Improvement of Tribological Properties and Corrosion Resistance of AISI 4340M Steel by Shot Peening and Plating Technologies

Abstract

:1. Introduction

2. Experiments

2.1. Specimen Preparation, Heat Treatment and Shot Peening

2.2. Surface Roughness and Hardness Measurements

2.3. Wear Resistance Experiment

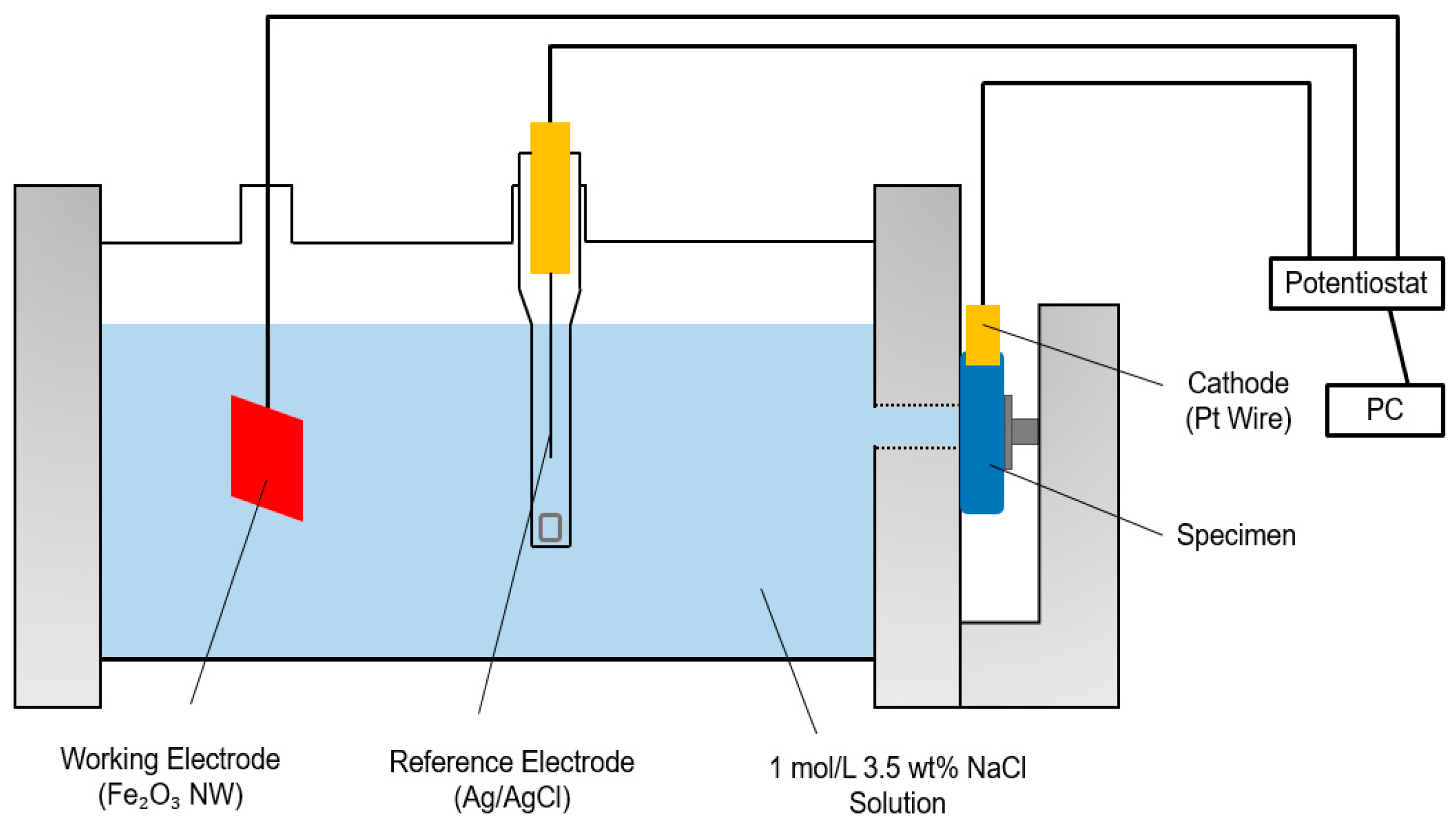

2.4. Electrochemical Corrosion Resistance Experiment

2.5. Surface and Wear Track Characterizations

3. Results and Discussion

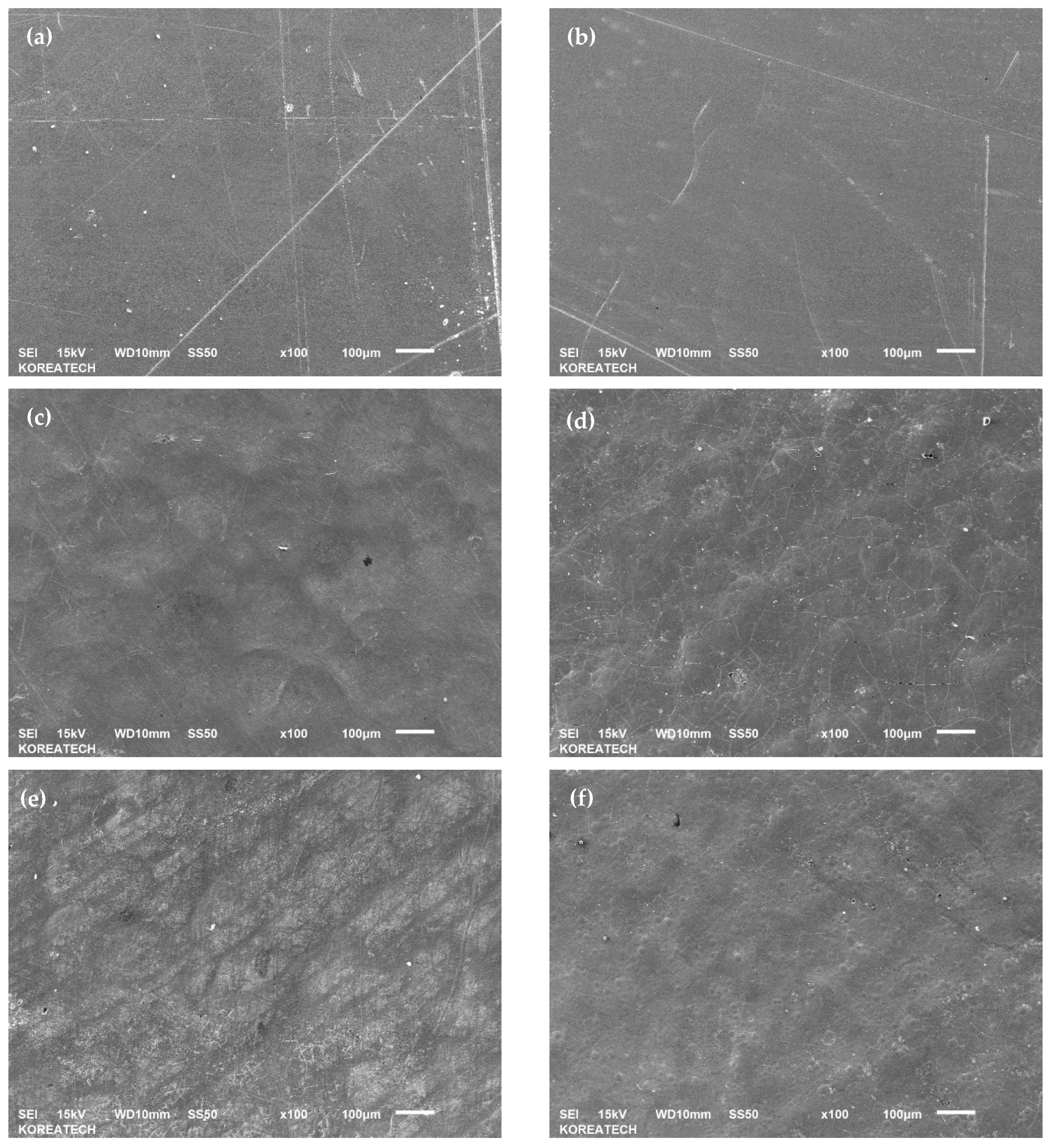

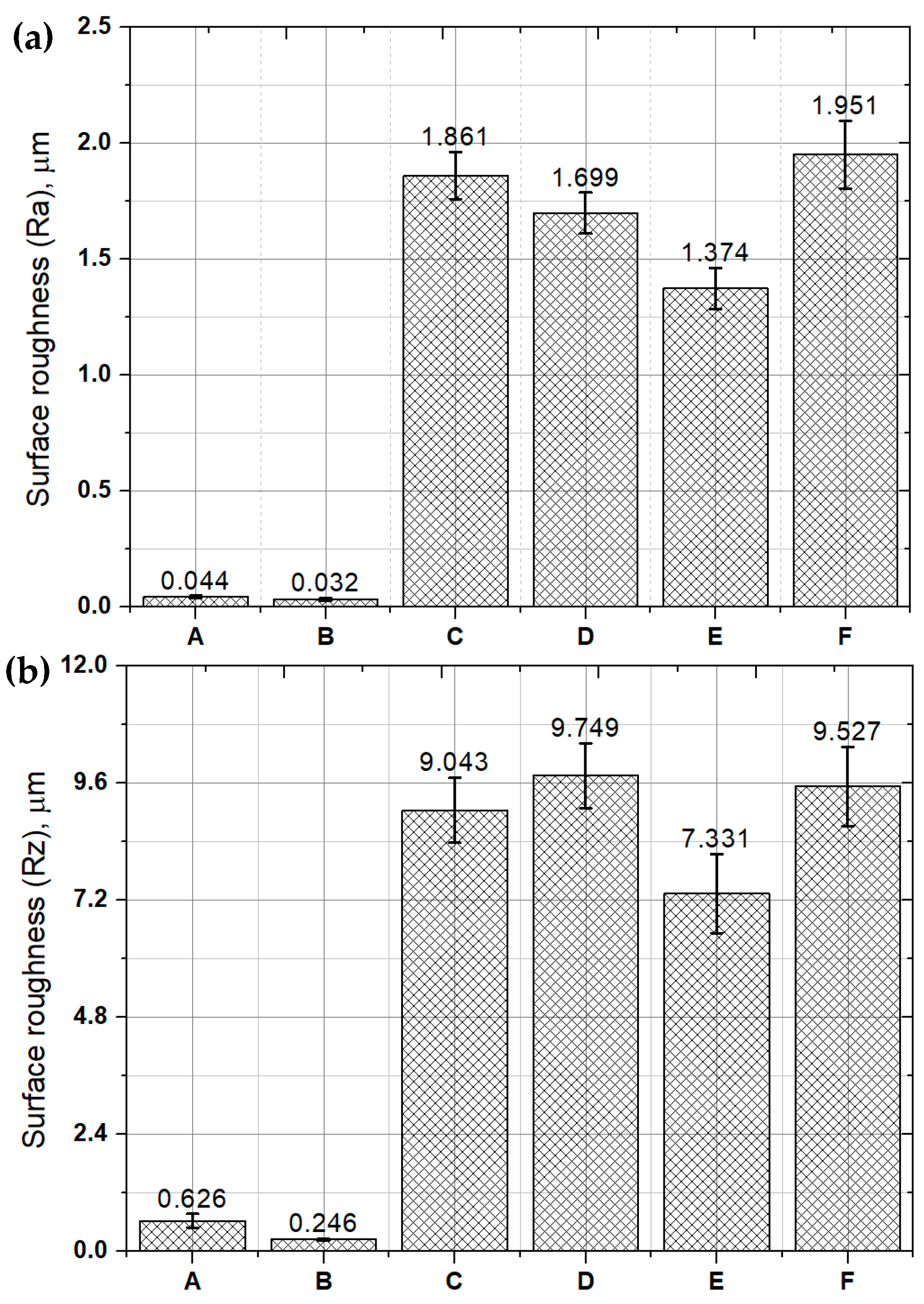

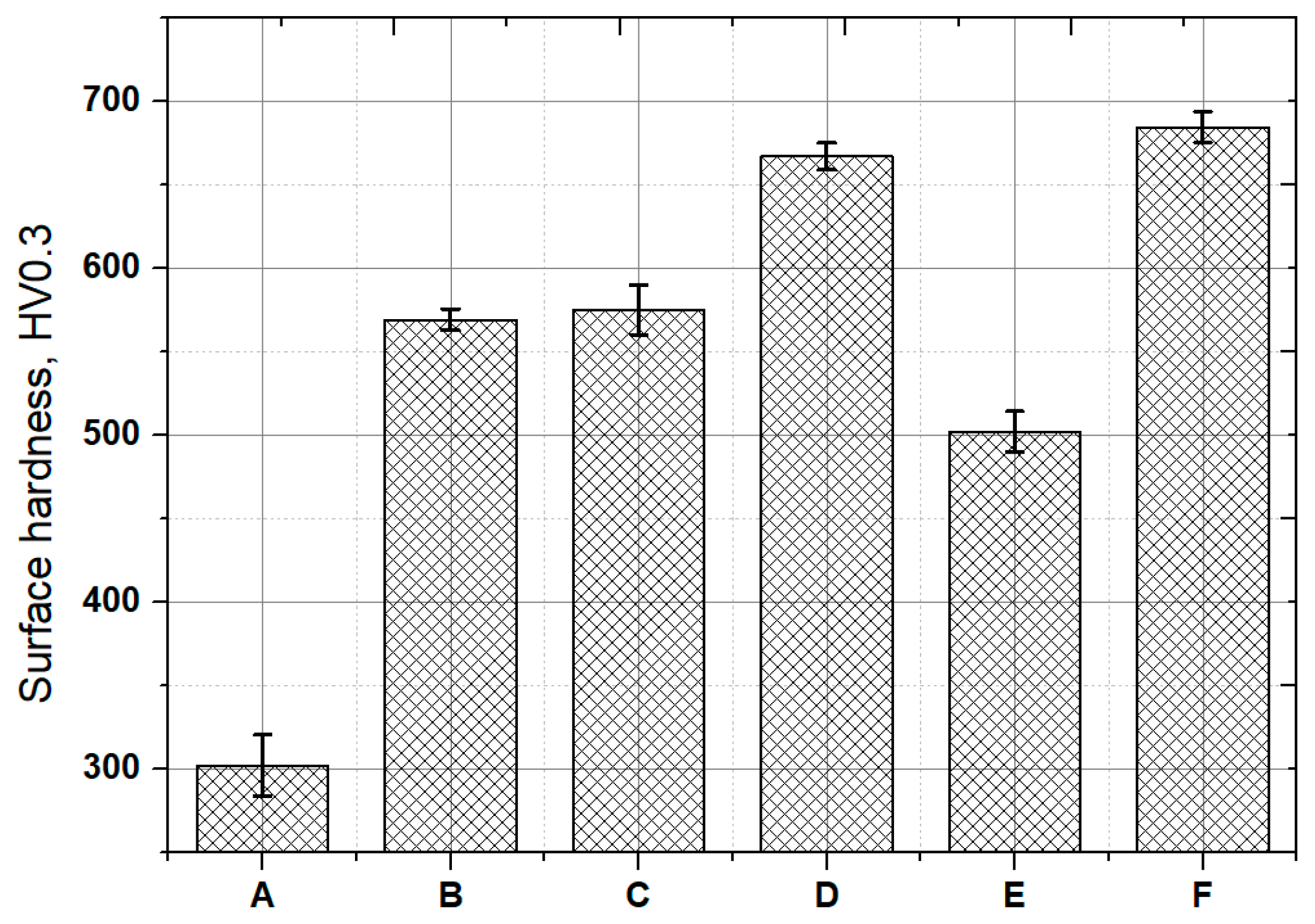

