Current State of Semi-Solid Net-Shape Die Casting

Abstract

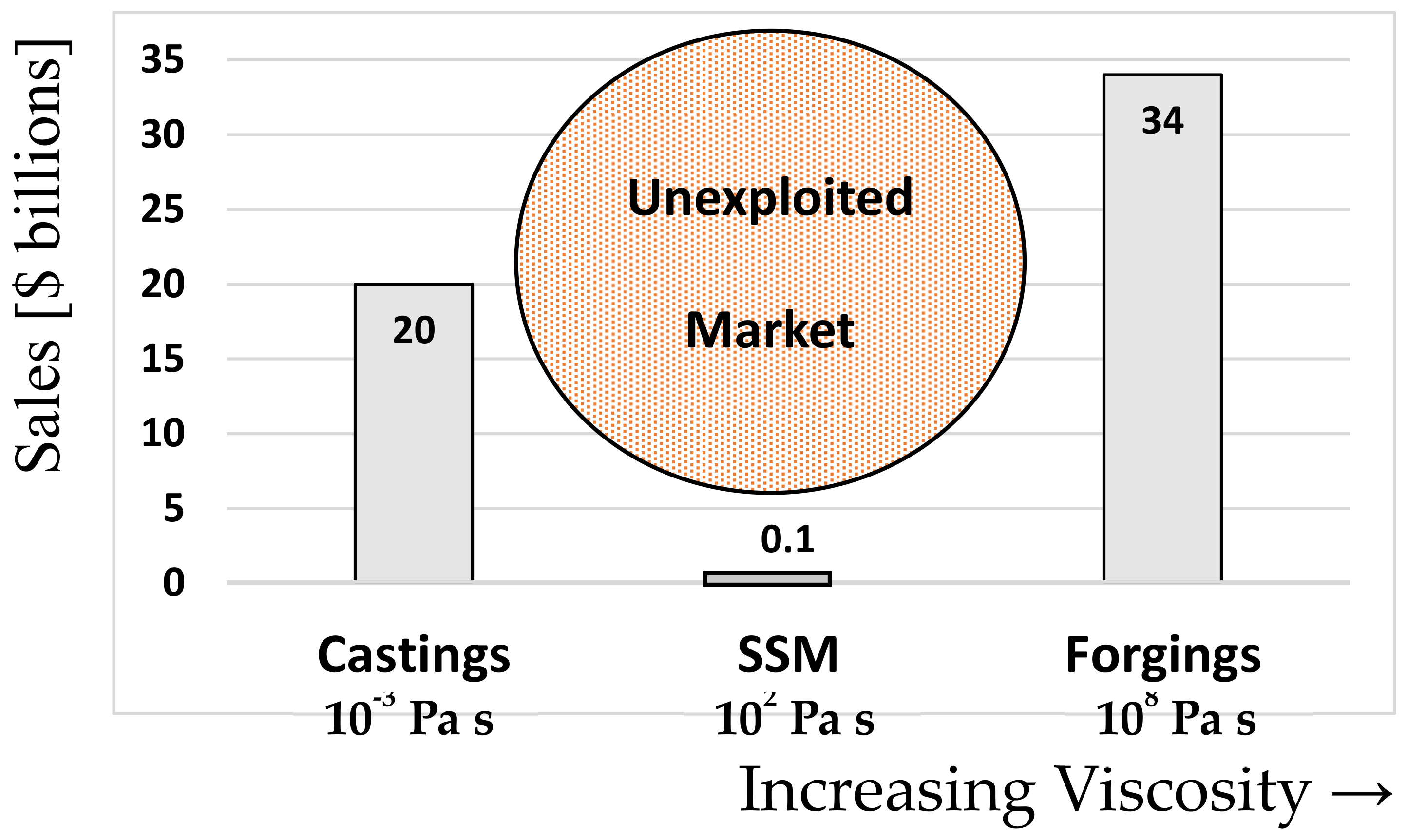

:1. Introduction

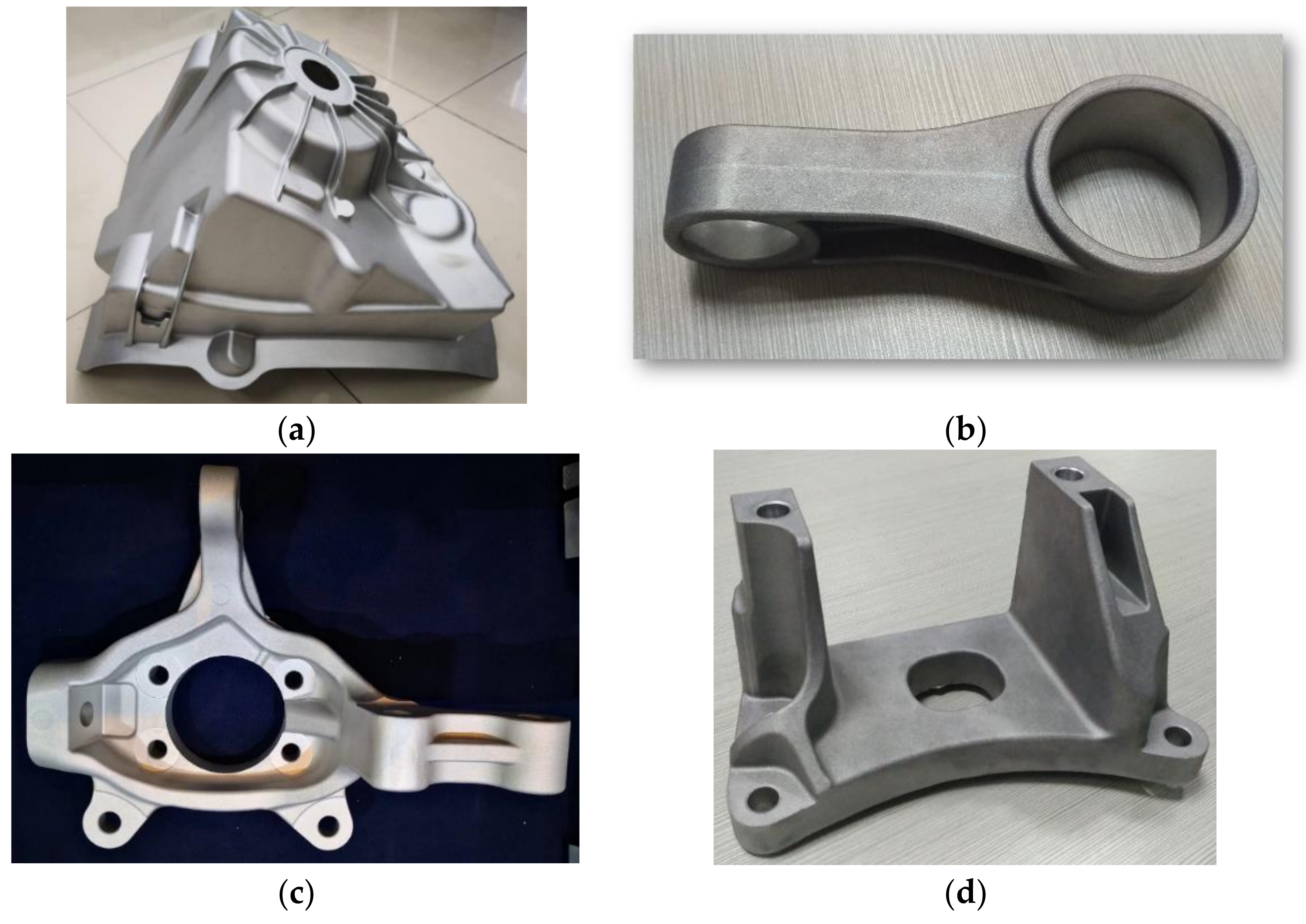

2. Past SSM Processes

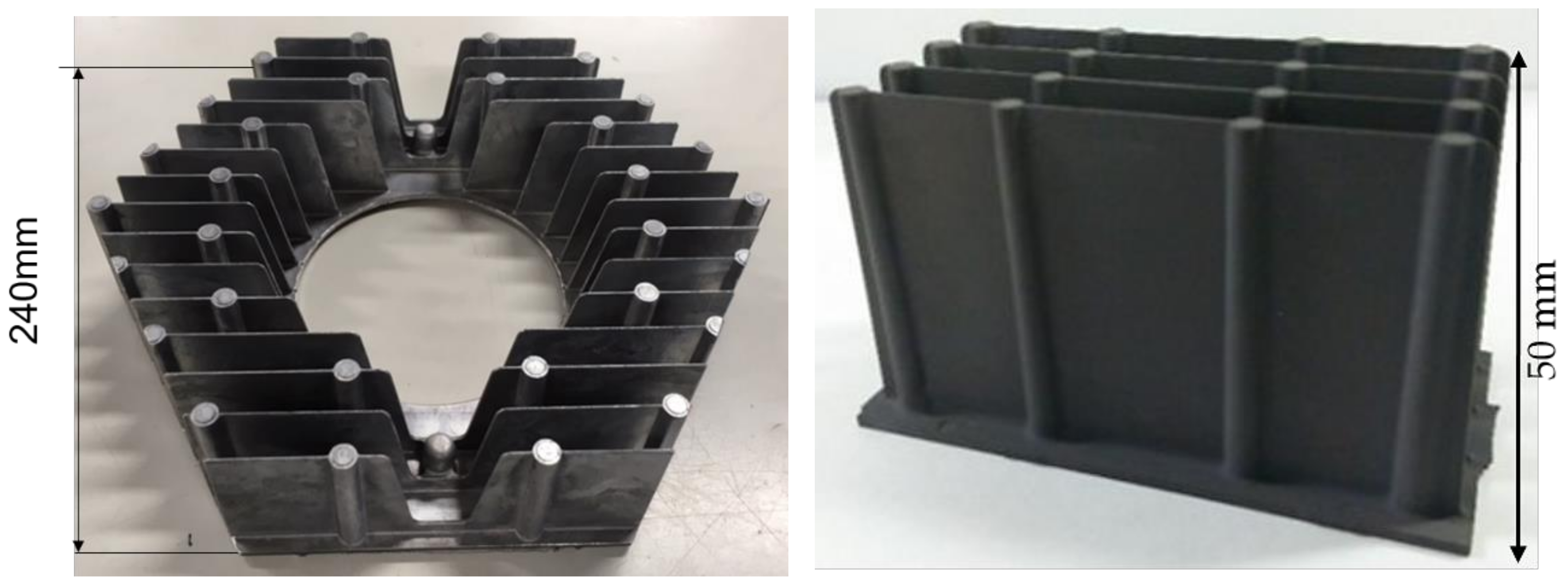

3. Present SSM Processes

4. Future Prospects

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Spencer, D.B.; Mehrabian, R.; Flemings, M.C. Rheological behavior of Sn-15 pct Pb in the crystallization range. Metall. Mater. Trans. 1972, 3, 1925–1932. [Google Scholar] [CrossRef]

- Suery, M.; Martin, C.L.; Salvo, L. Overview of the rheological behaviour of globular and dendritic slurries. In Proceedings of the 4th International Conference on Semi-Solid Processing of Alloys and Composites, Sheffield, UK, 19–21 June 1996; pp. 21–29. [Google Scholar]

- Quaak, C.J.; Katgerman, L.; Kool, W.H. Viscosity evolution of partially solidified aluminum slurries after shear rate jump. In Proceedings of the 4th International Conference on Semi-Solid Processing of Alloys and Composites, Sheffield, UK, 19–21 June 1996; pp. 35–39. [Google Scholar]

- Alexandrou, A.N. Modelling of Semisolid Metals Processing: A tool for Process Design and Optimization. In Proceedings of the Inaugural Meeting of the Semi-Solid Materials Processing Laboratory, Worcester, MA, USA, 30 May 1997. [Google Scholar]

