Study on the Influence of Thickness on the Pre-Bending Process of the JCOE Forming Plate Edge of Nickel-Based Alloy N08810

Abstract

:1. Introduction

2. Materials and Methods: Mold Optimization and Process Parameter Modeling

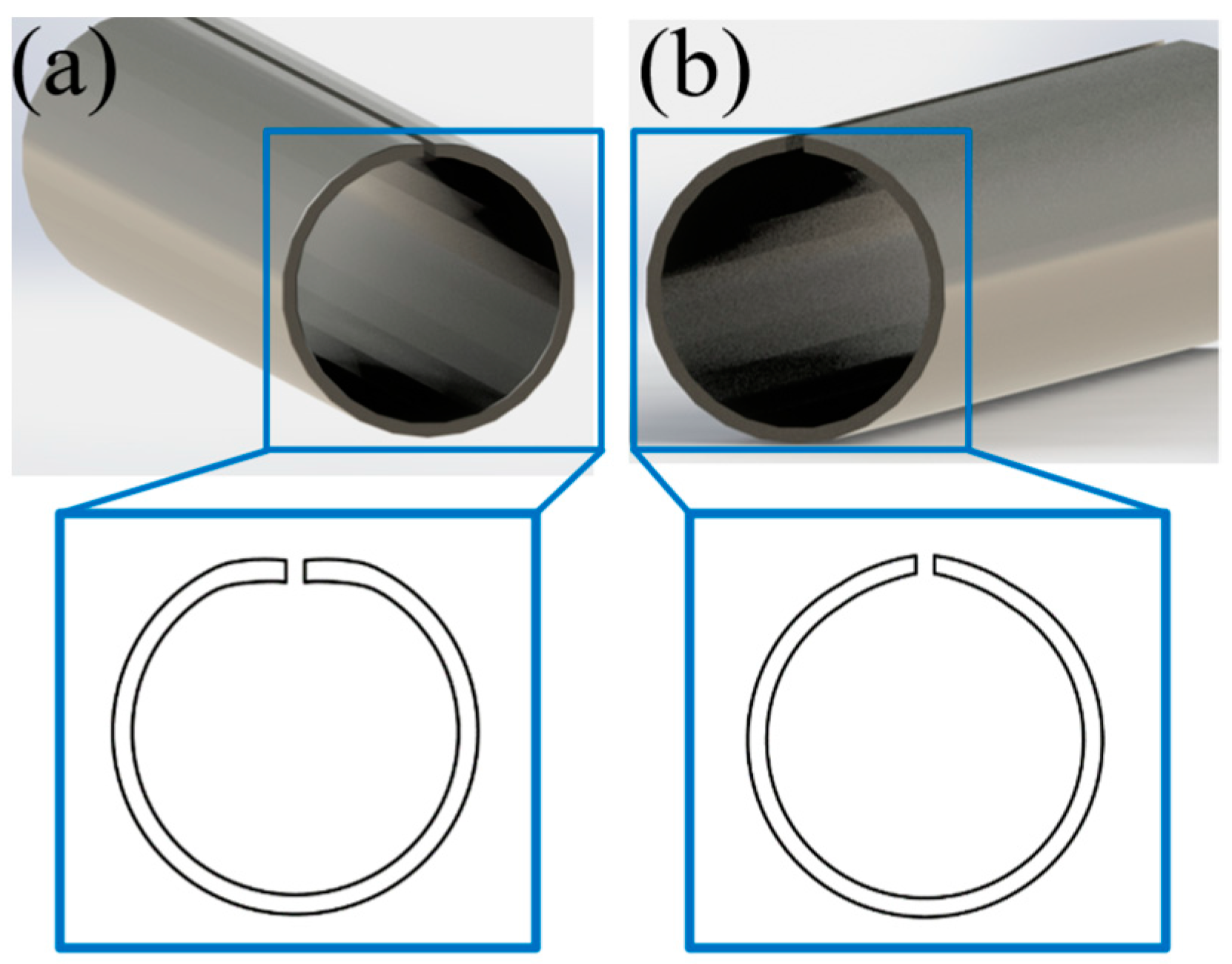

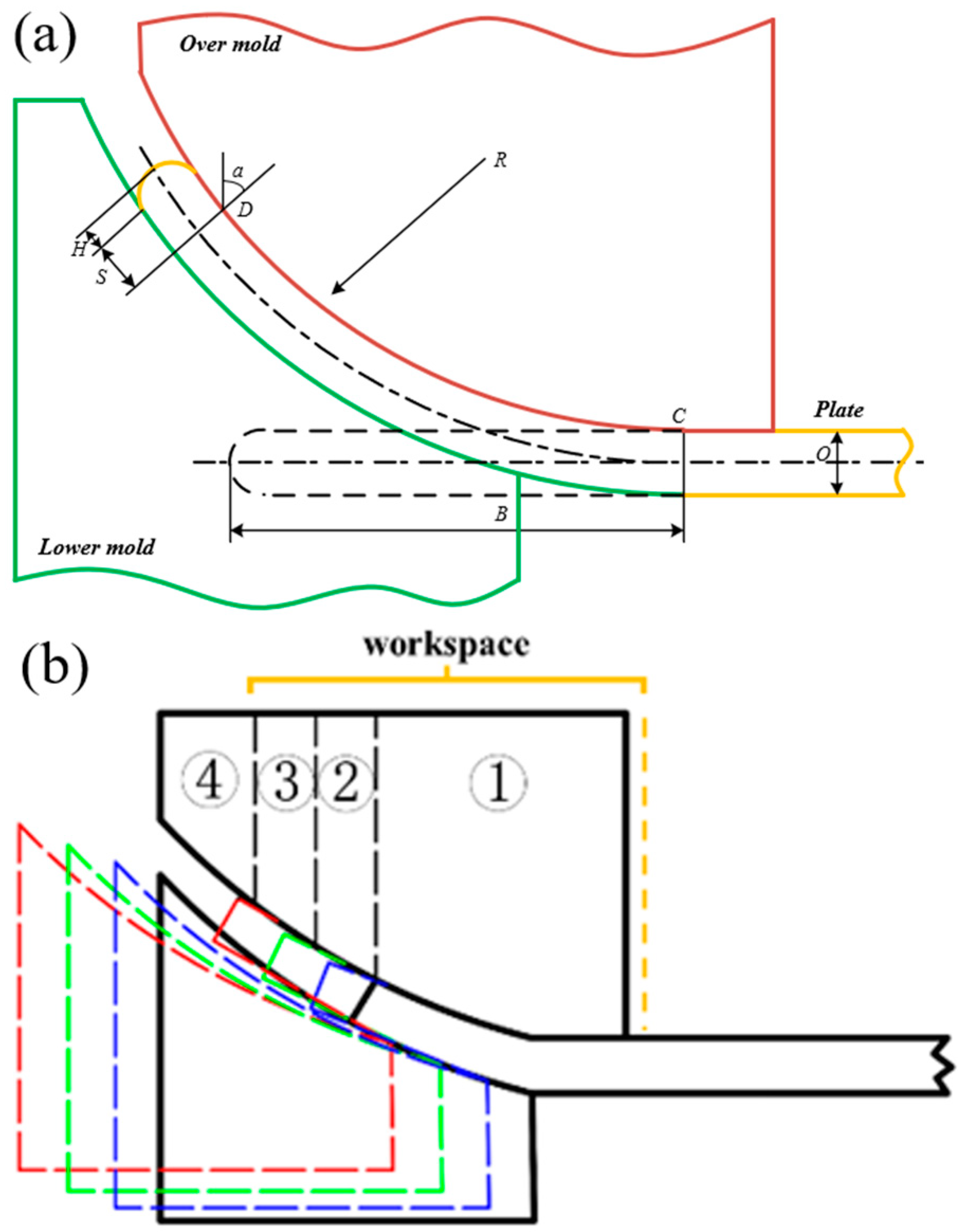

2.1. Optimization of the Pre-Bending Mold

2.2. Optimization of Key Parameters of Pre-Bending Theory

