Optimising Additive Manufacturing of NiTi and NiMnGa Shape Memory Alloys: A Review

Abstract

1. Introduction

2. Driving Principles of Shape Memory Effect and Superelasticity

2.1. NiTi

2.1.1. Thermal SME in NiTi

2.1.2. Superelasticity in NiTi

2.2. NiMnGa

2.2.1. Phase Evolution in NiMnGa

| Martensite Phases | Description | [MPa] | [MPa] | ] | Reference |

|---|---|---|---|---|---|

| 5M/10M | Modulated pseudo-tetragonal lattice; three twin variants | 2.8 | 0.5–4 | >6 | [63,74,75] |

| 7M/14M | Modulated orthorhombic lattice; six twin variants | 1.6 | 3–5 | 0.47 | [63,74] |

| NM | Non-modulated L10 tetragonal lattice; three twin variants | 0.7 | 17–25 | None | [63,74] |

2.2.2. Magnetic Field-Induced Shape Memory Effect in NiMnGa

3. Additive Manufacturing of Shape Memory Alloys

3.1. NiTi

3.1.1. Powder Bed Fusion-Based Additive Manufacturing of NiTi

3.1.2. Directed Energy Deposition

3.2. Magnetic Shape Memory NiMnGa Alloys

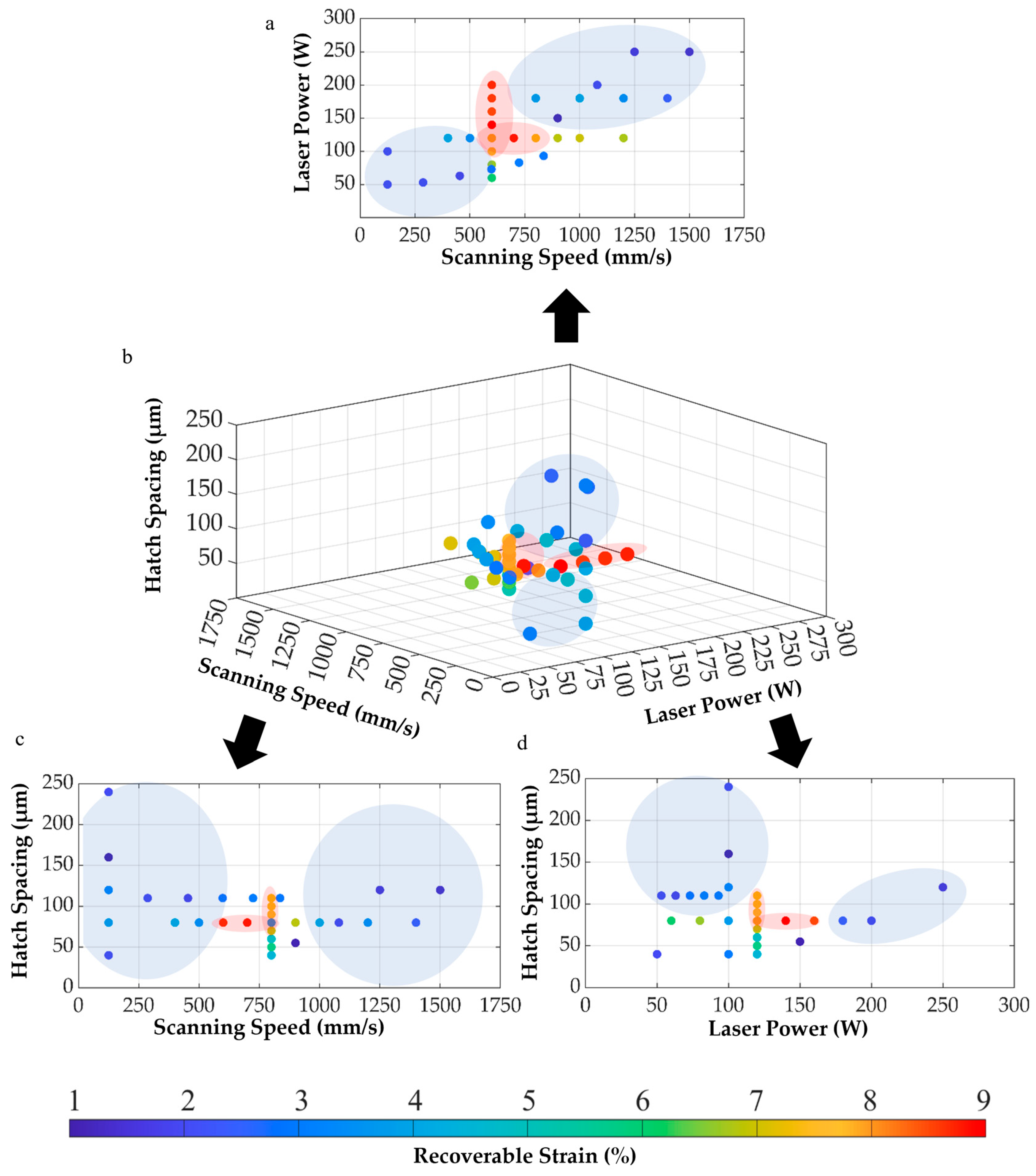

3.2.1. Laser Powder Bed Fusion

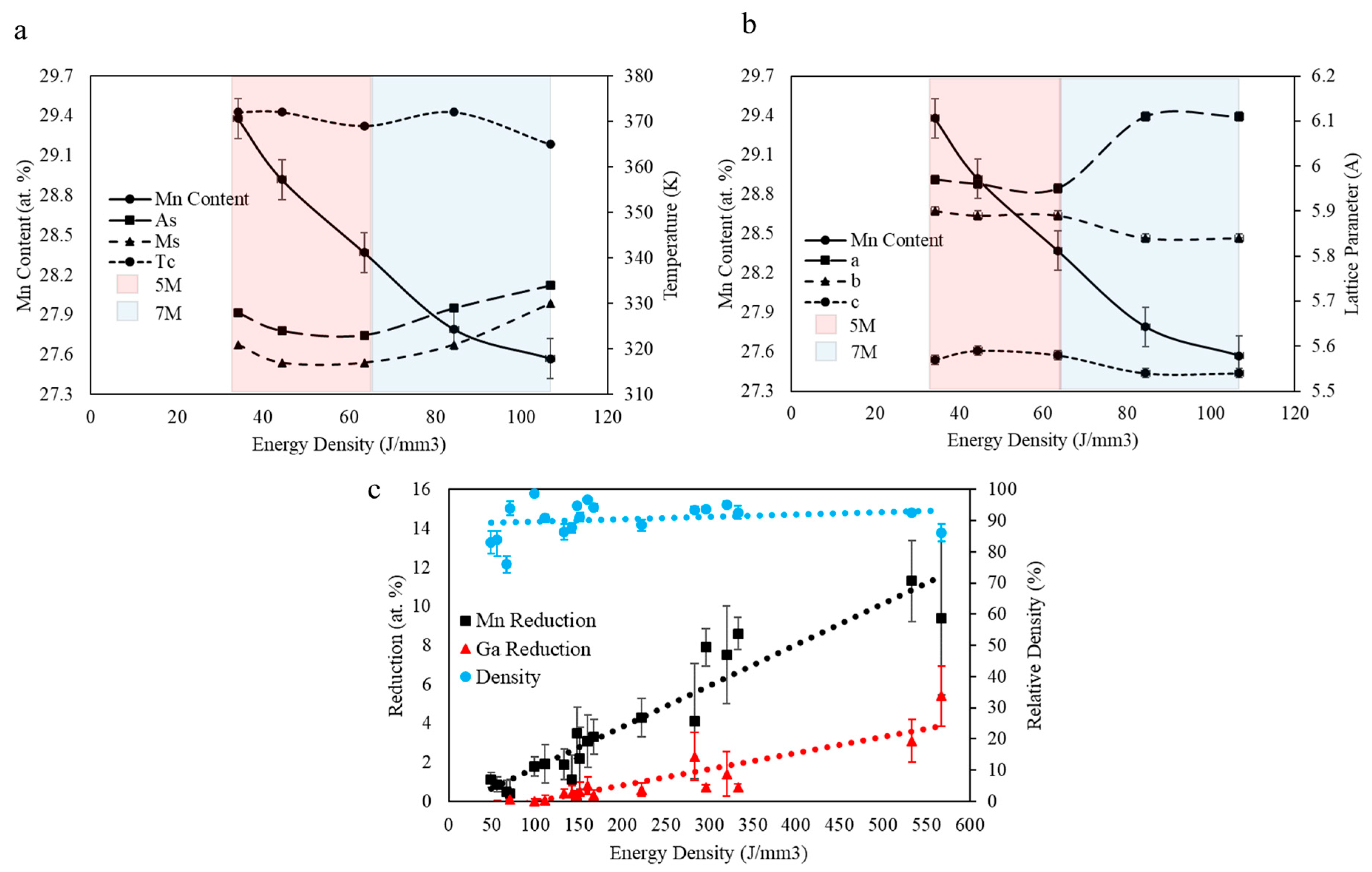

Elemental Evaporation and Its Effect on Magneto-Structural Properties

Twin Boundary Mobility

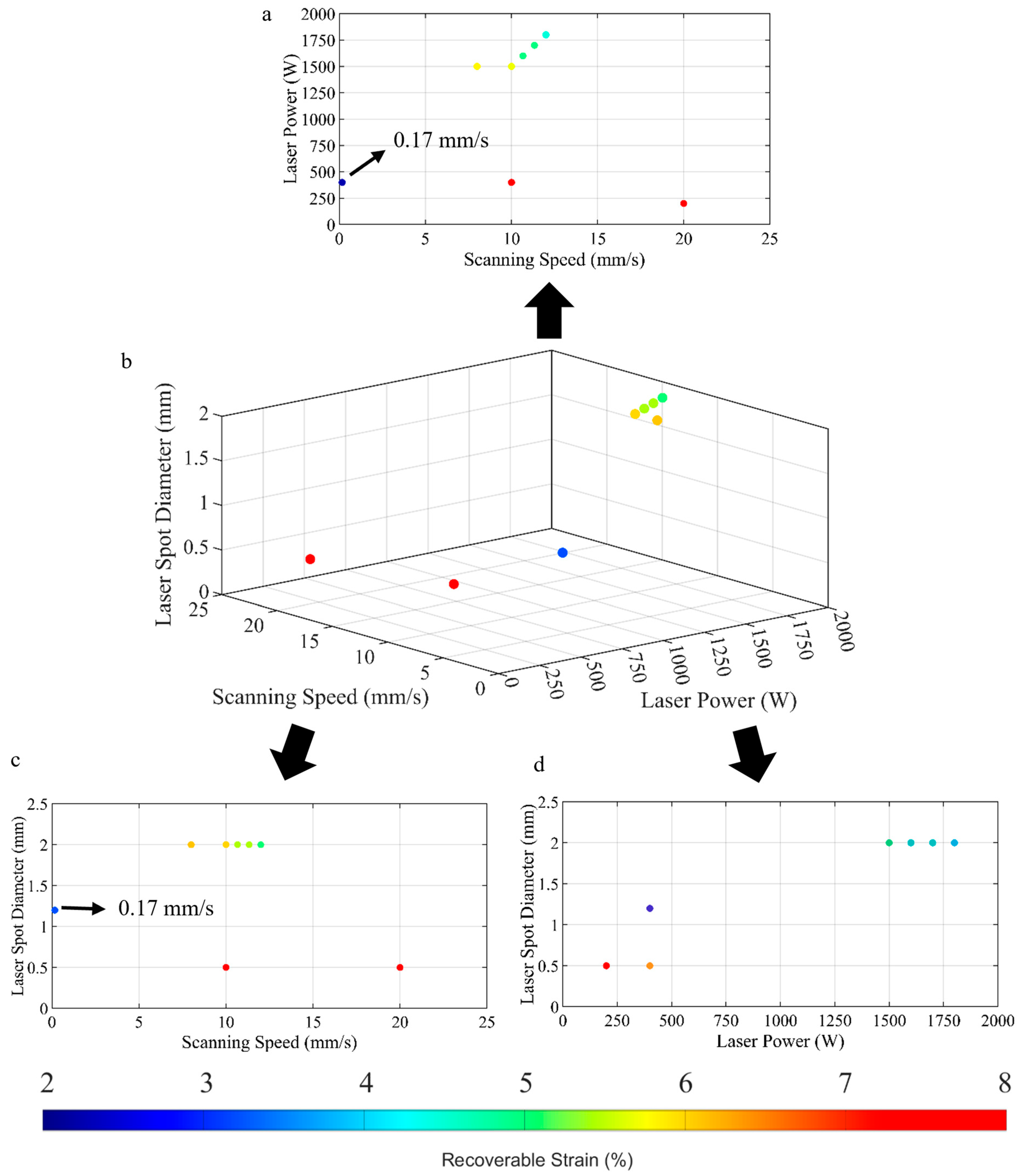

3.2.2. Directed Energy Deposition

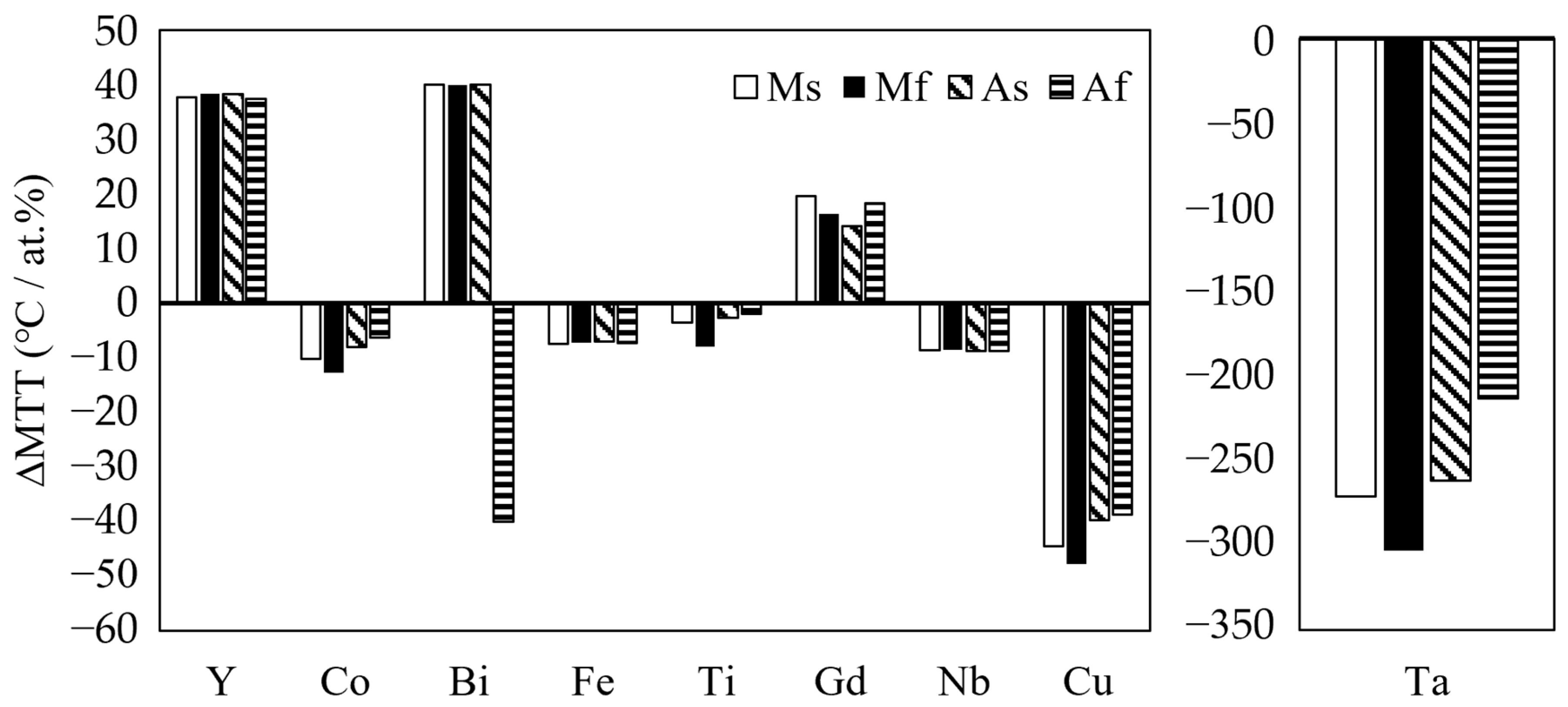

3.2.3. Effect of Quaternary Elements

Enhancement of Ductility and Strength

Crystal Size

MTTs and the Curie Temperature

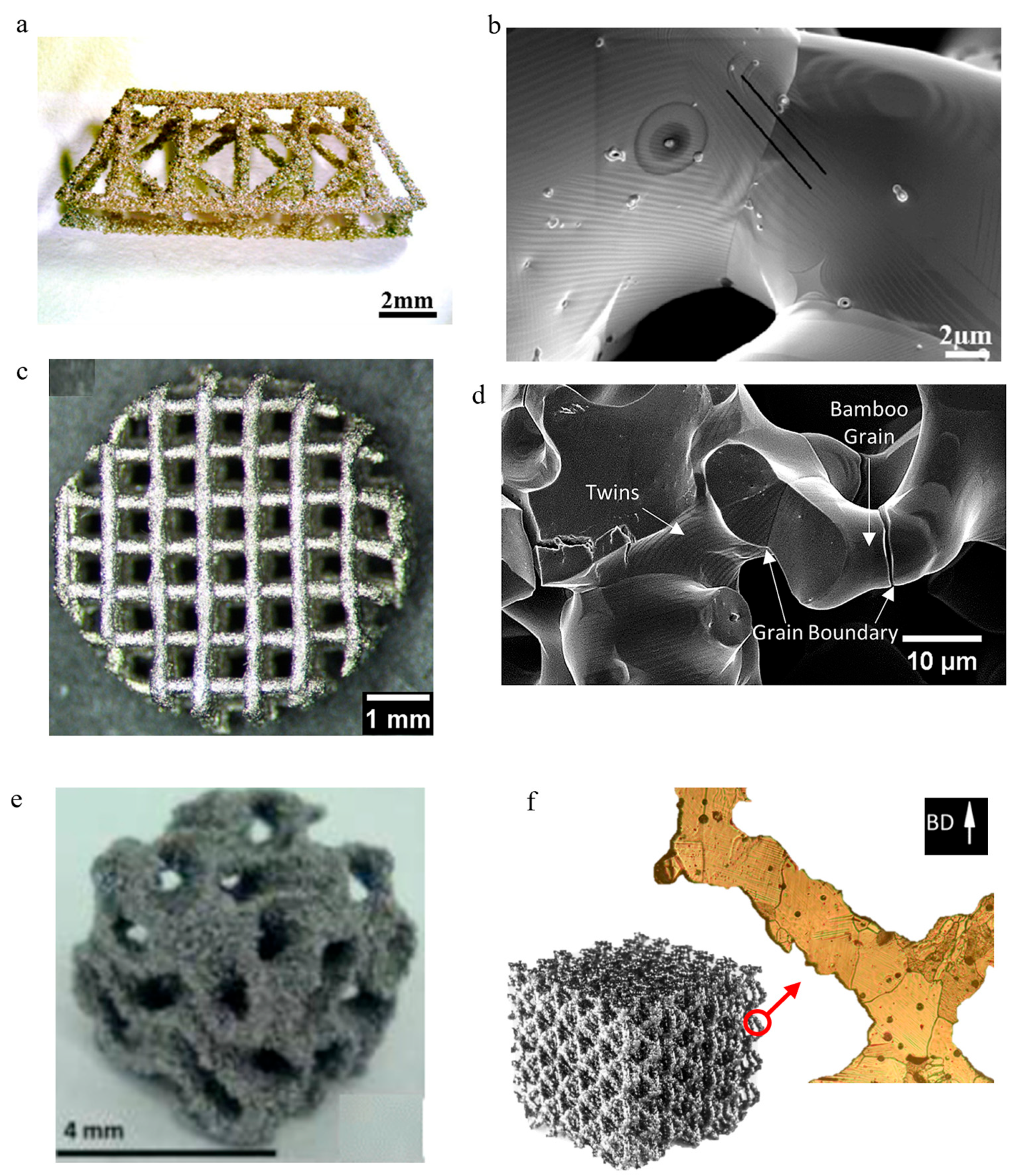

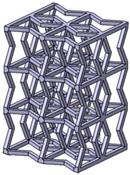

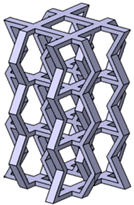

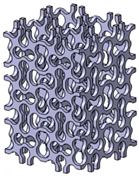

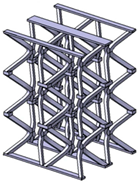

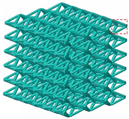

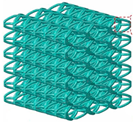

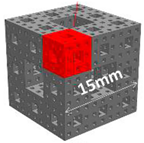

4. Additive Manufacturing of Shape Memory Lattice Structures

4.1. NiTi Lattice Structures

4.2. NiMnGa Lattice Structures

5. Summary and Future Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| BAA | Bionic Arc Angles |

| BJ | Binder Jetting |

| CAD | Computer-Aided Design |

| CFD | Computational Fluid Dynamics |

| CMT | Cold Metal Transfer |

| CsCl | Cesium Chloride |

| DED | Directed Energy Deposition |

| EIGA | Electrode Induction Inert Gas Atomisation |

| FCC | Face Centred Cubic |

| GMAW | Gas Metal Arc Welding |

| GTAW | Gas Tungsten Arc Welding |

| LENS | Laser Engineered Net Shaping |

| LPBF | Laser Powder Bed Fusion |

| MFIS | Magnetic Field-Induced Strain |

| MIR | Magnetically Induced Martensite Reorientation |

| MTTs | Martensitic Transformation Temperatures |

| MVR | Martensite Variant Reorientation |

| NiMnGa | Nickel Manganese Gallium |

| NiTi | Nickel Titanium |

| NM | Non-Modulated |

| NPR | Negative Poisson’s Ratio |

| PBF | Powder Bed Fusion |

| RR | Recovery Ratio |

| SE | Superelasticity |

| SEA | Specific Energy Absorption |

| SEBM | Selective Electron Beam Melting |

| SM | Shape Memory |

| SMAs | Shape Memory Alloys |

| SME | Shape Memory Effect |

| SMS | Shape Memory Strain |

| TPMS | Triply Periodic Minimal Surface |

| TSA | Traditional Sharp Angles |

| TWSM | Two-Way Shape Memory |

| U-GCS | Gyroid Cellular Structures with Uniform Porosity |

