Abstract

This study systematically investigates the impact of the material properties of soft magnetic composites (SMCs) on the powder metallurgy forming process. It proposes a suitable material selection process for various motor types and shapes and determines the optimal forming conditions for each SMC material. This study employed the Taguchi design method to identify key control factors such as powder type, forming temperature, and forming speed, and analyzed their effects on relative density. Simulation results indicated that AncorLam HR exhibited superior properties compared with AncorLam and Fe-6.5wt.%Si. The optimal conditions determined through signal-to-noise ratio (SNR) calculations were AncorLam HR at 60 °C and five cycles per minute (CPMs). Validation through simulation and SEM analysis confirmed improved density uniformity and reduced defects in products formed under optimal conditions. Final prototype testing demonstrated that the selected conditions achieved the target density with minimal variance, enhancing the mechanical properties and performance of the motors. These results suggest that the appropriate application of SMC materials can significantly enhance motor efficiency and reliability.

1. Introduction

The global trends for eco-friendly cars and carbon neutrality are driving efforts across industries to increase energy efficiency and minimize environmental pollution. In this context, advancements in formation technology for motor-core materials for automobiles play a crucial role. High-performance magnetic materials, such as soft magnetic composites (SMCs), are essential for enhancing the energy efficiency of electric and hybrid vehicle motors. SMCs provide excellent magnetic properties and low energy loss, even under high-frequency operating conditions [1,2,3,4].

Traditional laminated electrical steel methods in motor-core manufacturing have limitations in efficiency and design flexibility. As an alternative, powder metallurgy technology using SMCs is attracting attention. SMC-based motor cores offer superior magnetic properties and can be more easily fabricated into complex shapes, enabling miniaturization and high-density motor design through optimal processes reflecting the mechanical properties of the SMC. This represents a significant technological advancement that can significantly enhance motor performance. Additionally, the use of SMCs can reduce losses during the manufacturing process and improve the overall efficiency of the motor [5,6].

Powder metallurgy (PM) technology can be employed to manufacture metal components using solid powders. It is particularly suitable for producing parts that need precision, such as motor stator cores, and offers unique advantages over traditional metalworking technologies like casting and forging in terms of material utilization, precision, and the creation of complex shapes. The PM process using SMCs can be broadly divided into three stages: powder production, powder compaction, and heat treatment [7,8,9]. In the first stage, controlling the powder’s characteristics during the production of SMC powder is crucial. Particle size, shape, distribution, and chemical purity directly affect the quality and performance of the final product. The particle size of the SMC powder must be uniformly maintained to ensure consistent density and mechanical properties during the heat treatment process. Additionally, particle shape must be controlled to minimize non-uniform shrinkage and distortion during heat treatment, and chemical purity must be high to minimize impurities that could affect the electrical and magnetic properties of the final product. In the second stage, the powder compaction process involves compressing the metal powder to form a green body of the desired shape. During this process, mechanical contact and friction occur between the powder particles, causing them to become closely packed and arranged under compressive force, which increases the density. This process varies depending on the shape and size of the powder, and precise control is necessary to achieve optimal compactness and mechanical strength. The control of compaction speed and pressure is critical to the arrangement and density of the powder particles. Too fast a compaction speed can cause non-uniform density, while too slow a speed can reduce production efficiency. Therefore, choosing an appropriate compaction speed is essential. The final stage, i.e., heat treatment, involves heating the compacted green body at high temperatures to strengthen the bonds between the particles. SMCs should be sintered at lower temperatures than those for typical metal components, to maximize electrical properties. This aims to prevent the destruction of the insulating coating surrounding each powder particle during the heat treatment process, thus minimizing electrical losses in the final product. Lower heat treatment temperatures enhance physical and electrical contact between particles while preserving the insulating layer, allowing the SMC core to maintain high magnetic properties and low energy loss. The theory of sintering, which is a crucial aspect of heat treatment, involves the bonding of particles by atomic diffusion. Sintering typically occurs at temperatures below the melting point of the material, enabling particles to adhere without melting. This process reduces porosity, increases mechanical strength, and improves the overall structural integrity of the material. Key mechanisms in sintering include surface diffusion, grain boundary diffusion, and volume diffusion, each contributing to the densification and bonding of the powder particles. Understanding these mechanisms is essential for optimizing the sintering process to achieve desired material properties [10,11,12,13,14,15,16].

Additionally, the final performance of SMC cores is highly dependent on the density of the compacted body. High density implies low porosity, which influences magnetic resistance, saturation flux density, magnetic permeability, magnetic loss, and thermal properties. High porosity can decrease the efficiency of the magnetic circuit, reduce saturation flux density and magnetic permeability, and lead to electrical losses and decreased thermal management capability due to eddy currents. Therefore, it is essential to conduct heat treatment within a temperature range that does not destroy the insulating coating layer formed between the metal powder particles. This is crucial for enhancing the overall energy efficiency of the motor system [17,18,19,20,21].

The manufacturing process for motor cores using SMCs is still in its early stages, and most processes rely on the recommendations of SMC powder suppliers. This situation limits the optimization of the shape and performance of motor cores. To overcome these issues and fully exploit the potential of SMC-based motor cores, it is necessary to systematically study the impact of SMCs’ material properties on the motor core manufacturing process, particularly the PM process [22,23].

Recent research has focused on various aspects of SMCs’ material properties and their applications in motor design. For example, Hea-Ran Kim and colleagues explored the effects of annealing temperature control on the magnetic properties of SMCs, demonstrating significant improvements in core loss and permeability through optimal temperature control [16]. Emir Pošković and his team introduced efficient methods for quickly assessing and selecting SMC materials based on key magnetic properties, thus facilitating better material choices for motor applications [24]. Additionally, Vidhya B and collaborators highlighted advancements in using SMC materials to design high-power-density electric motors, emphasizing their benefits in reducing weight and improving efficiency in electric vehicle applications [25].

Despite these advancements, there is still a lack of comprehensive research specifically addressing the process design for SMC cores in motor manufacturing. While the aforementioned studies provide valuable insights into the material properties and preliminary selection processes, the optimization of manufacturing processes for SMC cores remains underexplored. Therefore, further systematic studies are required to bridge this gap and develop optimized process designs that fully leverage the unique properties of SMC materials.

In this study, we aim to analyze the impact of SMCs’ material properties on the powder-metallurgy forming process. We propose a material-selection process for SMCs applicable to different types and shapes of motors and derive the forming process conditions for each SMC material. To achieve this, we carried out the following:

- (1)

- Identified the characteristics of each SMC material by testing their material properties.

- (2)

- Analyzed the process impact through finite element method (FEM) analysis based on material properties using experimental design methods.

- (3)

- Derived optimal process conditions by calculating the signal-to-noise ratio (SNR).

- (4)

- Verified reliability by manufacturing toroidal model products for each SMC material and comparing the actual products with the analysis results.

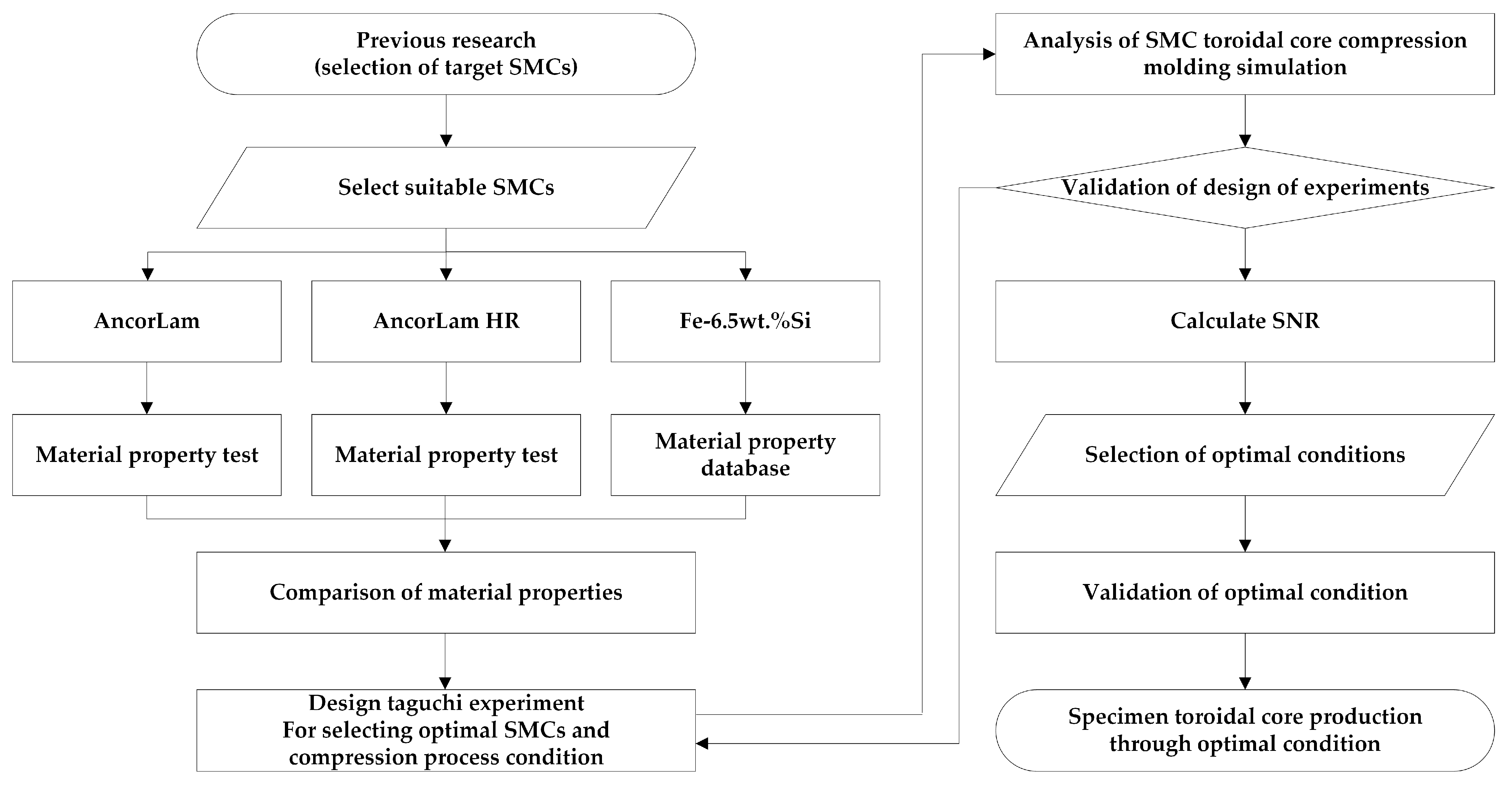

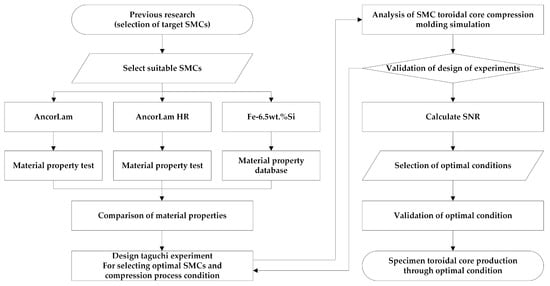

The flow chart of this study is shown in Figure 1.

