Effects of Cr3C2 Addition on Wear Behaviour of WC-Co Based Cemented Carbides

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

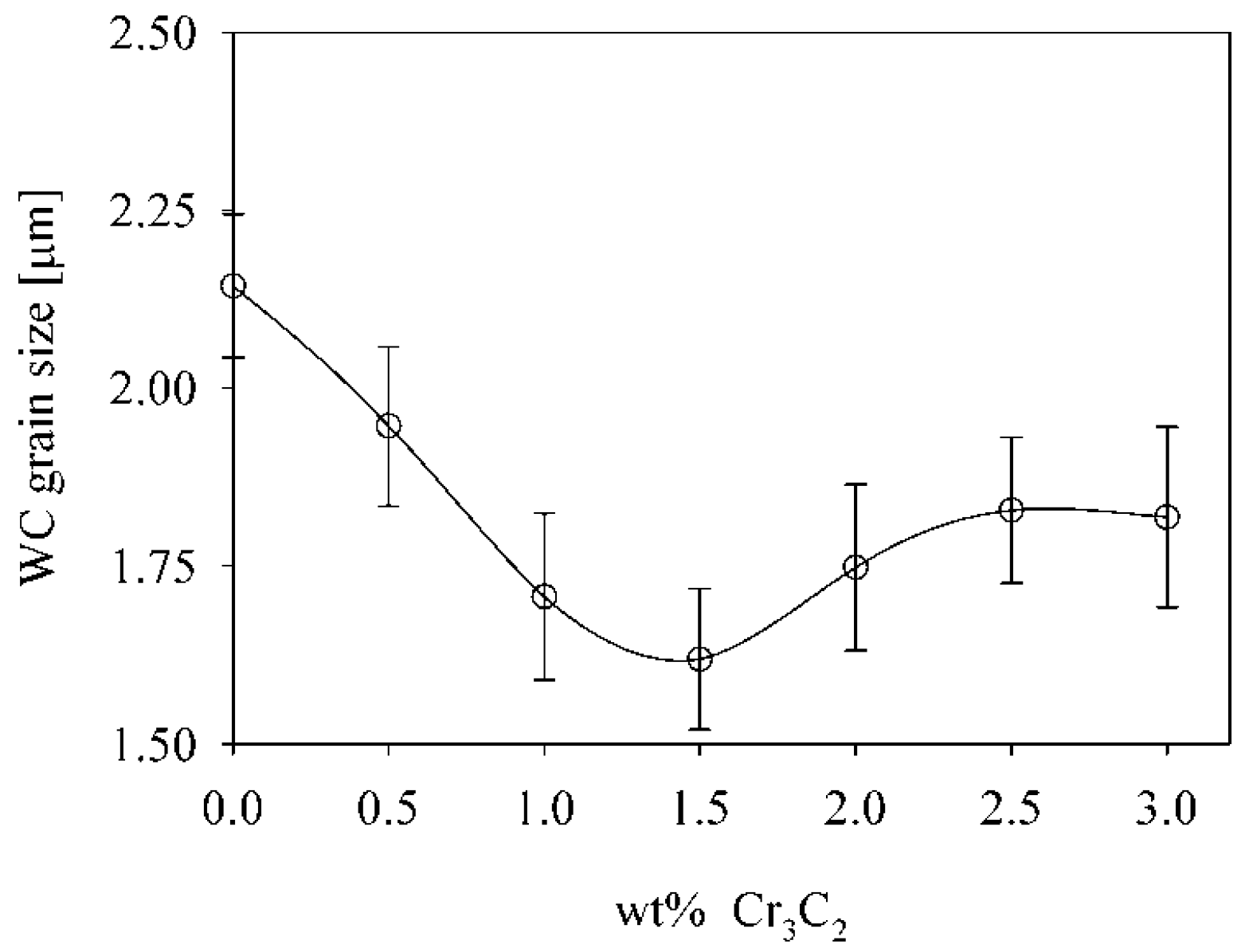

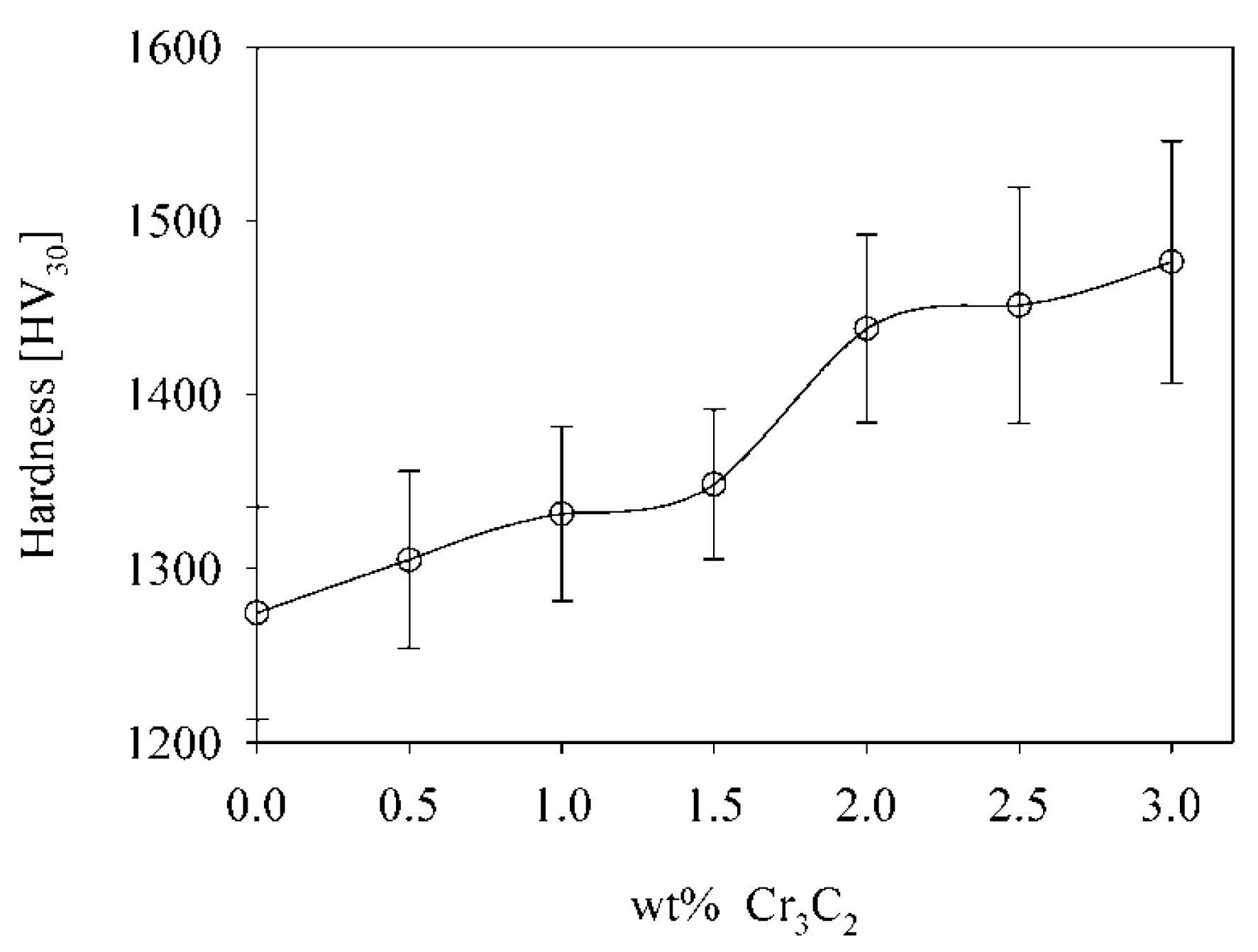

- Addition of up to 1.5 wt% of Cr3C2 greatly increases the hardness of the WC-10Co hardmetal due to the effect of grain size refinement. The slight increase in hardness observed beyond 1.5 wt% addition is caused only by the increased presence of M7C3.