2.2.1. Springback Bending Angle

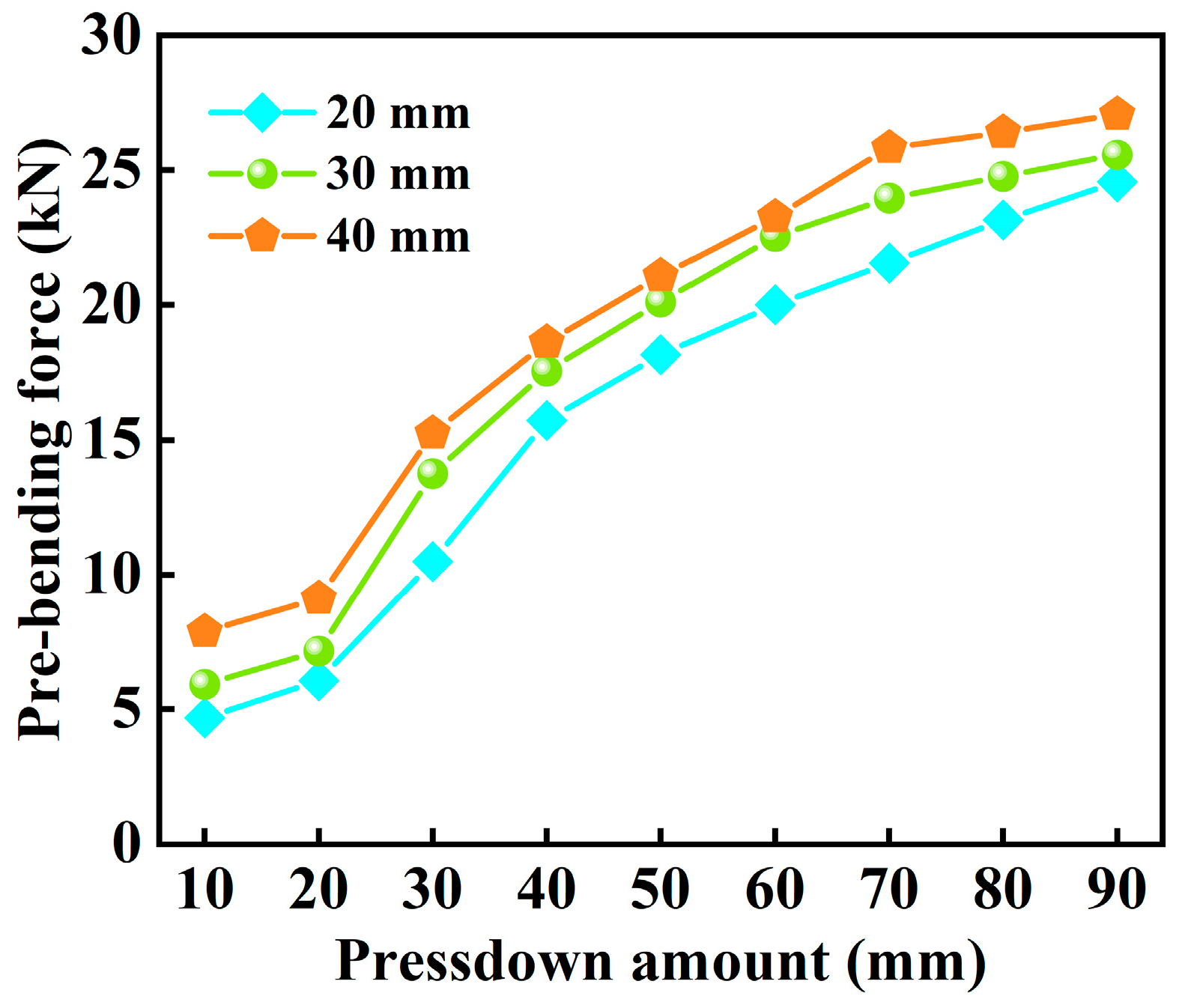

2.2.2. Pre-Bending Force

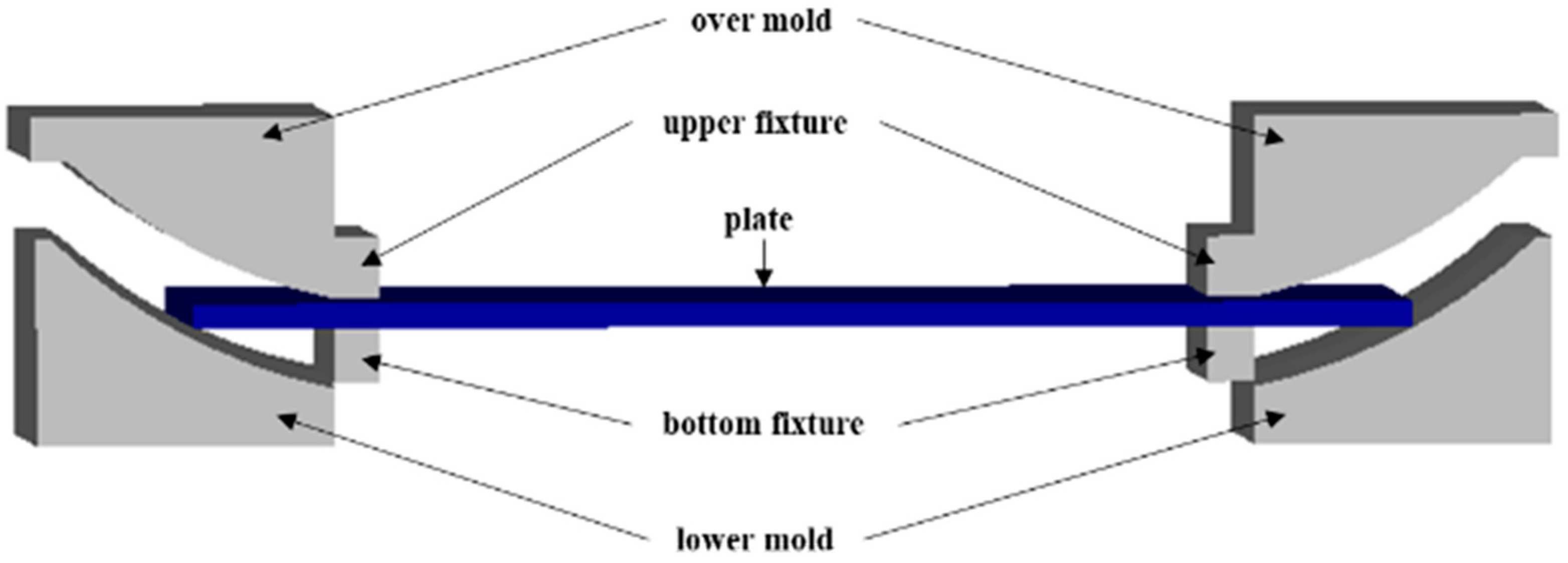

3. Experimental Methods and Numerical Simulations

3.1. Test Materials and Methods