| Y-GCS | Gyroid Cellular Structures with Porosity Gradient Along the Build Direction |

| WAAM | Wire-Arc Additive Manufacturing |

| WEBAM | Wire-Feed Electron Beam Additive Manufacturing |

| YS | Yield Strength |

References

- Robertson, S. On the Mechanical Properties and Microstructure of Nitinol for Biomedical Stent Applications; University of California: Berkeley, CA, USA, 2006. [Google Scholar]

- Duerig, T.; Pelton, A.; Stöckel, D. An overview of nitinol medical applications. Mater. Sci. Eng. A 1999, 273–275, 149–160. [Google Scholar] [CrossRef]

- Duerig, T.W.; Tolomeo, D.E.; Wholey, M. An overview of superelastic stent design. Minim. Invasive Ther. Allied Technol. 2000, 9, 235–246. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Qian, M. (Eds.) An Overview on Magnetic Shape Memory Alloys. In Magnetic Shape Memory Alloys: Preparation, Martensitic Transformation and Properties; Springer: Singapore, 2022; pp. 1–33. [Google Scholar]

- Ramezannejad, A.; Xu, W.; Xiao, W.L.; Fox, K.; Liang, D.; Qian, M. New insights into nickel-free superelastic titanium alloys for biomedical applications. Curr. Opin. Solid State Mater. Sci. 2019, 23, 100783. [Google Scholar] [CrossRef]

- Han, D.; Chiu, W.-T.; Tahara, M.; Chernenko, V.; Lanceros-Mendez, S.; Hosoda, H. Coupled magneto-mechanical response of laminate composites comprising a layer of Ni-Mn-Ga microparticles. Acta Mater. 2024, 277, 120158. [Google Scholar] [CrossRef]

- Hatcher, N.; Kontsevoi, O.Y.; Freeman, A.J. Martensitic transformation path of NiTi. Phys. Rev. B 2009, 79, 020202. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Martensitic transformations in nonferrous shape memory alloys. Mater. Sci. Eng. A 1999, 273–275, 89–105. [Google Scholar] [CrossRef]

- Huang, X.; Ackland, G.; Rabe, K. Crystal structures and shape-memory behaviour of NiTi. Nat. Mater. 2003, 2, 307–311. [Google Scholar] [CrossRef]

- Hehemann, R.F.; Sandrock, G.D. Relations between the premartensitic instability and the martensite structure in TiNi. Scr. Metall. 1971, 5, 801–805. [Google Scholar] [CrossRef]

- Michal, G.; Sinclair, R. The structure of TiNi martensite. Acta Crystallogr. Sect. B Struct. Crystallogr. Cryst. Chem. 1981, 37, 1803–1807. [Google Scholar] [CrossRef]

- Wang, F.E.; Pickart, S.J.; Alperin, H.A. Mechanism of the TiNi Martensitic Transformation and the Crystal Structures of TiNi-II and TiNi-III Phases. J. Appl. Phys. 1972, 43, 97–112. [Google Scholar] [CrossRef]

- Prokoshkin, S.D.; Korotitskiy, A.V.; Brailovski, V.; Turenne, S.; Khmelevskaya, I.Y.; Trubitsyna, I.B. On the lattice parameters of phases in binary Ti–Ni shape memory alloys. Acta Mater. 2004, 52, 4479–4492. [Google Scholar] [CrossRef]

- Wiezorek, J.; Fu, C.L.; Takeyama, M.; Morris, D.; Clemens, H. Advanced Intermetallic-Based Alloys; Materials Research Society: Warrendale, PA, USA, 2007; Volume 980. [Google Scholar]

- Donohue, J.; Mills, S.H.; Savitzky, B.H.; Zeltmann, S.E.; Ophus, C.; Minor, A.M. Dynamics and structure of the B2→B19’ phase transformation in NiTi revealed through in situ 4D-STEM. Mater. Sci. Eng. A 2025, 926, 147951. [Google Scholar] [CrossRef]

