Enhanced Strength–Ductility Combination in Laser Welding of CrCoNi Medium-Entropy Alloy with Ultrasonic Assistance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

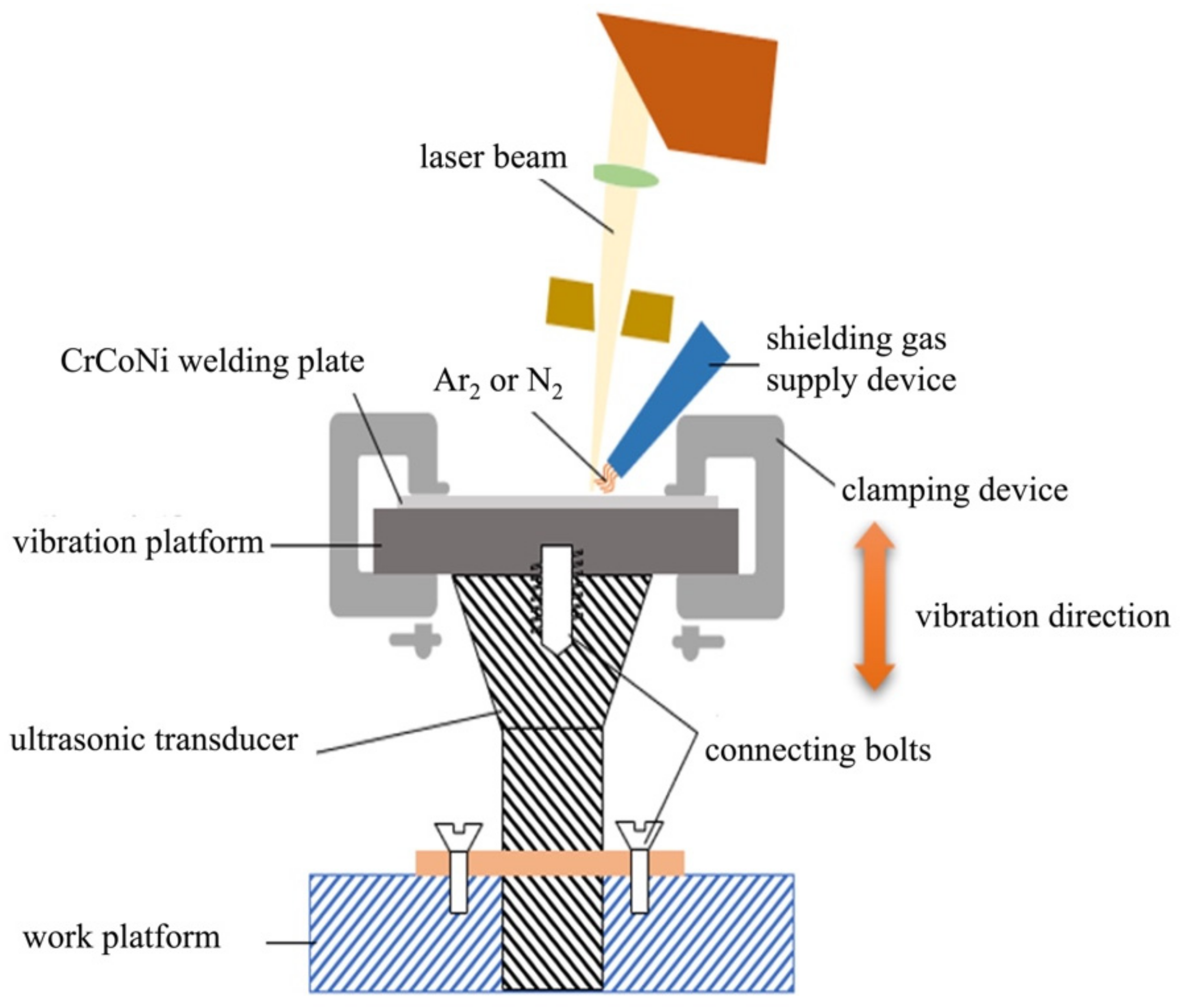

2.2. Welding Process