3.1. Surface Morphology, Roughness and Hardness Results

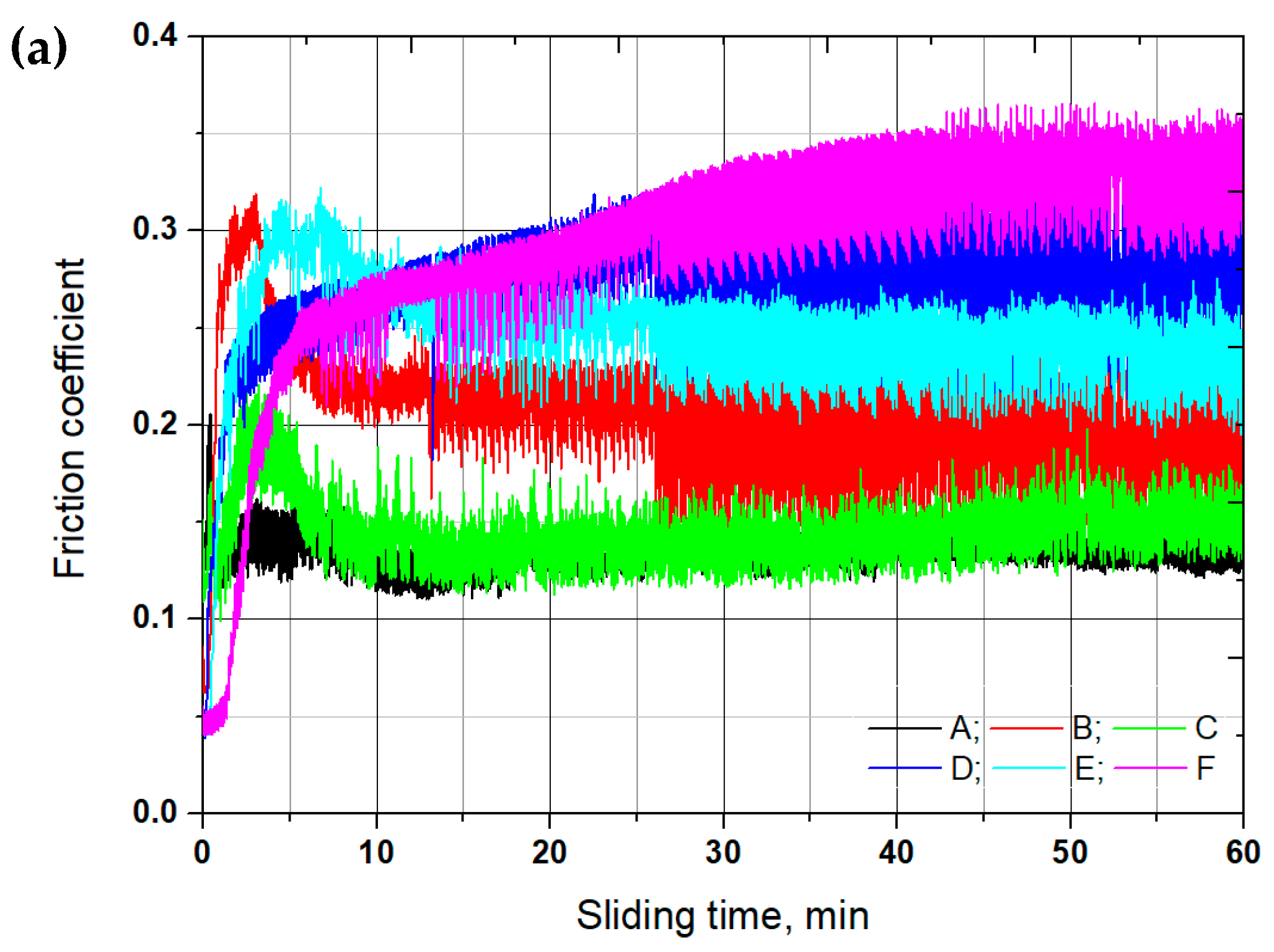

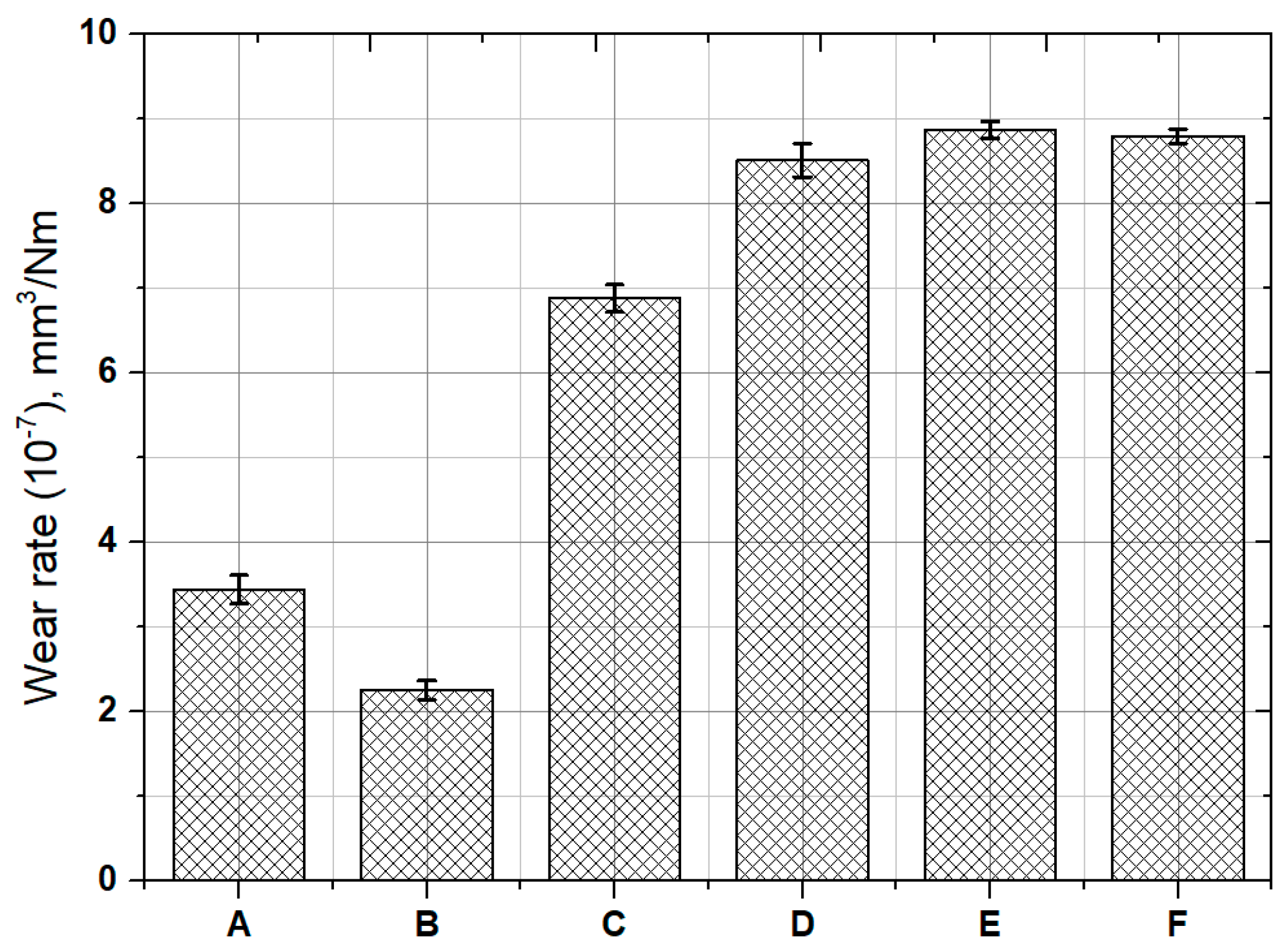

3.2. Frictional Behavior and Wear Resistance

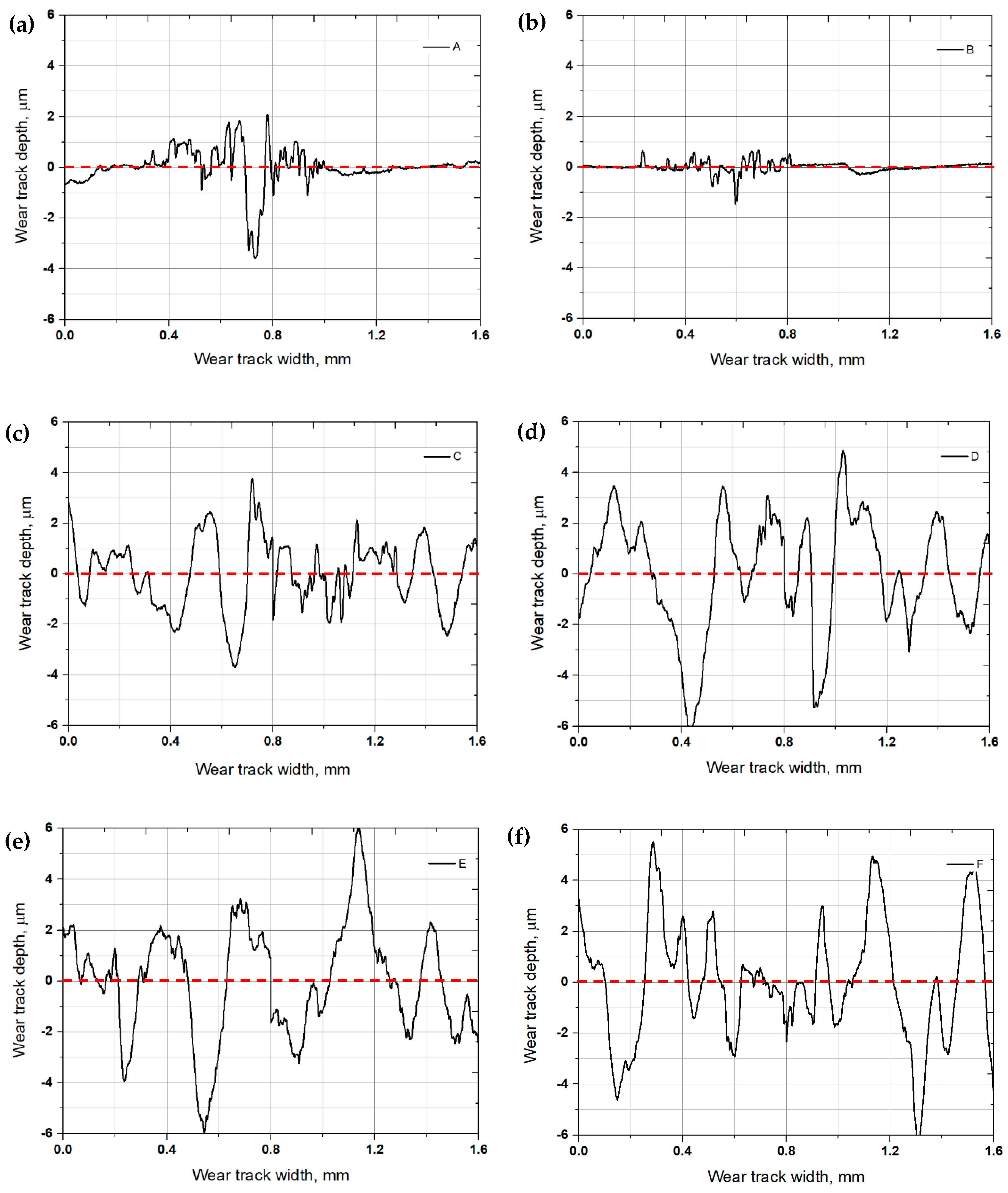

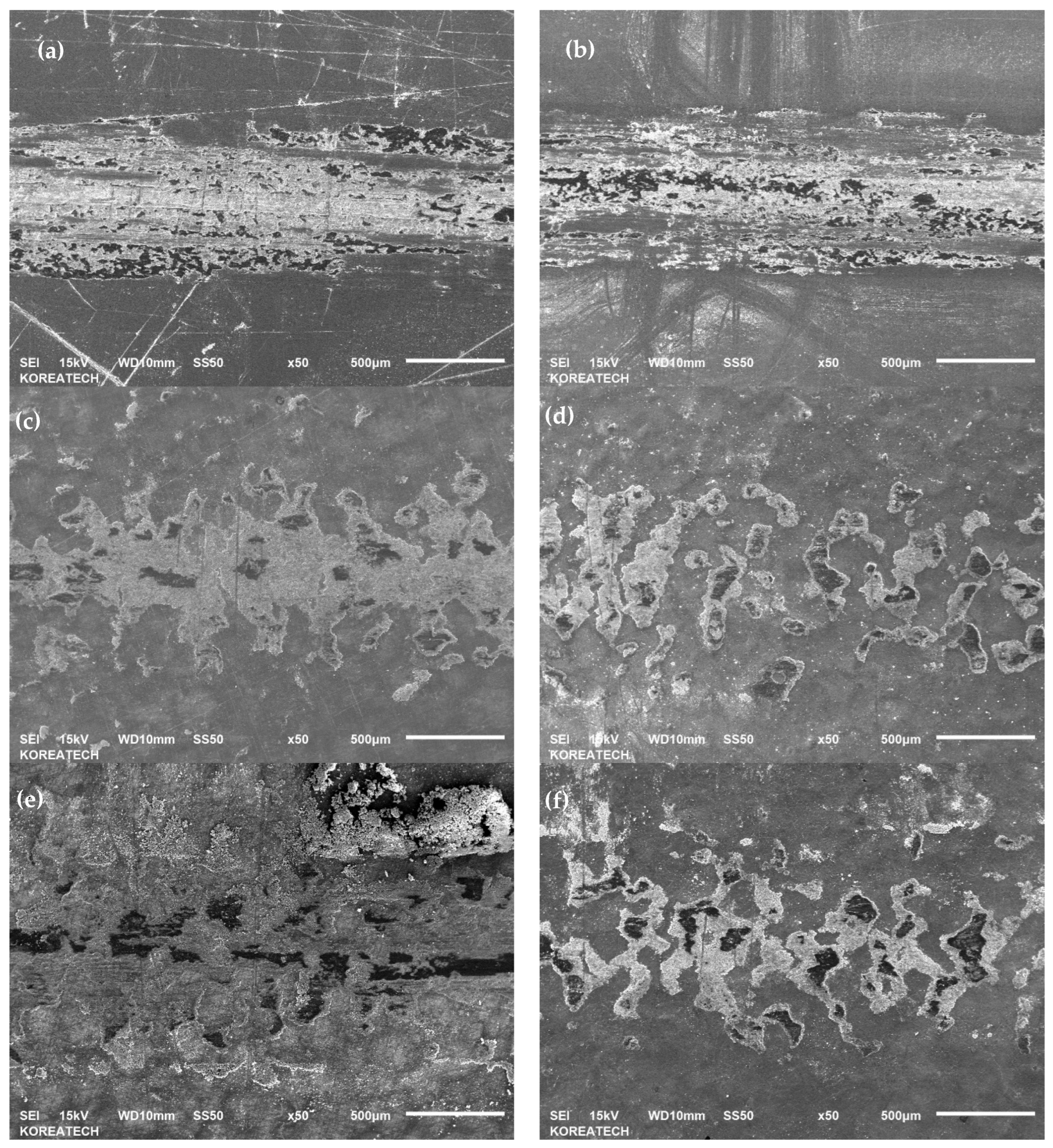

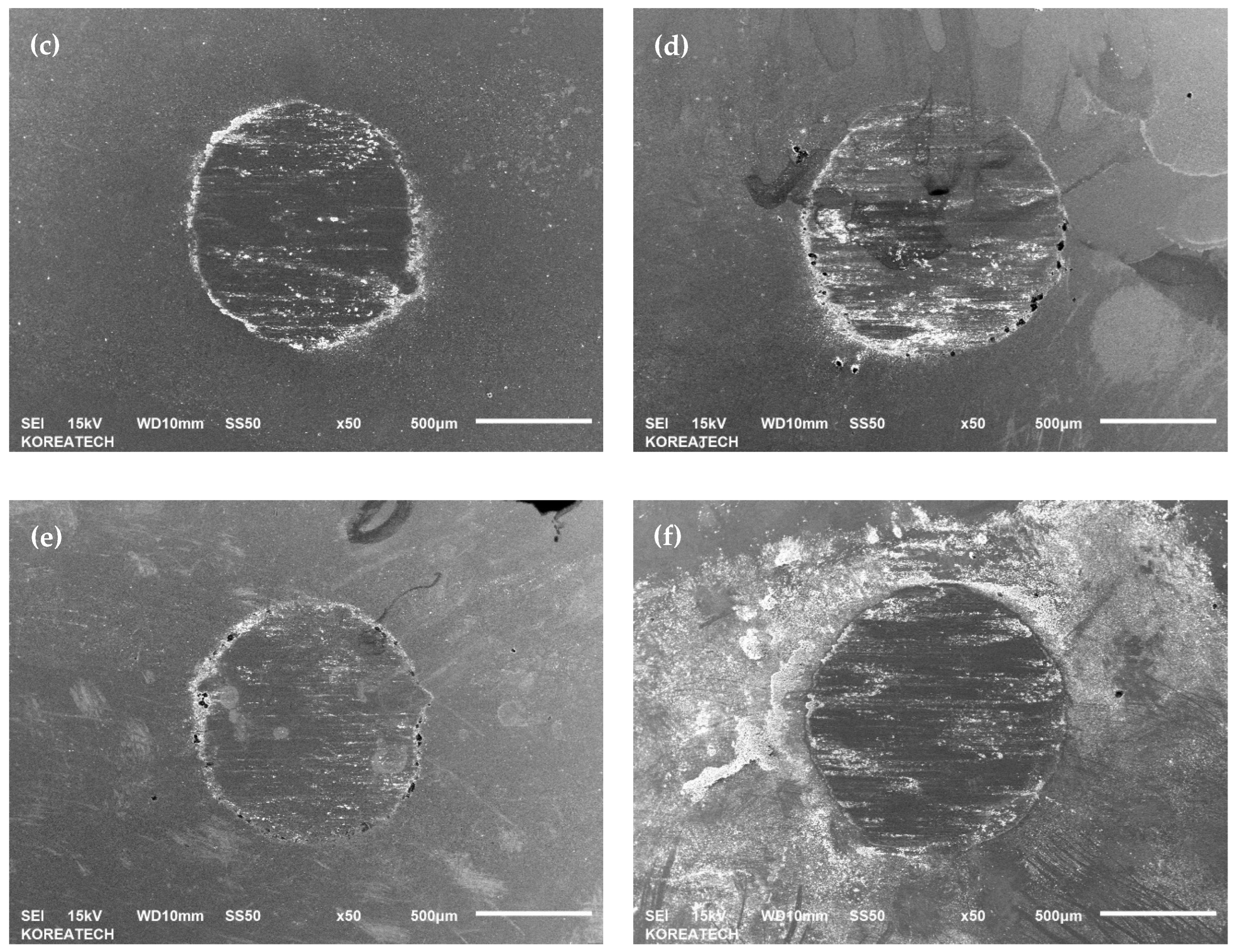

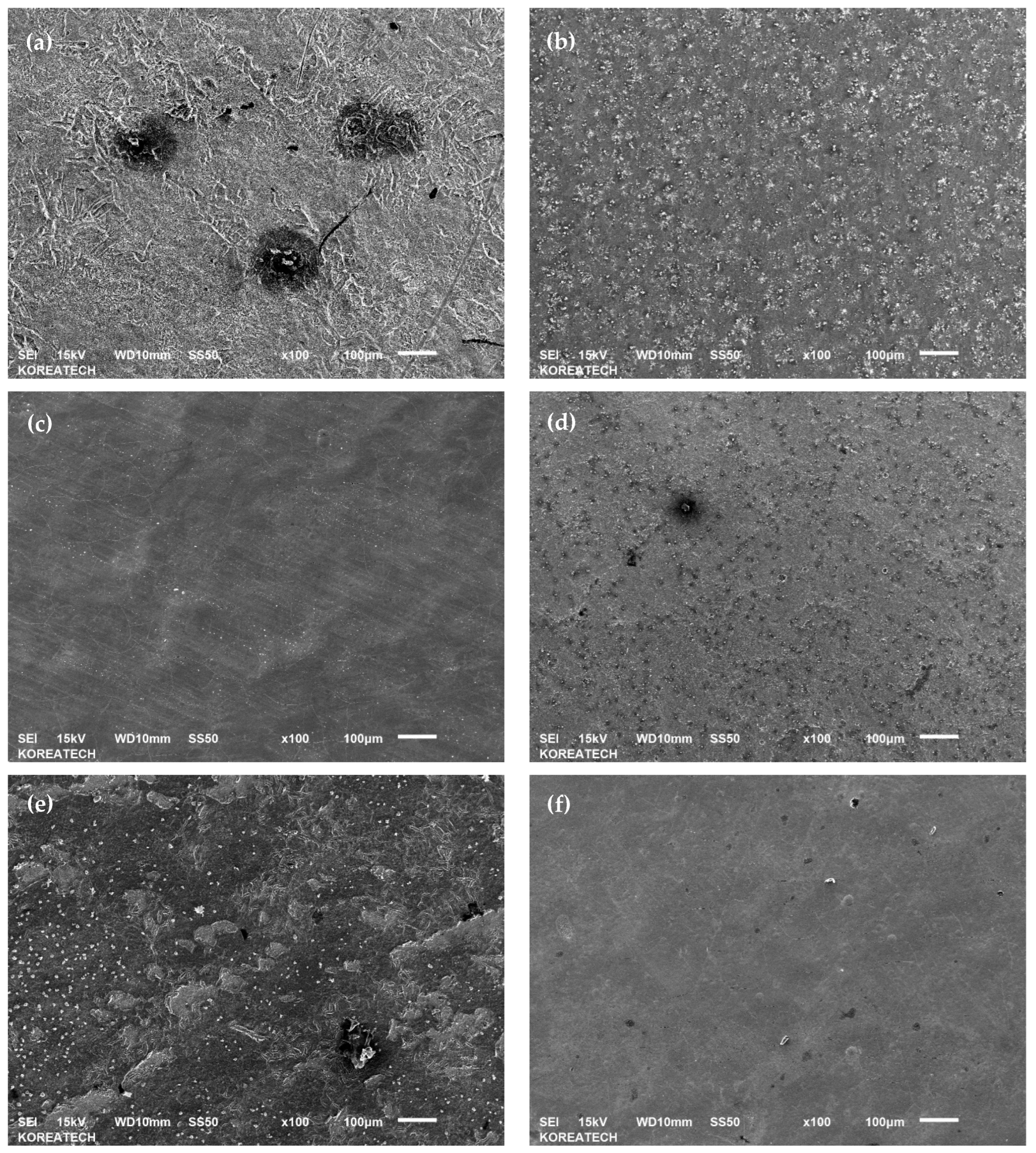

3.3. Worn-Out Surface Morphology and Wear Mechanisms

3.4. Corrosion Resistance

4. Conclusions

- -

- It was found that the surface roughness was changed, where the SP increased the surface roughness of the control, Cr-plated and stripped specimens. The control specimen was found to have the lowest surface roughness among the other specimens.