- Yang, S.; Liu, Y.; Wang, C.; Liu, X. Martensite stabilization and thermal cycling stability of two-phase NiMnGa-based high-temperature shape memory alloys. Acta Mater. 2012, 60, 4255–4267. [Google Scholar] [CrossRef]

- Aaltio, I.; Sozinov, A.; Ge, Y.; Ullakko, K.; Lindroos, V.K.; Hannula, S.-P. Giant Magnetostrictive Materials. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Milleret, A. 4D printing of Ni–Mn–Ga magnetic shape memory alloys: A review. Mater. Sci. Technol. 2022, 38, 593–606. [Google Scholar] [CrossRef]

- Villa, F.; Nespoli, A.; Fanciulli, C.; Passaretti, F.; Villa, E. Physical Characterization of Sintered NiMnGa Ferromagnetic Shape Memory Alloy. Materials 2020, 13, 4806. [Google Scholar] [CrossRef]

- Ituarte, I.F.; Nilsén, F.; Nadimpalli, V.K.; Salmi, M.; Lehtonen, J.; Hannula, S.-P. Towards the additive manufacturing of Ni-Mn-Ga complex devices with magnetic field induced strain. Addit. Manuf. 2022, 49, 102485. [Google Scholar] [CrossRef]

- Yu, Z.; Xin, R.; Xu, Z.; Sha, L.; Chen, L.; Zhu, Y.; Liang, P.; Zhang, Z.; Liu, Z.; Cao, Q. Shock-Resistant and Energy-Absorbing Properties of Bionic NiTi Lattice Structure Manufactured by SLM. J. Bionic Eng. 2022, 19, 1684–1698. [Google Scholar] [CrossRef]

- Saxena, K.K.; Das, R.; Calius, E.P. Three Decades of Auxetics Research—Materials with Negative Poisson’s Ratio: A Review. Adv. Eng. Mater. 2016, 18, 1847–1870. [Google Scholar] [CrossRef]

- Babamiri, B.B.; Barnes, B.; Soltani-Tehrani, A.; Shamsaei, N.; Hazeli, K. Designing additively manufactured lattice structures based on deformation mechanisms. Addit. Manuf. 2021, 46, 102143. [Google Scholar] [CrossRef]

- Caputo, M.; Solomon, C.V. Microstructure and Chemical Composition Analysis of Additive Manufactured Ni-Mn-Ga Parts Sintered in Different Conditions. Microsc. Microanal. 2017, 23, 2078–2079. [Google Scholar] [CrossRef]

- Wang, B.; Li, B.; Yang, Y.; Wang, L.; Su, B.; Dong, F.; Su, Y. Local strain fluctuations enable sluggish martensitic transformation in additively manufactured NiTi alloys with <001> growth texture under tensile loading. J. Mater. Sci. Technol. 2025. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, S.; Shin, Y.C. In-Process monitoring of porosity during laser additive manufacturing process. Addit. Manuf. 2019, 28, 497–505. [Google Scholar] [CrossRef]

- Laitinen, V.; Salminen, A.; Ullakko, K. First investigation on processing parameters for laser powder bed fusion of Ni-Mn-Ga magnetic shape memory alloy. J. Laser Appl. 2019, 31, 022303. [Google Scholar] [CrossRef]

- Elahinia, M.; Shayesteh Moghaddam, N.; Taheri Andani, M.; Amerinatanzi, A.; Bimber, B.A.; Hamilton, R.F. Fabrication of NiTi through additive manufacturing: A review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef]

- Tsuchiya, K. 1—Mechanisms and properties of shape memory effect and superelasticity in alloys and other materials: A practical guide. In Shape Memory and Superelastic Alloys; Yamauchi, K., Ohkata, I., Tsuchiya, K., Miyazaki, S., Eds.; Woodhead Publishing: New Delhi, India, 2011; pp. 3–14. [Google Scholar]

- Elahinia, M.H.; Hashemi, M.; Tabesh, M.; Bhaduri, S.B. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Miyazaki, S.; Kim, H.Y. 2—Basic characteristics of titanium–nickel (Ti–Ni)-based and titanium–niobium (Ti–Nb)-based alloys. In Shape Memory and Superelastic Alloys; Yamauchi, K., Ohkata, I., Tsuchiya, K., Miyazaki, S., Eds.; Woodhead Publishing: New Delhi, India, 2011; pp. 15–42. [Google Scholar]

- Liu, Y.; Liu, Y.; Van Humbeeck, J. Two-way shape memory effect developed by martensite deformation in NiTi. Acta Mater. 1998, 47, 199–209. [Google Scholar] [CrossRef]

- Duerig, T.W.; Melton, K.; Stöckel, D. Engineering Aspects of Shape Memory Alloys; Butterworth-Heinemann: Oxford, UK, 1990. [Google Scholar]

- Perkins, J.; Sponholz, R.O. Stress-Induced Martensitic Transformation Cycling and Two-Way Shape Memory Training in Cu-Zn-Al Alloys. Metall. Trans. A 1984, 15, 313–321. [Google Scholar] [CrossRef]

- Reyhani, M.; McCormick, P. The Japan Inst. of Metals. In Proceedings of the International Conference on Martensitic Transformations ICOMAT 86, Nara, Japan, 26–30 August 1986; p. 896. [Google Scholar]

- Contardo, L.; Guénin, G. Training and two way memory effect in Cu-Zn-Al alloy. Acta Metall. Mater. 1990, 38, 1267–1272. [Google Scholar] [CrossRef]

- Liu, Y.; McCormick, P.G. Factors influencing the development of two-way shape memory in NiTi. Acta Metall. Mater. 1990, 38, 1321–1326. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Z.; Van Humbeeck, J.; Delaey, L. Asymmetry of stress–strain curves under tension and compression for NiTi shape memory alloys. Acta Mater. 1998, 46, 4325–4338. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Humbeeck, J. Lüders-like deformation associated with martensite reorientation in NiTi. Scr. Mater. 1998, 39, 1047–1055. [Google Scholar] [CrossRef]

- Lee, A.Y.; An, J.; Chua, C.K. Two-Way 4D Printing: A Review on the Reversibility of 3D-Printed Shape Memory Materials. Engineering 2017, 3, 663–674. [Google Scholar] [CrossRef]

- Khalil-Allafi, J.; Amin-Ahmadi, B. The effect of chemical composition on enthalpy and entropy changes of martensitic transformations in binary NiTi shape memory alloys. J. Alloys Compd. 2009, 487, 363–366. [Google Scholar] [CrossRef]

- Bahador, A.; Hamzah, E.; Kondoh, K.; Asma Abubakar, T.; Yusof, F.; Umeda, J.; Saud, S.N.; Ibrahim, M.K. Microstructure and superelastic properties of free forged Ti–Ni shape-memory alloy. Trans. Nonferrous Met. Soc. China 2018, 28, 502–514. [Google Scholar] [CrossRef]

- Li, H.; Yuan, B.; Gao, Y.; Chung, C.Y.; Zhu, M. High-porosity NiTi superelastic alloys fabricated by low-pressure sintering using titanium hydride as pore-forming agent. J. Mater. Sci. 2009, 44, 875–881. [Google Scholar] [CrossRef]

- Chu, C.L.; Chung, C.Y.; Lin, P.H.; Wang, S.D. Fabrication of porous NiTi shape memory alloy for hard tissue implants by combustion synthesis. Mater. Sci. Eng. A 2004, 366, 114–119. [Google Scholar] [CrossRef]

- Chu, C.-l.; Chung, J.-C.Y.; Chu, P.-K. Effects of heat treatment on characteristics of porous Ni-rich NiTi SMA prepared by SHS technique. Trans. Nonferrous Met. Soc. China 2006, 16, 49–53. [Google Scholar] [CrossRef]

- Shen, F.L.; Li, H.Q.; Guo, H.; Guo, N.N.; Fang, X.Y. Effect of energy density on the superelastic property of Ni-rich NiTi alloy fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2022, 854, 143874. [Google Scholar] [CrossRef]

- Gan, J.; Duan, L.; Li, F.; Che, Y.; Zhou, Y.; Wen, S.; Yan, C. Effect of laser energy density on the evolution of Ni4Ti3 precipitate and property of NiTi shape memory alloys prepared by selective laser melting. J. Alloys Compd. 2021, 869, 159338. [Google Scholar] [CrossRef]

- Kim, J.I.; Miyazaki, S. Effect of nano-scaled precipitates on shape memory behavior of Ti-50.9at.%Ni alloy. Acta Mater. 2005, 53, 4545–4554. [Google Scholar] [CrossRef]

- Jiang, S.-y.; Zhang, Y.-q.; Zhao, Y.-n.; Liu, S.-w.; Hu, L.; Zhao, C.-z. Influence of Ni4Ti3 precipitates on phase transformation of NiTi shape memory alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 4063–4071. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Radev, D.D. Mechanical synthesis of nanostructured titanium–nickel alloys. Adv. Powder Technol. 2010, 21, 477–482. [Google Scholar] [CrossRef]

- Jiang, M.; Jiang, H.; Xi, R.; Ren, D.; Ji, H.; Lei, J.; Wang, X. Superior superelasticity of laser powder bed fusion fabricated NiTi alloys achieved by post heat treatment. Scr. Mater. 2025, 257, 116476. [Google Scholar] [CrossRef]

- Zhao, C.; Liang, H.; Luo, S.; Yang, J.; Wang, Z. The effect of energy input on reaction, phase transition and shape memory effect of NiTi alloy by selective laser melting. J. Alloys Compd. 2020, 817, 153288. [Google Scholar] [CrossRef]

- Miyazaki, S.; Kimura, S.; Otsuka, K.; Suzuki, Y. The habit plane and transformation strains associated with the martensitic transformation in Ti-Ni single crystals. Scr. Metall. 1984, 18, 883–888. [Google Scholar] [CrossRef]

- Miyazaki, S.; Igo, Y.; Otsuka, K. Effect of thermal cycling on the transformation temperatures of Ti-Ni alloys. Acta Metall. 1986, 34, 2045–2051. [Google Scholar] [CrossRef]

- Miyazaki, S.; Wayman, C.M. The R-phase transition and associated shape memory mechanism in Ti-Ni single crystals. Acta Metall. 1988, 36, 181–192. [Google Scholar] [CrossRef]

- Zheng, P.; Kucza, N.J.; Patrick, C.L.; Müllner, P.; Dunand, D.C. Mechanical and magnetic behavior of oligocrystalline Ni–Mn–Ga microwires. J. Alloys Compd. 2015, 624, 226–233. [Google Scholar] [CrossRef]

- Satapathy, D.K.; Al-Omari, I.A.; Aich, S. Magnetocaloric properties of Ni50Mn28Ga22 melt-spun ribbons. Philos. Mag. Lett. 2022, 102, 1–14. [Google Scholar] [CrossRef]

- Jin, X.; Marioni, M.; Bono, D.; Allen, S.M.; O’Handley, R.C.; Hsu, T.Y. Empirical mapping of Ni-Mn-Ga properties with composition and valence electron concentration. J. Appl. Phys. 2002, 91, 8222–8224. [Google Scholar] [CrossRef]

- Chernenko, V.A. Compositional instability of β-phase in Ni-Mn-Ga alloys. Scr. Mater. 1999, 40, 523–527. [Google Scholar] [CrossRef]

- Pons, J.; Chernenko, V.A.; Santamarta, R.; Cesari, E. Crystal structure of martensitic phases in Ni–Mn–Ga shape memory alloys. Acta Mater. 2000, 48, 3027–3038. [Google Scholar] [CrossRef]

- Webster, P.J. Heusler alloys. Contemp. Phys. 1969, 10, 559–577. [Google Scholar] [CrossRef]

- Nilsén, F.M.C. Processing and Properties of MSM Based Hybrid Materials. Ph.D. Thesis, Aalto University, Espoo, Finland, 2018. [Google Scholar]

- Noda, Y.; Shapiro, S.M.; Shirane, G.; Yamada, Y.; Tanner, L.E. Martensitic transformation of a Ni-Al alloy. I. Experimental results and approximate structure of the seven-layered phase. Phys. Rev. B 1990, 42, 10397–10404. [Google Scholar] [CrossRef]

- Pons, J.; Santamarta, R.; Chernenko, V.A.; Cesari, E. Long-period martensitic structures of Ni-Mn-Ga alloys studied by high-resolution transmission electron microscopy. J. Appl. Phys. 2005, 97, 083516. [Google Scholar] [CrossRef]

- Jiang, C.; Muhammad, Y.; Deng, L.; Wu, W.; Xu, H. Composition dependence on the martensitic structures of the Mn-rich NiMnGa alloys. Acta Mater. 2004, 52, 2779–2785. [Google Scholar] [CrossRef]

- Dai, L.; Cullen, J.; Wuttig, M. Intermartensitic transformation in a NiMnGa alloy. J. Appl. Phys. 2004, 95, 6957–6959. [Google Scholar] [CrossRef]

- Wang, W.H.; Hu, F.X.; Chen, J.L.; Li, Y.X.; Wang, Z.; Gao, Z.Y.; Zheng, Y.F.; Zhao, L.C.; Wu, G.H.; Zan, W.S. Magnetic properties and structural phase transformations of NiMnGa alloys. IEEE Trans. Magn. 2001, 37, 2715–2717. [Google Scholar] [CrossRef]

