Inconel 740H Prepared by Additive Manufacturing: Microstructure and Mechanical Properties

Abstract

1. Introduction

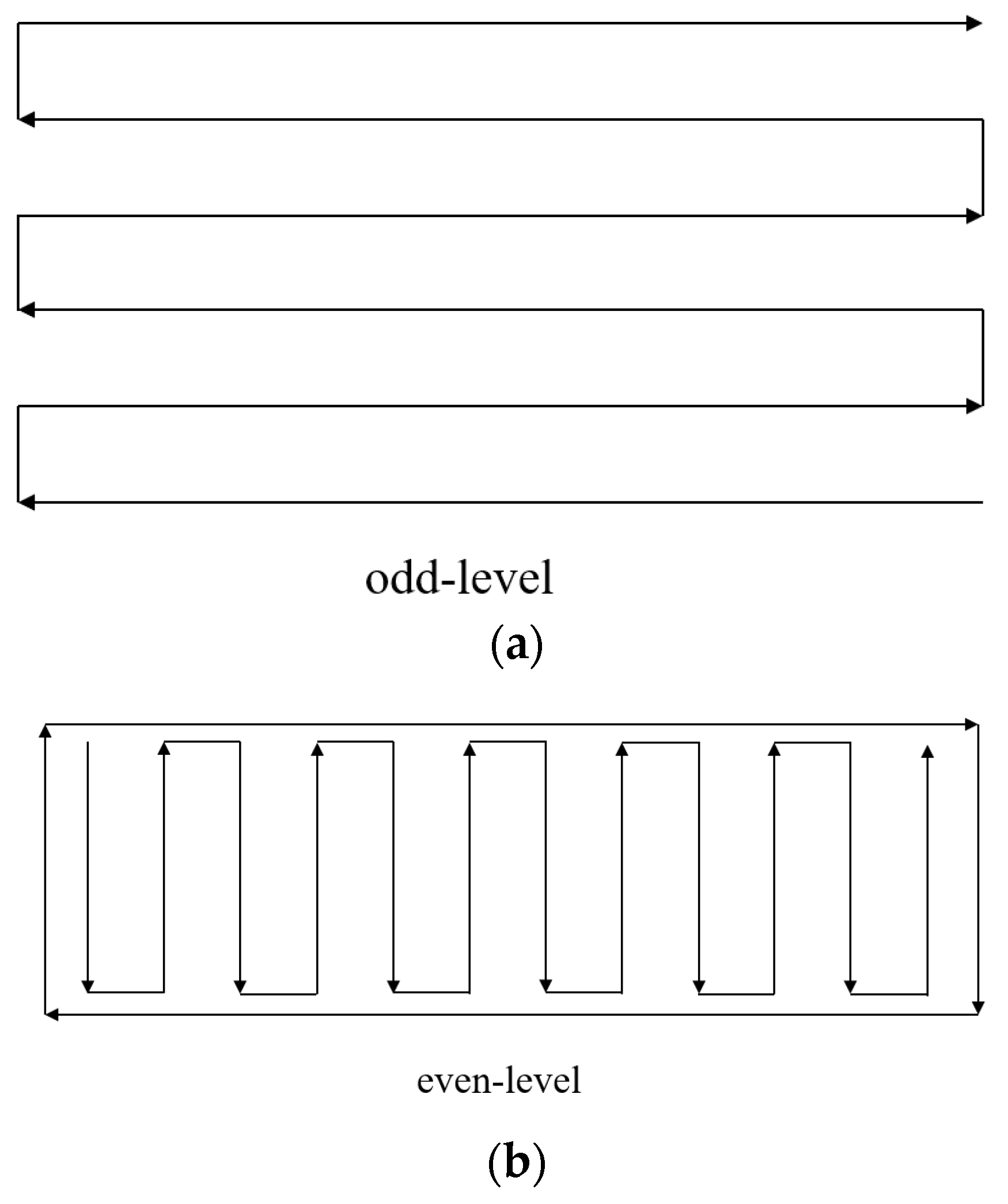

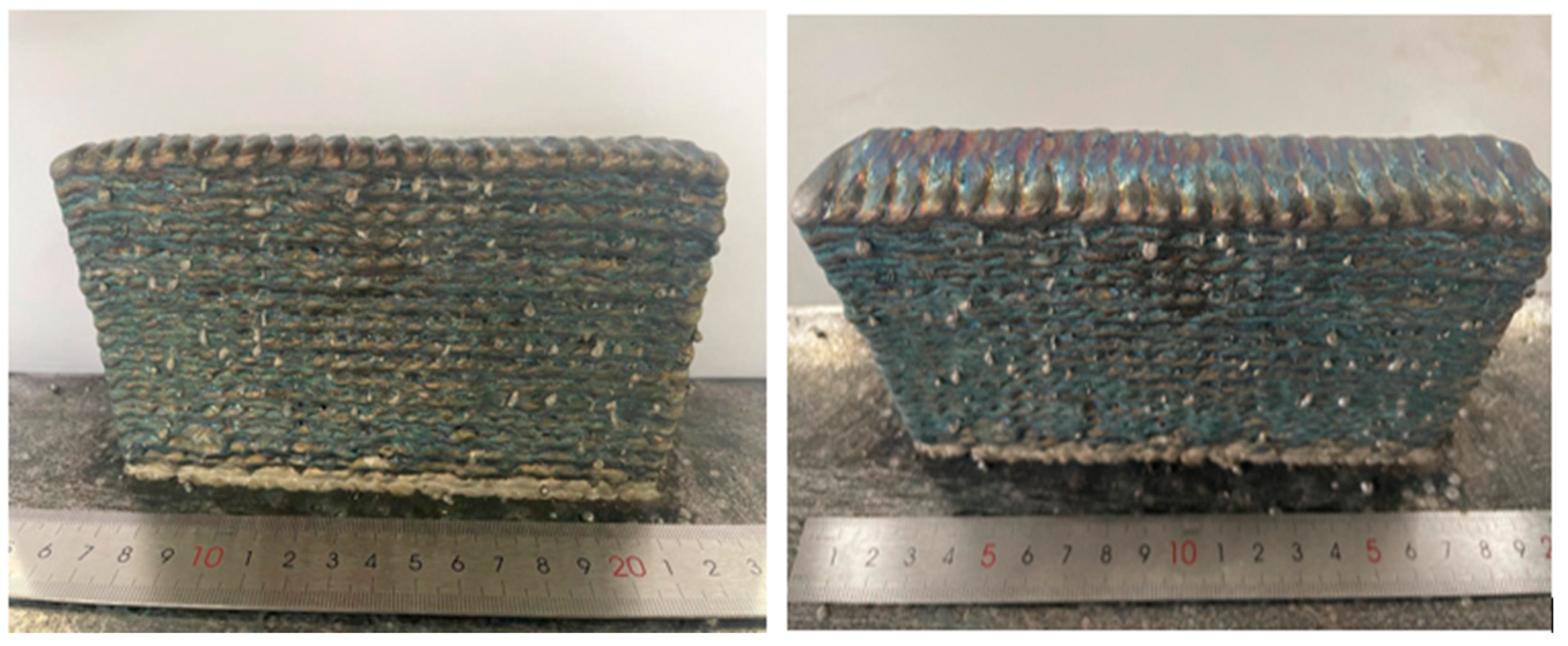

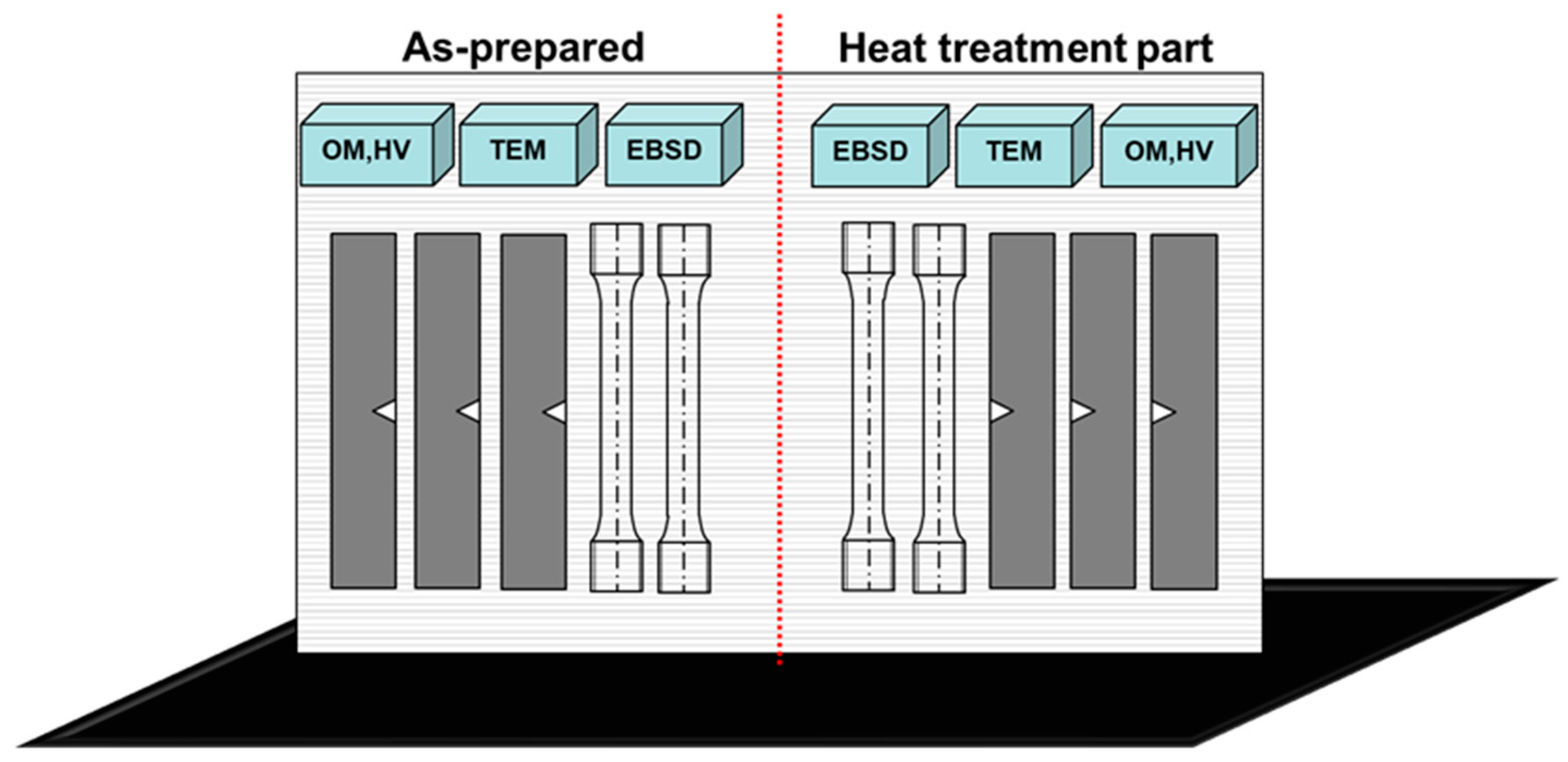

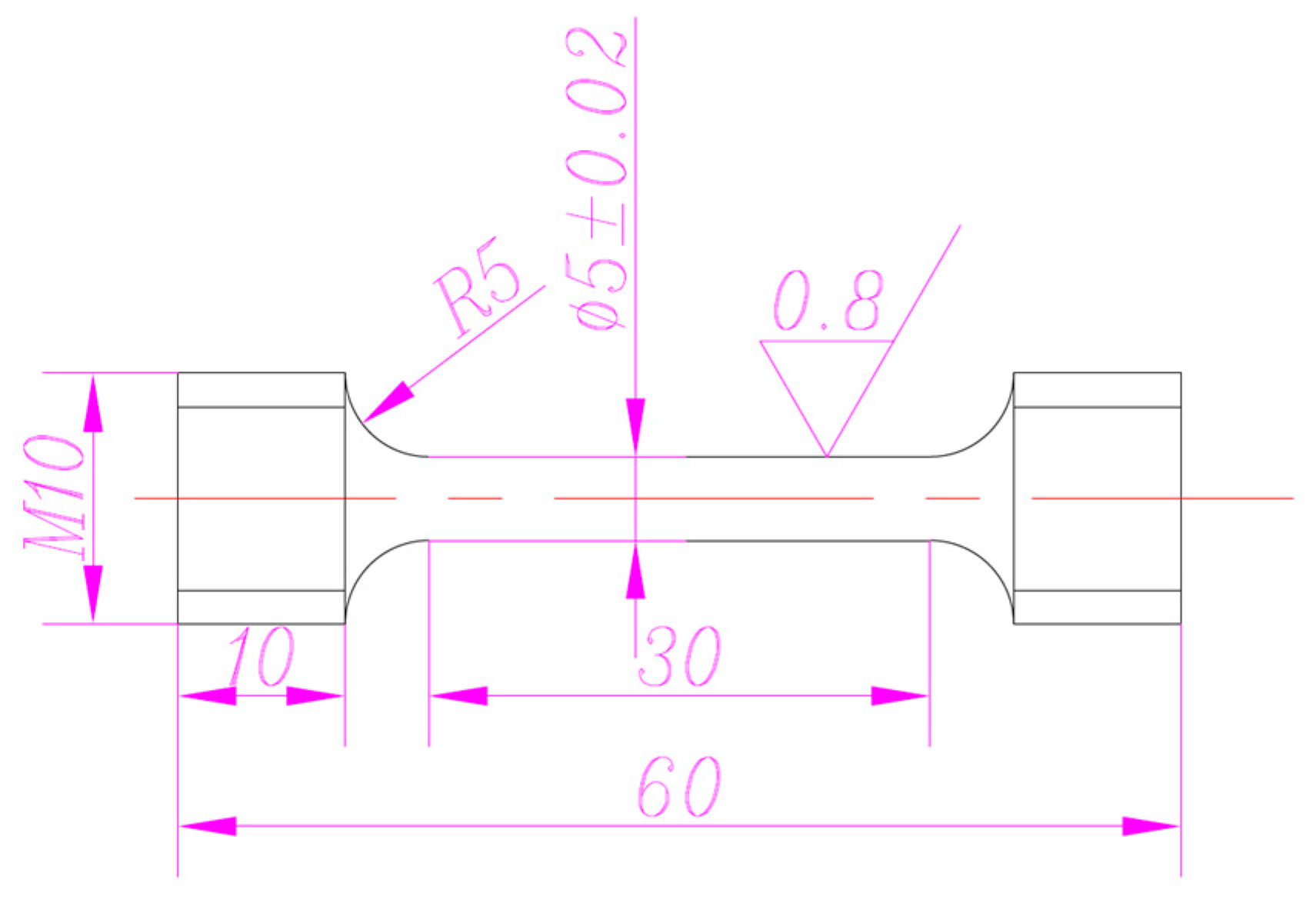

2. Materials and Methods

3. Results

3.1. Composition and Microstructure of Inconel 740H Ni-Based Alloy

