Abstract

High-entropy alloys (HEAs) represent a paradigm-shifting material system offering vast compositional space for tailoring mechanical properties. The yield strength and hardness are critical performance metrics, yet their interrelationships in diverse HEAs remain incompletely understood, partly due to data limitations. This work employs an integrated machine learning framework to investigate the compressive yield strength (σy) and hardness (HV) correlation across a dataset of cast HEAs. Random forest models are successfully developed for phase structure classification (accuracy = 92%), hardness prediction (test R2 = 0.90), and yield strength prediction (test R2 = 0.91), enabling data imputation to expand the analysis dataset. Correlation analysis on the expanded dataset reveals a general positive trend between σy and HV (overall Pearson r = 0.75) but highlights a strong dependence on the predicted phase structure. The single-phase BCC alloys exhibit the strongest linear correlation between σy and HV (r = 0.88), whereas the single-phase FCC alloys show a weaker linear dependence (r = 0.59), and multiphase alloy systems display varied behavior. The specific ranges of compositional parameters (highly negative mixing enthalpy ΔH, low atomic size difference δ, high mixing entropy ΔS, and intermediate-to-high valence electron concentration VEC) are associated with a stronger σy-HV correlation, potentially linked to the formation of stable solid solutions. Furthermore, artificial neural network modeling confirms the varying complexity of the σy-HV relationship across different phases, outperforming simple models for some multiphase systems. This work provides robust predictive models for HEA properties and advances the fundamental understanding of the composition- and phase-dependent coupling between yield strength and hardness, aiding rational HEA design.

1. Introduction

High-entropy alloys (HEAs) have emerged as a new class of materials, distinguished by their near-equiatomic compositions (3–35 at.%) of five or more principal elements [1,2]. Unlike traditional alloys that are based on one or two major elements, HEAs benefit from high configurational entropy, severe lattice distortion, cocktail effects, and sluggish diffusion [3,4,5]. The severe lattice distortion, resulting from the mixture of differently sized atoms on the lattice, creates significant internal strain fields to impede dislocation motion for increasing both strength and hardness [6,7,8]. Furthermore, complex synergistic interactions between the multiple elements can further enhance resistance to deformation [8], while sluggish diffusion kinetics help maintain fine microstructures and impede softening mechanisms [9]. These features endow HEAs with remarkable properties, such as high yield strength and excellent hardness.

Despite extensive investigation into the mechanical properties of HEAs, a definitive relationship between yield strength and hardness remains insufficiently established. Based on the slip-line field theory, the well-known relationship between hardness and yield strength H ≈ 3σy is first proposed [10]. Using this empirical relation, the tensile yield strength of AlCuCrFeMnWx HEA is calculated [11]. However, this relationship is only valid for these non-work-hardening materials [12]. Hence, understanding the relationship between yield strength and hardness is crucial for evaluating HEA strength using faster hardness tests with smaller sample volumes instead of traditional uniaxial tension tests [13,14,15,16,17].

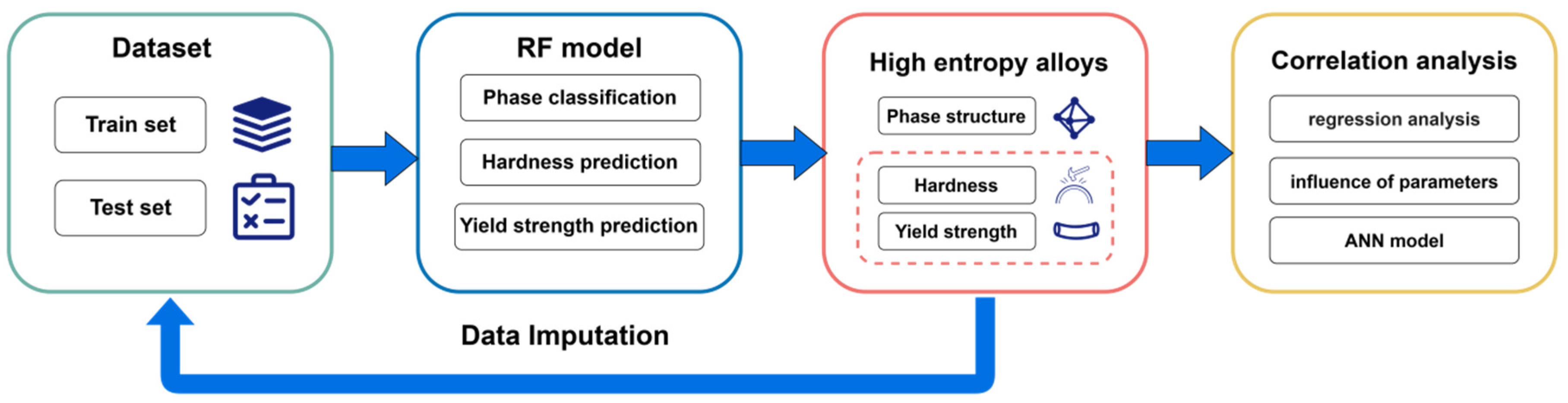

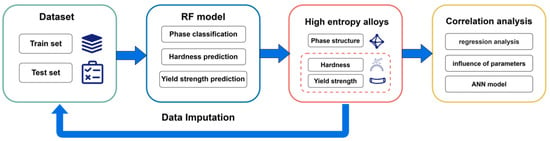

The advent of machine learning (ML) offers unprecedented opportunities to address data scarcity in HEAs. By leveraging predictive modeling, ML can extrapolate beyond limited experimental datasets while capturing hidden relationships between composition, microstructure, and properties. Previous studies on HEAs have focused predominantly on phase prediction or single-property optimization [18,19,20,21], leaving the hardness–yield strength correlation largely unexplored. As shown in Figure 1, this work bridges this gap through a three-tier ML framework integrating the development of predictive ML models, data imputation, and a comprehensive correlation analysis. Firstly, we compile 304 sets of HEA data. ML models are trained using these data, which simultaneously include the phase structure classification, hardness, and yield strength. Following this training ML model, the missing phase structure, yield strength, or hardness values are obtained, resulting in an expanded dataset. This expanded dataset enables us to conduct a comprehensive correlation analysis, exploring the intrinsic relationship between yield strength and hardness. This analysis specifically explores (1) the phase-dependence of this relationship, examining how it varies across different predicted phase combinations; (2) the influence of key compositional parameters (mixing enthalpy, valence electron concentration, mixing entropy, atomic radius difference, and electronegativity difference) by identifying parameter ranges where strong correlations exist; and (3) characterizing the potentially non-linear nature of the relationship using phase-specific artificial neural network (ANN) models. This multi-faceted approach provides a pathway to move beyond simple empirical relationships and gain a deeper, more nuanced understanding of the interplay between composition, microstructure, and mechanical properties in HEAs.

Figure 1.

A three-tier ML framework integrating the development of the predictive model, data imputation, and a comprehensive correlation analysis.

2. Methods

2.1. Dataset Construction and Description

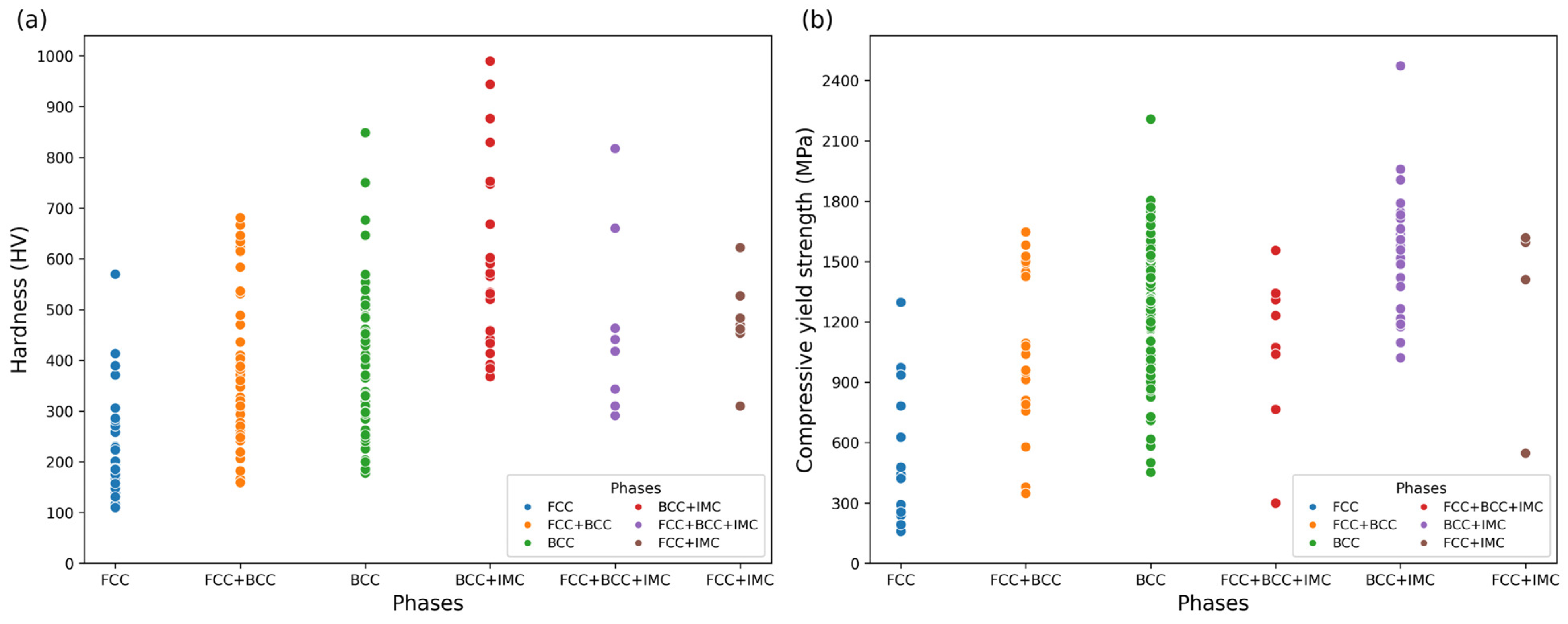

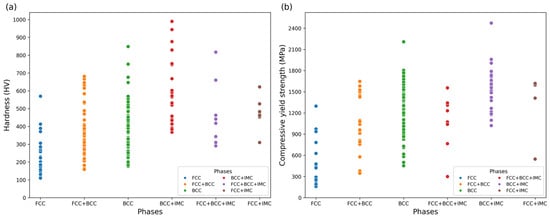

The dataset for this investigation is compiled from publicly available experimental studies [22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82] documenting HEA properties, such as phase structure, strength, or hardness. Since manufacturing processes significantly influence the mechanical properties of HEAs, we primarily included data from cast alloys to enhance consistency. To ensure uniformity in yield strength measurements, only compressive yield strength data are selected. The application of these criteria yielded an initial dataset of 304 HEAs. From this dataset, we created three distinct subsets to build separate predictive models: one for phase structure classification, another for hardness prediction, and a third for compressive yield strength prediction. The HEA phase structures comprise face-centered cubic (FCC), body-centered cubic (BCC), and intermetallic compound (IMC) phases. These structures are classified into six specific categories within the dataset, FCC, BCC, FCC + IMC, BCC + IMC, FCC + BCC, and FCC + BCC + IMC, which serve as classification labels for the phase structure model. Figure 2 presents the distribution of key mechanical properties categorized by HEA phase structure. Figure 2a illustrates the hardness distribution within the hardness dataset, while Figure 2b shows the compressive yield strength distribution within the corresponding dataset.

Figure 2.

(a) Scatter plot illustrating the distribution of hardness values within the hardness dataset. (b) Scatter plot illustrating the distribution of compressive yield strength values within the compressive yield strength dataset.

2.2. Selection and Optimization of Input Features

Table 1 provides the features used for ML along with their corresponding mathematical expressions. Ci is the atomic concentration of the i-th element, and the total number of species in the HEAs is denoted by n. The enthalpy of mixing, ΔH, quantifies the total energy change when elements are mixed. The entropy of mixing, ΔS, is a measure of the disorder introduced during mixing. The atomic size difference, δ, reflects the variation in atomic radii among the constituent elements, which plays a crucial role in phase formation and stability. The valence electron concentration (VEC) is an essential parameter, calculated based on the atomic concentration and the valence electron of each element in the alloy. Electronegativity difference, Δχ, measures the variance in electronegativity to affect the compound formation tendencies. Phases refer to the phase structure, which includes six categories: FCC, BCC, FCC + BCC, BCC + IMC, FCC + IMC, and FCC + BCC + IMC. The five characteristic parameters (ΔH, VEC, δ, ΔS, Δχ) in Table 1 are used as input features to build a classification model for predicting phase structures. The six characteristic parameters in Table 1, specifically the five physicochemical parameters (ΔH, VEC, δ, ΔS, Δχ) and the phase structure of HEAs, are used as input features to build regression models for predicting strength and hardness.

Table 1.

Six empirical parametric equations used to obtain the input values for the features.

