1. Introduction

Cast steel components are commonly utilized in modern manufacturing processes for complexly shaped structures and demands towards higher strengths. Despite elaborated efforts in terms of numerical process simulations during component design, casting defects, such as sand inclusions, hot tears and shrinkage porosities, are manufacturing based intrinsic material properties [

1]. This is caused by the material’s high shrinkage during cooling and solidification. Therefore, the fatigue assessment of cast steel defects is of utmost importance referring to an operationally endurable design.

Despite the use of radiograph standards [

2,

3,

4] for quality assurance, which allow casting defects to be classified according to their accumulation and sizes, into defect and severity grades, it is difficult to attain a conservative estimation of the local strength properties in cast steel components. A fundamental relation between casting defects, including surface and near-surface discontinuities, on the fatigue strength and the impact behaviour of cast steels has been the topic of various preliminary studies [

5,

6,

7,

8]. Furthermore, the influence of shrinkage porosity on the elastic monotonic and fatigue life by computed tomography and X-ray scanning has been studied in depth by Hardin et al. [

9,

10,

11,

12,

13,

14], whereas finite-element simulations were utilized for a proper localized fatigue assessment. Next, Collini et al. [

15] studied the influence of casting defects on the fatigue crack initiation of ductile cast iron concluding a significant drop in fatigue strength due to defects within the material.

In addition to these simulation-based fatigue assessment approaches, fracture mechanical concepts, like Murakami’s

concept [

16], are frequently used for the assessment of casting defects, especially in aluminium alloys, which exhibit shrinkage and gas porosities with sizes up to approximately 700

m [

17]. Recent works also depicted the applicability of Murakami’s concept for non-metallic inclusion in cast steel materials, which are presented in [

18,

19,

20]. Thereby it should be noted, that according to the literature [

16], the application of the fracture mechanics-based concept provides confident results only for defect sizes with

1000

m.

As presented by Hardin and Beckermann [

21], shrinkage porosity can feature sizes up to several millimetres, which exceed the application limit of Murakami’s

and therefore leads to an unsatisfying design result. On the other hand, as published in recent works [

22,

23], the generalized Kitagawa-Takahashi diagram, which can be considered as an extended form of the linear-elastic fracture mechanical design [

24], enables an auspicious assessment of shrinkage porosity afflicted large-scale cast steel specimens. Early works by Williams, Gross and Mendelson [

25,

26] contributed to the development of the notch stress intensity factor (NSIF) concept in terms of an analytical solution of the angle-dependent Williams eigenvalue

at sharp V-notches, as defined in Equation (

1).

Thereby,

represents the V-notch opening angle and

q the relative complementarity angle. As the NSIF concept can be understood as a generalization of the fracture mechanical approach, the notch stress intensity factor at a V-notch under mode I loading can be formulated as given in Equation (

2), by considering a gross-section stress

as uniaxial load condition. Whereat

represents the opening-angle dependent stress singularity at the notch root and is determined as given in

. In addition, the effective fatigue notch depth is defined by the factor

, which is composed of the actual notch depth

a and the geometry dependent factor

[

27,

28,

29].

In case of a V-notch with an opening-angle equal to

, the Williams eigenvalue results in a value of

and therefore leads to the fracture mechanical base equation [

30,

31].

The Kitagawa–Takahashi diagram (KTD) is basically specified by two material threshold parameters: the fatigue limit range

, and the long crack stress intensity factor threshold range

. The KTD features two different areas that can be subdivided into a region of non-propagating cracks and, on the contrary, into a region of flaws, which exhibits a size larger than the materials intrinsic crack length

. Thereon, the intrinsic crack grows under cyclic loading if the applied stress exceeds the materials threshold value, which is often ended by structural failure [

24,

32].

Concerning the generalized Kitagawa diagram (GKD), the corresponding values, including the long crack notch stress intensity factor threshold range

and the intrinsic El-Haddad length for V-notches

, have to be derived from the crack-related parameters

and

, respectively. According to Atzori et al. [

28],

can be determined by means of by Equation (

3) under consideration of the opening angle dependent stress singularity

.