3.2. Mechanical Properties of Inconel 740H Ni-Based Alloy Sample

4. Conclusions

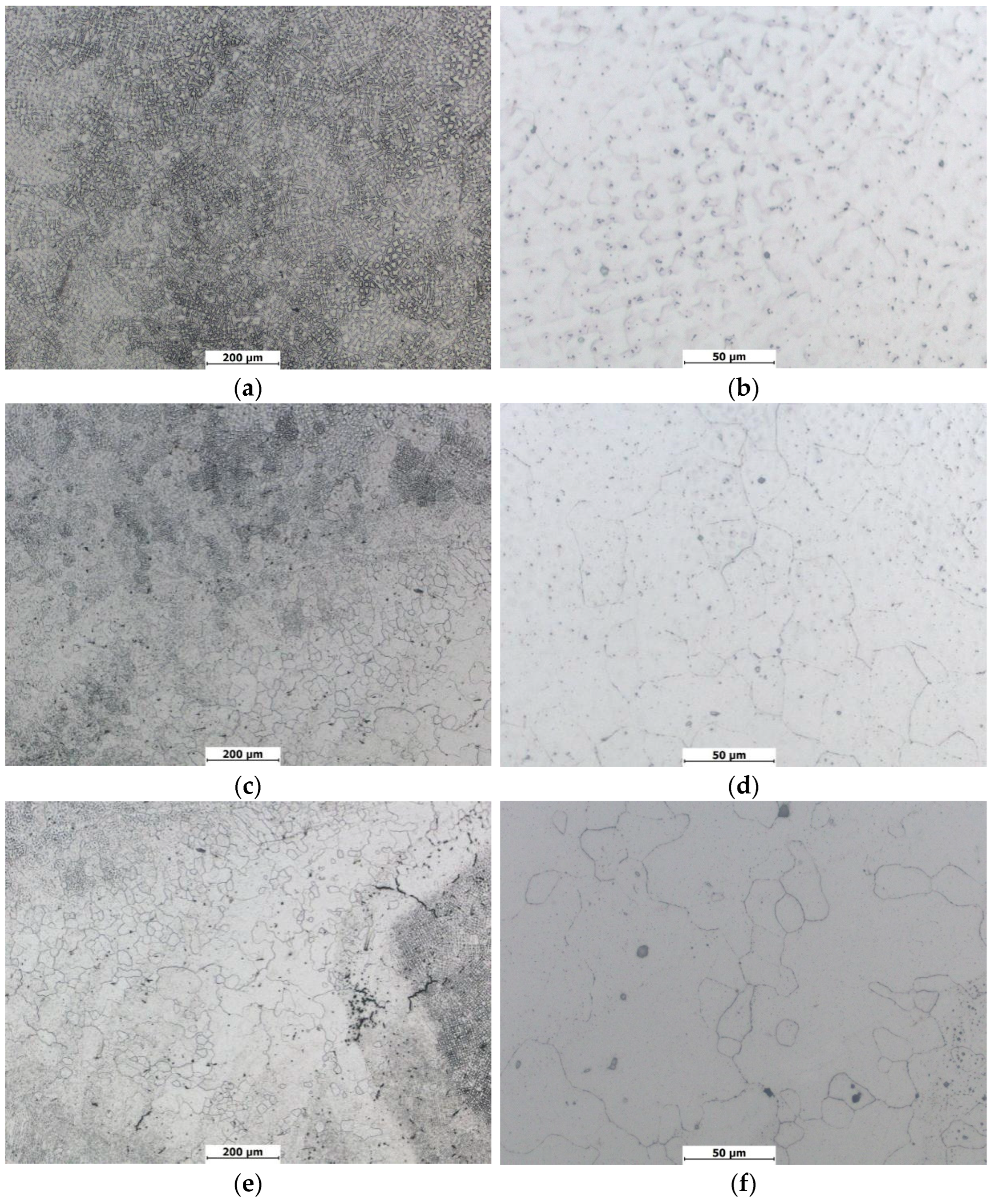

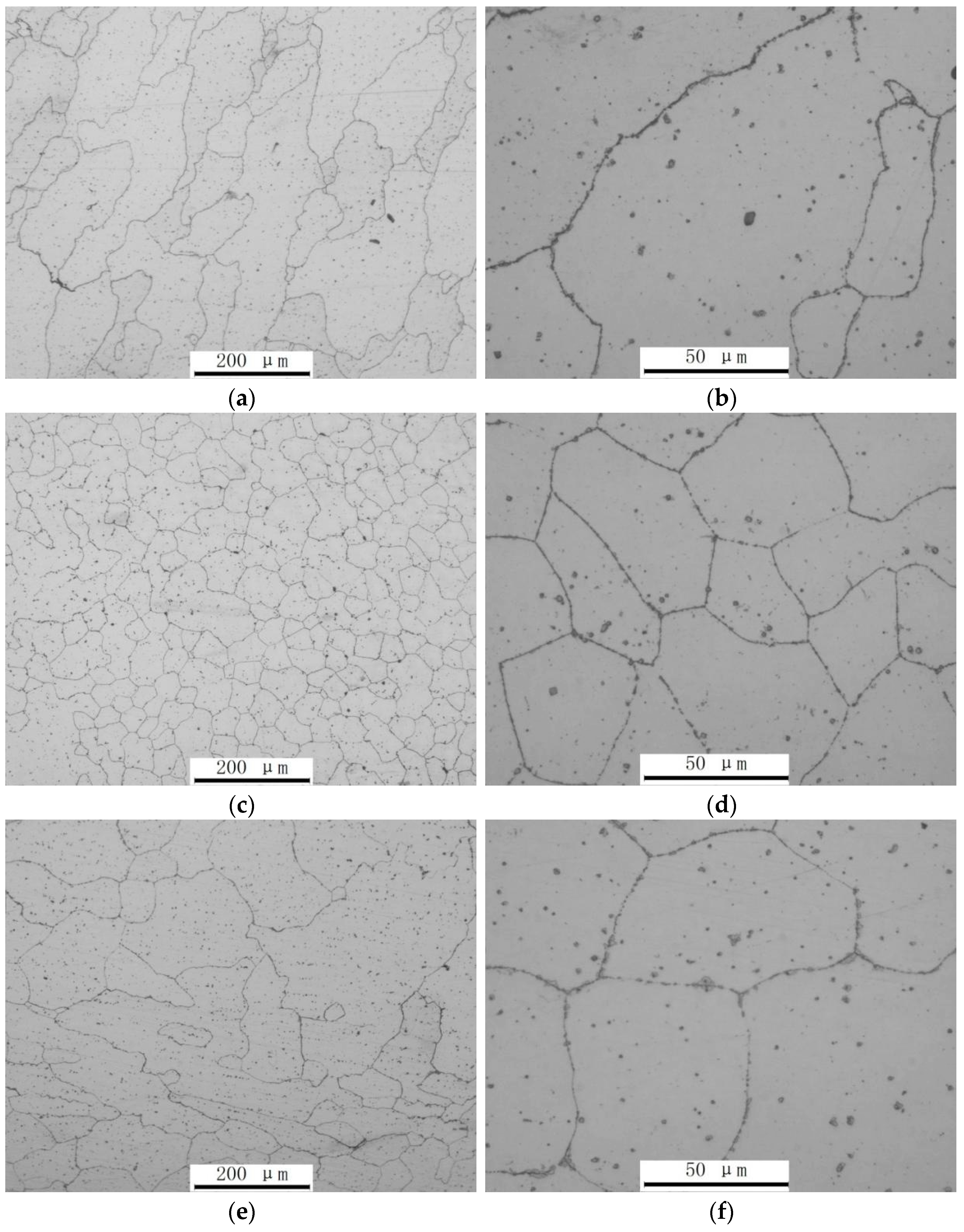

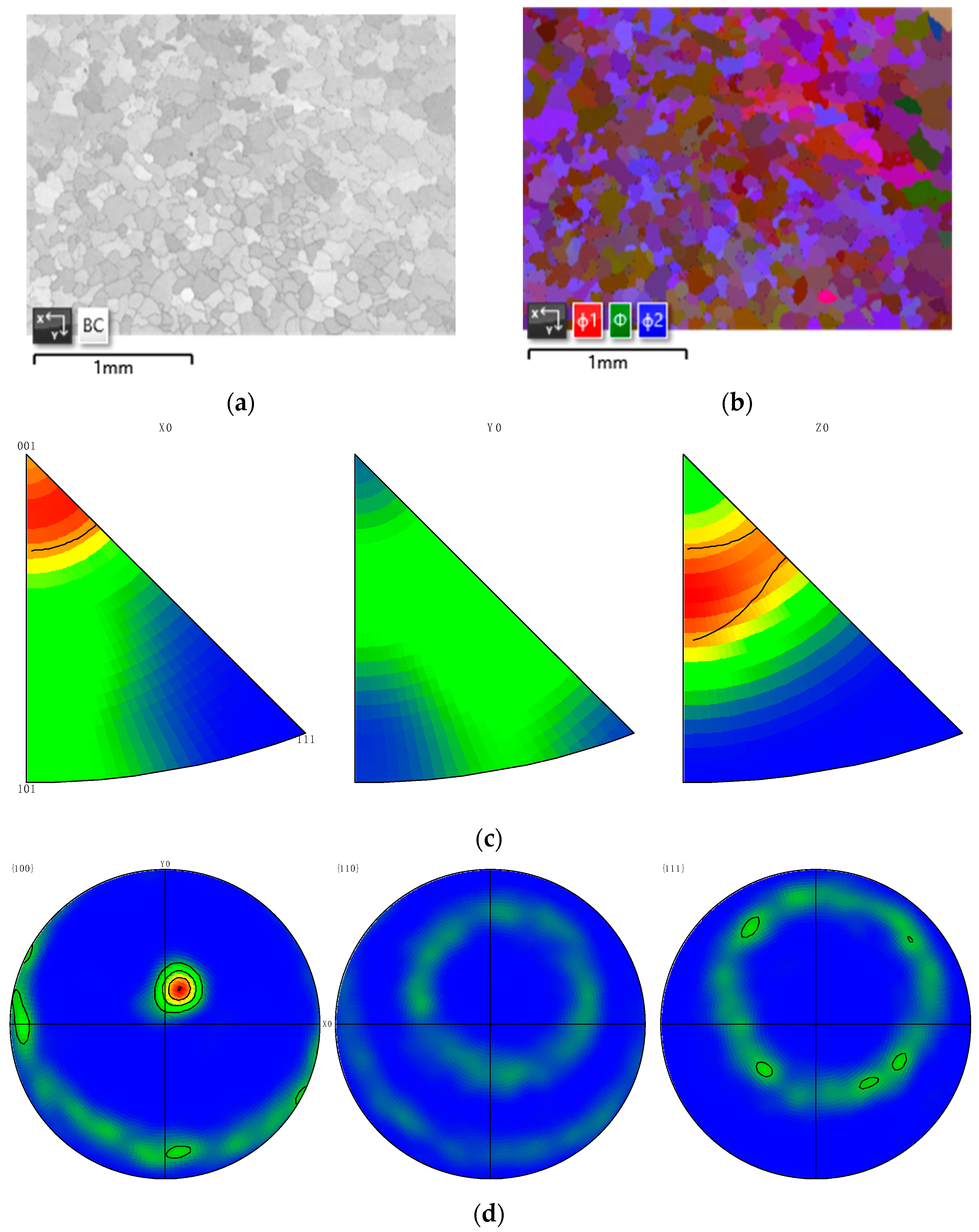

- The non-heat-treated sample exhibited the following microstructures: dendritic γ + precipitated phase in the columnar zone, equiaxed γ + precipitated phase in the remelting zone, and equiaxed γ + precipitated phase in the HAZ. After the solid solution heat-treatment process, the columnar crystal zone had a γ matrix + precipitated phase microstructure, the remelting zone metallographic structure was a γ matrix + precipitated phase, and the HAZ metallographic structure was a γ matrix + precipitated phase. This alloy had a microstructure that was mainly bulk and lath grains.