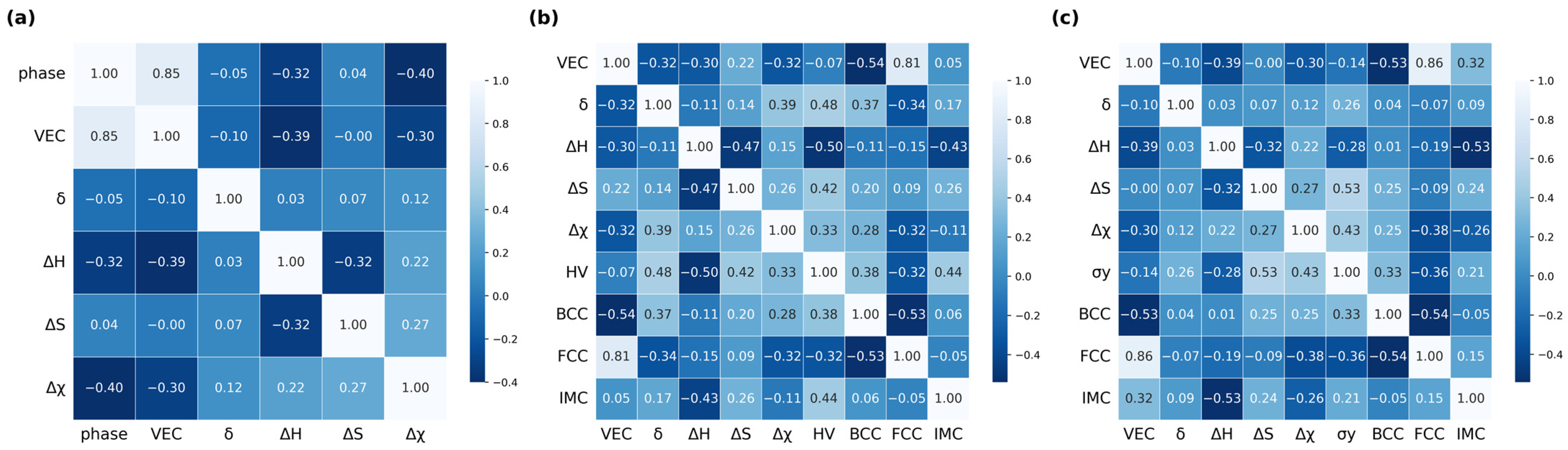

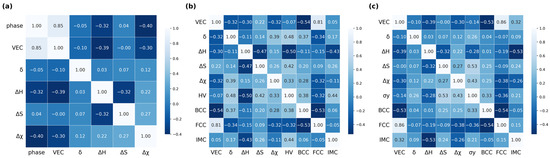

The heat map in Figure 3a shows the correlation between the characteristic parameters of the data in the phase structure dataset. Figure 3b,c shows the correlation between the characteristic parameters of the hardness dataset and the yield strength dataset. Values of −1 and 1 indicate negative and positive correlations, respectively. The inclusion of irrelevant features during training negatively impacts the accuracy of model. Therefore, identifying the most significant features is crucial. To assess the feature relevance, statistical analysis is conducted using the Pearson correlation coefficient, which is used to evaluate the significance of selected feature parameters. From Figure 3a, it can be concluded that VEC has a strong positive correlation with the phase structure, and the correlations of the five parameters are not overly redundant. Figure 3b,c shows a positive correlation between VEC, ΔH, the existence of the FCC phase, and the yield strength or hardness. There are no clearly redundant correlations between these six parameters.

Figure 3.

Pearson correlation heatmaps for different HEA feature subsets. (a) Correlations among features within the phase structure dataset. (b) Feature correlations within the hardness dataset. (c) Feature correlations within the compressive yield strength dataset. A coefficient “1” represents a perfect positive correlation, while “−1” represents a perfect negative correlation.

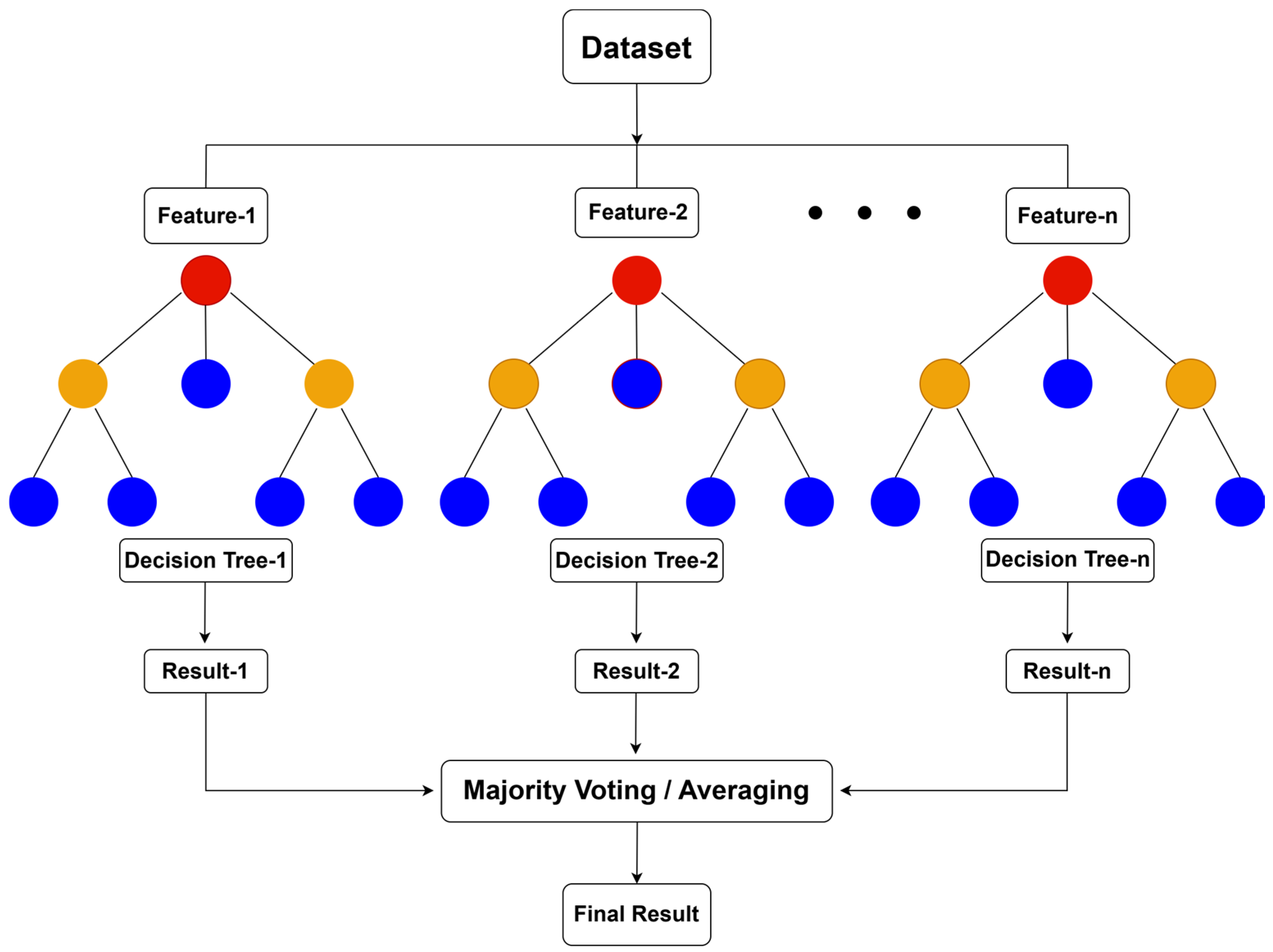

2.3. Machine Learning Model

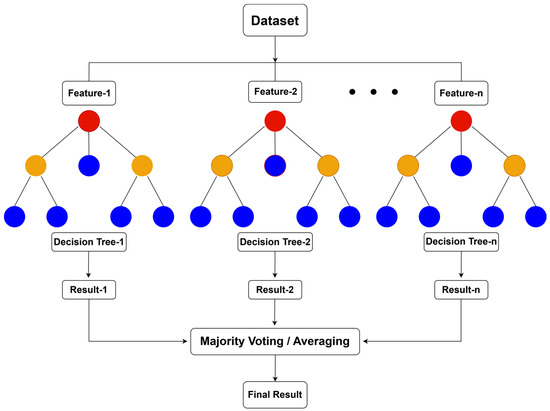

As shown in Figure 4, the random forest model is an ensemble learning method used for both classification and regression tasks [86]. It operates by constructing multiple decision trees during training and outputting the mode of their predictions for classification (or the mean prediction for regression) [87]. Each decision tree is trained on a random subset of the data and features to reduce overfitting and improve the generalization ability. For classification, the model predicts the class with the highest frequency among the tree predictions. For the regression, the predicted values are averaged. This approach leverages the diversity of the trees to enhance the robustness and accuracy of the model.

Figure 4.

Simplified flowchart of the random forest model with majority voting or average prediction. In this depiction, the red dots represent the root nodes performing the initial data split. Yellow dots represent intermediate nodes, which are subsequent decision points based on feature criteria. Blue dots represent leaf nodes, indicating the final prediction outcome, either a class or a value, for an individual decision tree.

The complex nature of phase structures is given in HEAs, where combinations of multiple phases can coexist. Here, we approach phase structure prediction as a multi-class classification problem with six possible categories: FCC, BCC, FCC + BCC, FCC + IMC, BCC + IMC, and FCC + BCC + IMC. Simultaneously, the prediction of yield strength and hardness is formulated as a regression task.

Based on different prediction types, we construct distinct ML models to predict these key properties. First, a random forest classifier is employed to predict the phase structure based on five input features: ΔH, VEC, δ, ΔS, and Δχ. To ensure optimal model performance, GridSearchCV is used for hyperparameter tuning [88], systematically searching through a predefined parameter grid to identify the best combination of hyperparameters. This optimization focuses on critical hyperparameters that govern the behavior and complexity of the random forest. The key hyperparameters tuned included the following:

- n_estimators: The number of decision trees in the forest.

- max_depth: This controls the maximum level allowed for each individual tree to prevent overfitting.

- min_samples_split: This meets the minimum number of samples required to split an internal node, influencing tree growth.

- min_samples_leaf: This defines the minimum number of samples required to be present at a leaf node, influencing generalization.

- max_features: This determines the number or fraction of input features considered when looking for the best split at each node, introducing diversity among the trees.

- bootstrap: This indicates whether samples are drawn with replacement.

The optimal parameters identified through this process for each model are presented in Table 2. Furthermore, to enhance the generalizability and ensure a balanced evaluation, stratified K-Fold Cross-Validation is employed [89]. This technique ensures that each fold maintains the proportion of each class in the target variable, which is particularly useful when dealing with imbalanced datasets. Second, random forest regressors are employed to predict mechanical properties. These models are trained on six input features ΔH, VEC, δ, ΔS, Δχ, and the encoded phase structure. The phase structure is considered a crucial feature for determining its mechanical properties. Similar to the classification model, the regression models also utilize GridSearchCV for hyperparameter tuning, and the optimal parameters are listed in Table 2.

Table 2.

Optimal model parameters.

The performance of the phase structure model is evaluated using accuracy:

where TP represents the number of true positives, TN represents the number of true negatives, FP represents the number of false positives, and FN represents the number of false negatives.

For the yield strength and hardness models, the performance is assessed using two metrics: root mean square error (RMSE) and R-squared (R2).

where represents the observed value, is the predicted value, is the mean of the observed values, and n is the total number of observations.