Figure 1.

Flow chart of the study.

2. Materials and Methods

In commercial applications, SMC materials designed for electric vehicle motors, provided by companies like Höganäs (Höganäs, Sweden), are used. These commercial SMCs are custom made to meet the stringent requirements of the automotive industry and offer optimized properties for the high performance and efficiency of electric vehicle motors. However, the use of such commercial materials presents limitations for users in relation to versatility across various frequency ranges, and the material properties necessary for motor-specific design in molding environments are not provided. Therefore, separate data collection is required by the end user [26].

It is essential to develop SMCs tailored to various frequency ranges. This necessitates further diversification of SMCs’ material properties and research and development to provide optimized performance for each frequency range.

In this study, we include the simulation results of powder compaction for two types of powders produced by Höganäs, AncorLam (Höganäs, Sweden), and AncorLam HR (Höganäs, Sweden), as well as Fe-6.5wt.%Si alloy powder with 6.5% Si content, which was produced in previous research. As part of the study, we conducted testing for density, SEM analysis, strength, and thermal properties.

2.1. Testing Material Properties

For the powder compaction simulation at ~100 °C, the following properties were evaluated. Additionally, to evaluate the reliability of the simulation results during the analysis and outcome stages, we conducted density measurements and SEM analysis of the toroidal core prototype.

2.1.1. Methods for Testing Properties

The high-temperature compression tests were conducted following the ASTM E209 test standard [27]. The testing apparatus used was a dynamic thermal mechanical testing machine from Gleeble (Gleeble 3800-GTC, Gleeble, Poestenkill, NY, USA). The temperature points for the measurements were 25 °C, 60 °C, and 90 °C, with a strain rate of 0.1 mm/s. The specimens, complying to the ASTM E209 standard, had dimensions of 10 mm in diameter and 15 mm in height.

Thermal conductivity tests were conducted in accordance with the KS L 1604 test standard [28] using the LFA 427 apparatus from NETZSCH (NETZSCH, Selb, Bayern, Germany). Measurements were taken from 25 to 500 °C. Disk-type specimens were employed, complying with the KS L 1604 standard, with dimensions of 12.7 mm in diameter and 2 mm in height.

The coefficients of thermal expansion were assessed according to the ASTM E228 standard [29] using a DIL 402 HT from NETZSCH (NETZSCH, Selb, Bayern, Germany), with measurements taken in the range of 25 °C to 500 °C. The specimens used were cylindrical in shape, complying with the ASTM E 228 standard, and they had dimensions of 5 mm in diameter and 25 mm in height.

2.1.2. AncorLam/AncorLam HR

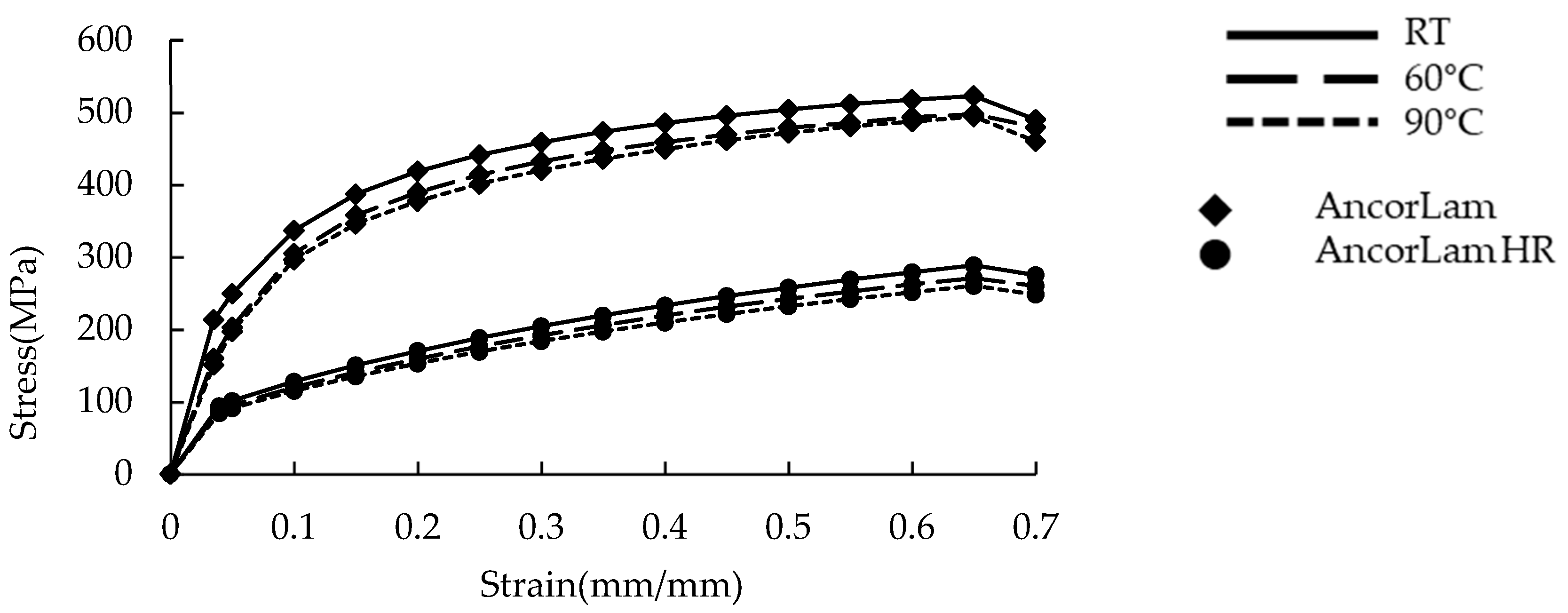

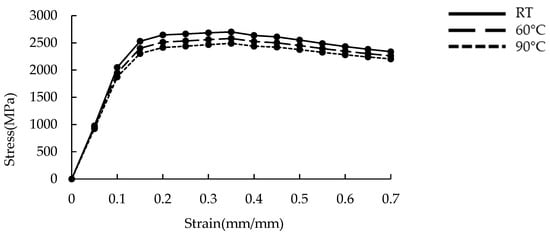

Figure 2 illustrates the strain–stress curves obtained through high-temperature compression tests for AncorLam and AncorLam HR. The powder compaction simulation using SMC properties employed the FEM within the elastoplastic region. Consequently, only the plastic region values, excluding the elastic region, were utilized as input parameters.

Figure 2.

Strain–stress curves of AncorLam and AncorLam HR.

Table 1, Table 2, Table 3 and Table 4 present the thermal conductivity and coefficient of thermal expansion properties measured from 100 to 500 °C, respectively. These values were utilized in the simulations.

Table 1.

Thermal conductivity test results for AncorLam.

Table 2.

Thermal expansion coefficient test results for AncorLam.

Table 3.

Thermal conductivity test results for AncorLam HR.

Table 4.

Thermal expansion coefficient test results for AncorLam HR.

2.1.3. Fe-6.5wt.%Si

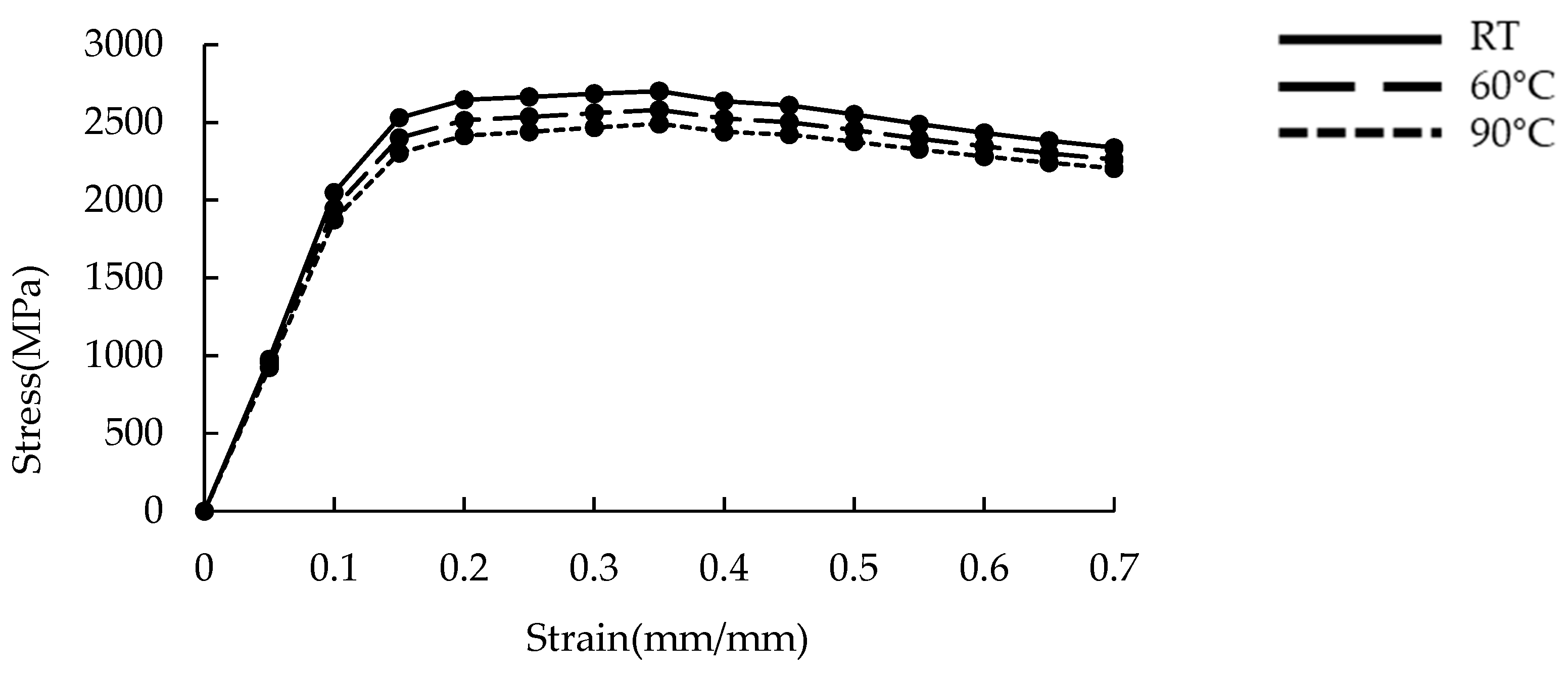

The strain–stress curve data for Fe-6.5wt.%Si, obtained from a previous study [30], are depicted in Figure 3. Similar to the SMC materials, the powder compaction simulation for Fe-6.5wt.%Si employed the FEM within the elastoplastic region. Consequently, only the plastic region values, excluding the elastic region, were utilized as input parameters. Table 5 and Table 6 list the thermal conductivity and coefficient of thermal expansion properties measured from 100 to 500 °C, respectively. These values were incorporated into the simulations.

