Texture Evolution of 1060 Aluminum Alloy Featuring Initial Rotated β Fiber During Accumulative Roll Bonding Process

Abstract

:1. Introduction

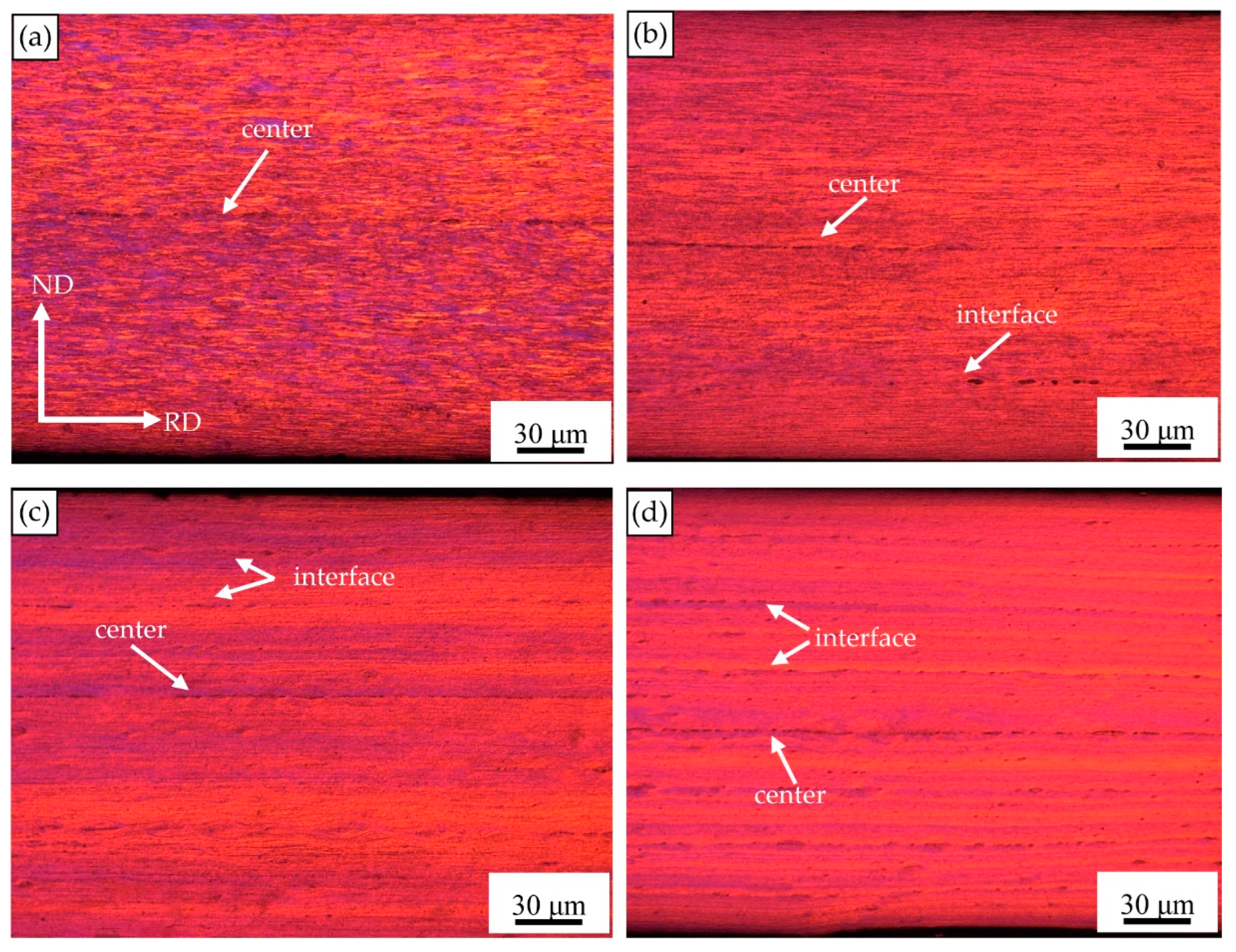

2. Materials and Methods

3. Results and Discussion

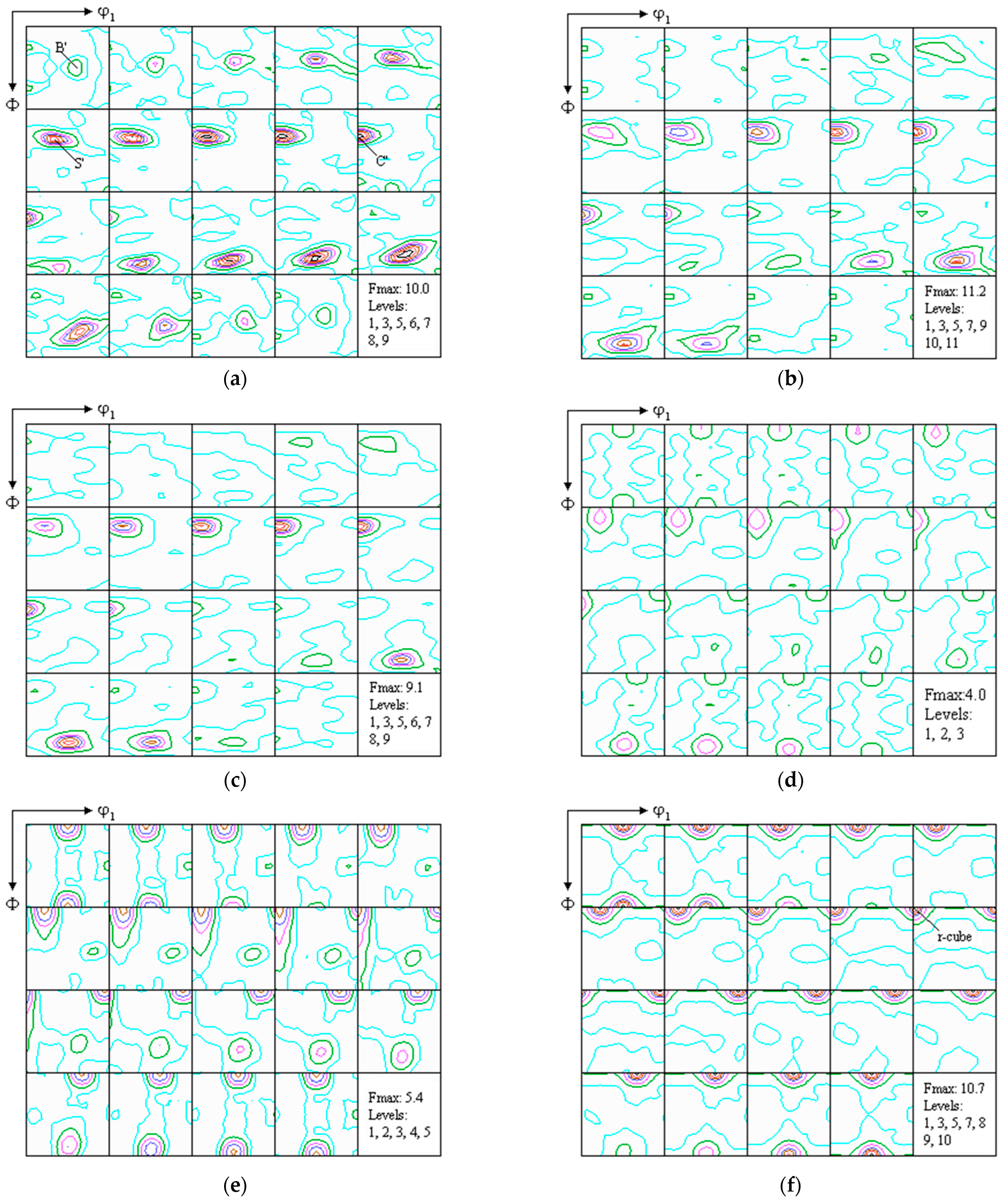

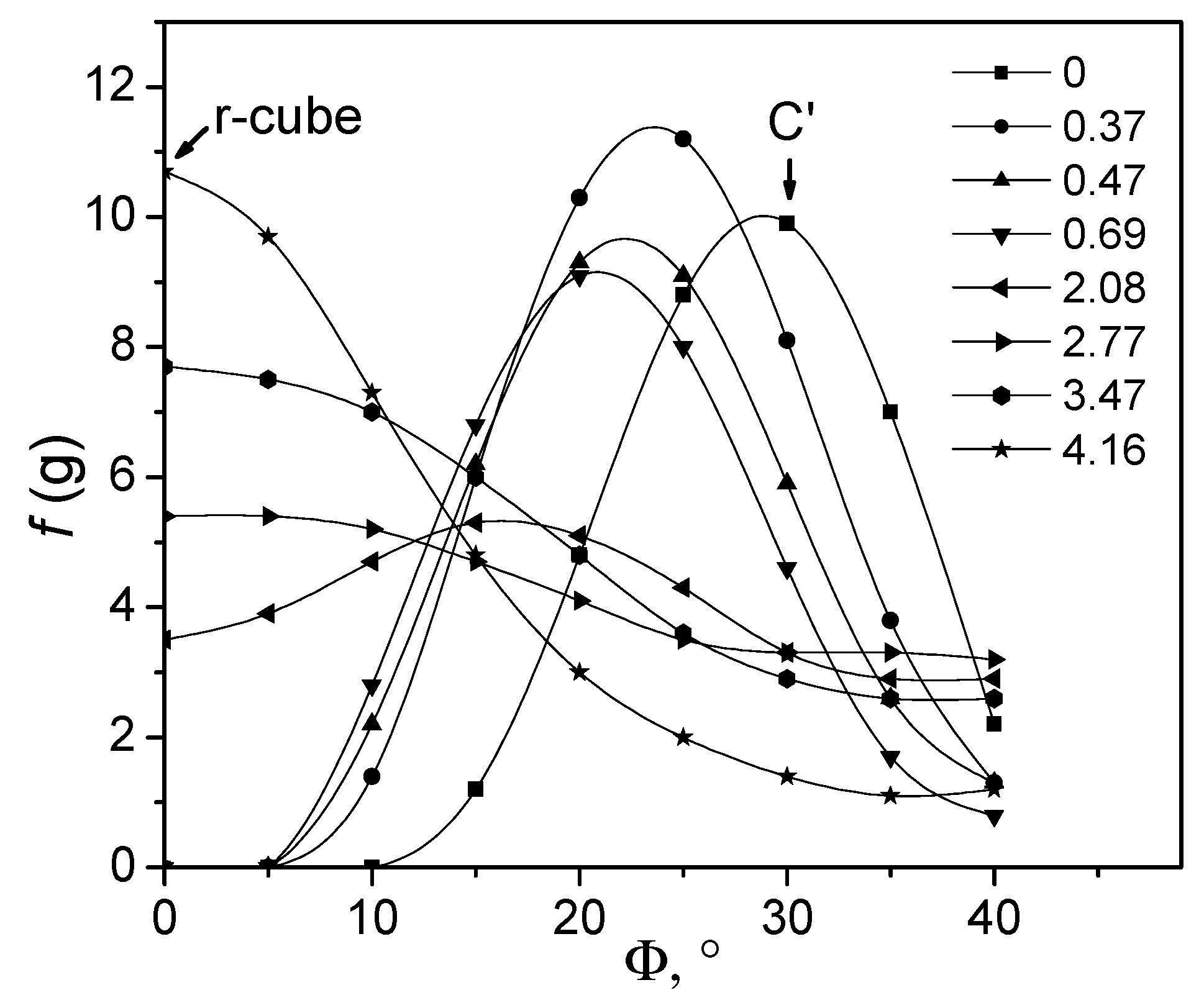

3.1. Texture Development During Shear Deformation

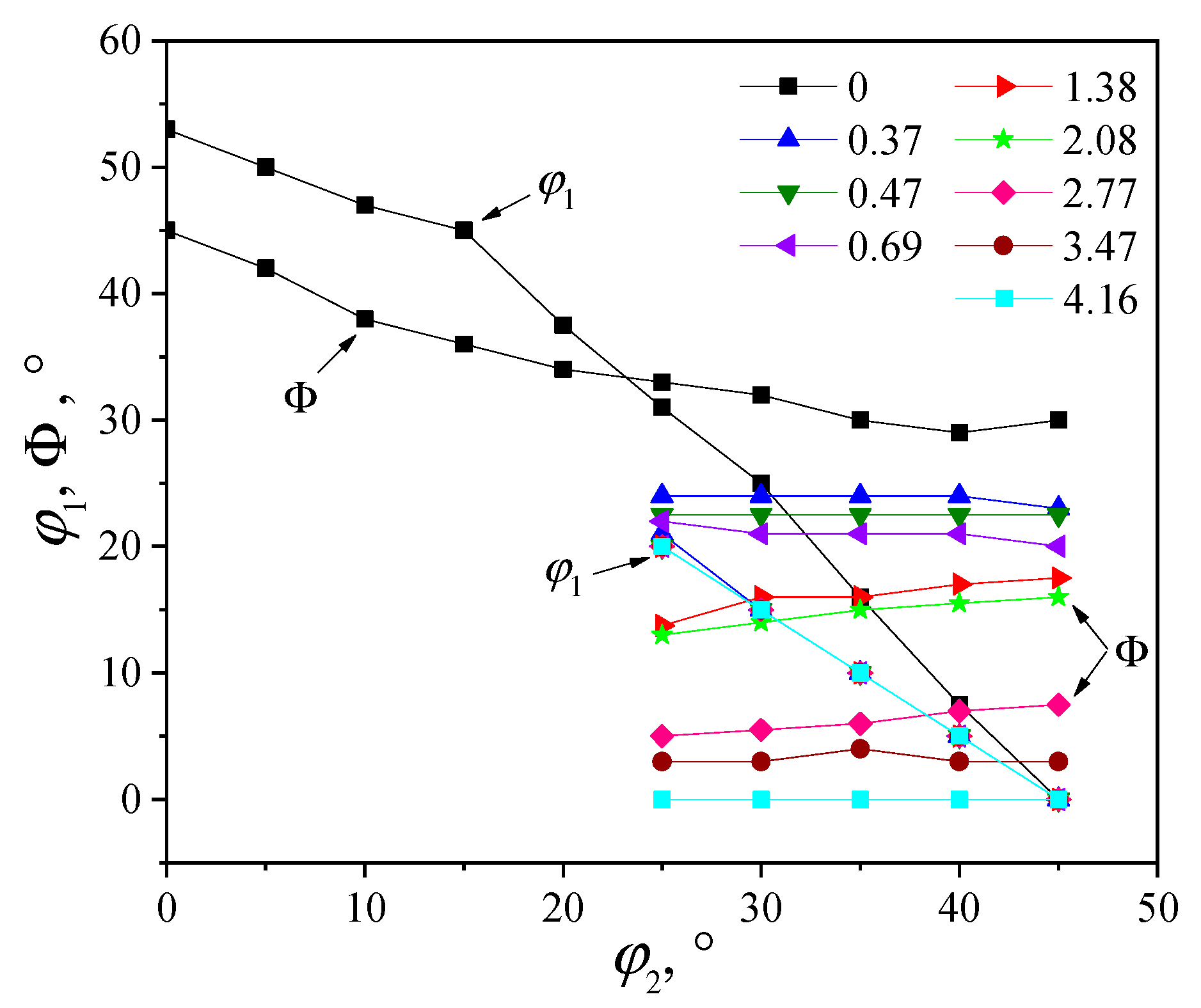

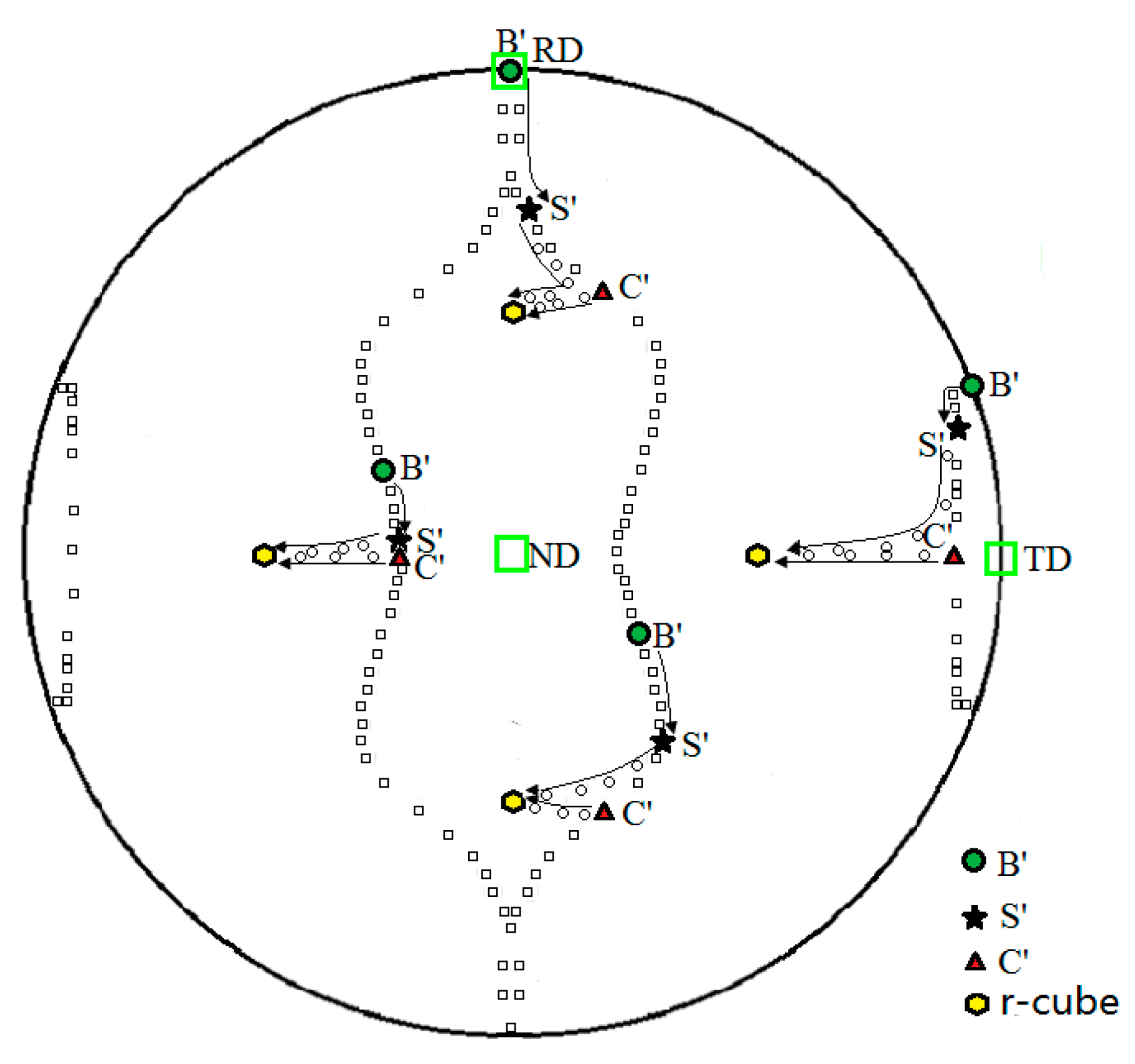

3.2. The Rotation Paths of the B’, S’, and C’ Orientations

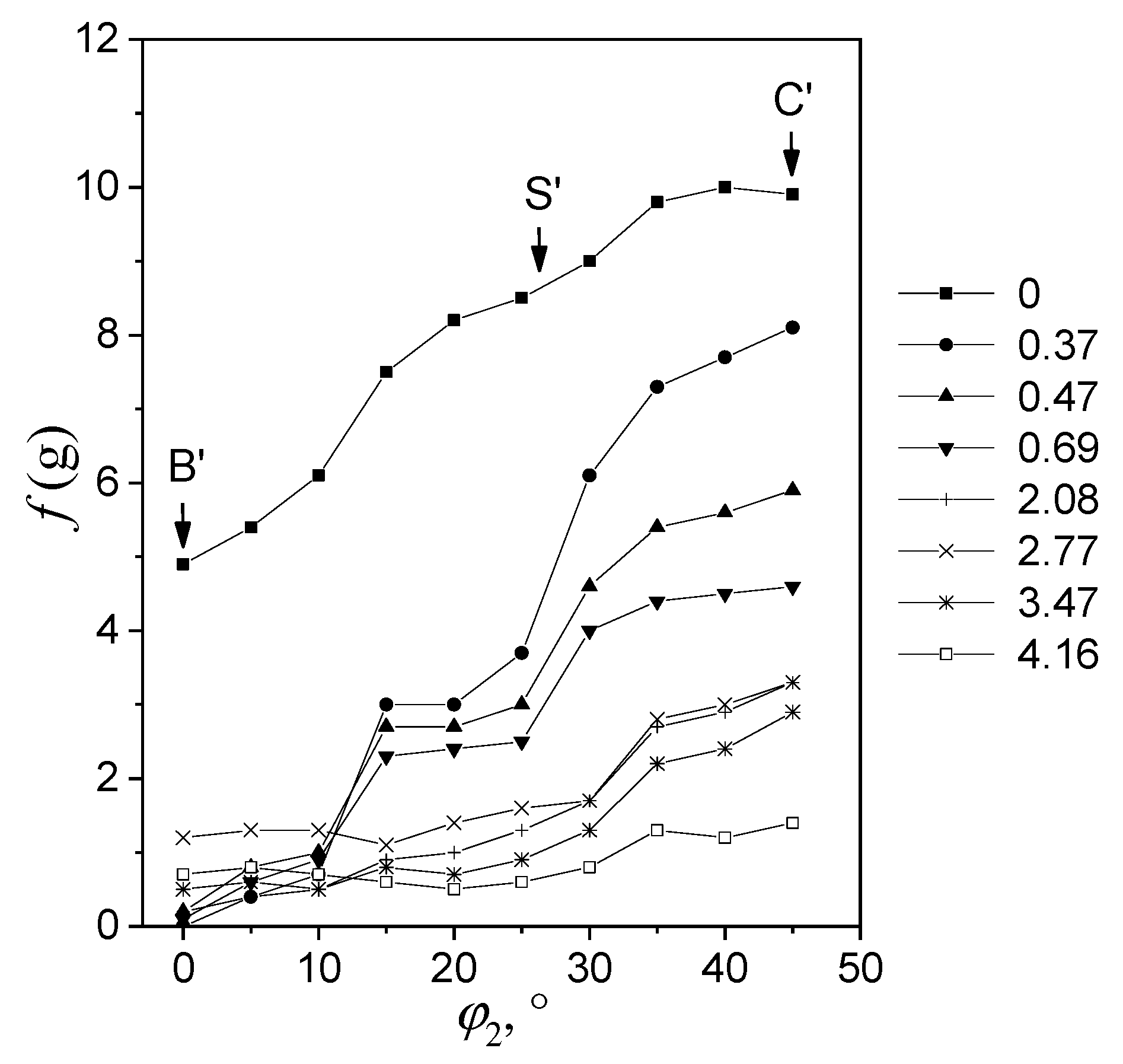

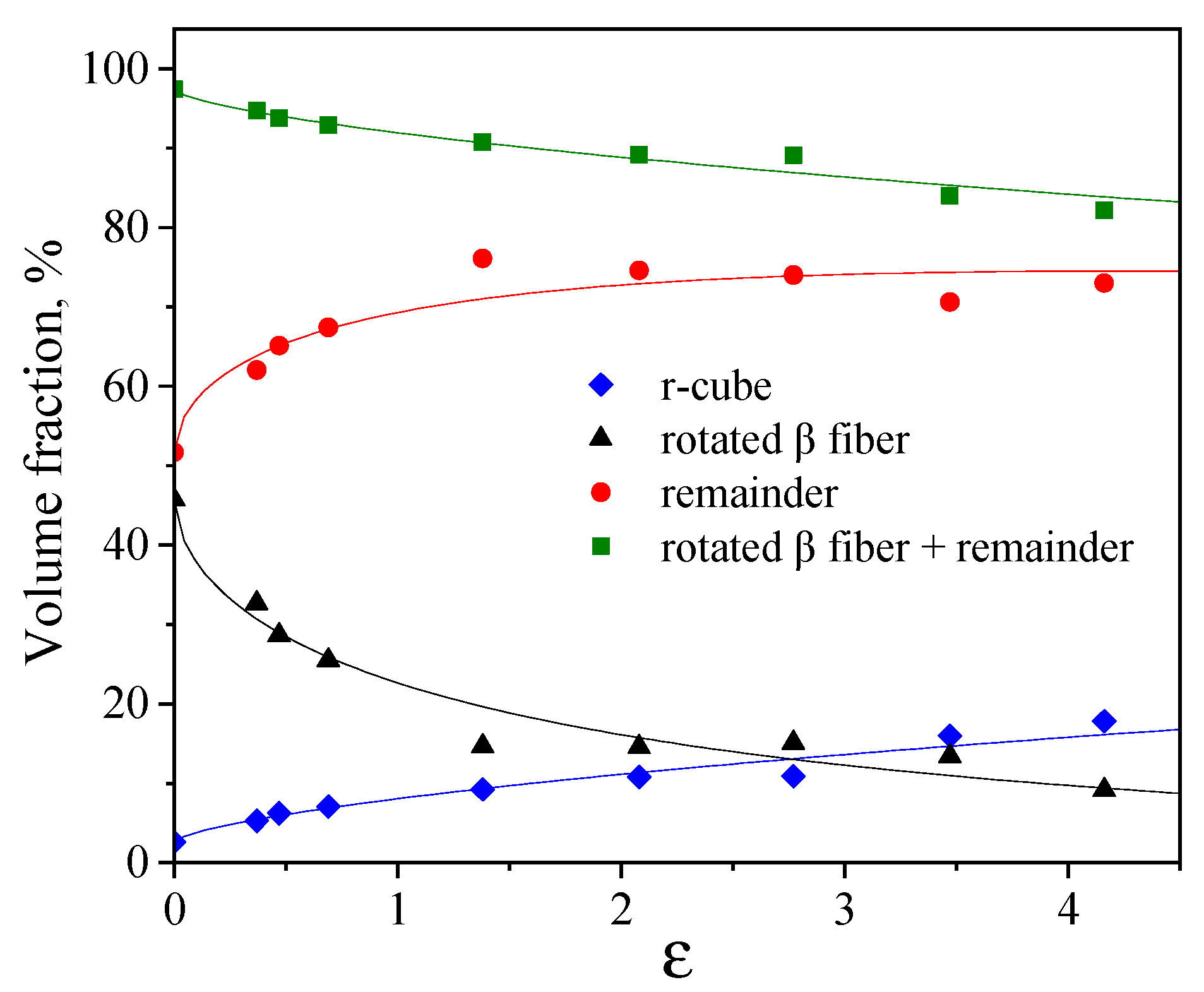

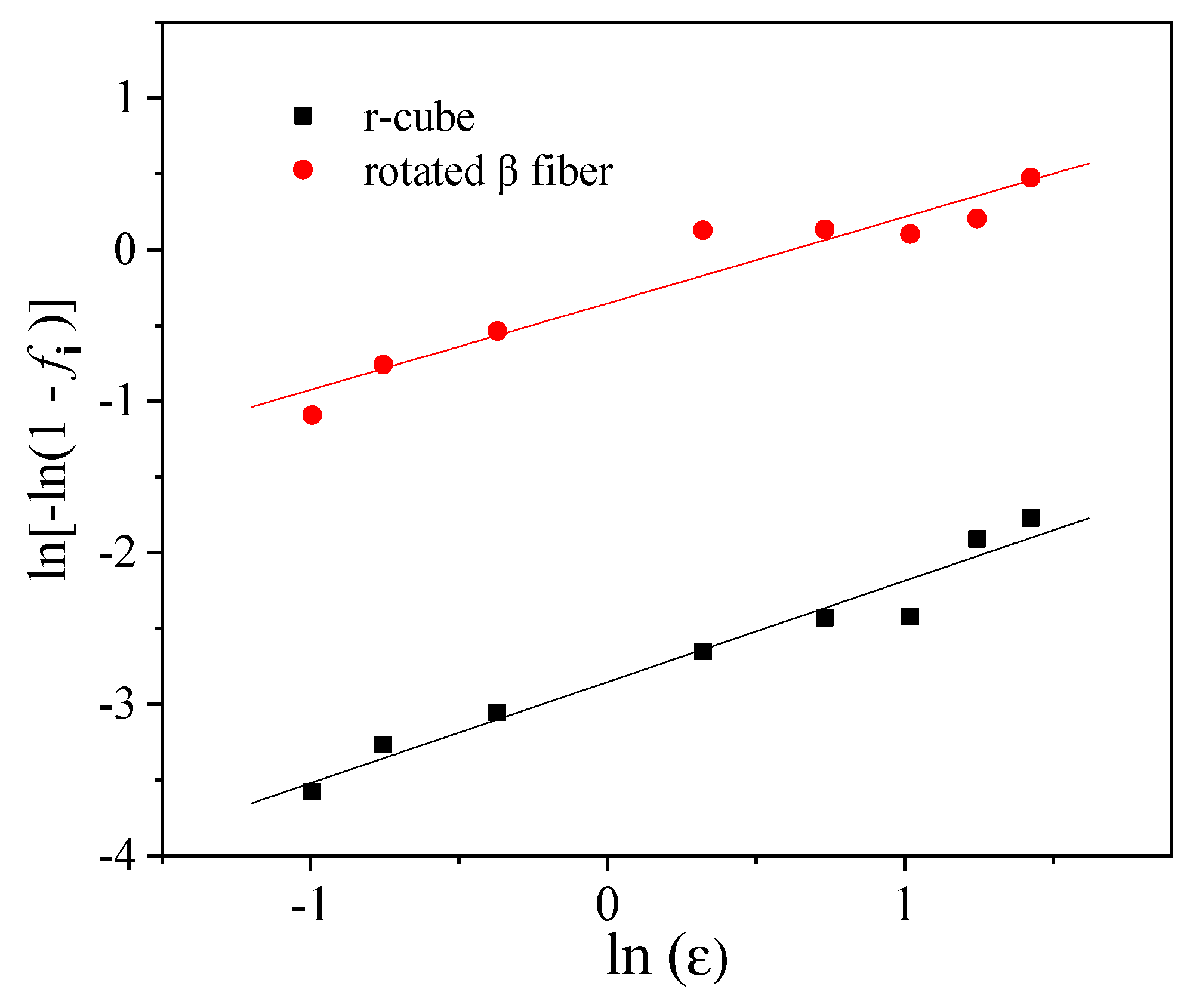

