Optimizing Tempering Parameters to Enhance Precipitation Behavior and Impact Toughness in High-Nickel Steel

Abstract

:1. Introduction

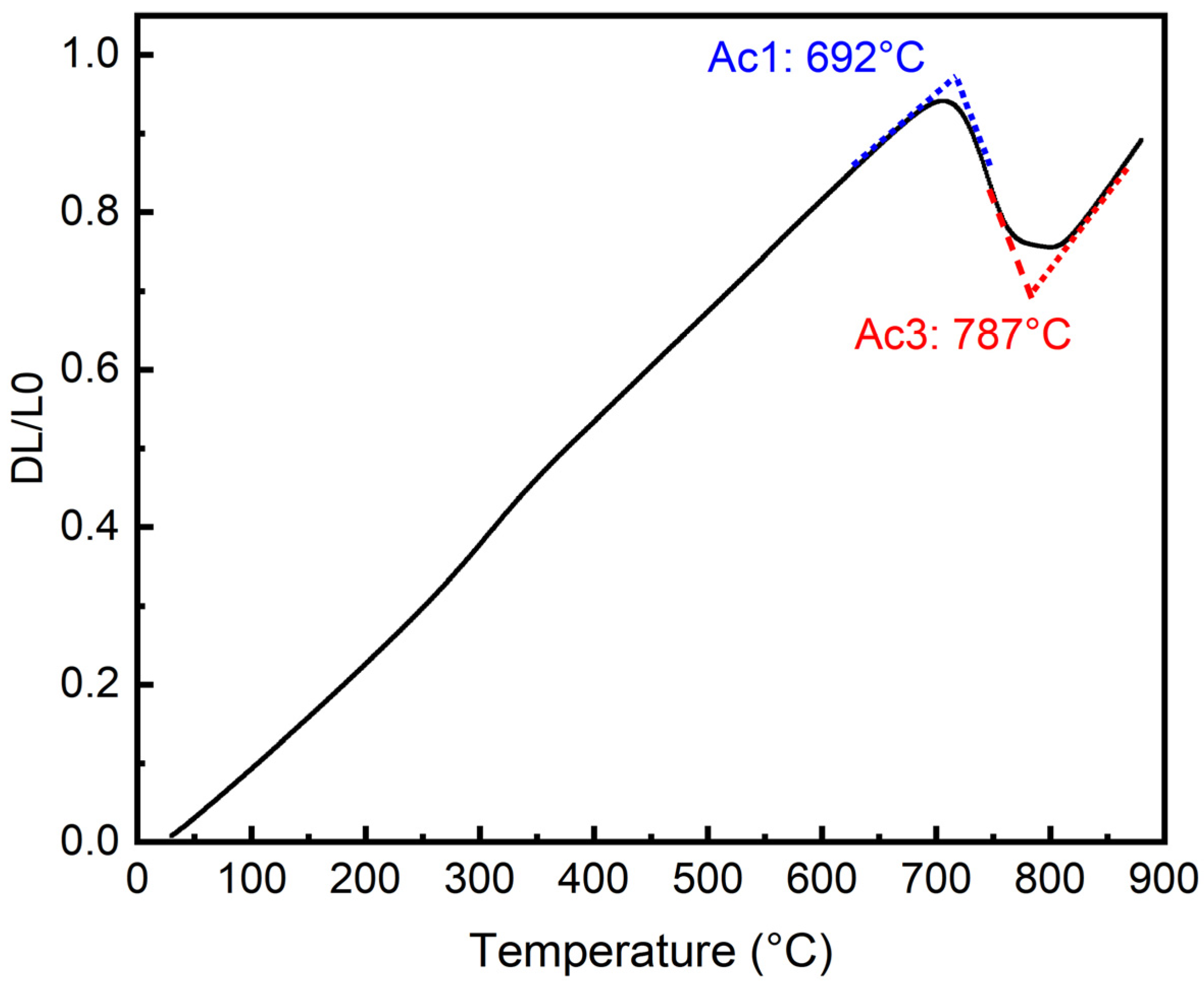

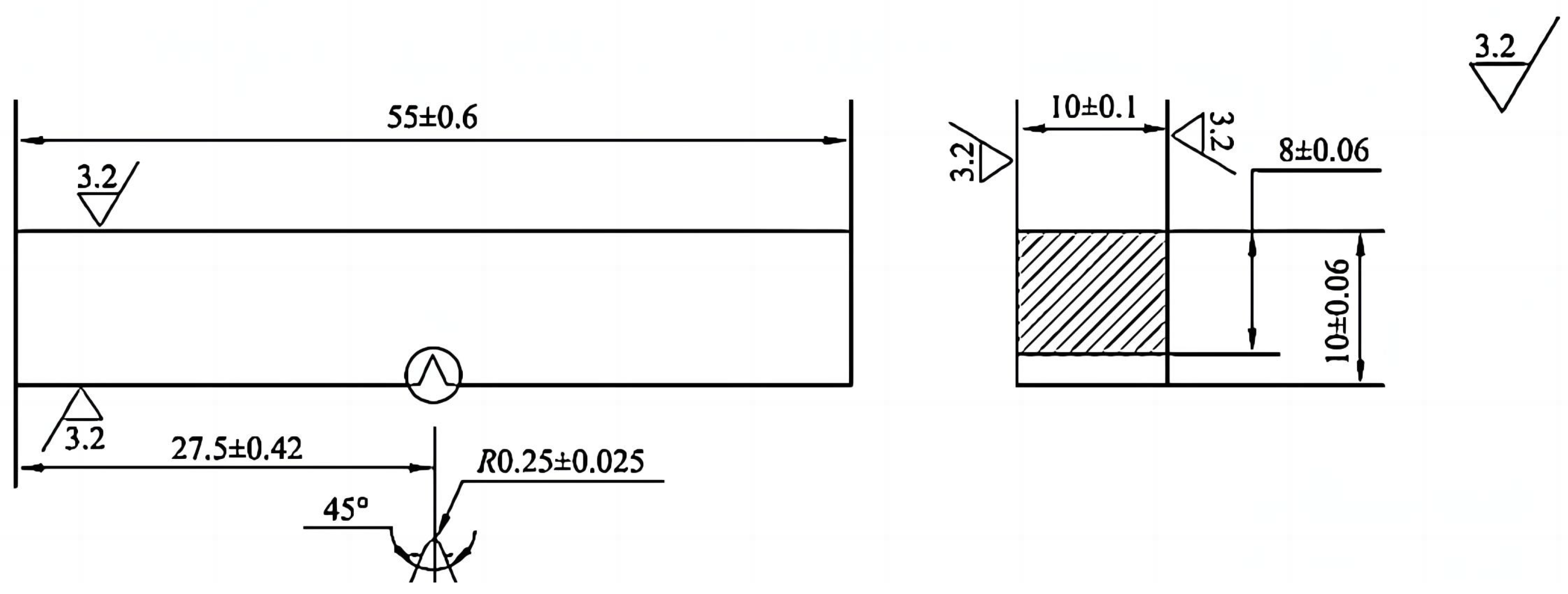

2. Experimental Procedures and Sample Characterization

