Evaluation of the Thermal Comfort and Energy Demand in a Building with Rammed Earth Walls in Spain: Influence of the Use of In Situ Measured Thermal Conductivity and Estimated Values

Abstract

:1. Introduction

- Exploring the differences between estimated and measured data is necessary to characterise the thermal properties of earthen structures, and it is much more accurate if it is related to a specific climatic zone;

- A common methodology to monitor earth buildings should be established;

- Occupation and activity in the building is usually not studied, and it can highly influence the results;

- The adaptative model as per the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), standard number 55, is the most common to describe thermal comfort, and the (ISO) 9869 to characterise thermal parameters of walls;

- In order to study different parameters in buildings via simulations, the validation of the numerical model is necessary.

2. Materials and Methods

2.1. Case Study Analysis

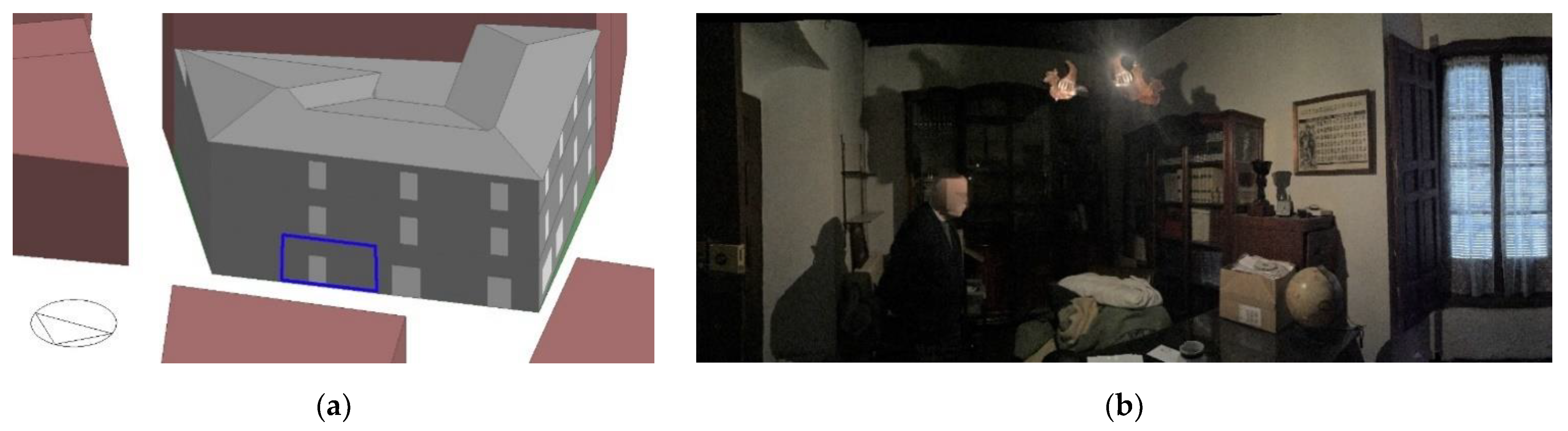

2.1.1. Description of the Studied Building and Room

2.1.2. In Situ Experimentation and Survey Research

- We have monitored the environmental conditions of the described room, recording the indoor temperature and humidity and outdoors dry-bulb temperature and relative humidity values;

- We have collected information about the use of the building through surveys to the users every six months (October–March and April–September).

2.2. Building Energy Performance Simulations

- We have used the Conduction Transfer Function (CTF) solution algorithm, which only considers heat transfer. Previous research compared three different methods to assess energy performance: CTF, HAMT (Heat and Moisture Transfer) and EMPD (Effective Moisture Penetration Depth), and concluded that for a hot and dry climate, the CTF is the best option for building energy simulation analysis [38];

- Ground monthly temperatures were not measured. According to the program’s manual: “a reasonable default value of 2 °C less than the average monthly indoor building temperature is appropriate for large buildings”. Therefore, this was introduced in the location level of the software;

- The density of the rammed earth wall has not been determined in situ, so we have used a density of 1885 kg/m3, which is the mean value we can find in the Technical code of Spain [6] and it is in accordance with values provided by different characterisation studies of this type of construction [39,40,41]. Nevertheless, we have also analysed the effect of using different values for the density of the earth in the wall on the correlation between the model and the actual building.