- Wuttig, M.; Craciunescu, C.; Li, J. Phase Transformations in Ferromagnetic NiMnGa Shape Memory Films. Mater. Trans. JIM 2000, 41, 933–937. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Qin, G.; Zhang, C.; Zhang, S.; Chen, X.; He, Y. Compatibility effect on stress-free two-way memory of Ni-Mn-Ga single crystal. J. Alloys Compd. 2023, 935, 168134. [Google Scholar] [CrossRef]

- Yang, S.; Wang, C.; Shi, Z.; Liu, X. Microstructure, thermomechanical and shape memory properties of two-phase Ni–Mn–Fe–Ga high-temperature shape memory alloys with B addition. Intermetallics 2013, 37, 1–6. [Google Scholar] [CrossRef]

- Yang, S.Y.; Liu, Y.; Wang, C.P.; Shi, Z.; Liu, X.J. The mechanism clarification of Ni–Mn–Fe–Ga alloys with excellent and stable functional properties. J. Alloys Compd. 2013, 560, 84–91. [Google Scholar] [CrossRef]

- Heczko, O.; Straka, L.; Ullakko, K. Relation between structure, magnetization process and magnetic shape memory effect of various martensites occurring in Ni-Mn-Ga alloys. J. Phys. IV Fr. 2003, 112, 959–962. [Google Scholar] [CrossRef]

- Straka, L.; Lanska, N.; Ullakko, K.; Sozinov, A. Twin microstructure dependent mechanical response in Ni–Mn–Ga single crystals. Appl. Phys. Lett. 2010, 96, 131903. [Google Scholar] [CrossRef]

- Tellinen, J.; Suorsa, I.; Jääskeläinen, A.; Aaltio, I.; Ullakko, K. Basic properties of magnetic shape memory actuators. In Proceedings of the 8th International Conference ACTUATOR, Bremen, Germany, 10–12 June 2002; pp. 10–12. [Google Scholar]

- Chmielus, M.; Chernenko, V.A.; Knowlton, W.B.; Kostorz, G.; Müllner, P. Training, constraints, and high-cycle magneto-mechanical properties of Ni-Mn-Ga magnetic shape-memory alloys. Eur. Phys. J. Spec. Top. 2008, 158, 79–85. [Google Scholar] [CrossRef]

- Aaltio, I.; Soroka, A.; Ge, Y.; Söderberg, O.; Hannula, S.P. High-cycle fatigue of 10M Ni–Mn–Ga magnetic shape memory alloy in reversed mechanical loading. Smart Mater. Struct. 2010, 19, 075014. [Google Scholar] [CrossRef]

- Omotosho, E.; Qin, Z.; Birkett, M.; Chen, X.; Xu, B.B. Thermo-magnetic loading effects on high-frequency dynamic behaviour of magnetic shape memory alloys. Eur. J. Mech. A/Solids 2022, 96, 104725. [Google Scholar] [CrossRef]

- Chernenko, V.A.; L’Vov, V.A.; Cesari, E.; Barandiaran, J.M. Chapter 1—Fundamentals of magnetocaloric effect in magnetic shape memory alloys. In Handbook of Magnetic Materials; Brück, E., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 28, pp. 1–45. [Google Scholar]

- Laitinen, V.; Sozinov, A.; Saren, A.; Chmielus, M.; Ullakko, K. Characterization of as-built and heat-treated Ni-Mn-Ga magnetic shape memory alloy manufactured via laser powder bed fusion. Addit. Manuf. 2021, 39, 101854. [Google Scholar] [CrossRef]

- Musiienko, D.; Straka, L.; Klimša, L.; Saren, A.; Sozinov, A.; Heczko, O.; Ullakko, K. Giant magnetic-field-induced strain in Ni-Mn-Ga micropillars. Scr. Mater. 2018, 150, 173–176. [Google Scholar] [CrossRef]

- Musiienko, D.; Saren, A.; Straka, L.; Vronka, M.; Kopeček, J.; Heczko, O.; Sozinov, A.; Ullakko, K. Ultrafast actuation of Ni-Mn-Ga micropillars by pulsed magnetic field. Scr. Mater. 2019, 162, 482–485. [Google Scholar] [CrossRef]

- Hobza, A.; Patrick, C.L.; Ullakko, K.; Rafla, N.; Lindquist, P.; Müllner, P. Sensing strain with Ni-Mn-Ga. Sens. Actuators A Phys. 2018, 269, 137–144. [Google Scholar] [CrossRef]

- Saren, A.; Musiienko, D.; Smith, A.R.; Tellinen, J.; Ullakko, K. Modeling and design of a vibration energy harvester using the magnetic shape memory effect. Smart Mater. Struct. 2015, 24, 095002. [Google Scholar] [CrossRef]

- Lindquist, P.; Hobza, T.; Patrick, C.; Müllner, P. Efficiency of Energy Harvesting in Ni–Mn–Ga Shape Memory Alloys. Shape Mem. Superelasticity 2018, 4, 93–101. [Google Scholar] [CrossRef]

- Ullakko, K.; Wendell, L.; Smith, A.; Müllner, P.; Hampikian, G. A magnetic shape memory micropump: Contact-free, and compatible with PCR and human DNA profiling. Smart Mater. Struct. 2012, 21, 115020. [Google Scholar] [CrossRef]

- Smith, A.R.; Saren, A.; Järvinen, J.; Ullakko, K. Characterization of a high-resolution solid-state micropump that can be integrated into microfluidic systems. Microfluid. Nanofluidics 2015, 18, 1255–1263. [Google Scholar] [CrossRef]

- Barker, S.; Rhoads, E.; Lindquist, P.; Vreugdenhil, M.; Müllner, P. Magnetic Shape Memory Micropump for Submicroliter Intracranial Drug Delivery in Rats. J. Med. Devices 2016, 10, 041009. [Google Scholar] [CrossRef]

- Saren, A.; Smith, A.R.; Ullakko, K. Integratable magnetic shape memory micropump for high-pressure, precision microfluidic applications. Microfluid. Nanofluidics 2018, 22, 38. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Besseghini, S. Ferromagnetic shape memory alloys: Scientific and applied aspects. Sens. Actuators A Phys. 2008, 142, 542–548. [Google Scholar] [CrossRef]

- Karaca, H.E.; Karaman, I.; Basaran, B.; Lagoudas, D.C.; Chumlyakov, Y.I.; Maier, H.J. On the stress-assisted magnetic-field-induced phase transformation in Ni2MnGa ferromagnetic shape memory alloys. Acta Mater. 2007, 55, 4253–4269. [Google Scholar] [CrossRef]

- Jeong, S.; Inoue, K.; Inoue, S.; Koterazawa, K.; Taya, M.; Inoue, K. Effect of magnetic field on martensite transformation in a polycrystalline Ni2MnGa. Mater. Sci. Eng. A 2003, 359, 253–260. [Google Scholar] [CrossRef]

- Vronka, M.; Straka, L.; De Graef, M.; Heczko, O. Antiphase boundaries, magnetic domains, and magnetic vortices in Ni–Mn–Ga single crystals. Acta Mater. 2020, 184, 179–186. [Google Scholar] [CrossRef]

- Okamoto, N.; Fukuda, T.; Kakeshita, T. Magnetocrystalline anisotropy and twinning stress in Ni-Mn-Ga ferromagnetic shape memory alloys. J. Phys. Conf. Ser. 2006, 51, 315. [Google Scholar] [CrossRef]

- Webster, P.J.; Ziebeck, K.R.A.; Town, S.L.; Peak, M.S. Magnetic order and phase transformation in Ni2MnGa. Philos. Mag. B 1984, 49, 295–310. [Google Scholar] [CrossRef]

- Bruno, N.M.; Ciocanel, C.; Feigenbaum, H.P.; Waldauer, A. A theoretical and experimental investigation of power harvesting using the NiMnGa martensite reorientation mechanism. Smart Mater. Struct. 2012, 21, 094018. [Google Scholar] [CrossRef]

- Karaman, I.; Basaran, B.; Karaca, H.E.; Karsilayan, A.I.; Chumlyakov, Y.I. Energy harvesting using martensite variant reorientation mechanism in a NiMnGa magnetic shape memory alloy. Appl. Phys. Lett. 2007, 90, 172505. [Google Scholar] [CrossRef]

- Soroka, A.; Sozinov, A.; Lanska, N.; Rameš, M.; Straka, L.; Ullakko, K. Composition and temperature dependence of twinning stress in non-modulated martensite of Ni-Mn-Ga-Co-Cu magnetic shape memory alloys. Scr. Mater. 2018, 144, 52–55. [Google Scholar] [CrossRef]

- Müllner, P.; Chernenko, V.A.; Kostorz, G. Large cyclic magnetic-field-induced deformation in orthorhombic (14M) Ni–Mn–Ga martensite. J. Appl. Phys. 2004, 95, 1531–1536. [Google Scholar] [CrossRef]

- Sozinov, A.; Likhachev, A.A.; Lanska, N.; Ullakko, K. Giant magnetic-field-induced strain in NiMnGa seven-layered martensitic phase. Appl. Phys. Lett. 2002, 80, 1746–1748. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Chmielus, M.; Müllner, P. Large magnetic-field-induced strains in Ni–Mn–Ga nonmodulated martensite. Appl. Phys. Lett. 2009, 95, 104103. [Google Scholar] [CrossRef]

- Sozinov, A.; Lanska, N.; Soroka, A.; Straka, L. Highly mobile type II twin boundary in Ni-Mn-Ga five-layered martensite. Appl. Phys. Lett. 2011, 99, 124103. [Google Scholar] [CrossRef]

- Straka, L.; Heczko, O.; Seiner, H.; Lanska, N.; Drahokoupil, J.; Soroka, A.; Fähler, S.; Hänninen, H.; Sozinov, A. Highly mobile twinned interface in 10M modulated Ni–Mn–Ga martensite: Analysis beyond the tetragonal approximation of lattice. Acta Mater. 2011, 59, 7450–7463. [Google Scholar] [CrossRef]

- Acet, M.; Mañosa, L.; Planes, A. Chapter Four—Magnetic-Field-Induced Effects in Martensitic Heusler-Based Magnetic Shape Memory Alloys. In Handbook of Magnetic Materials; Buschow, K.H.J., Ed.; Elsevier: Amsterdam, The Netherlands, 2011; Volume 19, pp. 231–289. [Google Scholar]

- Ullakko, K.; Huang, J.K.; Kantner, C.; O’Handley, R.C.; Kokorin, V.V. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966–1968. [Google Scholar] [CrossRef]

- Sozinov, A.; Likhachev, A.; Lanska, N.; Ullakko, K.; Lindroos, V. 10% magnetic-field-induced strain in Ni-Mn-Ga seven-layered martensite. In Proceedings of the Journal de Physique IV (Proceedings), Porto, Portugal, 8–10 September 2003; pp. 955–958. [Google Scholar]

- Pagounis, E.; Chulist, R.; Szczerba, M.J.; Laufenberg, M. Over 7% magnetic field-induced strain in a Ni-Mn-Ga five-layered martensite. Appl. Phys. Lett. 2014, 105, 052405. [Google Scholar] [CrossRef]

- Sozinov, A.; Lanska, N.; Soroka, A.; Zou, W. 12% magnetic field-induced strain in Ni-Mn-Ga-based non-modulated martensite. Appl. Phys. Lett. 2013, 102, 021902. [Google Scholar] [CrossRef]

- Alexander Anatolyevich, L.; Alexei, S.; Kari, U. Influence of external stress on the reversibility of magnetic-field-controlled shape memory effect in Ni-Mn-Ga. In Smart Structures and Materials 2001: Active Materials: Behavior and Mechanics; SPIE: San Francisco, CA, USA, 2001; pp. 197–206. [Google Scholar]

- Likhachev, A.A.; Ullakko, K. Magnetic-field-controlled twin boundaries motion and giant magneto-mechanical effects in Ni–Mn–Ga shape memory alloy. Phys. Lett. A 2000, 275, 142–151. [Google Scholar] [CrossRef]

- Chiu, W.-T.; Goto, A.; Tahara, M.; Inamura, T.; Hosoda, H. Investigation of the martensite variant reorientation of the single crystal Ni-Mn-Ga alloy via training processes and a modification with a silicone rubber. Mater. Chem. Phys. 2023, 297, 127390. [Google Scholar] [CrossRef]

- Chmielus, M.; Zhang, X.X.; Witherspoon, C.; Dunand, D.C.; Müllner, P. Giant magnetic-field-induced strains in polycrystalline Ni–Mn–Ga foams. Nat. Mater. 2009, 8, 863–866. [Google Scholar] [CrossRef]

- Dunand, D.C.; Müllner, P. Size Effects on Magnetic Actuation in Ni-Mn-Ga Shape-Memory Alloys. Adv. Mater. 2011, 23, 216–232. [Google Scholar] [CrossRef]

- Ullakko, K.; Ezer, Y.; Sozinov, A.; Kimmel, G.; Yakovenko, P.; Lindroos, V.K. Magnetic-field-induced strains in polycrystalline Ni-Mn-Ga at room temperature. Scr. Mater. 2001, 44, 475–480. [Google Scholar] [CrossRef]