3. Results and Discussion

3.1. Robustness and Accuracy of Predictive Models

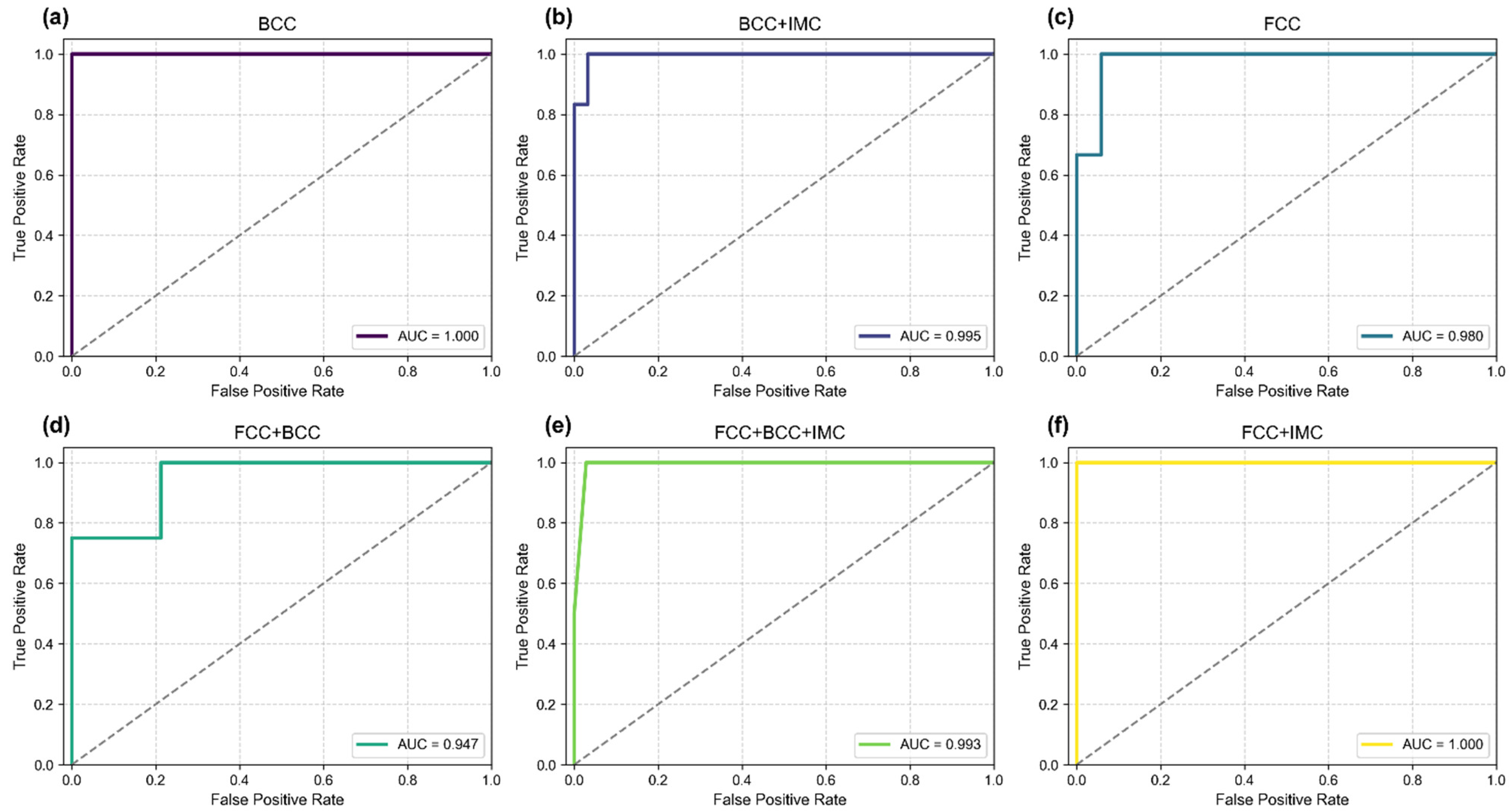

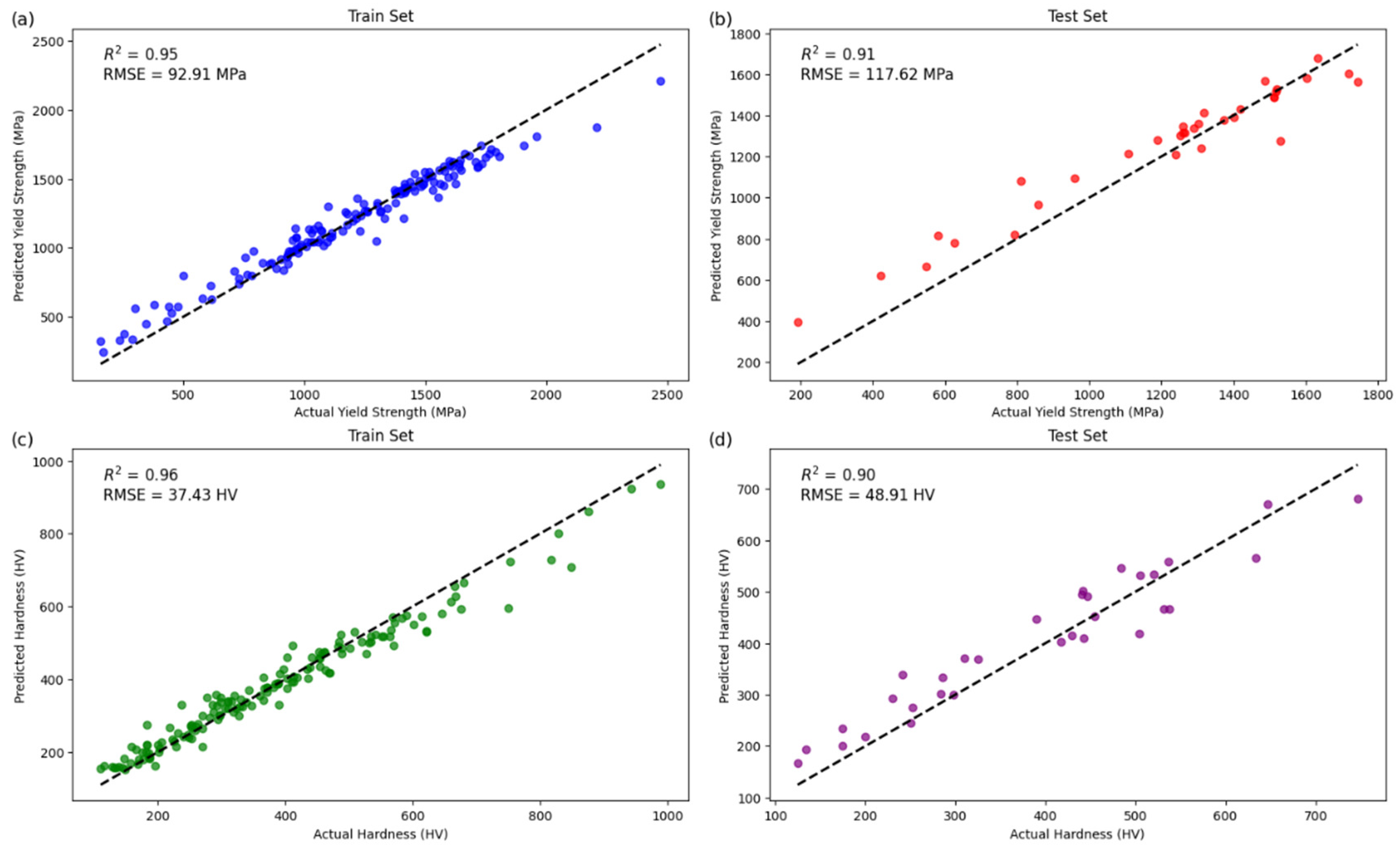

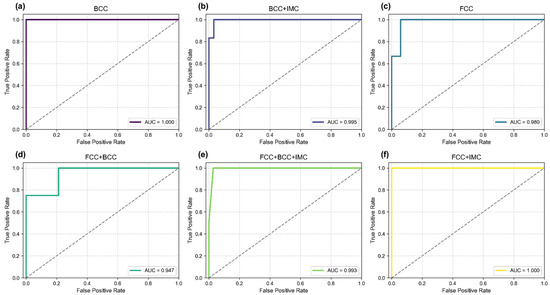

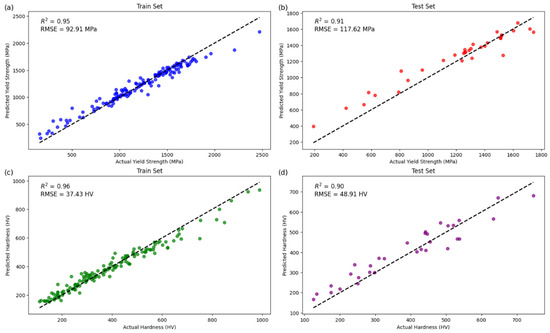

The performance of the phase structure, compressive yield strength, and hardness prediction model are summarized in Table 3. The optimized random forest classifier achieved a high overall accuracy of 91.9% when predicting HEA phase structures on the test set. Figure 5 presents the one-vs-rest receiver operating characteristic (ROC) curves for the optimized random forest classifier on the test set. The high area under the curve (AUC) values across all plots demonstrate the model’s ability to distinguish individual phase structures from the others. The observed step-like pattern in the curves is expected when evaluating discrete classifier predictions on a finite dataset. Notably, the model achieved perfect discrimination (AUC = 1.000) for the BCC and FCC + IMC phases. Even the phase with the relatively lowest performance, FCC + BCC, yielded a good AUC of 0.947, confirming the overall effectiveness of the classifier in ranking phase probabilities correctly across various decision thresholds. Meanwhile, the random forest regression models exhibit outstanding predictive performance for both yield strength and hardness. For yield strength predictions, Figure 6a shows that the model achieved R2 = 0.95 and RMSE = 92.91 MPa on the training set. Figure 6b indicates slightly lower but still good performance on the test set with R2 = 0.91 and RMSE = 117.62 MPa. Similarly, for hardness predictions, Figure 6c exhibits excellent accuracy with R2 = 0.96 and RMSE = 37.43 HV for the training set, and Figure 6d demonstrates maintained robust performance on the test set with R2 = 0.90 and RMSE = 48.91 HV. Given the high R2 values achieved and the typical property ranges in HEAs, these RMSE results reflect a reasonable predictive accuracy. Crucially, the training and testing data are sourced from experimentally validated results reported in the literature, providing a reliable foundation for these evaluations. The strong R2 values maintained on the unseen test set underscore the robustness and generalization ability of the developed regression models.

Table 3.

Model performance.

Figure 5.

ROC curves for each phase structure class, evaluated on the held-out test set. Each subplot displays the ROC curve for a single class (indicated in the subplot title) using a one-vs-rest strategy. The solid line shows the trade-off between the true positive rate (TPR) and the false positive rate (FPR). The AUC value, quantifying the model’s discriminative performance for that specific class against all others, is provided in the legend. The dashed diagonal line indicates the performance expected by random chance (AUC = 0.5). The individual subplots show results for: (a) BCC (AUC = 1.000); (b) BCC + IMC (AUC = 0.995); (c) FCC (AUC = 0.980); (d) FCC + BCC (AUC = 0.947); (e) FCC + BCC + IMC (AUC = 0.993); (f) FCC + IMC (AUC = 1.000).

Figure 6.

Comparison between the predicted and experimental values from the literature for yield strength and hardness using random forest regression models. Yield strength predictions on (a) training set (R2 = 0.95, RMSE = 92.91 MPa), and (b) test set (R2 = 0.91, RMSE = 117.62 MPa). Hardness predictions on (c) training set (R2 = 0.96, RMSE = 37.43 HV), and (d) test set (R2 = 0.90, RMSE = 48.91 HV).

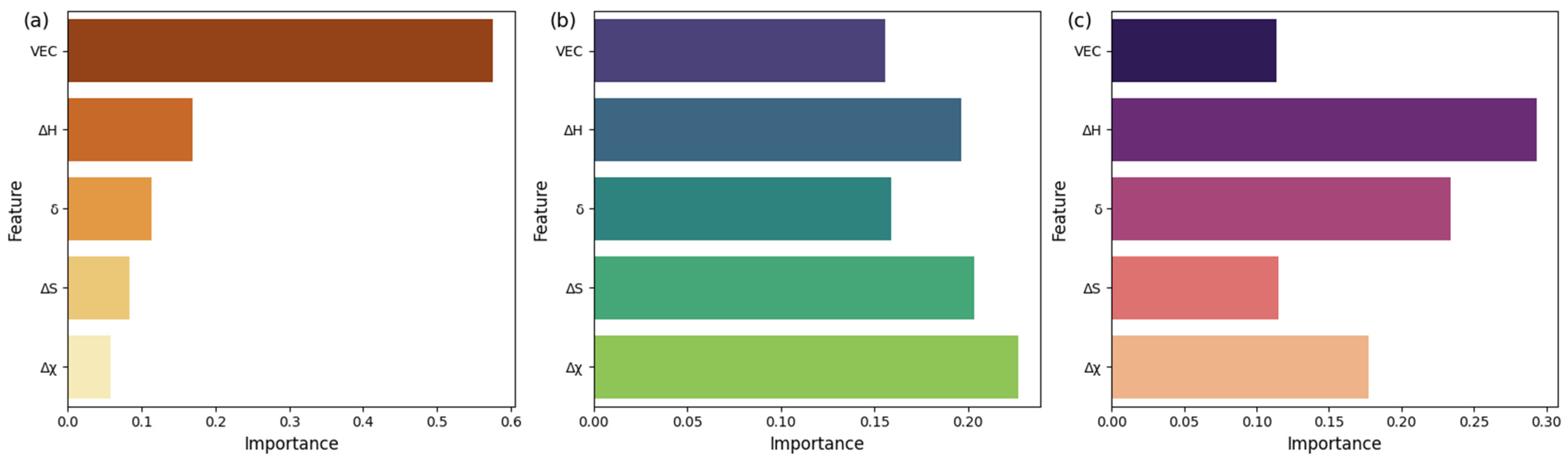

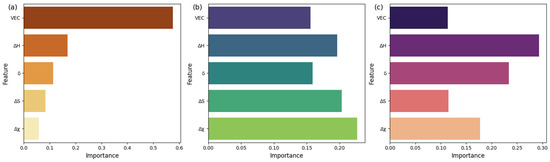

Figure 7 presents the feature importance derived from the random forest models used to predict phase structure, yield strength, and hardness. These importance scores quantify the relative contribution of each input feature to the model’s predictive performance calculated via the mean decrease impurity (MDI) method based on average reduction in Gini impurity (for phase classification) or variance/MSE (for strength/hardness regression) across the forest’s trees. As shown in Figure 7a, VEC exhibits the highest importance (0.576) for phase prediction, significantly exceeding that of ΔH (0.169), δ (0.114), ΔS (0.084), and Δχ (0.057). This aligns with established metallurgical principles, as VEC is a crucial factor in determining electron density and, consequently, the stability of different crystal structures in alloys [90].

Figure 7.

Feature importance rankings derived from the random forest models for (a) phase prediction, (b) yield strength prediction, and (c) hardness prediction. The importance values represent the relative contribution of each feature to the predictive accuracy of the model.

The feature importance for yield strength and hardness exhibits a similar pattern, highlighting the interconnected nature of these mechanical properties. For yield strength (Figure 7b), Δχ (0.227) and ΔS (0.203) are the most influential, followed by ΔH (0.196), δ (0.159), and VEC (0.156). For hardness (Figure 7c), ΔH (0.294) and δ (0.234) are the most dominant, followed by Δχ (0.177), ΔS (0.115), and VEC (0.114). This similarity is expected, as both properties are fundamentally related to a material’s resistance to plastic deformation. The prominence of ΔH and δ for hardness and the significant contributions of Δχ, ΔS, ΔH, and δ for yield strength suggest that a combination of factors related to interatomic bonding strength (ΔH, Δχ), configurational entropy (ΔS), and lattice strain due to atomic size mismatch are critical determinants of these mechanical properties.