2.3. Characterization of the Mechanical Properties and Microstructure

3. Results and Discussion

3.1. Microstructure

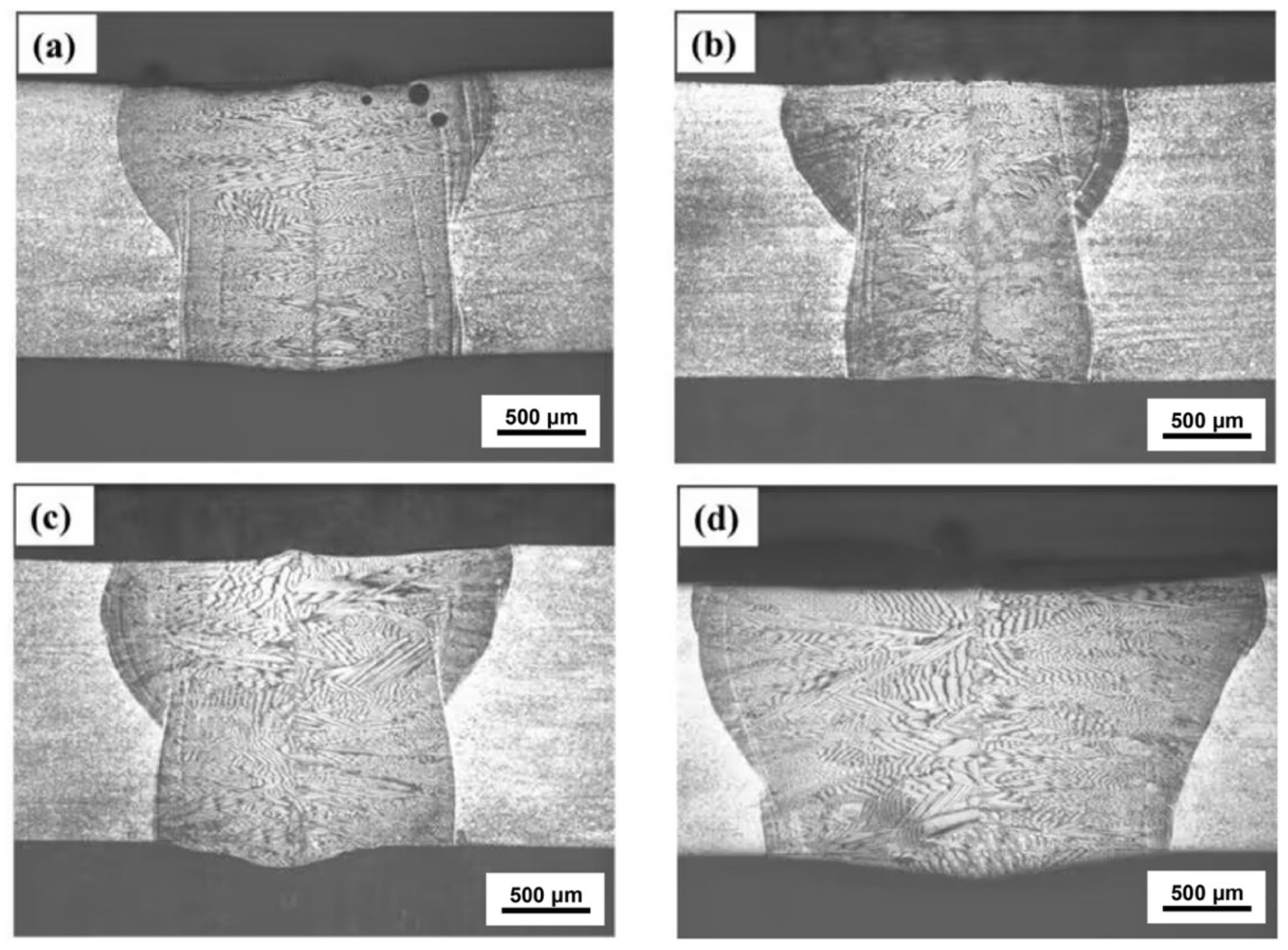

3.1.1. Macroscopic View of the Joint