Figure 3.

Strain–stress curve of Fe-6.5wt.%Si.

Table 5.

Thermal conductivity test results for Fe-6.5wt.%Si.

Table 6.

Thermal expansion coefficient test results for Fe-6.5wt.%Si.

2.1.4. SMCs Powder Compaction Simulation

The powder forming process is a crucial stage in the manufacturing of SMCs, where factors such as powder particle size and shape, compaction conditions, heat treatment temperature, and time influence the material properties at each stage. Among these factors, the type of powder, forming temperature, and forming speed are the primary variables that significantly impact the final performance of SMCs. This is because key performance indicators of SMC cores, such as coercivity and saturation flux density, are greatly influenced by the density of the final product. Therefore, optimizing these variables in the manufacturing process is essential to enhance the overall performance of SMC cores.

2.2. Yield Criteria for Porous Materials

The Von Mises yield criterion is suitable for describing the yield behavior of isotropic materials [31]. However, it does not directly account for porosity, which significantly influences the yield behavior of porous materials. Therefore, for porous materials, the plastic yield criterion used in FEM analysis typically follows the Shima–Oyane criterion [32]. This theory extends the traditional Von Mises yield criterion by considering the impact of porosity on the material’s yield behavior, as represented by Equation (1) [33]:

where is the effective stress, and , , and are the principal stresses.

The Shima–Oyane criterion further modifies the yield condition by incorporating the porosity . The modified Shima–Oyane equation is shown in Equation (2) [34]:

where is the yield strength of the material, is the material constant, and is porosity. This equation directly explains how an increase in porosity reduces the yield stress. For a fully dense material with no porosity, equals 0, making and equal. In contrast, for a porous material, is greater than 0, resulting in being less than .

2.3. Taguchi Experimental Design

Without proper planning of experiments, achieving the desired goals would necessitate a large number of experiments, making it challenging to identify optimal values. In processes like PM, numerous variables exist, each significantly impacting the overall results. Especially with SMC materials, predicting the quantitative impact of each variable on the outcomes is challenging. Therefore, applying experimental design methods to determine the optimal values of key factors is essential.

Design of experiments (DOE) is a methodology that selects various factors affecting product characteristics and performs experiments based on them to economically derive optimal conditions for the product. This methodology should effectively identify control factors and their levels that significantly impact product characteristics to achieve experimental goals.

In this study, we chose to apply the Taguchi method to optimize the characteristics of SMC cores. This method minimizes the number of experiments while being highly effective in result analysis, allowing efficient extraction of maximum information with minimal experimentation [35].

This method assumes no interaction effects and uses orthogonal arrays to design experimental conditions, significantly reducing the number of experiments compared with other experimental design methods. Additionally, the SNR analysis facilitates quality measurement based on product characteristics. Evaluation of experimental data is conducted using the loss function proposed by Taguchi, where the loss function is given by Equation (3):

where y, m, and k indicate quality characteristic value of product, target value of y, and the quality loss coefficient.

To evaluate the impact of noise factors on product performance, the SNR, as specified in Equation (4), serves as a key criterion. The Taguchi method proposes estimating the effects of design parameters and noise factors using orthogonal arrays and calculating the SNR based on this estimation. This approach enables the efficient evaluation of the product and quantitatively analyzes the extent to which noise factors affect product performance.

SNR can be classified into three types based on the requirements of the target characteristic: smaller-the-better, larger-the-better, and nominal-the-best. The smaller-the-better and larger-the-better characteristics apply to situations where a lower or higher target value, respectively, is desirable, while the nominal-the-best characteristic indicates that an optimal target value should be achieved.

The calculation methods for SNR for each type of characteristic are defined as follows: Equations (5)–(7) are used for the smaller-the-better, larger-the-better, and nominal-the-best characteristics, respectively:

where represents the -th measured characteristic value. Additionally, is the number of measured target characteristic values, and is the target value of the characteristic. This calculation method reflects various requirements for the target characteristic, and it is applied in the result analysis and optimization process of the experiments, providing a suitable statistical evaluation criterion for each situation [36,37].

3. Simulation Conditions

3.1. Analysis Model

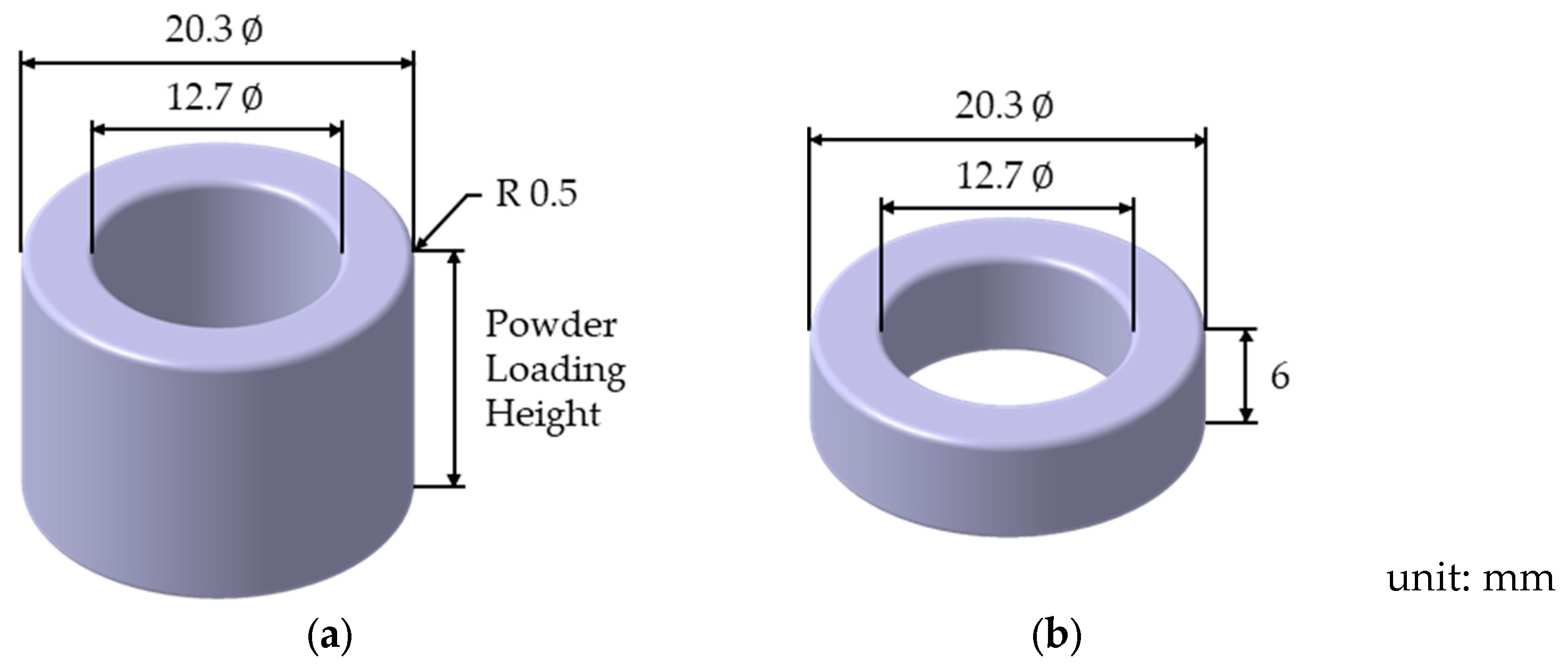

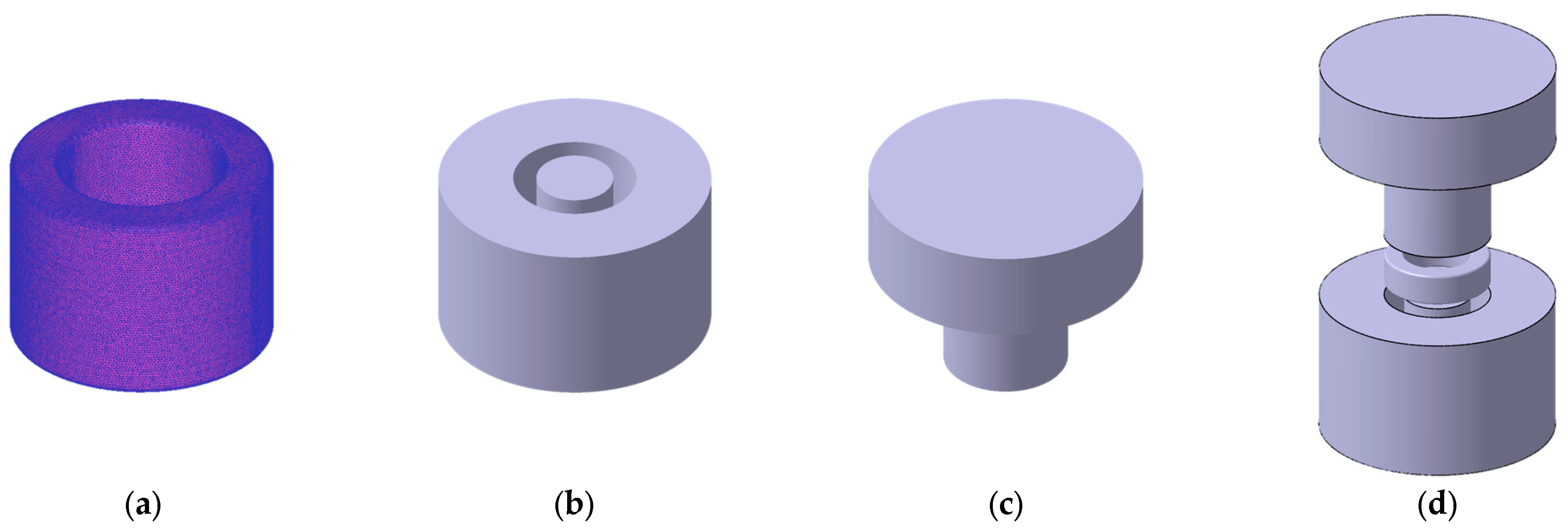

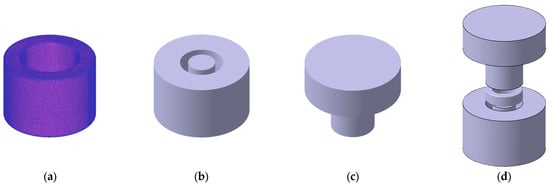

Figure 4 illustrates the initial shape of the green body and the shape after compaction, designed using CATIA V5. The initial green body was assumed to be porous, with the initial loading height varying based on the apparent density of each powder. Table 7 summarizes the apparent density of each powder, initial relative density (calculated as 0.9 relative density at 7.4 g/cm3), and initial loading height. The initial loading height was determined by dividing the volume obtained from the same amount of powder loading, according to the final shape and target density, by the apparent density.

Figure 4.

FEA toroidal core model feature: (a) before and (b) after the pressing process.

Table 7.

Boundary conditions of design of experiments.