Relating to the determination of the intrinsic El-Haddad length for V-notches

, the Equations (

2) and (

3) can be utilized, where

is substituted by the fatigue limit

. By re-arranging the resulting formula, Equation (

4) is easily obtained.

Representing an enhancement of the KTD, the generalized Kitagawa diagram additionally takes the opening-angle, in terms of the stress singularity, into account. Considering a V-notch in a double infinite plate exhibiting an opening angle

greater than zero and a size of

, the local fatigue strength increases with an increase of the opening-angle, despite keeping a constant size, as it is illustrated in

Figure 1. According to Atzori et al. [

33,

34,

35], the Kitagawa–Takahashi can be separated into the regions of non-propagating short cracks, crack closure-afflicted long cracks and the notch mechanics.

Additionally to the geometrical influences of the notch, the consideration of the mean stress sensitivity is of utmost importance for service design. Thereby it is necessary to distinguish between the mean stress effect concerning the fracture mechanical behaviour and the fatigue strength of the material. Relating to the fracture mechanical literature, several methodologies, such as the approach from Elber [

36] and the corresponding adaptions by Schijve [

37] and Walker [

38] are known to take the load stress ratio (R-ratio) into account. Mann illustrates a comparison of the referred models, which can be found in [

39]. Further approaches in regard to the mean stress influence on the crack growth are given in [

40,

41,

42].

An analytical estimation of the crack opening function, see Equation (

5), was proposed by Newman [

43] based on finite-element simulations and subsequently correlated between the R-ratio and the long crack threshold value [

44].

In accordance with Newman, the long crack threshold

diminishes continuously as the R-ratio increases due to the steadily growing separation of the crack flanks in the contact field until the effective short crack threshold

is attained. Relating to elevated load ratios, from approximately

, crack closure will not occur [

43,

45,

46].

Thereby,

represents the long crack stress intensity factor threshold range at a tumescent load ratio of

. The factor

is the crack opening function,

is the Newman coefficient and

is a material constant. The applicability of Newman’s approach, concerning the characterization of load ratio dependent crack growth thresholds, is illustrated in [

44].

