Tensile Properties and Fracture Analysis of Duplex (2205) and Super Duplex (2507) Stainless Steels, Produced via Laser Powder Bed Fusion Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

2.1. DSS and SDSS Powders

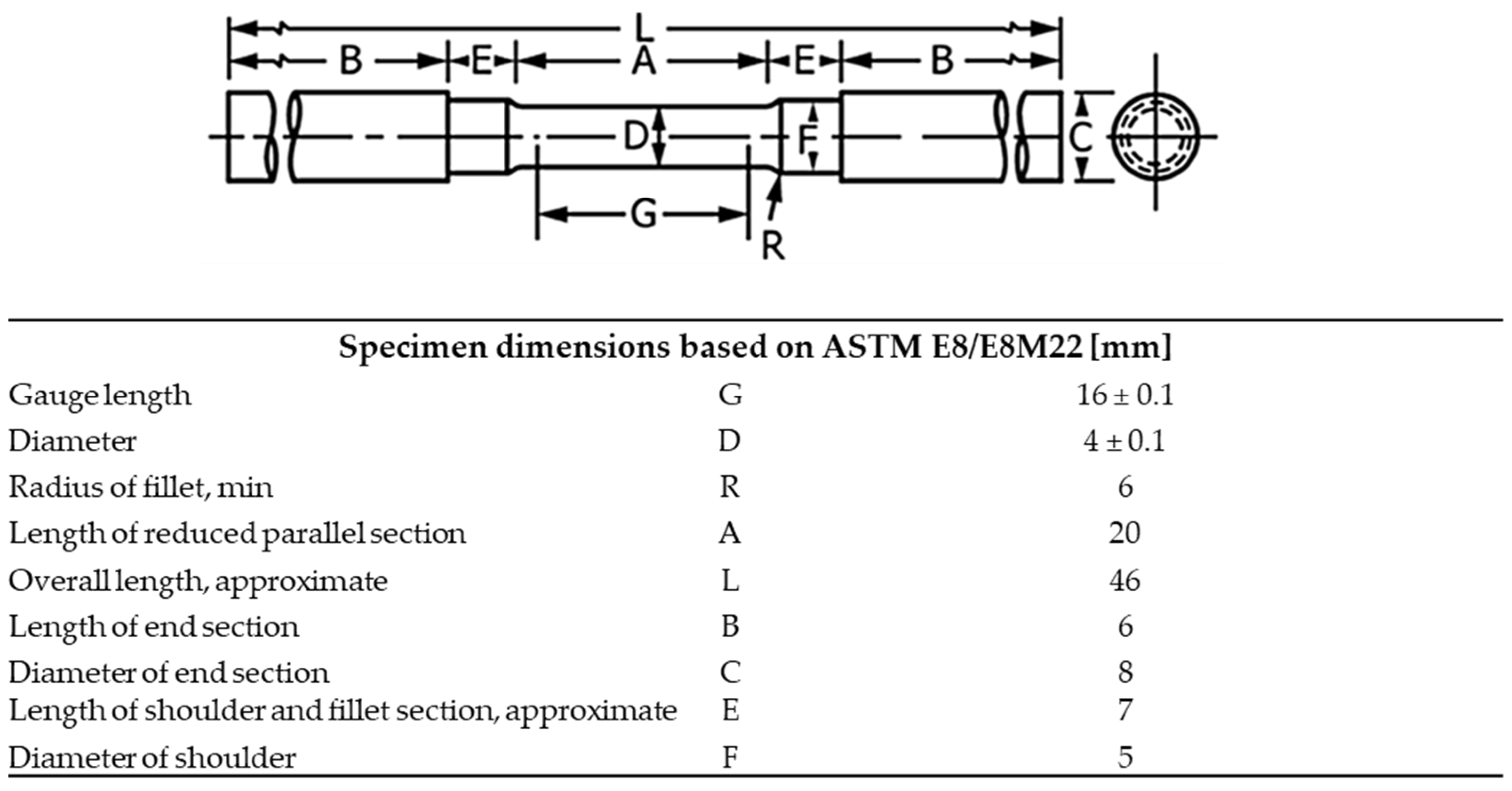

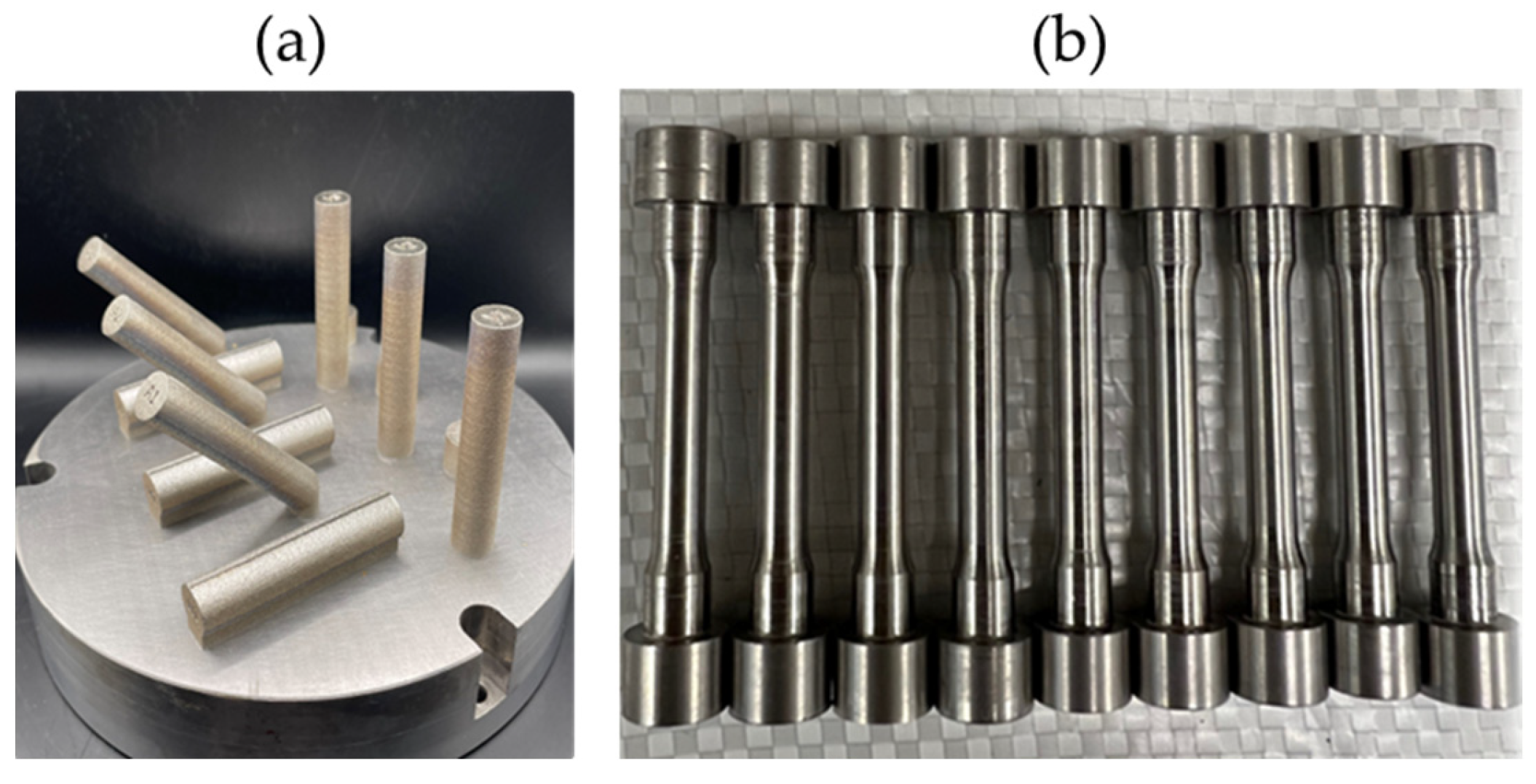

2.2. Manufacturing of Tensile Bars and Heat Treatment Procedures

2.3. Fracture Surface and Microstructure Examination

