Investigation of Properties in Magnesium Alloy Thin Plates after Die Casting Processes

Abstract

:1. Introduction

2. Theoretical Background

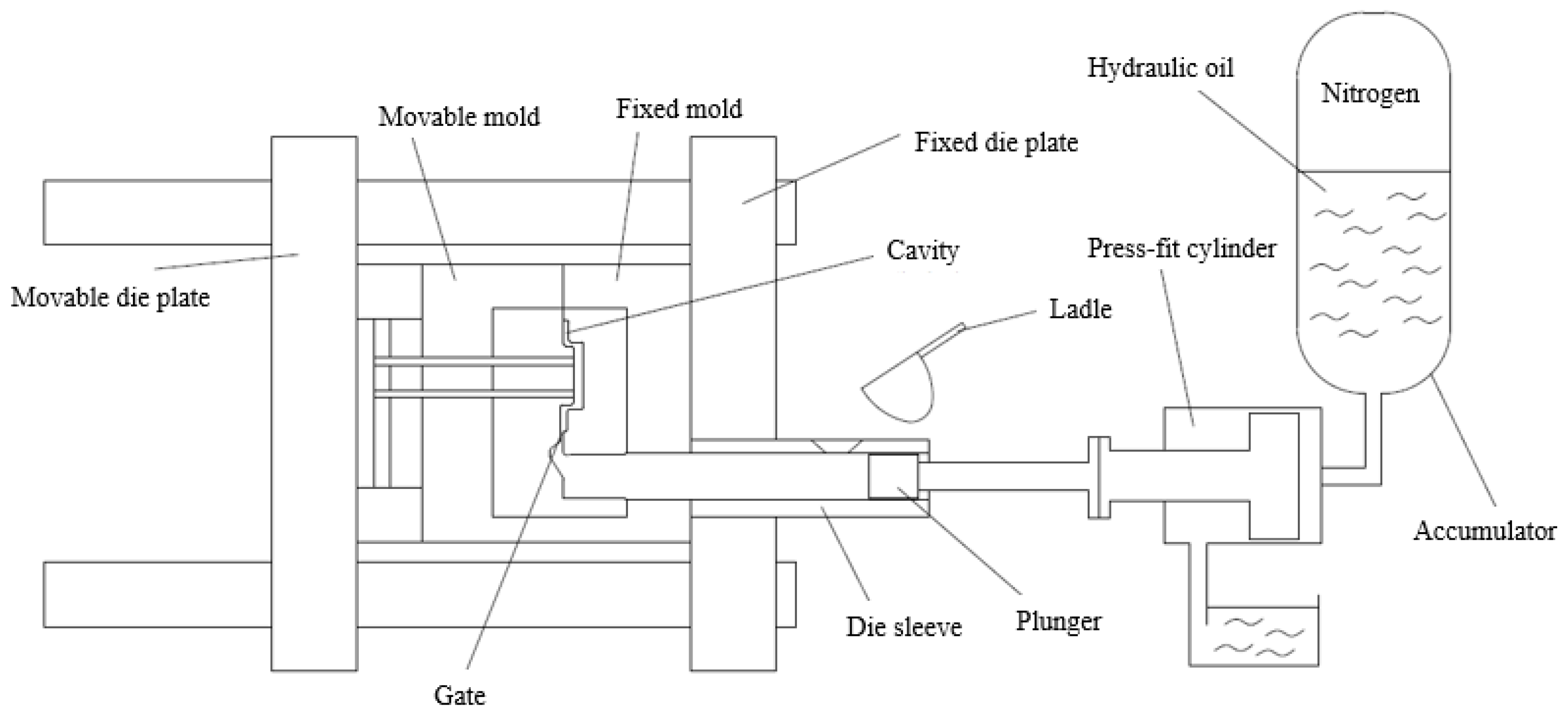

2.1. Features of the Die Casting Process

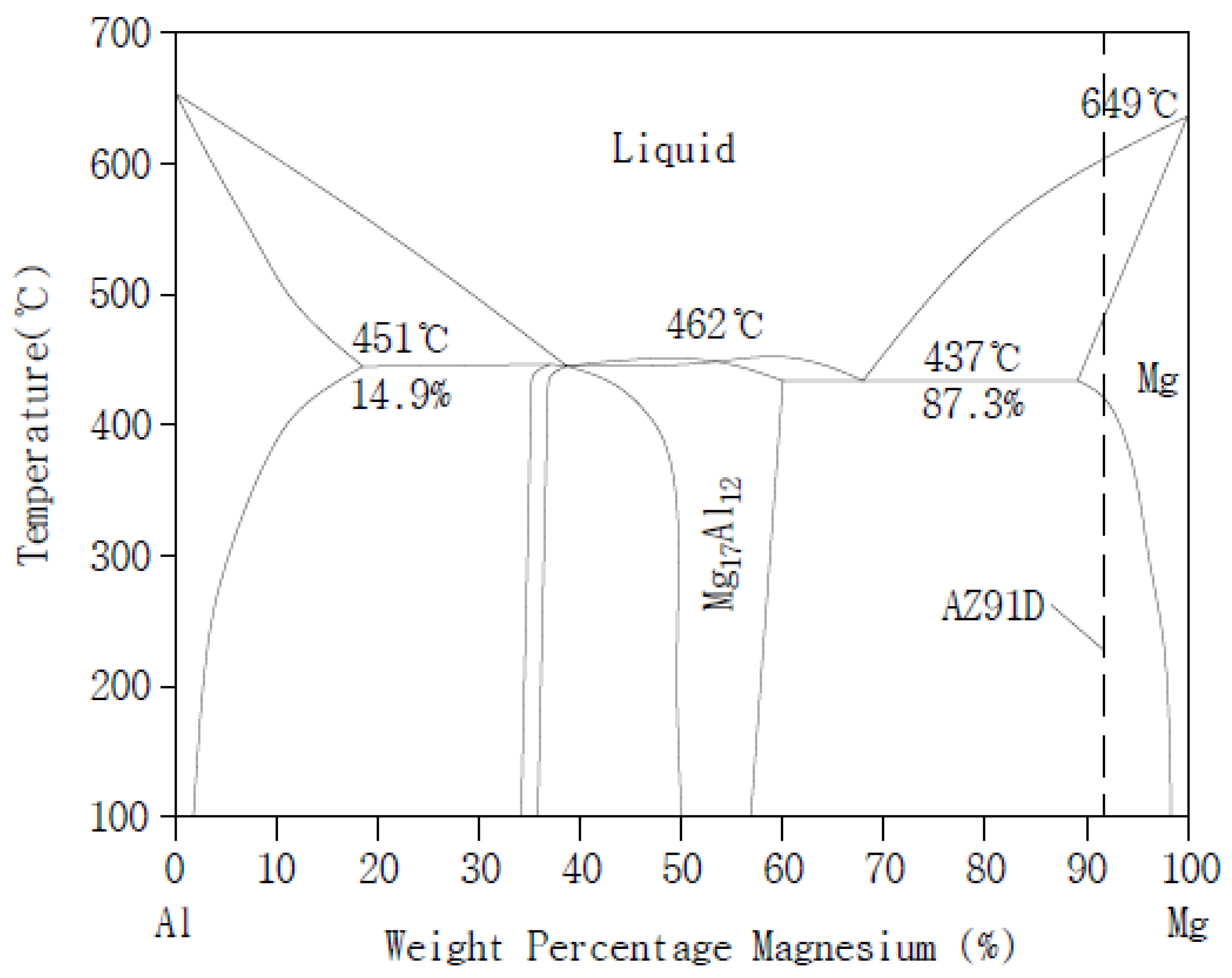

2.2. Properties of Magnesium Alloys