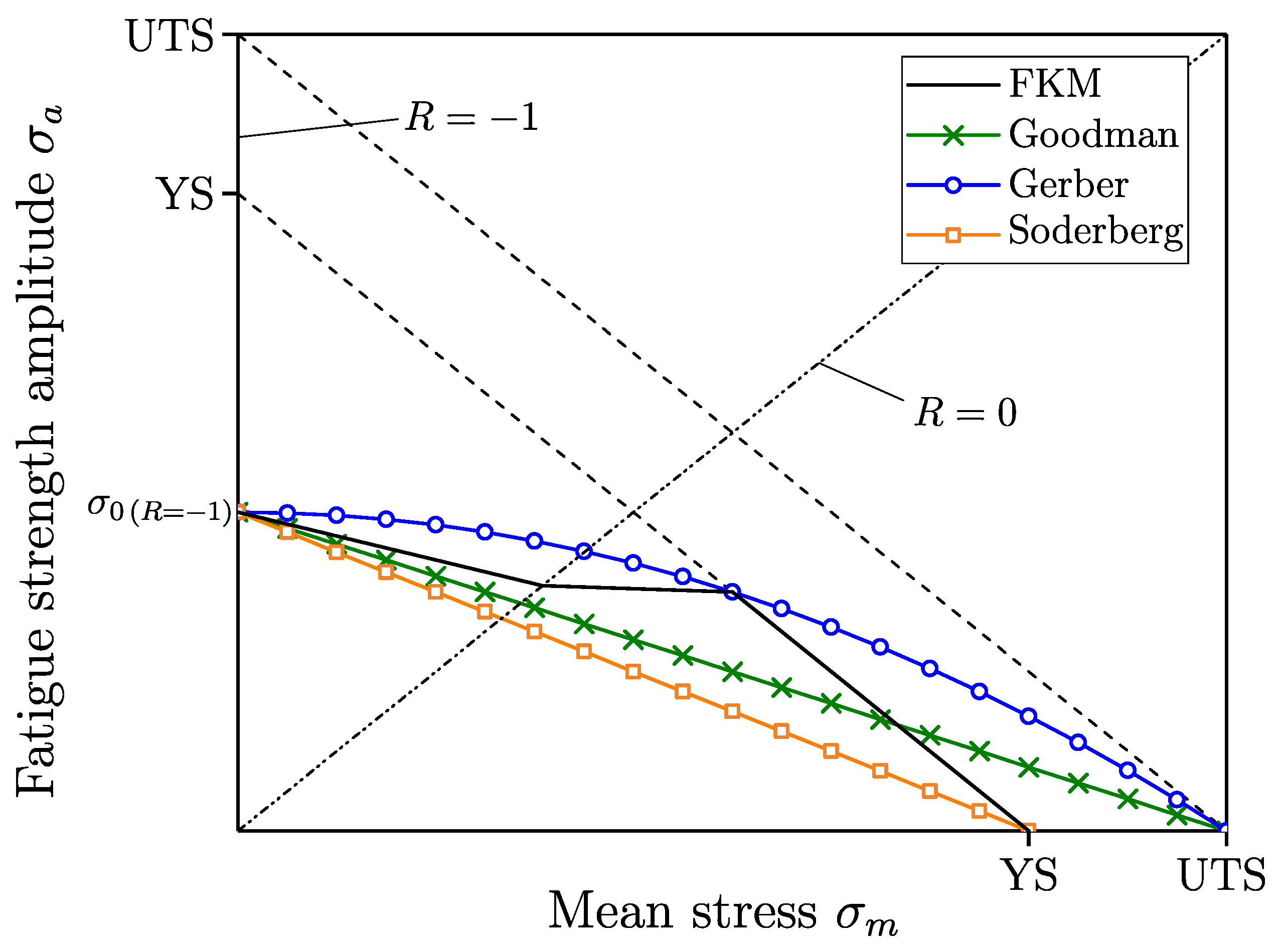

Referring to the influence of the mean stress on the fatigue strength, several approaches, such as by Goodman [

47], Gerber [

48], and Soderberg [

49] have been proposed in preliminary studies.

Figure 2 illustrates these commonly applied mean stress models, as well as the FKM guideline approach [

50], which introduces a mean stress dependent sensitivity factor

.

An overview of these and further state-of-the-art common mean stress models can be found in [

51]. The FKM approach features a reduced sensitivity at high load stress ratios and is therefore characterized by a bilinear formulation. Accordingly, the R-dependent fatigue strength amplitude can be determined by Equation (

6).

where the mean stress sensitivity

is directly related to the material’s ultimate tensile strength

by the material dependent parameters

and

, depicted in Equation (

7).

A basic differentiation of mean stress models can be conducted based on the model’s dependency. Since the approaches according to Goodman, Gerber, and Soderberg are related to the material’s yield strength

or rather the ultimate tensile strength

, the fatigue strength amplitude at a given mean stress can be determined with diminishing experimental effort. On the contrary, further state-of-the-art models [

16,

38,

52,

53] exhibit an additional material dependent parameter, which leads to a sound consistency between model and material behaviour, but they also require more extensive material testing.

The majority of casting defects are caused by the disturbance of the local feeding condition and therefore facilitate the formation of local shrinkage porosity, which can be considered as internal notches, leading to a significantly diminished fatigue strength. Furthermore, the influence of the mean stress on the long crack threshold and the material’s fatigue strength in correspondence with macroscopic casting defects has to be taken into account. Since various models highlight the effect of the mean stress on homogeneous materials, the impairment of casting flaws has to be studied comprehensively. Hence, this work aims for the accessibility of mean stress exposed macroscopic shrinkage porosities and the corresponding estimation of the local fatigue limits based on computed tomography and X-ray investigations. Furthermore, focus is laid on the comparison between real casting defects and geometrically similar, artificially generated macroscopic pores.

Hence this paper scientifically contributes to the following topics:

Evaluation of the mean stress sensitivity of both homogeneous and defect afflicted cast steel material.

Fatigue strength assessment of large-scale cast steel specimens exhibiting macroscopic shrinkage porosities based on the NSIF approach applying the generalized Kitagawa diagram.

