Study on the Morphology, Wear Resistance, and Corrosion Resistance of CuSn12 Alloys Subjected to Machine Hammer Peening

Abstract

1. Introduction

2. Material and Experiment

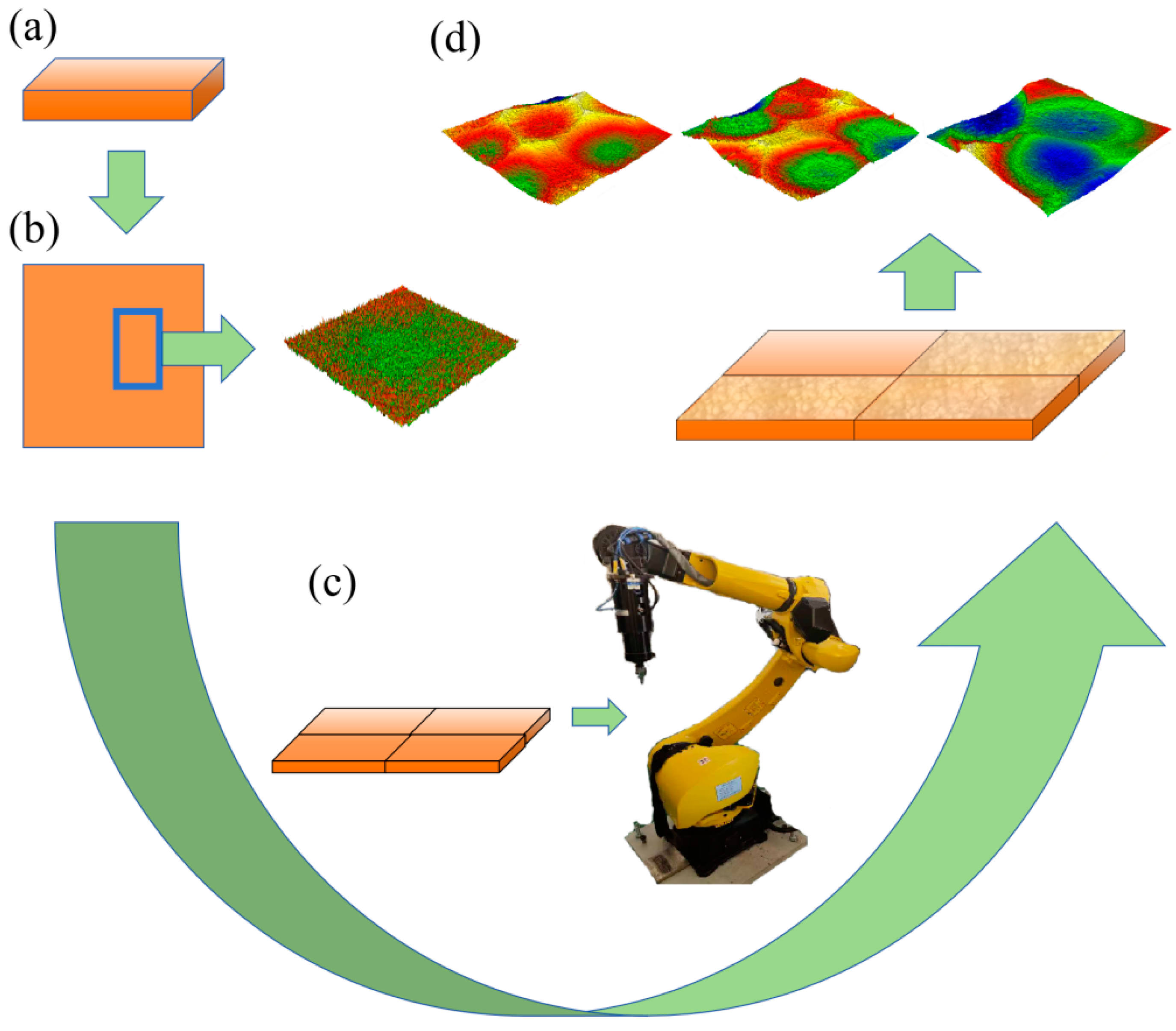

2.1. Material and MHP

2.2. Microhardness Measurement

2.3. Surface Morphology Investigation