3. Results

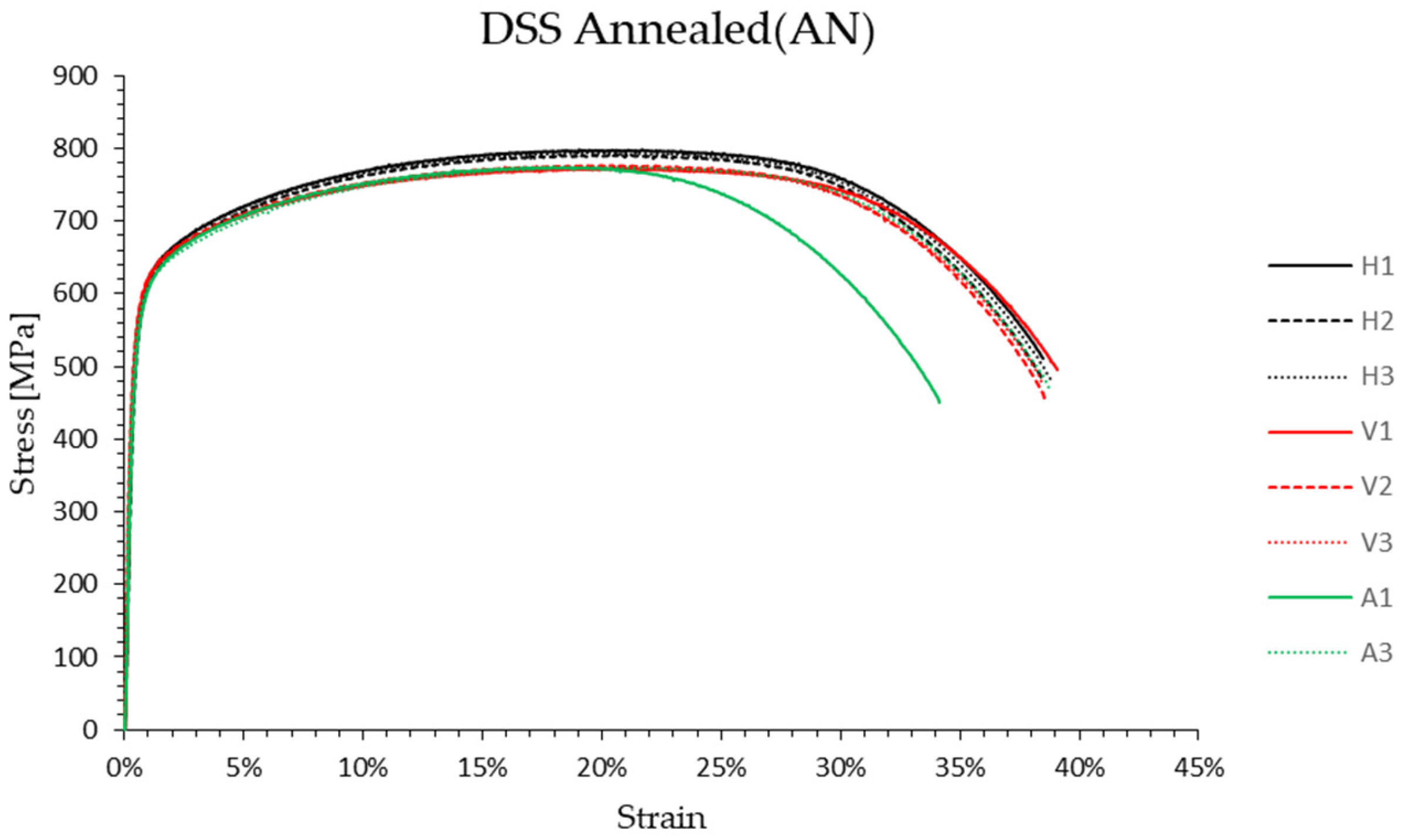

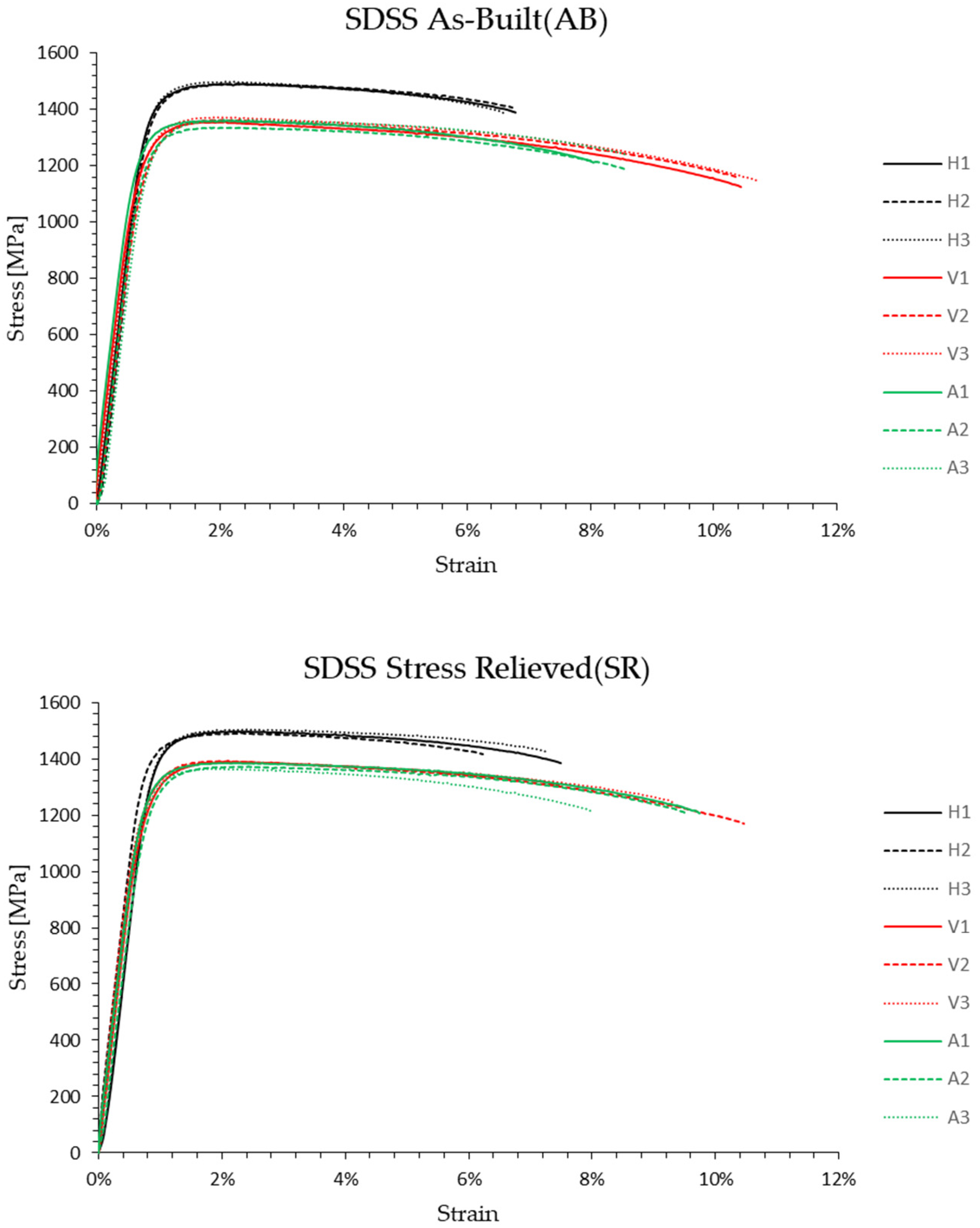

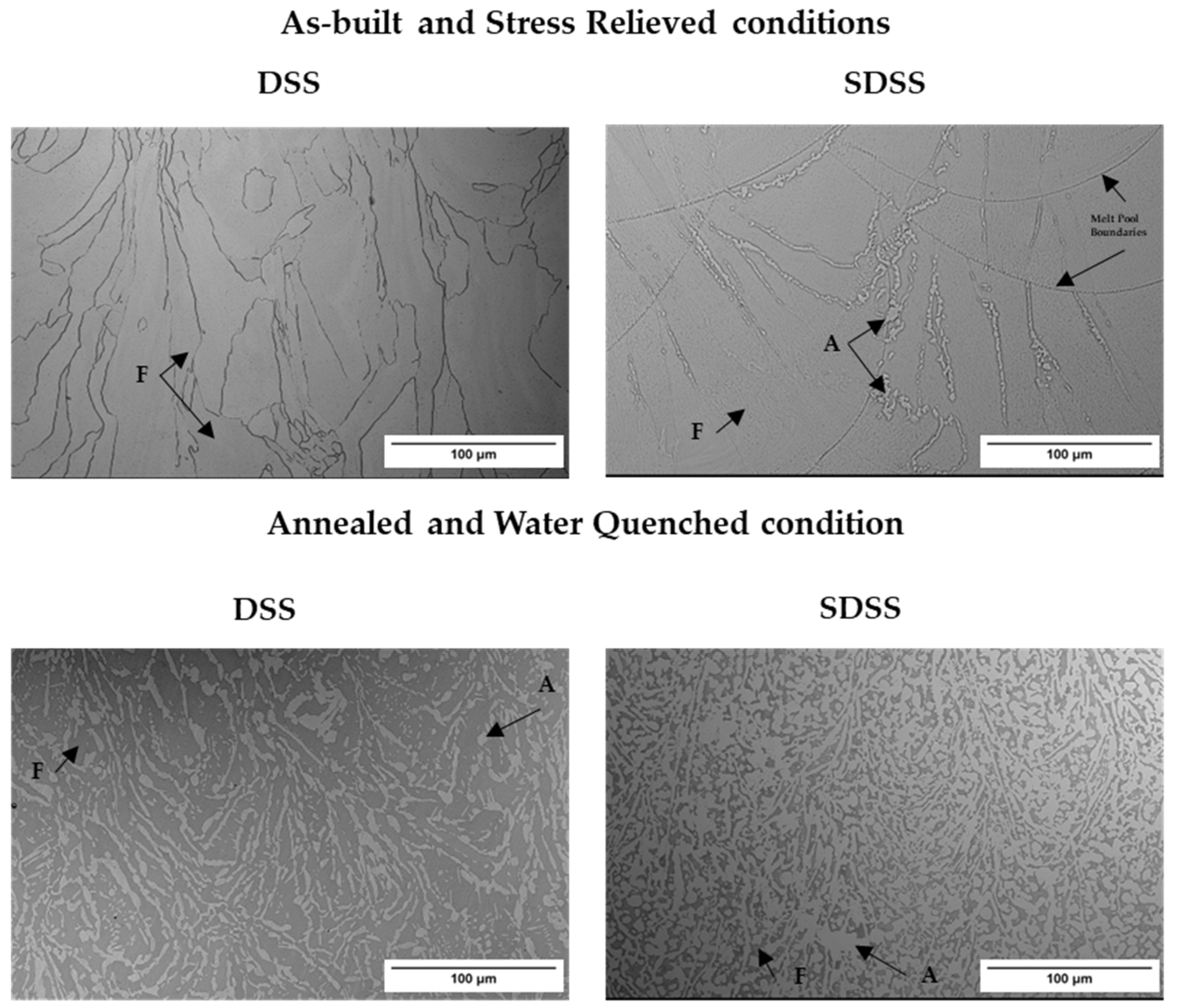

3.1. Mechanical Properties and Microstructure

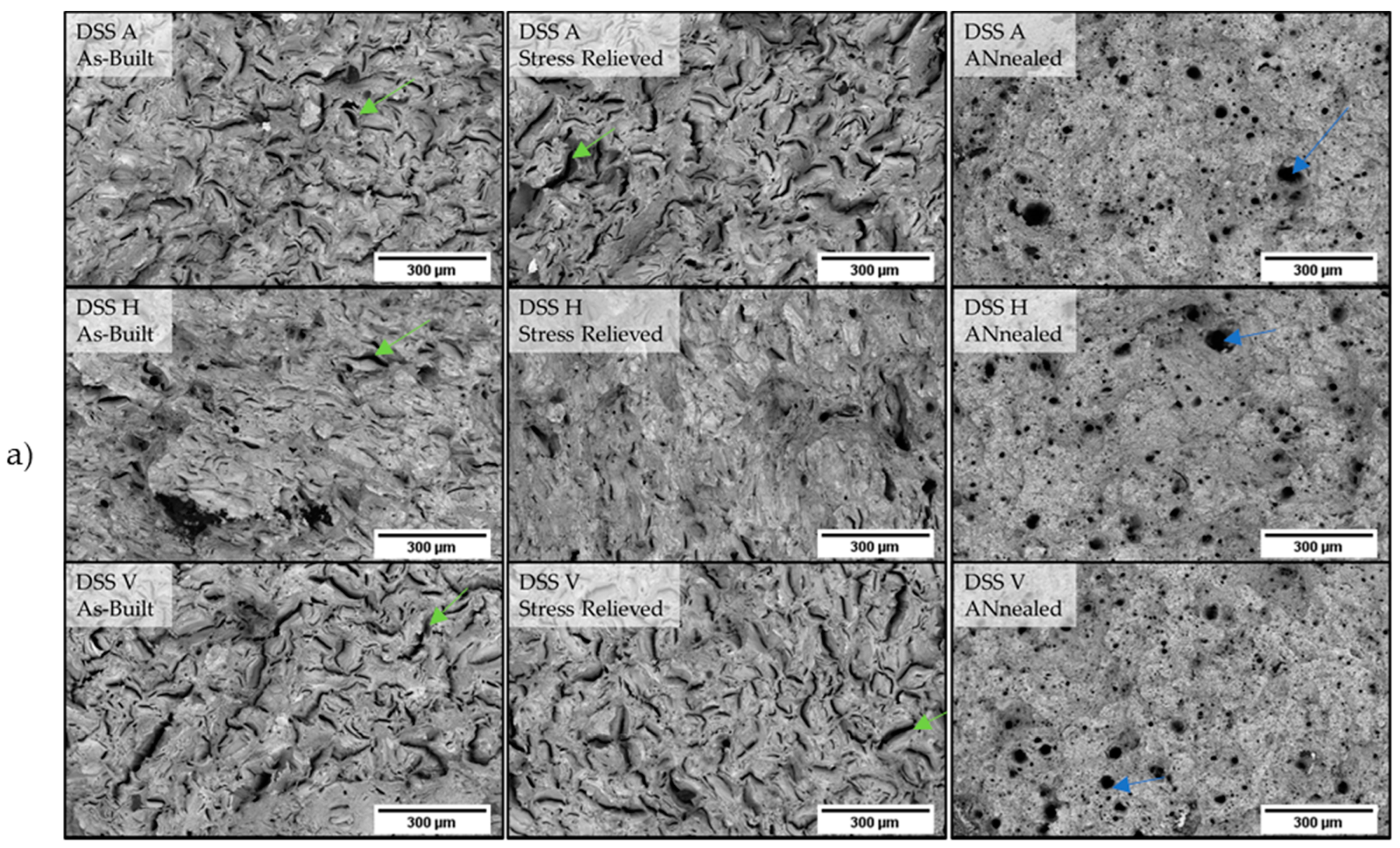

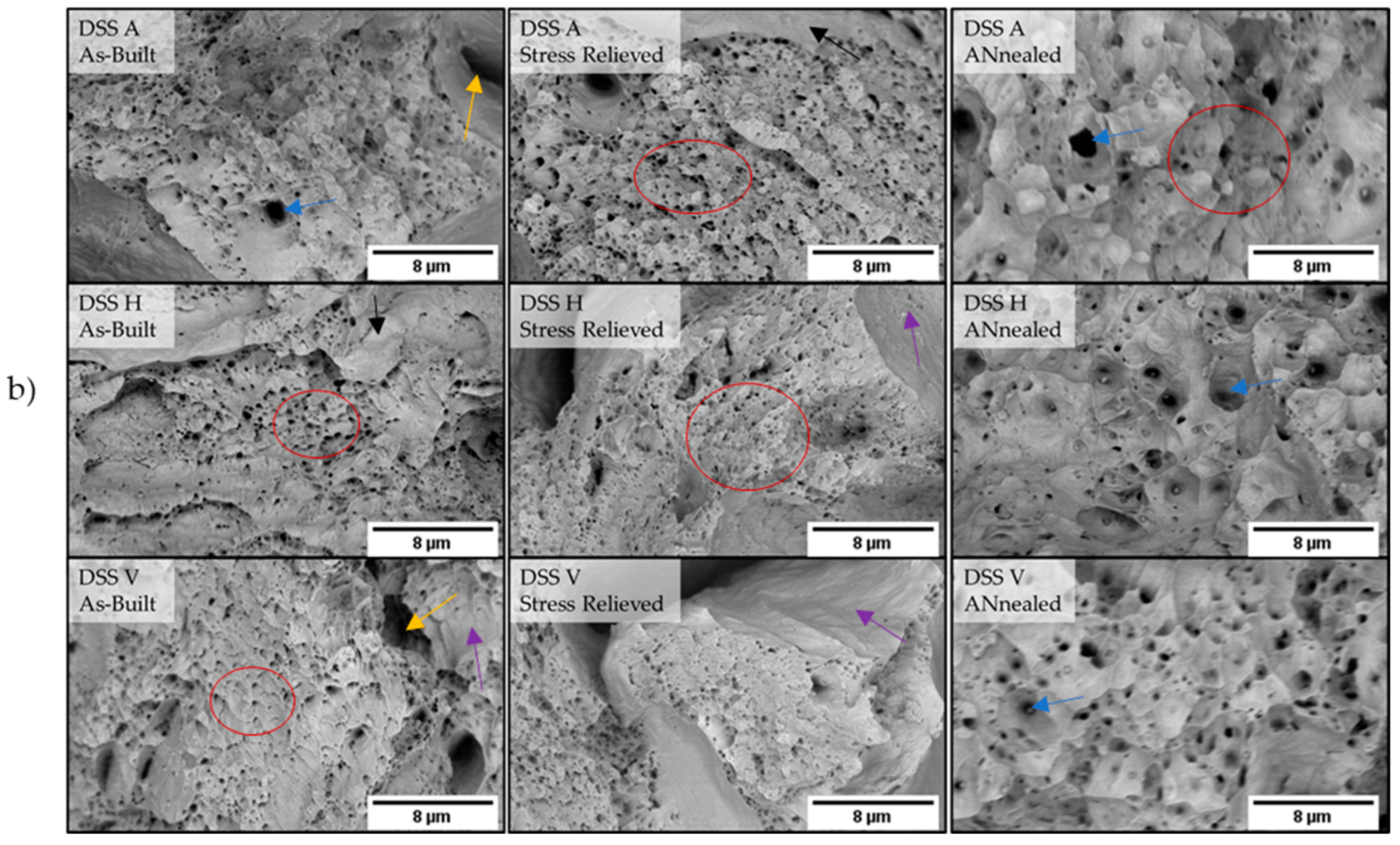

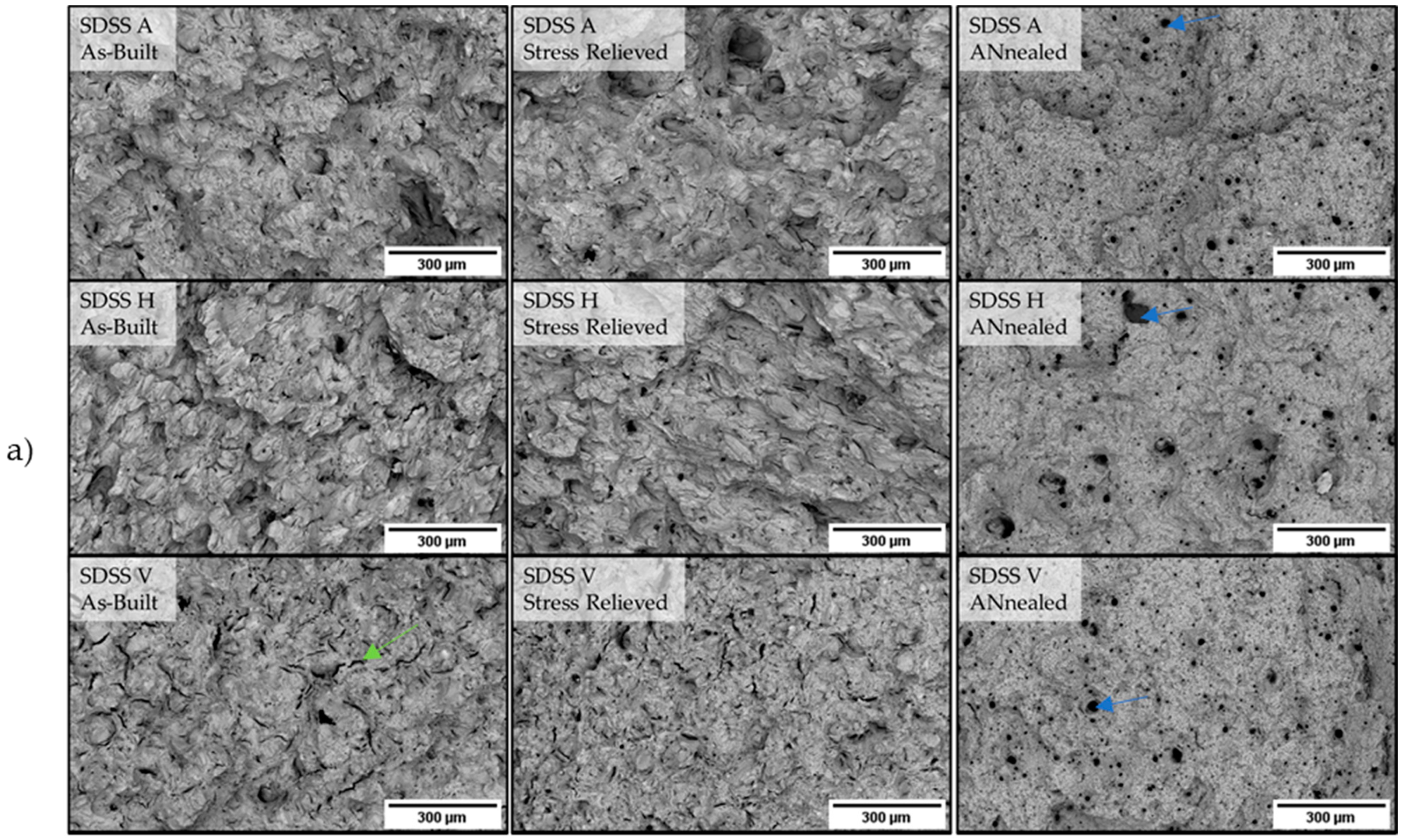

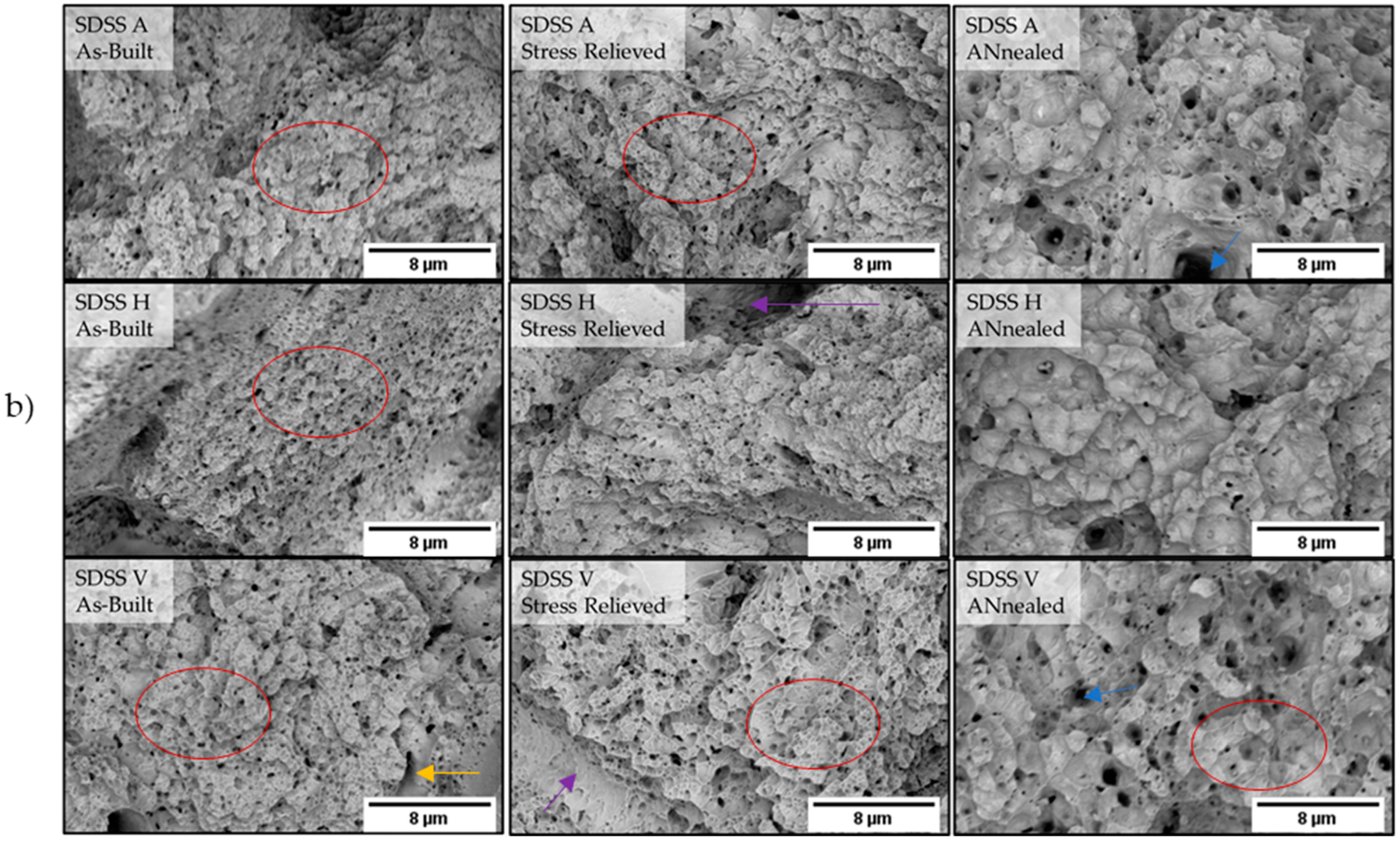

3.2. Fractography