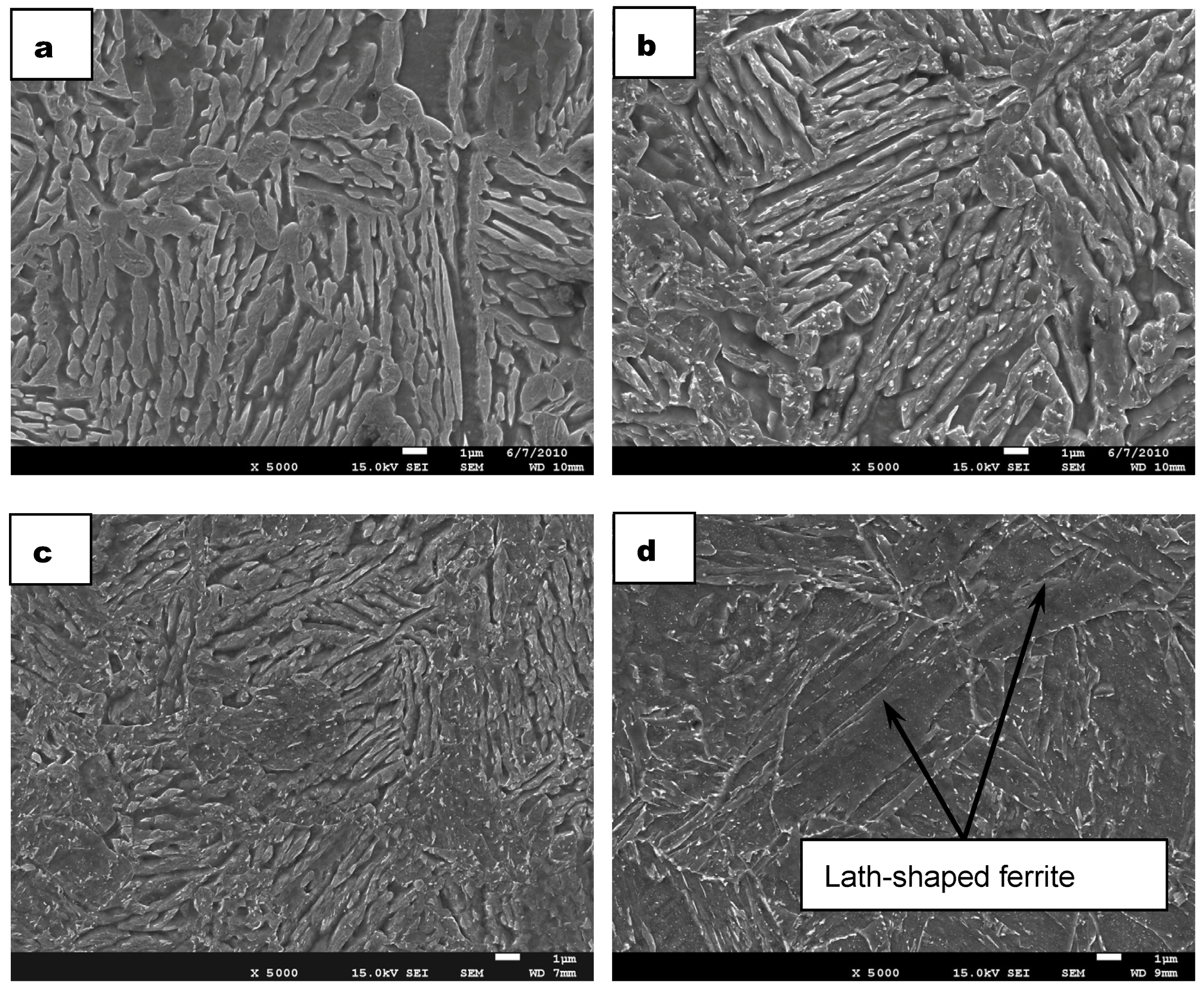

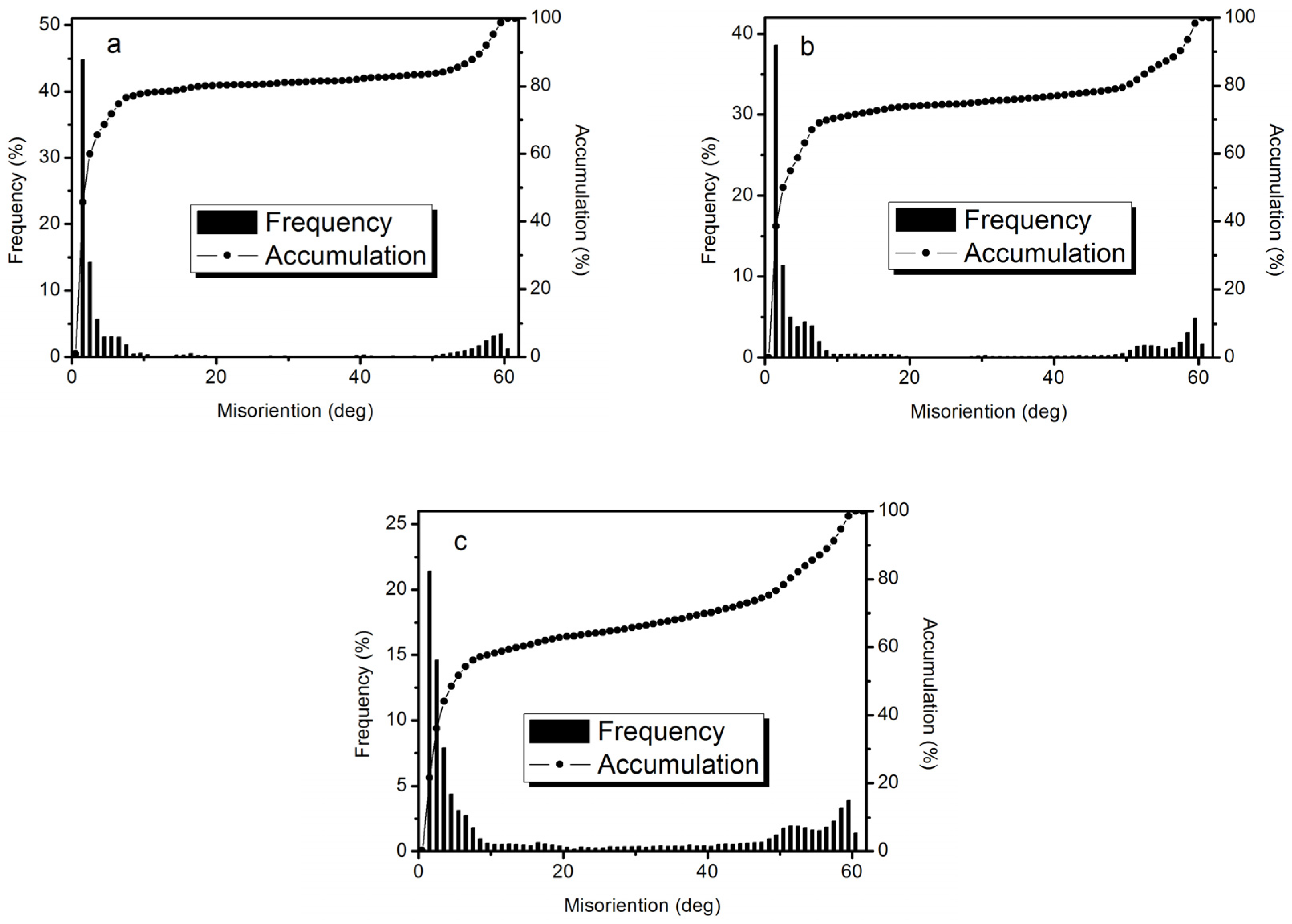

3. Results and Discussion

4. Conclusions

- (1)