2.4. Friction and Wear Testing

2.5. Electrochemical Test

3. Results and Discussion

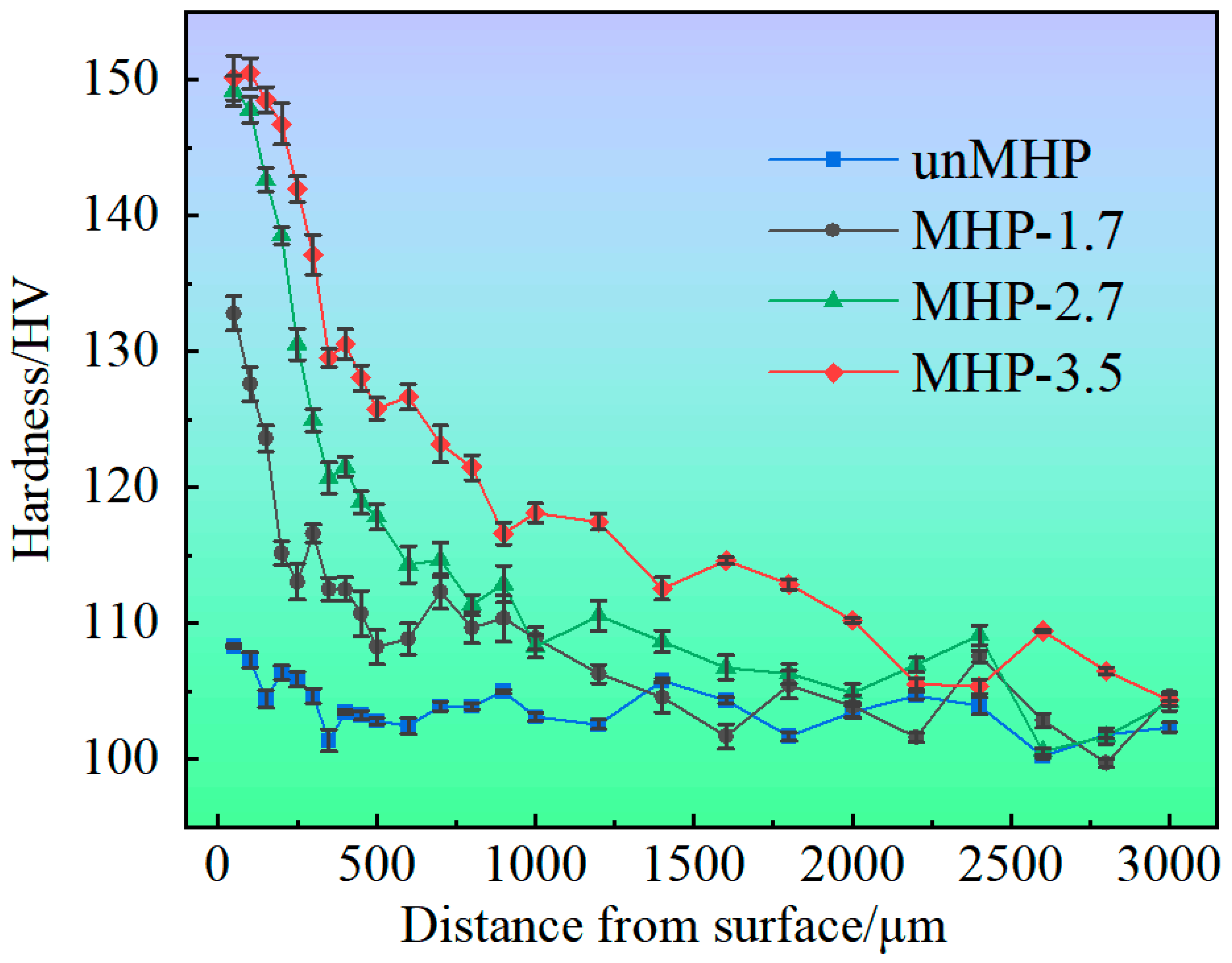

3.1. Microhardness

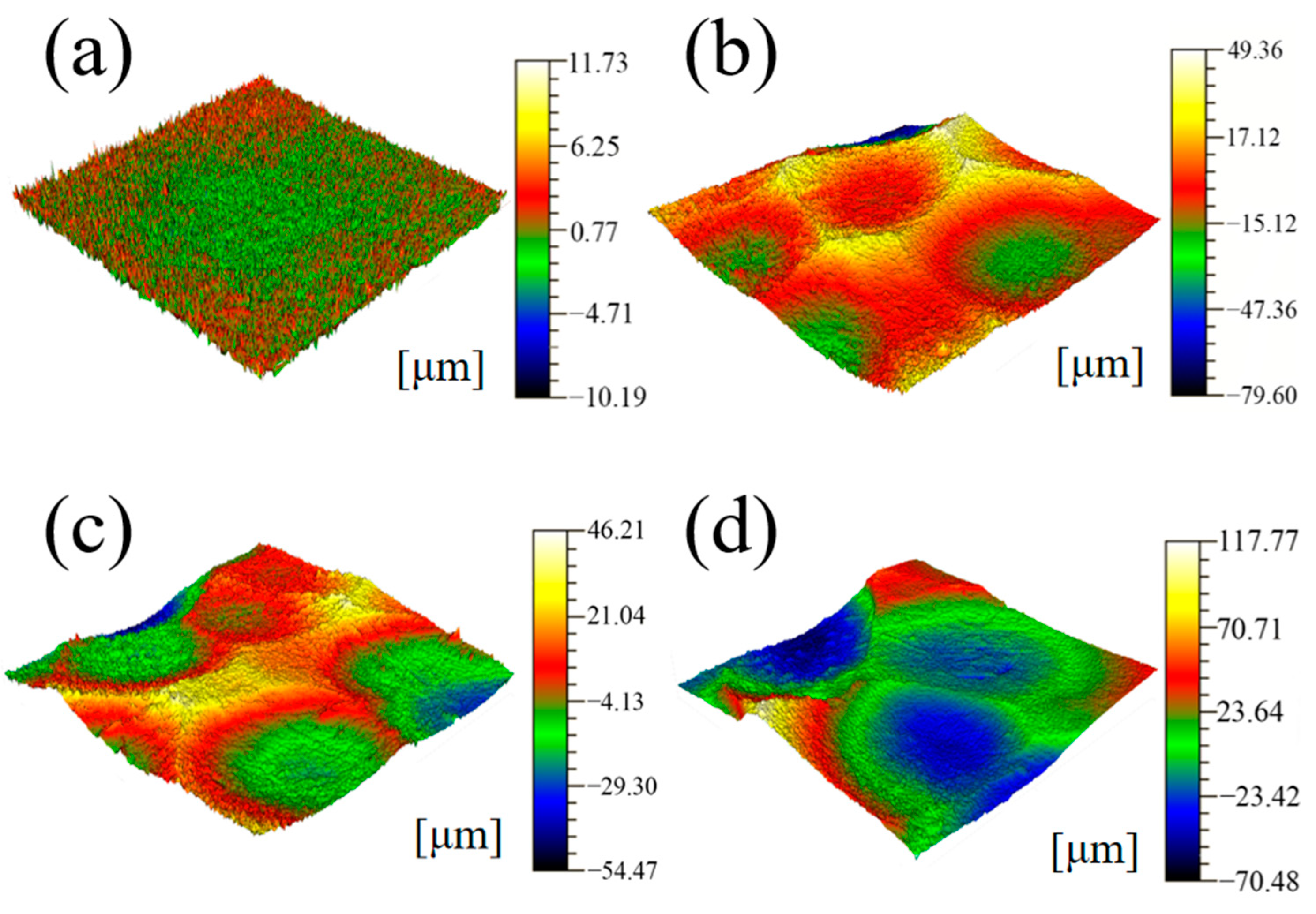

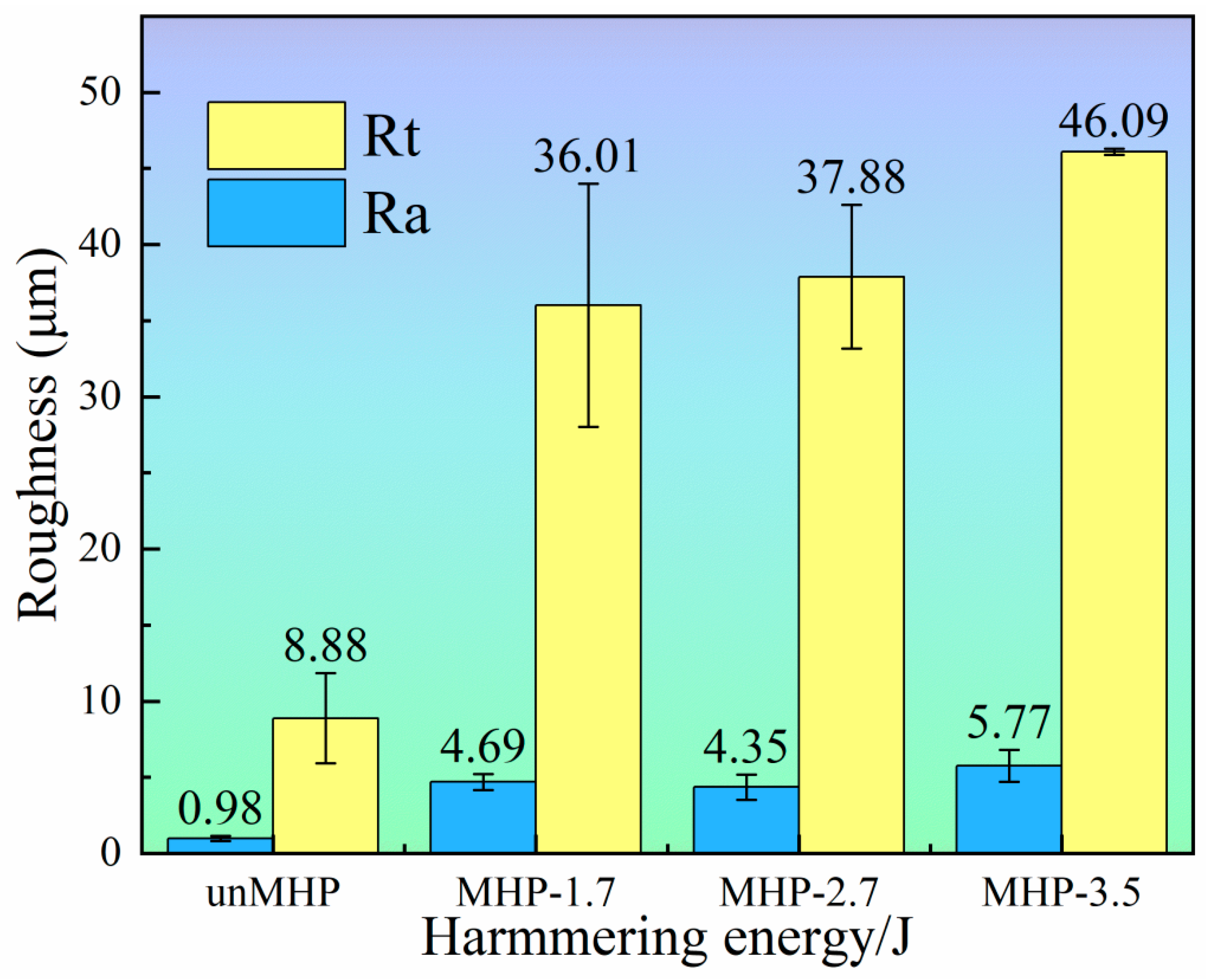

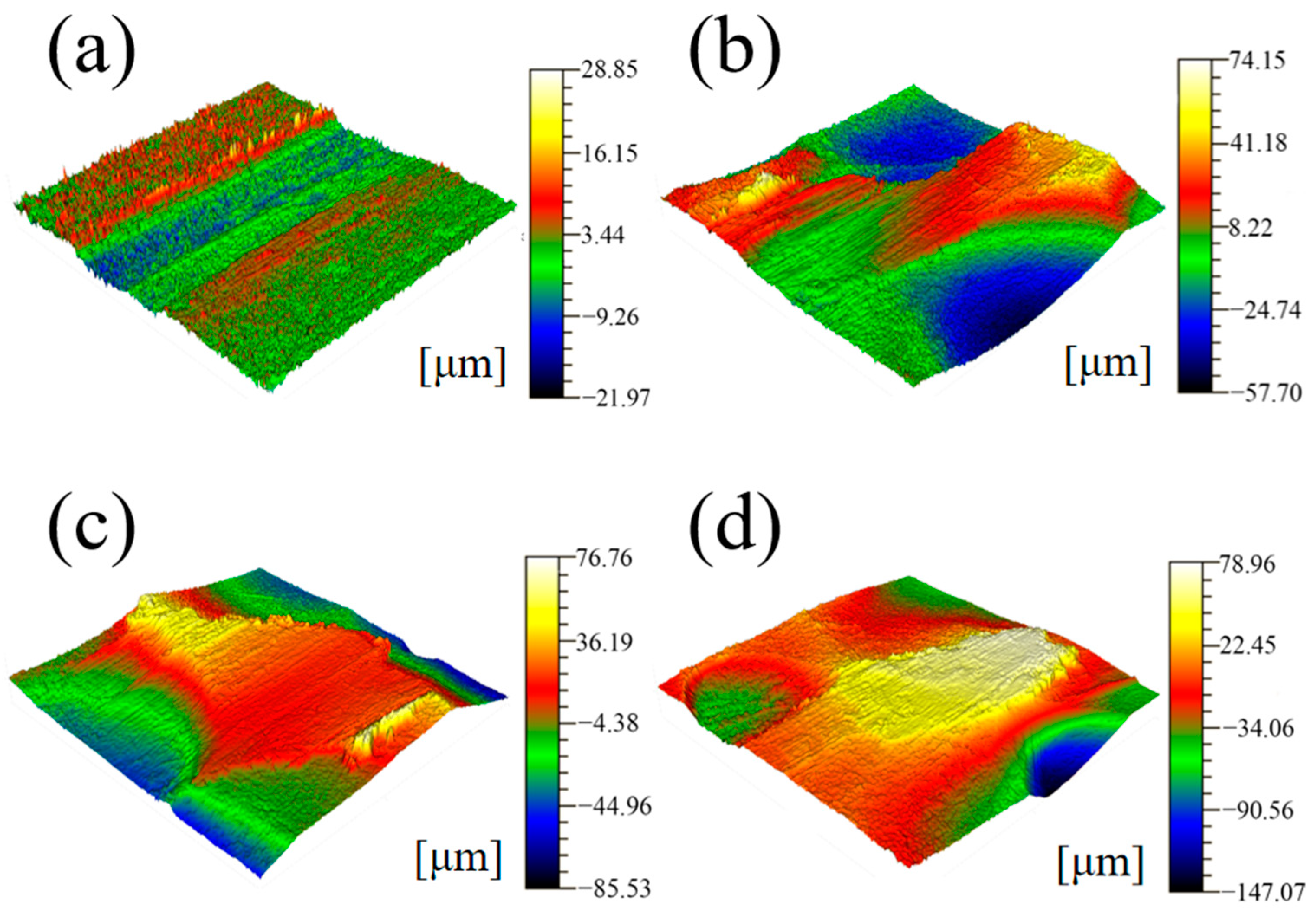

3.2. Surface Morphology