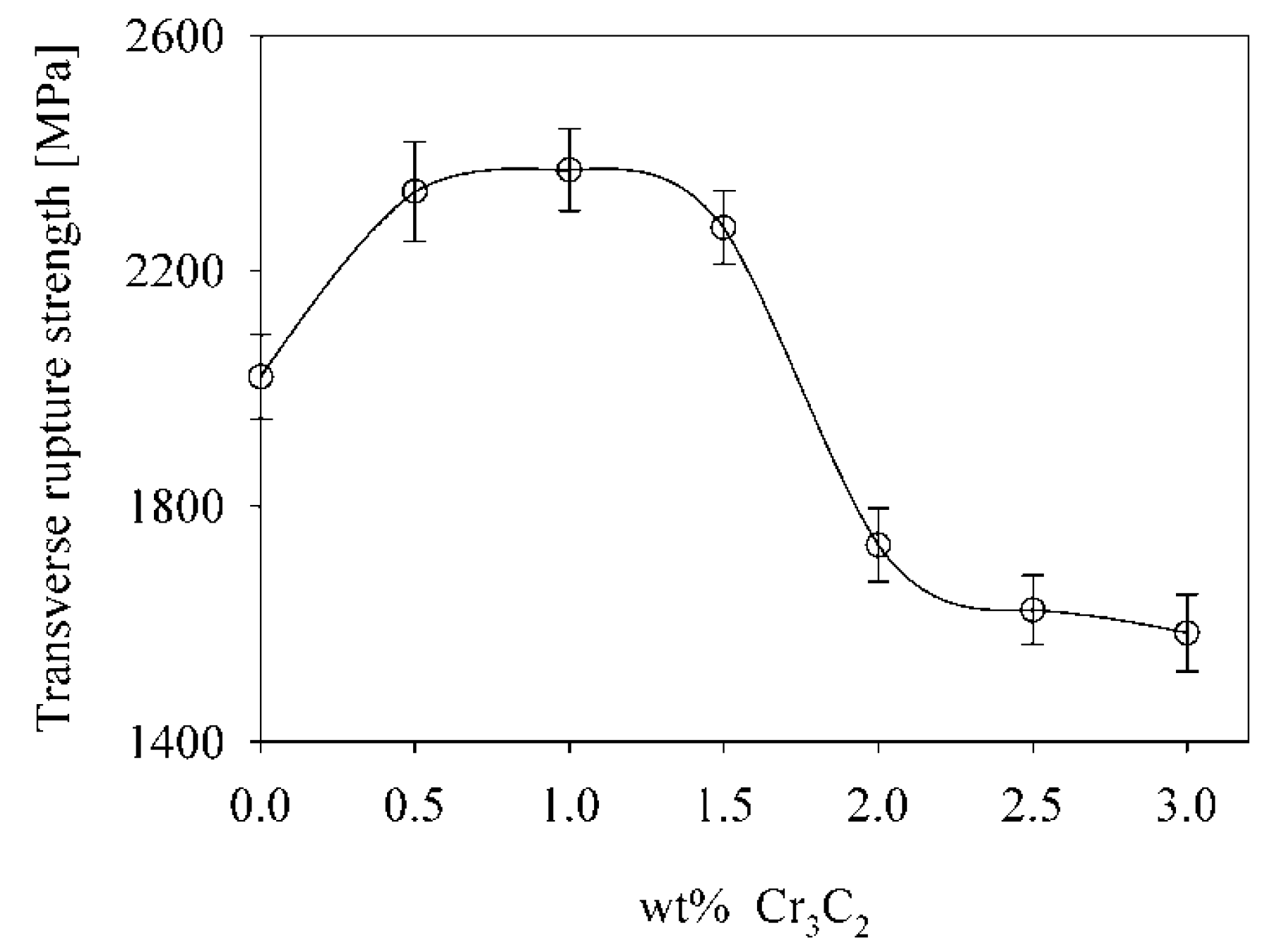

- The addition of Cr3C2, up to 1.5 wt%, greatly improves the TRS of the WC-10Co hardmetal. However, larger amounts of such additions have the reverse effect due to the embrittlement of the binder.