- Zheng, D.; Li, R.-d.; Yuan, T.-c.; Xiong, Y.; Song, B.; Wang, J.-x.; Su, Y.-d. Microstructure and mechanical property of additively manufactured NiTi alloys: A comparison between selective laser melting and directed energy deposition. J. Cent. South Univ. 2021, 28, 1028–1042. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Kruth, J.-P.; Van Humbeeck, J. Influence of SLM on shape memory and compression behaviour of NiTi scaffolds. CIRP Ann. 2015, 64, 209–212. [Google Scholar] [CrossRef]

- Haberland, C.; Elahinia, M.; Walker, J.M.; Meier, H.; Frenzel, J. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater. Struct. 2014, 23, 104002. [Google Scholar] [CrossRef]

- Haberland, C.; Elahinia, M.; Walker, J.; Meier, H. Visions, Concepts and Strategies for Smart Nitinol Actuators and Complex Nitinol Structures Produced by Additive Manufacturing. In Smart Materials, Adaptive Structures and Intelligent Systems; American Society of Mechanical Engineers: New York, NY, USA, 2013. [Google Scholar]

- Yang, X.; Ren, Y.-j.; Liu, S.-f.; Wang, Q.-j.; Shi, M.-j. Microstructure and tensile property of SLM 316L stainless steel manufactured with fine and coarse powder mixtures. J. Cent. South Univ. 2020, 27, 334–343. [Google Scholar] [CrossRef]

- Taheri Andani, M.; Saedi, S.; Turabi, A.S.; Karamooz, M.R.; Haberland, C.; Karaca, H.E.; Elahinia, M. Mechanical and shape memory properties of porous Ni50.1Ti49.9 alloys manufactured by selective laser melting. J. Mech. Behav. Biomed. Mater. 2017, 68, 224–231. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Additive Manufacturing of Shape Memory Alloys. Shape Mem. Superelasticity 2018, 4, 309–312. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y. Laser powder bed fusion for metal additive manufacturing: Perspectives on recent developments. Virtual Phys. Prototyp. 2020, 15, 359–370. [Google Scholar] [CrossRef]

- Jang, T.-S.; Kim, D.; Han, G.; Yoon, C.-B.; Jung, H.-D. Powder based additive manufacturing for biomedical application of titanium and its alloys: A review. Biomed. Eng. Lett. 2020, 10, 505–516. [Google Scholar] [CrossRef]

- Kubášová, K.; Drátovská, V.; Losertová, M.; Salvetr, P.; Kopelent, M.; Kořínek, F.; Havlas, V.; Džugan, J.; Daniel, M. A Review on Additive Manufacturing Methods for NiTi Shape Memory Alloy Production. Materials 2024, 17, 1248. [Google Scholar] [CrossRef]

- Bram, M.; Ahmad-Khanlou, A.; Heckmann, A.; Fuchs, B.; Buchkremer, H.P.; Stöver, D. Powder metallurgical fabrication processes for NiTi shape memory alloy parts. Mater. Sci. Eng. A 2002, 337, 254–263. [Google Scholar] [CrossRef]

- Otubo, J.; Rigo, O.D.; Coelho, A.A.; Neto, C.M.; Mei, P.R. The influence of carbon and oxygen content on the martensitic transformation temperatures and enthalpies of NiTi shape memory alloy. Mater. Sci. Eng. A 2008, 481–482, 639–642. [Google Scholar] [CrossRef]

- Rahim, M.; Frenzel, J.; Frotscher, M.; Pfetzing-Micklich, J.; Steegmüller, R.; Wohlschlögel, M.; Mughrabi, H.; Eggeler, G. Impurity levels and fatigue lives of pseudoelastic NiTi shape memory alloys. Acta Mater. 2013, 61, 3667–3686. [Google Scholar] [CrossRef]

- Elahinia, M.H. Shape Memory Alloy Actuators: Design, Fabrication, and Experimental Evaluation; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Bram, M.; Bitzer, M.; Buchkremer, H.P.; Stöver, D. Reproducibility Study of NiTi Parts Made by Metal Injection Molding. J. Mater. Eng. Perform. 2012, 21, 2701–2712. [Google Scholar] [CrossRef]

- Haberland, C.; Elahinia, M.; Walker, J.; Meier, H.; Frenzel, J. Additive Manufacturing of Shape Memory Devices and Pseudoelastic Components. In Smart Materials, Adaptive Structures and Intelligent Systems; American Society of Mechanical Engineers: New York, NY, USA, 2013. [Google Scholar]

- Haberland, C. Additive Verarbeitung von NiTi-Formgedächtniswerkstoffen Mittels Selective-Laser-Melting; Shaker: Düren, Germany, 2012. [Google Scholar]

- Farber, E.; Zhu, J.-N.; Popovich, A.; Popovich, V. A review of NiTi shape memory alloy as a smart material produced by additive manufacturing. Mater. Today Proc. 2020, 30, 761–767. [Google Scholar] [CrossRef]

- Saedi, S.; Turabi, A.S.; Andani, M.T.; Haberland, C.; Elahinia, M.; Karaca, H. Thermomechanical characterization of Ni-rich NiTi fabricated by selective laser melting. Smart Mater. Struct. 2016, 25, 035005. [Google Scholar] [CrossRef]

- Bormann, T.; Schumacher, R.; Müller, B.; Mertmann, M.; de Wild, M. Tailoring Selective Laser Melting Process Parameters for NiTi Implants. J. Mater. Eng. Perform. 2012, 21, 2519–2524. [Google Scholar] [CrossRef]

- Saedi, S.; Shayesteh Moghaddam, N.; Amerinatanzi, A.; Elahinia, M.; Karaca, H.E. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi. Acta Mater. 2018, 144, 552–560. [Google Scholar] [CrossRef]

- Sequeda Leon, E.M.; Singamneni, S.; Guraya, T.; Chen, Z.W. Effect of laser power in laser powder bed fusion on Ni content and structure of Nitinol. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Khademzadeh, S. Precision additive manufacturing of NiTi shape memory parts using micro-laser powder bed fusion. Prog. Addit. Manuf. 2022, 7, 419–432. [Google Scholar] [CrossRef]

- Wang, X.; Yu, J.; Liu, J.; Chen, L.; Yang, Q.; Wei, H.; Sun, J.; Wang, Z.; Zhang, Z.; Zhao, G.; et al. Effect of process parameters on the phase transformation behavior and tensile properties of NiTi shape memory alloys fabricated by selective laser melting. Addit. Manuf. 2020, 36, 101545. [Google Scholar] [CrossRef]

- Saedi, S.; Turabi, A.S.; Andani, M.T.; Moghaddam, N.S.; Elahinia, M.; Karaca, H.E. Texture, aging, and superelasticity of selective laser melting fabricated Ni-rich NiTi alloys. Mater. Sci. Eng. A 2017, 686, 1–10. [Google Scholar] [CrossRef]

- Cai, W.S.; Luo, Y.; Yan, A.; Kang, L.M.; Zhang, L.C.; Suryanarayana, C.; Yang, C. Balanced strength-ductility combination and good recoverable strain of Ni50.7Ti49.3 alloy fabricated by high scanning velocity in selective laser melting. Mater. Charact. 2023, 195, 112490. [Google Scholar] [CrossRef]

- Chekotu, J.C.; Degli-Alessandrini, G.; Mughal, M.Z.; Chatterjee, S.; Goodall, R.; Kinahan, D.; Brabazon, D. Control of mechanical and shape memory characteristics in martensitic NiTi by setting L-PBF parameters and build orientation. J. Mater. Res. Technol. 2023, 25, 6407–6431. [Google Scholar] [CrossRef]

- Zhan, J.; Wu, J.; Ma, R.; Li, K.; Huang, T.; Lin, J.; Murr, L.E. Effect of microstructure on the superelasticity of high-relative-density Ni-rich NiTi alloys fabricated by laser powder bed fusion. J. Mater. Process. Technol. 2023, 317, 117988. [Google Scholar] [CrossRef]

- Ehsan Saghaian, S.; Nematollahi, M.; Toker, G.; Hinojos, A.; Shayesteh Moghaddam, N.; Saedi, S.; Lu, C.Y.; Javad Mahtabi, M.; Mills, M.J.; Elahinia, M.; et al. Effect of hatch spacing and laser power on microstructure, texture, and thermomechanical properties of laser powder bed fusion (L-PBF) additively manufactured NiTi. Opt. Laser Technol. 2022, 149, 107680. [Google Scholar] [CrossRef]

- Zhang, C.; Ozcan, H.; Xue, L.; Atli, K.C.; Arróyave, R.; Karaman, I.; Elwany, A. On the effect of scan strategies on the transformation behavior and mechanical properties of additively manufactured NiTi shape memory alloys. J. Manuf. Process. 2022, 84, 260–271. [Google Scholar] [CrossRef]

- Hou, M.; Gu, Q.; Yang, Z.; Zhang, Y.; Liu, X.; Zhang, Y.; Yang, J.; Lin, X.; Li, H. Enhancing shape memory properties of 3D-printed NiTi alloys by laser powder bed fusion through microstructural control. J. Alloys Compd. 2025, 1010, 178029. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, X.; Xi, R.; Li, G.; Wei, H.; Liu, J.; Zhang, B.; Kustov, S.; Vanmeensel, K.; Van Humbeeck, J.; et al. Size effect on the microstructure, phase transformation behavior, and mechanical properties of NiTi shape memory alloys fabricated by laser powder bed fusion. J. Mater. Sci. Technol. 2023, 157, 200–212. [Google Scholar] [CrossRef]

- Salvetr, P.; Vavřík, J.; Školáková, A.; Novák, P. Formation of intermetallics layers in Ni-Ti system prepared by direct energy deposition. Manuf. Technol. 2019, 19, 674–679. [Google Scholar] [CrossRef]

- Ma, J.; Franco, B.; Tapia, G.; Karayagiz, K.; Johnson, L.; Liu, J.; Arroyave, R.; Karaman, I.; Elwany, A. Spatial Control of Functional Response in 4D-Printed Active Metallic Structures. Sci. Rep. 2017, 7, 46707. [Google Scholar] [CrossRef]

- Duerig, T.; Pelton, A.; Trepanier, C. Nitinol—PART I Mechanisms and Behavior. In SMST e-Elastic Newsletter; ASM International: Almere, The Netherlands, 2011. [Google Scholar]

- Marattukalam, J.J.; Balla, V.K.; Das, M.; Bontha, S.; Kalpathy, S.K. Effect of heat treatment on microstructure, corrosion, and shape memory characteristics of laser deposited NiTi alloy. J. Alloys Compd. 2018, 744, 337–346. [Google Scholar] [CrossRef]

- Zhang, D.; Li, Y.; Wang, H.; Cong, W. Laser Engineered Net Shaping In-Situ Synthesis of NiTi Alloy: Effects of Processing Parameters. In Proceedings of the ASME 2020 15th International Manufacturing Science and Engineering Conference, Virtual, 3 September 2020. [Google Scholar]

- Niu, P.; Li, R.; Zhu, S.; Wang, M.; Chen, C.; Yuan, T. Hot cracking, crystal orientation and compressive strength of an equimolar CoCrFeMnNi high-entropy alloy printed by selective laser melting. Opt. Laser Technol. 2020, 127, 106147. [Google Scholar] [CrossRef]

- Hamilton, R.F.; Bimber, B.A.; Taheri Andani, M.; Elahinia, M. Multi-scale shape memory effect recovery in NiTi alloys additive manufactured by selective laser melting and laser directed energy deposition. J. Mater. Process. Technol. 2017, 250, 55–64. [Google Scholar] [CrossRef]

- Hamilton, R.F.; Palmer, T.A.; Bimber, B.A. Spatial characterization of the thermal-induced phase transformation throughout as-deposited additive manufactured NiTi bulk builds. Scr. Mater. 2015, 101, 56–59. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Rogal, Ł.; Kalita, D.; Węglowski, M.; Błacha, S.; Berent, K.; Czeppe, T.; Antolak-Dudka, A.; Durejko, T.; Czujko, T. Superelastic Effect in NiTi Alloys Manufactured Using Electron Beam and Focused Laser Rapid Manufacturing Methods. J. Mater. Eng. Perform. 2020, 29, 4463–4473. [Google Scholar] [CrossRef]

- Honma, T. The Effect of Aging on the Spontaneous Shape Change and the All-Round Shape Memory Effect in Ni--Rich TiNi Alloy. In Proceedings of the International Conference on Martensitic Transformations, ICOMAT-86, Nara, Japan, 26–30 August 1986; pp. 709–716. [Google Scholar]

- Wang, X.; Kustov, S.; Van Humbeeck, J. A Short Review on the Microstructure, Transformation Behavior and Functional Properties of NiTi Shape Memory Alloys Fabricated by Selective Laser Melting. Materials 2018, 11, 1683. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Kruth, J.-P.; Schrooten, J.; Luyten, J.; Van Humbeeck, J. Effect of SLM Parameters on Transformation Temperatures of Shape Memory Nickel Titanium Parts. Adv. Eng. Mater. 2014, 16, 1140–1146. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Rogal, L.; Kalita, D.; Berent, K.; Kawałko, J.; Antolak-Dudka, A.; Durejko, T.; Czujko, T.; Cesari, E. Microstructure and Mechanical Properties of LENS Manufactured NiTi Shape Memory Alloy After Ageing and During In-Situ SEM Tensile Test. J. Mate Sci. Met. 2021, 2, 104. [Google Scholar]