4. Discussion

4.1. Effect of Heat Treatments

4.2. Effect of Build Orientations

4.3. Comparisons of Mechanical Properties between Manufacturing Methods

4.4. Fractographic Analysis

5. Conclusions

- DSS and SDSS alloys manufactured by LPBF exhibit better mechanical properties when compared with existing literature values for parts produced either by LPBF or by conventional manufacturing (as-cast, hot-rolled, and cold-rolled).

- DSS and SDSS in the as-built state feature high YS and UTS (greater than 1000 Mpa) accompanied by low EL (lower than 20%) due to their fully ferritic microstructure. The higher alloying element content in SDSS leads to superior YS and UTS but lower elongation (EL) compared to DSS.

- Stress relief annealing at 300 °C does not significantly alter mechanical properties of both alloys, as the microstructure does not change.

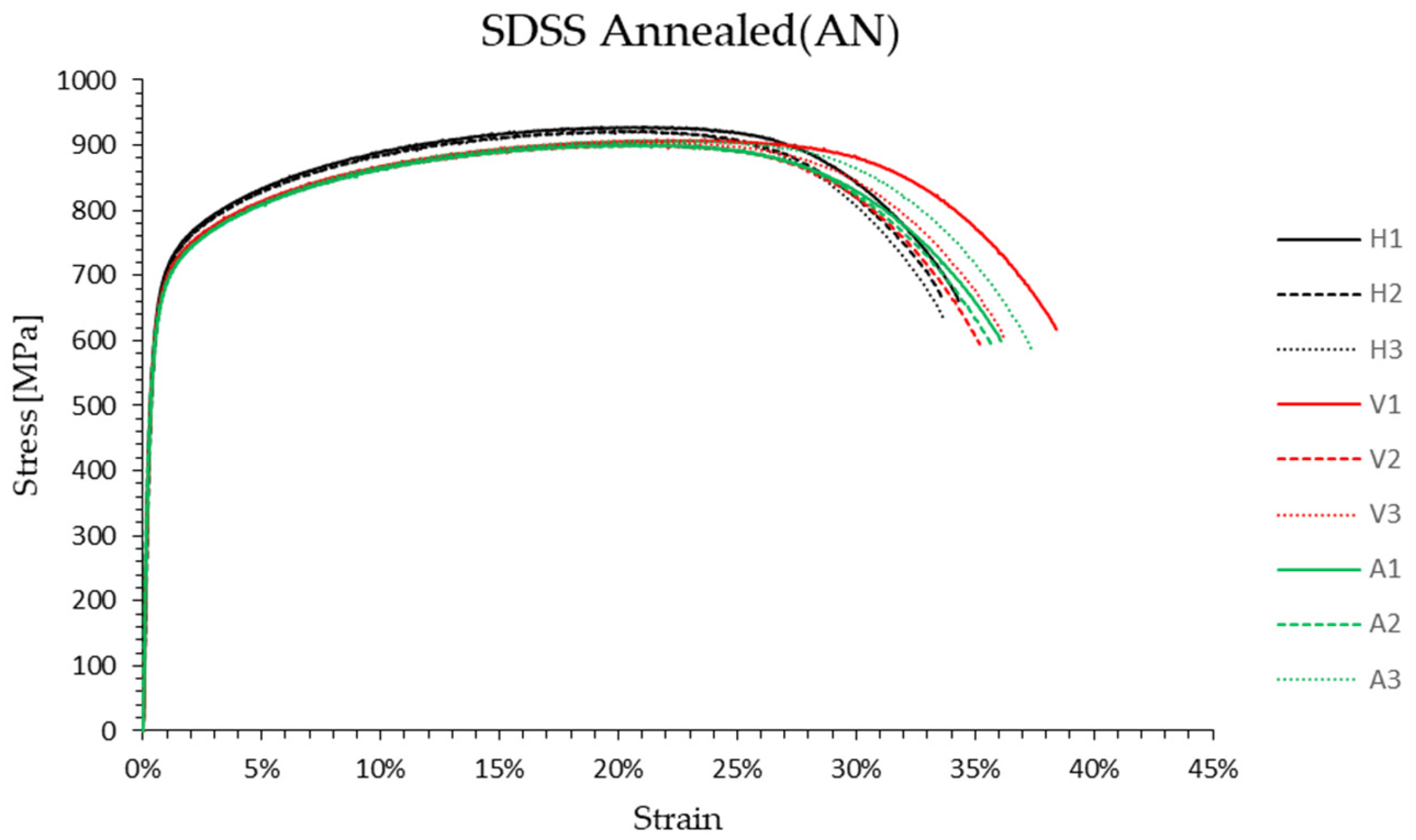

- Solution annealing and water quenching at 1100 °C for 1 h increases ductility (greater than 34%) but reduces the YS and UTS (lower than 950 MPa) of the DSS and SDSS as-built samples, attributed to austenite nucleation and growth, recrystallized microstructure, and the absence of secondary phases.