- Flemings, M.C. Dendrite Fragmentation in Semisolid Casting: Could we do this Better? Solid State Phenom. 2019, 285, 3–11. [Google Scholar] [CrossRef]

- Young, K.P.; Taylor, D.E.; Cheskis, H.P.; Watson, W.G. Process and apparatus for continuous slurry casting. U.S. Patent 4,482,012, 1 June 1982. [Google Scholar]

- Kirkwood, D.H.; Suéry, M.; Kapranos, P.; Atkinson, H.V.; Young, K.P. Semi-Solid Processing of Alloys; Springer: New York, NY, USA, 2010; ISBN 978-3-642-00705-7. [Google Scholar]

- Yurko, J.A.; Flemings, M.C.; Martinez, A. Semisolid Rheocasting (SSR)—Increasing the capabilities of Die casting. J. Die Cast Eng. 2004, 48, 50–52. [Google Scholar]

- Yurko, J.A.; Brower, R.W.; Martinez, R.A.; Flemings, M.C.; Bertelli, P. Process and Apparatus for Preparing a Metal Alloy. U.S. Patent 6918427, 19 July 2005. [Google Scholar]

- Wannasin, J.; Junudom, S.; Rattanochaikul, T.; Flemings, M.C. Development of the Gas Induced Semi-Solid Metal Process for Aluminum Die Casting Applications. Solid State Phenom. 2008, 141–143, 97–102. [Google Scholar] [CrossRef]

- Wannasin, J.; Flemings, M.C. Process for Preparing Molten Metals for Casting at a Low to Zero Superheat Temperature. WO Patent PCT/TH2014/000025, 2014. Available online: http://www.gissco.com/GISS-process (accessed on 26 November 2019).

- Doutre, D.; Langlais, J.; Roy, S. The seed process for semi-solid forming. In Proceedings of the 8th International Conference on Semi-Solid Processing of Alloys and Composites (S2P ‘04), Limassol, Cyprus, 21–23 September 2004; pp. 397–408. [Google Scholar]

- Doutre, D.; Hay, G.; Wales, P. Semisolid Concentration Processing of Metallic Alloys. U.S. Patent 6,428,636 B2, 6 August 2002. [Google Scholar]

- Decker, R.; LeBeau, S.; Wilson, B.; Reagan, J.; Moskovich, N.; Bronfin, B. Thixomolding® at 25 Years. Solid State Phenom. 2016, 256, 3–8. [Google Scholar] [CrossRef]

- Mihelich, J.; Decker, R.F. Apparatus for Processing Corrosive Molten Metals. U.S. Patent 5,711,366A, 27 January 1998. [Google Scholar]

- Kapranos, P. Semi-Solid Metal Processing—A Process Looking for a Market. Solid State Phenom. 2008, 141–143, 1–8. [Google Scholar]

- Kapranos, P. ‘Thixoforming: From automotive to aerospace’. APT Alum. Process Prod. Technol. 2008, 5, 39–44. [Google Scholar]

- Nafisi, S.; Ghomashchi, R. Semi-Solid Processing of Aluminum Alloys; Springer: New York, NY, USA, 2016; ISBN 978-3-319-40333-5. [Google Scholar]

- Brown, S.B. Fundamentals of Semi-Solid Processing. In Proceedings of the Inaugural Meeting of the Semi-Solid Materials Processing Laboratory, Worcester, MA, USA, 30 May 1997. [Google Scholar]

- Midson, S.P. Semi-Solid Metal Casting of Lightweight Components. In Proceedings of the Inaugural Meeting of the Semi-Solid Materials Processing Laboratory, Worcester, MA, USA, 30 May 1997. [Google Scholar]

- Adachi, M.; Sato, S.; Harada, Y.; Kawasaki, T. Apparatus for Producing Metal to be Semimolten-Molded. U.S. Patent 6,165,411, 26 December 2000. [Google Scholar]

- Kraly, A. Production and Processing of Thixalloy®; The Solution for the Automotive Industry; SAG: Los Angeles, CA, USA, 2003. [Google Scholar]

- Winklhofer, J. Semi-Solid Casting of Aluminium from an Industrial Point of View. Solid State Phenom. 2019, 285, 24–30. [Google Scholar] [CrossRef]

- Available online: https://www.vforge.com/ (accessed on 26 November 2019).