- -

- The QT heat treatment increased the hardness of the control specimen. SP performed on the control specimen increased the surface hardness, which was a bit higher than that of the QT heat-treated specimen.

- -

- The wear resistance of the control specimen was increased by QT heat treatment, where the QT heat-treated specimen showed the highest wear resistance due to increased surface hardness. Although the SPed specimen had a similar hardness compared to that of the QT heat-treated specimen, the wear resistance was found to be lower than the QT heat-treated specimen.

- -

- The wear mechanism under severe dry wear conditions and the refined structure by SP with a higher hardness did not demonstrate better wear resistance due to highly increased surface roughness.

- -

- SP and re-SP had better corrosion resistance compared to that of the QT heat-treated, Cr-plated and stripped specimens. It was found that the SP increased the corrosion resistance, which may be attributed to the surface roughness and other properties, but these results need to be confirmed with a more significant number of specimens to clearly understand the passivation mechanisms.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Park, J.B.; Jeon, J.H.; Seo, N.H.; Kang, S.O.; Son, S.B.; Lee, S.J.; Jung, J.G. Microstructure and mechanical behavior of AISI 4340 steel fabricated via spark plasma sintering and post-heat treatment. Mater. Sci. Eng. A 2023, 862, 144433. [Google Scholar] [CrossRef]

- Gowthaman, P.S.; Gowthaman, J.; Nagasundaram, N. A study of machining characteristics of AISI 4340 alloy steel by wire electrical discharge machining process. Mater. Today Proceed. 2020, 27, 565–570. [Google Scholar] [CrossRef]