Calculation of the fatigue strength on the basis of X-ray examinations of cast specimens.

Numerical analysis of artificially generated macroscopic defects as basis for a probabilistic fatigue assessment of imperfections with varying, but cast steel process related, geometry.

3. Application of the Generalized Kitagawa Diagram

Firstly, in order to set up the GKD, the characteristic values

and

must be determined utilizing Equations (

3) and (

4). In order to take the mean stress sensitivity into account, the R-ratio dependencies according to the

FKM guideline [

50] and Newman’s approach [

43] are used.

Secondly, considering the assessment of the macroscopic shrinkage porosities, a relation between the defect size, referring to the equivalent circle diameter (ECD), and the effective defect size

has to be established. Defect types, as depicted in

Figure 16, are difficult to assess concerning the effect on the local fracture mechanical stress intensity factors due to their partially irregular shapes. The literature offers a wide variety of studied simple geometrical shapes and the corresponding fracture mechanical geometry factor solutions [

67,

68]. Referring to an engineering-feasible substitutional shape, a correlation between the arbitrarily-shaped defects and a corresponding penny-shaped crack has been studied in [

23] by means of numerical crack growth simulations. In the following, the assessment approach is briefly reviewed. Details about the crack propagation rates, corresponding simulations and the results were given in [

23].

The numerical analysis aims to link the arbitrary flaw ECD and the initial diameter of the penny-shaped crack in terms of a similar crack propagation lifetime. Therefore, several defect shapes of both defect types, FT#A and FT#B, are imported from the fracture surfaces into three-dimensional finite-element models, whereas the defects are simplified and integrated as two-dimensional cracks, considering an already initiated crack. The applied stresses in the simulation are in correspondence with the applied stresses of the experimental tests. The calculation of the local stress intensity factor ranges

is conducted by the finite-element simulation tool Abaqus

© (Version: 6.14). The subsequent determination of the local crack propagation rate

around the perimeter is executed by means of the modified NASGRO equation [

44]. The incremental simulations feature a crack growth of

m per step. Furthermore, the self-iterating crack growth model is stopped if the critical stress intensity range

is detected at any point of the crack front perimeter.

A subsequent comparison of the numerical results exhibits a similar crack propagation rate between an FT#A defect and an

penny-shaped crack. But for the FT#B defects, a penny-shaped crack of size

results in a similar lifetime [

23].

According to these findings, the defect ECDs, which are derived from the fracture surface analysis, are recalculated to obtain the effective defect sizes. Depending on the shape and orientation of the pores, the

values are either determined by the factor

or

[

23]. The results of the fatigue assessment are illustrated in

Figure 21 and

Figure 22, where the effective defect sizes are obtained by fracture surface analysis. Thereby, the experimental load level of each specimen is plotted over the corresponding effective defect size. The aforementioned defect types are distinct by means of blue and green markers for FT#A and FT#B defects, respectively. Furthermore, tests that resulted in premature burst failure are depicted as ‘×’ and run-outs are illustrated as ‘∘’. The blue and green lines represent the long-life fatigue limits at ten million load cycles for V-notches with

and

opening-angles and are calculated in accordance with Equation (

2). Additionally, it should be noted that the sketched fatigue strength design curves correspond to a probability of survival of 50%.

The calculated fracture mechanics results show a sound agreement for both opening angles. Thereby, a valid relation between the FT#A and the

line and between FT#B and the

line can be detected for both R-ratios. Consequently, a link between the spatial orientation of the defects and the opening-angle dependent GKD design curves is present in this context. The FT#A defects, which are rectangularly aligned regarding the specimen’s axis and additionally exhibit a shallow depth, depict a crack similar geometry. The determined stress singularity of a

V-notch results in

, calculated by Equation (

1). As a comparison, the stress singularity of a crack results in a value of

. Hence, the assessment of shrinkage pores, which exhibit a crack like orientation and shape, can be satisfactorily conducted by a

NSIF approximation based on these results.