2.2.1. Simulation Variables

2.2.2. Correlation between S1 to S4 Alternatives and Measured Values

- Coefficient of determination (R2), which is used in statistics to predict future results or to prove a hypothesis. In our case, it is employed to determine the quality of the model in DesignBuilder and the difference between the model and the actual air temperature in the measured spaces, as can be found in previous research [42,43,44]. We have analysed periods of 24 h, 72 h and a week, in Winter and in Summer. We have not used longer periods as we have considered that the R2 value is too low;

- Using graphs that show short periods of time: a week in Winter and a week in Summer. These weeks are the same that have been used for the R2 coefficient;

- Comparison of results during a month in Summer, using the adaptative model described in the ASHRAE 55 [45].

2.2.3. Comfort Analysis

2.2.4. Energy Demand Analysis

- Winter: setpoint = 20.9 °C; set back = 17.4 °C

- Summer: setpoint = 26.5 °C; set back = 30 °C

2.3. Compliance with the Spanish Energy Saving Code

3. Results

3.1. Correlation between S1 to S4 Alternatives and Measured Values

3.1.1. R2 Correlation

3.1.2. Graphical Correlation

3.1.3. RMSE and Maximum Temperature Deviation

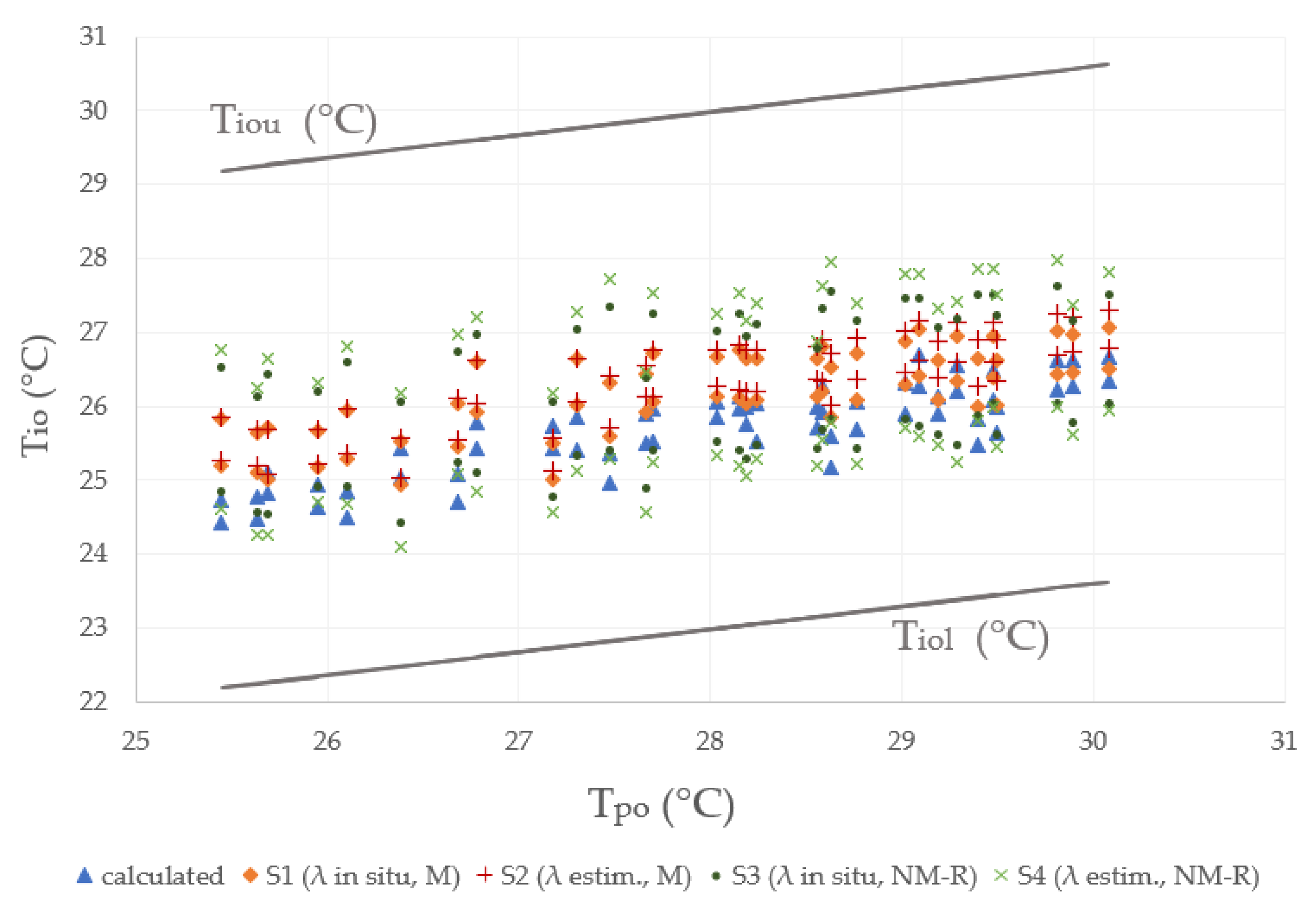

3.1.4. Indoor Operative Temperature (Tio)

3.2. Analysis of Simulated Comfort and Energy Demand

3.2.1. Thermal Comfort

3.2.2. Energy Demand

4. Discussion

4.1. Validation of the S1 Alternative

4.2. Influence of Estimated vs. Actual Properties of the Wall in Comfort and Energy Demand

4.3. Influence of Estimated vs. Actual Properties of the Wall in the Compliance with the Spanish Code

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IEA. Global Status Report for Buildings and Construction; Paris, France, 2019; Available online: https://www.iea.org/reports/global-status-report-for-buildings-and-construction-2019 (accessed on 7 December 2021).

- IEA. Tracking Buildings 2020; Paris, France, 2020; Available online: https://www.iea.org/reports/tracking-buildings-2020 (accessed on 25 October 2021).