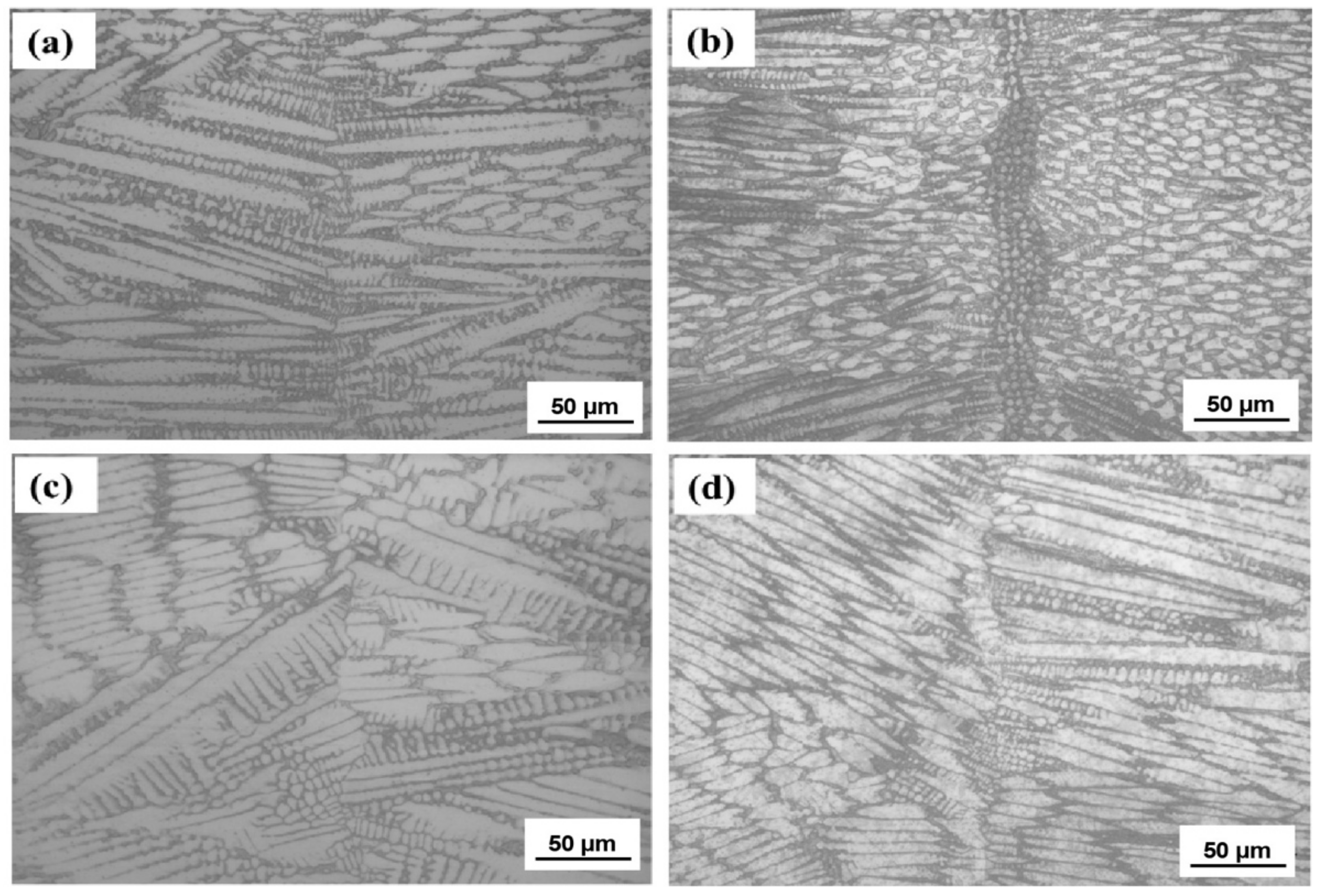

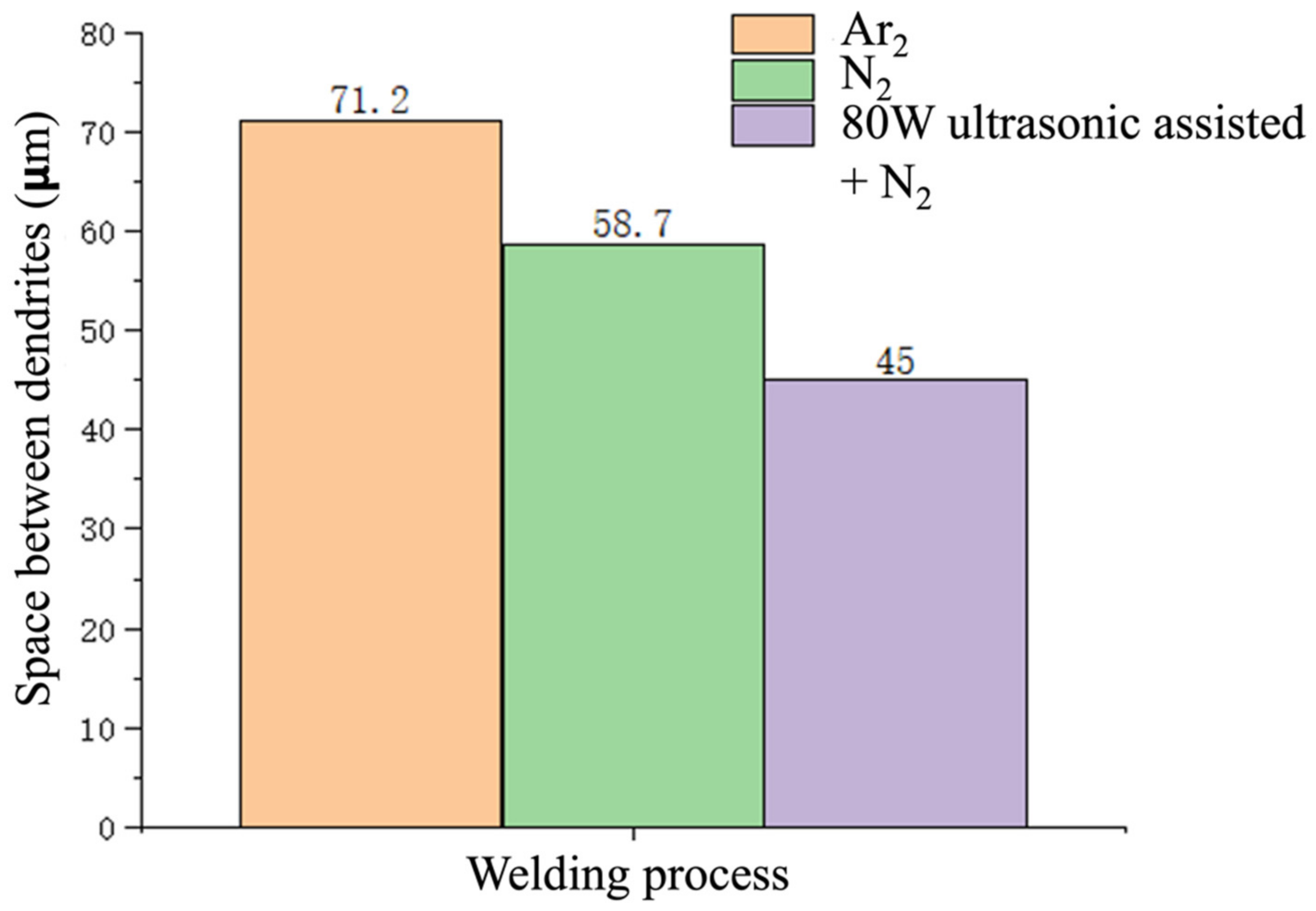

3.1.2. Dendrites

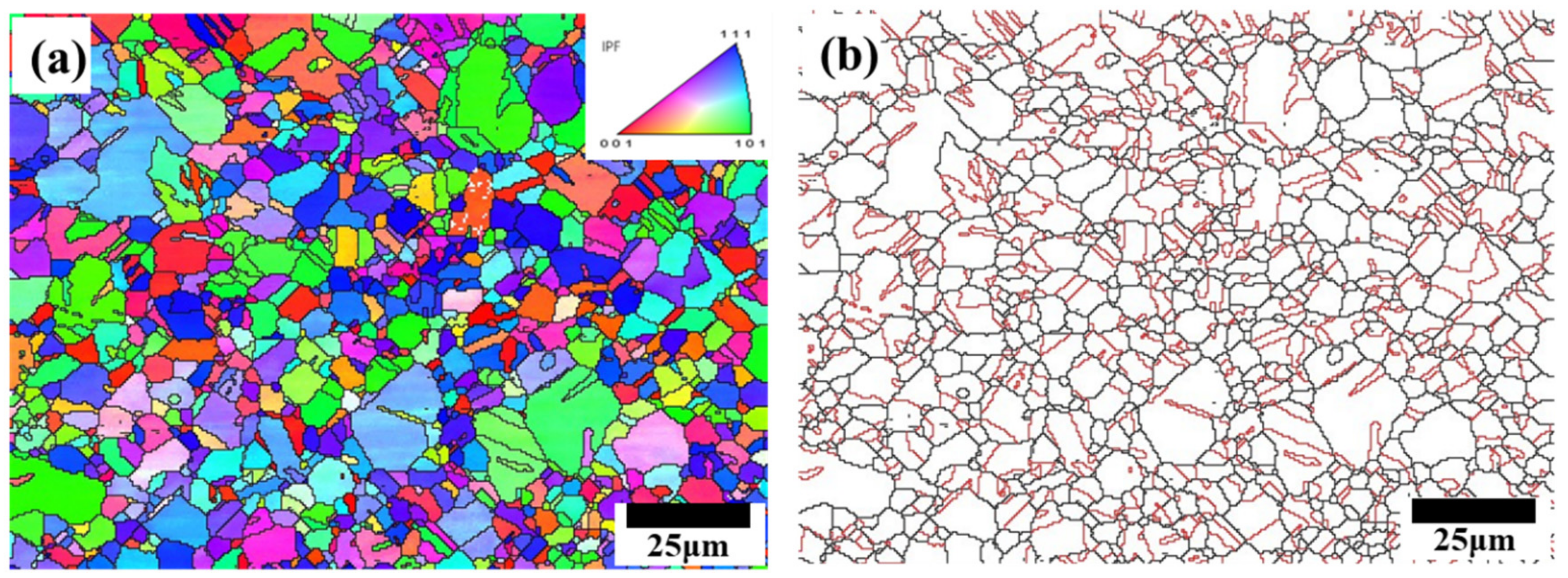

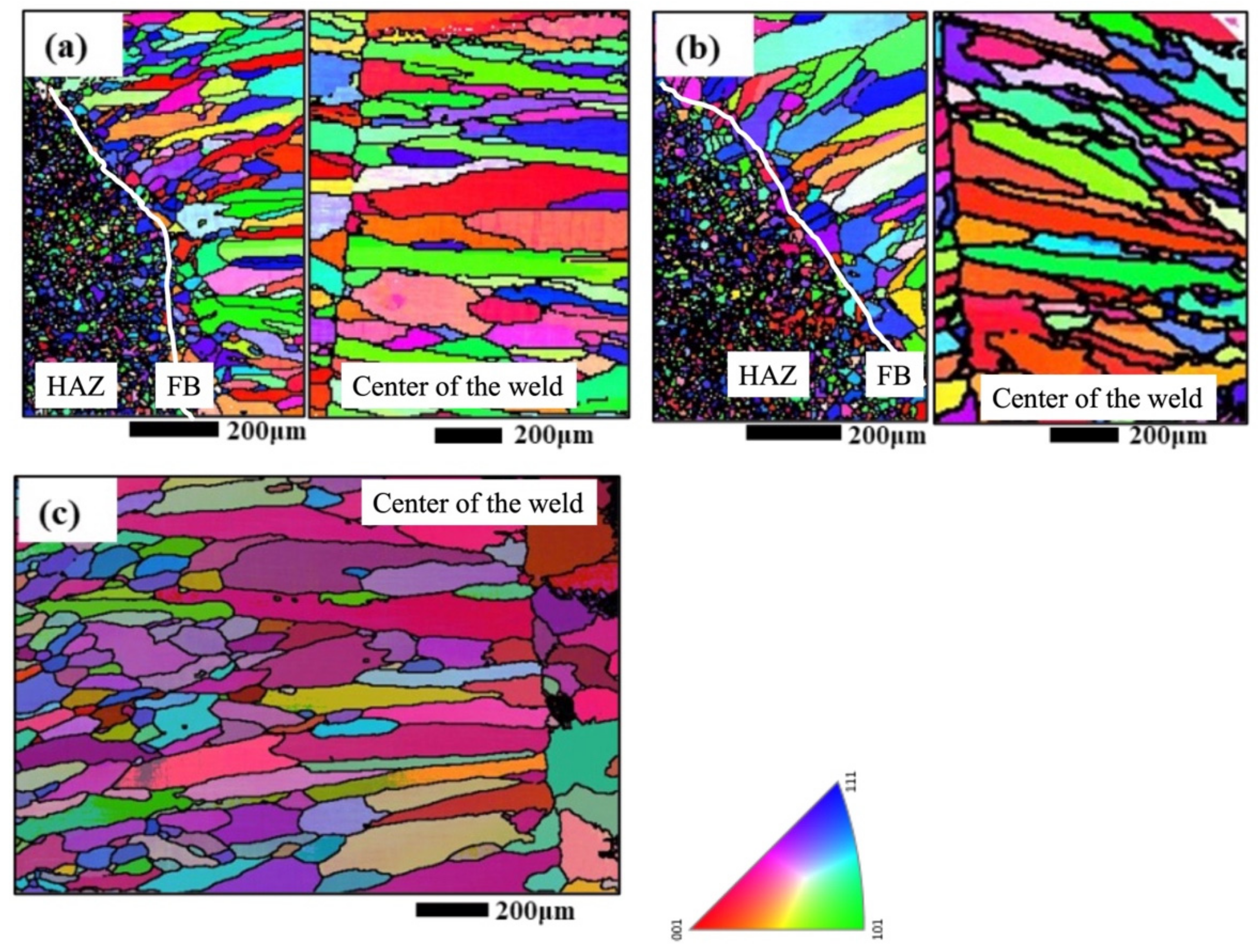

3.1.3. Grain Morphology

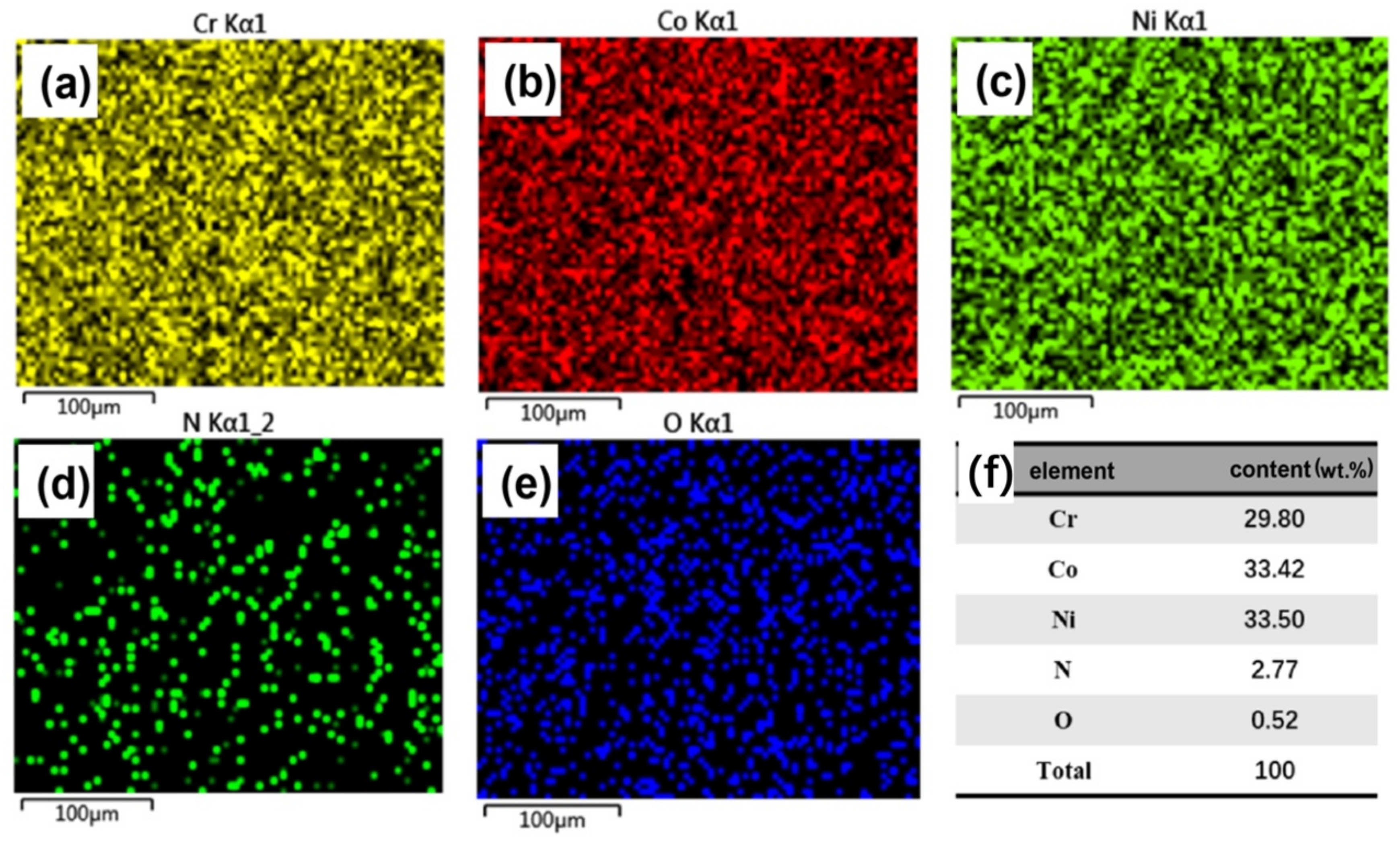