- Horizontal build orientation results in the highest YS and UTS across all build conditions, surpassing vertical orientation values. Grain size and shape affect how the tensile load is applied, leading to higher strength in horizontally built samples. However, vertical orientation shows the highest EL in all build conditions for SDSS, while DSS shows varied behavior depending on the condition. Diagonal and vertical build orientations showed similar mechanical properties for both alloys in all build conditions due to their similar grain sizes and shapes. DSS and SDSS alloys manifest isotropic mechanical behavior in the annealed and quenched condition due to their homogeneous recrystallized microstructure with uniform grain size and shape in all build conditions.

- Fractographic analysis of tensile test samples reveals a quasi-ductile fracture of the as-built and stress-relieved samples for both alloys. In addition, DSS and SDSS annealed and quenched samples demonstrate a fully ductile microstructure with fine dimples and absence of cleavage facets. Secondary cracks in vertical and diagonal DSS samples (as-built and stress-relieved) are induced by pre-existing lack-of fusion and gas pores during necking. Gas pores are consistently found in all annealed and quenched DSS and SDSS fractured samples. Horizontal samples (as-built and stress-relieved) exhibit lower porosity on the fracture surface compared to vertical and diagonal samples in the same conditions. Pores on the fracture surface serve as crack initiation points.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stainless, T. Practical Guidelines for the Fabrication of Duplex Stainless Steels; IMOA (International Molybdenum Association): London, UK, 2014; ISBN 9781907470097. [Google Scholar]

- Fargas, G.; Akdut, N.; Anglada, M.; Mateo, A. Microstructural Evolution during Industrial Rolling of a Duplex Stainless Steel. ISIJ Int. 2008, 48, 1596–1602. [Google Scholar] [CrossRef]

- Gowthaman, P.S.; Jeyakumar, S.; Saravanan, B.A. Machinability and Tool Wear Mechanism of Duplex Stainless Steel—A Review. Mater. Today Proc. 2019, 26, 1423–1429. [Google Scholar] [CrossRef]

- Fritz, J. Practical Guide to Using Duplex Stainless Steels (10044), 2nd ed.; Moe, G., Ed.; Nickel Institute: Toronto, ON, Canada, 2020. [Google Scholar]

- Liu, Q.; Wang, G.; Qiu, C. On the Role of Dynamic Grain Movement in Deformation and Mechanical Anisotropy Development in a Selectively Laser Melted Stainless Steel. Addit. Manuf. 2020, 35, 101329. [Google Scholar] [CrossRef]

- Chowdhury, S.; Yadaiah, N.; Prakash, C.; Ramakrishna, S.; Dixit, S.; Gupta, L.R.; Buddhi, D. Laser Powder Bed Fusion: A State-of-the-Art Review of the Technology, Materials, Properties & Defects, and Numerical Modelling. J. Mater. Res. Technol. 2022, 20, 2109–2172. [Google Scholar] [CrossRef]

- Santonocito, D.; Fintová, S.; Di Cocco, V.; Iacoviello, F.; Risitano, G.; D’Andrea, D. Comparison on Mechanical Behavior and Microstructural Features between Traditional and AM AISI 316L. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 379–395. [Google Scholar] [CrossRef]

- Cobbinah, P.V.; Nzeukou, R.A.; Onawale, O.T.; Matizamhuka, W.R. Laser Powder Bed Fusion of Potential Superalloys: A Review. Metals 2021, 11, 58. [Google Scholar] [CrossRef]

- Hengsbach, F.; Koppa, P.; Duschik, K.; Holzweissig, M.J.; Burns, M.; Nellesen, J.; Tillmann, W.; Tröster, T.; Hoyer, K.P.; Schaper, M. Duplex Stainless Steel Fabricated by Selective Laser Melting—Microstructural and Mechanical Properties. Mater. Des. 2017, 133, 136–142. [Google Scholar] [CrossRef]

- Islam, M.M.; Bayati, P.; Nematollahi, M.; Jahadakbar, A.; Elahinia, M.; Haghshenas, M. Strain Rate Dependent Micromechanical Properties of NiTi Shape Memory Alloys: Laser Powder Bed Fusion versus Casting. Forces Mech. 2021, 5, 100055. [Google Scholar] [CrossRef]

- Rafi, H.K.; Starr, T.L.; Stucker, B.E. A Comparison of the Tensile, Fatigue, and Fracture Behavior of Ti-6Al-4V and 15-5 PH Stainless Steel Parts Made by Selective Laser Melting. Int. J. Adv. Manuf. Technol. 2013, 69, 1299–1309. [Google Scholar] [CrossRef]

- Nilsson, J.O. Super Duplex Stainless Steels. Mater. Sci. Technol. 1992, 8, 685–700. [Google Scholar] [CrossRef]

- Steiner Petrovič, D.; Pirnat, M.; Klančnik, G.; Mrvar, P.; Medved, J. The Effect of Cooling Rate on the Solidification and Microstructure Evolution in Duplex Stainless Steel: A DSC Study. J. Therm. Anal. Calorim. 2012, 109, 1185–1191. [Google Scholar] [CrossRef]

- Narasimharaju, S.R.; Zeng, W.; See, T.L.; Zhu, Z.; Scott, P.; Jiang, X.; Lou, S. A Comprehensive Review on Laser Powder Bed Fusion of Steels: Processing, Microstructure, Defects and Control Methods, Mechanical Properties, Current Challenges and Future Trends. J. Manuf. Process. 2022, 75, 375–414. [Google Scholar] [CrossRef]

- David, S.A.; Vitek, J.M.; Hebble, T.L. Effect of Rapid Solidification on Stainless Steel Weld Metal Microstructures and Its Implications on the Schaeffler Diagram. Weld. J. 1987, 66, 289-s–300-s. [Google Scholar]

- Gargalis, L.; Karavias, L.; Graff, J.S.; Diplas, S.; Koumoulos, E.P.; Karaxi, E.K. A Comparative Investigation of Duplex and Super Duplex Stainless Steels Processed through Laser Powder Bed Fusion. Metals 2023, 13, 1897. [Google Scholar] [CrossRef]

- Nigon, G.N.; Burkan Isgor, O.; Pasebani, S. The Effect of Annealing on the Selective Laser Melting of 2205 Duplex Stainless Steel: Microstructure, Grain Orientation, and Manufacturing Challenges. Opt. Laser Technol. 2021, 134, 106643. [Google Scholar] [CrossRef]

- Xie, C.; Li, B.; Liu, G.; Liu, J.; Ying, H.; Li, D.; Wang, S.; Wang, L. Study on the Effect of Solution Treatment on Mechanical and Corrosion Properties of SAF 2507DSS Produced by LPBF. J. Mater. Res. Technol. 2023, 26, 2070–2081. [Google Scholar] [CrossRef]

- Mulhi, A.; Dehgahi, S.; Waghmare, P.; Qureshi, A.J. Process Parameter Optimization of 2507 Super Duplex Stainless Steel Additively Manufactured by the Laser Powder Bed Fusion Technique. Metals 2023, 13, 725. [Google Scholar] [CrossRef]

- Haghdadi, N.; Ledermueller, C.; Chen, H.; Chen, Z.; Liu, Q.; Li, X.; Rohrer, G.; Liao, X.; Ringer, S.; Primig, S. Evolution of Microstructure and Mechanical Properties in 2205 Duplex Stainless Steels during Additive Manufacturing and Heat Treatment. Mater. Sci. Eng. A 2022, 835, 142695. [Google Scholar] [CrossRef]

- Llorca-Isern, N.; López-Luque, H.; López-Jiménez, I.; Biezma, M.V. Identification of Sigma and Chi Phases in Duplex Stainless Steels. Mater. Charact. 2016, 112, 20–29. [Google Scholar] [CrossRef]

- Di Cocco, V.; Iacoviello, F.; Ischia, G. Duplex Stainless Steels “475 °C Embrittlement”: Influence of the Chemical Composition on the Fatigue Crack Propagation. Procedia Struct. Integr. 2017, 3, 299–307. [Google Scholar] [CrossRef]

- Knyazeva, M.; Pohl, M. Duplex Steels. Part II: Carbides and Nitrides. Metallogr. Microstruct. Anal. 2013, 2, 343–351. [Google Scholar] [CrossRef]