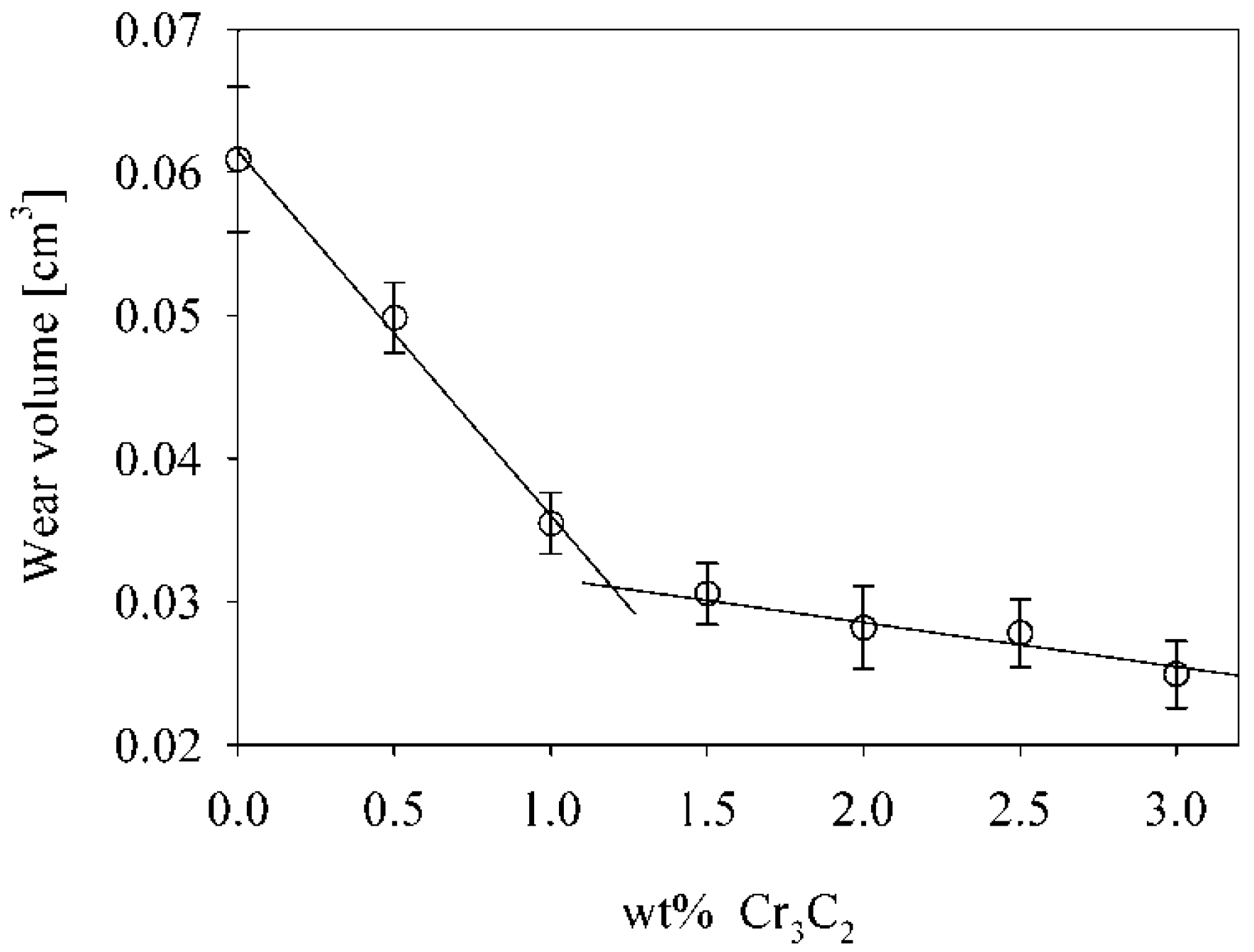

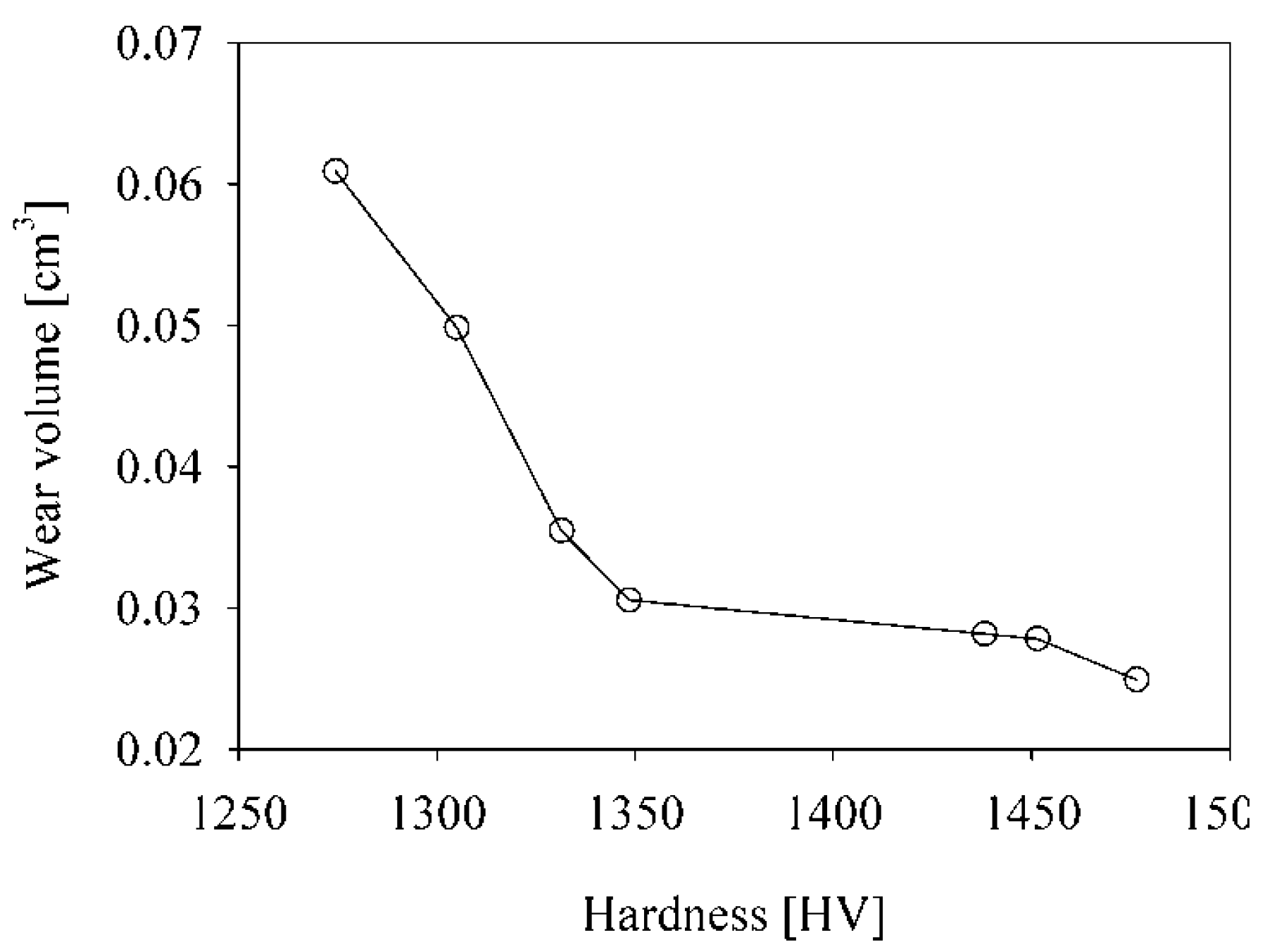

- Wear performance is significantly enhanced by the addition of Cr3C2 due to the hardness increase and reduction of the grain size. However, addition of Cr3C2 above 1.5 wt% brings about a moderate increase of the wear performance which is produced just by the progressively increasing presence of the M7C3 carbide and not by a further decrease of grain size. Aiming at the combined optimization of the wear resistance and the mechanical properties of the WC-10Co cemented carbides, to add amounts of Cr3C2 higher than 1.5 wt% is then detrimental.