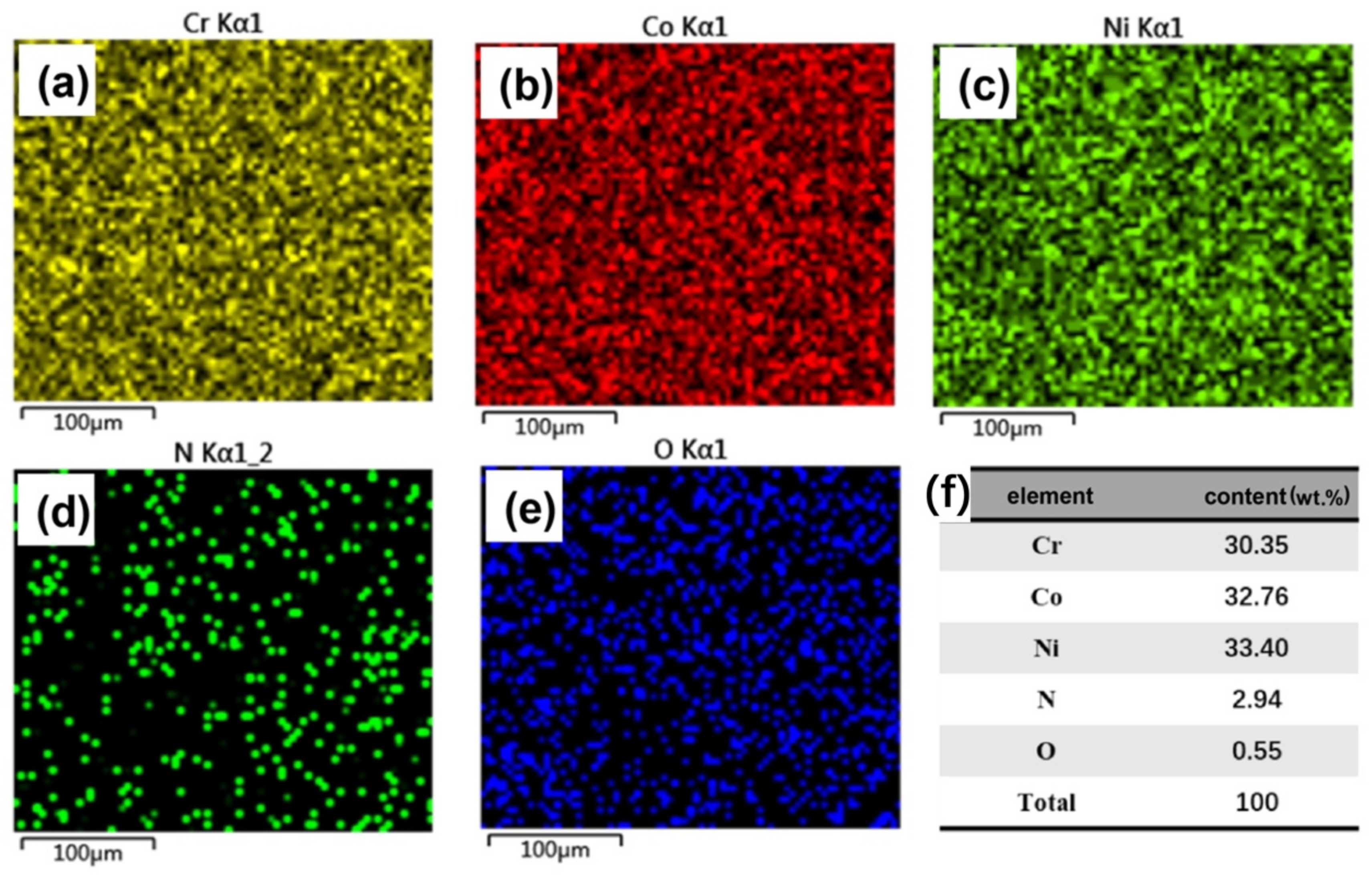

3.1.4. Chemical Elements

3.2. Mechanical Properties

3.2.1. Microhardness

3.2.2. Tensile Testing

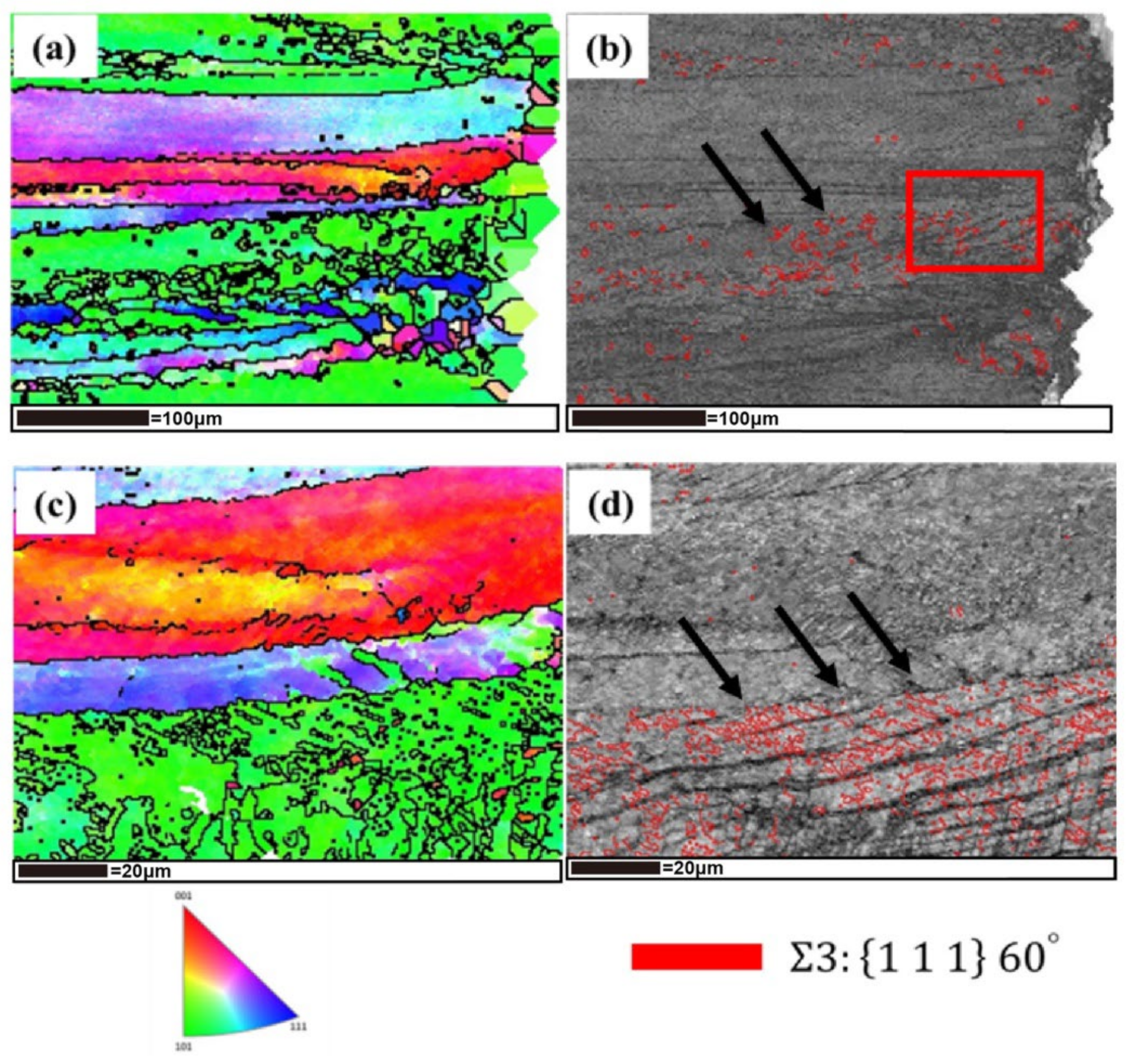

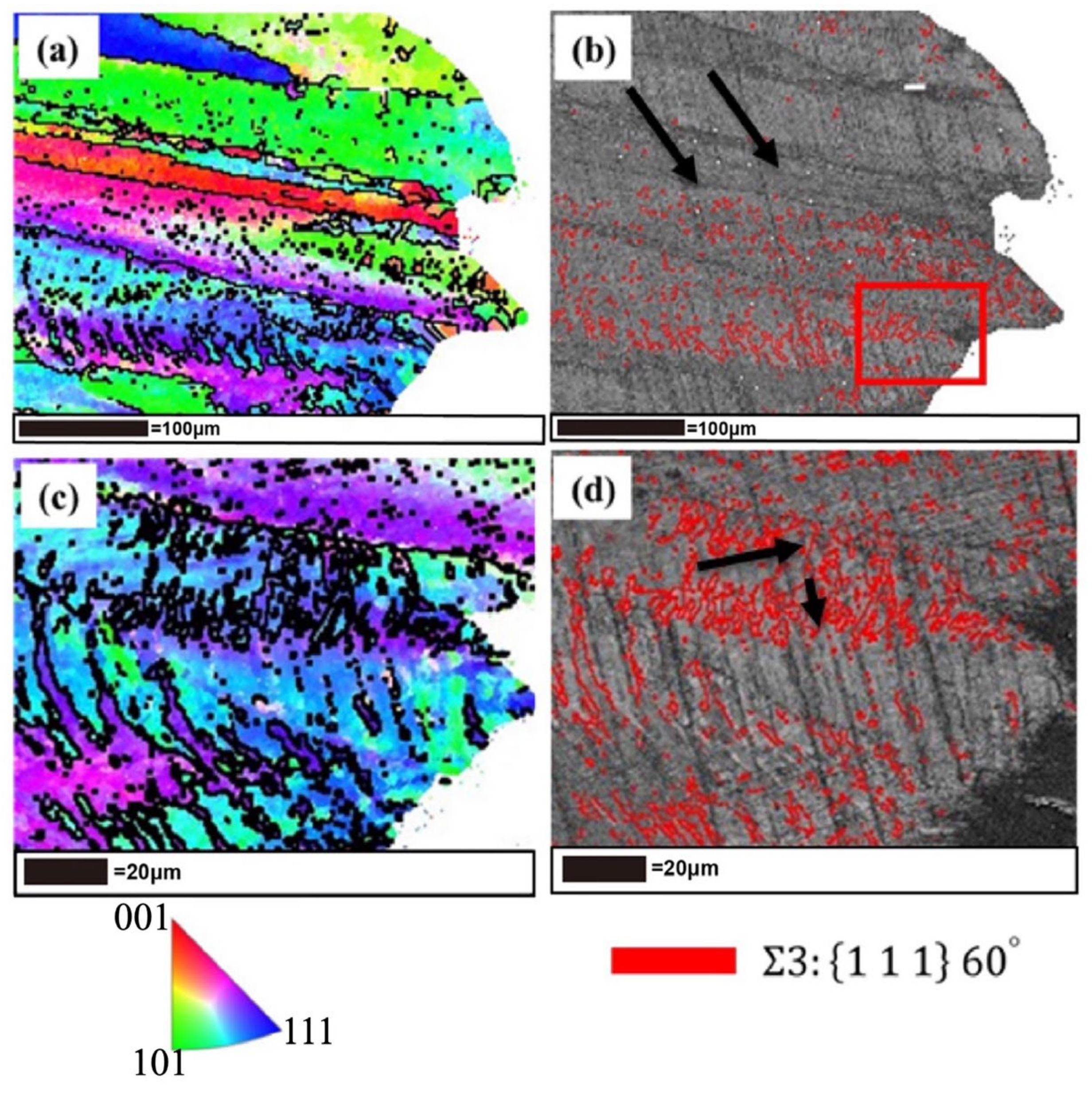

3.3. Deformation Mechanisms

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chan, S.-Y. Nanostructured High-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375, 213–218. [Google Scholar] [CrossRef]