The compression simulation of the SMC toroidal core was conducted using a uniaxial compression method. The toroidal core was meshed using tetrahedral elements, totaling 667,844 elements. Figure 5a illustrates the mesh configuration of the toroidal core. The fixed die is depicted in Figure 5b, while Figure 5c shows the upper punch descending in the -Z direction. The overall assembly configuration is shown in Figure 5d. The powder compaction simulation analysis was performed using DEFORM-3D (SFTC, version 13.1) [38].

Figure 5.

FEA simulation model features: (a) meshing, (b) die, (c) upper punch, and (d) assembly.

3.2. DOE Factor and Level Settings

In stabilizing the electrical properties of porous products, achieving the target density and ensuring uniformity of internal porosity are crucial. To assess this uniformity, the maximum–minimum deviation of relative density was selected as the characteristic value for the experiments. In this study, the main control factors affecting relative density were powder type, forming temperature, and forming speed.

Specifically, to evaluate the impact of the material properties of SMCs, the powder type was set as an experimental variable, considering its mechanical and thermal properties. The forming temperature was selected within the recommended range for commercial powders, between room temperature and 100 °C, specifically set at 20, 60, and 90 °C. The forming process was conducted using a mechanical press. To determine the forming speed per stroke, considering the relative density of each powder, the number of cycles per minute (CPMs) was adjusted to 5, 10, and 15. The factors and levels of the control variables are listed in Table 8 and Table 9.

Table 8.

Design of control factor and level.

Table 9.

L9(33) orthogonal array.

Here, the CPM values followed the operating mechanism of the mechanical press, and the punch speed during the forming process depended on the CPMs and the forming stroke. The punch speed conversion values for the CPMs according to the initial loading height of each powder are shown in Table 10.

Table 10.

Converted punch speed according to initial loading height.