- Feng, Y.; Liu, B.; Wan, X.; Liu, Q.; Lin, X.; Wang, P. Influence of processing parameter on phase transformation and superelastic recovery strain of laser solid forming NiTi alloy. J. Alloys Compd. 2022, 908, 164568. [Google Scholar] [CrossRef]

- Xiang, R.; Huang, J.; Yu, X.; Zhao, H.; Song, X.; Fan, D. The effect of Ni/Ti atomic ratios on residual stress and deformation in WAAM of dissimilar filler wire NiTi alloys. J. Mater. Res. Technol. 2025, 35, 1813–1828. [Google Scholar] [CrossRef]

- Ke, W.C.; Oliveira, J.P.; Cong, B.Q.; Ao, S.S.; Qi, Z.W.; Peng, B.; Zeng, Z. Multi-layer deposition mechanism in ultra high-frequency pulsed wire arc additive manufacturing (WAAM) of NiTi shape memory alloys. Addit. Manuf. 2022, 50, 102513. [Google Scholar] [CrossRef]

- Resnina, N.; Palani, I.A.; Belyaev, S.; Prabu, S.S.M.; Liulchak, P.; Karaseva, U.; Manikandan, M.; Jayachandran, S.; Bryukhanova, V.; Sahu, A.; et al. Structure, martensitic transformations and mechanical behaviour of NiTi shape memory alloy produced by wire arc additive manufacturing. J. Alloys Compd. 2021, 851, 156851. [Google Scholar] [CrossRef]

- Yu, L.; Chen, K.; Zhang, Y.; Liu, J.; Yang, L.; Shi, Y. Microstructures and mechanical properties of NiTi shape memory alloys fabricated by wire arc additive manufacturing. J. Alloys Compd. 2022, 892, 162193. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Yang, G.; Han, J.; Chen, X.; Li, H. Location dependence of microstructure, phase transformation temperature and mechanical properties on Ni-rich NiTi alloy fabricated by wire arc additive manufacturing. Mater. Sci. Eng. A 2019, 749, 218–222. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Carpenter, K.; Han, J.; Wang, Z.; Li, H. Comparative study on crystallographic orientation, precipitation, phase transformation and mechanical response of Ni-rich NiTi alloy fabricated by WAAM at elevated substrate heating temperatures. Mater. Sci. Eng. A 2021, 800, 140307. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Wang, Y.; Wang, L.; Su, L.; Cuiuri, D.; Zhao, Y.; Li, H. Evolution of crystallographic orientation, precipitation, phase transformation and mechanical properties realized by enhancing deposition current for dual-wire arc additive manufactured Ni-rich NiTi alloy. Addit. Manuf. 2020, 34, 101240. [Google Scholar] [CrossRef]

- Zeng, Z.; Cong, B.Q.; Oliveira, J.P.; Ke, W.C.; Schell, N.; Peng, B.; Qi, Z.W.; Ge, F.G.; Zhang, W.; Ao, S.S. Wire and arc additive manufacturing of a Ni-rich NiTi shape memory alloy: Microstructure and mechanical properties. Addit. Manuf. 2020, 32, 101051. [Google Scholar] [CrossRef]

- Jia, Z.; Wan, X.; Guo, D. Study on microstructure and mechanical properties of Inconel718 components fabricated by UHFP-GTAW technology. Mater. Lett. 2020, 261, 127006. [Google Scholar] [CrossRef]

- Li, L.; Yang, M.; Qi, B.; Liu, H. Study of high frequency pulsed arc on molten pool thermal properties of Ti-6Al-4V. J. Manuf. Process. 2019, 38, 308–312. [Google Scholar] [CrossRef]

- Yang, Z.; Qi, B.; Cong, B.; Liu, F.; Yang, M. Microstructure, tensile properties of Ti-6Al-4V by ultra high pulse frequency GTAW with low duty cycle. J. Mater. Process. Technol. 2015, 216, 37–47. [Google Scholar] [CrossRef]

- Paul, S.; Liu, J.; Strayer, S.T.; Zhao, Y.; Sridar, S.; Klecka, M.A.; Xiong, W.; To, A.C. A Discrete Dendrite Dynamics Model for Epitaxial Columnar Grain Growth in Metal Additive Manufacturing with Application to Inconel. Addit. Manuf. 2020, 36, 101611. [Google Scholar] [CrossRef]

- Bai, X.; Colegrove, P.; Ding, J.; Zhou, X.; Diao, C.; Bridgeman, P.; roman Hönnige, J.; Zhang, H.; Williams, S. Numerical analysis of heat transfer and fluid flow in multilayer deposition of PAW-based wire and arc additive manufacturing. Int. J. Heat Mass Transf. 2018, 124, 504–516. [Google Scholar] [CrossRef]

- Taylor, S.L.; Shah, R.N.; Dunand, D.C. Microstructure and porosity evolution during sintering of Ni-Mn-Ga wires printed from inks containing elemental powders. Intermetallics 2019, 104, 113–123. [Google Scholar] [CrossRef]

- Caputo, M.; Solomon, C.V.; Nguyen, P.-K.; Berkowitz, A.E. Electron Microscopy Investigation of Binder Saturation and Microstructural Defects in Functional Parts Made by Additive Manufacturing. Microsc. Microanal. 2016, 22, 1770–1771. [Google Scholar] [CrossRef]

- Mostafaei, A.; Kimes, K.A.; Stevens, E.L.; Toman, J.; Krimer, Y.L.; Ullakko, K.; Chmielus, M. Microstructural evolution and magnetic properties of binder jet additive manufactured Ni-Mn-Ga magnetic shape memory alloy foam. Acta Mater. 2017, 131, 482–490. [Google Scholar] [CrossRef]

- Caputo, M.P.; Solomon, C.V. A facile method for producing porous parts with complex geometries from ferromagnetic Ni-Mn-Ga shape memory alloys. Mater. Lett. 2017, 200, 87–89. [Google Scholar] [CrossRef]

- Caputo, M.P.; Berkowitz, A.E.; Armstrong, A.; Müllner, P.; Solomon, C.V. 4D printing of net shape parts made from Ni-Mn-Ga magnetic shape-memory alloys. Addit. Manuf. 2018, 21, 579–588. [Google Scholar] [CrossRef]

- Caputo, M.P.; Waryoba, D.R.; Solomon, C.V. Sintering effects on additive manufactured Ni–Mn–Ga shape memory alloys: A microstructure and thermal analysis. J. Mater. Sci. 2020, 55, 5311–5321. [Google Scholar] [CrossRef]

- Mostafaei, A.; Rodriguez De Vecchis, P.; Stevens, E.L.; Chmielus, M. Sintering regimes and resulting microstructure and properties of binder jet 3D printed Ni-Mn-Ga magnetic shape memory alloys. Acta Mater. 2018, 154, 355–364. [Google Scholar] [CrossRef]

- Ullakko, K.; Laitinen, V.; Saren, A.; Sozinov, A.; Musiienko, D.; Chmielus, M.; Salminen, A. Ni-Mn-Ga actuating elements manufactured using 3D printing. In Proceedings of the 11th European Symposium on Martensitic Transformations, Metz, France, 27–31 August 2018; pp. 27–31. [Google Scholar]

- Laitinen, V.; Sozinov, A.; Saren, A.; Salminen, A.; Ullakko, K. Laser powder bed fusion of Ni-Mn-Ga magnetic shape memory alloy. Addit. Manuf. 2019, 30, 100891. [Google Scholar] [CrossRef]

- Nilsén, F.; Ituarte, I.F.; Salmi, M.; Partanen, J.; Hannula, S.-P. Effect of process parameters on non-modulated Ni-Mn-Ga alloy manufactured using powder bed fusion. Addit. Manuf. 2019, 28, 464–474. [Google Scholar] [CrossRef]

- Taylor, S.L.; Shah, R.N.; Dunand, D.C. Ni-Mn-Ga micro-trusses via sintering of 3D-printed inks containing elemental powders. Acta Mater. 2018, 143, 20–29. [Google Scholar] [CrossRef]

- Toman, J.; Müllner, P.; Chmielus, M. Properties of as-deposited and heat-treated Ni-Mn-Ga magnetic shape memory alloy processed by directed energy deposition. J. Alloys Compd. 2018, 752, 455–463. [Google Scholar] [CrossRef]

- Laitinen, V.; Saren, A.; Sozinov, A.; Ullakko, K. Giant 5.8% magnetic-field-induced strain in additive manufactured Ni-Mn-Ga magnetic shape memory alloy. Scr. Mater. 2022, 208, 114324. [Google Scholar] [CrossRef]

- Milleret, A.; Laitinen, V.; Ullakko, K.; Fenineche, N.; Attallah, M.M. Laser powder bed fusion of (14 M) Ni-Mn-Ga magnetic shape memory alloy lattices. Addit. Manuf. 2022, 60, 103231. [Google Scholar] [CrossRef]

- Wójcik, A.; Chulist, R.; Szewczyk, A.; Morończyk, B.; Żrodowski, Ł.; Wróblewski, R.; Kowalczyk, M.; Kolano-Burian, A.; Zackiewicz, P.; Schell, N.; et al. Microstructure and texture control of Ni-Mn-Ga magnetic shape memory alloys manufactured by laser powder bed fusion. Addit. Manuf. 2024, 86, 104225. [Google Scholar] [CrossRef]

- Norouzi-Inallu, M.; Laitinen, V.; Vinogradova, M.; Kumthekar, A.; Ullakko, K. Solidification of Ni-Mn-Ga magnetic shape memory alloy built via laser powder bed fusion on a single crystal substrate. J. Alloys Compd. 2024, 998, 174907. [Google Scholar] [CrossRef]

- Milleret, A.; Laitinen, V.; Ullakko, K.; Fenineche, N.; Attallah, M.M. In-situ alloying laser powder bed fusion of Ni-Mn-Ga magnetic shape memory alloy using liquid Ga. Prog. Addit. Manuf. 2024, 9, 2363–2373. [Google Scholar] [CrossRef]

- Maziarz, W.; Czaja, P.; Chulist, R.; Wójcik, A.; Żrodowski, Ł.; Morończyk, B.; Wróblewski, R.; Kowalczyk, M. Microstructure and Magnetic Properties of Selected Laser Melted Ni-Mn-Ga and Ni-Mn-Ga-Fe Powders Derived from as Melt-Spun Ribbons Precursors. Metals 2021, 11, 903. [Google Scholar] [CrossRef]

- Laitinen, V.; Milleret, A.; Namvari, M.; De Vecchis, P.R.; Attallah, M.M.; Chmielus, M.; Ullakko, K. Powder-blown laser-based directed energy deposition of (14M) Ni-Mn-Ga magnetic shape memory alloy. Addit. Manuf. 2024, 90, 104328. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Saren, A.; Laitinen, V.; Vinogradova, M.; Ullakko, K. Twin boundary mobility in additive manufactured magnetic shape memory alloy 10M Ni-Mn-Ga. Acta Mater. 2023, 246, 118666. [Google Scholar] [CrossRef]

- Pötschke, M.; Gaitzsch, U.; Roth, S.; Rellinghaus, B.; Schultz, L. Preparation of melt textured Ni–Mn–Ga. J. Magn. Magn. Mater. 2007, 316, 383–385. [Google Scholar] [CrossRef]

- Exner, H.E.; Petzow, G. A Critical Assessment of Porosity Coarsening during Solid State Sintering. Adv. Sci. Technol. 2006, 45, 539–548. [Google Scholar] [CrossRef]

- Spears, M.A.; Evans, A.G. Microstructure development during final/ intermediate stage sintering—II. Grain and pore coarsening. Acta Metall. 1982, 30, 1281–1289. [Google Scholar] [CrossRef]

- Ghouse, S.; Babu, S.; Van Arkel, R.J.; Nai, K.; Hooper, P.A.; Jeffers, J.R.T. The influence of laser parameters and scanning strategies on the mechanical properties of a stochastic porous material. Mater. Des. 2017, 131, 498–508. [Google Scholar] [CrossRef]

- Tian, Y.; McAllister, D.; Colijn, H.; Mills, M.; Farson, D.; Nordin, M.; Babu, S. Rationalization of Microstructure Heterogeneity in INCONEL 718 Builds Made by the Direct Laser Additive Manufacturing Process. Metall. Mater. Trans. A 2014, 45, 4470–4483. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Z.; Nie, P.; Wu, Y. Effect of Cooling Rate on the Microstructure of Laser-Remelted INCONEL 718 Coating. Metall. Mater. Trans. A 2013, 44, 5513–5521. [Google Scholar] [CrossRef]

- Kobryn, P.A.; Moore, E.H.; Semiatin, S.L. The effect of laser power and traverse speed on microstructure, porosity, and build height in laser-deposited Ti-6Al-4V. Scr. Mater. 2000, 43, 299–305. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Gaitzsch, U.; Pötschke, M.; Roth, S.; Rellinghaus, B.; Schultz, L. A 1% magnetostrain in polycrystalline 5M Ni–Mn–Ga. Acta Mater. 2009, 57, 365–370. [Google Scholar] [CrossRef]