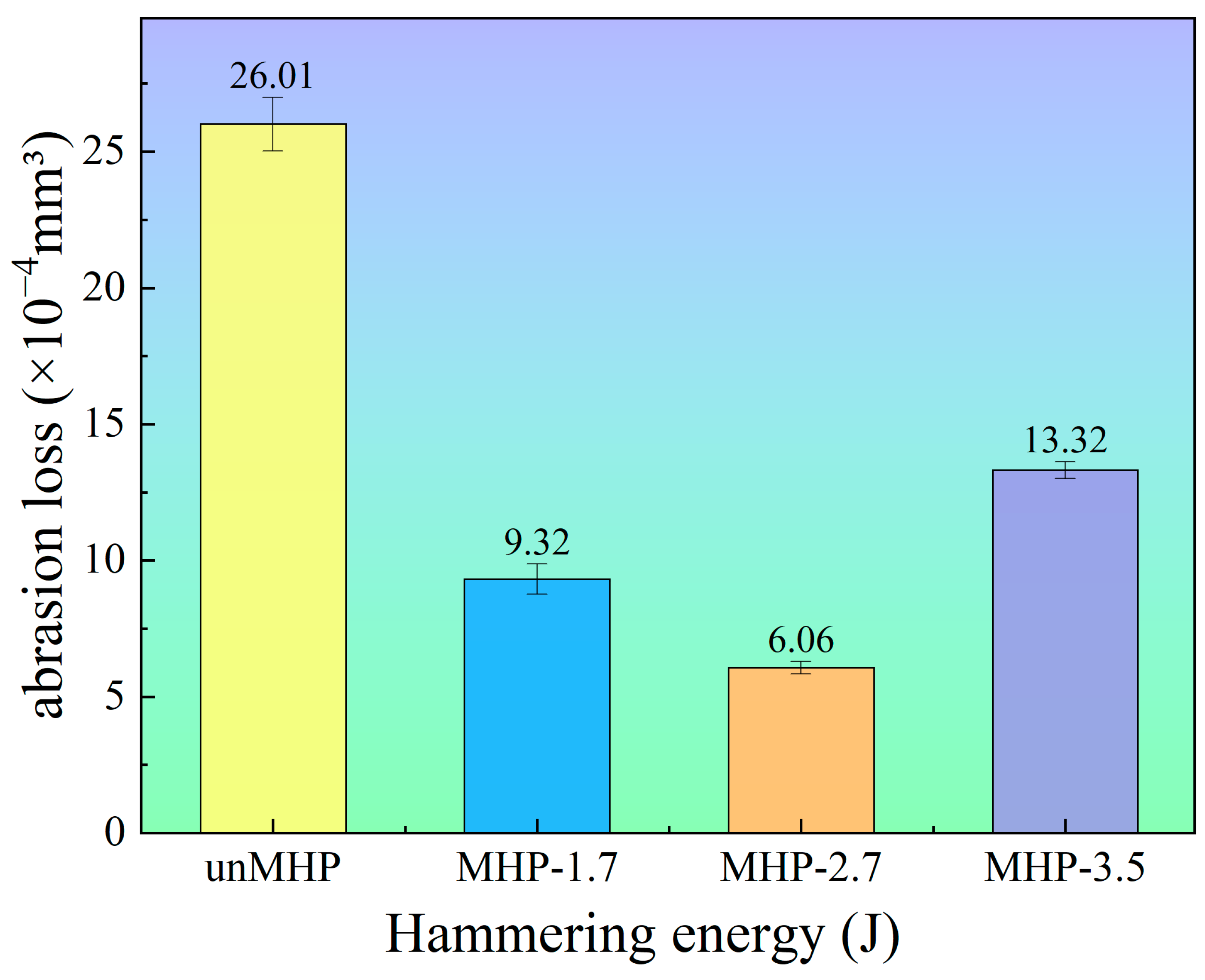

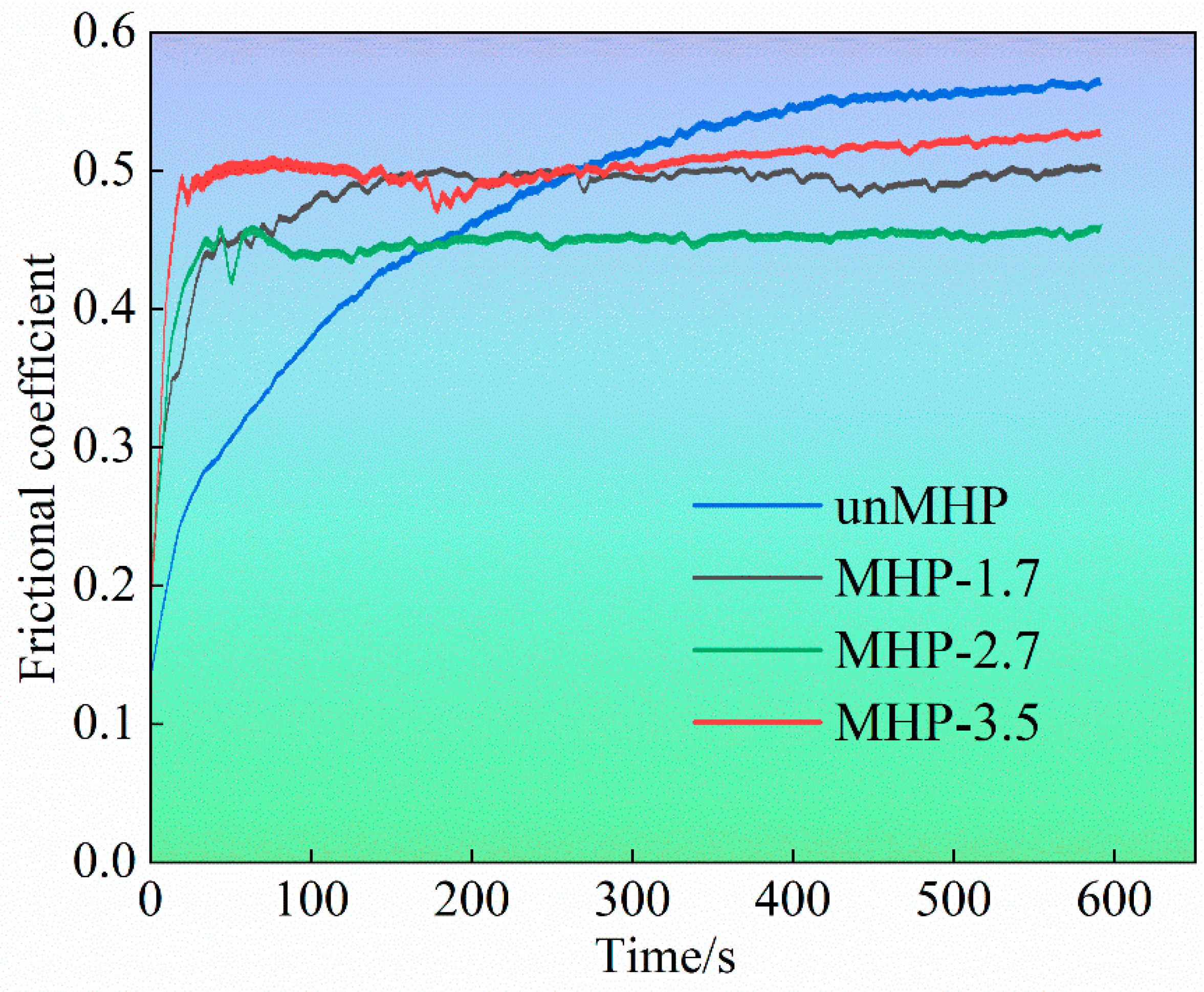

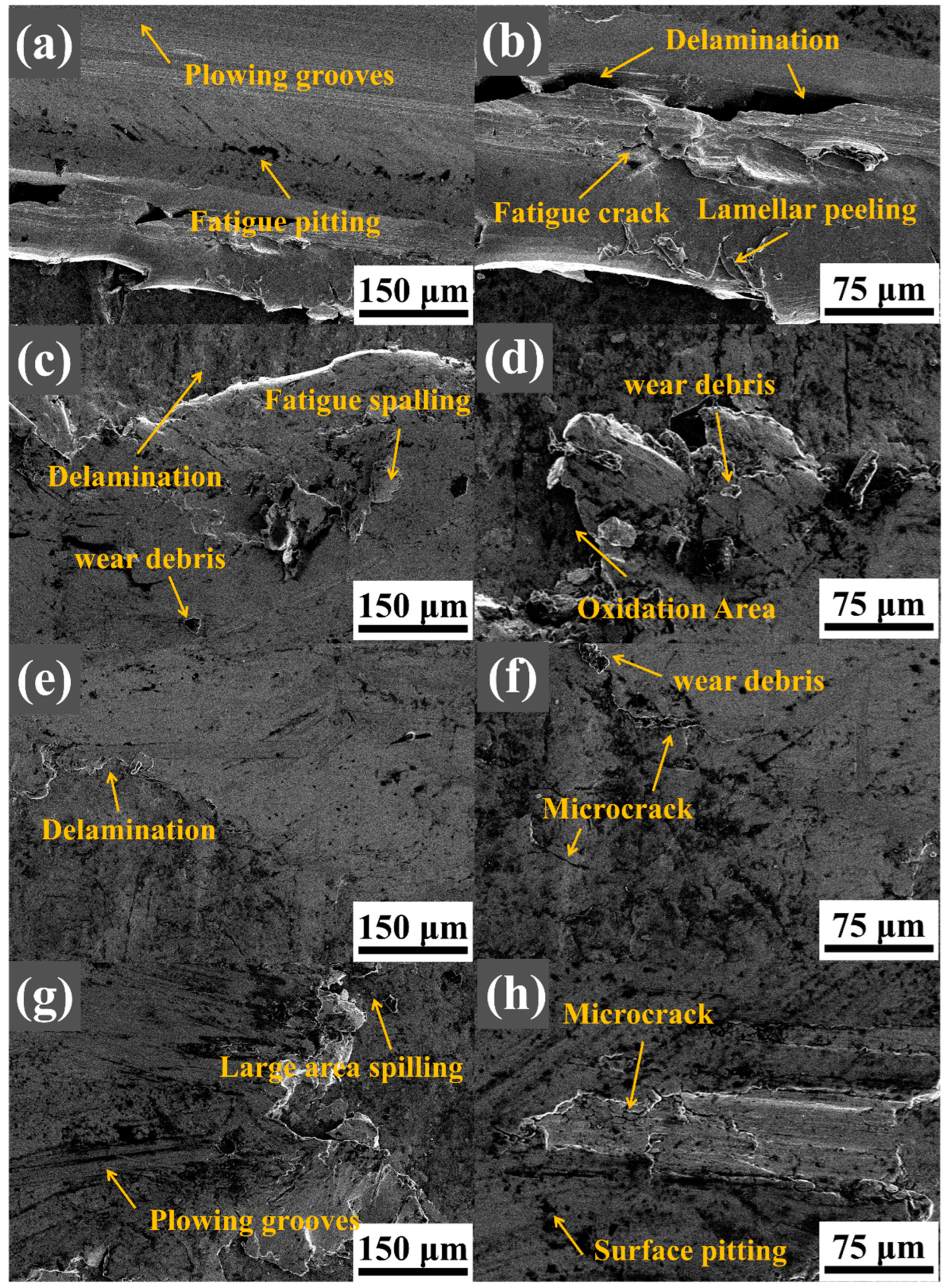

3.3. Wear Behavior

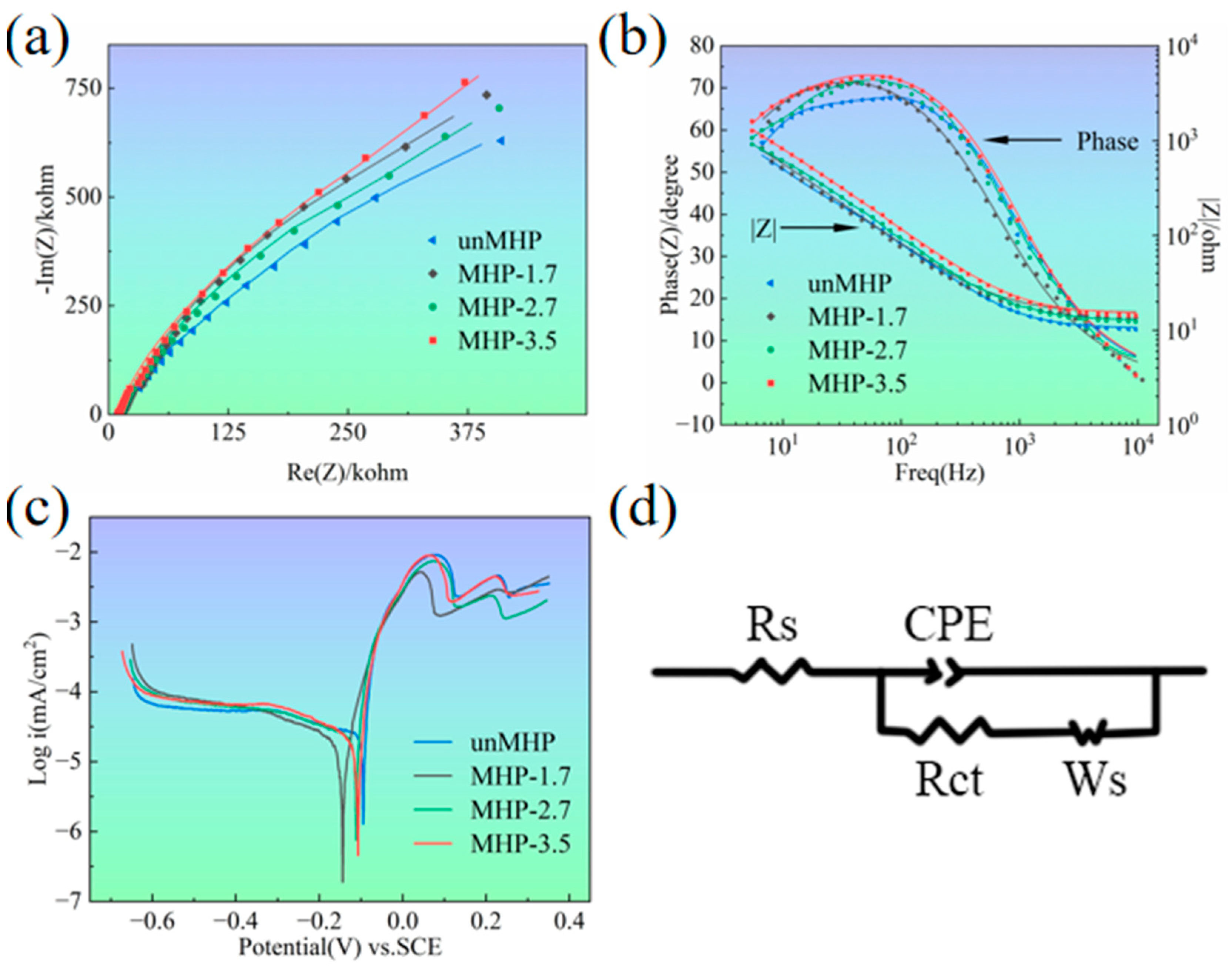

3.4. Electrochemical Corrosion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Demirsöz, R. Wear behavior of bronze vs. 100Cr6 friction pairs under different lubrication conditions for bearing applications. Lubricants 2022, 10, 212. [Google Scholar] [CrossRef]

- Zhao, L.; Li, J.; Yang, Q.; Wang, Y.; Zhang, X.; Li, H.; Yang, Z.; Xu, D.; Liu, J. Study on friction and wear properties of new self-lubricating bearing materials. Crystals 2022, 12, 834. [Google Scholar] [CrossRef]

- Francis, R. Copper Alloys in Seawater: Avoidance of Corrosion; Copper Development Association: McLean, VA, USA, 2016. [Google Scholar]

- Haq, M.I.U.; Raina, A.; Vohra, K.; Kumar, R.; Anand, A. An assessment of tribological characteristics of different materials under sea water environment. Mater. Today Proc. 2018, 5, 3602–3609. [Google Scholar] [CrossRef]

- Babu, M.; Krishna, A.R.; Suman, K. Review of journal bearing materials and current trends. Am. J. Mater. Sci. Technol. 2015, 4, 72–83. [Google Scholar] [CrossRef]