- George, E.P.; Curtin, W.A.; Tasan, C.C. High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Mater. 2020, 188, 435–474. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Thurston, K.V.; Bei, H.; Wu, Z.; George, E.P.; Ritchie, R.O. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 2016, 7, 10602. [Google Scholar] [CrossRef] [PubMed]

- Laplanche, G.; Kostka, A.; Reinhart, C.; Hunfeld, J.; Eggeler, G.; George, E.P. Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi. Acta Mater. 2017, 128, 292–303. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, S.; Ding, J.; Chong, Y.; Jia, T.; Ophus, C.; Asta, M.; Ritchie, R.O.; Minor, A.M. Short-range order and its impact on the CrCoNi medium-entropy alloy. Nature 2020, 581, 283–287. [Google Scholar] [CrossRef]

- Yan, S.; Chen, H.; Zhu, Z.; Gou, G. Hybrid laser-Metal Inert Gas welding of Al–Mg–Si alloy joints: Microstructure and mechanical properties. Mater. Des. 2014, 61, 160–167. [Google Scholar] [CrossRef]

- Yan, S.; Nie, Y.; Zhu, Z.; Chen, H.; Gou, G.; Yu, J.; Wang, G. Characteristics of microstructure and fatigue resistance of hybrid fiber laser-MIG welded Al–Mg alloy joints. Appl. Surf. Sci. 2014, 298, 12–18. [Google Scholar] [CrossRef]

- Yan, S.; He, X.; Krüger, M.; Li, Y.; Jia, Q. Additive manufacturing of a new non-equiatomic high-entropy alloy with exceptional strength-ductility synergy via in-situ alloying. Mater. Des. 2024, 238, 112676. [Google Scholar] [CrossRef]

- Rackwitz, J.; Yu, Q.; Yang, Y.; Laplanche, G.; George, E.P.; Minor, A.M.; Ritchie, R.O. Effects of cryogenic temperature and grain size on fatigue-crack propagation in the medium-entropy CrCoNi alloy. Acta Mater. 2020, 200, 351–365. [Google Scholar] [CrossRef]

- Yan, S.; Zhou, H.; Zhu, Z.; Fu, Y.; Tian, J. High strength-ductility synergy in a laser welded dissimilar joint of CrCoNi medium-entropy alloy and stainless steel. Mater. Sci. Eng. A 2022, 840, 142854. [Google Scholar] [CrossRef]

- Hao, X.; Dong, H.; Li, P.; Xia, Y. Dissimilar joining of TC4 alloy to ST16 steel by GTAW. J. Manuf. Process. 2019, 37, 413–417. [Google Scholar] [CrossRef]

- Lv, S.; Cui, Q.; Huang, Y.; Jing, X. Influence of Zr addition on TIG welding–brazing of Ti–6Al–4V toAl5A06. Mater. Sci. Eng. A 2013, 568, 150–154. [Google Scholar] [CrossRef]

- Abed, H.; Malek Ghaini, F.; Shahverdi, H.R. Characterization of Fe49Cr18Mo7B16C4Nb6 high-entropy hardfacing layers produced by gas tungsten arc welding (GTAW) process. Surf. Coat. Technol. 2018, 352, 360–369. [Google Scholar] [CrossRef]

- Tavoosi, M.; Arjmand, S.; Adelimoghaddam, B. Surface alloying of commercially pure titanium with aluminium and nitrogen using GTAW processing. Surf. Coat. Technol. 2017, 311, 314–320. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S.; Zhang, Y. A review on wire arc additive manufacturing: Monitoring, control and a framework of automated system. J. Manuf. Syst. 2020, 57, 31–45. [Google Scholar] [CrossRef]

- Sokkalingam, R.; Mishra, S.; Cheethirala, S.R.; Muthupandi, V.; Sivaprasad, K. Enhanced Relative Slip Distance in Gas-Tungsten-Arc-Welded Al0.5CoCrFeNi High-Entropy Alloy. Metall. Mater. Trans. A 2017, 48, 3630–3634. [Google Scholar] [CrossRef]

- Martin, A.C.; Fink, C. Initial weldability study on Al0.5CrCoCu0.1FeNi high-entropy alloy. Weld. World 2019, 63, 739–750. [Google Scholar] [CrossRef]

- Shinde, G.; Gajghate, S.; Dabeer, P.S.; Seemikeri, C.Y. Low Cost Friction Stir Welding: A Review. Mater. Today Proc. 2017, 4, 8901–8910. [Google Scholar] [CrossRef]

- Singh, K.; Singh, G.; Singh, H. Review on friction stir welding of magnesium alloys. J. Magnes. Alloys 2018, 6, 399–416. [Google Scholar] [CrossRef]

- Panaskar, N.; Terkar, R. A Review on Recent Advances in Friction Stir Lap Welding of Aluminium and Copper. Mater. Today Proc. 2017, 4, 8387–8393. [Google Scholar] [CrossRef]

- Wang, X.-N.; Chen, C.-J.; Wang, H.-S.; Zhang, S.-H.; Zhang, M.; Luo, X. Microstructure formation and precipitation in laser welding of microalloyed C–Mn steel. J. Mater. Process. Technol. 2015, 226, 106–114. [Google Scholar] [CrossRef]

- Sun, Q.; Di, H.-S.; Li, J.-C.; Wang, X.-N. Effect of pulse frequency on microstructure and properties of welded joints for dual phase steel by pulsed laser welding. Mater. Des. 2016, 105, 201–211. [Google Scholar] [CrossRef]

- Qi, X.; Di, H.; Wang, X.; Liu, Z.; Misra, R.D.K.; Huan, P.; Gao, Y. Effect of secondary peak temperature on microstructure and toughness in ICCGHAZ of laser-arc hybrid welded X100 pipeline steel joints. J. Mater. Res. Technol. 2020, 9, 7838–7849. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Z.; Hu, Z.; Sun, Q.; Di, H.; Lv, F.; Sun, L. Effect of Ni foil thickness on the microstructure of fusion zone during PHS laser welding. Opt. Laser Technol. 2020, 125, 106014. [Google Scholar] [CrossRef]

- Errico, V.; Campanelli, S.L.; Angelastro, A.; Mazzarisi, M.; Casalino, G. On the feasibility of AISI 304 stainless steel laser welding with metal powder. J. Manuf. Process. 2020, 56, 96–105. [Google Scholar] [CrossRef]

- Dai, W.; Wenjun, S.; Xin, J.; Wang, S.; Fang, C.; Wei, J.; Song, Y. Weldability and mechanical properties of IC10 single crystal and GH3039 superalloy dissimilar laser beam welding joint. Mater. Sci. Eng. A 2020, 791, 139797. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Liu, Z.; Hu, Z.; Huan, P.; Yan, Q.; Hiromi, N. Effect of Cu content on microstructure transformation and mechanical properties of Fe-Al dissimilar laser welded joints. Opt. Laser Technol. 2020, 126, 106078. [Google Scholar] [CrossRef]

- Chen, X.; Lei, Z.; Chen, Y.; Han, Y.; Jiang, M.; Tian, Z.; Bi, J.; Lin, S. Microstructure and tensile properties of Ti/Al dissimilar joint by laser welding-brazing at subatmospheric pressure. J. Manuf. Process. 2020, 56, 19–27. [Google Scholar] [CrossRef]

- Malikov, A.; Vitoshkin, I.; Orishich, A.; Filippov, A.; Karpov, E. Microstructure and mechanical properties of laser welded joints of Al-Cu-Li and Ti-Al-V alloys. J. Manuf. Process. 2020, 53, 201–212. [Google Scholar] [CrossRef]

- Gu, Z.; Mao, P.; Gou, Y.; Chao, Y.; Xi, S. Microstructure and properties of MgMoNbFeTi2Yx high entropy alloy coatings by laser cladding. Surf. Coat. Technol. 2020, 402, 126303. [Google Scholar] [CrossRef]