- Giesekam, J.; Barrett, J.R.; Taylor, P. Construction sector views on low carbon building materials. Build. Res. Inf. 2016, 44, 423–444. [Google Scholar] [CrossRef]

- IEA. Building Envelopes; Paris, France, 2019; Available online: https://www.iea.org/reports/building-envelopes (accessed on 7 December 2021).

- CTE. DB HE: Código Técnico de la Edificación, Documento Básico de Ahorro de Energía (Spanish Energy Saving Code); Ministerio de Fomento: Madrid, Spain, 2019. [Google Scholar]

- CTE. Código Técnico de la Edificación: Catálogo Informático de Elementos Constructivos (CEC). Available online: https://www.codigotecnico.org/Programas/CatalogoElementosConstructivos.html (accessed on 29 November 2021).

- Baker, P. U-Values and Traditional Buildings in Situ Measurements and Their Comparisons to Calculated Values (Historic Scotland Technical Paper 10); 2011; Available online: https://www.historicenvironment.scot/archives-and-research/publications/publication/?publicationId=16d0f7f7-44c4-4670-a96b-a59400bcdc91 (accessed on 7 December 2021).

- Rhee-Duverne, S.; Baker, P. Research into the Thermal Performance of Traditional Brick Walls (English Heritage Research Report); 2013; Available online: https://historicengland.org.uk/research/results/reports/70-2013 (accessed on 5 December 2021).

- Asdrubali, F.; D’Alessandro, F.; Baldinelli, G.; Bianchi, F. Evaluating in situ thermal transmittance of green buildings masonries—A case study. Case Stud. Constr. Mater. 2014, 1, 53–59. [Google Scholar] [CrossRef]

- Biddulph, P.; Gori, V.; Elwell, C.A.; Scott, C.; Rye, C.; Lowe, R.; Oreszczyn, T. Inferring the thermal resistance and effective thermal mass of a wall using frequent temperature and heat flux measurements. Energy Build. 2014, 78, 10–16. [Google Scholar] [CrossRef] [Green Version]

- Li, F.G.N.; Smith, A.Z.P.; Biddulph, P.; Hamilton, I.G.; Lowe, R.; Mavrogianni, A.; Oikonomou, E.; Raslan, R.; Stamp, S.; Stone, A.; et al. Solid-wall U-values: Heat flux measurements compared with standard assumptions. Build. Res. Inf. 2015, 43, 238–252. [Google Scholar] [CrossRef] [Green Version]