- Shifler, D.A. Understanding material interactions in marine environments to promote extended structural life. Corros. Sci. 2005, 47, 2335–2352. [Google Scholar] [CrossRef]

- Sharif, K.; Evans, H.; Snidle, R. Prediction of the wear pattern in worm gears. Wear 2006, 261, 666–673. [Google Scholar] [CrossRef]

- Sharif, K.; Evans, H.P.; Snidle, R.W.; Barnett, D.; Egorov, I.M. Effect of elastohydrodynamic film thickness on a wear model for worm gears. Proc. Inst. Mech. Eng. Part J. J. Eng. Tribol. 2006, 220, 295–306. [Google Scholar] [CrossRef]

- Tekeli, S. Enhancement of fatigue strength of SAE 9245 steel by shot peening. Mater. Lett. 2002, 57, 604–608. [Google Scholar] [CrossRef]

- Jia, M.; Wang, Y.; Yue, J.; Cao, C.; Li, K.; Yu, Y.; Li, Y.; Lu, Z. Recent progress in laser shock peening: Mechanism, laser systems and development prospects. Surf. Interfaces 2024, 44, 103757. [Google Scholar] [CrossRef]

- Soyama, H. Cavitation peening: A review. Metals 2020, 10, 270. [Google Scholar] [CrossRef]

- Huang, H.; Niu, J.; Xing, X.; Lin, Q.; Chen, H.; Qiao, Y. Effects of the shot peening process on corrosion resistance of aluminum alloy: A review. Coatings 2022, 12, 629. [Google Scholar] [CrossRef]

- Ming, T.; Peng, Q.; Han, Y.; Zhang, T. Effect of water jet cavitation peening on electrochemical corrosion behavior of nickel-based alloy 600 in NaCl solution. Mater. Chem. Phys. 2023, 295, 127122. [Google Scholar] [CrossRef]

- Soyama, H. Comparison between the improvements made to the fatigue strength of stainless steel by cavitation peening, water jet peening, shot peening and laser peening. J. Mater. Process. Technol. 2019, 269, 65–78. [Google Scholar] [CrossRef]

- Jia, Y.; Cai, Z.; Yuan, M.; Wang, S.; Ma, L. Influence of shot-peening treatment on wear resistance of medium manganese steel. J. Mater. Res. Technol. 2024, 31, 3703–3711. [Google Scholar] [CrossRef]

- Li, X.; Zhou, L.; Zhao, T.; Pan, X.; Liu, P. Research on wear resistance of AISI 9310 steel with micro-laser shock peening. Metals 2022, 12, 2157. [Google Scholar] [CrossRef]

- Cho, K.T.; Song, K.; Oh, S.H.; Lee, Y.-K.; Lim, K.M.; Lee, W.B. Surface hardening of aluminum alloy by shot peening treatment with Zn based ball. Mater. Sci. Eng. A 2012, 543, 44–49. [Google Scholar] [CrossRef]

- Kikuchi, S.; Nakamura, Y.; Nambu, K.; Ando, M. Effect of shot peening using ultra-fine particles on fatigue properties of 5056 aluminum alloy under rotating bending. Mater. Sci. Eng. A 2016, 652, 279–286. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y. Producing bulk ultrafine-grained materials by severe plastic deformation: Ten years later. JOM 2016, 68, 1216–1226. [Google Scholar] [CrossRef]

- Niu, J.; Liu, Z.; Wang, G.; Huang, W.; Xu, Y. Anticorrosion property enhancement of Al–Li alloy 2A97 by lowering machined surface roughness. Mater. Corros. 2020, 71, 1980–1988. [Google Scholar] [CrossRef]

- Wu, Y.; Kang, Y.; Chen, Y. Effect of shot peening on the corrosion and wear resistance of 2205 duplex stainless steel. J. Mater. Eng. Perform. 2023, 32, 3186–3201. [Google Scholar] [CrossRef]

- Lv, Y.; Zhao, B.; Zhang, H.; Su, C.; Nie, B.; Wang, R.; Cao, L.; Lyu, F. Improving corrosion resistance properties of nickel-aluminum bronze (NAB) alloys via shot peening treatment. Mater. Trans. 2019, 60, 1629–1637. [Google Scholar] [CrossRef]

- Niu, J.; Liu, Z.; Qiao, Y.; Wang, X.; Chen, H. Novel combination of indicators to compare the corrosion behaviors of Al, Al–Li alloy 2A97, and other Al alloys. Mater. Corros. 2022, 73, 171–179. [Google Scholar] [CrossRef]

- Deng, Y.; Liu, J.; Qiao, Y.; Niu, J. Comparative investigations on the electrochemical behaviors among Al and aluminum alloys. Mater. Res. Express 2020, 7, 116510. [Google Scholar] [CrossRef]

- Tang, W.; Li, S.; Huang, Y.; Ming, H.; Wang, X.; Li, L.; Wang, X.; Liu, Z. Surface strengthening mechanisms of laser shock peening additive manufacturing CuSn alloys: Experimental and numerical simulation investigations. Surf. Coat. Technol. 2025, 495, 131567. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Chen, B.; Gao, M.; Jiang, C.; Yuan, H.; Zhang, X.; Liang, T. Effect of ultrasonic surface rolling process on the surface properties of CuCr alloy. Vacuum 2023, 209, 111819. [Google Scholar] [CrossRef]

- Revilla-Gomez, C.; Buffiere, J.-Y.; Verdu, C.; Peyrac, C.; Daflon, L.; Lefebvre, F. Assessment of the surface hardening effects from hammer peening on high strength steel. Procedia Eng. 2013, 66, 150–160. [Google Scholar] [CrossRef]

- Curtat, J.-L.; Lanteigne, J.; Champliaud, H.; Liu, Z.; Lévesque, J.-B. Influence of hammer peening on fatigue life of E309L steel used for 13% Cr-4% Ni blade runner repairs. Int. J. Fatigue 2017, 100, 68–77. [Google Scholar] [CrossRef]