3.3. Quantitative Analysis of Texture Evolution During ARB Process

4. Conclusions

- (1)

- The rotated β fiber was unstable, and it rotated to the r-cube shear texture. The B’ orientation disappeared quickly in the early deformation stage, while the S’ and C’ orientation intensities decreased gradually as the accumulated true strain increased. In the meantime, the r-cube orientation intensity increased as the accumulated true strain increased.

- (2)

- The rotation paths from the rotated β fiber to the r-cube orientation were determined according to the ODFs. The B’ orientation moved to the S’ orientation along the initial rotated β fiber skeleton, while the C’ orientation moved along the TD axis to the r-cube orientation. The S’ orientation to the r-cube orientation rotation path slightly deviated from the C’ orientation.

- (3)

- The texture evolution of 1060 aluminum alloy featuring an initial rotated β fiber during shear deformation was analyzed in a quantitative manner by establishing a mathematical relationship between the texture volume fractions and accumulated true strain, which allowed us to make more precise predictions regarding the texture evolution during shear deformation.

- (4)

- To obtain a better understanding of texture evolution and lattice rotation during shear deformation, future studies could focus on the lattice rotation based on the analysis of slip systems, calculating the slip systems under shear deformation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mehr, V.Y.; Toroghinejad, M.R. On the texture evolution of aluminum-based composites manufactured by ARB rocess: A review. J. Mater. Res. Technol. 2022, 21, 1095–1109. [Google Scholar] [CrossRef]

- Attarilar, S.; Ebrahimi, M.; Hsieh, T.H.; Uan, J.Y.; Göde, C. An insight into the vibration-assisted rolling of AA5052 aluminum alloy: Tensile strength, deformation microstructure, and texture evolution. Mater. Sci. Eng. A 2021, 803, 140489. [Google Scholar] [CrossRef]