- Papula, S.; Song, M.; Pateras, A.; Chen, X.B.; Brandt, M.; Easton, M.; Yagodzinskyy, Y.; Virkkunen, I.; Hänninen, H. Selective Laser Melting of Duplex Stainless Steel 2205: Effect of Post-Processing Heat Treatment on Microstructure, Mechanical Properties, and Corrosion Resistance. Materials 2019, 12, 2468. [Google Scholar] [CrossRef] [PubMed]

- Kunz, J.; Boontanom, A.; Herzog, S.; Suwanpinij, P.; Kaletsch, A.; Broeckmann, C. Influence of Hot Isostatic Pressing Post-Treatment on the Microstructure and Mechanical Behavior of Standard and Super Duplex Stainless Steel Produced by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2020, 794, 139806. [Google Scholar] [CrossRef]

- Jeffs, S.; Douglas, R.; Beard, W.; Coleman, M.; Adams, J.; Jones, T.; Poole, D.; Lancaster, R. Characterising the High Temperature Tensile Behaviour of Laser Powder Bed Fused Duplex Stainless Steel 2205 Using the Small Punch Test. Mater. Charact. 2022, 189, 111953. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, H.; Xi, X.; Li, X.; Xiao, Z. Anisotropic Response in Mechanical and Corrosion Performances of UNS S31803 Duplex Stainless Steel Fabricated by Laser Powder Bed Fusion. J. Mater. Res. Technol. 2023, 26, 4860–4870. [Google Scholar] [CrossRef]

- Somlo, K.; Poulios, K.; Funch, C.V.; Niordson, C.F. Anisotropic Tensile Behaviour of Additively Manufactured Ti-6Al-4V Simulated with Crystal Plasticity. Mech. Mater. 2021, 162, 104034. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C. Anisotropic Mechanical Behavior of AlSi10Mg Parts Produced by Selective Laser Melting. Jom 2017, 69, 516–522. [Google Scholar] [CrossRef]

- Pitrmuc, Z.; Šimota, J.; Beránek, L.; Mikeš, P.; Andronov, V.; Sommer, J.; Holešovský, F. Mechanical and Microstructural Anisotropy of Laser Powder Bed Fusion 316L Stainless Steel. Materials 2022, 15, 551. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.; Ni, X.; Dong, C.; Zhang, L.; Man, C.; Cheng, X.; Li, X. Anisotropy in the Microstructure and Mechanical Property for the Bulk and Porous 316L Stainless Steel Fabricated via Selective Laser Melting. Mater. Lett. 2019, 235, 1–5. [Google Scholar] [CrossRef]

- Alfieri, V.; Giannella, V.; Caiazzo, F.; Sepe, R. Influence of Position and Building Orientation on the Static Properties of LPBF Specimens in 17-4 PH Stainless Steel. Forces Mech. 2022, 8, 100108. [Google Scholar] [CrossRef]

- Hovig, E.W.; Azar, A.S.; Solberg, K.; Sørby, K. An Investigation of the Anisotropic Properties of Heat-Treated Maraging Steel Grade 300 Processed by Laser Powder Bed Fusion. Int. J. Adv. Manuf. Technol. 2021, 114, 1359–1372. [Google Scholar] [CrossRef]

- ASTM E8/E8M-22; Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2010.

- Gong, H.; Rafi, K.; Gu, H.; Janaki Ram, G.D.; Starr, T.; Stucker, B. Influence of Defects on Mechanical Properties of Ti-6Al-4V Components Produced by Selective Laser Melting and Electron Beam Melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Saeidi, K.; Kevetkova, L.; Lofaj, F.; Shen, Z. Novel Ferritic Stainless Steel Formed by Laser Melting from Duplex Stainless Steel Powder with Advanced Mechanical Properties and High Ductility. Mater. Sci. Eng. A 2016, 665, 59–65. [Google Scholar] [CrossRef]

- S Ghosh, S.K.; Mondal, S. Mondal Effect Of Heat Treatment On Microstructure And Mechanical Properties of Duplex Stainless Steel. Trans. Indian Inst. Met. 2008, 61, 33–37. [Google Scholar] [CrossRef]

- Lakhdari, M.A.; Krajcarz, F.; Mithieux, J.D.; Van Landeghem, H.P.; Veron, M. Strength Enhancement of Superduplex Stainless Steel Using Thermomechanical Processing. Metals 2021, 11, 1094. [Google Scholar] [CrossRef]

- Chail, G.; Kangas, P. Super and Hyper Duplex Stainless Steels: Structures, Properties and Applications. Procedia Struct. Integr. 2016, 2, 1755–1762. [Google Scholar] [CrossRef]

- Raffeis, I.; Vroomen, U.; Adjei-Kyeremeh, F.; Großmann, D.; Hammelrath, H.; Westhoff, E.; Bremen, S.; Boscolo Bozza, D.; Bührig-Polaczek, A. Comparative Investigations into Microstructural and Mechanical Properties of As-Cast and Laser Powder Bed Fusion (LPBF) Fabricated Duplex Steel (1.4517). Materwiss. Werksttech. 2020, 51, 432–444. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Brandi, S.D.; Lippold, J.C. Secondary Austenite and Chromium Nitride Precipitation in Simulated Heat Affected Zones of Duplex Stainless Steels. Sci. Technol. Weld. Join. 2004, 9, 301–313. [Google Scholar] [CrossRef]

- Liou, H.Y.; Hsieh, R.I.; Tsai, W.T. Microstructure and Pitting Corrosion in Simulated Heat-Affected Zones of Duplex Stainless Steels. Mater. Chem. Phys. 2002, 74, 33–42. [Google Scholar] [CrossRef]

- Migiakis, K.; Papadimitriou, G.D. Effect of Nitrogen and Nickel on the Microstructure and Mechanical Properties of Plasma Welded UNS S32760 Super-Duplex Stainless Steels. J. Mater. Sci. 2009, 44, 6372–6383. [Google Scholar] [CrossRef]

- Wang, H.; Wang, A.; Li, C.; Yu, X.; Xie, J.; Liu, C. Effect of Secondary-Phase Precipitation on Mechanical Properties and Corrosion Resistance of 00Cr27Ni7Mo5N Hyper-Duplex Stainless Steel during Solution Treatment. Materials 2022, 15, 7533. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively Manufactured Hierarchical Stainless Steels with High Strength and Ductility. Nat. Mater. 2018, 17, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Kunze, K.; Etter, T.; Grässlin, J.; Shklover, V. Texture, Anisotropy in Microstructure and Mechanical Properties of IN738LC Alloy Processed by Selective Laser Melting (SLM). Mater. Sci. Eng. A 2015, 620, 213–222. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and Heterogeneity of Microstructure and Mechanical Properties in Metal Additive Manufacturing: A Critical Review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Im, Y.D.; Kim, K.H.; Jung, K.H.; Lee, Y.K.; Song, K.H. Anisotropic Mechanical Behavior of Additive Manufactured AISI 316L Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2019, 50, 2014–2021. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.P. Residual Stresses in Selective Laser Sintering and Selective Laser Melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An Experimental Investigation into Additive Manufacturing-Induced Residual Stresses in 316L Stainless Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 6260–6270. [Google Scholar] [CrossRef]

- Robinson, J.; Ashton, I.; Fox, P.; Jones, E.; Sutcliffe, C. Determination of the Effect of Scan Strategy on Residual Stress in Laser Powder Bed Fusion Additive Manufacturing. Addit. Manuf. 2018, 23, 13–24. [Google Scholar] [CrossRef]

- Liao, L. Ferrite Percentage Prediction of Duplex Stainless Steels as a Function of Cooling Rates. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2018. [Google Scholar]

- Kan, W.H.; Chiu, L.N.S.; Lim, C.V.S.; Zhu, Y.; Tian, Y.; Jiang, D.; Huang, A. A Critical Review on the Effects of Process-Induced Porosity on the Mechanical Properties of Alloys Fabricated by Laser Powder Bed Fusion. J. Mater. Sci. 2022, 57, 9818–9865. [Google Scholar] [CrossRef]