3.2. Analysis of Yield Strength and Hardness Predictions

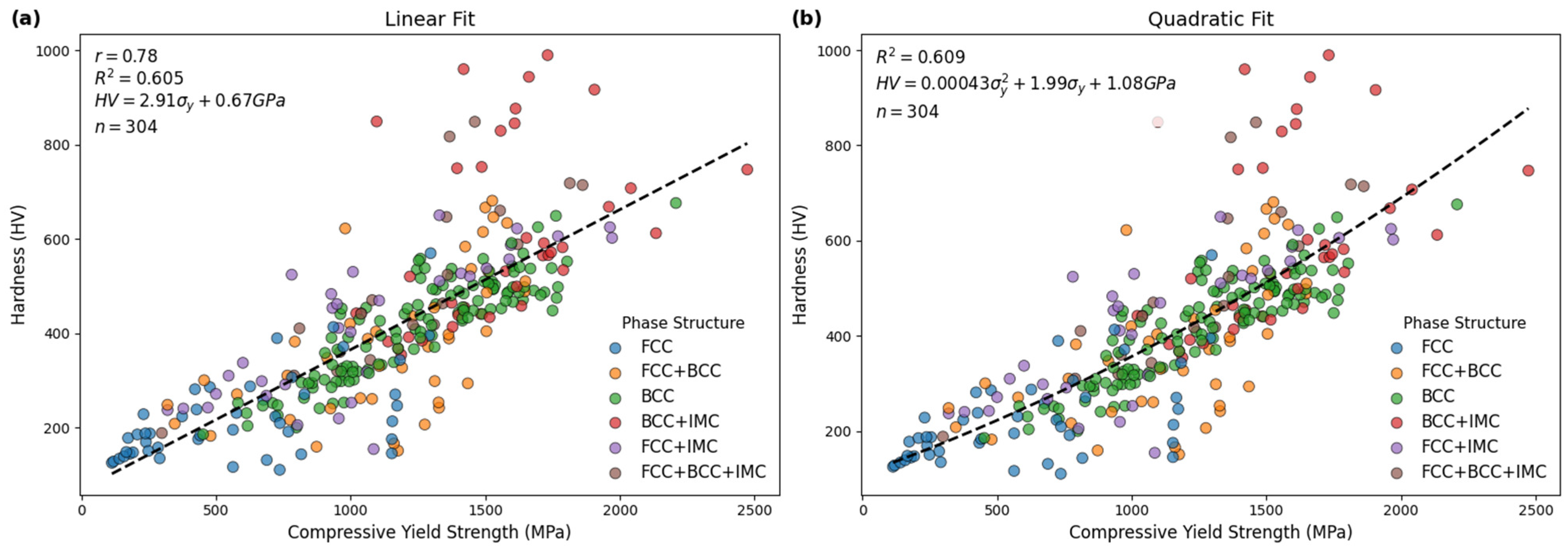

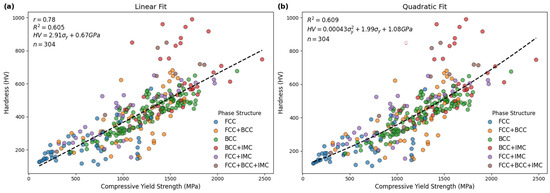

After this training, ML-based imputation is utilized to fill in the missing values for phase structure, yield strength, or hardness in the remaining partial entries. As shown in Figure 8, the compressive yield strength and hardness of the HEAs exhibit a relatively strong positive correlation, with a Pearson coefficient of 0.75. While a linear regression yields the equation HV = 2.91σy + 665.69 MPa (R2 = 0.605), a quadratic fit, represented by the equation HV = 0.00043σy2 + 1.99σy + 1078.46 MPa, is found to achieve a slightly higher coefficient of determination (R2 = 0.609), indicating that it better captures the nuances between yield strength and hardness compared to the linear approximation.

Figure 8.

Relationship between compressive yield strength (σy) and predicted hardness (HV). In total, 304 data points are colored and marked according to their predicted phase structure. (a) Scatter plot with a linear regression fit applied to the entire dataset. The dashed line shows the best linear fit (HV = 2.91σy + 665.69 MPa), with the calculated Pearson correlation coefficient (r), the coefficient of determination, the specific linear equation, and the total number of data points annotated. (b) Scatter plot of the same data with a quadratic regression fit (HV = 0.00043σy2 + 1.99σy + 1078.46 MPa). The dashed line represents the best quadratic fit, annotated with the coefficient of determination, the specific quadratic equation, and the total sample size.

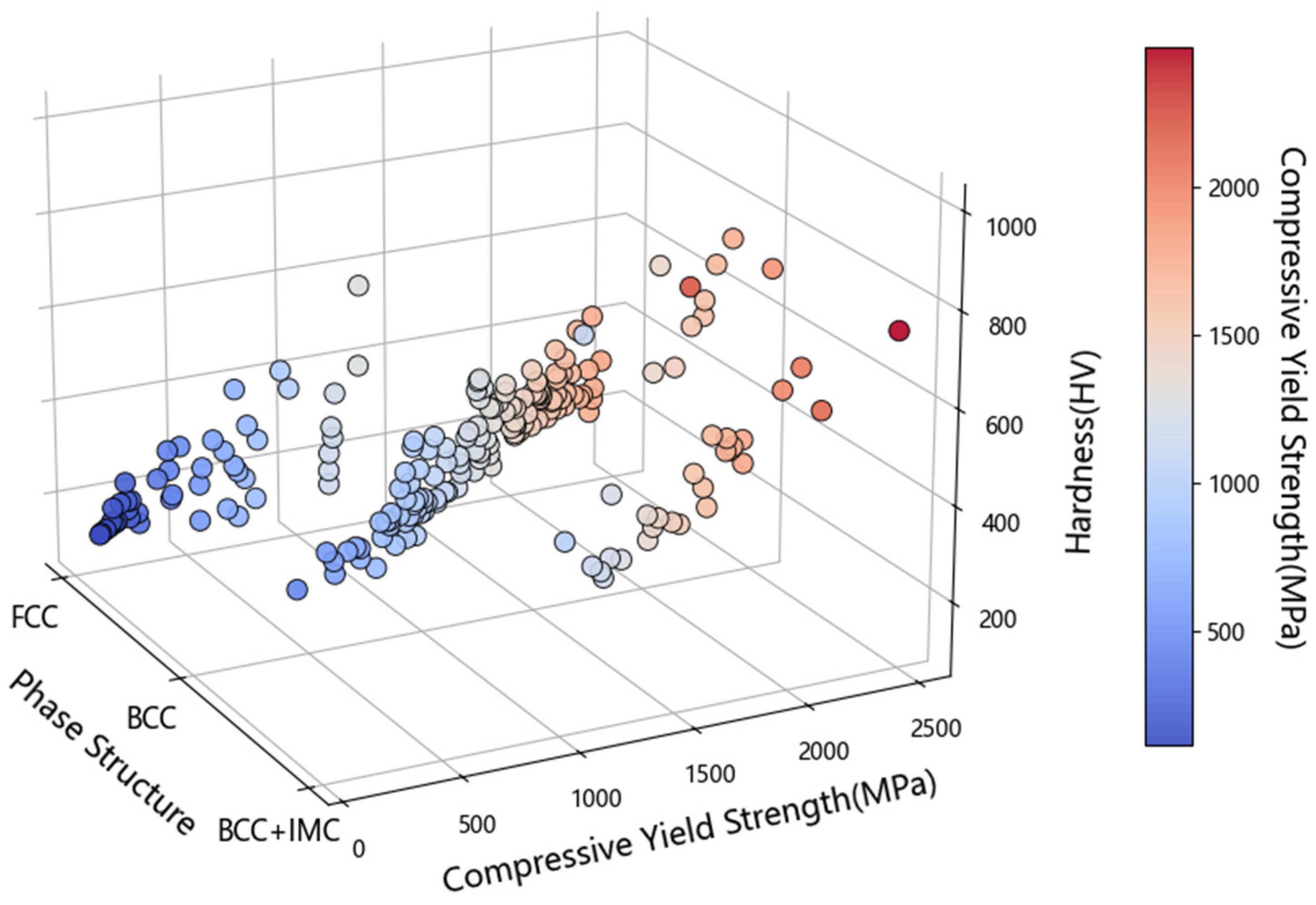

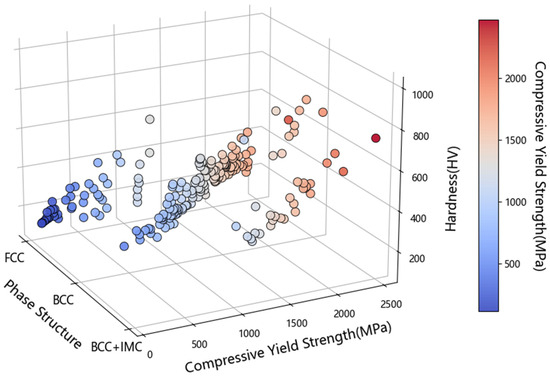

As illustrated in Figure 9, the phase constitution plays a critical role in determining the mechanical properties of HEAs. FCC-structured HEAs typically display low compressive yield strength and hardness values. This is generally attributed to the FCC HEA possessing a higher number of close-packed slip systems, which allows for dislocation glide at low applied stresses compared to BCC structures [91]. In contrast, BCC-structured HEAs generally demonstrate superior strength and hardness, often exhibiting greater variability in these properties. The higher strength of BCC phases is often linked to their higher intrinsic lattice resistance to dislocation motion, stemming from the lack of truly close-packed planes and the nature of dislocation core structures, thus requiring greater stress to initiate plastic flow [91]. Furthermore, the introduction of IMC phases alongside the BCC matrix tends to yield high yield strength and hardness. This phenomenon can be attributed to factors such as the specific IMC species and their volume fraction. For instance, the B2 phase, an ordered derivative of the BCC lattice, possesses long-range atomic order, which hinders dislocation movement effectively, partly through the creation of anti-phase boundaries [92], thereby enhancing both yield strength and hardness.

Figure 9.

Three-dimensional scatter plot correlating compressive yield strength and hardness across different phase structures. The point color indicates the magnitude of the compressive yield strength, with the scale provided by the color bar.