Since a fracture surface based defect assessment is not feasible in an industrial manufacturing environment, the sizes of the defects are additionally non-destructively determined from X-ray results on specimens before cyclic testing. Therefore, the radiographic films from two rectangular directions are utilized for the measurement of the defect size. The average flaw size values are further utilized for the generalized Kitagawa diagram, as illustrated in

Figure 23. Compared to

Figure 22, which illustrates the GKD where the defect sizes are obtained by fracture surface analysis, a similar distribution concerning FT#A and FT#B failures and run-outs can be determined. Nevertheless, a reduced quantity of data points is depicted in the X-ray based diagram, due to a limited detectability of the porosities during the non-destructive testing. Hence, an X-ray based assessment enables equivalent results compared to a fracture surface based evaluation; however, the probability and reliability of detection represents the key aspects in this concern for engineering applicability.

Due to the estimations based on Newman’s approach and the fatigue limit model of the FKM guideline, the GKD can be enhanced towards the load stress ratio as the diagram’s third axis. This enables a holistic defect assessment considering the spatial orientation, defect size and the present mean stress, as depicted by

Figure 24 and

Figure 25.

Based on the overall shape, the derived GKD can be separated into two regions, represented by the red line as a common border. The area exhibiting defect sizes is solely influenced by the Haigh diagram given by the FKM guideline. Contrarily, the area based on notch fracture mechanics, , is additionally affected by Newman’s approach. Therefore, the overall shape of the GKD surface is dependent on the applied load stress ratio, except the slope towards the defect size, which is itself entirely influenced by the stress singularity , hence the notch-opening angle. The red transition line exhibits a slight decrease of the in the range . However, if the load stress ratio exceeds a value of , the transition knee point increases significantly to higher effective defect sizes. Furthermore, a considerable drop of the fatigue limit is obtained at load stress ratios due to elastic yield limitations resulting from the Haigh diagram.

Since the build-up of a probabilistic fatigue database, which consists of a large bulk of defects that exhibit varying shapes and spatial orientations, can substitute a high quantity of experimental effort, a numerical algorithm is further developed in order to generate such artificial porosities. Thereby, it is necessary to partially specify and limit the global shape of the flaws to keep the investigated geometries related to the investigated manufacturing process itself, but to also leave space for randomly artificially generated defects.

4. Assessment of Artificially Generated Defects

In order to establish artificial casting defects numerically, the algorithm of cellular automata (CA) is utilized. As already proposed in recent publications, the application of CA leads to satisfying results concerning the modelling of porosity formation and pore growth [

69,

70,

71]. The presented results within this paper demonstrate the basic applicability of the developed tool, further details are provided in a preceding scientific work [

72].

At first, a 50 mm × 50 mm square grid, which acts as the plane basis of the porosity is generated. To construct a third dimension, 50 entities of this grid are equidistantly stacked on top of each other. Each cell of the generated cube can exhibit a state of either zero or one. For an initial set of the generated array, a random distribution of the available states is assigned. Thereby, a limiting hull curve is prescribed to constrain the basic shape of the porosity. Inside of the hull curve, the cells are able to be assigned either zero or one. Contrarily, outside the limiting curve, the individual cells are allocated with zero.

Secondly, the algorithm of the cellular automaton is applied under consideration of the three-dimensional Moore neighbourhood [

73]. In order to avoid an excessive smoothing of the surface, the routine is applied in two subsequent runs.

Finally, the resulting array is converted into a point cloud, representing all cells that have the value of one assigned. Thereafter, the surface points are triangulated and smoothed.

Figure 26 exemplarily illustrates a generated defect, which represents quite well the observed shrinkage porosity of FT#B within the investigated cast steel large-scale specimens.

Moreover, the triangulated pore is subsequently imported into a finite-element model exhibiting the large-scale specimen’s geometry. The model is meshed by means of quadratic tetrahedral elements and loaded with a uniform tensile stress along the model’s z-axis.