3.2. Numerical Simulation

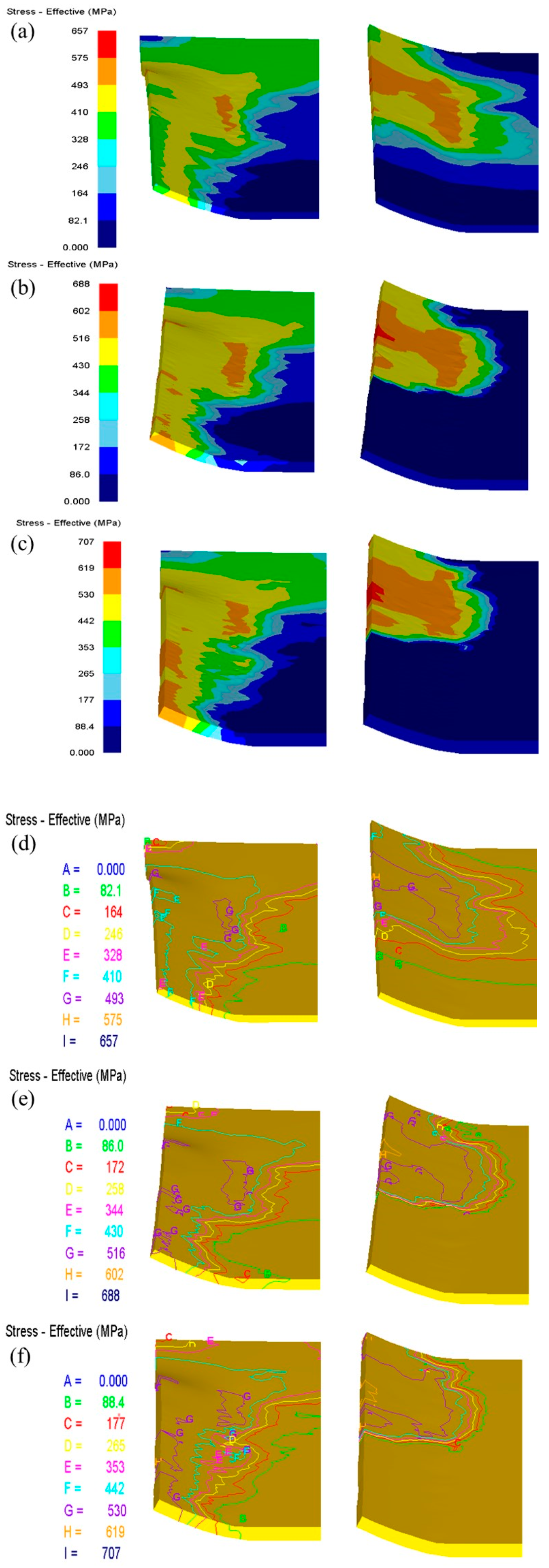

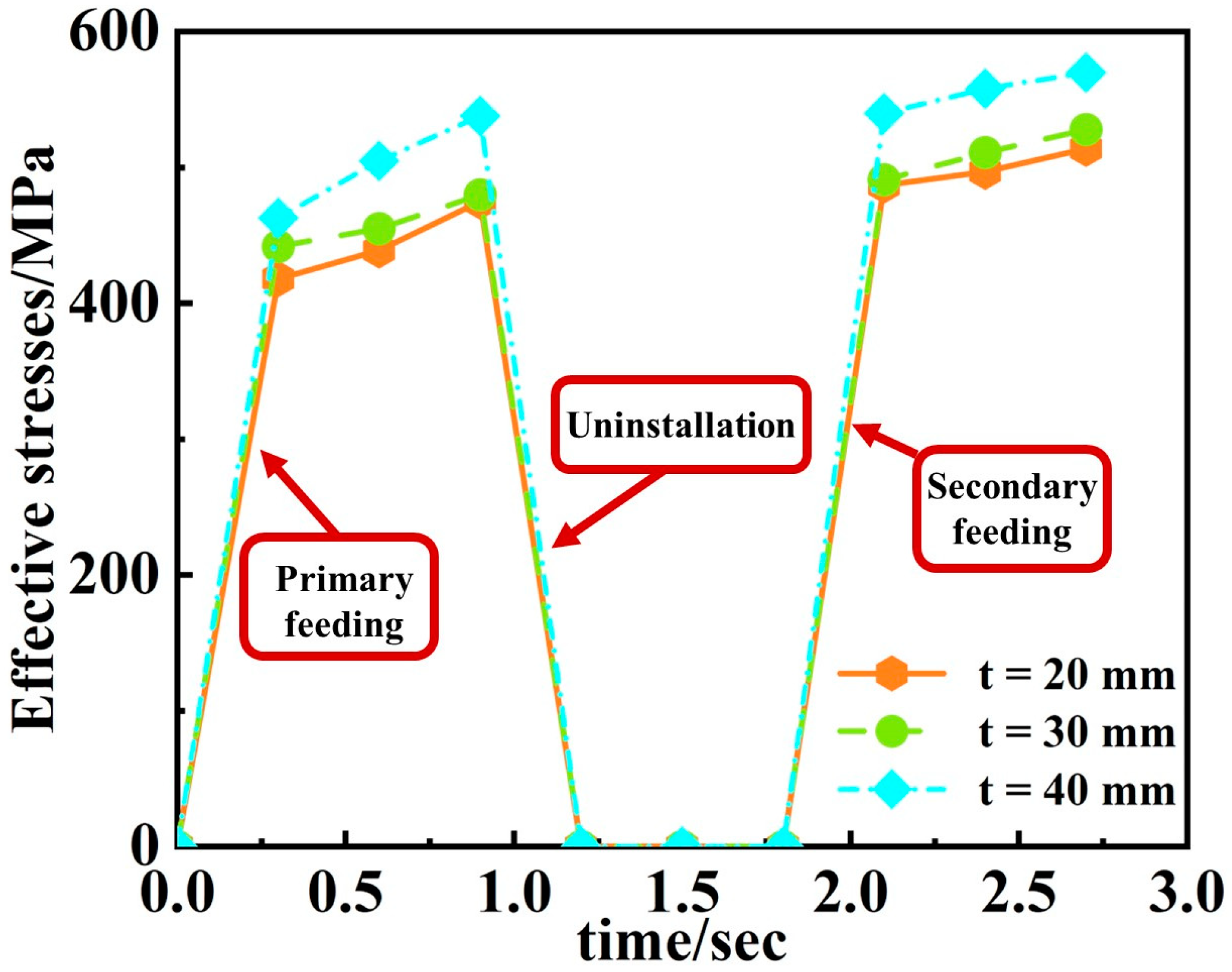

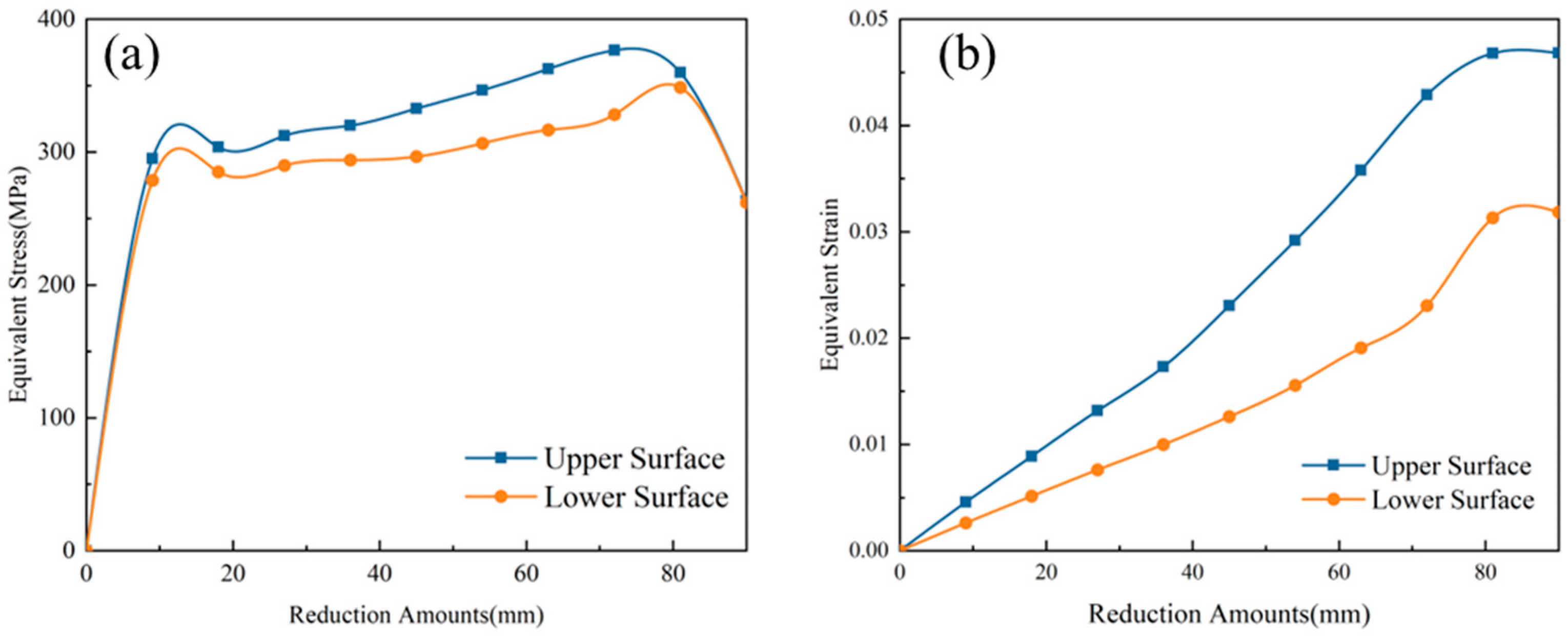

3.2.1. Stress Distribution at Plate Edge