2.3. Process Design Conditions for Sheet Metal Forming

2.3.1. Gate System Design

2.3.2. Overflow and Air Vent Design

2.3.3. Cooling System Design

2.3.4. Casting Analysis Simulation

3. Experiment Method

3.1. Optimizing Design Conditions through Simulation

3.1.1. Experimental Conditions and Variables

3.1.2. Charging Behavior and Defect Prediction

3.2. Prototype Production under Optimal Conditions

3.2.1. Materials and Equipment

3.2.2. Process Conditions

3.3. Evaluation of Prototype Properties

3.3.1. Microstructure Observation

3.3.2. Mechanical Property Measurement

4. Results and Discussion

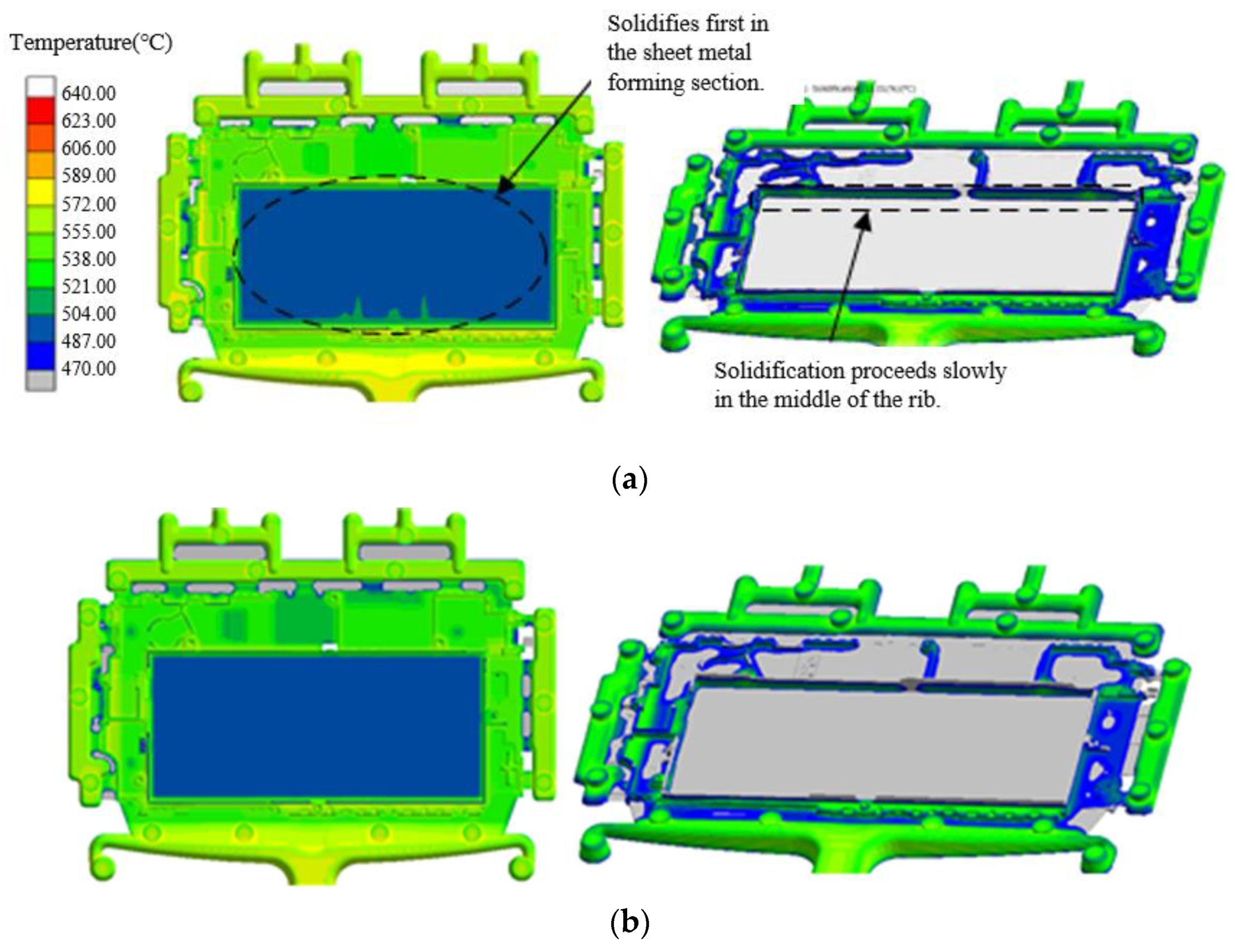