In order to assess the numerically generated pores on the basis of the generalized Kitagawa diagram, the defect’s ECD and an effective notch-opening angle has to be determined. The equivalent circle diameter is determined during the numerical generation of the pore by means of the projected defect area in the

x–

y plane. Relating to the effective notch-opening angle, an assessment of the vicinity around the maximum stress has to be conducted. Therefore, the nodal maximum principal stress and the corresponding normal surface vector has to obtained for the whole modelled defect surface. Subsequently, the defect is intersected with a plane that is spanned by the normal surface vector and a parallel vector, to the centre axis of the specimen. The obtained intersection curve of the pore, especially the section around the node of the maximum principal stress, is utilized for the assessment of an effective notch-opening angle. Hence, an empirical study of computed tomography measured imperfections fatigue data yielded that the length of the used secants should correspond to a value of

for a proper assessment of the equivalent notch-opening angle

as depicted in

Figure 27. The resulting angle between both secants is subsequently evaluated and further utilized as the equivalent opening angle for the determination of the local NSIF value, applicable both for measured and artificially generated defects. Additionally, it should be mentioned that Neuber’s rule may also be applicable once the defects and notch radii attain a certain size.

In order to examine the sensitivity of the proposed approach, the numerical algorithm is utilized to generate several macro-geometry related porosities for each individually measured defect. Hereby, attention is paid to the occurrence of similar geometrical characteristics, as found at the computed tomography scans of the large-scale specimens. Further on, finite-element simulations, with a unified applied stress, are conducted in order to assess the local NSIF values and the corresponding fatigue limits, according to Equation (

9). The resulting data is subsequently averaged and compared to the experimental test data as sensitivity qualifier, see Equation (

10).

For illustration, three different porosities from the CT measurements are selected. Correspondingly, artificially numerical pores, which possess a similar overall shape and ECD, are generated. The selected casting defects and a corresponding numerically generated defect are sketched in

Figure A1.

The results of the finite-element simulation and the subsequent calculation of the estimated fatigue limits as well as the equivalent circle diameters are summarized in

Table 6.

Referring to the results of the specimens #31 and #32, the estimated mean fatigue limits are both below the applied experimental stress ranges. In the case of specimen #31, the applied load was endured for about

load cycles, whereby ten million load cycles are regarded as run-out. In terms of specimen #32, the test was aborted due to burst failure at about

load cycles. Considering both estimated stress range limits, specimen #31 exhibits a smaller deviation to the applied stress range by 6 MPa than specimen #32 with 23 MPa. Concerning the third illustrated porosity, specimen #34, the experiment resulted in a run-out at

MPa, and further, to a burst failure at 175 MPa at about

load cycles. The accordingly generated defects and the accompanying fatigue assessment obtained an estimated fatigue stress range of 162 MPa, which is located between both experiments. Summing up, the numerical algorithm and the subsequent fatigue assessment deliver an averaged conservative deviation of 7.8%. Moreover, in [

72] an extended study of ten specimens and their corresponding defects is performed, which results an average conservative deviation of 6%.

Furthermore, a mesh sensitivity study is conducted in order to evaluate the fatigue limit dependency on the element size. Therefore, the artificially generated porosity of specimen #31 is numerically evaluated by means of constant boundary conditions and an identical flaw shape, but exhibiting four different mesh sizes, including the average element sizes 500

m, 250

m, 167

m and 125

m as depicted in

Figure 28. The results of the subsequent assessment is listed in

Table 7.

Thereby it can be stated that the node of maximum principal stress is almost unchanged and thus independent from the mesh size. Contrarily, the refined mesh exhibits an increasing stress concentration factor, but the evaluated NSIF-value is only slightly affected. Referring to the evaluated fatigue limits, which are normalized to the result of the 500 m model, the refined mesh study exhibits only small deviations. In detail, models with mesh seed of 250 m, 167 m and 125 m lead to variances of 4%, 3% and 1%, respectively.

Concluding, an increasing mesh refinement results in a more accurate stress concentration factor. Furthermore, the study shows that the estimated fatigue limits are nearly unchanged. Additionally, it should be noted that a mesh refinement of the analysed imperfections lead to a significant increase of up to 400 times in terms of in calculation time.

Considering the results and a comparison of the experiments and numerically generated artificial pores, the NSIF-based approach offers sound applicability as an assessment tool. Furthermore, the utilization of artificially generated porosities provides a basic database for the probabilistic assessment of non-destructively detected casting flaws, which will be statistically covered in more detail in ongoing research work.