3.3. Underlying Mechanisms of Yield Strength–Hardness Correlation

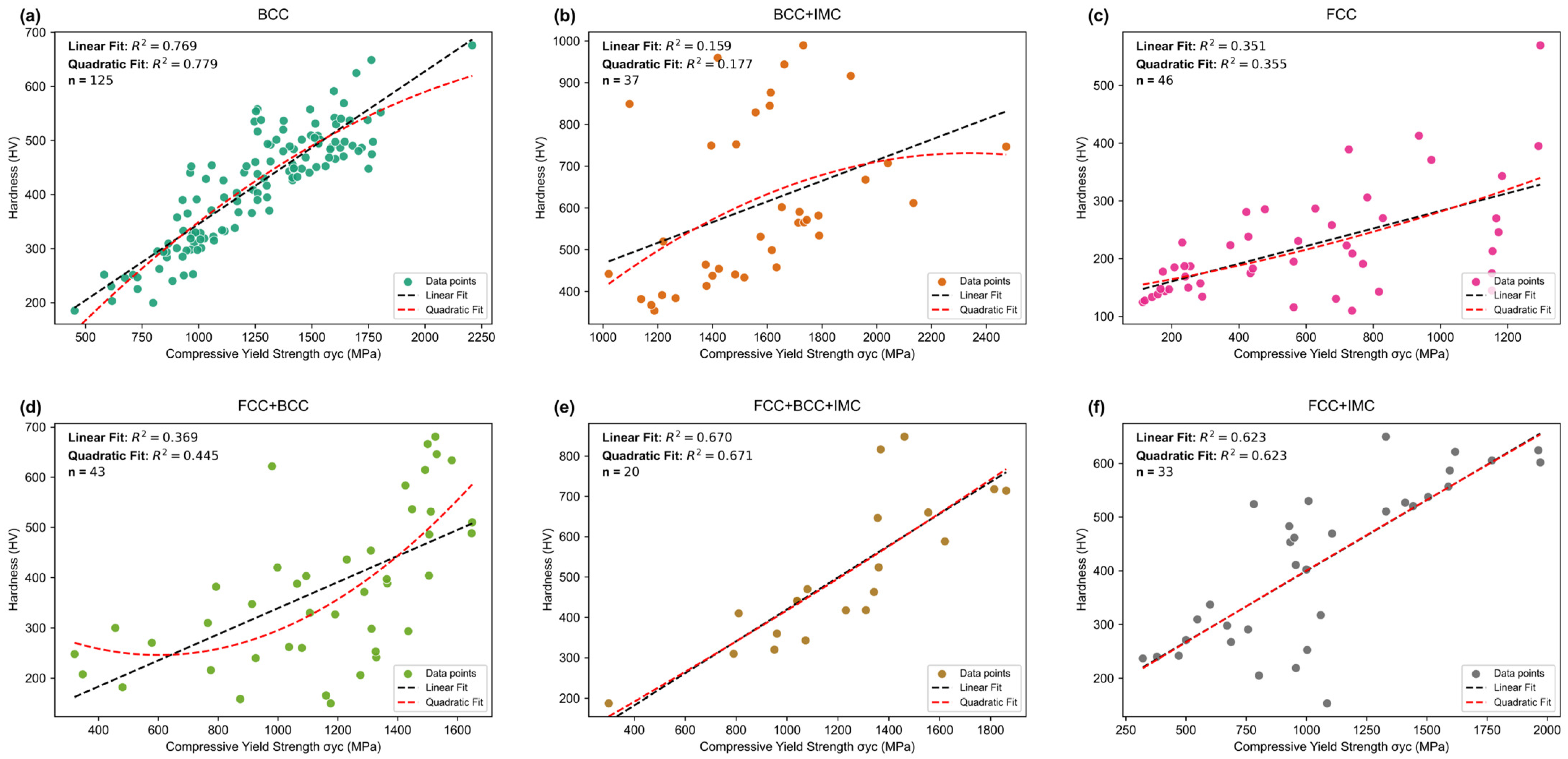

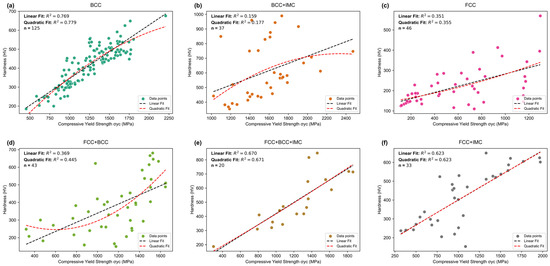

Figure 10 presents the correlation between yield strength and hardness, revealing a strong dependence on the HEA phase constituents. The specific linear and quadratic regression equations quantifying these relationships for each phase structure are provided in Table 4. For the single-phase BCC HEAs, a strong positive linear correlation is observed (Pearson r = 0.877, linear R2 = 0.769), with a quadratic fit offering only a marginal improvement (R2 = 0.779). This aligns with the expectation of relatively uniform deformation behavior dominated by dislocation motion resistance in solid-solution-strengthened BCC structures [93], leading to a predictable strength–hardness relationship. In contrast, the BCC + IMC system exhibits a significantly weaker linear correlation (Pearson r = 0.399, linear R2 = 0.159), with the quadratic fit also showing a poor fit (R2 = 0.177). This suggests that the introduction of IMC phases, while potentially increasing hardness through pinning effects, disrupts the simple linear relationship, possibly due to the differentiation of deformation mechanisms at multiphase interfaces or an imbalance between strengthening and plastic deformation capacity [94].

Figure 10.

Relationship between hardness and compressive yield strength for different phase structures. Each subplot represents a unique phase structure, showing individual data points and linear (black dashed line) and quadratic (red dashed line) regression fits. The coefficient of determination for each fit type and the number of data points are annotated. The unique phase structures represented are: (a) BCC, (b) BCC + IMC, (c) FCC, (d) FCC + BCC, (e) FCC + BCC + IMC, and (f) FCC + IMC.

Table 4.

Regression analysis for compressive yield strength with hardness for different phases.

The single-phase FCC and dual-phase FCC + BCC HEAs display moderate linear correlations (Pearson r = 0.59–0.61, linear R2 = 0.35–0.37). For the FCC + BCC system, a quadratic model provides a noticeably better fit (R2 = 0.445) compared to the linear one, suggesting some non-linearity in the relationship. The generally lower correlations in these FCC-containing systems compared to single-phase BCC HEAs might stem from the more complex deformation mechanisms possible in FCC HEAs, such as planar slip or deformation twinning, which can affect yield strength and hardness differently than processes in BCC HEAs [95].

Interestingly, the HEA systems involving both FCC and IMC phases show stronger correlations than the single-phase FCC and dual-phase FCC + BCC systems. The FCC + IMC alloys exhibit a good linear correlation (Pearson r = 0.790, linear R2 = 0.623), and the complex FCC + BCC + IMC system displays a strong linear relationship (Pearson r = 0.819, linear R2 = 0.670). For these two systems, quadratic fits do not significantly improve upon the linear model. This indicates that despite the microstructural complexity, the combined effects of the different phases in these specific alloys lead to a relatively predictable strength–hardness trend. Overall, the results highlight that while a positive trend exists, the specific phase makeup and interactions critically influence the strength and nature of the correlation between yield strength and hardness.

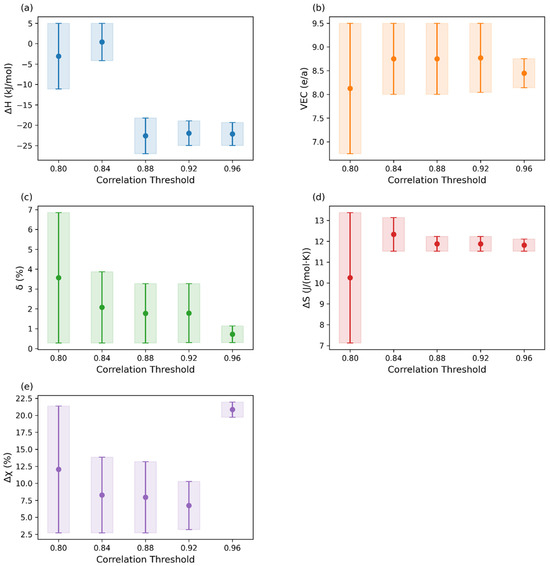

Additionally, to investigate the effect of specific parameters (ΔH, VEC, δ, ΔS, Δχ) on the strength–hardness relationship, an interval detection algorithm is developed. This algorithm systematically examines all possible continuous intervals of each parameter and calculates the Pearson correlation between yield strength and hardness within each interval. The algorithm identifies the longest interval for each parameter where the correlation exceeds a specified threshold. This approach allows us to pinpoint parameter ranges where the predicted yield strength and hardness exhibit a strong positive correlation.

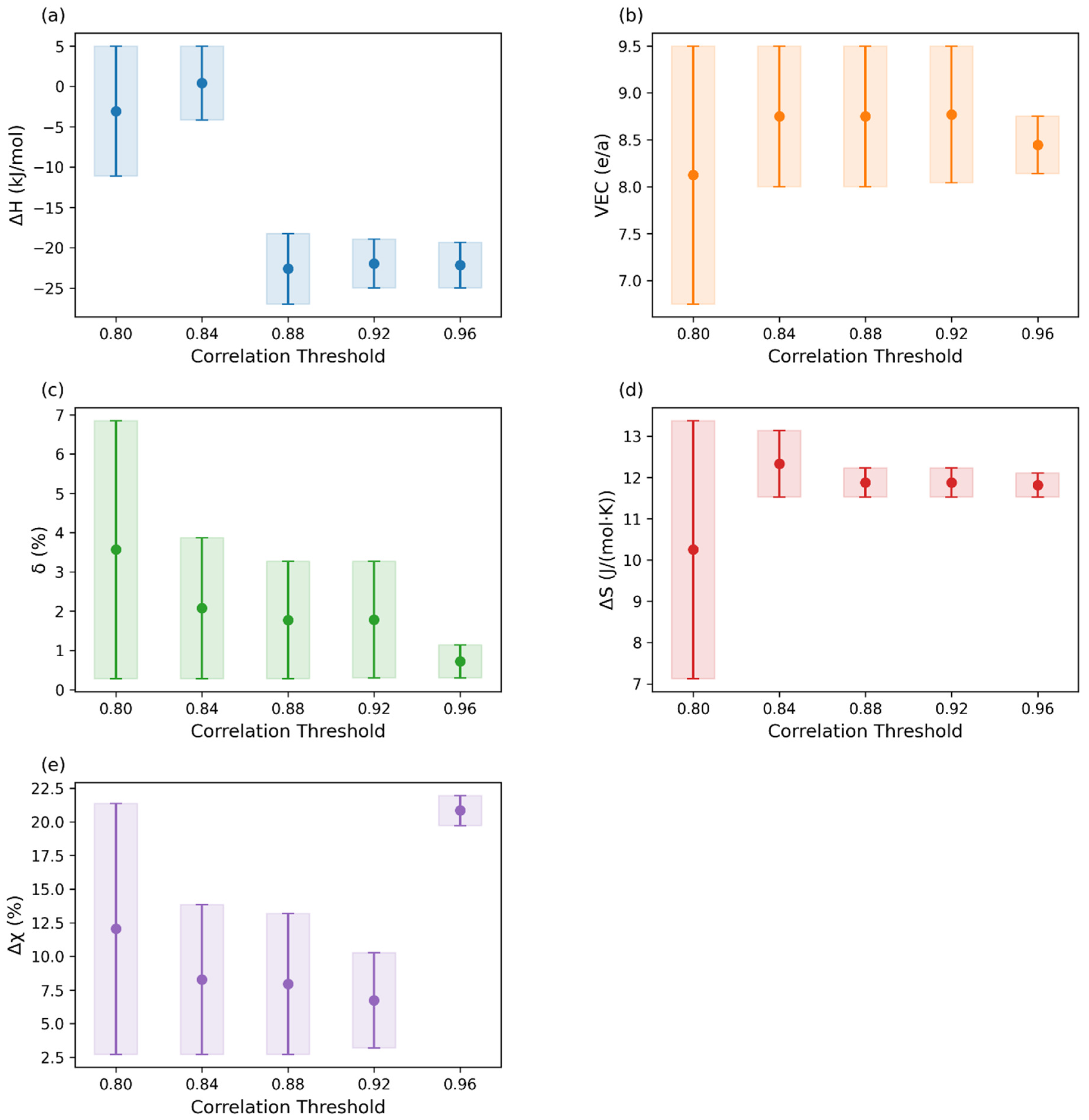

As shown in Figure 11, the analysis reveals specific compositional parameter ranges associated with a strong positive correlation between predicted yield strength and hardness. For ΔH (Figure 11a), the required interval shifts dramatically from a broad range (−11.1 to 5.0 kJ/mol) to a distinctly negative one (−27.0 to −18.2 kJ/mol) as the correlation threshold increases to 0.88, stabilizing around −25.0 to −19.3 kJ/mol at the threshold value of 0.96. This strong preference for a specific, highly negative ΔH range at high correlation levels is significant. Since more negative enthalpy values may favor IMC formation [83,96], potentially leading to complex multiphase systems, this finding aligns with our previous observation that IMC-containing phases like FCC + IMC and FCC + BCC + IMC can exhibit a relatively high correlation between compressive strength and hardness. Concurrently, the requirement for δ (Figure 11c) systematically narrows to very low values, and the preferred range for ΔS (Figure 11d) quickly converges to high values. Both trends strongly align with criteria favoring stable solid solution formation, minimized lattice distortion (low δ), and maximized configurational entropy (high ΔS) [83]. This preference for parameters promoting single-phase solid solution likely explains the observed high correlation between yield strength and hardness. In such relatively uniform microstructures, both properties are governed by the same fundamental mechanisms resisting dislocation motion. Consequently, factors influencing one tend to affect the other predictably, leading to a stronger statistical correlation.

Figure 11.

Variation in the largest continuous intervals of five physicochemical parameters, (a) ΔH, (b) VEC, (c) δ, (d) ΔS, and (e) Δχ, across given correlation thresholds between yield strength and hardness. The circles represent the mean value of each parameter at the corresponding threshold. The vertical error bars and shaded regions represent the largest continuous interval of the parameter values.

The preferred VEC range narrows to an intermediate-to-high regime, which is often associated with the formation of specific phase structures in HEAs (Figure 11b). The parameter Δχ (Figure 11e) exhibits less regular behavior, narrowing significantly before jumping to a high positive range only at the highest correlation threshold, making its direct interpretation less straightforward in this context. Overall, achieving a high correlation between compressive strength and hardness might necessitate a specific combination of thermodynamic and electronic parameters: a strongly negative ΔH, very low δ, high ΔS, or intermediate-high VEC. This points towards specific compositions likely forming stable solid solutions (low δ, high ΔS), potentially with tendencies towards ordering or secondary phase formation (influenced by negative ΔH and VEC), yielding microstructures where strength and hardness are strongly and positively correlated.

To better explore the potentially complex and non-linear relationship between compressive yield strength and hardness in the studied HEAs, the ANN model is developed. ANNs are advanced computational frameworks that emulate the organizational principles of biological nervous systems. These systems excel in modeling highly non-linear relationships and detecting complex structural relationships within datasets through adaptive learning mechanisms, independent of predefined assumptions about data dependencies [97]. This makes them particularly suitable for materials science problems.