4.1. Simulation Analysis Results

4.1.1. Changes in Charging Behavior Depending on Design Conditions

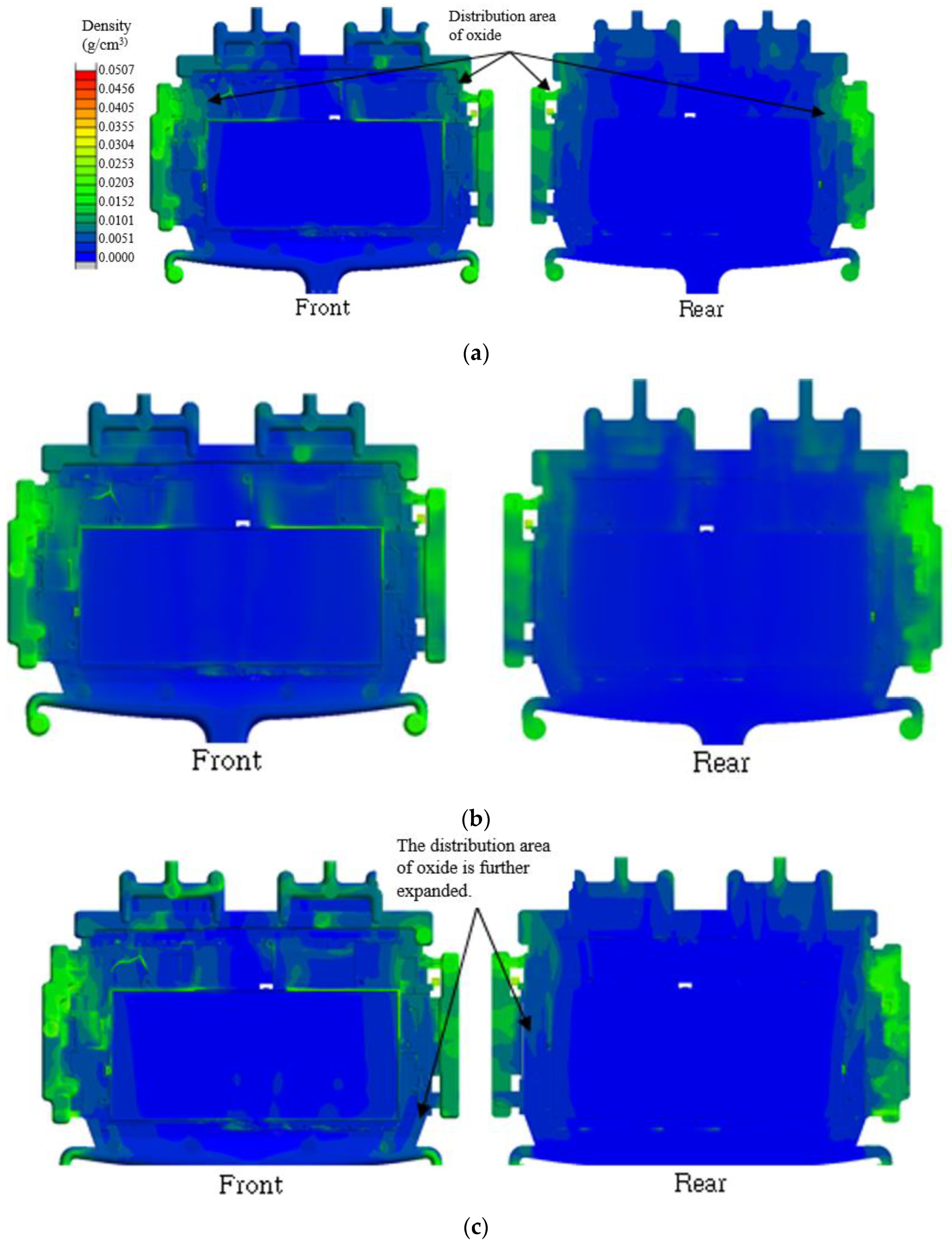

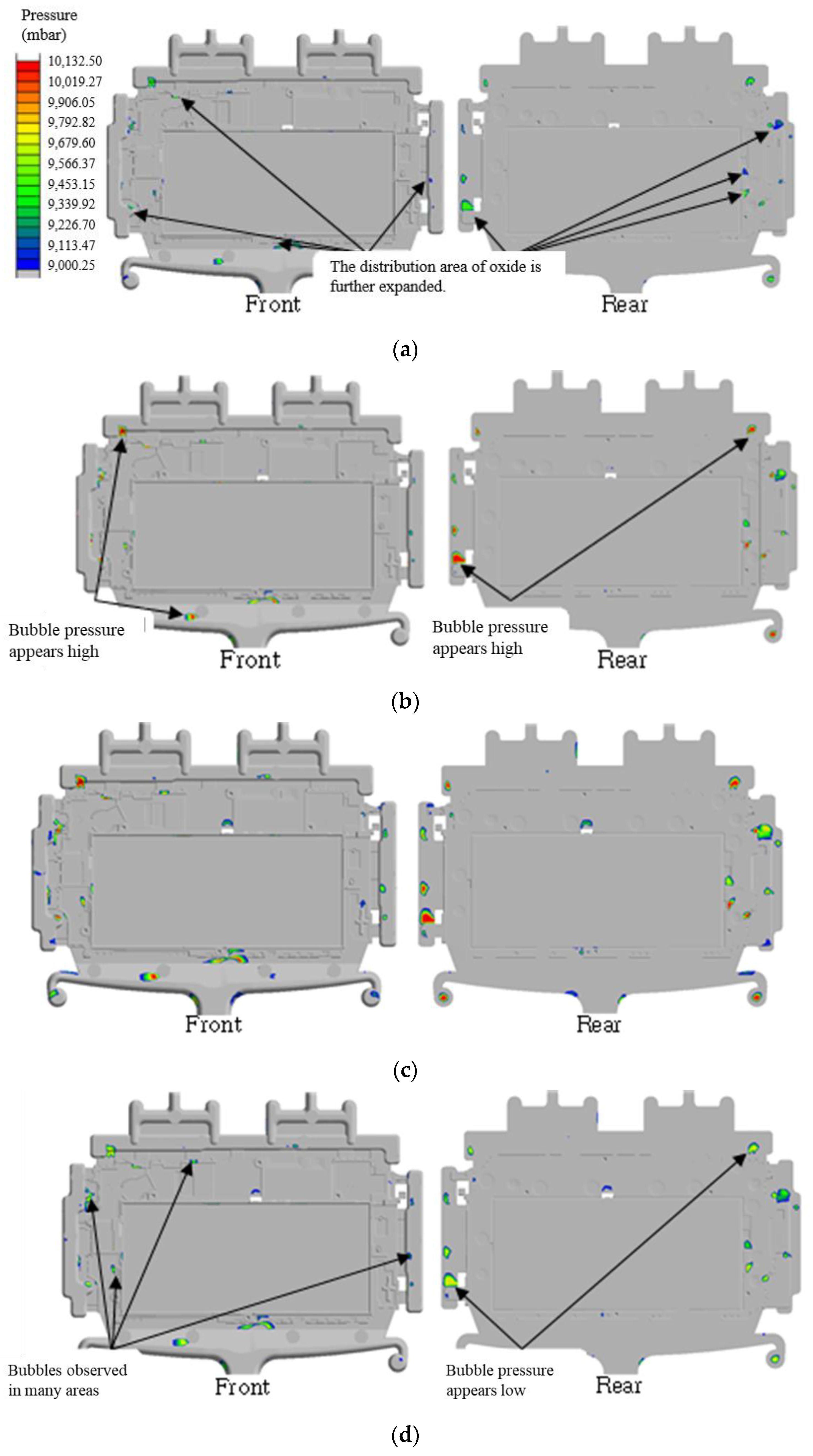

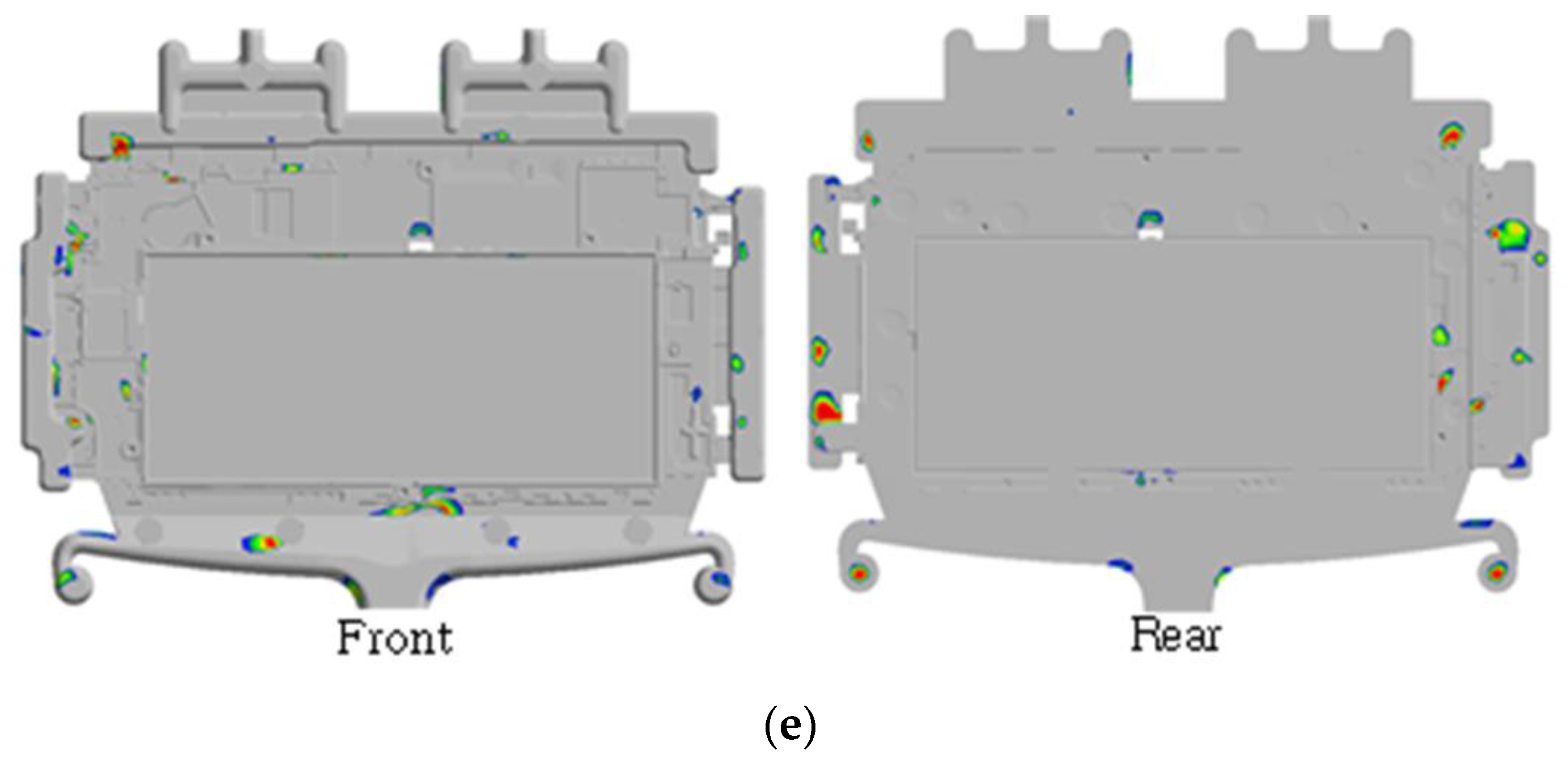

4.1.2. Predicting Defect Occurrence Pattern

4.2. Characteristics of the Prototype

4.2.1. Influence of Microstructure

4.2.2. Influence of Mechanical Properties

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Polmear, I.J. Magnesium alloys and applications. Mater. Sci. Technol. 1994, 10, 1–16. [Google Scholar] [CrossRef]

- Yang, Y.; Xiong, X.; Chen, J.; Peng, X.; Chen, D.; Pan, F. Research Advances in Magnesium and Magnesium Alloys Worldwide in 2020. J. Magnes. Alloys 2021, 9, 705–747. [Google Scholar] [CrossRef]

- Xu, T.; Yang, Y.; Peng, X.; Song, J.; Pan, F. Overview of Advancement and Development Trend on Magnesium Alloy. J. Magnes. Alloys 2019, 7, 536–544. [Google Scholar] [CrossRef]