- Cuerda, E.; Romero, N.; Neila, F.J.; Guerra-Santin, O. Post-Occupancy Monitoring of Two Flats in Madrid: Development and Assessment of a Mixed Methods Methodology. In Proceedings of the PLEA 2015 Conference, Bolonia, Italia, 9–11 September 2015. [Google Scholar]

- Ficco, G.; Iannetta, F.; Ianniello, E.; Alfano, F.R.D.; Dell’Isola, M. U-value in situ measurement for energy diagnosis of existing buildings. Energy Build. 2015, 104, 108–121. [Google Scholar] [CrossRef]

- Marshall, A.; Fitton, R.; Swan, W.; Farmer, D.; Johnston, D.; Benjaber, M.; Ji, Y. Domestic building fabric performance: Closing the gap between the in situ measured and modelled performance. Energy Build. 2017, 150, 307–317. [Google Scholar] [CrossRef]

- Lucchi, E. Thermal transmittance of historical brick masonries: A comparison among standard data, analytical calculation procedures, and in situ heat flow meter measurements. Energy Build. 2017, 134, 171–184. [Google Scholar] [CrossRef]

- Balaguer, L.; Lopez-Manzanares, F.V.; Mileto, C.; Garcia-Soriano, L. Assessment of the Thermal Behaviour of Rammed Earth Walls in the Summer Period. Sustainability 2019, 11, 1924. [Google Scholar] [CrossRef] [Green Version]

- Mascaraque, M.A.M.; Pacual, F.J.C.; Oteiza, I.; Secanellas, S.A. Hygrothermal assessment of a traditional earthen wall in a dry Mediterranean climate. Build. Res. Inf. 2020, 48, 632–644. [Google Scholar] [CrossRef]

- ISO 9869-1. Thermal Insulation—Building Elements—In Situ Measurement of Thermal Resistance and Thermal Transmittance; International Organization for Standardization: Geneva, Switzerland, 2014.

- Mellado Mascaraque, M.Á.; Castilla Pascual, F.J.; Oteiza, I.; Martín-Consuegra, F. In situ monitoring and characterisation of earthen envelopes: A review. In Proceedings of the SOSTierra 2017: International Conference on Vernacular Earthen Architecture, Conservation and Sustainability, Valencia, Spain, 14–16 September 2017. [Google Scholar]

- Carrobe, A.; Rincon, L.; Martorell, I. Thermal Monitoring and Simulation of Earthen Buildings. A Review. Energies 2021, 14, 2080. [Google Scholar] [CrossRef]

- Rincon, L.; Carrobe, A.; Medrano, M.; Sole, C.; Castell, A.; Martorell, I. Analysis of the Thermal Behavior of an Earthbag Building in Mediterranean Continental Climate: Monitoring and Simulation. Energies 2020, 13, 162. [Google Scholar] [CrossRef] [Green Version]

- de Dear, R.J. Adaptative thermal comfort in building management and performance. In Proceedings of the Healthy Buildings: Creating a Healthy Indoor Environment for People, Lisbon, Portugal, 4–8 June 2006. [Google Scholar]

- Heathcote, K. The thermal performance of earth buildings. Informes de la Construcción 2011, 63, 117–126. [Google Scholar] [CrossRef] [Green Version]

- Serrano, S.; de Gracia, A.; Cabeza, L.F. Adaptation of rammed earth to modern construction systems: Comparative study of thermal behavior under summer conditions. Appl. Energy 2016, 175, 180–188. [Google Scholar] [CrossRef] [Green Version]

- Olukoya Obafemi, A.P.; Kurt, S. Environmental impacts of adobe as a building material: The north cyprus traditional building case. Case Stud. Constr. Mater. 2016, 4, 32–41. [Google Scholar] [CrossRef] [Green Version]

- Wati, E.; Meukam, P.; Damfeu, J.C. Modeling thermal performance of exterior walls retrofitted from insulation and modified laterite based bricks materials. Heat Mass Transf. 2017, 53, 3487–3499. [Google Scholar] [CrossRef]

- Martin-Garin, A.; Millan-Garcia, J.A.; Teres-Zubiaga, J.; Oregi, X.; Rodriguez-Vidal, I.; Bairi, A. Improving Energy Performance of Historic Buildings through Hygrothermal Assessment of the Envelope. Buildings 2021, 11, 410. [Google Scholar] [CrossRef]