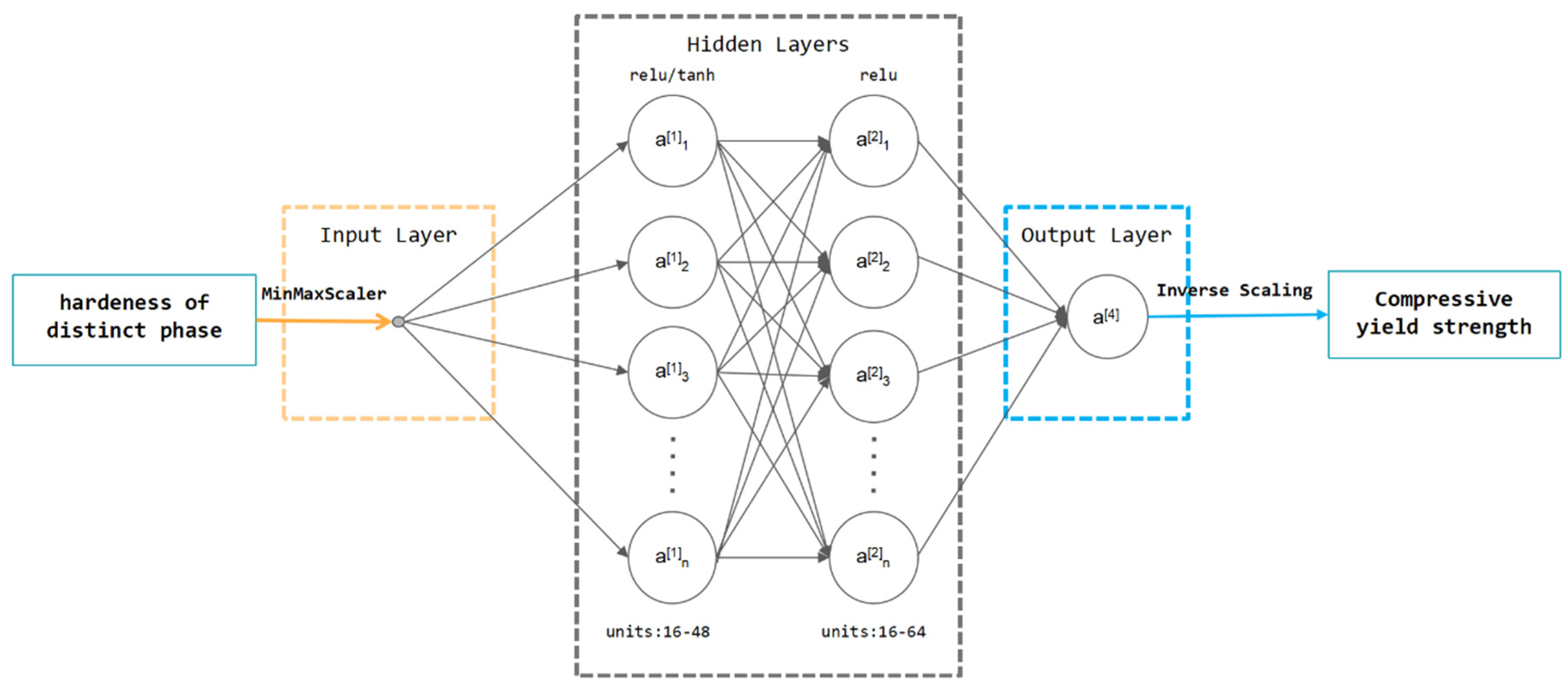

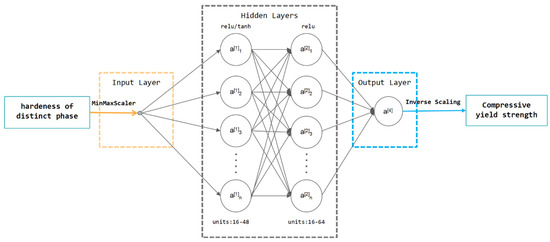

As shown in Figure 12, the model utilizes MinMax-scaled hardness as the input, processed through two hidden layers with optimized neuron counts and activations (ReLU/Tanh), and predicted scaled yield strength via a linear output layer. Key hyperparameters, including hidden unit numbers, activation functions, and the Adam optimizer’s learning rate, are optimized using Keras Tuner to minimize mean squared error (MSE). The final yield strength prediction is obtained by inverse-scaling the network’s output.

Figure 12.

Architecture of the phase-specific ANN model for compressive yield strength prediction from hardness. The model utilizes MinMax scaling for the input hardness feature, feeding into a network with two dense hidden layers. Hyperparameters, including the number of units in both hidden layers (within the ranges indicated) and the activation function (ReLU/Tanh) for the first hidden layer, are optimized via Keras Tuner. A linear output layer provides the scaled prediction, which is then inverse-scaled to obtain the compressive yield strength.

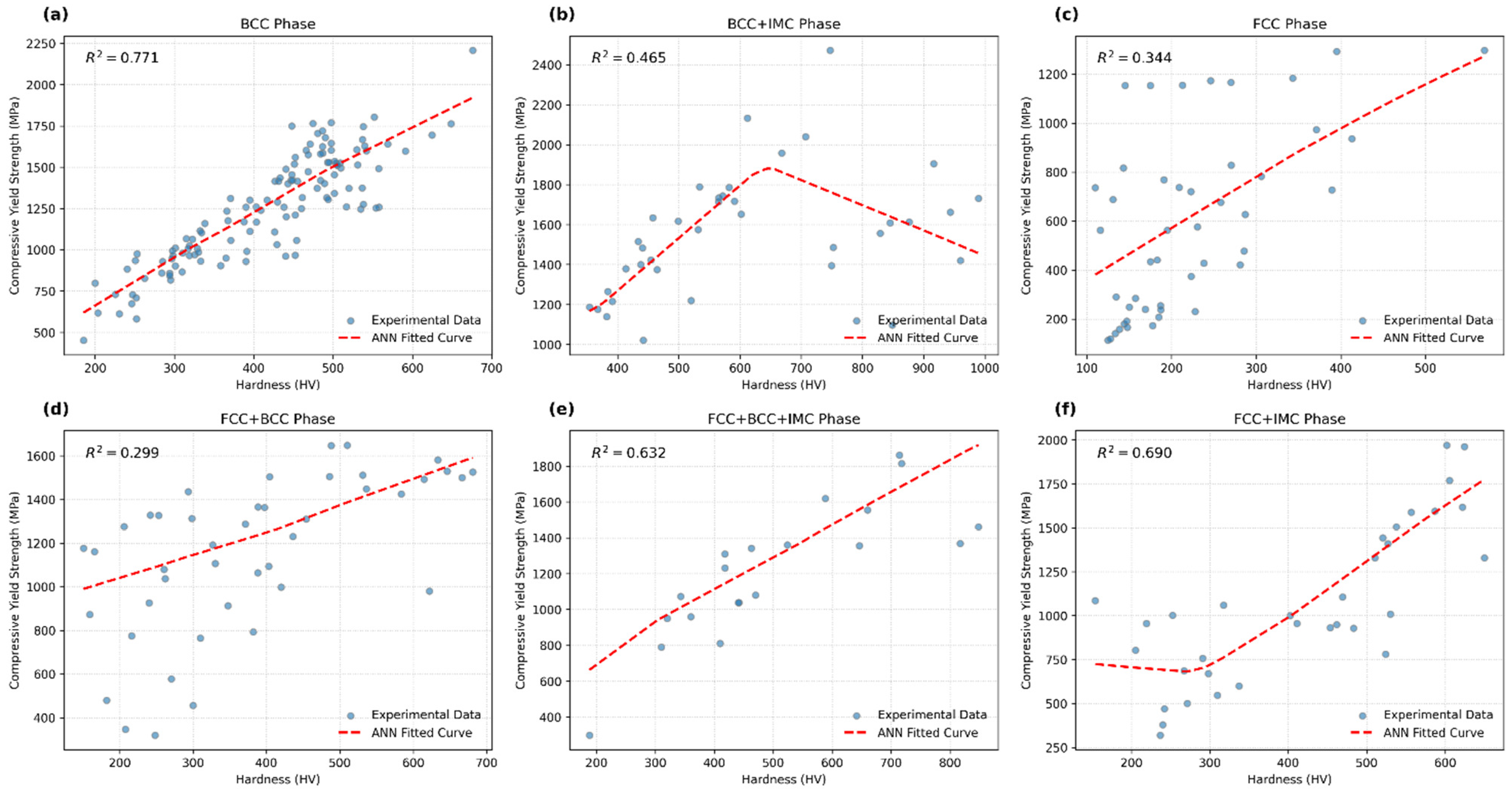

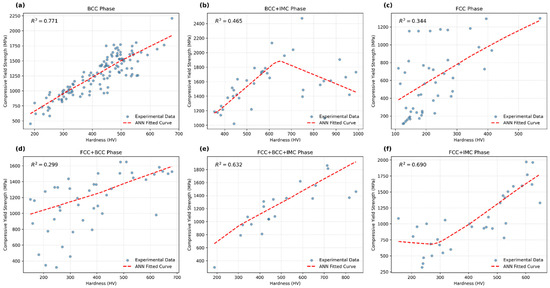

The relationship between hardness and compressive yield strength is further investigated using ANN models. Figure 13 displays the resulting ANN regression curves (dashed red lines) against the experimental data for the six identified phases, with corresponding R2 values indicated. Generally, a positive correlation between hardness and yield strength is observed across all phases, although the data exhibits considerable scatter, particularly noticeable in phases like BCC + IMC (Figure 13b) and FCC (Figure 13c). These plots illustrate the ANN’s capability to model the observed trends, including potential non-linear patterns suggested by the data (Figure 13b). Table 5 quantitatively compares the goodness-of-fit R2 of the ANN models against linear and quadratic fits. The overall moderate R2 values across models (many below 0.5) suggest that hardness alone explains only a portion of the variance in yield strength, implying other microstructural factors are also significant. While the ANN achieves the highest R2 for the BCC + IMC phase (0.465 against 0.177 for quadratic), demonstrating its effectiveness for capturing more complex relationships where simpler models falter, its performance varied across other phases (R2 from 0.299 to 0.771). In several cases, like BCC and FCC, the ANN’s R2 is comparable to or only marginally better than the simpler regression models, indicating that for those specific phase conditions, the underlying relationship captured by the available data might be closer to linear or simple quadratic relationships within the observed hardness range.

Figure 13.

ANN model fits (dashed lines) illustrating the learned correlation between hardness and compressive yield strength for different phase structures. These ANN-generated curves are compared against the experimental data points (scatter) for (a) BCC, (b) BCC + IMC, (c) FCC, (d) FCC + BCC, (e) FCC + BCC + IMC, and (f) FCC + IMC. R2 indicates the goodness-of-fit achieved by each phase-specific ANN model.

Table 5.

Goodness-of-fit (R2) comparison for linear, quadratic, and ANN models.

4. Conclusions

In this work, a three-tier ML framework integrating the development of predictive ML models, data imputation, and a comprehensive correlation analysis is implemented to investigate the relationship between yield strength and hardness in HEAs. The following conclusions are drawn:

- The ML models demonstrate strong predictive capabilities. The phase structure classification model achieves an accuracy of 0.92. The regression models achieve test R2 of 0.90 and 0.91 for yield strength and hardness, respectively, indicating reliable predictions of these key mechanical properties.

- While a general positive correlation exists between σy and HV across the dataset (overall Pearson r ≈ 0.75), the strength and nature of this relationship are highly dependent on the HEA’s phase constitution. Single-phase BCC HEAs demonstrate the strongest and most linear correlation (linear R2 = 0.77, r = 0.88). In contrast, FCC alloys showed a weaker correlation (linear R2= 0.35, r = 0.59), and multiphase systems (e.g., BCC + IMC, FCC + BCC) exhibited more complex behavior, sometimes better captured by non-linear (quadratic or ANN) models.

- The analysis identifies specific ranges of thermodynamic and electronic parameters (ΔH, VEC, δ, ΔS, Δχ) that favor a stronger correlation between σy and HV. Notably, achieving high correlation coefficients often requires combinations like highly negative ΔH, very low δ, and high ΔS, suggesting that microstructures promoting stable solid solutions might exhibit more predictable σy-HV relationships.

- Phase-specific ANN models further confirm the varying complexity. While ANNs significantly improve the fit for certain complex microstructures like BCC + IMC compared to linear/quadratic models, their advantage is less pronounced for phases like BCC or FCC, where simpler relationships appear dominant within the dataset.

Hence, this work demonstrates the power of ML not only for predicting key mechanical properties of HEAs, but also for dissecting the intricate, phase-dependent relationships between them. The findings move beyond simplified empirical rules, revealing the significant influence of both phase structure and specific compositional parameters on the yield strength–hardness correlation. This enhanced understanding provides valuable insights for the rational design and optimization of HEAs with targeted mechanical performance.

Author Contributions

Conceptualization, J.L.; validation, H.W., B.X. and H.F.; formal analysis, B.X.; investigation, H.W., B.X., H.F. and J.L.; data curation, H.W. and B.X.; writing—original draft preparation, H.W., B.X. and H.F.; writing—review and editing, J.L.; supervision, J.L.; project administration, H.F. and J.L.; funding acquisition, H.F. All authors have read and agreed to the published version of the manuscript.