4. Result

4.1. Simulation Results

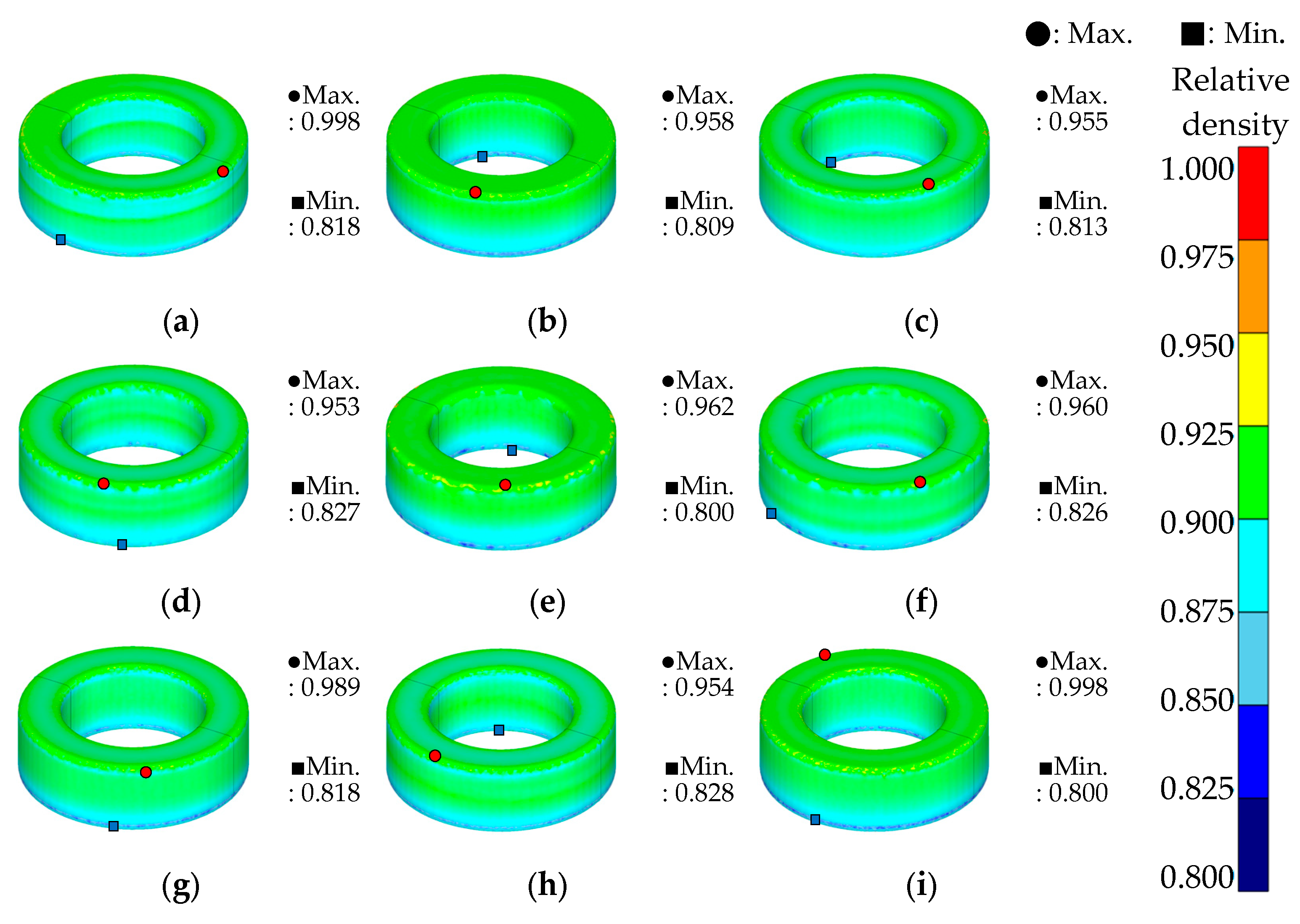

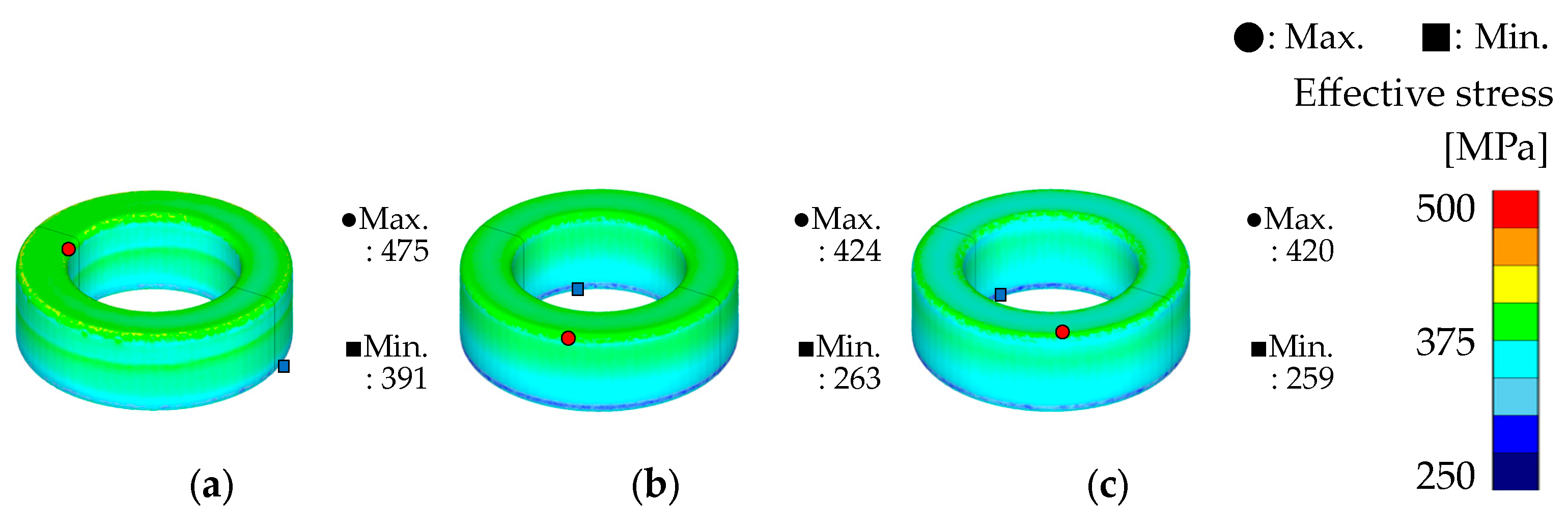

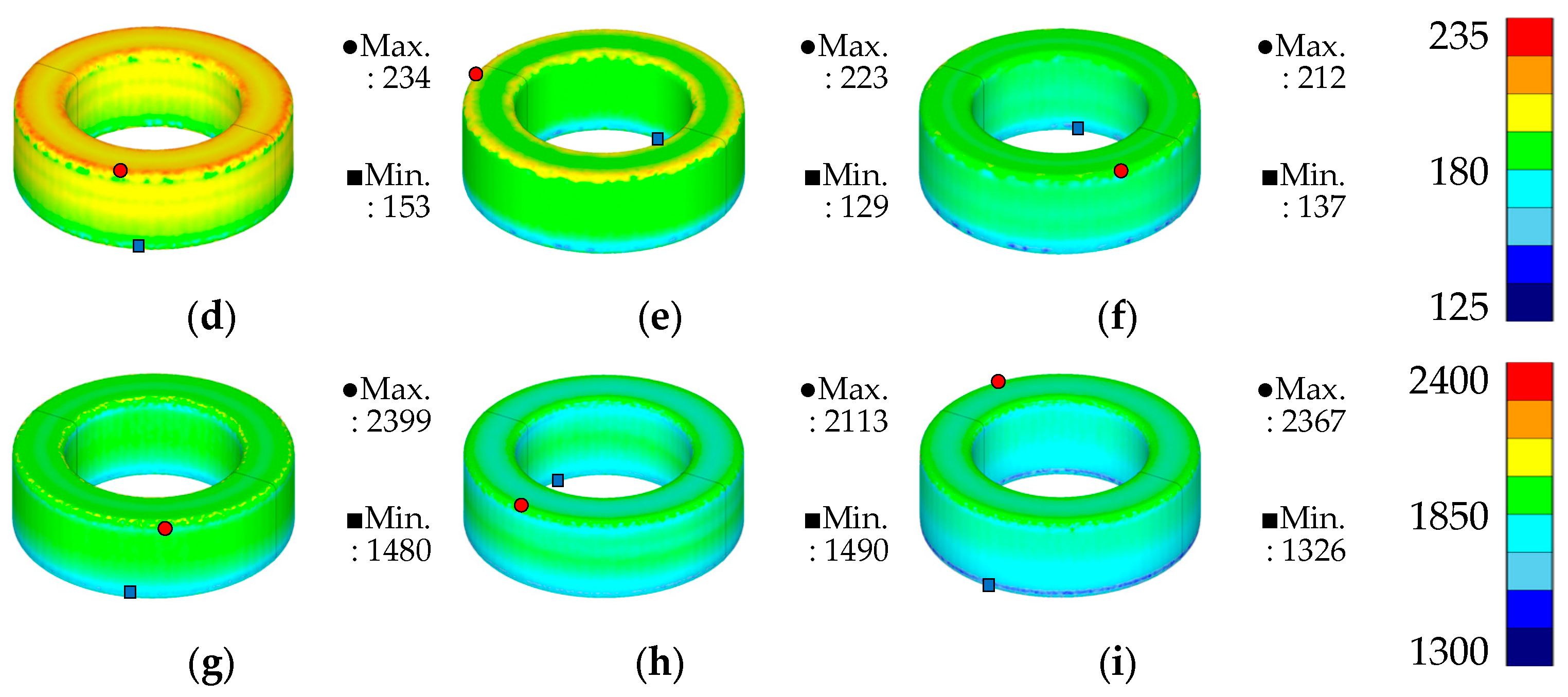

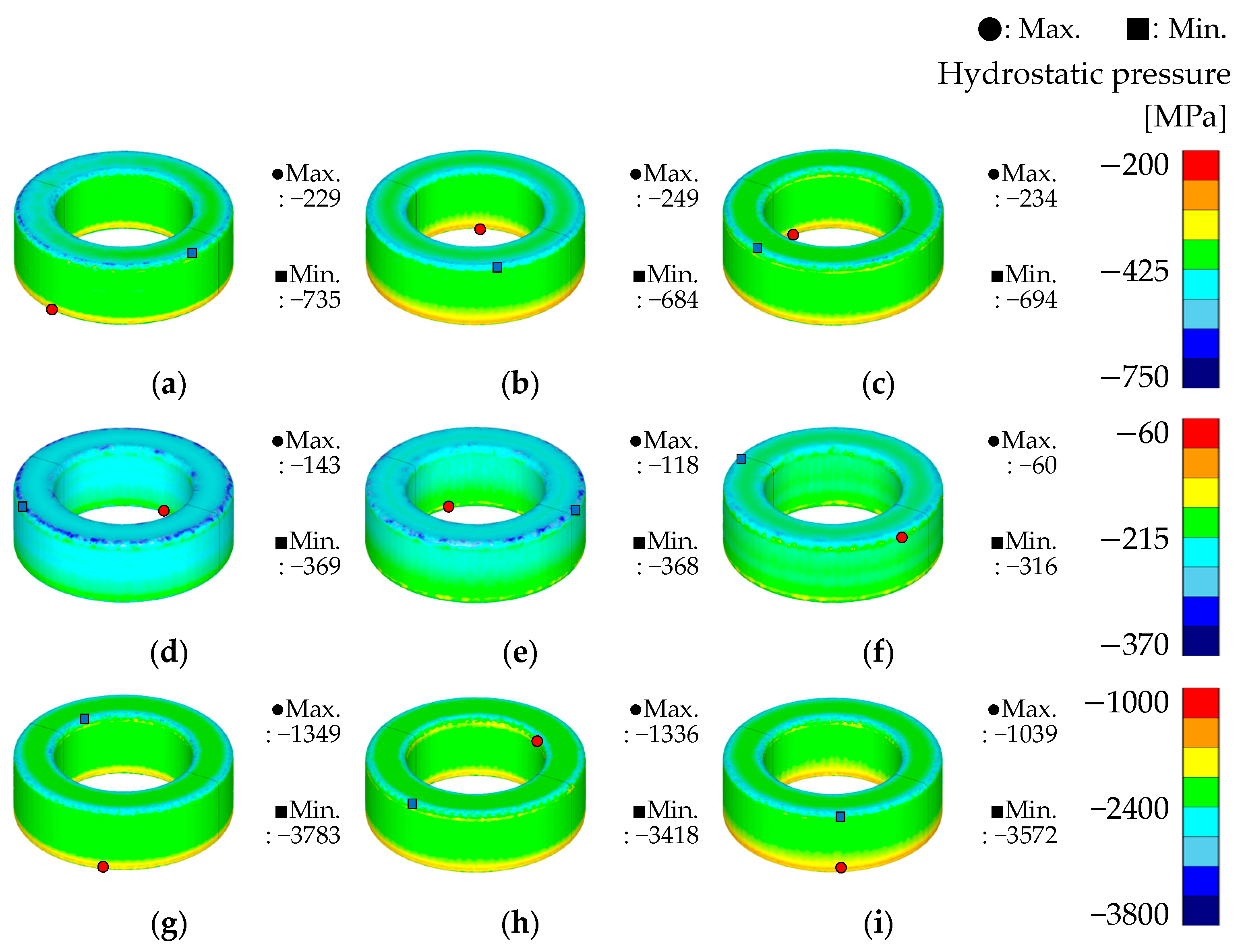

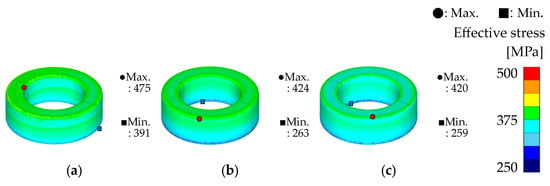

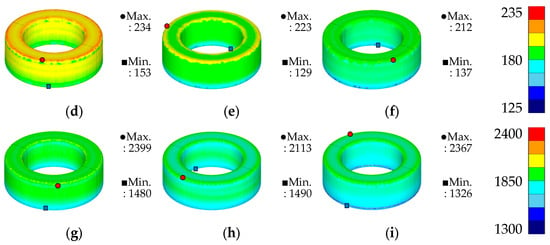

To determine the optimized conditions based on the powder compaction simulation results, the relative density, effective stress, and mean stress for each case were examined, and the results are illustrated in Figure 6, Figure 7 and Figure 8 and summarized in Table 11. In terms of effective stress and hydrostatic pressure, AncorLam HR, AncorLam, and Fe-6.5wt.%Si consistently showed decreasing values, in that order. This trend was attributed to the mechanical strength of each powder, which decreased in the order AncorLam HR, AncorLam, and Fe-6.5wt.%Si.

Figure 6.

Relative density results of DOE: Case (a) 1, (b) 2, (c) 3, (d) 4, (e) 5, (f) 6, (g) 7, (h) 8, and (i) 9.

Figure 7.

Effective stress results of DOE: Case (a) 1, (b) 2, (c) 3, (d) 4, (e) 5, (f) 6, (g) 7, (h) 8, and (i) 9.

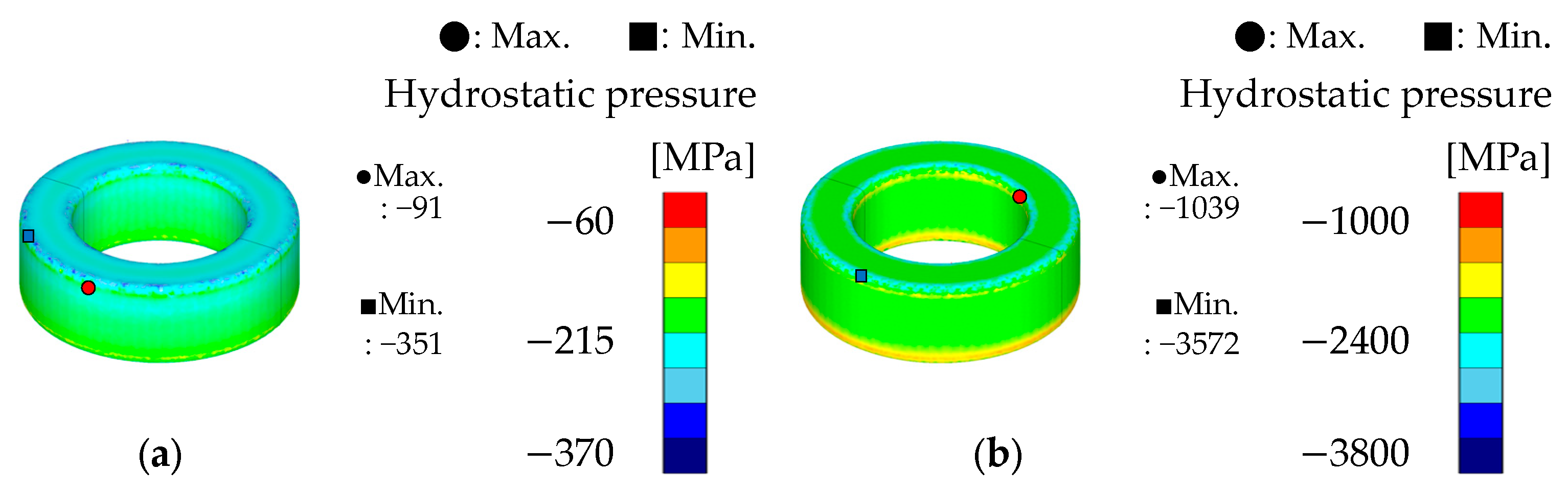

Figure 8.

Hydrostatic pressure results of DOE: Case (a) 1, (b) 2, (c) 3, (d) 4, (e) 5, (f) 6, (g) 7, (h) 8, and (i) 9.

Table 11.

Results for each case according to DOE.

In addition, the maximum density was concentrated in the upper round of the toroidal core, and the minimum density was concentrated in the lower round. As a result, it was observed that during the process of compressing the powder, the densification of the powder proceeded more at the top of the bulk, which was the part that the upper punch directly touched. In addition, the stress concentration phenomenon occurred according to the densification of the powder, as shown in Figure 7 and Figure 8, which shows the stress results and hydrostatic pressure results for each case.