- Marques, A.; Souza, R.A.; Pinto, G.A.M.; Galdino, A.G.S.; Machado, M.L.P. Evaluation of the softening mechanisms of AISI 4340 structural steel using hot torsion test. J. Mater. Res. Technol. 2020, 9, 10886–10900. [Google Scholar] [CrossRef]

- Torres, M.A.S.; Voorwald, H.J.C. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue 2002, 24, 877–886. [Google Scholar] [CrossRef]

- Sirin, S.Y.; Sirin, K.; Kaluc, E. Effect of the ion nitriding surface hardening process on fatigue behaviour of AISI 4340 steel. Mater. Charact. 2008, 59, 351–358. [Google Scholar] [CrossRef]

- Amanov, A. Surface engineering-controlled tribological behavior and adhesion strength of Ni-Cr coating sprayed onto carburized AISI 4340 steel substrate. Surf. Coat. Technol. 2019, 370, 144–156. [Google Scholar] [CrossRef]

- Clarke, A.J.; Klemm-Toole, J.; Clarke, K.D.; Coughlin, D.R.; Pierce, D.T.; Euser, V.K.; Poplawsky, J.D.; Clausen, B.; Brown, D.; Almer, J.; et al. Perspectives on quenching and tempering 4340 steel. Metall. Mater. Trans. A 2020, 51, 4984–5005. [Google Scholar] [CrossRef]

- Nascimento, M.P.; Souza, R.C.; Pigatin, W.L.; Voorwald, H. Effects of surface treatments on the fatigue strength of AISI 4340 aeronautical steel. Int. J. Fatigue 2001, 23, 607–618. [Google Scholar] [CrossRef]