Funding

The present study was supported by the National Natural Science Foundation of China (12172123), the Science and Technology Innovation 2035 Major Project of Yongjiang under Grant (2025Z009), and the Science and Technology Innovation Program of Hunan Province (2022RC1200).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural Development in Equiatomic Multicomponent Alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yang, Y.F.; Hu, F.; Xia, T.; Li, R.H.; Bai, J.Y.; Zhu, J.Q.; Xu, J.Y.; Zhang, G.F. High Entropy Alloys: A Review of Preparation Techniques, Properties and Industry Applications. J. Alloys Compd. 2024, 1010, 177691. [Google Scholar] [CrossRef]

- Odetola, P.I.; Babalola, B.J.; Afolabi, A.E.; Anamu, U.S.; Olorundaisi, E.; Umba, M.C.; Phahlane, T.; Ayodele, O.O.; Olubambi, P.A. Exploring High Entropy Alloys: A Review on Thermodynamic Design and Computational Modeling Strategies for Advanced Materials Applications. Heliyon 2024, 1010, e39660. [Google Scholar] [CrossRef]

- Yernat, K.; Mazhyn, S.; Sherzod, K.; Gulzhaz, U.; Abil, K.; Aibar, K.; Nurken, M. High-Entropy Alloys: Innovative Materials with Unique Properties for Hydrogen Storage and Technologies for Their Production. Metals 2025, 15, 100. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and Properties of High-Entropy Alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-Entropy Alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, Z.; Wu, Q.; He, F.; Li, J.; Wang, J. Enhancing the Yield Strength of Ni–Co–Cr–Fe–al As-Cast Hypoeutectic High-Entropy Alloys by Introducing γ′ Precipitation. Mater. Sci. Eng. A 2022, 858, 144190. [Google Scholar] [CrossRef]

- Tsai, K.Y.; Tsai, M.H.; Yeh, J.W. Sluggish Diffusion in Co–Cr–Fe–Mn–Ni High-Entropy Alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Tabor, D. The Hardness of Metals; Clarendon Press: New York, NY, USA; Oxford, UK, 2007. [Google Scholar]

- Kumar, D.; Sharma, V.K.; Prasad, Y.V.S.S.; Kumar, V. Materials-Structure-Property Correlation Study of Spark Plasma Sintered AlCuCrFeMnWx (X = 0, 0.05, 0.1, 0.5) High-Entropy Alloys. J. Mater. Res. 2019, 34, 767–776. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials, 2nd ed.; Cambridge University: Cambridge, UK, 2013. [Google Scholar]

- Fan, X.; Qu, R.; Zhang, Z. Relation between Strength and Hardness of High-Entropy Alloys. Acta Metall. Sin. 2021, 34, 1461–1482. [Google Scholar] [CrossRef]

- Tokarewicz, M.; Grądzka-Dahlke, M. Review of Recent Research on AlCoCrFeNi High-Entropy Alloy. Metals 2021, 11, 1302. [Google Scholar] [CrossRef]

- Wang, Q.; Zeng, L.; Gao, T.; Du, H.; Liu, X. On the Room-Temperature Tensile Deformation Behavior of a Cast Dual-Phase High-Entropy Alloy CrFeCoNiAl0.7. J. Mater. Sci. Technol. 2021, 87, 29–38. [Google Scholar] [CrossRef]

- Hong, Y.; Wang, C.; Lei, J.; Yang, T.; Ji, V.; Song, P.; Huang, T.; Zhang, X. Combined Effect of B2 Phase Transformation and FCC/BCC Lamellar Structure on the Mechanical Property of Heat Treated Dual-Phase Al0.7CoCrFeNi High Entropy Alloy. J. Alloys Compd. 2025, 1020, 179456. [Google Scholar] [CrossRef]

- Joseph, J.; Stanford, N.; Hodgson, P.; Fabijanic, D.M. Understanding the Mechanical Behaviour and the Large Strength/Ductility Differences between FCC and BCC AlxCoCrFeNi High Entropy Alloys. J. Alloys Compd. 2017, 726, 885–895. [Google Scholar] [CrossRef]

- Shen, L.; Chen, L.; Huang, J.; He, J.; Li, Z.; Pan, J.; Chang, F.; Dai, P.; Tang, Q. Predicting Phases and Hardness of High Entropy Alloys Based on Machine Learning. Intermetallics 2023, 162, 108030. [Google Scholar] [CrossRef]

- Zhao, D.Q.; Pan, S.P.; Zhang, Y.; Liaw, P.K.; Qiao, J.W. Structure Prediction in High-Entropy Alloys with Machine Learning. Appl. Phys. Lett. 2021, 118, 231904. [Google Scholar] [CrossRef]

- Ding, S.; Wang, W.; Zhang, Y.; Ren, W.; Weng, X.; Chen, J. A Yield Strength Prediction Framework for Refractory High-Entropy Alloys Based on Machine Learning. Int. J. Refract. Met. Hard Mater. 2024, 125, 106884. [Google Scholar] [CrossRef]

- Bhandari, U.; Rafi, M.R.; Zhang, C.; Yang, S. Yield Strength Prediction of High-Entropy Alloys Using Machine Learning. Mater. Today Commun. 2021, 26, 101871. [Google Scholar] [CrossRef]

- Dilshodbek, Y.; Hong, S.H.; Abbas, M.A.; Kang, G.C.; Park, H.J.; Jumaev, E.; Wang, W.-M.; Kim, K.B. Evolution of Microstructure and Mechanical Characteristics of (CrFeNiCu)100–XTix High-Entropy Alloys. Rare Met. 2023, 42, 3088–3098. [Google Scholar] [CrossRef]

- Fang, Y.; Hu, Z.; Ji, J.; Sun, L.; Wang, L.; Zhan, X. Preparation of a Novel High-Entropy Alloy AlNbTiVZr with Excellent Strength and Ductility: The Effect of Zr Composition on Microstructure and Properties. Mater. Sci. Eng. A 2024, 918, 147441. [Google Scholar] [CrossRef]

- Gan, Z.; Huang, Y.; Wu, C.; Yang, T.; Shen, S.; Luo, G.; Liu, J. Microstructural Evolution and Elevated-Temperature Strengthening Mechanism of Co-Free FeCrMnNiV0.2Alx High-Entropy Alloys during Annealing. Mater. Sci. Eng. A 2024, 895, 146213. [Google Scholar] [CrossRef]

- Qiao, D.X.; Jiang, H.; Jiao, W.N.; Lu, Y.P.; Cao, Z.Q.; Li, T.J. A Novel Series of Refractory High-Entropy Alloys Ti2ZrHf0.5VNbx with High Specific Yield Strength and Good Ductility. Acta Metall. Sin. 2019, 32, 925–931. [Google Scholar] [CrossRef]

- Yao, H.; Qiao, J.W.; Hawk, J.A.; Zhou, H.; Chen, M.; Gao, M. Mechanical Properties of Refractory High-Entropy Alloys: Experiments and Modeling. J. Alloys Compd. 2017, 696, 1139–1150. [Google Scholar] [CrossRef]

- Kao, Y.F.; Chen, T.J.; Chen, S.K.; Yeh, J.W. Microstructure and Mechanical Property of As-Cast, -Homogenized, and -Deformed AlxCoCrFeNi (0 ≤ X ≤ 2) High-Entropy Alloys. J. Alloys Compd. 2009, 488, 57–64. [Google Scholar] [CrossRef]

- Xu, C.; Chen, D.; Yang, X.; Liu, T.; Chen, R. Achieving Excellent Strength and Ductility of Ti2ZrNbHfV Refractory High-Entropy Alloys by v Addition. Int. J. Refract. Met. Hard Mater. 2024, 121, 106681. [Google Scholar] [CrossRef]

- Wang, E.; Dong, J.; Cao, Y.; Kang, F.; Liu, X.; Jiang, F.; Li, J.; Liu, Z.; Jiang, W.; Kang, K. Effects of Gd on the Microstructure and Mechanical Properties of GdxCoCrFeNiV0.4 High-Entropy Alloys. J. Mater. Res. Technol. 2024, 33, 714–724. [Google Scholar] [CrossRef]

- Shen, X.; Guo, Z.; Liu, F.; Dong, F.; Zhang, Y.; Liu, C.; Wang, B.; Luo, L.; Su, Y.; Cheng, J.; et al. Microstructural Evolution and Mechanical Behavior of Novel TiZrTaxNbMo Refractory High-Entropy Alloys. J. Alloys Compd. 2024, 990, 174459. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Liaw, P.K. Microstructure and Compressive Properties of NbTiVTaAlx High Entropy Alloys. Procedia Eng. 2012, 36, 292–298. [Google Scholar] [CrossRef]

- Nie, Q.; Liang, H.; Qiao, D.; Qi, Z.; Cao, Z. Microstructures and Mechanical Properties of Multi-Component AlxCrFe2Ni2Mo0.2 High-Entropy Alloys. Acta Metall. Sin. 2020, 33, 1135–1144. [Google Scholar] [CrossRef]

- Cheng, P.; Zhao, Y.; Xu, X.; Wang, S.; Sun, Y.; Hou, H. Microstructural Evolution and Mechanical Properties of Al0.3CoCrFeNiSix High-Entropy Alloys Containing Coherent Nanometer-Scaled Precipitates. Mater. Sci. Eng. A 2020, 772, 138681. [Google Scholar] [CrossRef]

- Yan, Y.; Fang, L.; Tan, Y.; Tao, X.; Ouyang, Y.; Du, Y. Mechanical Properties and Corrosion Resistance of AlxCoCuFeMn High-Entropy Alloys. J. Mater. Res. Technol. 2023, 24, 5250–5259. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Sun, L.; Wang, X. Mechanical Properties and Wear Behaviors of FeCoNiCrMnTix High-Entropy Alloys Manufactured by Vacuum Arc Melting. J. Mater. Res. Technol. 2024, 30, 1962–1977. [Google Scholar] [CrossRef]

- Ma, S.G.; Zhang, Y. Effect of Nb Addition on the Microstructure and Properties of AlCoCrFeNi High-Entropy Alloy. Mater. Sci. Eng. A 2012, 532, 480–486. [Google Scholar] [CrossRef]

- Xiao, Y.; Peng, X. Design of Lightweight Ti3Zr1.5NbV Refractory High-Entropy Alloys with Superior Mechanical Properties. J. Mater. Res. Technol. 2023, 27, 330–341. [Google Scholar] [CrossRef]

- Wang, W.; Wang, J.; Yi, H.; Qi, W.; Peng, Q. Effect of Molybdenum Additives on Corrosion Behavior of (CoCrFeNi)100−XMox High-Entropy Alloys. Entropy 2018, 20, 908. [Google Scholar] [CrossRef]

- Zhang, M.; Yao, L.; Zhu, M.; Liu, Y.; Jian, Z. Structural Evolution and Mechanical and Magnetic Properties of Nonequiatomic CoFe2NiMn0.3Alx (0.25 ≤ X ≤ 1.00) High-Entropy Alloys. J. Mater. Eng. Perform. 2021, 30, 1472–1478. [Google Scholar] [CrossRef]

- Lin, C.M.; Juan, C.C.; Chang, C.H.; Tsai, C.W.; Yeh, J.W. Effect of al Addition on Mechanical Properties and Microstructure of Refractory AlxHfNbTaTiZr Alloys. J. Alloys Compd. 2015, 624, 100–107. [Google Scholar] [CrossRef]

- Qiao, D.X.; Jiang, H.; Chang, X.X.; Lu, Y.P.; Li, T.J. Microstructure and Mechanical Properties of VTaTiMoAlx Refractory High Entropy Alloys. Mater. Sci. Forum 2017, 898, 638–642. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Yurchenko, N.Y.; Panina, E.S.; Tikhonovsky, M.A.; Zherebtsov, S.V. Precipitation-Strengthened Refractory Al0.5CrNbTi2V0.5 High Entropy Alloy. Mater. Lett. 2016, 188, 162–164. [Google Scholar] [CrossRef]

- Chen, G.; Yan, H.; Wang, Z.; Wang, K.; Yves, N.I.; Tong, Y. Effects of Mo Content on the Microstructure and Mechanical Properties of TiNbZrMox High-Entropy Alloys. J. Alloys Compd. 2022, 930, 167373. [Google Scholar] [CrossRef]

- Wang, N.; Ma, K.; Li, Q.; Yuan, Y.; Zhao, Y.; Feng, L. Effect of Mn Content on Microstructure and Properties of AlCrCuFeMnx High-Entropy Alloy. China Foundry 2024, 21, 147–158. [Google Scholar] [CrossRef]

- Zhang, L.; Tu, J.; Liang, Y.; Yang, W.; Zhang, X.; Zhou, Z.; Gu, Y.; Liu, Y.; Du, Y. Titanium Doping Levels and Their Effects on FeCoCrNi High-Entropy Alloys: From Microstructure to Performance. Mater. Charact. 2024, 215, 114136. [Google Scholar] [CrossRef]

- Chen, S.; Bao, L.; Yang, H.; Si, X.; Yu, Q. Effect of al Content on Microstructure and Mechanical Properties of Alx(Nb3TaTi3Zr)100-x Refractory High-Entropy Alloys. J. Phys. Conf. Ser. 2024, 2691, 012071. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Liaw, P.K. Alloy Design and Properties Optimization of High-Entropy Alloys. JOM 2012, 64, 830–838. [Google Scholar] [CrossRef]

- Ji, G.; Zhou, Z.; Meng, F.; Yang, X.; Sheng, R.; Qiao, J.; Liaw, P.K.; Li, M.; Jiang, L.; Chen, S.; et al. Effect of Zr Addition on the Local Structure and Mechanical Properties of Ti–Ta–Nb–Zr Refractory High-Entropy Alloys. J. Mater. Res. Technol. 2022, 19, 4428–4438. [Google Scholar] [CrossRef]

- Duan, S.; Zhang, Q.; Li, W.; Dong, Y.; Jiang, B.; Liu, S.; Li, C.; Zhang, Z. Effects of v Addition on Microstructural Evolution and Mechanical Properties of AlCrFe2Ni2 High-Entropy Alloys. Acta Metall. Sin. 2022, 36, 391–404. [Google Scholar] [CrossRef]

- Lei, H.; Ye, X.; Feng, J.; Chen, J.; Diao, Z.; Fang, D.; Li, B.; Zhao, G.; Liu, R. Microstructure and Mechanical Properties of CrFeNiBx Eutectic High Entropy Alloys. Mater. Sci. Eng. A 2023, 887, 145741. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Ma, K.H.; Wang, Q.; Shek, C.H. Compositional Dependence of Phase Formation and Mechanical Properties in Three CoCrFeNi-(Mn/Al/Cu) High Entropy Alloys. Intermetallics 2016, 79, 1–11. [Google Scholar] [CrossRef]

- Chen, L.B.; Wei, R.; Tang, K.; Zhang, J.; Jiang, F.; Lin, H.; Sun, J. Heavy Carbon Alloyed FCC-Structured High Entropy Alloy with Excellent Combination of Strength and Ductility. Mater. Sci. Eng. A 2018, 716, 150–156. [Google Scholar] [CrossRef]