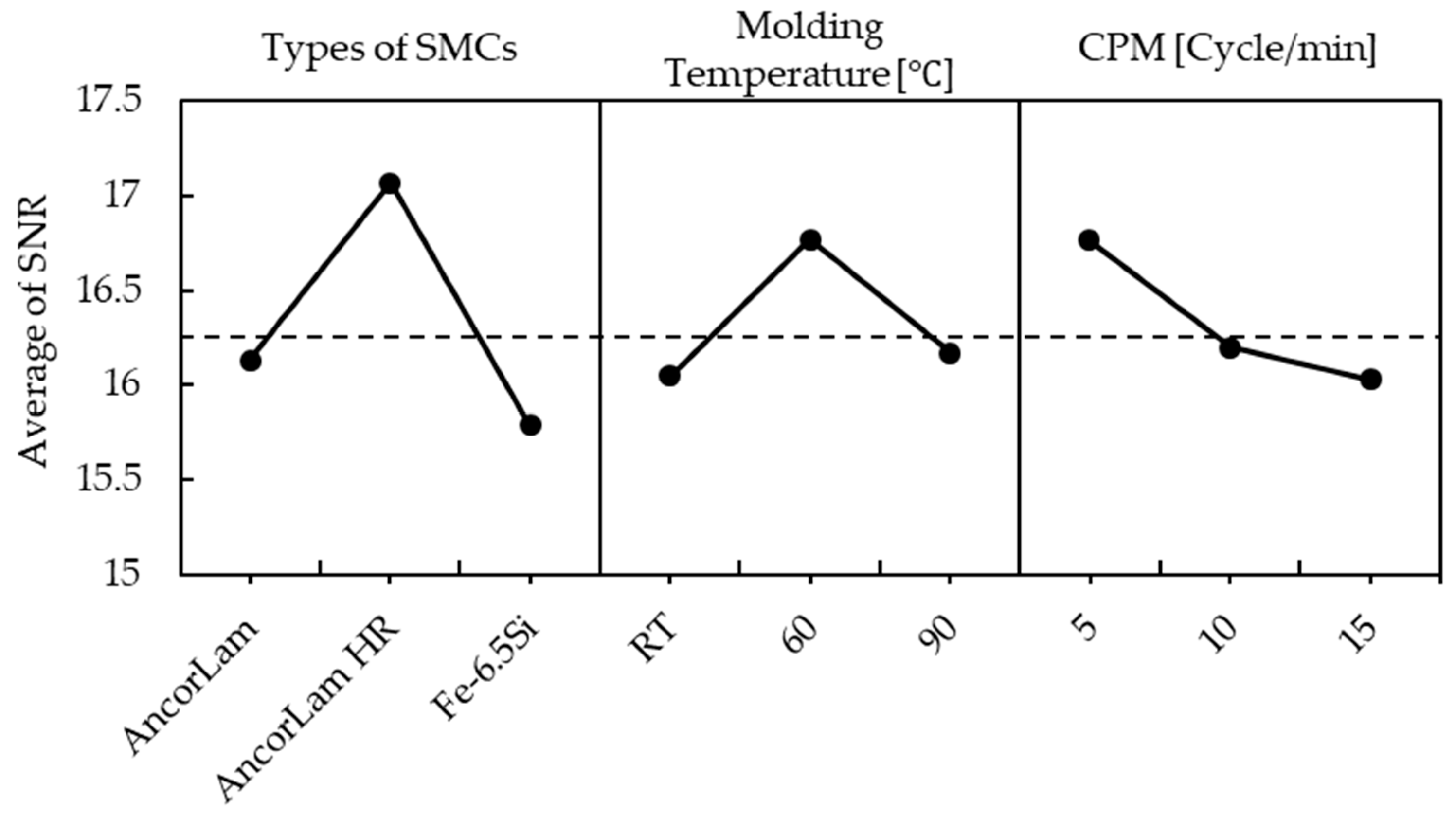

4.2. DOE Results

The maximum–minimum values of relative density, selected as the characteristic values of the experiment, were calculated using the smaller-the-better method. Smaller values indicated better product characteristics. The SNR results based on the difference between the maximum and minimum relative densities from the simulation results are summarized in Table 12. The SNR for each level of the control factors is shown in Table 13 and Figure 9. In the graph, the y-axis represents the SNR values, which indicate the quality of the output in response to the varying levels of the control factors. Higher SNR values correspond to better performance and lower variability of the process. The x-axis lists the different levels of each control factor being analyzed.

Table 12.

SNR results of L9(33) orthogonal array.

Table 13.

SNR results for each control factor.

Figure 9.

Average SNR of control factor represented graphically.

Simulation analysis results indicated that density variation occurred simultaneously in Cases 4 and 8, with the maximum SNR observed in Case 8. The SNR analysis for each control factor revealed that the factors influencing density variation were, in order of significance, the type of SMC powder, CPMs, and forming temperature. The optimal conditions were determined to be AncorLam HR, 60 °C, and five CPMs, as these levels yielded the highest SNR for each control factor.

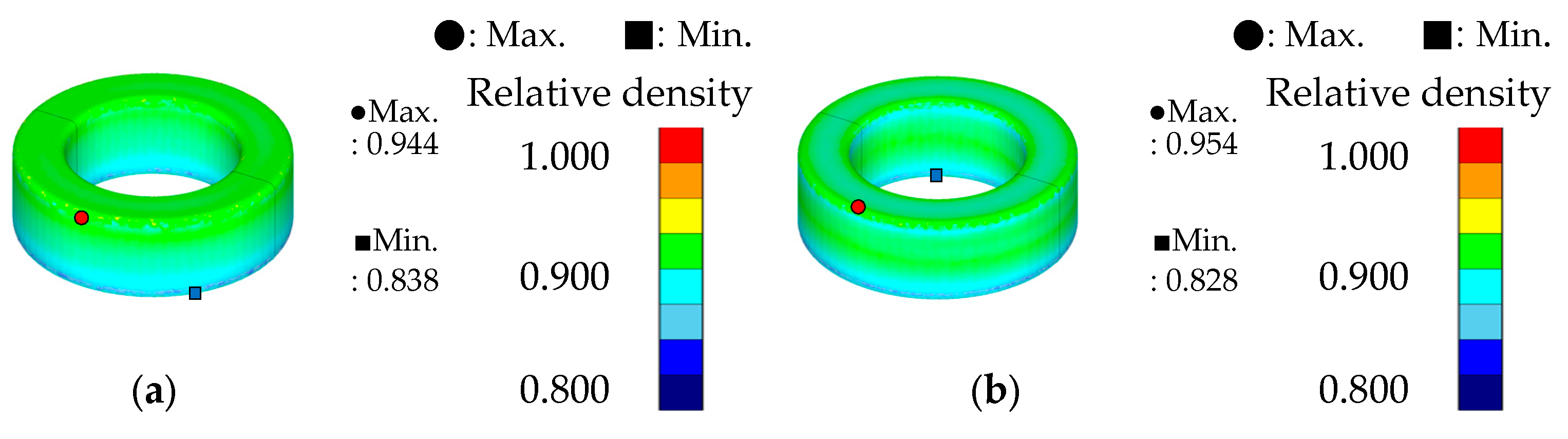

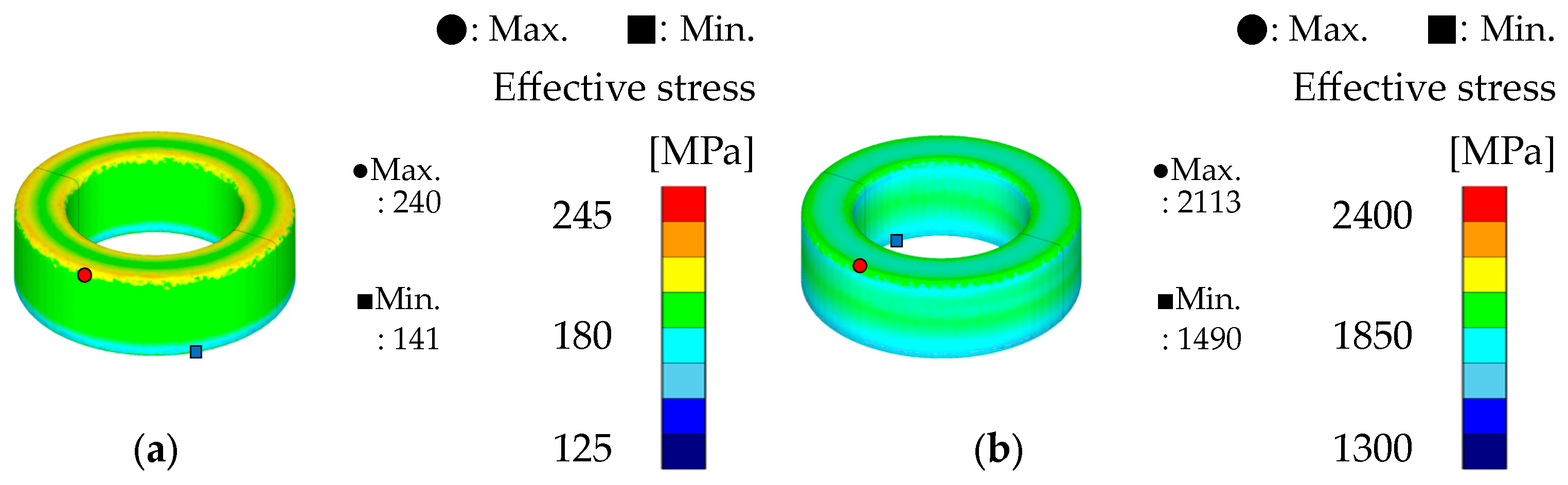

4.3. Optimal Condition Simulation

The optimal conditions of AncorLam HR, 60 °C, and five CPMs were selected for the powder compaction simulation, based on the SNR of each factor from the experimental design. The results of the optimal condition simulation were compared with those of Case 8, which had the maximum SNR, and are illustrated in Figure 10, Figure 11 and Figure 12 and summarized in Table 14. Under optimal process conditions, the deviation between the maximum and minimum relative densities decreased by 0.02 compared with Case 8. Analysis of the density results in Figure 10 revealed a reduction in the low-density distribution occurring at the top of the green body. In addition, it was confirmed that the tendency for maximum and minimum densities to appear under optimal conditions was similar. Similarities were also confirmed in the effective stress results and the hydrostatic pressure results. The effective stress under the optimal conditions was 1642.879 MPa lower than that in Case 8. Additionally, the hydrostatic pressure under optimal conditions decreased by 1883.19 MPa compared with Case 8, indicating a more uniform pressure distribution within the green body.

Figure 10.

Relative density results: (a) optimal conditions and (b) Case 8.

Figure 11.

Effective stress results: (a) optimal conditions and (b) Case 8.

Figure 12.

Hydrostatic pressure results: (a) optimal conditions and (b) Case 8.

Table 14.

Comparison of optimal case results according to DOE.

These results suggest that the forming process using the optimal conditions led to a reduction in internal defects and an overall improvement in performance compared with Case 8, which had the maximum SNR value.

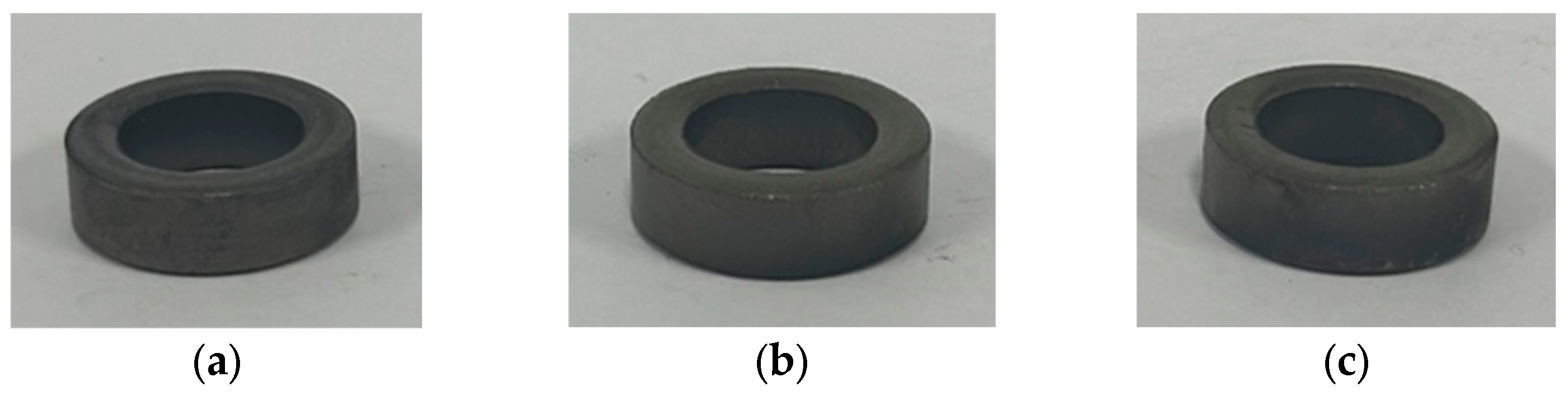

4.4. Validation of Toroidal Core Production

4.4.1. Density Analysis

Density tests were conducted following the KS-D-0033 standard [39]. The testing apparatus used was an XS204 from METTLER-TOLEDO (METTLER-TOLEDO, Columbus, OH, USA). Due to the porous nature of the specimen, paraffin coating was applied before measurement using the Archimedes method. The specimens used are illustrated in Figure 13. In addition to density measurements, the outer diameter, inner diameter, and height of each specimen were also measured, and these measurements are detailed in Table 15.