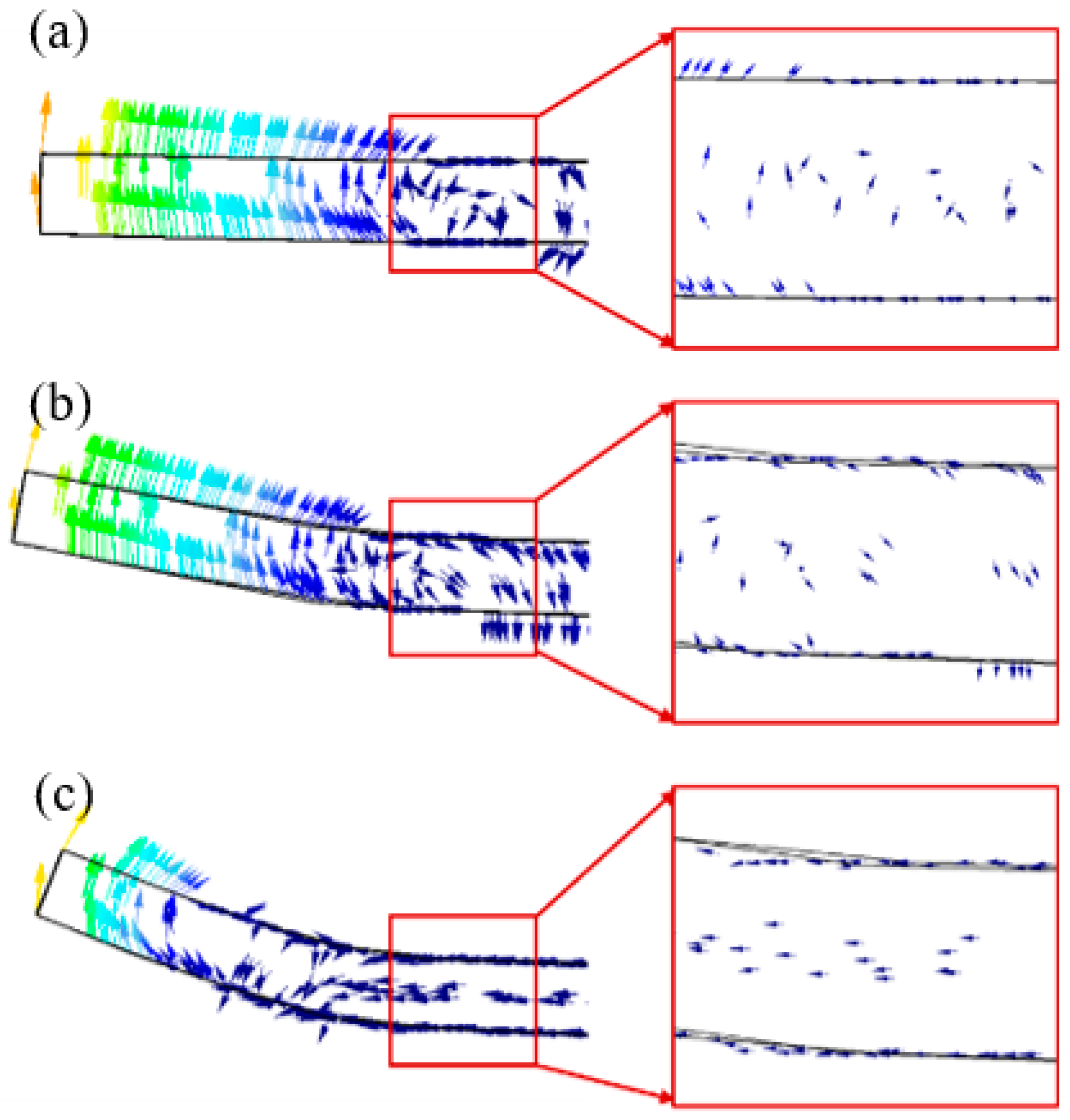

3.2.2. Pre-Bending Metal Flow at the Plate Edge

4. Results and Analysis

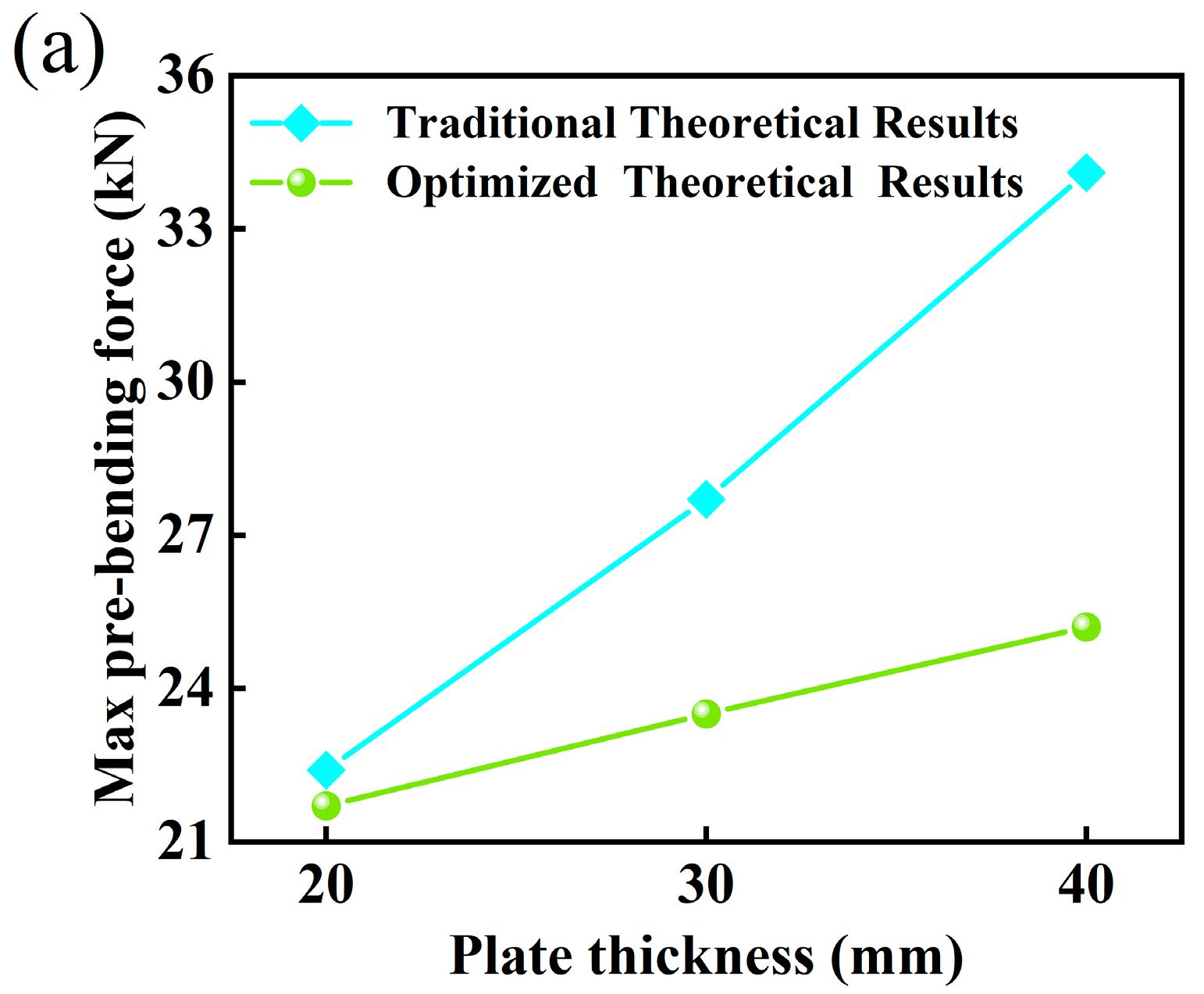

4.1. Influence of Different Plate Thicknesses on the Pre-Bending Force at the Plate Edge