- Panina, E.; Yurchenko, N.; Zherebtsov, S.; Stepanov, N.; Salishchev, G.; Ventzke, V.; Dinse, R.; Kashaev, N. Laser Beam Welding of a Low Density Refractory High Entropy Alloy. Metals 2018, 9, 1351. [Google Scholar] [CrossRef]

- Nam, H.; Park, C.; Kim, C.; Kang, N. Effect of post weld heat treatment on weldability of high entropy alloy welds. Sci. Technol. Weld. Join. 2017, 23, 420–427. [Google Scholar] [CrossRef]

- Chen, G.; Yin, Q.; Zhang, G.; Zhang, B. Underlying causes of poor mechanical properties of aluminum-lithium alloy electron beam welded joints. J. Manuf. Process. 2020, 50, 216–223. [Google Scholar] [CrossRef]

- Sun, W.; Wang, S.; Xin, J.; Tan, G.; Hong, M.; Wu, M.; Ke, L. Microstructure and mechanical properties of the IC10/GH3039 dissimilar electron beam welded joint. Vacuum 2020, 181, 109592. [Google Scholar] [CrossRef]

- Vijayanand, D.; Vanaja, J.; Das, C.; Mariappan, K.; Thakur, A.; Hussain, S.; Prasad Reddy, G.V.; Sasikala, G.; Albert, S. An Investigation of Microstructural Evolution in Electron Beam Welded RAFM steel and 316LN SS dissimilar joint under creep loading conditions. Mater. Sci. Eng. A 2018, 742, 432–441. [Google Scholar] [CrossRef]

- Chen, G.; Liu, J.; Shu, X.; Zhang, B.; Feng, J. Study on microstructure and performance of molybdenum joint welded by electron beam. Vacuum 2018, 154, 1–5. [Google Scholar] [CrossRef]

- Chen, G.; Liu, J.; Shu, X.; Gu, H.; Zhang, B.; Feng, J. Beam scanning effect on properties optimization of thick-plate 2A12 aluminum alloy electron-beam welding joints. Mater. Sci. Eng. A 2019, 744, 583–592. [Google Scholar] [CrossRef]

- Sang, S.; Li, D.; Wang, C.; Ding, L.; Tang, Y.; Xiong, Q. Microstructure and mechanical properties of electron beam welded joints of tantalum and GH3128. Mater. Sci. Eng. A 2019, 768, 138431. [Google Scholar] [CrossRef]

- Gao, F.; Yu, W.; Song, D.; Gao, Q.; Guo, L.; Liao, Z. Fracture toughness of TA31 titanium alloy joints welded by electron beam welding under constrained condition. Mater. Sci. Eng. A 2020, 772, 138612. [Google Scholar] [CrossRef]

- Yang, Z.W.; Wang, C.L.; Han, Y.; Zhao, Y.T.; Wang, Y.; Wang, D.P. Design of reinforced interfacial structure in brazed joints of C/C composites and Nb by pre-oxidation surface treatment combined with in situ growth of CNTs. Carbon 2019, 143, 494–506. [Google Scholar] [CrossRef]

- Wang, Z.; De-Chun, B.; Cao, P.J.; Liang, J. Effect of Boron-Doping on Morphology and Microstructure of Carbon Nanotube. J. Northeast. Univ. 2005, 26, 582–584. [Google Scholar]

- Chang, S.-H.; Wu, S.-K.; Kuo, C. Effect of reinforced multiwall carbon nanotubes on the damping characteristics of Sn-Ag-Cu lead-free solder. Mater. Lett. 2020, 276, 128196. [Google Scholar] [CrossRef]

- Luo, C.; Qiu, X.; Ruan, Y.; Lu, Y.; Xing, F. Effect of Bi addition on the corrosion resistance and mechanical properties of sintered NdFeB permanent magnet/steel soldered joints. Mater. Sci. Eng. A 2020, 792, 139832. [Google Scholar] [CrossRef]

- Lin, J.; Wang, J.; Baoxin, H.; Zhengxiang, Z.; Qiang, Z. Carbon nanotubes-reinforced Ni foam interlayer for brazing SiO2-BN with Ti6A14V alloy using TiZrNiCu brazing alloy. Ceram. Int. 2018, 44, 3684–3691. [Google Scholar]

- Li, Y.; Chen, C.; Yi, R.; Ouyang, Y. Review: Special brazing and soldering. J. Manuf. Process. 2020, 60, 608–635. [Google Scholar] [CrossRef]

- Peng, H.; Yi, Y.; Fang, W.; Hu, L.; Baker, I.; Li, L.; Luo, B. Optimization of the microstructure and mechanical properties of electron beam welded high-strength medium-entropy alloy (NiCoCr)94Al3Ti3. Intermetallics 2022, 141, 107439. [Google Scholar] [CrossRef]

- Li, N.; Wang, R.X.; Zhao, H.B.; Tang, Y.; Xue, P.; Ni, D.R.; Xiao, B.L.; Ma, Z.Y.; Wu, L.H. Microstructure and mechanical properties of electron beam welded TiZrNbTa refractory high entropy alloy. Mater. Today Commun. 2022, 32, 103847. [Google Scholar] [CrossRef]

- Chen, C.; Sun, G.; Sun, X.; Zhao, X.; Wang, S. AC/DC mixed gas tungsten arc welding of a (FeCoNi)96Al4 high-entropy alloy. J. Mater. Res. Technol. 2024, 30, 1531–1538. [Google Scholar] [CrossRef]

- Moravcik, I.; Hadraba, H.; Li, L.; Dlouhy, I.; Li, Z. Yield strength increase of a CoCrNi medium entropy alloy by interstitial nitrogen doping at maintained ductility. Scr. Mater. 2020, 178, 391–397. [Google Scholar] [CrossRef]

- Yan, S.; Zhou, H.; Xing, B.; Zhang, S.; Li, L.; Qin, Q.H. Crystal plasticity in fusion zone of a hybrid laser welded Al alloys joint: From nanoscale to macroscale. Mater. Des. 2018, 160, 313–324. [Google Scholar] [CrossRef]

- Yan, S.; Qin, Q.H.; Chen, H.; Zhong, Z. Hybrid laser welding of dissimilar aluminum alloys: Welding processing, microstructure, properties and modelling. J. Manuf. Process. 2020, 56, 295–305. [Google Scholar] [CrossRef]

- Yan, S.; Ma, C.; Chen, H. Modifying microstructures and mechanical properties of laser-arc welded joints of dissimilar advanced aluminum alloys. Mater. Charact. 2020, 164, 110331. [Google Scholar] [CrossRef]

- Talebi, M.; Setareh, M.; Saffar-Avval, M.; Hosseini Abardeh, R. Numerical investigation of natural convection heat transfer in a cylindrical enclosure due to ultrasonic vibrations. Ultrasonics 2017, 76, 52–62. [Google Scholar] [CrossRef]

- Kim, H.-Y.; Kim, Y.G.; Kang, B.H. Enhancement of natural convection and pool boiling heat transfer via ultrasonic vibration. Int. J. Heat Mass Transf. 2004, 47, 2831–2840. [Google Scholar] [CrossRef]

- Drezet, J.-M.; Pellerin, S.; Bezençon, C.; Mokadem, S. Modelling Marangoni convection in laser heat treatment. J. Phys. IV (Proc.) 2004, 120, 299–306. [Google Scholar] [CrossRef]

- Wu, Z.; David, S.A.; Feng, Z.; Bei, H. Weldability of a high entropy CrMnFeCoNi alloy. Scr. Mater. 2016, 124, 81–85. [Google Scholar] [CrossRef]

