | 10,485 | 10,452 | 10,458 | 10,454 | 10,442 |

| A | 4885.5 | 4865.5 | 4854.5 | 4842.5 | 4832.5 | 4825.5 | 4815.5 | 4812.2 | 4810.5 | 4800.5 |

| ξ | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| m | 0.4 | 0.43 | 0.45 | 0.47 | 0.49 | 0.50 | 0.52 | 0.52 | 0.54 | 0.55 |

| h0 | 120,000 | 122,120 | 122,650 | 122,770 | 127,470 | 128,100 | 128,850 | 131,450 | 132,450 | 133,100 |

| 32.5 | 32.9 | 33.3 | 33.6 | 34.2 | 34.6 | 35.1 | 35.7 | 36.0 | 36.2 | |

| n | 0.009 | 0.0092 | 0.0094 | 0.0096 | 0.0098 | 0.011 | 0.013 | 0.015 | 0.017 | 0.018 |

| a | 1.8 | 1.79 | 1.78 | 1.76 | 1.75 | 1.74 | 1.73 | 1.72 | 1.71 | 1.70 |

| SAC405 + 3 wt.%Bi | As-Cast | 30 d, 25 °C | 30 d, 75 °C | 30 d, 125 °C | 60 d, 25 °C | 60 d, 75 °C | 60 d, 125 °C | 90 d, 25 °C | 90 d, 75 °C | 90 d, 125 °C |

|---|---|---|---|---|---|---|---|---|---|---|

| s0 | 20.15 | 20.55 | 20.68 | 20.98 | 21.16 | 21.33 | 21.64 | 21.85 | 21.95 | 22.05 |

| Q/R | 11,900 | 11,900 | 11,896 | 11,899 | 11,865 | 11,936 | 11,954 | 11,997 | 11,985 | 11,968 |

| A | 6150.2 | 6147.5 | 6140.5 | 6133.6 | 6135.6 | 6125.6 | 6115.3 | 6087.9 | 6064.5 | 6050.3 |

| ξ | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| m | 0.42 | 0.43 | 0.44 | 0.46 | 0.47 | 0.48 | 0.5 | 0.52 | 0.54 | 0.56 |

| h0 | 80,000 | 80,541 | 80,780 | 80,990 | 81,450 | 81,650 | 81,950 | 83,500 | 83,654 | 83,840 |

| 35.54 | 35.65 | 35.75 | 35.8 | 36.1 | 36.33 | 36.45 | 36.77 | 37 | 37.4 | |

| n | 0.006 | 0.007 | 0.007 | 0.007 | 0.008 | 0.008 | 0.009 | 0.01 | 0.011 | 0.012 |

| a | 1.98 | 1.96 | 1.95 | 1.94 | 1.94 | 1.92 | 1.91 | 1.91 | 1.9 | 1.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shukla, V.; Ahmed, O.; Su, P.; Tian, T.; Jiang, T. Effect of Bi on the Tensile and Viscoplastic Behavior of Sn-Ag-Cu-Bi Alloys Used for Microelectronics Applications. Metals 2024, 14, 803. https://doi.org/10.3390/met14070803

Shukla V, Ahmed O, Su P, Tian T, Jiang T. Effect of Bi on the Tensile and Viscoplastic Behavior of Sn-Ag-Cu-Bi Alloys Used for Microelectronics Applications. Metals. 2024; 14(7):803. https://doi.org/10.3390/met14070803

Chicago/Turabian StyleShukla, Vishnu, Omar Ahmed, Peng Su, Tian Tian, and Tengfei Jiang. 2024. "Effect of Bi on the Tensile and Viscoplastic Behavior of Sn-Ag-Cu-Bi Alloys Used for Microelectronics Applications" Metals 14, no. 7: 803. https://doi.org/10.3390/met14070803

APA StyleShukla, V., Ahmed, O., Su, P., Tian, T., & Jiang, T. (2024). Effect of Bi on the Tensile and Viscoplastic Behavior of Sn-Ag-Cu-Bi Alloys Used for Microelectronics Applications. Metals, 14(7), 803. https://doi.org/10.3390/met14070803