- Saad, A.S.; Samrand, S.; Hu, Q.; Johan, A.; Persson, C.; Jaroslav, V.; Jiří, Z.; Klement, U.; Guo, S. Alloy Design for Intrinsically Ductile Refractory High-Entropy Alloys. J. Appl. Phys. 2016, 120, 164902. [Google Scholar] [CrossRef]

- Fang, S.; Meng, L.; Ke, L.; Fu, W.; Qi, T. Mechanism of Gd Doping on Microstructure and Mechanical Properties of FeCrNiCuTi0.4 High Entropy Alloy. J. Alloys Compd. 2024, 1003, 175699. [Google Scholar] [CrossRef]

- Zuo, T.T.; Li, R.B.; Ren, X.J.; Zhang, Y. Effects of al and Si Addition on the Structure and Properties of CoFeNi Equal Atomic Ratio Alloy. J. Magn. Magn. Mater. 2014, 371, 60–68. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, W.; Wang, H.; Xie, J.; Zhang, T.; Yin, L.; Huang, Y. Effect of Ti Content on the Microstructure and Properties of CoCrFeNiMnTix High Entropy Alloy. Entropy 2022, 24, 241. [Google Scholar] [CrossRef]

- Wu, M.; Yuan, J.; Diao, G.; Li, D. Achieving a Combination of Higher Strength and Higher Ductility for Enhanced Wear Resistance of AlCrFeNiTi0.5 High-Entropy Alloy by Mo Addition. Metals 2022, 12, 1910. [Google Scholar] [CrossRef]

- Xu, C.; Chen, D.; Yang, X.; Wang, S.; Fang, H.; Chen, R. Enhancing Mechanical Performance of Ti2ZrNbHfVAlx Refractory High-Entropy Alloys through Laves Phase. Mater. Sci. Eng. A 2024, 918, 147438. [Google Scholar] [CrossRef]

- Wang, E.; Li, J.; Kang, F.; Jiang, F.; Lv, L.; Dai, B.; Cao, Y.; Jiang, W. Balancing the Mechanical Properties of Al0.45CoCrFeNiTix High-Entropy Alloys by Tailoring Titanium Content. J. Mater. Res. Technol. 2023, 28, 967–979. [Google Scholar] [CrossRef]

- Ye, X.; Wang, T.; Xu, Z.; Liu, C.; Wu, H.; Zhao, G.; Fang, D. Effect of Ti Content on Microstructure and Mechanical Properties of CuCoFeNi High-Entropy Alloys. Int. J. Miner. Metall. Mater. 2020, 27, 1326–1331. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, J.B.; Li, L.; Li, J.C.; Jiang, Q. Microstructure and Tensile Properties of FeMnNiCuCoSnx High Entropy Alloys. Mater. Des. 2012, 44, 223–227. [Google Scholar] [CrossRef]

- Salishchev, G.A.; Tikhonovsky, M.A.; Shaysultanov, D.G.; Stepanov, N.; Kuznetsov, A.; Kolodiy, I.V.; Tortika, A.S.; Senkov, O.N. Effect of Mn and v on Structure and Mechanical Properties of High-Entropy Alloys Based on CoCrFeNi System. J. Alloys Compd. 2014, 591, 11–21. [Google Scholar] [CrossRef]

- Zýka, J.; Málek, J.; Veselý, J.; Lukáč, F.; Čížek, J.; Kuriplach, J.; Melikhova, O. Microstructure and Room Temperature Mechanical Properties of Different 3 and 4 Element Medium Entropy Alloys from HfNbTaTiZr System. Entropy 2019, 21, 114. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Yang, X.; Dahmen, K.; Liaw, P.; Zhang, Y. Microstructures and Crackling Noise of AlxNbTiMoV High Entropy Alloys. Entropy 2014, 16, 870–884. [Google Scholar] [CrossRef]

- Yao, H.; Qiao, J.W.; Gao, M.; Hawk, J.A.; Ma, S.; Zhou, H.; Zhang, Y. NbTaV-(Ti,W) Refractory High-Entropy Alloys: Experiments and Modeling. Mater. Sci. Eng. A 2016, 674, 203–211. [Google Scholar] [CrossRef]

- Guo, N.N.; Wang, L.; Luo, L.S.; Li, X.Z.; Chen, R.R.; Su, Y.Q.; Guo, J.J.; Fu, H.Z. Microstructure and Mechanical Properties of In-Situ MC-Carbide Particulates-Reinforced Refractory High-Entropy Mo0.5NbHf0.5ZrTi Matrix Alloy Composite. Intermetallics 2016, 69, 74–77. [Google Scholar] [CrossRef]

- Zhang, M.; Zhou, X.; Li, J. Microstructure and Mechanical Properties of a Refractory CoCrMoNbTi High-Entropy Alloy. J. Mater. Eng. Perform. 2017, 26, 3657–3665. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, L.; Fan, J.; Yu, P.; Li, G. Anomalous Microstructure and Excellent Mechanical Behaviors of (CoCrFeNi)6-x-YCrxAly High-Entropy Alloy Induced by Cr and al Addition. Mater. Sci. Eng. A 2019, 752, 63–74. [Google Scholar] [CrossRef]

- Fazakas, E.; Zadorozhnyy, V.; Varga, L.K.; Inoue, A.; Louzguine-Luzgin, D.V.; Tian, F.; Vitos, L. Experimental and Theoretical Study of Ti20Zr20Hf20Nb20X20 (X = v or Cr) Refractory High-Entropy Alloys. Int. J. Refract. Met. Hard Mater. 2014, 47, 131–138. [Google Scholar] [CrossRef]

- Wu, Y.; Cai, Y.; Chen, X.H.; Wang, T.; Si, J.; Wang, L.; Wang, Y.D.; Hui, X. Phase Composition and Solid Solution Strengthening Effect in TiZrNbMoV High-Entropy Alloys. Mater. Des. 2015, 83, 651–660. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Zhang, H.; Wang, N.; Chen, X.; Zhang, H.; Li, Y. Microstructure and Mechanical Properties of Refractory HfMo0.5NbTiV0.5Six High-Entropy Composites. J. Alloys Compd. 2017, 694, 869–876. [Google Scholar] [CrossRef]

- Juan, C.C.; Tseng, K.K.; Hsu, W.L.; Tsai, M.H.; Tsai, C.W.; Lin, C.M.; Chen, S.K.; Lin, S.J.; Yeh, J.W. Solution Strengthening of Ductile Refractory HfMoxNbTaTiZr High-Entropy Alloys. Mater. Lett. 2016, 175, 284–287. [Google Scholar] [CrossRef]

- Han, Z.; Luan, H.; Liu, X.J.; Chen, N.C.; Li, X.; Shao, Y.; Yao, K.L. Microstructures and Mechanical Properties of Ti NbMoTaW Refractory High-Entropy Alloys. Mater. Sci. Eng. A 2018, 712, 380–385. [Google Scholar] [CrossRef]

- Han, Z.; Chen, N.C.; Zhao, S.J.; Fan, L.T.; Yang, G.-Y.; Shao, Y.; Yao, K.L. Effect of Ti Additions on Mechanical Properties of NbMoTaW and VNbMoTaW Refractory High Entropy Alloys. Intermetallics 2017, 84, 153–157. [Google Scholar] [CrossRef]

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of al Addition on Structural Evolution and Tensile Properties of the FeCoNiCrMn High-Entropy Alloy System. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- Yang, W.; Pang, S.J.; Wang, G.; Liu, Y.; Liaw, P.K.; Zhang, T. Ti–Zr–Hf–Nb–Ta–Sn High-Entropy Alloys with Good Properties as Potential Biomaterials. Rare Met. 2022, 41, 2305–2315. [Google Scholar] [CrossRef]

- Gan, Y.; Duan, S.; Mo, Y.; Dong, Y.; Yi, J.; Hu, Y. Effects of al Addition on the Microstructure and Mechanical Properties of AlxCoCrFeNi2.1 High-Entropy Alloys. Intermetallics 2023, 166, 108172. [Google Scholar] [CrossRef]

- Xu, T.; Lu, Y.; Cao, Z.; Wang, T.; Li, T. Effects of Ta Addition on the Microstructure and Mechanical Properties of CoCu0.5FeNi High-Entropy Alloy. J. Mater. Eng. Perform. 2019, 28, 7642–7648. [Google Scholar] [CrossRef]

- Dong, Y.; Zhou, K.; Lu, Y.; Gao, X.; Wang, T.; Li, T. Effect of Vanadium Addition on the Microstructure and Properties of AlCoCrFeNi High Entropy Alloy. Mater. Des. 2014, 57, 67–72. [Google Scholar] [CrossRef]

- Cao, L.; Wang, X.; Wang, Y.; Zhang, L.; Yang, Y.; Liu, F.; Cui, Y. Microstructural Evolution, Phase Formation and Mechanical Properties of Multi-Component AlCoCrFeNix Alloys. Appl. Phys. A 2019, 125, 699. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, L.; Fan, J.; Li, G.; Liaw, P.K.; Liu, R. Microstructure and Enhanced Mechanical Behavior of the Al7Co24Cr21Fe24Ni24 High-Entropy Alloy System by Tuning the Cr Content. Mater. Sci. Eng. A 2018, 733, 299–306. [Google Scholar] [CrossRef]

- Jiang, L.L.; Cao, Z.; Jie, J.; Zhang, J.; Lu, Y.; Wang, T.; Li, T. Effect of Mo and Ni Elements on Microstructure Evolution and Mechanical Properties of the CoFeNixVMoy High Entropy Alloys. J. Alloys Compd. 2015, 649, 585–590. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-Solution Phase Formation Rules for Multi-Component Alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- GUO, S.; LIU, C.T. Phase Stability in High Entropy Alloys: Formation of Solid-Solution Phase or Amorphous Phase. Prog. Nat. Sci. Mater. Int. 2011, 21, 433–446. [Google Scholar] [CrossRef]

- Fang, S.; Xiao, X.; Xia, L.; Li, W.; Dong, Y. Relationship between the Widths of Supercooled Liquid Regions and Bond Parameters of Mg-Based Bulk Metallic Glasses. J. Non-Cryst. Solids 2003, 321, 120–125. [Google Scholar] [CrossRef]

- Ignatenko, V.; Surkov, A.; Sergei, K. Random forests with Parametric Entropy-Based Information Gains for Classification and Regression Problems. PeerJ Comput. Sci. 2024, 10, e1775. [Google Scholar] [CrossRef] [PubMed]

- Breiman, L. Bagging Predictors. Mach. Learn. 1996, 24, 123–140. [Google Scholar] [CrossRef]

- Ghate, V.; Hemalatha C, S. A Comprehensive Comparison of Machine Learning Approaches with Hyper-Parameter Tuning for Smartphone Sensor-Based Human Activity Recognition. Meas. Sens. 2023, 30, 100925. [Google Scholar] [CrossRef]

- Ahmadi, A.; Sharif, S.S.; Banad, Y.M. A Comparative Study of Sampling Methods with Cross-Validation in the FedHome Framework. IEEE Trans. Parallel Distrib. Syst. 2025, 36, 570–579. [Google Scholar] [CrossRef]

- Guo, S.; Ng, C.; Lu, J.; Liu, C.T. Effect of Valence Electron Concentration on Stability of Fcc or Bcc Phase in High Entropy Alloys. J. Appl. Phys. 2011, 109, 103505. [Google Scholar] [CrossRef]

- Dieter, G.E. Mechanical Metallurgy; Mcgraw-Hill Education: New Delhi, India, 2013. [Google Scholar]

- Yao, Y.; Cappola, J.; Zhang, Z.; Zhu, Q.; Cai, W.; Yu, X.; Li, L. Nanostructure and Dislocation Interactions in Refractory Complex Concentrated Alloy: From Chemical Short-Range Order to Nanoscale B2 Precipitates. Acta Mater. 2024, 281, 120457. [Google Scholar] [CrossRef]

- Lugovy, M.; Slyunyayev, V.; Brodnikovskyy, M. Solid Solution Strengthening in Multicomponent Fcc and Bcc Alloys: Analytical Approach. Prog. Nat. Sci. Mater. Int. 2021, 31, 95–104. [Google Scholar] [CrossRef]

- Zhu, X.; Yang, X.; Huang, W.; Liu, Y.; Qiu, W.; Wang, X.; Li, M. Influence of Precipitation on Geometrically Necessary Dislocations Distribution and Fracture Behavior in an Al-Cu-Li Alloy. J. Alloys Compd. 2025, 1013, 178561. [Google Scholar] [CrossRef]

- Li, Y.; Yu, L.; Pang, X.; Qin, G. Tuning Stacking Fault Energy and Enhancing Mechanical Properties of al through Mg and Sc Doping: Insights from Density Functional Theory. Mater. Today Commun. 2025, 43, 111639. [Google Scholar] [CrossRef]

- Huang, E.W.; Lam, T.N.; Aitken, Z.H.; Luo, M.Y.; Chiang, N.E.; Sun, Y.; Tseng, J.C.; Chiang, C.Y.; Hsieh, W.Z.; Lee, W.J.; et al. Mixing-Enthalpy Modulation on Phase Transformation in the Gradient Chemical Core/Shell High-Entropy Shape-Memory Alloys. Mater. Des. 2025, 251, 113623. [Google Scholar] [CrossRef]

- Agatonovic-Kustrin, S.; Beresford, R. Basic Concepts of Artificial Neural Network (ANN) Modeling and Its Application in Pharmaceutical Research. J. Pharm. Biomed. Anal. 2000, 22, 717–727. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).