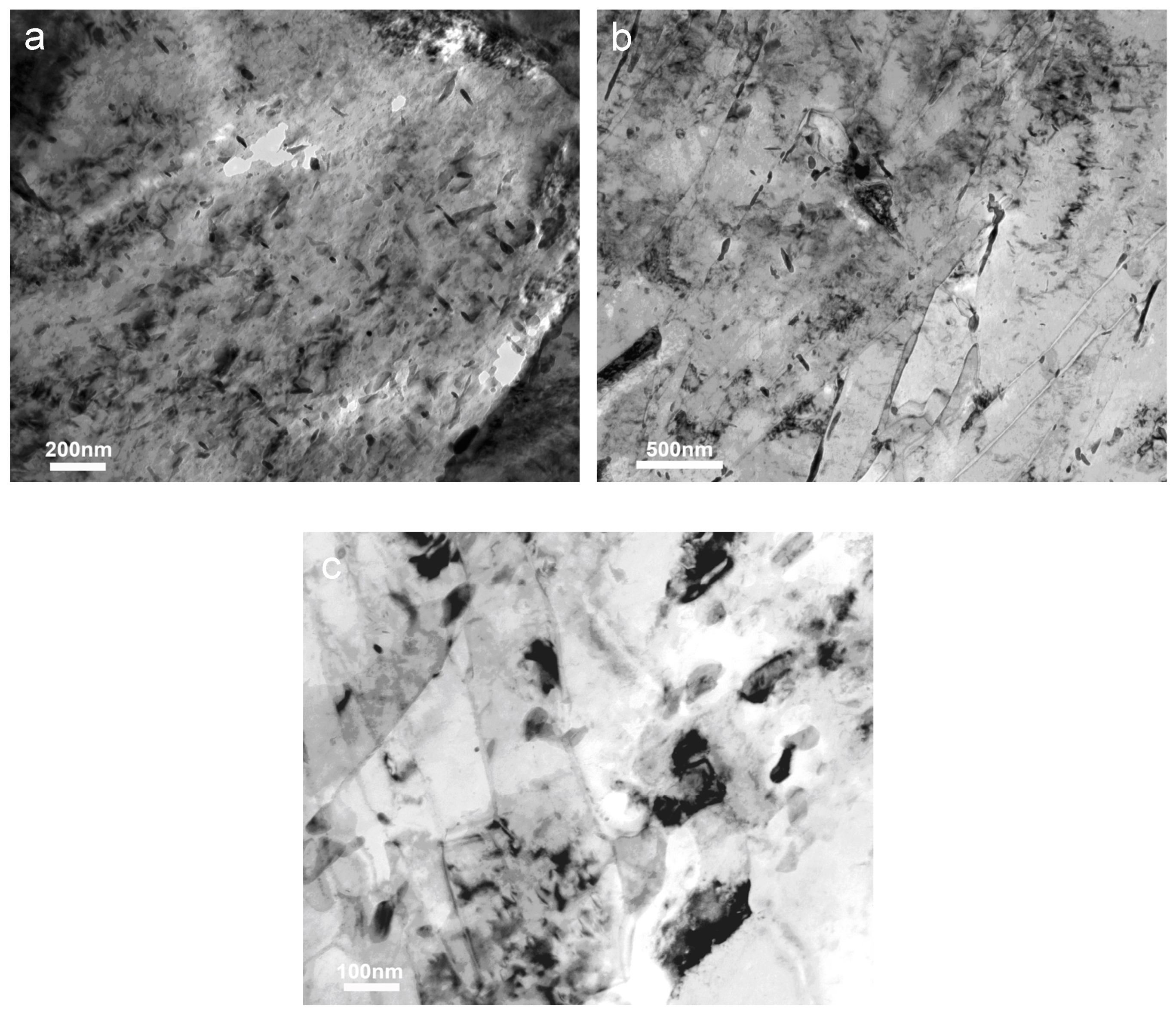

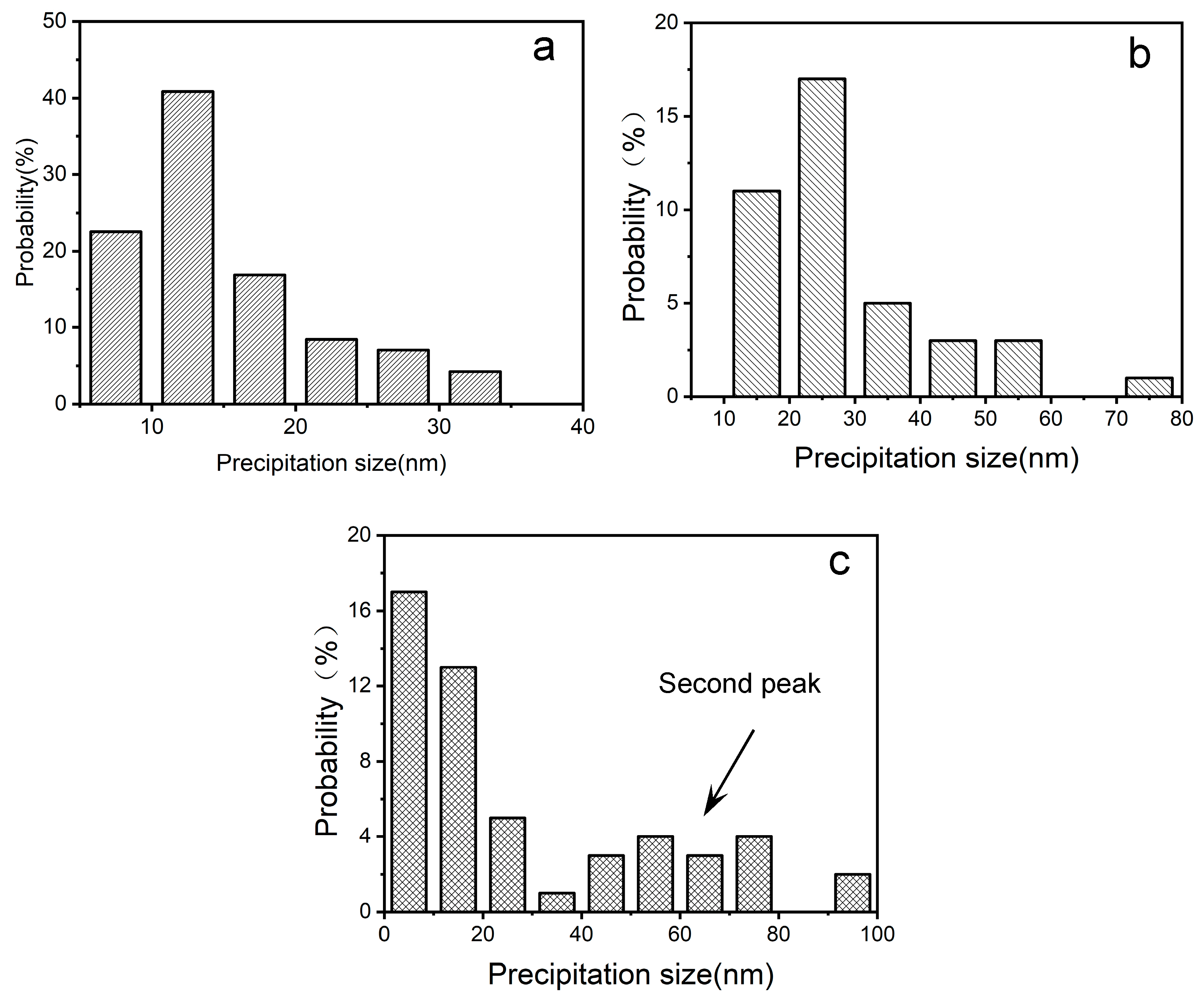

- Tempering high-nickel steel at different temperatures significantly influences the precipitation of carbides. At 500 °C, the steel exhibits a prevalence of fine carbides. As the tempering temperature is raised to 580 °C, the carbides start to lose their distinct crystallographic morphology. By 620 °C, substantial coarsening of the carbides is observed, with smaller precipitates dissolving and larger particles growing.

- (2)