- Yan, S.; Xing, B.; Zhou, H.; Xiao, Y.; Qin, Q.-H.; Chen, H. Effect of filling materials on the microstructure and properties of hybrid laser welded Al-Mg-Si alloys joints. Mater. Charact. 2018, 144, 205–218. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Horst, O.M.; Eggeler, G.; George, E.P. Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2016, 118, 152–163. [Google Scholar] [CrossRef]

- Traversier, M.; Mestre-Rinn, P.; Peillon, N.; Rigal, E.; Boulnat, X.; Tancret, F.; Dhers, J.; Fraczkiewicz, A. Nitrogen-induced hardening in an austenitic CrFeMnNi high-entropy alloy (HEA). Mater. Sci. Eng. A 2021, 804, 140725. [Google Scholar] [CrossRef]

- Yoshida, S.; Ikeuchi, T.; Bhattacharjee, T.; Bai, Y.; Shibata, A.; Tsuji, N. Effect of elemental combination on friction stress and Hall-Petch relationship in face-centered cubic high/medium entropy alloys. Acta Mater. 2019, 171, 201–215. [Google Scholar] [CrossRef]

- Lopes, J.G.; Agrawal, P.; Shen, J.; Schell, N.; Mishra, R.S.; Oliveira, J.P. Evolution of microstructure and mechanical properties in gas tungsten arc welded dual-phase Fe50Mn30Co10Cr10 high entropy alloy. Mater. Sci. Eng. A 2023, 878, 145233. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Shamsolhodaei, A.; Shen, J.; Lopes, J.G.; Gonçalves, R.M.; Ferraz, M.d.B.; Piçarra, L.; Zeng, Z.; Schell, N.; Zhou, N.; et al. Improving the ductility in laser welded joints of CoCrFeMnNi high entropy alloy to 316 stainless steel. Mater. Des. 2022, 219, 110717. [Google Scholar] [CrossRef]

- Sang, Y.; Li, D.; Deng, W. Electron beam weldability of TiZrNbTa refractory high-entropy alloy and TC4 titanium alloy. Mater. Today Commun. 2024, 38, 107890. [Google Scholar] [CrossRef]

- Deng, W.; Li, D.; Yang, B.; Wu, H.; Yu, S. Microstructure and mechanical properties of electron beam welded joints of GH3128 and CoCrFeNi high-entropy alloy. Mater. Today Commun. 2024, 39, 108898. [Google Scholar] [CrossRef]

- Palguna, Y.; Sairam, K.; Kannan, A.R.; Shanmugam, N.S.; Korla, R.; Oliveira, J.P. Effect of post weld heat treatment on the microstructure and mechanical properties of gas tungsten arc welded Al0.3CoCrFeNi high entropy alloy. Scr. Mater. 2024, 241, 115887. [Google Scholar] [CrossRef]

- Xin, J.; Wang, W.; Yang, X.; Boubeche, M.; Wang, S.; Zhang, H.; Huang, C.; Li, Y.; Lyu, B.; Shen, F.; et al. Dissimilar laser welding of CrMnFeCoNi high entropy alloy and 316LN stainless steel for cryogenic application. J. Mater. Sci. Technol. 2023, 163, 158–167. [Google Scholar] [CrossRef]

- Wu, S.C.; Yu, C.; Yu, P.S.; Buffière, J.Y.; Helfen, L.; Fu, Y.N. Corner fatigue cracking behavior of hybrid laser AA7020 welds by synchrotron X-ray computed microtomography. Mater. Sci. Eng. A 2016, 651, 604–614. [Google Scholar] [CrossRef]

- Kashaev, N.; Ventzke, V.; Petrov, N.; Horstmann, M.; Zherebtsov, S.; Shaysultanov, D.; Sanin, V.; Stepanov, N. Fatigue behaviour of a laser beam welded CoCrFeNiMn-type high entropy alloy. Mater. Sci. Eng. A 2019, 766, 138358. [Google Scholar] [CrossRef]

- Zhu, Z.; Yan, S.; Chen, H.; Gou, G. Unprecedented combination of strength and ductility in laser welded NiCoCr medium entropy alloy joints. Mater. Sci. Eng. A 2021, 803, 140501. [Google Scholar] [CrossRef]

- Kubin, L.P.; Mortensen, A. Geometrically necessary dislocations and strain-gradient plasticity: A few critical issues. Scr. Mater. 2003, 48, 119–125. [Google Scholar] [CrossRef]

- Eftekharimilani, P.; van der Aa, E.M.; Hermans, M.J.M.; Richardson, I.M. Microstructural characterisation of double pulse resistance spot welded advanced high strength steel. Sci. Technol. Weld. Join. 2017, 22, 545–554. [Google Scholar] [CrossRef]

- Yan, S.; Nie, Y.; Paradowska, A. Effect of specimen size and crystallographic orientation on the nano/microscale mechanical properties and deformation behavior of CrCoNi medium-entropy alloy. Mater. Des. 2023, 235, 112387. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Nie, Y.; Yan, S. Small-scale mechanical properties and deformation mechanisms of a laser welded CrCoNi medium-entropy alloy joint. Mater. Sci. Eng. A 2022, 855, 143959. [Google Scholar] [CrossRef]

| Process Number | Welding Method | Power (kW) | Welding Speed (mm/s) | Laser Inclination Angle (°) | Gas Flow (L·min−1) | Shielding Gas |

|---|---|---|---|---|---|---|

| Process 1 | Laser welding | 1.8 | 10 | 10 | 30 | Ar2 |

| Process 2 | Laser welding | 1.8 | 10 | 10 | 30 | N2 |

| Process 3 | Ultrasonic (40 W) + Laser welding | 1.8 | 10 | 10 | 30 | N2 |

| Process 4 | Ultrasonic (80 W) + Laser welding | 1.8 | 10 | 10 | 30 | N2 |

| Material | Yield Strength (MPa) | Tensile Strength (MPa) | Uniform Elongation (%) | |||

|---|---|---|---|---|---|---|

| 300 K | 77 K | 300 K | 77 K | 300 K | 77 K | |

| Joint (Ar) | 405.6 ± 9 | / | 662 ± 2 | / | 19.6 | / |

| Joint (N2) | 413.7 ± 10 | / | 678.9 ± 8 | / | 22.7 | / |

| Joint (ultrasonic + N2) | 421 ± 6 | 681.17 ± 14 | 686 ± 10 | 1071 ± 19 | 26.8 | 28 ± 1 |

| Base material | 527 ± 9 | 856.2 ± 33 | 886 ± 19 | 1313 ± 28 | 56.4 ± 3 | 69 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Yan, S.; Zhu, Z. Enhanced Strength–Ductility Combination in Laser Welding of CrCoNi Medium-Entropy Alloy with Ultrasonic Assistance. Metals 2024, 14, 971. https://doi.org/10.3390/met14090971

Zhou H, Yan S, Zhu Z. Enhanced Strength–Ductility Combination in Laser Welding of CrCoNi Medium-Entropy Alloy with Ultrasonic Assistance. Metals. 2024; 14(9):971. https://doi.org/10.3390/met14090971

Chicago/Turabian StyleZhou, Hongmei, Shaohua Yan, and Zhongyin Zhu. 2024. "Enhanced Strength–Ductility Combination in Laser Welding of CrCoNi Medium-Entropy Alloy with Ultrasonic Assistance" Metals 14, no. 9: 971. https://doi.org/10.3390/met14090971

APA StyleZhou, H., Yan, S., & Zhu, Z. (2024). Enhanced Strength–Ductility Combination in Laser Welding of CrCoNi Medium-Entropy Alloy with Ultrasonic Assistance. Metals, 14(9), 971. https://doi.org/10.3390/met14090971