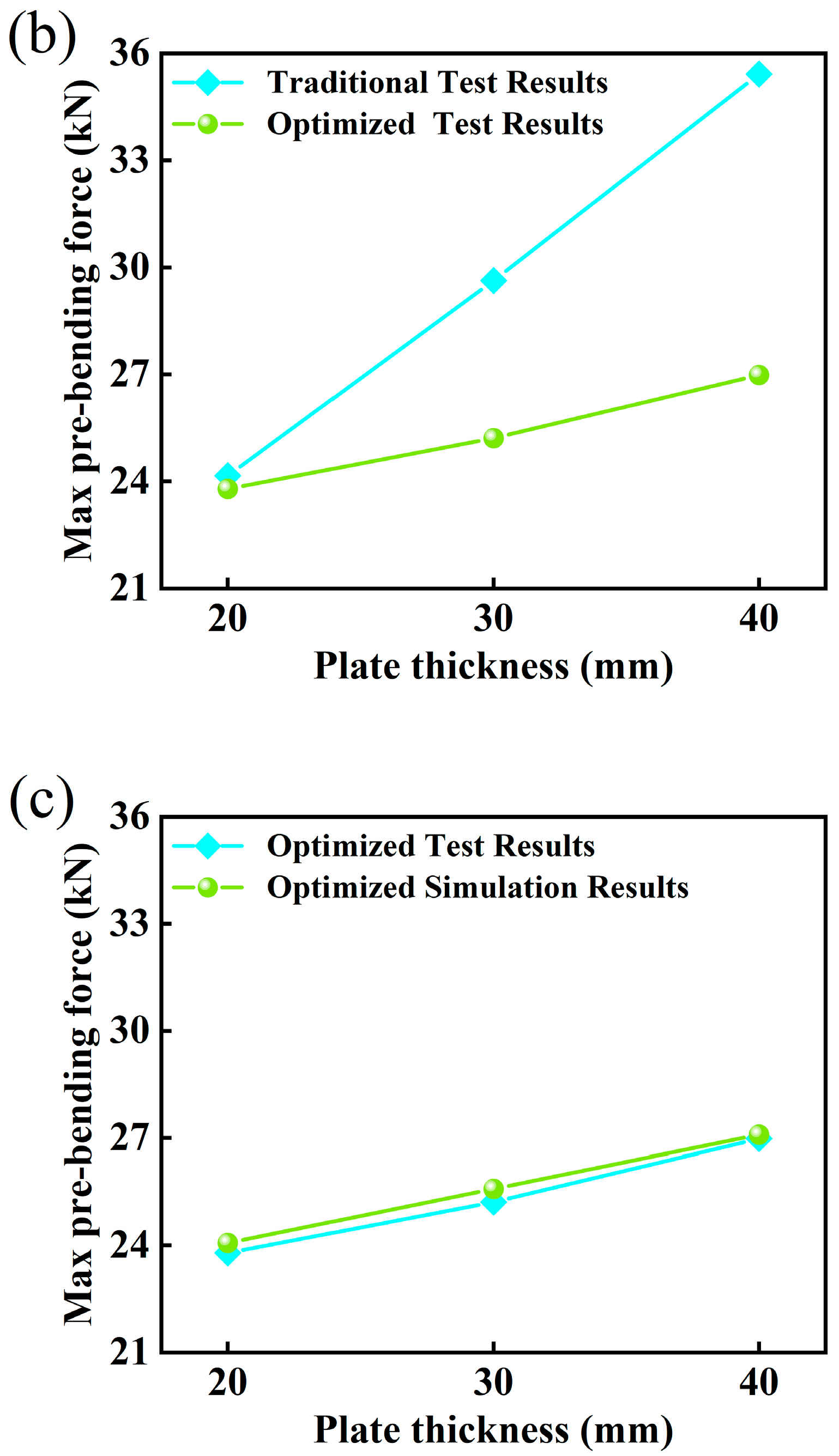

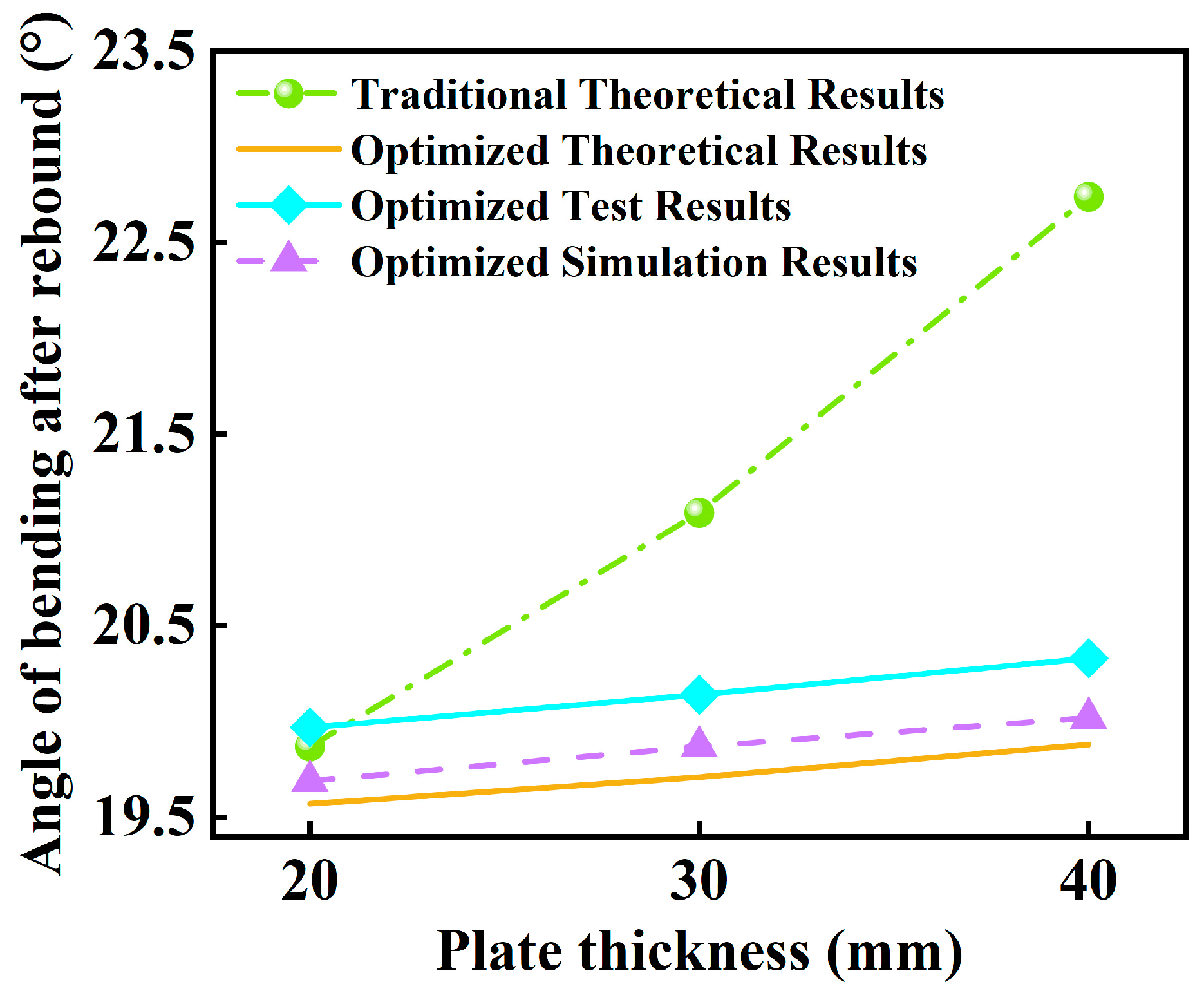

4.2. Effect of Different Plate Thicknesses on the Bending Angle after Springback

5. Conclusions

- (1)