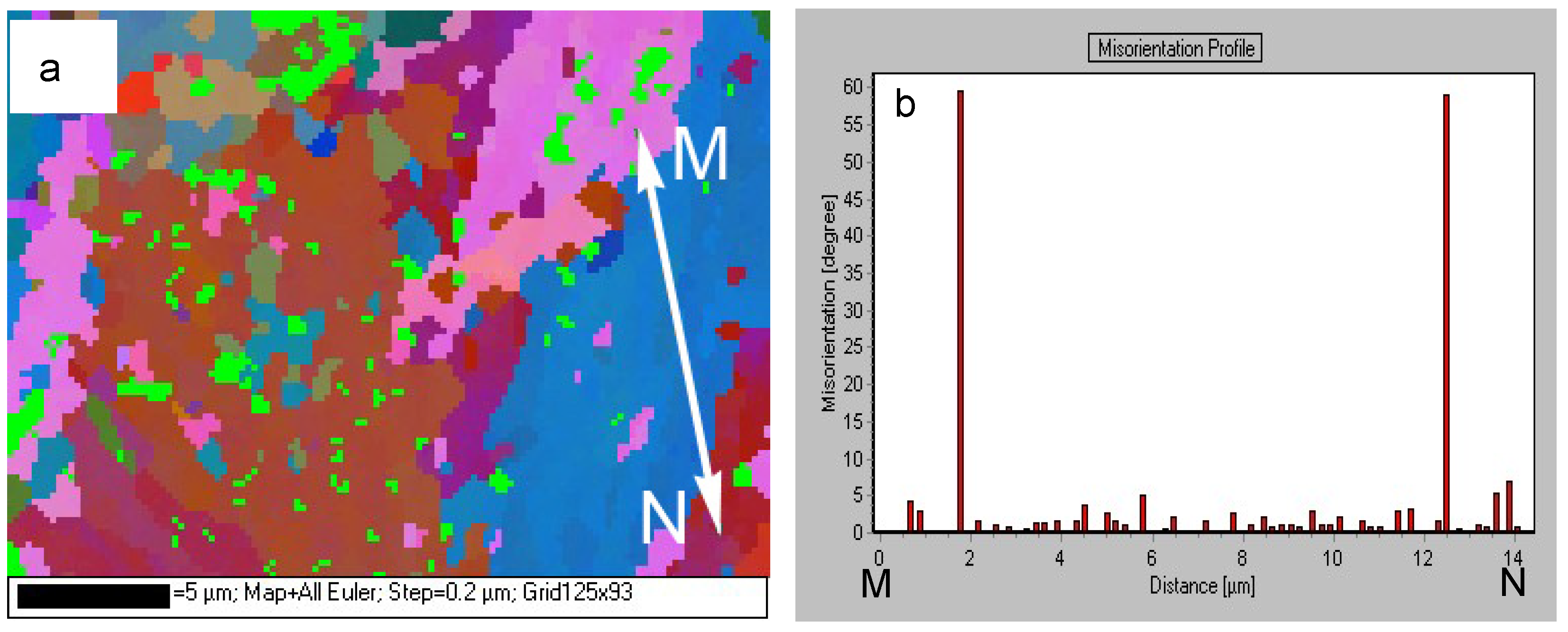

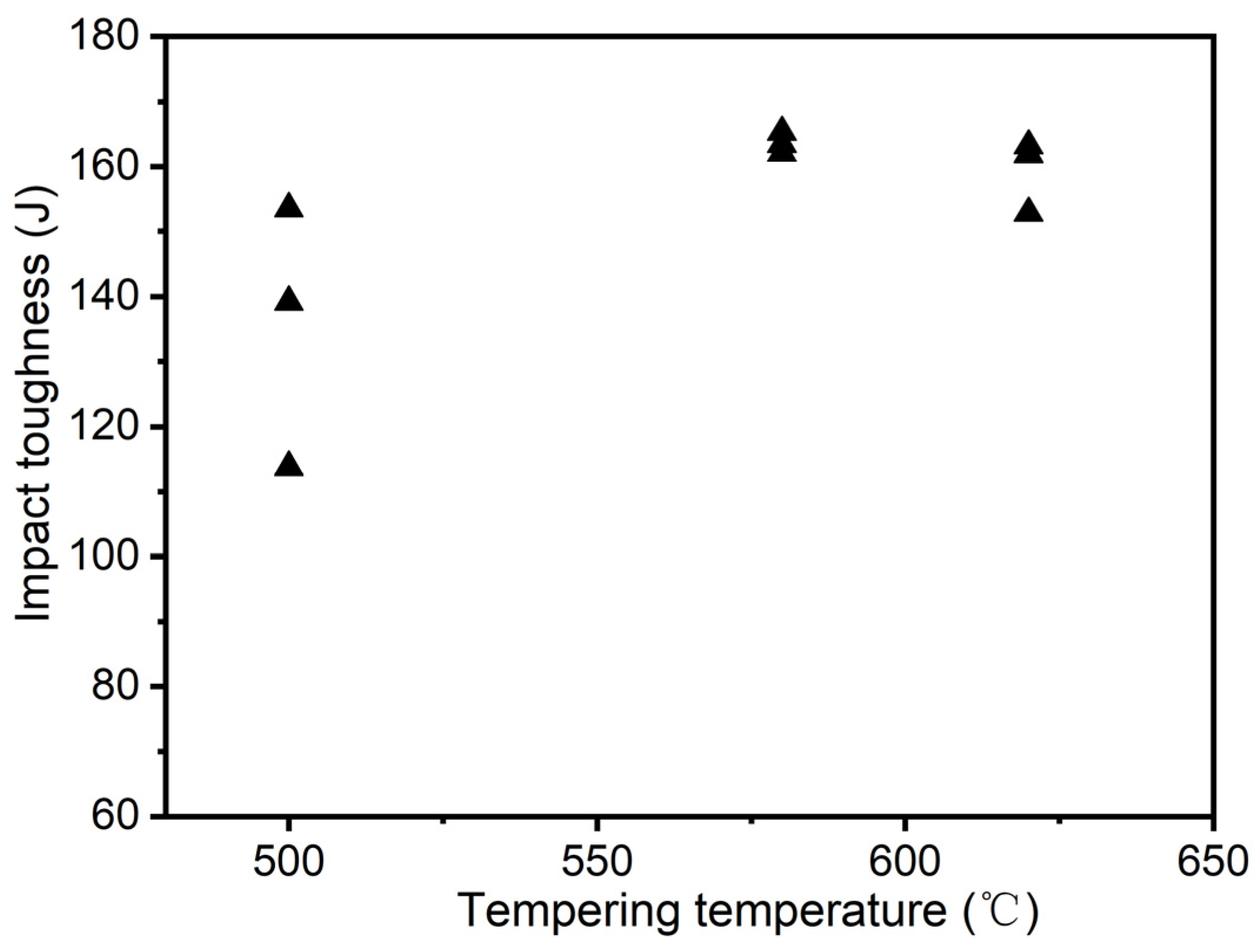

- The study indicates that the proportion of low-angle grain boundaries decreases with increasing tempering temperature. At 500 °C, low-angle boundaries constitute over 75% of the grain boundaries. This proportion decreases to about 70% at 580 °C and further declines at 620 °C. The reduction in low-angle boundaries is associated with the randomization of precipitate orientations, which enhances the steel’s impact toughness up to 580 °C. However, at 620 °C, the formation of high-angle boundaries and the coarsening of carbides adversely affect the toughness.