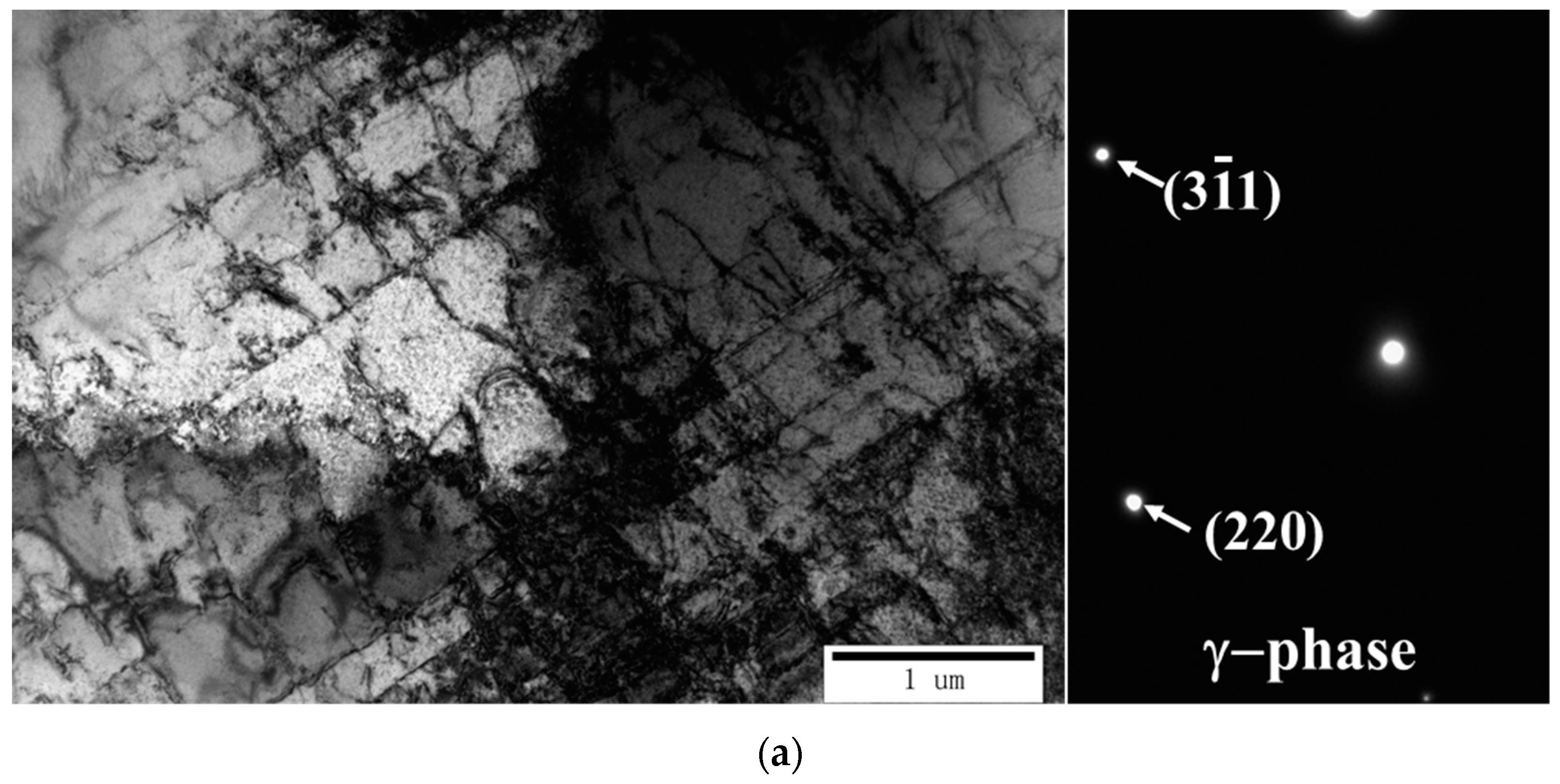

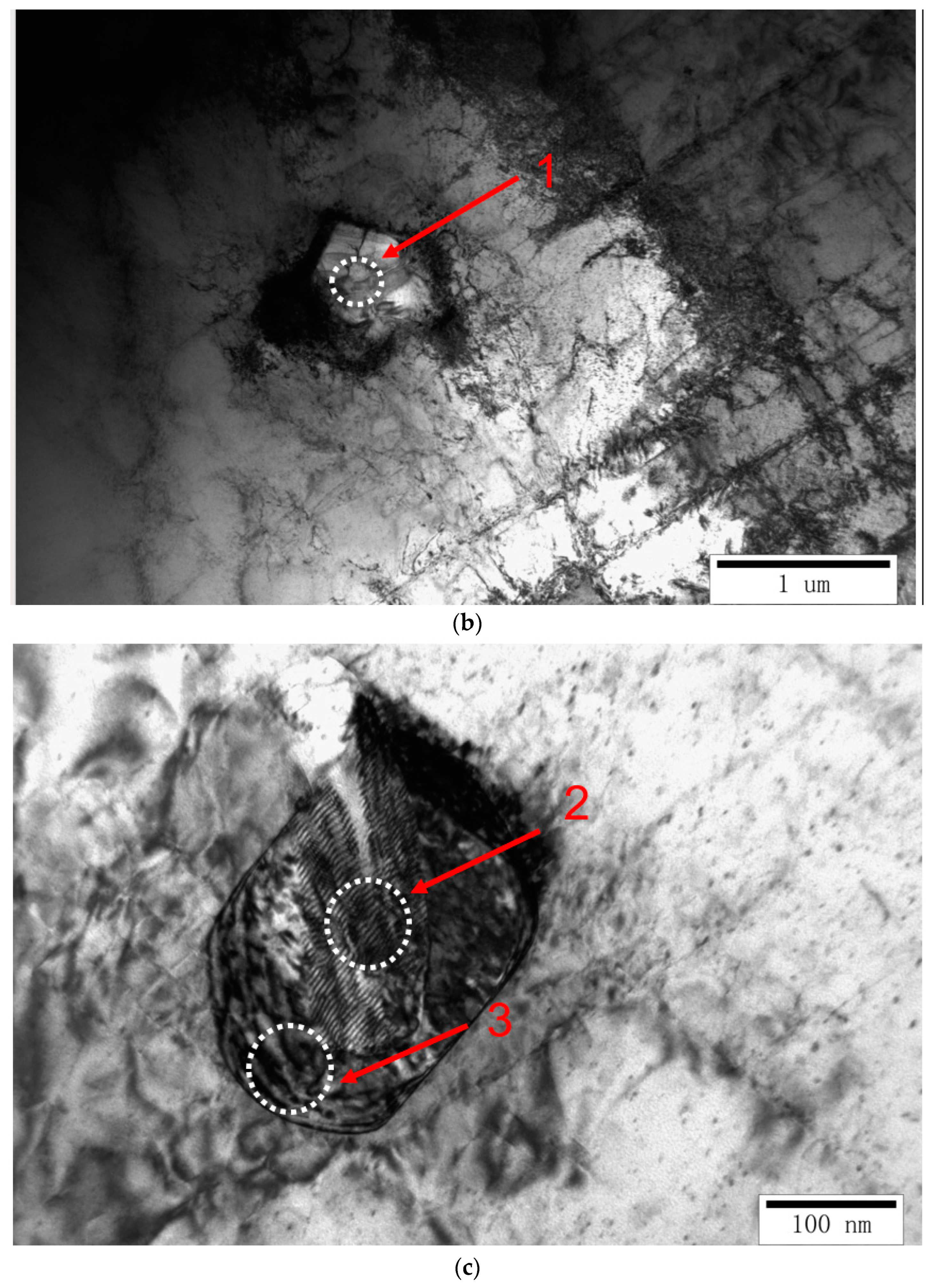

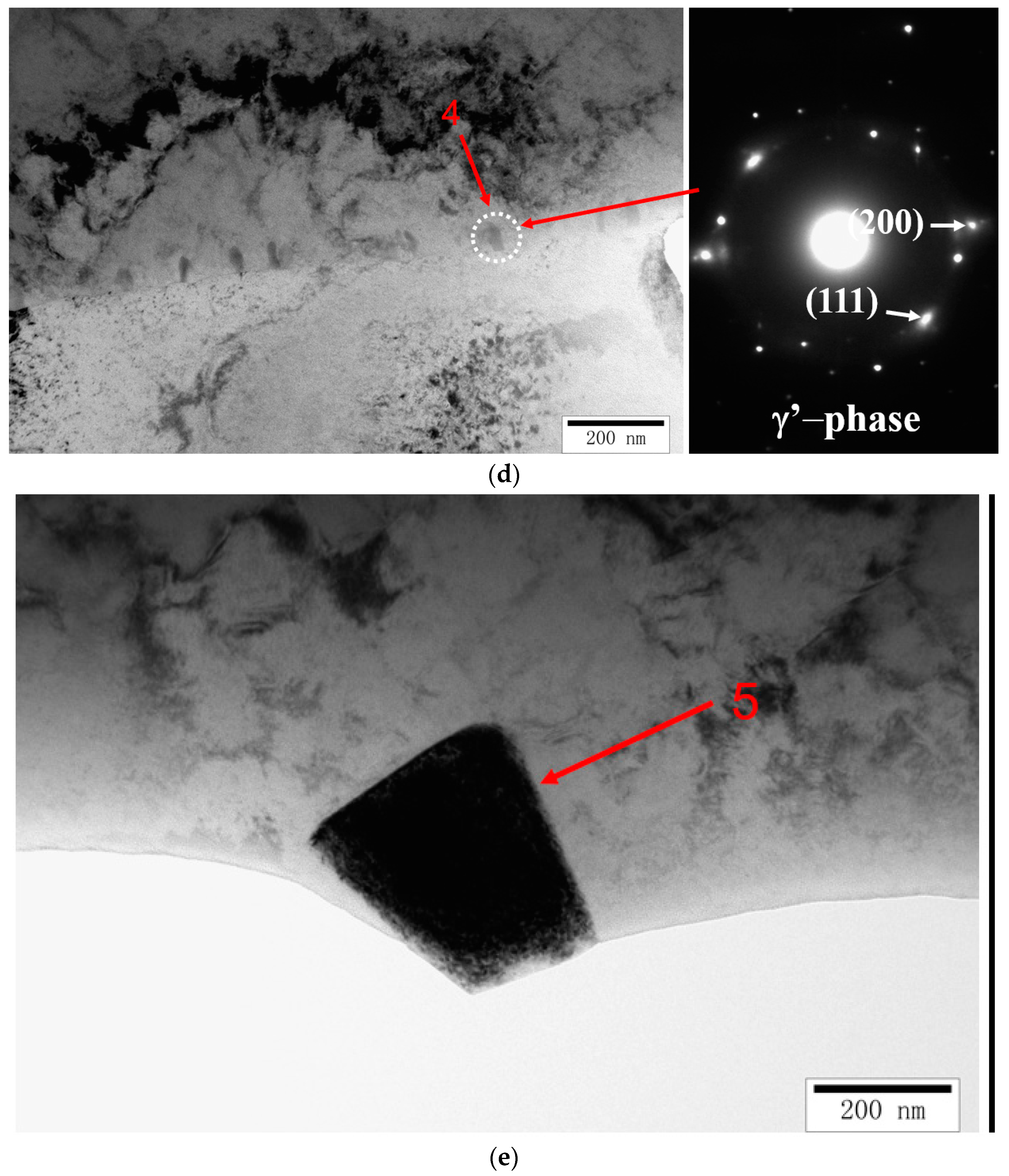

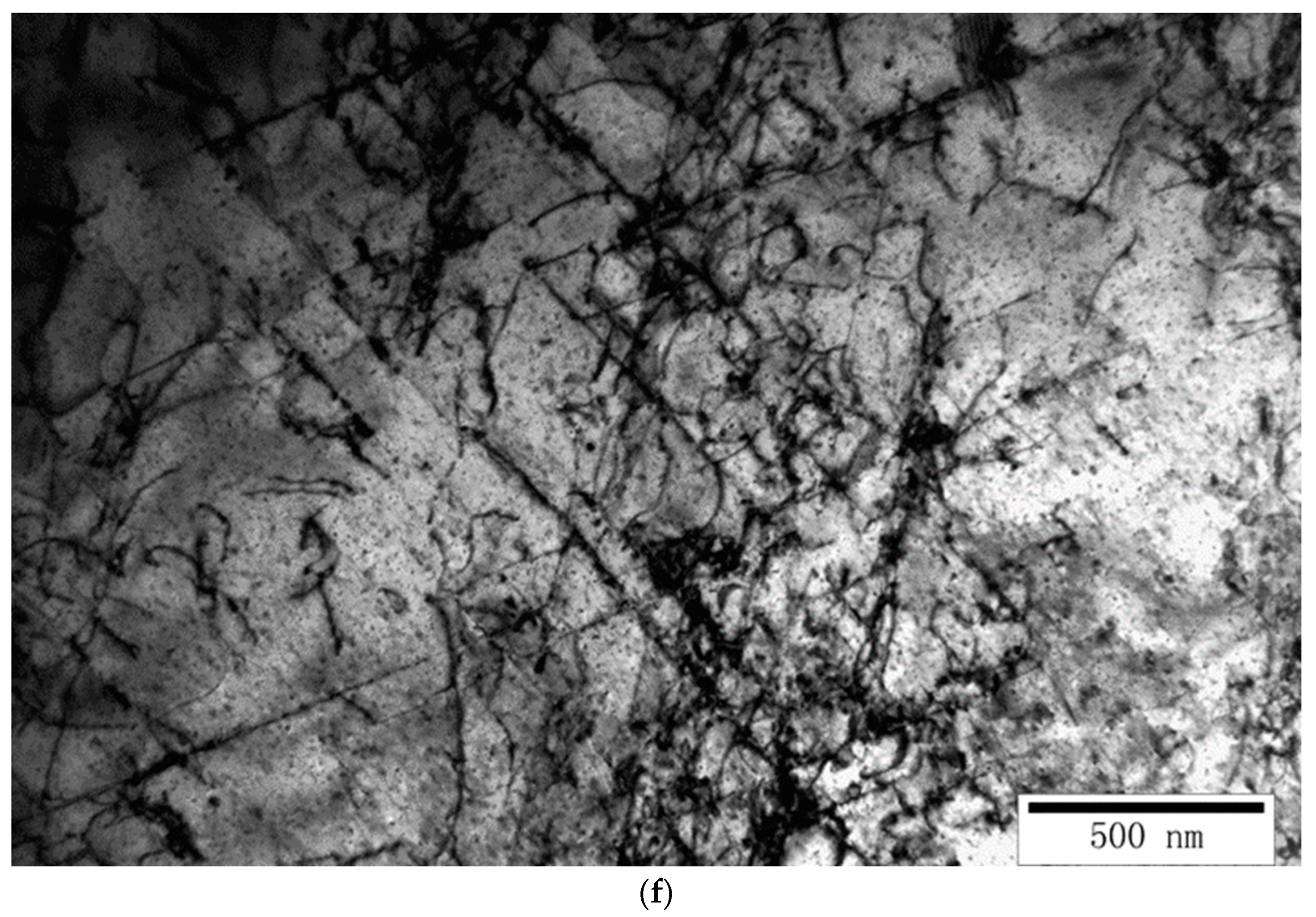

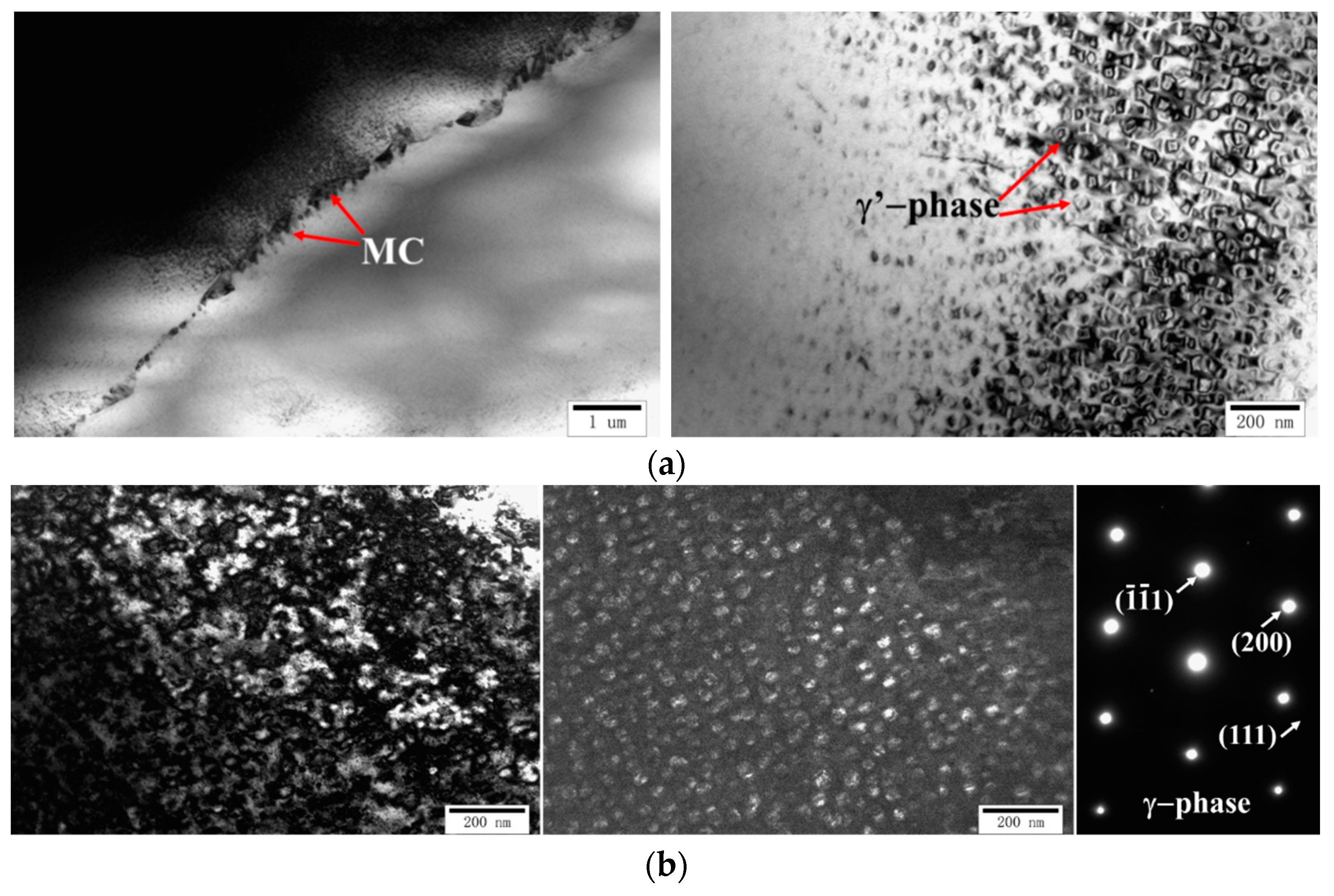

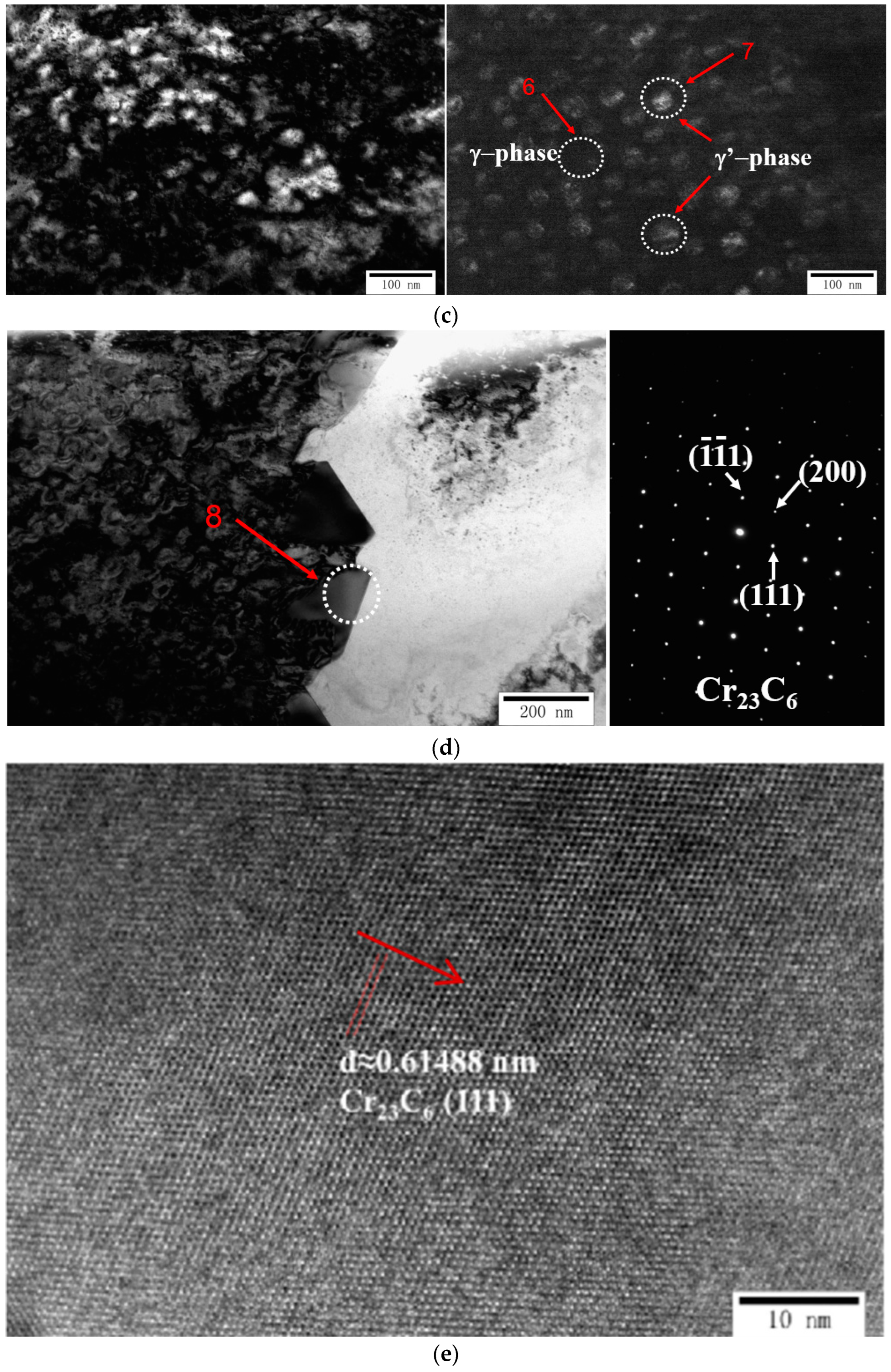

- Dislocations, a small number of oxide inclusions, nitrides, and γ’ phase precipitates were observed by TEM in the non-heat-treated sample. The oxide inclusions were