- Upon the foundation of the conventional pre-bending process, this paper addresses the issue of frequent mold exchange necessitated by varying plate thicknesses during pre-bending operations. To overcome this challenge, we introduce an innovative mold phase difference model and subsequently develop a theoretical framework that aligns key parameters with the optimized springback bending angle and pre-bending force, achieved through meticulous mold configuration optimization.

- (2)

- In this study, we employed the finite element method to simulate the pre-bending process of nickel-based alloy N08810 plates of varying thicknesses. Following mold optimization, we delved into the evolution of the equivalent stress and metal flow behavior during the pre-bending phase, subsequently elucidating the influence of plate thickness on both the pre-bending force and the springback bending angle. Our findings indicate that the pre-bending force escalates in tandem with an increase in plate thickness, while the overall trend of the pre-bending force curve remains consistent across different plate thicknesses. Furthermore, we discovered a linear correlation between plate thickness and the springback bending angle, with the latter also progressively augmenting as plate thickness increases.

- (3)

- By means of comprehensive theoretical calculations, rigorous simulation analyses, and extensive experimental verifications, this paper introduces an innovative pre-bending methodology aimed at enhancing the forming quality of JCOE pipes. This method effectively attains the optimal springback bending angle while minimizing the pre-bending force required, thereby furnishing a robust theoretical foundation that underpins practical applications in industrial production.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiao, L.; Li, W.; Cota-Sanchez, G. Mechanical property and microstructure characterization of incoloy 800H alloy and its welds after corrosion testing in high temperature steam. Nucl. Eng. Des. 2022, 398, 111970. [Google Scholar] [CrossRef]

- Ju, J.; Ma, Y.; Chen, J.; Shuai, L.; Zhang, Y. Effect of Heat Treatment on Structure Evolution and Mechanical Property Strengthening of Low-Cobalt Nickel-Based Superalloy. Metals 2024, 14, 872. [Google Scholar] [CrossRef]

- Zhao, X.L.; Ren, K.M.; Lu, X.H.; He, F.; Jiang, Y.K. Investigation on microstructure and mechanical properties of ni-based alloy overlayer by ultrasonic impact treatment. J. Mech. Sci. Technol. 2022, 36, 3973–3981. [Google Scholar] [CrossRef]

- Chintada, V.B.; Koona, R.; Raju Bahubalendruni, M.V.A. State of Art Review on Nickel-Based Electroless Coatings and Materials. J. Bio- Tribo-Corros. 2021, 7, 134. [Google Scholar] [CrossRef]

- Tovmasyan, M.A.; Samsuev, S.V.; Sidorova, T.Y.; Nguen, V.T. Study of Changes in the Shape of a Pipe Blank Taking into Account the Peculiarities of Contact Interaction with a Deforming Tool during JCOE Molding in the TESA 1420 Line. Steel Transl. 2023, 53, 938–944. [Google Scholar] [CrossRef]

- Xu, L.Z.; Qiao, G.Y.; Lu, X.X.; Gu, Y.; Xu, K.; Chen, X.W.; Xiao, F.R. Microstructure evolution and deformation mechanism along the thickness of heavy-wall ferrite-bainite dual-phase offshore pipelines by the progressive forming process. J. Mater. Process. Technol. 2024, 326, 18355. [Google Scholar] [CrossRef]

- Shabalov, I.P.; Solov’ev, D.M.; Filippov, G.A.; Livanova, O.V. Mechanical properties of a pipe workpiece at the stages of JCOE pipe forming. Russ. Metall. (Met.) 2015, 38, 309–316. [Google Scholar] [CrossRef]

- Qi, S.C.; Yu, G.C.; Chen, S.G. Numerical Simulation of Residual Stress in the JCO-Welding-Calibration Whole Process Forming of the Submarine Pipeline Pipes. In Proceedings of the 14th International Conference on the Technology of Plasticity—Current Trends in the Technology of Plasticity; Mocellin, K., Bouchard, P.-O., Bigot, R., Balan, T., Eds.; Springer: Cham, Switzerland, 2024; Volume 2, pp. 653–663. [Google Scholar]

- Fan, L.F.; Yan, J.X.; Gao, Y.; Yun, J.B. Research on deformation characteristics of JCOE forming in large diameter welding pipe. Adv. Manuf. 2016, 4, 268–277. [Google Scholar] [CrossRef]

- Antoniou, K.; Chatzopoulou, G.; Karamanos, S.; Tazedakis, A.; Palagas, C.; Dourdounis, E. Numerical simulation of JCO-E pipe manufacturing process and its effect on the external pressure capacity of the pipe. J. Offshore Mech. Arct. Eng. 2019, 141, 011704. [Google Scholar] [CrossRef]

- Chandel, J.D.; Singh, N.L. Formation of X-120 M Line Pipe through J-C-0-E Technique. Engineering 2011, 3, 400–410. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Song, J.L.; Fu, J.H. A Refined Model of Three-roller Elastoplastic Asymmetrical Pre-bending of Plate. J. Iron Steel Res. Int. 2014, 3, 328–334. [Google Scholar] [CrossRef]

- Lv, G.M.; Zhang, S.F.; Song, L.H. Influence of auxiliary mold stretch-bend forming on the forming quality for L-section aluminum alloy profile. Int. J. Lightweight Mater. Manuf. 2023, 2, 254–263. [Google Scholar] [CrossRef]

- Borges, J.G.O.; Karam, V.J. Elastic-viscoplastic analysis of plate bending with Reissner’s theory by the Boundary Element Method. Eng. Anal. Bound. Elem. 2021, 132, 146–158. [Google Scholar] [CrossRef]