- Ahn, S.H.; Heo, J.M.; Kim, J.S.; Hwang, H.S.; Cho, I.S. The effect of baking heat treatment on the fatigue strength and life of shot peened 4340M landing gear steel. Materials 2020, 13, 5711. [Google Scholar] [CrossRef] [PubMed]

- Tabieva, E.E.; Zhurerova, L.G.; Baizhan, D. Influence of electrolyte-plasma hardening technological parameters on the structure and properties of banding steel. Key Eng. Mater. 2020, 839, 57–62. [Google Scholar] [CrossRef]

- Karimbaev, R.; Pyun, Y.S.; Maleki, E.; Unal, O.; Amanov, A. An improvement in fatigue behavior of AISI 4340 steel by shot peening and ultrasonic nanocrystal surface modification. Mater. Sci. Eng. A 2020, 791, 139752. [Google Scholar] [CrossRef]

- ASTM G133-05; Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear. ASTM International: West Conshohocken, PA, USA, 2016.

- Sang, Y.; Sun, G.; Liu, J. A 4340 steel with superior strength and toughness achieved by heterostructure via intercritical quenching and tempering. Metals 2023, 13, 1139. [Google Scholar] [CrossRef]

- Torres, M.A.S.; Harada, D.T.; Baptista, C.A.R.P.; Cindra Fonseca, M.P. Effect of shot peening on fatigue behavior of AISI 4340 in different loading conditions. Key Eng. Mater. 2016, 713, 30–33. [Google Scholar] [CrossRef]

- Lin, Q.; Liu, H.; Zhu, C.; Chen, D.; Zhou, S. Effects of different shot peening parameters on residual stress, surface roughness and cell size. Surf. Coat. Technol. 2020, 398, 126054. [Google Scholar] [CrossRef]

- Tomaz, I.D.; Martins, M.C.; Meneses Costa, H.R.; Bastos, I.N.; Cindra Fonseca, M.P. Influence of residual stress on the sliding wear of AISI 4340 steel. Materia 2020, 25, e-12618. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batcehlor, A.W. Engineering Tribology, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Ma, H.; Liang, G.; Lv, M.; Huang, Y.; Han, Y. Investigation on friction and wear behavior of AISI 4340 steel in dry sliding condition. J. Tribol. 2018, 38, 59–66. [Google Scholar] [CrossRef]

- Lorenzo-Martin, C.; Ajayi, O.O. Rapid surface hardening and enhanced tribological performance of 4140 steel by friction stir processing. Wear 2015, 332–333, 962–970. [Google Scholar] [CrossRef]

- Peral, L.B.; Ebrahimzadeh, P.; Gutierrez, A.; Fernandez-Pariente, I. Effect of tempering temperature and grain refinement induced by severe shot peening on the corrosion behavior of a low alloy steel. J. Electroanal. Chem. 2023, 932, 117207. [Google Scholar] [CrossRef]

- da Silva Peltz, J.; Rossa Beltrami, L.V.; Kunst, S.R.; Brandolt, C.; de Fraga Malfatti, C. Effect of the shot peening process on the corrosion and oxidation resistance of AISI 430 stainless steel. Mater. Res. 2015, 18, 538–545. [Google Scholar] [CrossRef]

| C | Mn | Si | Cr | Ni | Mo | V | N | Nb |

|---|---|---|---|---|---|---|---|---|

| 0.43 | 0.83 | 1.62 | 0.81 | 1.82 | 0.39 | 0.07 | 0.002 | 0.01 |

| P | S | Cu | B | Ti | Al | W | Co | Ca |

| 0.006 | 0.001 | 0.12 | 0.0002 | 0.006 | 0.07 | <0.05 | <0.005 | <0.001 |

| Control | A |

| QT heat treatment | B |

| Shot peening before baking heat treatment | C |

| Cr-plating and baking heat treatment | D |

| Stripping after Cr-plating and baking heat treatment | E |

| Re-shot-peening before Cr-plating | F |

| Cast steel shot | Shot diameter [mm] | Nozzle diameter [mm] | Shot flow [kg/min] | Angle of impingement [degree] |

| ASH 230 with HRC 55-60 | 0.7 | 7.9 | 3 | 90 |

| Air pressure [bar] | Peening time [min/place] | Working distance [mm] | Arc height [mmA] | Coverage [%] |

| 3 | 2 | 50 ± 5 | 0.36 | 200 |

| Applied load, N | 10 |

| Sliding velocity, cm/s | 2.51 |

| Total sliding time, min | 60 |

| Temperature, C | 24 |

| Environment | Dry |

| Counterface ball material | AISI 52100 |

| Counterface ball diameter, mm | 12.7 mm |

| Specimens | Current Density, 10−5 Amps/cm2 | Current Potential, V |

|---|---|---|

| A | 8.0152 | −0.88 |

| B | 1.3839 | −0.68 |

| C | 7.6125 | −0.87 |

| D | 9.4587 | −0.92 |

| E | 9.1753 | −0.84 |

| F | 1.9839 | −0.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, S.-H.; Kim, J.; Amanov, A. Improvement of Tribological Properties and Corrosion Resistance of AISI 4340M Steel by Shot Peening and Plating Technologies. Metals 2024, 14, 1037. https://doi.org/10.3390/met14091037

Ahn S-H, Kim J, Amanov A. Improvement of Tribological Properties and Corrosion Resistance of AISI 4340M Steel by Shot Peening and Plating Technologies. Metals. 2024; 14(9):1037. https://doi.org/10.3390/met14091037

Chicago/Turabian StyleAhn, Seok-Hwan, Jungsik Kim, and Auezhan Amanov. 2024. "Improvement of Tribological Properties and Corrosion Resistance of AISI 4340M Steel by Shot Peening and Plating Technologies" Metals 14, no. 9: 1037. https://doi.org/10.3390/met14091037

APA StyleAhn, S.-H., Kim, J., & Amanov, A. (2024). Improvement of Tribological Properties and Corrosion Resistance of AISI 4340M Steel by Shot Peening and Plating Technologies. Metals, 14(9), 1037. https://doi.org/10.3390/met14091037