mainly titanium and aluminum oxides. After heat treatment, many carbides precipitated at the grain boundary, and these carbides mainly exhibited a Cr23C6 phase. Moreover, a significant amount of γ’ phase precipitated in the grains.

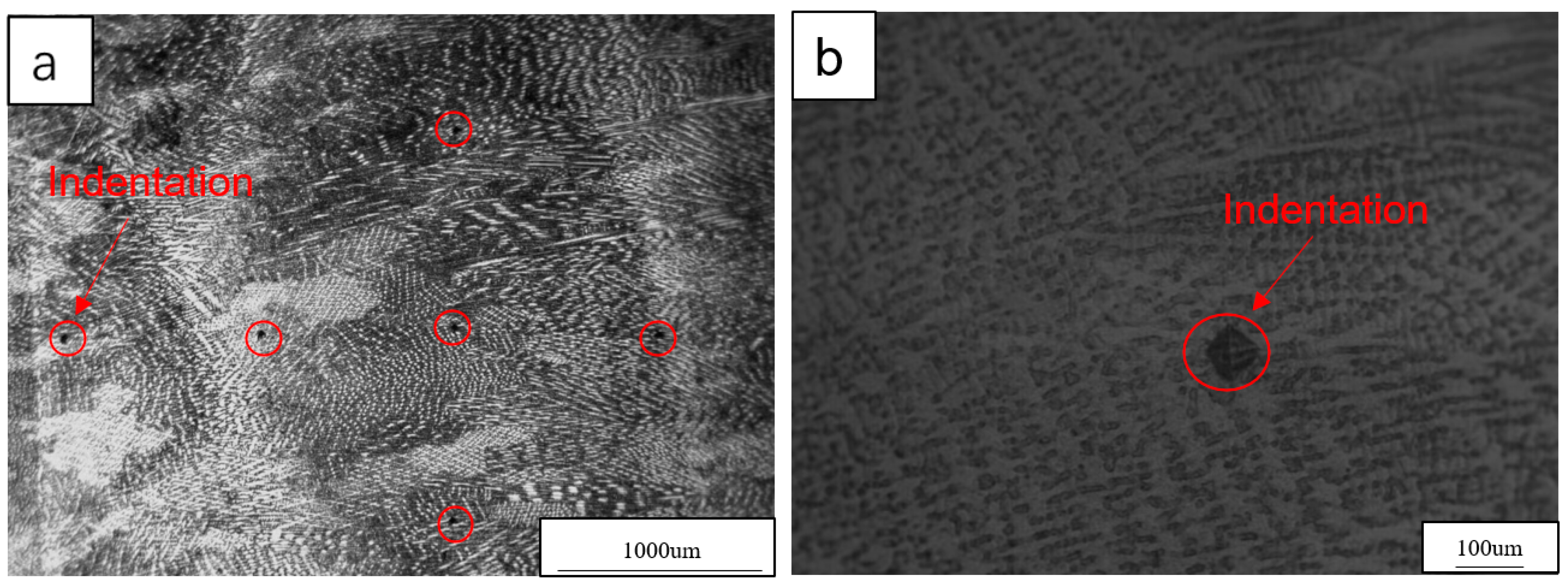

- The transverse microhardness distribution range of the non-heat-treated Inconel 740H Ni-based alloy was 285–311 HV0.2, and the average value was 296.5 HV0.2. The longitudinal microhardness distribution range of this sample was 274–310 HV0.2, and the average value was 290.6 HV0.2. The transverse microhardness distribution range of the heat-treated Inconel 740H Ni-based alloy was 352–383 HV0.2, and the average value was 368.5 HV0.2. The longitudinal microhardness distribution range of this sample was 347–390 HV0.2, and the average value was 367.9 HV0.2.