- Rassili, A.; Ceuzaine, C.; Legros, W.; Bobadilla, M.; Cucatto, A.; Robelet, M.; Abdelfattah, S.; Dohmann, J.; Hornradt, C. Simulation of adequate heating parameters and the Magneto-thermal coupling involved in the SSM Processing of Steels. In Proceedings of the 6th International Conference on Semi-Solid Processing of Alloys and Composites, Turin, Italy, 27–29 September 2000; pp. 559–564. [Google Scholar]

- Kapranos, P. Routes to Thixoformable Starting Material. In Thixoforming of Steel; Atkinson, H.V., Rassili, A., Eds.; Shaker Verlag: Aachen, Germany, 2010; Chapter 2; pp. 13–36. [Google Scholar]

- Kapranos, P. High-Melting-Point Materials: Semi-Solid Processing. In Encyclopedia of Iron, Steel, and Their Alloys; Taylor and Francis: New York, NY, USA, 2016; pp. 1669–1672. [Google Scholar]

- Zhu, Q.; Rassili, A.; Midson, S.P.; Hu, X.G. (Eds.) Semi-Solid of Alloys and Composites XV. Proceedings of the 15 International Conference on Semi-Solid of Alloys and Composites XV (S2P 2018); Scientific.Net; Available online: https://www.scientific.net/SSP.285/book (accessed on 26 November 2019).

- Jarfors, A.E.; Zheng, J.C.; Chen, L.; Yang, J. Recent Advances in Commercial Application of the Rheometal Process in China and Europe. Solid State Phenom. 2019, 285, 405–410. [Google Scholar] [CrossRef]

- Côté, P.; Vlastimil, B.; Stunova, B.B. Case Study: Engine Bracket Made by Rheocasting Using the SEED Process. Solid State Phenom. 2019, 285, 441–445. [Google Scholar] [CrossRef]

- Qi, M.F.; Kang, Y.L.; Qiu, Q.Q. Industrialized Application of Rheo-HPDC Process for the Production of Large Thin-Walled Aluminum Alloy Parts. Solid State Phenom. 2019, 285, 453–458. [Google Scholar] [CrossRef]

- Wannasin, J.; Fuchs, M.; Lee, J.; Lee, C.U.; Narashima Rao, D.V.L.; Flemings, M.C. GISS Technology: Principle and Applications in Die Casting. Solid State Phenom. 2019, 285, 470–475. [Google Scholar] [CrossRef]

- Qi, M.; Zhuhai Runxingtai Electric Appliance co. Ltd. Research and Development by the School of Materials Science and Engineering, University of Science and Technology Beijing. Personal Communication, 2019.

- Li, D.Q.; Zhang, F.; Midson, S.P.; Liang, X.K.; Yao, H. Recent Developments of Rheo-Diecast Components for Transportation Markets. Solid State Phenom. 2019, 285, 417–422. [Google Scholar] [CrossRef]

- Chen, S.; Li, D.Q.; Zhang, F.; Luo, M.; Liang, X.K.; Zhu, Q. Die Design for Main Bearing Cap of Engine Block Based Semi-Solid Die Casting Process and the Comparison Analysis with Squeeze Casting Process. Solid State Phenom. 2019, 285, 429–435. [Google Scholar] [CrossRef]

- Zhu, Y.B.; Midson, S.P. The Status of Magnesium Injection Molding in China. Solid State Phenom. 2019, 285, 436–440. [Google Scholar] [CrossRef]