- Song, J.; She, J.; Chen, D.; Pan, F. Latest Research Advances on Magnesium and Magnesium Alloys Worldwide. J. Magnes. Alloys 2020, 8, 1–41. [Google Scholar] [CrossRef]

- Ali, Y.; Qiu, D.; Jiang, B.; Pan, F.; Zhang, M.X. Current Research Progress in Grain Refinement of Cast Magnesium Alloys: A Review Article. J. Alloys Compd. 2015, 619, 639–651. [Google Scholar] [CrossRef]

- Luo, A.A. Magnesium Casting Technology for Structural Applications. J. Magnes. Alloys 2013, 1, 2–22. [Google Scholar] [CrossRef]

- You, B.S.; Yim, C.D.; Kim, S.H. Solidification of AZ31 Magnesium Alloy Plate in a Horizontal Continuous Casting Process. Mater. Sci. Eng. A 2005, 413–414, 139–143. [Google Scholar] [CrossRef]

- Hu, L.; Chen, S.; Miao, Y.; Meng, Q. Die-Casting Effect on Surface Characteristics of Thin-Walled AZ91D Magnesium Components. Appl. Surf. Sci. 2012, 261, 851–856. [Google Scholar] [CrossRef]

- Barone, M.R.; Caulk, D.A. Analysis of Liquid Metal flow in Die Casting. Int. J. Eng. Sci. 2000, 38, 1279–1302. [Google Scholar] [CrossRef]

- Qin, X.-Y.; Su, Y.; Chen, J.; Liu, L.-J. Finite Element Analysis for Die Casting Parameters in High-Pressure Die Casting Process. China Foundry 2019, 16, 272–276. [Google Scholar] [CrossRef]

- Syrcos, G.P. Die Casting Process Optimization Using Taguchi Methods. J. Mater. Process. Technol. 2003, 135, 68–74. [Google Scholar] [CrossRef]

- Iwata, Y.; Dong, S.; Sugiyama, Y.; Iwahori, H. Change in Molten Metal Pressure and Its Effect on Defects of Aluminum Alloy Die Castings. Mater. Trans. 2014, 55, 311–317. [Google Scholar] [CrossRef]

- Ibrahim, M.D.; Rahman, M.R.A.; Khan, A.A.; Mohamad, M.R.; Suffian, M.S.Z.M.; Yunos, Y.S.; Wong, L.K.; Mohtar, M.Z. Effect of Mold Designs on Molten Metal Behaviour in High-Pressure Die Casting. J. Phys. Conf. Ser. 2017, 822, 12029. [Google Scholar] [CrossRef]

- Dumanić, I.; Jozić, S.; Bajić, D.; Krolo, J. Optimization of Semi-Solid High-Pressure Die Casting Process by Computer Simulation, Taguchi Method and Grey Relational Analysis. Int. J. Met. 2021, 15, 108–118. [Google Scholar] [CrossRef]

- Fu, J.; Wang, K. Modelling and Simulation of Die Casting Process for A356 Semisolid Alloy. In Proceedings of the Procedia Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2014; Volume 81, pp. 1565–1570. [Google Scholar]

- Li, Y.; Wei, Z. Numerical Simulation of Filling Process in Die Casting. Mater. Technol. 2003, 18, 36–41. [Google Scholar]

- Chen, Z.; Li, Y.; Zhao, F.; Li, S.; Zhang, J. Progress in Numerical Simulation of Casting Process. Meas. Control 2022, 55, 257–264. [Google Scholar] [CrossRef]

- Dou, K.; Lordan, E.; Zhang, Y.J.; Jacot, A.; Fan, Z.Y. A Complete Computer Aided Engineering (CAE) Modelling and Optimization of High Pressure Die Casting (HPDC) Process. J. Manuf. Process. 2020, 60, 435–446. [Google Scholar] [CrossRef]

- Ma, C.; Yu, W.; Zhang, T.; Zhang, Z.; Ma, Y.; Xiong, S. The Effect of Slow Shot Speed and Casting Pressure on the 3D Microstructure of High Pressure Die Casting AE44 Magnesium Alloy. J. Magnes. Alloys 2023, 11, 753–761. [Google Scholar] [CrossRef]