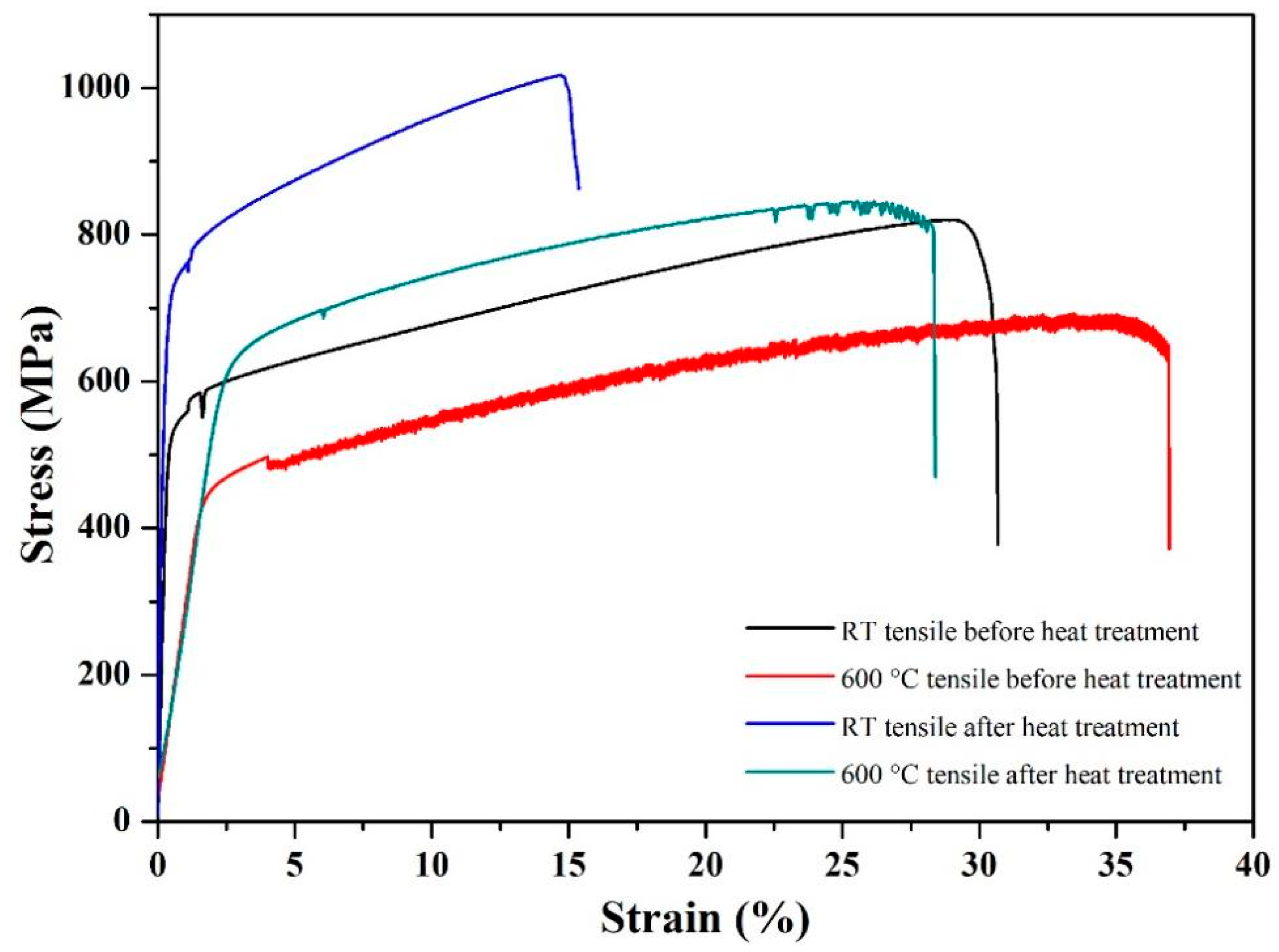

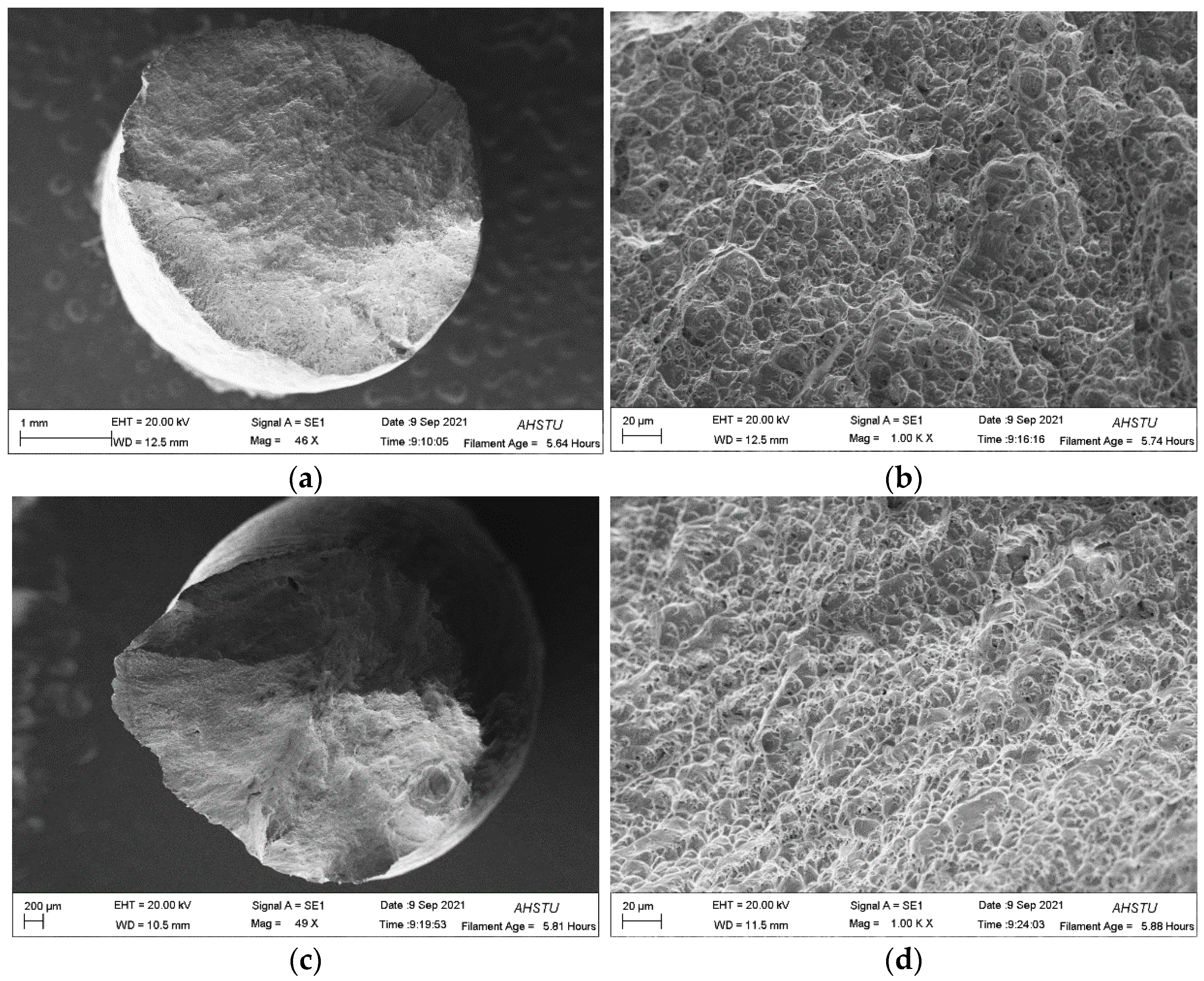

- The mechanical performance of these samples was excellent: at room temperature; the non-heat-treated sample had yield strength, tensile strength, elongation, and average Charpy impact values of 529 MPa, 820 MPa, 24%, and 129.7 J. At 600 °C, this sample had yield strength, tensile strength, and elongation values of 441 MPa, 692 MPa, and 38.5%. After heat treatment, the sample had room-temperature yield strength, tensile strength, elongation, and average Charpy impact values of 710 MPa, 1018 MPa, 17.5%, and 74 J. At 600 °C, a tensile strength of 846 MPa and an elongation of 22.5% were exhibited by the heat-treated sample. This heat-treatment process improved the sample strength by about 200 MPa, leading to better high-temperature mechanical properties. This work is anticipated to offer theoretical and experimental support for the use of additive manufacturing methods in the manufacturing of nickel-based superalloy components.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, S.; Takahashi, Y. Creep-fatigue life and damage evaluation under various strain waveforms for Ni-based Alloy 740H. Int. J. Fatigue 2023, 176, 107833. [Google Scholar] [CrossRef]

- Sridar, S.; Wang, X.; Shabani, M.; Klecka, M.A.; Xiong, W. Design of Graded Transition Interlayer for Joining Inconel 740H Superalloy with P91 Steel Using Wire-Arc Additive Manufacturing. In Proceedings of the 10th International Symposium on Superalloy 718 and Derivatives; Springer: Berlin/Heidelberg, Germany, 2023; pp. 755–772. [Google Scholar]

- Sridar, S.; Ladinos Pizano, L.F.; Klecka, M.A.; Xiong, W. Achieving High Strength and Creep Resistance in Inconel 740H Superalloy through Wire-Arc Additive Manufacturing and Thermodynamic-Guided Heat Treatment. Materials 2023, 16, 6388. [Google Scholar] [CrossRef]

- Sridar, S.; Klecka, M.A.; Xiong, W. Interfacial characteristics of P91 steel-Inconel 740H bimetallic structure fabricated using wire-arc additive manufacturing. J. Am. Acad. Dermatol. 2022, 300, 117396. [Google Scholar] [CrossRef]

- Render, M.; Santella, M.L.; Chen, X.; Tortorelli, P.F.; Cedro, V. Long-term creep-rupture behavior of alloy Inconel 740/740H. Metall. Mater. Trans. A 2021, 52, 2601–2612. [Google Scholar] [CrossRef]

- Kim, D.-M.; Kim, C.; Yang, C.-H.; Park, J.-U.; Jeong, H.-W.; Yim, K.-H.; Hong, H.-U. Heat treatment design of Inconel 740H superalloy for microstructure stability and enhanced creep properties. J. Alloy Compd. 2023, 946, 169341. [Google Scholar] [CrossRef]

- Shingledecker, J.; Griscom, E.; Bridges, A. Relationship between Grain Size and Sample Thickness on the Creep-Rupture Performance of Thin Metallic Sheets of INCONEL Alloy 740H. J. Mater. Eng. Perform. 2023, 32, 9309–9322. [Google Scholar] [CrossRef]

- Xiao, B.; Zhang, N.; Li, K.; Zhu, Z.; Zhang, T.; Zhou, M. Corrosion behaviour of Ni-based alloy Inconel 740H in supercritical carbon dioxide at 650-700° C. Corros. Eng. Sci. Technol. 2023, 58, 180–189. [Google Scholar] [CrossRef]

- Zhu, J.-Q.; Lu, Y.-X.; Sun, L.-G.; Huang, S.; Mei, L.-B.; Zhu, M.-L.; Xuan, F.-Z. Effect of microstructure on fatigue resistance of Inconel 740H and Haynes 282 nickel-based alloys at high temperature. Mater. Charact. 2023, 203, 113095. [Google Scholar] [CrossRef]

- Shingledecker, J.; Siefert, J.; Lolla, T.; Dupont, J.; deBarbadillo, J.; Gollihue, R. Factors Influencing Propensity for Stress Relaxation Cracking in Inconel® Alloy 740H® and Practical Guidance for Applications. In Proceedings of the 10th International Symposium on Superalloy 718 and Derivatives; Springer: Berlin/Heidelberg, Germany, 2023; pp. 431–443. [Google Scholar]

- Cheng, J.; Hu, X.; Lach, T.; Chen, X. Crystal plasticity modeling and analysis for the transition from intergranular to transgranular failure in nickel-based alloy Inconel 740H at elevated temperature. Mater. Sci. Eng. A 2024, 902, 146622. [Google Scholar]

- Guo, C.; Liu, S.; Hu, R.; Liu, C.; Chen, F. Microstructure and properties of a 2.25 Cr1Mo0. 25V heat-resistant steel produced by wire arc additive manufacturing. Adv. Mater. Sci. Eng. 2020, 2020, 1–9. [Google Scholar]

- de Vidales, M.J.M.; Nieto-Márquez, A.; Morcuende, D.; Atanes, E.; Blaya, F.; Soriano, E.; Fernández-Martínez, F. 3D printed floating photocatalysts for wastewater treatment. Catal. Today 2019, 328, 157–163. [Google Scholar] [CrossRef]