Author Contributions

Conflicts of Interest

References

- Upadhyaya, G.S. Cemented Tungsten Carbides: Production, Properties and Testing; Andrew William Publishing: Norwich, NY, USA, 1998. [Google Scholar]

- Prakash, L.J. Application of fine grained tungsten carbide based cemented carbides. Int. J. Refract. Met. Hard Mater. 1995, 13, 257–264. [Google Scholar] [CrossRef]

- Liu, X.; Song, X.; Wang, H.; Liu, X.; Tang, F.; Lu, H. Complexions in WC-Co cemented carbides. Acta Mater. 2018, 149, 164–178. [Google Scholar] [CrossRef]

- Mikado, H.; Ishihara, S.; Oguma, N.; Kawamura, S. On the short surface fatigue crack growth behavior in a fine-grained wc-co cemented carbide. Metals 2017, 7, 17. [Google Scholar] [CrossRef]

- Pirso, J.; Letunovitš, S.; Viljus, M. Friction and wear behaviour of cemented carbides. Wear 2004, 257, 257–265. [Google Scholar] [CrossRef]

- Upadhyaya, G.S. Materials science of cemented carbides—An overview. Mater. Des. 2001, 22, 483–489. [Google Scholar] [CrossRef]

- Alar, Ž.; Alar, V.; Fabijanić, T.A. Electrochemical corrosion behavior of near-nano and nanostructured wc-co cemented carbides. Metals 2017, 7, 12. [Google Scholar] [CrossRef]

- Kumar, S. Process chain development for additive manufacturing of cemented carbide. J. Manuf. Process. 2018, 34, 121–130. [Google Scholar] [CrossRef]

- Bonny, K.; De Baets, P.; Vleugels, J.; Huang, S.; Van der Biest, O.; Lauwers, B. Impact of Cr3C2/VC addition on the dry sliding friction and wear response of WC–Co cemented carbides. Wear 2009, 267, 1642–1652. [Google Scholar] [CrossRef]

- Gille, G.; Szesny, B.; Dreyer, K.; van den Berg, H.; Schmidt, J.; Gestrich, T.; Leitner, G. Submicron and ultrafine grained hardmetals for microdrills and metal cutting inserts. Int. J. Refract. Met. Hard Mater. 2002, 20, 3–22. [Google Scholar] [CrossRef]

- Klaasen, H.; Kübarsepp, J. Wear of advanced cemented carbides for metalforming tool materials. Wear 2004, 256, 846–853. [Google Scholar] [CrossRef]

- Liu, K.; Wang, Z.; Yin, Z.; Cao, L.; Yuan, J. Effect of Co content on microstructure and mechanical properties of ultrafine grained wc-co cemented carbide sintered by spark plasma sintering. Ceram. Int. 2018, 44, 18711–18718. [Google Scholar] [CrossRef]

- Sun, L.; Yang, T.e.; Jia, C.; Xiong, J. Vc, Cr3c2 doped ultrafine WC–Co cemented carbides prepared by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2011, 29, 147–152. [Google Scholar] [CrossRef]

- Huang, S.G.; Li, L.; Vanmeensel, K.; Van der Biest, O.; Vleugels, J. Vc, Cr3C2 and NBC doped WC–Co cemented carbides prepared by pulsed electric current sintering. Int. J. Refract. Met. Hard Mater. 2007, 25, 417–422. [Google Scholar] [CrossRef]

- Banerjee, D.; Lai, G.K.; Upadhyaya, G.S. Effect of binder-phase modification and Cr3C2 addition on properties of WC-Co cemented carbide. J. Mater. Eng. Perform. 1995, 4, 563–572. [Google Scholar] [CrossRef]

- Okamoto, S.; Ohtuka, K.; Nakazono, Y.; Shimoitani, Y.; Takada, J. Influence of WC grain size and Co mass content on mechanical properties of WC–Co cemented carbides. J. Soc. Mater. Sci. Jpn. 2005, 54, 447–452. [Google Scholar] [CrossRef]

- Almond, E.A.; Roebuck, B.J. Very fine-grained hardmetals. Int. J. Refract. Met. Hard Mater. 1987, 6, 137–144. [Google Scholar]

- Choi, K.; Hwang, N.M.; Kim, D.-Y. Effect of VC addition on microstructural evolution ofWC–Co alloy: Mechanism of grain growth inhibition. Powder Metall. 2000, 43, 168–172. [Google Scholar] [CrossRef]