- (3)

- The impact toughness of the steel improves with increasing tempering temperature, peaking at 163 J at 580 °C. This peak corresponds to an optimal balance of fine, randomly distributed precipitates. Beyond this temperature, specifically at 620 °C, the coarsening of carbides and the rise in high-angle grain boundaries result in a reduction in impact toughness. These findings highlight the critical importance of precise temperature control during tempering to achieve the desired mechanical properties in high-nickel steels.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, W.X.; Chen, Y.Z.; Cong, Y.B.; Liu, Y.H.; Liu, F. On the austenite stability of cryogenic Ni steels: Microstructural effects: A review. J. Mater. Sci. 2021, 56, 12539–12558. [Google Scholar] [CrossRef]

- Xiong, T.; Xu, G.; Yuan, Q.; Hu, H.-J.; Tian, J.-Y. Effects of initial austenite grain size on microstructure and mechanical properties of 5% nickel cryogenic steel. Met. Microstruct. Anal. 2019, 8, 241–248. [Google Scholar] [CrossRef]

- Wu, S.; Sun, G.; Ma, Q.; Shen, Q.; Xu, L. Influence of QLT treatment on microstructure and mechanical properties of a high nickel steel. J. Mech. Work. Technol. 2013, 213, 120–128. [Google Scholar] [CrossRef]

- Nakanishi, D.; Kawabata, T.; Aihara, S. Effect of dispersed retained γ-Fe on brittle crack arrest toughness in 9% Ni steel in cryogenic temperatures. Mater. Sci. Eng. A 2018, 723, 238–246. [Google Scholar] [CrossRef]

- Kim, J.I.; Kim, H.J.; Morris, J.W. The role of the constituent phases in determining the low temperature toughness of 5.5Ni cryogenic steel. Met. Trans. A 1984, 15, 2213–2219. [Google Scholar] [CrossRef]

- Zhao, X.-Q.; Pan, T.; Wang, Q.-F.; Su, H.; Yang, C.-F.; Yang, Q.-X. Effect of tempering temperature on microstructure and mechanical properties of steel containing Ni of 9%. J. Iron Steel Res. Int. 2011, 18, 47–51. [Google Scholar] [CrossRef]

- Cui, X.-B.; Liu, T.-L.; Zheng, Z.-B.; Guo, Z.-Q.; Zheng, K.-H.; Han, P.-X. Effects of Ni content and tempering temperatures on microstructure and properties of medium-carbon cast steel. J. Iron Steel Res. Int. 2023, 30, 1524–1536. [Google Scholar] [CrossRef]

- Zhao, F.; Zhang, S.; Cheng, T.; Su, L.; Zhang, Z. Ultrastrong Low-Alloy Steel with Good Ductility via Multiple Strengthening, Suppressed Carbides and Reversed Austenite in Quenching and Tempering. Met. Mater. Trans. A 2024, 55, 2400–2413. [Google Scholar] [CrossRef]

- Liesegang, M.; Lion, P.; Beck, T.; Gräf, M.; Steidl, G. Investigation of the tensile deformation behaviour in Ni-based superalloy inconel alloy 617 using EBSD-based finite element simulations and optical flow method. J. Mater. Sci. 2023, 58, 8990–9005. [Google Scholar] [CrossRef]

- Dobe, R.; Das, A.; Mukherjee, R.; Gupta, S. Evaluation of grain boundaries as percolation pathways in quartz-rich continental crust using Atomic Force Microscopy. Sci. Rep. 2021, 11, 9831. [Google Scholar] [CrossRef]

- Dey, S.; Chatterjee, S.; Ritanjali, S.R.; Dobe, R.; Mukherjee, R.; Mandal, S.; Gupta, S. Nanoscale visualization of high-angle misorientations in quartz-rich rocks using SEM-EBSD and Atomic Force Microscopy. J. Struct. Geol. 2024, 183, 105146. [Google Scholar] [CrossRef]

- Jiang, R.; Zhang, W.; Zhang, L.; Zhao, Y.; Zhang, L.; Song, Y. Strain localization and crack initiation behavior of a PM Ni-based superalloy: SEM-DIC characterization and crystal plasticity simulation. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 1635–1651. [Google Scholar] [CrossRef]

- Li, C.; Dubovi, J.; Klein, C. Application of electron backscatter diffraction in facet crystalline orientation study of Al-Cu-Fe alloy. Mater. Charact. 2022, 191, 112158. [Google Scholar] [CrossRef]

- Xu, J.; Brodin, H.; Peng, R.L.; Luzin, V.; Moverare, J. Effect of heat treatment temperature on the microstructural evolution of CM247LC superalloy by laser powder bed fusion. Mater. Charact. 2022, 185, 111742. [Google Scholar] [CrossRef]

- Liang, G.; Tan, Q.; Liu, Y.; Schneider, M.; Detemple, E.; Eggeler, G. Effect of cooling rate on microstructure and mechanical properties of a low-carbon low-alloy steel. J. Mater. Sci. 2021, 56, 3995–4005. [Google Scholar] [CrossRef]