Figure 13.

Shape of specimen for density measurement: Specimen (a) 1, (b) 2 and (c) 3.

Table 15.

Linear dimensions of density specimens.

To validate the optimal process conditions derived using the Taguchi experimental design method, three toroidal samples were produced under these conditions. The shapes of the fabricated samples are shown in Figure 13. The densities of the samples were measured to be 7.465, 7.397, and 7.438 g/cm3, with an average density of 7.433 g/cm3. The error rate compared with the simulation target density of 7.4 g/cm3 was 0.45%.

The dimensional consistency between specimens well demonstrated the effectiveness of the optimized process conditions. Despite some fluctuations in height and volume, the density measurement results showed high uniformity, ensuring consistency of mechanical and electrical properties. Minor errors in the density results indicated that the derived process conditions were effective in producing reliable specimens. Density uniformity improves the performance of the final product and plays an important role in reducing energy loss.

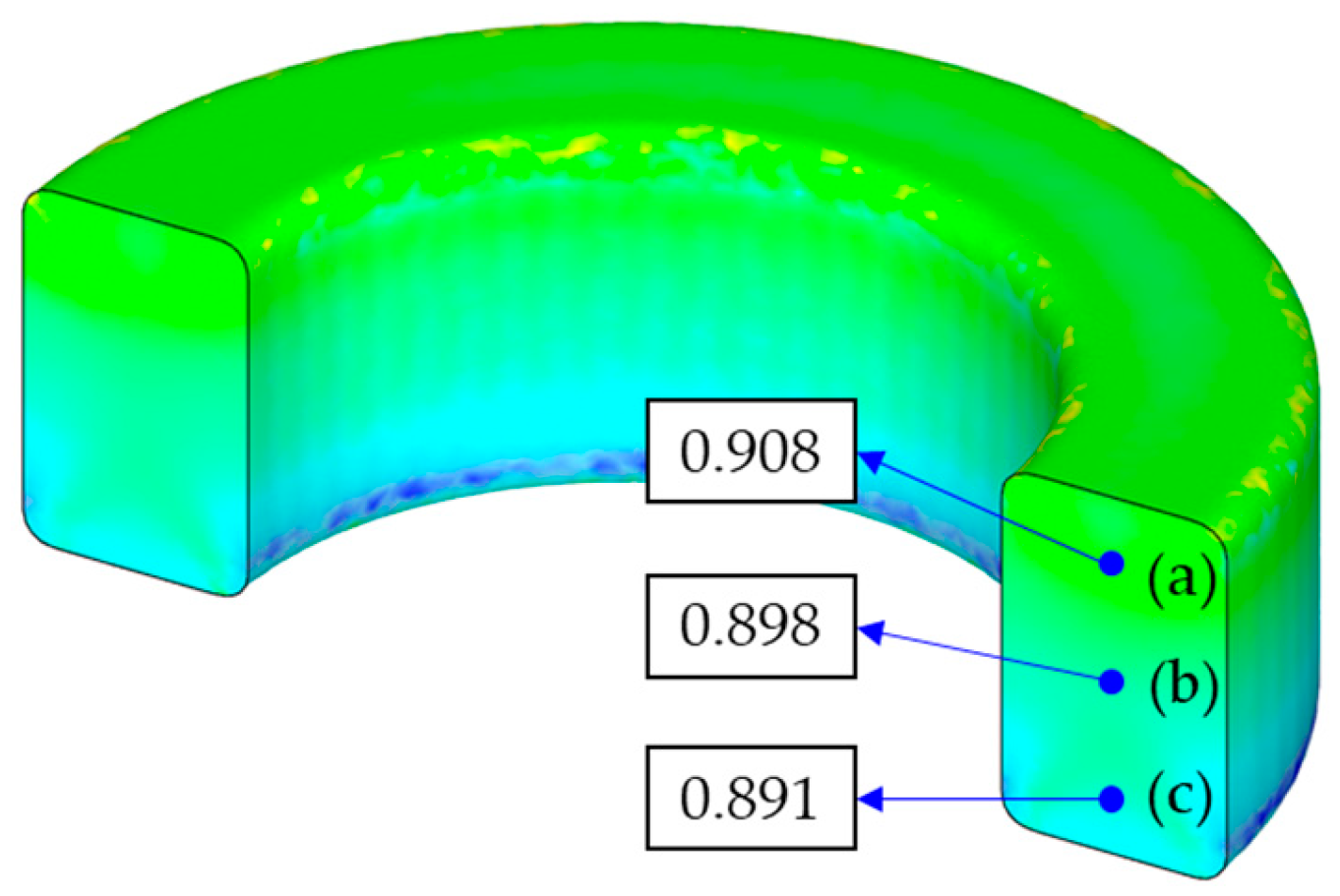

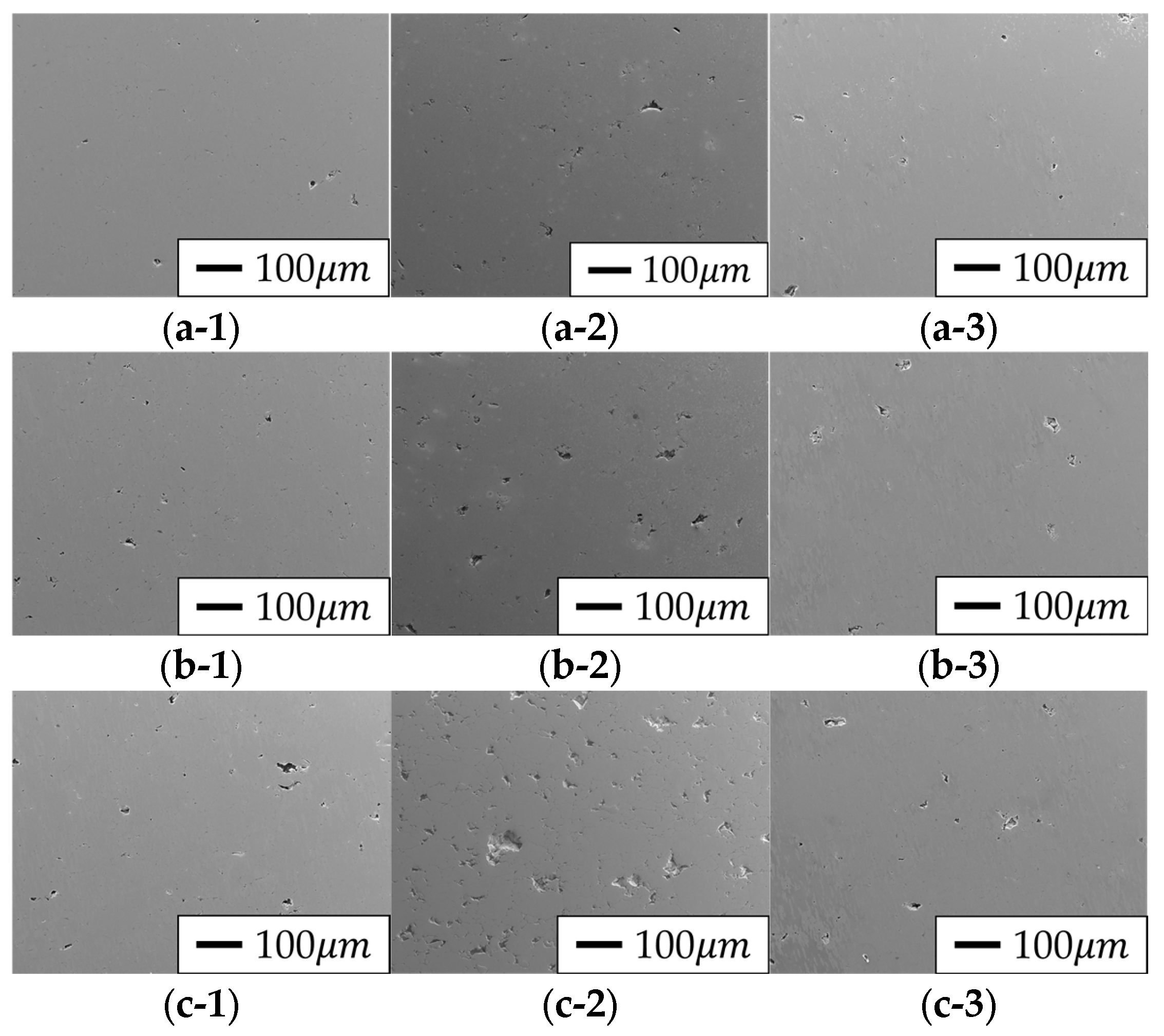

4.4.2. SEM Analysis

The SEM analysis was conducted using a JSM-7900F (JEOL Ltd., Tokyo, Japan). The pre-treatment shape of the SEM analysis samples is depicted in Figure 14. To facilitate comparison with the powder compaction simulation, the cross-sectional shape was divided into upper, middle, and lower sections at heights of 5, 3, and 1 mm from the bottom, respectively, as illustrated in Figure 15. The SEM images of these sections magnified 100 times are presented in Figure 16.

Figure 14.

SEM specimen.

Figure 15.

Relative density at three height points of the toroidal core.

Figure 16.

(a-1–a-3) SEM of upper point; (b-1–b-3) SEM of middle point; and (c-1–c-3) SEM of lower point.

Comparative analysis of the SEM and simulation results indicated that both showed higher densities in the upper, middle, and lower sections, in that order. This outcome is attributed to the uniaxial pressing method adopted in both the simulation and actual production of the toroidal core. The uniaxial pressing method tends to result in greater density variations between the top and bottom of the molded body compared with the bidirectional compression method. Therefore, further research is expected to improve this aspect by exploring alternative compression methods such as bidirectional compression and floating die compression techniques, which may help achieve more uniform density distribution throughout the molded body [40].

5. Conclusions

In this study, we systematically analyzed the impact of SMC material properties on the powder-metallurgy forming process and proposed a material-selection process for various motor types and shapes. Utilizing the Taguchi design method, we identified powder type, forming temperature, and forming speed as the main control factors. By evaluating the maximum–minimum deviation of relative density, we ensured the uniformity of SMC materials and derived optimized process conditions. Analysis of the simulation results revealed the relative density, effective stress, and mean stress for each case. Effective stress and hydrostatic pressure were lowest in the order AncorLam HR, AncorLam, and Fe-6.5wt.%Si, aligning with the mechanical strength of each powder.