- Liu, C.W.; Liao, K.; Chen, J.W. Simulation and Experimental Study on Effect of Shot Peening on Surface Roughness of 7075-T651 Aluminum Alloy. Trans. Mater. Heat Treat. 2021, 42, 172–180. (In Chinese) [Google Scholar] [CrossRef]

- Bhat, K.U.; Panemangalore, D.B.; Kuruveri, S.B.; John, M.; Menezes, P.L. Surface modification of 6xxx Series aluminum alloys. Coatings 2022, 12, 180. [Google Scholar] [CrossRef]

- Wang, H.; Ning, C.; Huang, Y.; Cao, Z.; Chen, X.; Zhang, W. Improvement of abrasion resistance in artificial seawater and corrosion resistance in NaCl solution of 7075 aluminum alloy processed by laser shock peening. Opt. Lasers Eng. 2017, 90, 179–185. [Google Scholar] [CrossRef]

- Lei, C.; Chen, X.; Li, Y.; Chen, Y.; Yang, B. Enhanced corrosion resistance of SA106B low-carbon steel fabricated by rotationally accelerated shot peening. Metals 2019, 9, 872. [Google Scholar] [CrossRef]

- Kumar, P.; Mahobia, G.; Mandal, S.; Singh, V.; Chattopadhyay, K. Enhanced corrosion resistance of the surface modified Ti-13Nb-13Zr alloy by ultrasonic shot peening. Corros. Sci. 2021, 189, 109597. [Google Scholar] [CrossRef]

- Hadzima, B.; Bukovina, M.; Dolezal, P. Shot peening influence on corrosion resistance of AE21 magnesium alloy. Mater. Eng. 2010, 17, 14–19. [Google Scholar]

- Mhaede, M. Influence of surface treatments on surface layer properties, fatigue and corrosion fatigue performance of AA7075 T73. Mater. Des. 2012, 41, 61–66. [Google Scholar] [CrossRef]

- Huttunen-Saarivirta, E.; Kilpi, L.; Pasanen, A.; Salminen, T.; Ronkainen, H. Tribocorrosion behaviour of tin bronze CuSn12 under a sliding motion in NaCl containing environment: Contact to inert vs. reactive counterbody. Tribol. Int. 2020, 151, 106389. [Google Scholar] [CrossRef]

- Fontanari, V.; Benedetti, M.; Girardi, C.; Giordanino, L. Investigation of the lubricated wear behavior of ductile cast iron and quenched and tempered alloy steel for possible use in worm gearing. Wear 2016, 350, 68–73. [Google Scholar] [CrossRef]

- Savaşkan, T.; Azaklı, Z. An investigation of lubricated friction and wear properties of Zn–40Al–2Cu–2Si alloy in comparison with SAE 65 bearing bronze. Wear 2008, 264, 920–928. [Google Scholar] [CrossRef]

- Ünlü, B.S.; Atik, E. Evaluation of effect of alloy elements in copper based CuSn10 and CuZn30 bearings on tribological and mechanical properties. J. Alloys Compd. 2010, 489, 262–268. [Google Scholar] [CrossRef]

- Chang, B.-Y.; Park, S.-M. Electrochemical impedance spectroscopy. Annu. Rev. Anal. Chem. 2010, 3, 207–229. [Google Scholar] [CrossRef]

- Lei, J.; Wenfang, C.; Xiu, S.; Guang, L.; Lian, Z. Surface Nanocrystalline Characteristics and Corrostion Resistance of beta-Type Titanium Alloy. Rare Met. Mater. Eng. 2014, 43, 80–84. [Google Scholar] [CrossRef]

- Patel, V.; Li, W.; Andersson, J.; Li, N. Enhancing grain refinement and corrosion behavior in AZ31B magnesium alloy via stationary shoulder friction stir processing. J. Mater. Res. Technol. 2022, 17, 3150–3156. [Google Scholar] [CrossRef]

- Parangusan, H.; Bhadra, J.; Al-Thani, N. A review of passivity breakdown on metal surfaces: Influence of chloride-and sulfide-ion concentrations, temperature, and pH. Emergent Mater. 2021, 4, 1187–1203. [Google Scholar] [CrossRef]

| Elements (wt.%) | Ni | Pb | Sn | Zn | P | Al | Fe | Mn | Cu |

|---|---|---|---|---|---|---|---|---|---|

| CuSn12 | 0.5 | 0.15 | 11.5 | 0.1 | 0.05 | 0.005 | 0.05 | 0.05 | Bal. |

| Sample | Ecorr (VSCE) | Icorr (mA/cm2) |

|---|---|---|

| unMHP | −0.0937 | −4.6352 |

| MHP-1.7 | −0.1482 | −4.7038 |

| MHP-2.7 | −0.1235 | −4.6436 |

| MHP-3.5 | −0.1202 | −4.6258 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nie, N.; Yu, L.; Xu, S.; Tian, Q.; Ding, C.; Su, L.; Wang, H. Study on the Morphology, Wear Resistance, and Corrosion Resistance of CuSn12 Alloys Subjected to Machine Hammer Peening. Metals 2025, 15, 444. https://doi.org/10.3390/met15040444

Nie N, Yu L, Xu S, Tian Q, Ding C, Su L, Wang H. Study on the Morphology, Wear Resistance, and Corrosion Resistance of CuSn12 Alloys Subjected to Machine Hammer Peening. Metals. 2025; 15(4):444. https://doi.org/10.3390/met15040444

Chicago/Turabian StyleNie, Ning, Lu Yu, Shouwei Xu, Qiyuan Tian, Chenchen Ding, Lihong Su, and Hui Wang. 2025. "Study on the Morphology, Wear Resistance, and Corrosion Resistance of CuSn12 Alloys Subjected to Machine Hammer Peening" Metals 15, no. 4: 444. https://doi.org/10.3390/met15040444

APA StyleNie, N., Yu, L., Xu, S., Tian, Q., Ding, C., Su, L., & Wang, H. (2025). Study on the Morphology, Wear Resistance, and Corrosion Resistance of CuSn12 Alloys Subjected to Machine Hammer Peening. Metals, 15(4), 444. https://doi.org/10.3390/met15040444