- Biffi, C.A.; Tuissi, A. Fiber laser drilling of Ni46Mn27Ga27 ferromagnetic shape memory alloy. Opt. Laser Technol. 2014, 63, 1–7. [Google Scholar] [CrossRef]

- Heczko, O.; Svec, P.; Janickovic, D.; Ullakko, K. Magnetic properties of Ni-Mn-Ga ribbon prepared by rapid solidification. IEEE Trans. Magn. 2002, 38, 2841–2843. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, C.; Techapiesancharoenkij, R.; Bono, D.; Allen, S.M.; O’Handley, R.C. Microstructure and magnetic properties of melt spinning Ni–Mn–Ga. Intermetallics 2013, 32, 151–155. [Google Scholar] [CrossRef]

- Namvari, M.; Laitinen, V.; Sozinov, A.; Saren, A.; Ullakko, K. Effects of 1 at.% additions of Co, Fe, Cu, and Cr on the properties of Ni-Mn-Ga-based magnetic shape memory alloys. Scr. Mater. 2023, 224, 115116. [Google Scholar] [CrossRef]

- Namvari, M.; Chernenko, V.; Saren, A.; Porro, J.M.; Ullakko, K. Structure-property control of polycrystalline Ni-Mn-Ga by moderate Co-doping. J. Alloys Compd. 2023, 944, 169184. [Google Scholar] [CrossRef]

- Dong, G.F.; Yan, H.B.; Gao, L.; Gao, Z.Y.; Cai, W. Physical property of a polycrystalline Ni53.5Mn25Ga21Ta0.5 high-temperature shape memory alloy. Mater. Sci. Eng. B 2023, 288, 116148. [Google Scholar] [CrossRef]

- Cai, W.; Gao, L.; Liu, A.L.; Sui, J.H.; Gao, Z.Y. Martensitic transformation and mechanical properties of Ni–Mn–Ga–Y ferromagnetic shape memory alloys. Scr. Mater. 2007, 57, 659–662. [Google Scholar] [CrossRef]

- Yang, S.; Ma, Y.; Jiang, H.; Liu, X. Microstructure and shape-memory characteristics of Ni56Mn25−xCoxGa19 (x = 4, 8) high-temperature shape-memory alloys. Intermetallics 2011, 19, 225–228. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, C. A single-phase wide-hysteresis shape memory alloy Ni50Mn25Ga17Cu8. Scr. Mater. 2010, 62, 298–300. [Google Scholar] [CrossRef]

- Chiu, W.-T.; Sratong-on, P.; Mark Chang, T.-F.; Tahara, M.; Sone, M.; Chernenko, V.; Hosoda, H. Bi-doping engineering of Ni-Mn-Ga polycrystals and resulting grain particles for smart Ni-Mn-Ga/polymer composites. J. Mater. Res. Technol. 2023, 23, 131–142. [Google Scholar] [CrossRef]

- Tong, W.; Peng, L.M. Microstructural characterization and functional performance of Ni54Mn25Ga21-xDyx high-temperature shape memory alloys. Mater. Sci. Technol. 2021, 37, 519–534. [Google Scholar] [CrossRef]

- Chernenko, V.A.; L’vov, V.; Pons, J.; Cesari, E. Superelasticity in high-temperature Ni–Mn–Ga alloys. J. Appl. Phys. 2003, 93, 2394–2399. [Google Scholar] [CrossRef]

- Chen, F.; Wang, H.; Zheng, Y.; Cai, W.; Zhao, L. Effect of Fe addition on transformation temperatures and hardness of NiMnGa magnetic shape memory alloys. J. Mater. Sci. 2005, 40, 219–221. [Google Scholar] [CrossRef]

- Łaszcz, A.; Hasiak, M.; Kaleta, J. Temperature dependence of anisotropy in Ti and Gd doped NiMnGa-based multifunctional ferromagnetic shape memory alloys. Materials 2020, 13, 2906. [Google Scholar] [CrossRef]

- Tian, B.; Ji, R.; Tong, Y.X.; Li, L.; Zheng, Y.F. Microstructure, phase transformation and mechanical property of Nb-doped Ni–Mn–Ga alloys. Intermetallics 2015, 64, 37–43. [Google Scholar] [CrossRef]

- Li, P.P.; Wang, J.M.; Jiang, C.B. Martensitic transformation in Cu-doped NiMnGa magnetic shape memory alloys. Chin. Phys. B 2011, 20, 028104. [Google Scholar] [CrossRef]

- Biffi, C.A.; Bassani, P.; Fiocchi, J.; Tuissi, A. Microstructural and Mechanical Response of NiTi Lattice 3D Structure Produced by Selective Laser Melting. Metals 2020, 10, 814. [Google Scholar] [CrossRef]

- Tang, Y.; Zhao, Y.F. A survey of the design methods for additive manufacturing to improve functional performance. Rapid Prototyp. J. 2016, 22, 569–590. [Google Scholar] [CrossRef]

- Zheng, X.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; DeOtte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.M.; Ge, Q.; Jackson, J.A.; et al. Ultralight, ultrastiff mechanical metamaterials. Science 2014, 344, 1373–1377. [Google Scholar] [CrossRef]

- Dudek, K.K.; Gatt, R.; Dudek, M.R.; Grima, J.N. Negative and positive stiffness in auxetic magneto-mechanical metamaterials. Proc. R. Soc. A Math. Phys. Eng. Sci. 2018, 474, 20180003. [Google Scholar] [CrossRef]

- Kadic, M.; Bückmann, T.; Stenger, N.; Thiel, M.; Wegener, M. On the practicability of pentamode mechanical metamaterials. Appl. Phys. Lett. 2012, 100, 191901. [Google Scholar] [CrossRef]

- Li, S.; Hassanin, H.; Attallah, M.M.; Adkins, N.J.E.; Essa, K. The development of TiNi-based negative Poisson’s ratio structure using selective laser melting. Acta Mater. 2016, 105, 75–83. [Google Scholar] [CrossRef]

- Xiong, Y.; Wang, W.; Gao, R.; Zhang, H.; Dong, L.; Qin, J.; Wang, B.; Jia, W.; Li, X. Fatigue behavior and osseointegration of porous Ti-6Al-4V scaffolds with dense core for dental application. Mater. Des. 2020, 195, 108994. [Google Scholar] [CrossRef]

- Speirs, M.; Wang, X.; Van Baelen, S.; Ahadi, A.; Dadbakhsh, S.; Kruth, J.P.; Van Humbeeck, J. On the Transformation Behavior of NiTi Shape-Memory Alloy Produced by SLM. Shape Mem. Superelasticity 2016, 2, 310–316. [Google Scholar] [CrossRef]

- McCue, I.D.; Valentino, G.M.; Trigg, D.B.; Lennon, A.M.; Hebert, C.E.; Seker, D.P.; Nimer, S.M.; Mastandrea, J.P.; Trexler, M.M.; Storck, S.M. Controlled shape-morphing metallic components for deployable structures. Mater. Des. 2021, 208, 109935. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Van Humbeeck, J.; Kruth, J.-P. Laser additive manufacturing of bulk and porous shape-memory NiTi alloys: From processes to potential biomedical applications. MRS Bull. 2016, 41, 765–774. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Tapia, G.; Franco, B.; Ma, J.; Arroyave, R.; Karaman, I.; Elwany, A. On the printability and transformation behavior of nickel-titanium shape memory alloys fabricated using laser powder-bed fusion additive manufacturing. J. Manuf. Process. 2018, 35, 672–680. [Google Scholar] [CrossRef]

- Bormann, T.; Müller, B.; Schinhammer, M.; Kessler, A.; Thalmann, P.; de Wild, M. Microstructure of selective laser melted nickel–titanium. Mater. Charact. 2014, 94, 189–202. [Google Scholar] [CrossRef]

- Saedi, S.; Saghaian, S.E.; Jahadakbar, A.; Shayesteh Moghaddam, N.; Taheri Andani, M.; Saghaian, S.M.; Lu, Y.C.; Elahinia, M.; Karaca, H.E. Shape memory response of porous NiTi shape memory alloys fabricated by selective laser melting. J. Mater. Sci. Mater. Med. 2018, 29, 40. [Google Scholar] [CrossRef]

- Taheri Andani, M.; Haberland, C.; Walker, J.M.; Karamooz, M.; Sadi Turabi, A.; Saedi, S.; Rahmanian, R.; Karaca, H.; Dean, D.; Kadkhodaei, M.; et al. Achieving biocompatible stiffness in NiTi through additive manufacturing. J. Intell. Mater. Syst. Struct. 2016, 27, 2661–2671. [Google Scholar] [CrossRef]

- Yang, Q.; Sun, K.; Yang, C.; Sun, M.; Peng, H.; Shen, X.; Huang, S.; Chen, J. Compression and superelasticity behaviors of NiTi porous structures with tiny strut fabricated by selective laser melting. J. Alloys Compd. 2021, 858, 157674. [Google Scholar] [CrossRef]

- Speirs, M.; Van Hooreweder, B.; Van Humbeeck, J.; Kruth, J.P. Fatigue behaviour of NiTi shape memory alloy scaffolds produced by SLM, a unit cell design comparison. J. Mech. Behav. Biomed. Mater. 2017, 70, 53–59. [Google Scholar] [CrossRef]

- Sun, J.; Gu, D.; Lin, K.; Yuan, L.; Yang, J.; Chen, W. Laser powder bed fusion of diatom frustule inspired bionic NiTi lattice structures: Compressive behavior and shape memory effect. Smart Mater. Struct. 2022, 31, 074003. [Google Scholar] [CrossRef]

- Zhao, M.; Qing, H.; Wang, Y.; Liang, J.; Zhao, M.; Geng, Y.; Liang, J.; Lu, B. Superelastic behaviors of additively manufactured porous NiTi shape memory alloys designed with Menger sponge-like fractal structures. Mater. Des. 2021, 200, 109448. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, J.; He, M.; Yang, L. Compressive Mechanics and Hyperelasticity of Ni-Ti Lattice Structures Fabricated by Selective Laser Melting. Crystals 2022, 12, 408. [Google Scholar] [CrossRef]

- Tan, C.; Zou, J.; Li, S.; Jamshidi, P.; Abena, A.; Forsey, A.; Moat, R.J.; Essa, K.; Wang, M.; Zhou, K.; et al. Additive manufacturing of bio-inspired multi-scale hierarchically strengthened lattice structures. Int. J. Mach. Tools Manuf. 2021, 167, 103764. [Google Scholar] [CrossRef]

- Gu, D.; Ma, C.; Dai, D.; Yang, J.; Lin, K.; Zhang, H.; Zhang, H. Additively manufacturing-enabled hierarchical NiTi-based shape memory alloys with high strength and toughness. Virtual Phys. Prototyp. 2021, 16, S19–S38. [Google Scholar] [CrossRef]

- Bouwhuis, B.A.; McCrea, J.L.; Palumbo, G.; Hibbard, G.D. Mechanical properties of hybrid nanocrystalline metal foams. Acta Mater. 2009, 57, 4046–4053. [Google Scholar] [CrossRef]

- Khezrzadeh, O.; Mirzaee, O.; Emadoddin, E.; Linul, E. Anisotropic compressive behavior of metallic foams under extreme temperature conditions. Materials 2020, 13, 2329. [Google Scholar] [CrossRef]

- McEvoy, M.A.; Correll, N. Materials that couple sensing, actuation, computation, and communication. Science 2015, 347, 1261689. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Zhao, S.; Da Ronch, A.; Xiang, J.; Drofelnik, J.; Li, Y.; Zhang, L.; Wu, Y.; Kintscher, M.; Monner, H.P.; et al. A review of modelling and analysis of morphing wings. Prog. Aerosp. Sci. 2018, 100, 46–62. [Google Scholar] [CrossRef]

- Wu, C.; Li, Y. AlN-induced reinforcement of nano-amorphous B–C–N compound for TiB2–B4C ceramic composite. J. Alloys Compd. 2020, 831, 154074. [Google Scholar] [CrossRef]

- Xu, Y.; Qiu, L.; Yuan, S.; Wang, Y. Research on shape memory alloy honeycomb structures fabricated by selective laser melting additive manufacturing. Opt. Laser Technol. 2022, 152, 108160. [Google Scholar] [CrossRef]

- Hamzehei, R.; Kadkhodapour, J.; Anaraki, A.P.; Rezaei, S.; Dariushi, S.; Rezadoust, A.M. Octagonal auxetic metamaterials with hyperelastic properties for large compressive deformation. Int. J. Mech. Sci. 2018, 145, 96–105. [Google Scholar] [CrossRef]

- Liu, W.; Li, H.; Zhang, J.; Li, H. Theoretical analysis on the elasticity of a novel accordion cellular honeycomb core with in-plane curved beams. J. Sandw. Struct. Mater. 2018, 22, 702–727. [Google Scholar] [CrossRef]

- Yang, E.; Leary, M.; Lozanovski, B.; Downing, D.; Mazur, M.; Sarker, A.; Khorasani, A.; Jones, A.; Maconachie, T.; Bateman, S.; et al. Effect of geometry on the mechanical properties of Ti-6Al-4V Gyroid structures fabricated via SLM: A numerical study. Mater. Des. 2019, 184, 108165. [Google Scholar] [CrossRef]