- Yaso, M.; Hayashi, S.; Morito, S.; Takuya, O.; Kunichika, K.; Kouji, M. Characteristics of Retained Austenite in Quenched High Carbon-High Chromium Alloy Steels. J. Jpn. Inst. Met. 2009, 73, 852–856. [Google Scholar] [CrossRef]

- Kawahara, Y.; Kaneko, K.; Sawada, H.; Takahashi, J. Transition from carbon clusters to ε, θ-carbides in a quenched and aged low-carbon ferritic steel. Acta Mater. 2023, 252, 118919. [Google Scholar] [CrossRef]

- Zeng, T.Y.; Li, W.; Wang, N.M.; Wang, W.; Yang, K. Microstructural evolution during tempering and intrinsic strengthening mechanisms in a low carbon martensitic stainless bearing steel. Mater. Sci. Eng. A 2022, 836, 142736. [Google Scholar] [CrossRef]

- Farber, V.M.; Khotinov, V.A.; Selivanova, O.V.; Ovsyannikov, A.B.; Karabanalov, M.S. Evolution of the Structure and Mechanical Properties of Medium-Carbon Microalloyed Steel during High-Temperature Tempering. Phys. Met. Metallogr. 2023, 124, 824–830. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Wang, G.; Li, Q.; Wen, J.; Yan, L.; Chen, S.; Gu, Y. Effect of Tempering Treatment on Microstructural Evolution and Mechanical Behavior of Heavy-Wall Heat Induction Seamless Bend Pipe. Materials 2022, 15, 259. [Google Scholar] [CrossRef]

- Liu, J.; Wei, S.; Sun, J.; Lu, S. Effect of Tempering Temperature on the Microstructural Evolution and Properties of 800 MPa Grade Low-Carbon Bainite-Deposited Metals. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2022, 53, 4272–4282. [Google Scholar] [CrossRef]

- He, B.B.; Guan, Q.W. Effect of Ausforming Strain on the Microstructural Evolution of Lath Martensite in Low Carbon Steel. Met. Mater. Int. 2022, 28, 2330–2339. [Google Scholar] [CrossRef]

- Chakraborty, A.; Webster, R.F.; Primig, S. Lath martensite substructure evolution in low-carbon microalloyed steels. J. Mater. Sci. 2022, 57, 10359–10378. [Google Scholar] [CrossRef]

- Wang, E.; Ding, C.; Gong, N.; Gu, C.; Liu, H.; Li, L.; Wu, H.; Niu, G. Effect of Nb Precipitates and Reversed Austenite Formed by QLT Process on Microstructure and Mechanical Properties of Nb-Bearing 7Ni Cryogenic Steel. Met. Mater. Trans. A 2024, 55, 247–260. [Google Scholar] [CrossRef]

- Masoumi, M.; Centeno, D.M.A.; Tressia, G.; Correa, P.A.; Ariza, E.A.; Mola, J. Microstructural Design via Quenching and Partitioning for Enhanced Mechanical and Wear Properties in AISI 9254 Spring Steel: A Comprehensive Investigation. Met. Mater. Trans. A 2024, 55, 3364–3387. [Google Scholar] [CrossRef]

- Liang, J.X.; Wang, Y.C.; Cheng, X.W.; Li, Z.; Du, J.K.; Li, S.K. Microstructure and mechanical properties of a Cr–Ni–W–Mo steel processed by thermo-mechanical controlled processing. J. Iron Steel Res. Int. 2021, 28, 713–721. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Q.; Yuan, Q.; Guan, J.; Yang, Y.; Xu, G. Effects of Tempering Temperature on the Microstructure, Strength, and Toughness of Medium-Carbon Ti–Mo-Bearing Martensitic Steel. Arab. J. Sci. Eng. 2022, 47, 9061–9073. [Google Scholar] [CrossRef]

- Fan, Z.J.; Shen, Y.Z.; Xu, Z.Q.; Zhu, P.C.; Liu, H.; Ma, Y.F.; Guan, W.Q. Evolution of Precipitate Phases in Ferritic and Martensitic Steel P92 During Normalizing and Tempering. JOM 2022, 74, 3578–3594. [Google Scholar] [CrossRef]

| Element | C | Si | Ni | P | Si | S | Mn | Cr | Cu | V | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content | 0.1 | 0.2 | 4.5 | 0.01 | 0.25 | 0.01 | 0.5 | 1.5 | 0.2 | 0.06 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, G.; Wang, Q. Optimizing Tempering Parameters to Enhance Precipitation Behavior and Impact Toughness in High-Nickel Steel. Metals 2024, 14, 898. https://doi.org/10.3390/met14080898

Sun G, Wang Q. Optimizing Tempering Parameters to Enhance Precipitation Behavior and Impact Toughness in High-Nickel Steel. Metals. 2024; 14(8):898. https://doi.org/10.3390/met14080898

Chicago/Turabian StyleSun, Guojin, and Qi Wang. 2024. "Optimizing Tempering Parameters to Enhance Precipitation Behavior and Impact Toughness in High-Nickel Steel" Metals 14, no. 8: 898. https://doi.org/10.3390/met14080898