- Chang, X.Y.; Shen, Q.; Fan, W.X.; Hao, H. Optimization of Magnesium Alloy Casting Process: An Integrated Computational Materials Engineering (ICME) Approach. Mater. Sci. Forum 2021, 1035, 808–812. [Google Scholar] [CrossRef]

- Li, J.; Chen, L.; Jiang, S.; Gan, H.; Hao, W. Numerical Simulation and Process Optimization of Magnesium Alloy Vehicle Dashboard Cross Car Beam (CCB) Based on MAGMA. Processes 2023, 11, 16. [Google Scholar] [CrossRef]

| Element | Strength (MPa) | Density (kg/m3) | Specific Strength (MPa m/kg) |

|---|---|---|---|

| Mg | 250 | 1.81 | 138 |

| Al | 315 | 2.7 | 2.7 |

| Zn | 221 | 6.6 | 33 |

| Element | AZ91D | ALDC12 |

|---|---|---|

| Al | 8.3~9.7 | Bal. |

| Zn | 0.35~1.0 | 1.0 or less |

| Mn | 0.15 or higher | 0.5 or less |

| Si | 0.1 of less | 9.6~12.0 |

| Cu | 0.03 or less | 1.5~3.5 |

| Ni | 0.002 or less | 0.5 or less |

| Fe | 0.005 or less | 0.9 or less |

| Mg | Bal. | 0.3 or less |

| Sn | - | 0.2 or less |

| Sample | Molten Metal Injection Temperature (°C) | Mold Temperature (°C) | Coolant Temperature (°C) | |

|---|---|---|---|---|

| Inlet | Outlet | |||

| CASE 1 | 640 | 190 | 25 | 40 |

| CASE 2 | 670 | 220 | 25 | 40 |

| CASE 3 | 610 | 160 | 25 | 40 |

| CASE 4 | 670 | 190 | 10 | 40 |

| CASE 5 | 610 | 190 | 40 | 55 |

| Property | Unit | Temp. Condition (°C) | AZ91D Properties |

|---|---|---|---|

| Density | g/cm3 | 20 | 1.81 |

| Linear thermal experimental coefficient | μm/m·K | 20–100 | 26 |

| Specific heat of fusion | kJ/kg | 370 | |

| Specific heat | 20 | 1.02 | |

| Thermal conductivity | 20 | 51 | |

| Electrical conductivity | MS/m | 20 | 6.6 |

| Microstructure |  |  |  |

| Measurement location | 2 (Ingate left) | 3 (Ingate center) | 4 (Ingate right) |

| Microstructure |  |  |  |

| Measurement location | 15 (Outgate left) | 1 (Runner center) | 16 (Outgate right) |

| Microstructure |  |  |  |

| Measurement location | 17 (Outgate left) | 14 (Product center) | 18 (Outgate right) |

| Microstructure |  |  |  |

| Measurement location | 5 (0.5 mm left) | 6 (0.5 mm center) | 7 (0.5 mm right) |

| Microstructure |  |  |  |

| Measurement location | 8 (0.5 mm left) | 9 (0.5 mm center) | 10 (0.5 mm right) |

| Microstructure |  |  |  |

| Measurement location | 11 (0.5 mm left) | 12 (0.5 mm center) | 13 (0.5 mm right) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, J.-T.; Ryu, C.-M.; Moon, S.-J. Investigation of Properties in Magnesium Alloy Thin Plates after Die Casting Processes. Metals 2024, 14, 970. https://doi.org/10.3390/met14090970

Han J-T, Ryu C-M, Moon S-J. Investigation of Properties in Magnesium Alloy Thin Plates after Die Casting Processes. Metals. 2024; 14(9):970. https://doi.org/10.3390/met14090970

Chicago/Turabian StyleHan, Jun-Tae, Choong-Mo Ryu, and Seung-Jae Moon. 2024. "Investigation of Properties in Magnesium Alloy Thin Plates after Die Casting Processes" Metals 14, no. 9: 970. https://doi.org/10.3390/met14090970

APA StyleHan, J.-T., Ryu, C.-M., & Moon, S.-J. (2024). Investigation of Properties in Magnesium Alloy Thin Plates after Die Casting Processes. Metals, 14(9), 970. https://doi.org/10.3390/met14090970