- Yang, L.; Yan, C.; Han, C.; Chen, P.; Yang, S.; Shi, Y. Mechanical response of a triply periodic minimal surface cellular structures manufactured by selective laser melting. Int. J. Mech. Sci. 2018, 148, 149–157. [Google Scholar] [CrossRef]

- Sun, J.; Gu, D.; Lin, K.; Yuan, L.; Sun, J.; Wang, R.; Liu, X. Laser additive manufacturing of a novel NiTi doubly periodic continuous surface for dispersing in-plane stresses and improving thermo-mechanical protection. Addit. Manuf. 2025, 98, 104643. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Young, P. Ti–6Al–4V triply periodic minimal surface structures for bone implants fabricated via selective laser melting. J. Mech. Behav. Biomed. Mater. 2015, 51, 61–73. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Bubb, S.L.; Young, P.; Raymont, D. Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J. Mater. Process. Technol. 2014, 214, 856–864. [Google Scholar] [CrossRef]

- Challis, V.J.; Xu, X.; Zhang, L.C.; Roberts, A.P.; Grotowski, J.F.; Sercombe, T.B. High specific strength and stiffness structures produced using selective laser melting. Mater. Des. 2014, 63, 783–788. [Google Scholar] [CrossRef]

- Chen, W.; Yang, Q.; Huang, S.; Kruzic, J.J.; Li, X. Compression Behavior of Graded NiTi Gyroid-Structures Fabricated by Laser Powder Bed Fusion Additive Manufacturing Under Monotonic and Cyclic Loading. JOM 2021, 73, 4154–4165. [Google Scholar] [CrossRef]

- Yang, X.; Yang, Q.; Shi, Y.; Yang, L.; Wu, S.; Yan, C.; Shi, Y. Effect of volume fraction and unit cell size on manufacturability and compressive behaviors of Ni-Ti triply periodic minimal surface lattices. Addit. Manuf. 2022, 54, 102737. [Google Scholar] [CrossRef]

- Isacco, S.; Winiarski, B.; Bansah, C.; Caputo, M.; Solomon, C.V. Modeling and characterization of binder jet 3D printed NiMnGa components using X-ray microscopy. Microsc. Microanal. 2021, 27, 2946–2950. [Google Scholar] [CrossRef]

- Zhang, X.; Qian, M. (Eds.) Preparation and Properties of Bulk Magnetic Shape Memory Alloys. In Magnetic Shape Memory Alloys: Preparation, Martensitic Transformation and Properties; Springer: Singapore, 2022; pp. 35–69. [Google Scholar]

| # | Training Method | Description |

|---|---|---|

| 1 | Over-deformation of martensite | Deform beyond the shape memory strain (SMS) limit below to set the first shape. Heat above the , recover the strain, and set the second shape. |

| 2 | Shape memory (SM) cycling | Deform within the SMS limit below . Heat to above to recover the undeformed shape. Repeat until TWSM is observed without the need for mechanical deformation. |

| 3 | Superelastic (SE) cycling | Cyclically load and unload the material above , but within the temperature rate suitable for superelasticity. Sufficient cycles will result in a TWSM upon heating and cooling within a fraction of the applied strain values. |

| 4 | SME + SE cycling | Deform above to induce a certain amount of stress-induced martensite, then cool to below while constraining the applied strain, followed by heating to above to recover the strain. Repeat these steps until two-way shape memory is observed. |

| 5 | Mechanically constrained temperature cycling | Deform below within the SMS limit and constrain the strain. Heat to above and release the mechanical strain. Repeat until TWSM is observed. |

| AM Instrument | S# | v (mm/s) | t (mm) | h (mm) | P (W) | ) | Density (%) | S. Type | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Laser Powder Bed Fusion | |||||||||

| Mlab Cusing, Concept Laser | 1 | 500 | 0.025 | 0.098 | 30 | 24.5 | 89.6 ± 0.6 | [184] | |

| 2 | 600 | 30 | 20.4 | 78.8 ± 0.6 | |||||

| 3 | 700 | 30 | 17.5 | 75.2 ± 0.7 | |||||

| 4 | 500 | 35 | 28.6 | 84.1 ± 0.6 | |||||

| 5 | 600 | 35 | 23.8 | 82.6 ± 0.6 | |||||

| 6 | 700 | 35 | 20.4 | 80.5 ± 0.6 | |||||

| 7 | 500 | 40 | 32.7 | 87.1 ± 0.6 | |||||

| 8 | 600 | 40 | 27.2 | 85.2 ± 0.6 | |||||

| 9 | 700 | 40 | 23.3 | 84.9 ± 0.6 | |||||

| Concept Laser M2 Cusing | 10 | 200 | 0.025 | No hatching | 70 | N/A | 97.3 * | [188] | |

| 11 | 450 | 70 | 98.9 * | ||||||

| 12 | 600 | 70 | 98.9 * | ||||||

| 13 | 200 | 100 | 94.0 * | ||||||

| 14 | 450 | 100 | 97.4 * | ||||||

| 15 | 600 | 100 | 97.9 * | ||||||

| SLM Solutions | 16 | 250 | 0.025 | No hatching | 37.5 | N/A | N/A | [189] | |

| Modified EOSINT M-Series | 17 | 200–600 | 0.06 | No hatching | 80–200 | N/A | N/A | [190] | |

| In-House Built | 18 | 300 | 0.05 | 0.1 | 200 | 133.3 | 96.8 | [27] | |

| 19 | 500 | 80.0 | 94.9 | ||||||

| 20 | 700 | 57.1 | 93.5 | ||||||

| Concept Laser M2 Cusing | 21 | 3000 | 0.025 | 0.09 | 200 | 29.6 | 80.14 | [191] | |

| 22 | 3000 | 0.09 | 300 | 44.4 | 76.89 | ||||

| 23 | 3000 | 0.045 | 250 | 74.1 | 82.21 | ||||

| 24 | 3000 | 0.015 | 100 | 88.9 | 76.98 | ||||

| 25 | 3000 | 0.045 | 150 | 44.4 | 83.06 | ||||

| 26 | 2000 | 0.09 | 150 | 33.3 | 79.15 | ||||

| 27 | 2000 | 0.045 | 200 | 88.9 | N/A | ||||

| 28 | 2000 | 0.09 | 200 | 44.4 | N/A | ||||

| 29 | 3000 | 0.09 | 300 | 44.4 | N/A | ||||

| 30 | 2000 | 0.09 | 250 | 55.6 | N/A | ||||

| In-House Built | 31 | 125 | 0.06 | 0.05 | 50 | 133.3 | 75.2 ± 4.8 | [183] | |

| 32 | 50 | 0.05 | 85 | 566.7 | 86.2 ± 2.8 | ||||

| 33 | 200 | 0.05 | 85 | 141.7 | 87.7 ± 1.6 | ||||

| 34 | 300 | 0.05 | 100 | 111.1 | 79.4 ± 2.1 | ||||

| 35 | 125 | 0.05 | 120 | 320.0 | 95.2 ± 0.9 | ||||

| 36 | 150 | 0.05 | 150 | 333.3 | 92.7 ± 2.1 | ||||

| 37 | 450 | 0.05 | 150 | 111.1 | 93.7 ± 0.4 | ||||

| 38 | 300 | 0.05 | 200 | 222.2 | 96.2 ± 0.5 | ||||

| 39 | 50 | 0.075 | 50 | 222.2 | 81.0 ± 3.2 | ||||

| 40 | 200 | 0.075 | 50 | 55.6 | 72.6 ± 5.2 | ||||

| 41 | 125 | 0.075 | 85 | 151.1 | 91.2 ± 1.5 | ||||

| 42 | 150 | 0.075 | 100 | 148.1 | 94.9 ± 0.6 | ||||

| 43 | 450 | 0.075 | 100 | 49.4 | 83.1 ± 3.7 | ||||

| 44 | 50 | 0.075 | 120 | 533.3 | 92.6 ± 0.5 | ||||

| 45 | 200 | 0.075 | 120 | 133.3 | 97.8 ± 0.3 | ||||

| 46 | 300 | 0.075 | 150 | 111.1 | 91.8 ± 2.4 | ||||

| 47 | 150 | 0.075 | 200 | 296.3 | 93.7 ± 0.9 | ||||

| 48 | 450 | 0.075 | 200 | 98.8 | 98.7 ± 0.5 | ||||

| 49 | 125 | 0.1 | 50 | 66.7 | 76.0 ± 2.7 | ||||

| 50 | 50 | 0.1 | 85 | 283.3 | 93.5 ± 0.9 | ||||

| 51 | 200 | 0.1 | 85 | 70.8 | 93.9 ± 2.3 | ||||

| 52 | 300 | 0.1 | 100 | 55.6 | 84.2 ± 1.8 | ||||

| 53 | 125 | 0.1 | 120 | 160.0 | 96.8 ± 0.6 | ||||

| 54 | 150 | 0.1 | 150 | 166.7 | 94.2 ± 1.1 | ||||

| 55 | 450 | 0.1 | 150 | 55.6 | 94.8 ± 1.1 | ||||

| 56 | 300 | 0.1 | 200 | 111.1 | 98.5 ± 0.3 | ||||

| In-House Built | 57 | 750 | 0.06 | 0.1 | 200 | 44.4 | 98.6 ± 0.33 | [81] | |

| Mlab Cusing, Concept Laser | 58 | 500 | 0.025 | 0.098 | 45 | 36.7 | 91.1 ± 0.6 | [20] | |

| 59 | 600 | 45 | 30.6 | 88.2 ± 0.6 | |||||

| 60 | 700 | 45 | 26.2 | 85.5 ± 0.6 | |||||

| 61 | 500 | 50 | 40.8 | 93.8 ± 0.6 | |||||

| 62 | 600 | 50 | 34.0 | 90.8 ± 0.6 | |||||

| 63 | 700 | 50 | 29.2 | 86.5 ± 0.7 | |||||

| 64 | 500 | 55 | 44.9 | 95.9 ± 0.6 | |||||

| 65 | 600 | 55 | 37.4 | 93.7 ± 0.6 | |||||

| 66 | 700 | 55 | 32.1 | 91.5 ± 0.6 | |||||

| SLM Realizer 50 | 67 | 250 | 0.025 | N/A | 37.5 | N/A | N/A | [192] | |

| Laser Based Directed Energy Deposition | |||||||||

| Laser-Based DED—LENS | 68 | 2.5 | 0.25 | No hatching | 350 | N/A | N/A | Five deposition layers | [186] |

| Laser-Based DED | 69 | 10.8 | N/A | No hatching | 300 | N/A | 97.71 ± 0.08 | —single track layers; bidirectional scan strategy | [193] |

| 70 | 400 | 98.68 ± 0.07 | |||||||

| 71 | 500 | 97.29 ± 0.12 | |||||||

| 72 | 600 | 94.88 ± 0.14 | |||||||

| 73 | 700 | N/A # | |||||||

| 74 | 300 | 96.92 ± 0.13 | —single track layers; unidirectional scan strategy | ||||||

| 75 | 400 | 98.44 ± 0.11 | |||||||

| 76 | 500 | 95.15 ± 0.13 | |||||||

| 77 | 600 | 92.31 ± 0.26 | |||||||

| 78 | 700 | N/A # | |||||||

| Structure No. | 2D | 3D | SEA (J/g) | RR (%) | Reference |

|---|---|---|---|---|---|

| 1 |  |  | 1.6 | 93.6 (SE)/98.5 (SE + SME) | [21] |

| 2 |  |  | 2.8 | 93.7 (SE)/98.7 (SE + SME) | [21] |

| 3 |  |  | 6.3 | 91.2 (SE)/98.7 (SE + SME) | [21] |

| 4 |  |  | 1.53 | 94.7 (SE)/99.7 (SE + SME) | [21] |

| 5 |  |  | 1.85 | 99.17 | [237] |

| 6 |  |  | 1.25 | 99.78 | [237] |

| 7 |  |  | N/A | 96.17 | [238] |

| 8 |  |  | N/A | 95.5 | [238] |

| 9 |  |  | N/A | 93.93 | [238] |

| 10 | Not Available |  | N/A | 74% | [239] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramezannejad, A.; East, D.; Murphy, A.B.; Lu, G.; Yang, K.V. Optimising Additive Manufacturing of NiTi and NiMnGa Shape Memory Alloys: A Review. Metals 2025, 15, 488. https://doi.org/10.3390/met15050488

Ramezannejad A, East D, Murphy AB, Lu G, Yang KV. Optimising Additive Manufacturing of NiTi and NiMnGa Shape Memory Alloys: A Review. Metals. 2025; 15(5):488. https://doi.org/10.3390/met15050488

Chicago/Turabian StyleRamezannejad, Ali, Daniel East, Anthony Bruce Murphy, Guoxing Lu, and Kun Vanna Yang. 2025. "Optimising Additive Manufacturing of NiTi and NiMnGa Shape Memory Alloys: A Review" Metals 15, no. 5: 488. https://doi.org/10.3390/met15050488

APA StyleRamezannejad, A., East, D., Murphy, A. B., Lu, G., & Yang, K. V. (2025). Optimising Additive Manufacturing of NiTi and NiMnGa Shape Memory Alloys: A Review. Metals, 15(5), 488. https://doi.org/10.3390/met15050488