- Xie, H.; Wang, M.P.; Chen, W.; Jia, Y. Microstructure, mechanical properties, and texture evolution of aluminum alloy 7005 by accumulative roll bonding. J. Mater. Eng. Perform. 2016, 25, 1199–1210. [Google Scholar] [CrossRef]

- Liu, W.C.; Man, C.-S.; Morris, J.G. Lattice rotation of the cube orientation to the β fiber during cold rolling of AA 5052 aluminum alloy. Scr. Mater. 2001, 45, 807–814. [Google Scholar] [CrossRef]

- Li, Z.J.; Godfrey, A.; Liu, Q. Macroscopic sub-division of rolled Al-1% Mn single crystals of {001}<110> orientation. Scr. Mater. 2001, 45, 847–852. [Google Scholar]

- Liu, W.C.; Kong, X.Y.; Chen, M.B.; Li, J.; Yuan, H.; Yang, Q.X. Texture development in a pseudo cross-rolled AA 3105 aluminum alloy. Mater. Sci. Eng. A 2009, 516, 263–269. [Google Scholar] [CrossRef]

- Liu, W.C.; Morris, J.G. Comparison of the texture evolution in cold rolled DC and SC AA 5182 aluminum alloys. Mater. Sci. Eng. A 2003, 339, 183–193. [Google Scholar] [CrossRef]

- Liu, W.C.; Morris, J.G. Quantitative analysis of texture evolution in cold-rolled, continuous-cast AA 5xxx-series aluminum alloys. Metall. Mater. Trans. A 2004, 35, 265–277. [Google Scholar] [CrossRef]

- Bednarczyk, I.; Dobkowska, A.; Hilšer, O.; Rusz, S.; Pastrňák, M.; Čada, R.; Mizera, J. Influence of temperature and number of passes during twist channel angular pressing (TCAP) on the microstructural, mechanical, and corrosion properties of Mg–4Li–Ca. Arch. Civ. Mech. Eng. 2024, 24, 89. [Google Scholar] [CrossRef]

- Wang, X.; Liu, H.; Tang, X.; Wang, Y.; Guo, M.; Zhuang, L. Influence of asymmetric rolling on the microstructure, texture evolution and mechanical properties of Al–Mg–Si alloy. Mater. Sci. Eng. A 2022, 844, 143154. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Wang, Q. Accumulative roll-bonding of aluminum alloys and composites: An overview of properties and performance. J. Mater. Res. Technol. 2022, 19, 4381–4403. [Google Scholar]