- ASTM. B611-13, Standard Test Method for Determining the High Stress Abrasion Resistance of Hard Materials; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ISO. ISO 6507-1:2018, Metallic Materials—Vickers Hardness Test—Test Method; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- ASTM. B406-76, standard test method for transverse rupture strength of cemented carbides. In Annual Book of ASTM Standards; ASTM Inetrnational: West Conshohocken, PA, USA, 1987; p. 2. [Google Scholar]

- Zackrisson, J.; Jansson, B.; Uphadyaya, G.S.; Andrén, H.-O. WC-Co based cemented carbides with large Cr3C2 additions. Int. J. Refract. Met. Hard Mater. 1998, 16, 417–422. [Google Scholar] [CrossRef]

- Henjered, A.; Hellsing, M.; Andrén, H.-O.; Nordén, H. Quantitative microanalysis of carbide/carbide interfaces in WC–Co-base cemented carbides. Mater. Sci. Technol. 1986, 2, 847–855. [Google Scholar] [CrossRef]

- Kusoffsky, A.; Jansson, B. A thermodynamic evaluation of the Co-Cr and the C.-Co-Cr systems. Calphad 1997, 21, 321–333. [Google Scholar] [CrossRef]

- Long, J.; Li, K.; Chen, F.; Yi, M.; Du, Y.; Lu, B.; Zhang, Z.; Wang, Y.; Cheng, K.; Zhang, K. Microstructure evolution of wc grains in WC–Co–Ni–Al alloys: Effect of binder phase composition. J. Alloys Compd. 2017, 710, 338–348. [Google Scholar] [CrossRef]

- Li, J.; Cheng, J.; Chen, P.; Chen, W.; Wei, C. Fabrication of WC-Co cemented carbides with gradient distribution of wc grain size and co composition by lamination pressing and microwave sintering. Ceram. Int. 2018, 44, 11225–11232. [Google Scholar] [CrossRef]

- Fabijanić, T.A.; Ćorić, D.; Musa, M.Š.; Sakoman, M. Vickers indentation fracture toughness of near-nano and nanostructured WC-Co cemented carbides. Metals 2017, 7, 16. [Google Scholar]

- Hume-Rothery, W.; Raynor, G.V. The Structure of Metals and Alloys, 3rd ed.; Institute of Metals: London, UK, 1954; p. viii + 363. [Google Scholar]

- Liu, X.; Zhang, J.; Hou, C.; Wang, H.; Song, X.; Nie, Z. Mechanisms of WC plastic deformation in cemented carbide. Mater Des. 2018, 150, 154–164. [Google Scholar] [CrossRef]

| Alloy | WC | Cr3C2 | Co |

|---|---|---|---|

| 0 wt% Cr3C2 | 90 | 0 | 10 |

| 0.5 wt% Cr3C2 | 89.5 | 0.5 | 10 |

| 1 wt% Cr3C2 | 89 | 1 | 10 |

| 1.5 wt% Cr3C2 | 88.5 | 1.5 | 10 |

| 2 wt% Cr3C2 | 88 | 2 | 10 |

| 2.5 wt% Cr3C2 | 87.5 | 2.5 | 10 |

| 3 wt% Cr3C2 | 87 | 3 | 10 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boccarusso, L.; Scherillo, F.; Prisco, U. Effects of Cr3C2 Addition on Wear Behaviour of WC-Co Based Cemented Carbides. Metals 2018, 8, 895. https://doi.org/10.3390/met8110895

Boccarusso L, Scherillo F, Prisco U. Effects of Cr3C2 Addition on Wear Behaviour of WC-Co Based Cemented Carbides. Metals. 2018; 8(11):895. https://doi.org/10.3390/met8110895

Chicago/Turabian StyleBoccarusso, Luca, Fabio Scherillo, and Umberto Prisco. 2018. "Effects of Cr3C2 Addition on Wear Behaviour of WC-Co Based Cemented Carbides" Metals 8, no. 11: 895. https://doi.org/10.3390/met8110895

APA StyleBoccarusso, L., Scherillo, F., & Prisco, U. (2018). Effects of Cr3C2 Addition on Wear Behaviour of WC-Co Based Cemented Carbides. Metals, 8(11), 895. https://doi.org/10.3390/met8110895