- Chiarmetta, G. Thixoforming and weight reduction: Industrial applications of SeSoF. In Proceedings of the 5th International Conference on Semi-Solid Processing of Alloys and Composites, Golden, CO, USA, 23–25 June 1998; pp. 87–95. [Google Scholar]

- Garat, M. Aluminium Semi-Solid Processing: From the Billet to the Finished Part. In Proceedings of the 5th International Conference on Semi-solid Processing of Alloys and Composites, Golden, CO, USA, 23–25 June 1998; pp. xvii–xxxi. [Google Scholar]

- Czerwinski, F. Thermomechanical Processing of Metal Feedstock for Semisolid Forming: A review. Metall. Mater. Trans. 2018, 49, 3220–3257. [Google Scholar] [CrossRef]

- Czerwinski, F. Exploring Thixoforming for Net-Shape Manufacturing. Adv. Mater. Process. 2019, 177, 14–19. [Google Scholar]

- Dutkiewicz, J.; Rogal, Ł.; Sołek, K.; Mitura, Z.; Kapranos, P. Thixoforming of Spay formed M2 Tool Steel. Int. J. Mater. Form. 2010, 3 (Suppl. 1), 755–758. [Google Scholar] [CrossRef]

- Czerwinski, F. Coarse particulates, A new material precursor for Net Shape Forming. Int. J. Powder Metall. 2005, 41, 64–70. [Google Scholar]

- Hogg, S.C.; Atkinson, H.V.; Kapranos, P. Thixoforming of Stellite Powder Compacts. In Proceedings of the 10th ESAFORM Conference, Zaragoza, Spain, 18–20 April 2007. [Google Scholar]

- Qi, M.; School of Materials Science and Engineering, University of Science and Technology Beijing. Personal Communication, 2019.

- Zhu, Q.; Founder and Head of SSM R&D Team at GRINM and Leader of a Research Team at Southern University of Science and Technology (SUSTech). Personal Communication, 2019.

- Yang, A.; Sales at Zhu Yibing’s Company www.ssd-magnesium.com. Personal Communication, 2019.

- Haga, T.; Fuse, H.; Terao, M. Fabrication of Thin Heat Sinks by the Die Casting of Semisolid Al-25%Si. Solid State Phenom. 2019, 285, 423–428. [Google Scholar] [CrossRef]

- Kapranos, P.; Kirkwood, D.H.; Atkinson, H.V.; Rheinlander, J.T.; Bentzen, J.J.; Toft, P.T.; Debel, C.P.; Laslaz, G.; Maenner, L.; Blais, S.; et al. Thixoforming of an automotive part in A390 hypereutectic Al-Si alloy. J. Mater. Process. Technol. 2003, 135, 271–277. [Google Scholar] [CrossRef]

- Semenov, A.B.; Ngo, T.B.; Semenov, B.I. Thixoforming of Hypereutectic AlSi12Cu2NiMg Automotive Pistons. Solid State Phenom. 2019, 285, 446–452. [Google Scholar] [CrossRef]

| Attributes | SSM Product | Traditional HPDC Products |

|---|---|---|

| Process | Rheo-HPDC | HPDC |

| Flatness | 0.4 mm | 0.6 mm |

| Minimum wall thickness | 3.5 mm | 4.5 mm |

| Condition | No pores or shrinkage holes | Porosity and shrinkage |

| Weight reduction | 300 g | Not achieved |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapranos, P. Current State of Semi-Solid Net-Shape Die Casting. Metals 2019, 9, 1301. https://doi.org/10.3390/met9121301

Kapranos P. Current State of Semi-Solid Net-Shape Die Casting. Metals. 2019; 9(12):1301. https://doi.org/10.3390/met9121301

Chicago/Turabian StyleKapranos, Plato. 2019. "Current State of Semi-Solid Net-Shape Die Casting" Metals 9, no. 12: 1301. https://doi.org/10.3390/met9121301

APA StyleKapranos, P. (2019). Current State of Semi-Solid Net-Shape Die Casting. Metals, 9(12), 1301. https://doi.org/10.3390/met9121301