- Khatami, R.; Fattah-alhosseini, A.; Mazaheri, Y.; Keshavarz, M.K.; Haghshenas, M. Microstructural evolution and mechanical properties of ultrafine grained AA2024 processed by accumulative roll bonding. J. Adv. Manuf. Technol. 2017, 93, 681–689. [Google Scholar]

- Sun, H.Y.; Du, P.; Wang, Z.J.; Ma, M.; Liu, W.C.; Sasaki, G.; Zhang, J.X. Study on the microstructure, texture and mechanical properties of hot-rolled and T6-treated Al1060/Al6061-TiCp/Al1060 laminated composites. J. Mater. Res. Technol. 2022, 18, 2808–2821. [Google Scholar]

- Wang, Z.J.; Liu, S.; Qiu, Z.X.; Sun, H.Y.; Liu, W.C. A Study of the Microstructure, Texture and tensile properties of 1060/Al-TiC/1060 sandwich composites prepared by hot-roll bonding. Metall. Mater. Trans. A 2020, 51, 6714–6726. [Google Scholar]

- Li, S.; Li, F.S.H. Observation and modeling of the through-thickness texture gradient in commercial-purity aluminum sheets processed by accumulative roll-bonding. Acta Mater. 2010, 58, 1317–1331. [Google Scholar]

- Jamaati, R.; Toroghinejad, M.R.; Hoseini, M.; Szpunar, J.A. Texture development in Al/Al2O3 MMCs produced by anodizing and ARB processes. Mater. Sci. Eng. A 2011, 528, 3573–3580. [Google Scholar]

- Shaarbaf, M.; Toroghinejad, M.R. Evaluation of texture and grain size of nanograined copper produced by the accumulative roll bonding process. Metall. Mater. Trans. A 2009, 40, 1693–1700. [Google Scholar]

- Beausir, B.; Scharnweber, J.; Jaschinski, J.; Brokmeier, H.G.; Oertel, C.G.; Skrotzki, W. Plastic anisotropy of ultrafine grained aluminium alloys produced by accumulative roll bonding. Mater. Sci. Eng. A 2010, 527, 3271–3278. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, D.N. Analysis of deformation textures of asymmetrically rolled aluminum sheets. Acta Mater. 2001, 49, 2583–2595. [Google Scholar] [CrossRef]

- Wang, Z.J.; Ma, M.; Qiu, Z.X.; Zhang, J.X.; Liu, W.C. Microstructure, texture and mechanical properties of AA 1060 aluminum alloy processed by cryogenic accumulative roll bonding. Mater. Charact. 2018, 139, 269–278. [Google Scholar] [CrossRef]

- Sun, H.Y.; Wang, Z.J.; Du, P.; Zhang, J.X.; Liu, W.C. Effect of rolling reduction and heat treatment on the microstructure and mechanical properties of Al1060/Al6061-0.5 SiC/Al1060 laminates. Mater. Sci. Eng. A 2022, 830, 142328. [Google Scholar] [CrossRef]

- Sun, H.Y.; Zhang, D.H.; Ma, M.; Zhang, J.X.; Liu, W.C. Effect of rolling parameters on microstructure, texture, and mechanical properties of Al/Mg/Al laminated composites. J. Mater. Eng. Perform. 2022, 31, 7624–7640. [Google Scholar] [CrossRef]

| Element | Si | Fe | Cu | Mn | Mg | Zn | Ti | V | Al |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.12 | 0.14 | 0.03 | 0.01 | 0.02 | 0.03 | 0.02 | 0.03 | 99.6 |

| Texture Component | Mi0 (%) | ki | ni | r |

|---|---|---|---|---|

| r-cube | 2.6 | 0.058 (0.055–0.061) | 0.667 ± 0.054 | 0.980 |

| rotated β fiber | 54.3 | 0.528 (0. 493–0.564) | 0.636 ± 0.072 | 0.961 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Ou, J.; Cheng, L.; Sun, L.; Lu, Y. Texture Evolution of 1060 Aluminum Alloy Featuring Initial Rotated β Fiber During Accumulative Roll Bonding Process. Metals 2025, 15, 418. https://doi.org/10.3390/met15040418

Sun H, Ou J, Cheng L, Sun L, Lu Y. Texture Evolution of 1060 Aluminum Alloy Featuring Initial Rotated β Fiber During Accumulative Roll Bonding Process. Metals. 2025; 15(4):418. https://doi.org/10.3390/met15040418

Chicago/Turabian StyleSun, Haiyang, Junfei Ou, Liang Cheng, Lingyan Sun, and Yalin Lu. 2025. "Texture Evolution of 1060 Aluminum Alloy Featuring Initial Rotated β Fiber During Accumulative Roll Bonding Process" Metals 15, no. 4: 418. https://doi.org/10.3390/met15040418

APA StyleSun, H., Ou, J., Cheng, L., Sun, L., & Lu, Y. (2025). Texture Evolution of 1060 Aluminum Alloy Featuring Initial Rotated β Fiber During Accumulative Roll Bonding Process. Metals, 15(4), 418. https://doi.org/10.3390/met15040418