- Gavriilidis, I.; Stamou, A.G.; Palagas, C.; Dourdounis, E.; Voudouris, N.; Tazedakis, A.; Karamanos, S.A. Heat treatment effects on collapse of JCO-E steel pipes under external pressure: Experiments and numerical predictions. Mar. Struct. 2024, 93, 103536. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Q.; Xiao, L.C. Numerical Simulation of JCOE Pipe Forming. In Proceedings of the 2009 World Congress on Computer Science and Information Engineering, Los Angeles, CA, USA, 31 March 2009. [Google Scholar]

- Marciniak, Z.; Duncan, J.L.; Hu, S.J. Mechanics of Sheet Metal Forming, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2002. [Google Scholar]

- Chatzopoulou, G.; Karamanos, S.A.; Varelis, G.E. Finite element analysis of UOE manufacturing process and its effect on mechanical behaviour of offshore pipes. Int. J. Solids Struct. 2016, 83, 13–27. [Google Scholar] [CrossRef]

- Xue, P.; Yu, T.X.; Chu, E. An energy approach for predicting springback of metal sheets after double-curvature forming part I:Axisymmetric stamping. Int. J. Mech. Sci. 2001, 43, 1893–1914. [Google Scholar] [CrossRef]

- Nader, A. Springback and fracture in v-die air bending of thick stainless steel sheets. Mater. Des. 2000, 21, 217–236. [Google Scholar]

- Du, B.; Li, H.X.; Zheng, W.; He, X.D.; Ma, T.; Yin, H.Q. Study of oxidation behavior and tensile properties of candidate superalloys in the air ingress simulation scenario. Nucl. Eng. Technol. 2023, 55, 71–79. [Google Scholar] [CrossRef]

- Yang, J.L.; Bai, J.J.; Li, J.J. Hardening behavior of nickel-base alloy irradiated by multi-energy Fe ions. J. Mater. Res. Technol. 2024, 29, 1000–1009. [Google Scholar] [CrossRef]

- Liu, M.M.; Liu, Y.L.; Li, H. Deformation analysis of double wall brazed tube in the multi-pass roll forming: Cross-sectional variation, stress-strain evolution and roundness assessment. J. Manuf. Process. 2023, 85, 479–491. [Google Scholar] [CrossRef]

- Madhav, V.; Krishnaswamy, H.; Majumdar, S. Analysis of UOE forming process accounting for Bauschinger effect and welding. Mater. Manuf. Process. 2020, 35, 910–921. [Google Scholar] [CrossRef]

- Al-Zahrani, E.S.; Ogunlakin, N.; Toor, I.U.; Djukic, M.B. Hydrogen-induced cracking of longitudinally submerged arc welded HSLA API 5L X65 carbon steel pipeline. Eng. Fail. Anal. 2024, 163. ISSN 1350–6307. [Google Scholar] [CrossRef]

- Zhao, J.; Yin, J.; Ma, R. Springback equation of small curvature plane bending. Sci. China Technol. 2021, 54, 2386–2396. [Google Scholar] [CrossRef]

- Zhang, L.J.; Pei, Q.; Zhang, J.X. Study on the microstructure and mechanical properties of explosive welded 2205/X65 bimetallic sheet. Mater. Des. 2014, 64, 462–476. [Google Scholar] [CrossRef]

- Hua, L.; Zhang, W.P.; Hu, L.; Zhang, Z.C.; Hu, Z.L. Mechanical responses and microstructure evolution of a 7A09 aluminum alloy extrusion profile during novel stretch bending. Mater. Charact. 2024, 212, 113938. [Google Scholar] [CrossRef]

- Qiu, C.; Xu, R.; Xu, X.; Ma, S. Finite Element Simulation of Multi-Pass Rolling of a Pure Aluminum Target under Different Rolling Routes and Methods. Metals 2024, 14, 845. [Google Scholar] [CrossRef]

- Hu, H.; Yu, F.; Zhang, S.; Yin, J.; Zhang, H.; Zhang, J.; Zhang, X.; Cao, M.; Murtaza, S. Ultrasonic-Assisted Granular Medium Forming of Aluminum Alloy 6063-T5: Simulations and Experiments. Metals 2024, 14, 847. [Google Scholar] [CrossRef]

- Koshmin, A.; Zinoviev, A.; Cherkasov, S.; Mahmoud Alhaj Ali, A.; Tsydenov, K.; Churyumov, A. Finite Element Modeling and Experimental Verification of a New Aluminum Al-2%Cu-2%Mn Alloy Hot Cladding by Flat Rolling. Metals 2024, 14, 852. [Google Scholar] [CrossRef]

- Gao, Y. Study on Theory and Computer Simulation of JCO Forming Forlarge-Diamater Longitudinal Welded Pipe. Ph.D. Thesis, Yanshan University, Qinhuangdao, China, 2011; pp. 16–41. [Google Scholar]

| Materials | Elastic Modulus /GPa) | Yield Strength RP (0.2N/mm2) | Tensile Strength Rm (N/mm2) | Poisson | Density (g/cm3) | Elongation A5% |

|---|---|---|---|---|---|---|

| N08810 | 216 | 180 | 450 | 0.3 | 8.04 | 35 |

| Materials | % | Ni | Cr | Fe | C | Mn | Si | Cu | S | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| N08810 | Min | 30 | 19 | - | 0.05 | - | - | - | - | 0.15 | 0.15 |

| Max | 35 | 23 | - | 0.10 | 1.5 | 1 | 0.75 | 0.015 | 0.60 | 0.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Ma, C.; Xue, C.; Gui, H.; Shuai, M.; Chu, Z. Study on the Influence of Thickness on the Pre-Bending Process of the JCOE Forming Plate Edge of Nickel-Based Alloy N08810. Metals 2024, 14, 1032. https://doi.org/10.3390/met14091032

Li T, Ma C, Xue C, Gui H, Shuai M, Chu Z. Study on the Influence of Thickness on the Pre-Bending Process of the JCOE Forming Plate Edge of Nickel-Based Alloy N08810. Metals. 2024; 14(9):1032. https://doi.org/10.3390/met14091032

Chicago/Turabian StyleLi, Tuo, Chuanchuan Ma, Chun Xue, Hailian Gui, Meirong Shuai, and Zhibing Chu. 2024. "Study on the Influence of Thickness on the Pre-Bending Process of the JCOE Forming Plate Edge of Nickel-Based Alloy N08810" Metals 14, no. 9: 1032. https://doi.org/10.3390/met14091032

APA StyleLi, T., Ma, C., Xue, C., Gui, H., Shuai, M., & Chu, Z. (2024). Study on the Influence of Thickness on the Pre-Bending Process of the JCOE Forming Plate Edge of Nickel-Based Alloy N08810. Metals, 14(9), 1032. https://doi.org/10.3390/met14091032