Employing DOE, we calculated the maximum–minimum relative density as a smaller-the-better characteristic and conducted SNR analysis. Case 8 exhibited the maximum SNR, leading to the determination of optimal conditions as AncorLam HR, 60 °C, and five CPMs. The derived optimal condition demonstrated a 0.02 reduction in the deviation between the maximum and minimum relative density compared with Case 8. Furthermore, it exhibited a decrease in low-density distribution at the top of the molded body. Both effective stress and hydrostatic pressure were reduced, indicating a more uniform pressure distribution within the molded body.

To verify the derived optimal process conditions, toroidal samples were produced and compared with the simulation results. The samples exhibited an average density with an error rate of 0.3% compared with the simulation target density, and SEM analysis results were consistent with the simulation, ensuring high reliability. However, the uniaxial pressing method caused density variations between the top and bottom, suggesting a potential area for improvement through further research.

These results underscore how selecting optimal materials and appropriate process conditions for each SMC material can enhance motor performance. This study provides essential foundational data that can enhance the utilization of SMC materials and contribute to improving motor performance.

This study selected optimal compression-molding conditions to maximize the mechanical properties of SMC materials, and further studies will be conducted to change electrical properties during processing and optimize them through processing under selected conditions.

Author Contributions

Conceptualization, S.L.; methodology, S.K. and S.L.; validation, S.K. and S.L.; formal analysis, S.L.; investigation, S.K.; software S.K.; data analysis, S.K. and S.L.; data curation, S.K.; writing—original draft preparation, S.K.; writing—review and editing, S.L.; supervision, S.L.; project administration, S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This paper and research were supported by a Korea Institute for Advancement of Technology (KIAT) grant funded by the Korea Government (MOTIE). (P0020536, HRD Program for Industrial Innovation).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Průša, F.; Proshchenko, O.; Školáková, A.; Kučera, V.; Laufek, F. Properties of FeAlSi-X-Y Alloys (X, Y = Ni, Mo) Prepared by Mechanical Alloying and Spark Plasma Sintering. Materials 2020, 13, 292. [Google Scholar] [CrossRef] [PubMed]

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Guo, Y.; Ba, X.; Liu, L.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. A Review of Electric Motors with Soft Magnetic Composite Cores for Electric Drives. Energies 2023, 16, 2053. [Google Scholar] [CrossRef]

- Xie, Y.; Yan, P.; Yan, B. Enhanced Soft Magnetic Properties of Iron-Based Powder Cores with Co-Existence of Fe3O4–MnZnFe2O4 Nanoparticles. Metals 2018, 8, 702. [Google Scholar] [CrossRef]

- Persson, M.; Jansson, P. Advances in Powder Metallurgy Soft Magnetic Composite Materials for Electrical Machines; IET Digital Library: London, UK, 1995. [Google Scholar]

- Boehm, A.; Hahn, I. Comparison of soft magnetic composites (SMCs) and electrical steel. In Proceedings of the 2012 2nd International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 15–18 October 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1–6. [Google Scholar]

- Sadeghi, B.; Cavaliere, P. Progress of flake powder metallurgy research. Metals 2021, 11, 931. [Google Scholar] [CrossRef]

- Huang, P.Y. Principles of Powder Metallurgy; China Metallurgy & Industry Press: Beijing, China, 1997. [Google Scholar]

- Saxena, A.; Saxena, K.K.; Jain, V.K.; Rajput, S.; Pathak, B. A review of reinforcements and process parameters for powder metallurgy-processed metal matrix composites. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Li, S.; Peng, K.; Zou, L. The improved magnetic properties of FeSi powders cores composed with different size particles. J. Mater. Sci. Mater. Electron. 2022, 33, 607–616. [Google Scholar] [CrossRef]

- Strondl, A.; Lyckfeldt, O.; Brodin, H.; Ackelid, U. Characterization and control of powder properties for additive manufacturing. Jom 2015, 67, 549–554. [Google Scholar] [CrossRef]

- Blumenthal, W.R.; Sheinberg, H.; Bingert, S.A. Compaction issues in powder metallurgy. MRS Bull. 1997, 22, 29–33. [Google Scholar] [CrossRef]

- Hammi, Y.; Stone, T.Y.; Horstemeyer, M.F. Constitutive modeling of metal powder behavior during compaction. SAE Trans. 2005, 114, 293–299. [Google Scholar]

- Bai, Y.; Li, L.; Fu, L.; Wang, Q. A review on high velocity compaction mechanism of powder metallurgy. Sci. Prog. 2021, 104, 00368504211016945. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Zhang, Y.; Wang, R.; Wei, F.; Zeng, L.; Liu, M. Finite Element Modeling and Optimization Analysis of Cutting Force in Powder Metallurgy Green Compacts. Processes 2023, 11, 3186. [Google Scholar] [CrossRef]

- Kim, H.-R.; Lee, D.; Yang, S.; Kwon, Y.-T.; Kim, J.; Kim, Y.; Jeong, J.-W. Optimizing Annealing Temperature Control for Enhanced Magnetic Properties in Fe-Si-B Amorphous Flake Powder Cores. Metals 2023, 13, 2016. [Google Scholar] [CrossRef]

- Nayak, K.C.; Rane, K.K.; Date, P.P.; Srivatsan, T.S. Synthesis of an aluminum alloy metal matrix composite using powder metallurgy: Role of sintering parameters. Appl. Sci. 2022, 12, 8843. [Google Scholar] [CrossRef]

- Kotnala, R.K.; Ahmad, S.; Ahmed, A.S.; Shah, J.; Azam, A. Investigation of structural, dielectric, and magnetic properties of hard and soft mixed ferrite composites. J. Appl. Phys. 2012, 112, 054323. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, C.; Zhang, X.; Si, Y.; Yu, J.; Ding, B. Super strong, shear resistant, and highly elastic lamellar structured ceramic nanofibrous aerogels for thermal insulation. J. Mater. Chem. A 2021, 9, 27415–27423. [Google Scholar] [CrossRef]

- Lu, L.; Wu, W.; Yu, X.; Jin, Z. High-temperature superconducting non-insulation closed-loop coils for electro-dynamic suspension system. Electronics 2021, 10, 1980. [Google Scholar] [CrossRef]

- Yuan, X.; Qu, X.; Yin, H.; Feng, Z.; Tang, M.; Yan, Z.; Tan, Z. Effects of sintering temperature on densification, microstructure and mechanical properties of Al-based alloy by high-velocity compaction. Metals 2021, 11, 218. [Google Scholar] [CrossRef]

- Burgess, W.; Devkota, J.; Howard, B. Wet chemistry-synthesized Fe/mixed ferrite soft magnetic composites for high-frequency power conversion. AIP Adv. 2024, 14, 025212. [Google Scholar] [CrossRef]

- Liu, C.; Lu, J.; Wang, Y.; Lei, G.; Zhu, J.; Guo, Y. Design Issues for claw pole machines with soft magnetic composite cores. Energies 2018, 11, 1998. [Google Scholar] [CrossRef]

- Pošković, E.; Franchini, F.; Ferraris, L.; Carosio, F.; Grande, M.A. Rapid characterization method for SMC materials for a preliminary selection. Appl. Sci. 2021, 11, 12133. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, L.; Ba, X.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. Designing high-power-density electric motors for electric vehicles with advanced magnetic materials. World Electr. Veh. J. 2023, 14, 114. [Google Scholar] [CrossRef]

- Pošković, E.; Franchini, F.; Ferraris, L.; Fracchia, E.; Bidulska, J.; Carosio, F.; Bidulsky, R.; Grande, M.A. Recent advances in multi-functional coatings for soft magnetic composites. Materials 2021, 14, 6844. [Google Scholar] [CrossRef] [PubMed]

- ASTM E209; Standard Practice for Compression Tests of Metallic Materials at Elevated Temperatures with Conventional or Rapid Heating Rates and Strain Rates. ASTM: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/e0209-00.html (accessed on 16 August 2017).

- KS-L-1604; Fine Ceramics—Determination of Thermal Diffusivity, Specific Heat Capacity, and Thermal Conductivity of Monolithic Ceramics by Laser Flash Method. Korean Agency for Technology and Standards: Eumseong-gun, Republic of Korea, 2022.

- ASTM E228; Standard Test Method for Linear Thermal Expansion of Solid Materials with a Push-Rod Dilatometer. ASTM: West Conshohocken, PA, USA, 2022. Available online: https://www.astm.org/e0228-22.html (accessed on 9 January 2023).

- Kim, J.; Lee, S. Study on Compressibility According to Mixing Ratio and Milling Time of Fe-6.5 wt.% Si. Materials 2024, 17, 1723. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, A.; Ganesh Narayanan, R.; Dixit, U.S. Implementation of Yield Criteria in ABAQUS for Simulations of Deep Drawing: A Review and Preliminary Results. Manuf. Eng. Sel. Proc. CPIE 2019, 2020, 575–588. [Google Scholar]

- Luo, X.; Liu, Y.; Mo, Z.; Gu, C. Semi-solid powder rolling of AA7050 alloy strips: Densification and deformation behaviors. Metall. Mater. Trans. A 2015, 46, 2185–2193. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, X. Deduction of a porosity-dependent yield criterion and its geometrical description for porous materials. Int. J. Mech. Sci. 2014, 89, 58–64. [Google Scholar] [CrossRef]

- Ternero, F.; Rosa, L.G.; Urban, P.; Montes, J.M.; Cuevas, F.G. Influence of the total porosity on the properties of sintered materials—A review. Metals 2021, 11, 730. [Google Scholar] [CrossRef]

- Liu, C.; Lei, G.; Ma, B.; Guo, Y.; Zhu, J. Robust design of a low-cost permanent magnet motor with soft magnetic composite cores considering the manufacturing process and tolerances. Energies 2018, 11, 2025. [Google Scholar] [CrossRef]

- Tsui, K.-L. An overview of Taguchi method and newly developed statistical methods for robust design. Iie Trans. 1992, 24, 44–57. [Google Scholar] [CrossRef]

- Lee, S.-L.; Kim, J.-H.; Lee, S.-B. A Study on mPPO Development and Injection Molding Process for Lightweight Stack Enclosure of FCEV. Polymers 2023, 15, 1303. [Google Scholar] [CrossRef] [PubMed]

- Hrairi, M.; Chtourou, H.; Gakwaya, A.; Guillot, M. Modeling the powder compaction process using the finite element method and inverse optimization. Int. J. Adv. Manuf. Technol. 2011, 56, 631–647. [Google Scholar] [CrossRef]

- KS-D-0033; Sintering Density Test Method for Metal Sintered Body. Korean Agency for Technology and Standards: Eumseong-gun, Republic of Korea, 2021.

- Grigoriev, S.N.; Dmitriev, A.M.; Korobova, N.V.; Fedorov, S.V. A cold-pressing method combining axial and shear flow of powder compaction to produce high-density iron parts. Technologies 2019, 7, 70. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).