- Ronneberg, T.; Davies, C.M.; Hooper, P.A. Revealing Relationships between Porosity, Microstructure and Mechanical Properties of Laser Powder Bed Fusion 316L Stainless Steel through Heat Treatment. Mater. Des. 2020, 189, 108481. [Google Scholar] [CrossRef]

- Choo, H.; White, L.P.; Xiao, X.; Sluss, C.C.; Morin, D.; Garlea, E. Deformation and Fracture Behavior of a Laser Powder Bed Fusion Processed Stainless Steel: In Situ Synchrotron x-ray Computed Microtomography Study. Addit. Manuf. 2021, 40, 101914. [Google Scholar] [CrossRef]

- Voisin, T.; Calta, N.P.; Khairallah, S.A.; Forien, J.B.; Balogh, L.; Cunningham, R.W.; Rollett, A.D.; Wang, Y.M. Defects-Dictated Tensile Properties of Selective Laser Melted Ti-6Al-4V. Mater. Des. 2018, 158, 113–126. [Google Scholar] [CrossRef]

- Smith, B.A.; Laursen, C.M.; Bartanus, J.; Carroll, J.D.; Pataky, G.J. The Interplay of Geometric Defects and Porosity on the Mechanical Behavior of Additively Manufactured Components. Exp. Mech. 2021, 61, 685–698. [Google Scholar] [CrossRef]

| Duplex Stainless Steel 2205 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | S | N | Cr | Fe | Mn | Mo | Ni | P | Si |

| 0.022 | 0.005 | 0.13 | 22.1 | Bal. | 1.03 | 3.2 | 5.2 | 0.01 | 0.51 |

| Super Duplex Stainless Steel 2507 | |||||||||

| 0.013 | 0.005 | 0.29 | 24.7 | Bal. | 0.77 | 3.6 | 8 | 0.011 | 0.45 |

| Alloy | Build Condition | Build Orientation | UTS (MPa) | YS 0.2% (MPa) | EL % |

|---|---|---|---|---|---|

| DSS | As-Built | Diagonal | 1010 ± 8 | 970 ± 9 | 16 ± 1 |

| Horizontal | 1113 ± 6 | 1055 ± 5 | 18 ± 1 | ||

| Vertical | 1066 ± 4 | 1027 ± 21 | 16 ± 0 | ||

| Stress-Relieved | Diagonal | 1006 ± 8 | 945 ± 22 | 17 ± 2 | |

| Horizontal | 1108 ± 2 | 1042 ± 19 | 19 ± 1 | ||

| Vertical | 1058 ± 4 | 1010 ± 17 | 16 ± 0 | ||

| Annealed and Quenched | Diagonal | 775 ± 1 | 528 ± 11 | 36 ± 3 | |

| Horizontal | 795 ± 3 | 542 ± 3 | 39 ± 0 | ||

| Vertical | 774 ± 2 | 540 ± 10 | 39 ± 0 | ||

| SDSS | As-Built | Diagonal | 1354 ± 15 | 1237 ± 58 | 8 ± 0 |

| Horizontal | 1495 ± 6 | 1390 ± 22 | 7 ± 0 | ||

| Vertical | 1366 ± 8 | 1247 ± 32 | 11 ± 0 | ||

| Stress-Relieved | Diagonal | 1374 ± 10 | 1265 ± 33 | 9 ± 1 | |

| Horizontal | 1498 ± 5 | 1387 ± 30 | 7 ± 1 | ||

| Vertical | 1390 ± 1 | 1257 ± 8 | 9 ± 2 | ||

| Annealed and Quenched | Diagonal | 905 ± 4 | 588 ± 10 | 36 ± 1 | |

| Horizontal | 925 ± 3 | 615 ± 5 | 34 ± 0 | ||

| Vertical | 905 ± 4 | 588 ± 26 | 37 ± 2 |

| Alloy | Manufacturing Method | Condition | Build Orientation | YS (MPa) | UTS (MPa) | EL % | Ref. |

|---|---|---|---|---|---|---|---|

| DSS | LPBF | As-Built | Vertical | 1027 | 1066 | 16 | Current Study |

| Annealed | Vertical | 540 | 774 | 39 | |||

| As-Built | Horizontal | 1055 | 1113 | 18 | |||

| Annealed | Horizontal | 542 | 795 | 39 | |||

| SDSS | LPBF | As-Built | Vertical | 1247 | 1366 | 11 | |

| Annealed | Vertical | 588 | 905 | 37 | |||

| As-Built | Horizontal | 1390 | 1495 | 7 | |||

| Annealed | Horizontal | 615 | 925 | 34 | |||

| DSS | LPBF | As-built | Vertical | 950 | 1071 | 16 | [24] |

| DSS | LPBF | As-Built | Vertical | 826 | 872 | 11 | [17] |

| Annealed | Vertical | 465 | 622 | 21 | |||

| DSS | LPBF | As-Built | Vertical | - | 940 | 12 | [9] |

| DSS | LPBF | As-Built | Vertical | 773 | 865 | 8 | [25] |

| DSS | LPBF | Annealed | Vertical | 639 | 859 | 52.9 | [27] |

| Horizontal | 717 | 912 | 50.2 | ||||

| DSS | LPBF | Annealed | Vertical | 482 | 753 | 52.1 | [26] |

| Horizontal | 523 | 832 | 36.9 | ||||

| SDSS | LPBF | As-Built | - | 1115 | 1257 | 10.7 | [19] |

| SDSS | LPBF | As-Built | - | - | 1173 | 18 | [18] |

| Annealed | - | - | 860 | 45 | |||

| SDSS | LPBF | As-Built | Vertical | 913 | 1031 | 14 | [25] |

| SDSS | LPBF | As-built | - | 1214 | 1321 | - | [36] |

| DSS | Casting | As-Cast | - | 462 | 660 | 29 | [37] |

| Annealed | - | 456 | 649 | 34 | |||

| Cold Rolling | Cold-Rolled | - | 814 | 890 | 18 | ||

| Hot Rolling | Hot-Rolled | - | 476 | 723 | 39 | ||

| SDSS | Cold Rolling | Annealed | Parallel to rolling direction | 710 | 920 | 20 | [38] |

| Hot Rolling + Annealing + Cold Rolling | Annealed | Parallel to rolling direction | 772 | 1000 | 16.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karavias, L.; Gargalis, L.; Graff, J.S.; Johansen, M.; Diplas, S.; Karaxi, E.K. Tensile Properties and Fracture Analysis of Duplex (2205) and Super Duplex (2507) Stainless Steels, Produced via Laser Powder Bed Fusion Additive Manufacturing. Metals 2024, 14, 838. https://doi.org/10.3390/met14070838

Karavias L, Gargalis L, Graff JS, Johansen M, Diplas S, Karaxi EK. Tensile Properties and Fracture Analysis of Duplex (2205) and Super Duplex (2507) Stainless Steels, Produced via Laser Powder Bed Fusion Additive Manufacturing. Metals. 2024; 14(7):838. https://doi.org/10.3390/met14070838

Chicago/Turabian StyleKaravias, Leonidas, Leonidas Gargalis, Joachim Seland Graff, Marius Johansen, Spyros Diplas, and Evaggelia K. Karaxi. 2024. "Tensile Properties and Fracture Analysis of Duplex (2205) and Super Duplex (2507) Stainless Steels, Produced via Laser Powder Bed Fusion Additive Manufacturing" Metals 14, no. 7: 838. https://doi.org/10.3390/met14070838

APA StyleKaravias, L., Gargalis, L., Graff, J. S., Johansen, M., Diplas, S., & Karaxi, E. K. (2024). Tensile Properties and Fracture Analysis of Duplex (2205) and Super Duplex (2507) Stainless Steels, Produced via Laser Powder Bed Fusion Additive Manufacturing. Metals, 14(7), 838. https://doi.org/10.3390/met14070838