- Gang, C.; Zhao, S.-y.; Ping, T.; Yin, J.-o.; Quan, Z.; Yuan, G.; Li, Z.-f.; Jian, W.; Tang, H.-p.; Peng, C. Shape memory TiNi powders produced by plasma rotating electrode process for additive manufacturing. Trans. Nonferrous Met. Soc. China 2017, 27, 2647–2655. [Google Scholar]

- Giannopoulos, A.A.; Mitsouras, D.; Yoo, S.-J.; Liu, P.P.; Chatzizisis, Y.S.; Rybicki, F.J. Applications of 3D printing in cardiovascular diseases. Nat. Rev. Cardiol. 2016, 13, 701–718. [Google Scholar] [CrossRef] [PubMed]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Xiao, D.; Jing, H.; Xu, L.; Zhao, L.; Han, Y. Microstructure and Damage Evolution of Inconel 740H Welded Joint during Creep Process at 750° C. J. Mater. Eng. Perform. 2021, 30, 4562–4571. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, F.; Yan, Z.; Ma, Q.; Li, X.; Huang, Y.; Rogers, J.A. Printing, folding and assembly methods for forming 3D mesostructures in advanced materials. Nat. Rev. Mater. 2017, 2, 1–17. [Google Scholar] [CrossRef]

- Rashid, M.; Sabu, S.; Kunjachan, A.; Agilan, M.; Anjilivelil, T.; Joseph, J. Manufacture. Advances in Wire-Arc Additive Manufacturing of Nickel-Based Superalloys: Heat Sources, DfAM Principles, Material Evaluation, Process Parameters, Defect Management, Corrosion Evaluation and Post-Processing Techniques. Int. J. Light. Mater. Manuf. 2024, 32, 144342. [Google Scholar]

- Guguloth, K.; Roy, N. Study on the creep deformation behavior and characterization of 9Cr-1Mo-V-Nb steel at elevated temperatures. Mater. Charact. 2018, 146, 279–298. [Google Scholar] [CrossRef]

- Watanabe, T.; Tabuchi, M.; Yamazaki, M.; Hongo, H.; Tanabe, T. Creep damage evaluation of 9Cr–1Mo–V–Nb steel welded joints showing Type IV fracture. Int. J. Press. Vessel. Pip. 2006, 83, 63–71. [Google Scholar] [CrossRef]

- Kościelniak, B.; Chmiela, B.; Sozańska, M.; Swadźba, R.; Drajewicz, M. Oxidation Behavior of Inconel 740H Nickel Superalloy in Steam Atmosphere at 750° C. Materials 2021, 14, 4536. [Google Scholar] [CrossRef]

- Ji, L.; Liying, T.; Jiang, L.; Rongcan, Z.; Li, Z.; Weiguo, L.; Xiaomin, L. Study on the Performance Evolution of Inconel 740H During Operation on the Key Component Test Facility at 700 degrees C. Rare Met. Mater. Eng. 2021, 50, 3304–3312. [Google Scholar]

- Bolton, J. Rupture modelling and extrapolation of a sparse dataset for Inconel 740H. Int. J. Press. Vessel. Pip. 2021, 194, 104543. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Kim, B.-K.; Lee, S.-H.; Kim, D.-I.; Shim, J.-H.; Jung, W.-S.; Suh, J.-Y. Formation of needle-like MC carbide at or near incoherent twin boundary in IN740H Ni-based superalloy. J. Alloy Compd. 2020, 813, 152222. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, R.; Wu, X.; Wu, X.; Khelfaoui, F. Microstructure and Hardness Investigation of Tribaloy Alloy T-400C Hardfacing Deposited on Nickel-Based Alloy Inconel 740H via Plasma Transferred Arc Welding Subjected to Long-Time Aging. Met. Microstruct. Anal. 2024, 13, 145–173. [Google Scholar] [CrossRef]

- Lu, X. Multi-scale study of hydrogen-assisted cracking in nickel-based superalloys. NTNU 2020, 32, 123511. [Google Scholar]

- Parnaik, A.; Pavan, A.; Silchonok, S.; Kislov, N.; Narayan, R. High-cycle fatigue behavior of Haynes 282 superalloy subjected to accelerated ageing. Int. J. Fatigue 2024, 182, 108234. [Google Scholar] [CrossRef]

- Sroka, M.; Zieliński, A.; Śliwa, A.; Nabiałek, M.; Kania-Pifczyk, Z.; Vasková, I. The Effect of Long-Term Ageing on the Degradation of the Microstructure the Inconel 740h Alloy. Acta Phys. Pol. A 2020, 137, 355–360. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, C.; Jin, S.; Tian, Y.; Wellmann, D.; Liu, W. Wire arc additive manufacturing of stainless steels: A review. Appl. Sci. 2020, 10, 1563. [Google Scholar] [CrossRef]

- Kumar, C.; Kumar, P. Analyzing dynamic strain aging and yield strength anomaly in IN740H, a nickel-based superalloy comprising low volume fraction of γ′. Materialia 2024, 33, 102028. [Google Scholar] [CrossRef]

- Yangfan, W.; Zhang, C.; Chuanchu, S. Microstructure and mechanical properties of Inconel 625 fabricated by wire-arc additive manufacturing. Surf. Coat. Technol. 2019, 374, 116–123. [Google Scholar] [CrossRef]

- Athira, K.S.; Chatterjee, S. Effect of keyhole gas tungsten arc welding and post-welding heat treatment on microstructure and hardness of inconel 740H. J. Mater. Eng. Perform. 2023, 1–15. [Google Scholar] [CrossRef]

- Song, R.-H.; Qin, H.-L.; Li, D.-F.; Bi, Z.-N.; Busso, E.P.; Yu, H.-Y.; Liu, X.-L.; Du, J.-H.; Zhang, J. An Experimental and Numerical Study of Quenching-Induced Residual Stresses under the Effect of Dynamic Strain Aging in an IN718 Superalloy Disc. J. Eng. Mater. Technol. 2022, 144, 011002. [Google Scholar] [CrossRef]

| Sample | C | Si | Mn | Ni | Cr | Co | Ti | Al | Nb + Ta | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| 740H | 0.03 | 0.1 | 0.24 | 49.48 | 24.6 | 20.3 | 1.5 | 1.4 | 1.49 | 0.5 |

| Sample | Voltage/V | Current/A | Wire Feed Speed/m·min−1 | Printing Speed/m·s−1 | Contact Tip to Work Distance/mm | Shielding Gas Flow/L·min−1 | Interpass Temperature/°C | Overlap Rate/% |

|---|---|---|---|---|---|---|---|---|

| Inconel 740H | 20 | 100 | 5 | 15 | 10–20 | 15–20 | 150 | 50 |

| Analyzed Precipitate | Chemical Composition (wt%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ni | Cr | Co | Ti | Al | Nb | Mo | Mg | C | N | O | |

| Inclusions (1) | 0.55 | 1.12 | 0.26 | 29.19 | 9.09 | 5.90 | - | 4.51 | - | 11.17 | 38.21 |

| Inclusions (2) | 1.10 | 2.66 | 0.49 | 69.22 | - | 6.62 | - | - | - | 19.92 | - |

| Inclusions (3) | 0.52 | 1.22 | 0.45 | 15.67 | 26.06 | 1.32 | - | 10.24 | - | - | 44.53 |

| γ’ phase (4) | 30.62 | 49.63 | 17.09 | - | 2.66 | - | - | - | - | - | - |

| Nitride (5) | 1.30 | 2.15 | 0.57 | 49.35 | - | 5.63 | - | - | - | 41 | - |

| γ phase (6) | 44.48 | 29.07 | 23.80 | 0.57 | 2.07 | - | - | - | - | - | - |

| γ’ phase (7) | 55.44 | 12.29 | 10.50 | 5.21 | 9.62 | 6.94 | |||||

| Cr23C6 (8) | 4.59 | 63.98 | 3.74 | - | - | - | 2.11 | - | 25.58 | - | - |

| Sample | Test Temperature | Yield Strength /MPa | Tensile Strength/MPa | Elongation (%) | RT Impact Toughness/J |

|---|---|---|---|---|---|

| Before heat treatment | Room temperature | 529 | 820 | 24 | 129 ± 6.78 |

| 600 °C | 441 | 692 | 38.5 | ||

| After heat treatment | Room temperature | 710 | 1018 | 17.5 | 74 ± 6.32 |

| 600 °C | 614 | 846 | 22.5 | ||

| Inconel 740H | Room temperature | 313 | 796 | 57 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, R.; Li, W.; Guo, C.; Huang, G.; Zhang, X.; Lin, Q. Inconel 740H Prepared by Additive Manufacturing: Microstructure and Mechanical Properties. Metals 2024, 14, 809. https://doi.org/10.3390/met14070809

Hu R, Li W, Guo C, Huang G, Zhang X, Lin Q. Inconel 740H Prepared by Additive Manufacturing: Microstructure and Mechanical Properties. Metals. 2024; 14(7):809. https://doi.org/10.3390/met14070809

Chicago/Turabian StyleHu, Ruizhang, Wenqing Li, Chun Guo, Guangcan Huang, Xinyu Zhang, and Qingcheng Lin. 2024. "Inconel 740H Prepared by Additive Manufacturing: Microstructure and Mechanical Properties" Metals 14, no. 7: 809. https://doi.org/10.3390/met14070809

APA StyleHu, R., Li, W., Guo, C., Huang, G., Zhang, X., & Lin, Q. (2024). Inconel 740H Prepared by Additive Manufacturing: Microstructure and Mechanical Properties. Metals, 14(7), 809. https://doi.org/10.3390/met14070809