- Lisitano, I.M.; Laggiard, D.; Fantucci, S.; Serra, V.; Fenoglio, E. Evaluating the Impact of Indoor Insulation on Historic Buildings: A Multilevel Approach Involving Heat and Moisture Simulations. Appl. Sci. Basel 2021, 11, 7944. [Google Scholar] [CrossRef]

- Webb, A.L. Energy retrofits in historic and traditional buildings: A review of problems and methods. Renew. Sustain. Energy Rev. 2017, 77, 748–759. [Google Scholar] [CrossRef]

- Hosseini, I.M.; Saradj, F.M.; Maddahi, S.M.; Ghobadian, V. Enhancing the facade efficiency of contemporary houses of Mashhad, using the lessons from traditional buildings. Int. J. Energy Environ. Eng. 2020, 11, 417–429. [Google Scholar] [CrossRef]

- Mukhtar, M.; Ameyaw, B.; Yimen, N.; Zhang, Q.X.; Bamisile, O.; Adun, H.; Dagbasi, M. Building Retrofit and Energy Conservation/Efficiency Review: A Techno-Environ-Economic Assessment of Heat Pump System Retrofit in Housing Stock. Sustainability 2021, 13, 983. [Google Scholar] [CrossRef]

- Parra-Saldivar, M.L.; Batty, W. Thermal behaviour of adobe constructions. Build. Environ. 2006, 41, 1892–1904. [Google Scholar] [CrossRef]

- Avendano-Vera, C.; Martinez-Soto, A.; Marincioni, V. Determination of optimal thermal inertia of building materials for housing in different Chilean climate zones. Renew. Sustain. Energy Rev. 2020, 131, 110031. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Koppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Sevilla, U.D. ENERGYTIC: Technology, Information and Communication Services for Engaging Social Housing Residents in Energy and Water Efficiency. Available online: https://grupo.us.es/grupotep130/es/proyectos/historico/506-energytic (accessed on 26 October 2021).

- IETcc-CSIC. REFAVIV: Rehabilitación Energética De Las Fachadas De Viviendas Sociales Deterioradas En Madrid y Sevilla. Available online: https://proyectorefaviv.ietcc.csic.es/ (accessed on 26 October 2021).

- Real Decreto 1027/2007, de 20 de julio, por el que se aprueba el Reglamento de Instalaciones Térmicas en los Edificios (RITE). 2021. Available online: https://www.boe.es/buscar/doc.php?id=BOE-A-2007-15820 (accessed on 5 December 2021).

- Qin, M.; Yang, J. Evaluation of different thermal models in EnergyPlus for calculating moisture effects on building energy consumption in different climate conditions. Build. Simul. 2016, 9, 15–25. [Google Scholar] [CrossRef]

- Houben, H.; Guillaud, H. Earth Construction: A Comprehensive Guide; Practical Action Publishing: London, UK, 1994. [Google Scholar]

- Bauluz del Río, G.; Bárcena Barrios, P. Bases Para el Diseño y Construcción Con Tapial; Ministerio de Obras Públicas y Transportes: Madrid, Spain, 1992. [Google Scholar]

- Minke, G. Building with Earth; Birkhäuser: Berlin, Germany, 2006. [Google Scholar]

- Soebarto, V. Analysis of indoor performance of houses using rammed earth walls. In Proceedings of the Eleventh International IBPSA Conference, Glasgow, Scotland, 27–30 July 2009. [Google Scholar]

- Mino-Rodriguez, I.; Naranjo-Mendoza, C.; Korolija, I. Thermal Assessment of Low-Cost Rural HousingA Case Study in the Ecuadorian Andes. Buildings 2016, 6, 36. [Google Scholar] [CrossRef] [Green Version]

- Chel, A.; Tiwari, G.N. Thermal performance and embodied energy analysis of a passive house—Case study of vault roof mud-house in India. Appl. Energy 2009, 86, 1956–1969. [Google Scholar] [CrossRef]

- ANSI/ASHRAE 55-2020. Thermal Environmental Conditions for Human Occupancy; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Peachtree Corners, GA, USA, 2021.

- Dong, X.; Soebarto, V.; Griffith, M. Achieving thermal comfort in naturally ventilated rammed earth houses. Build. Environ. 2014, 82, 588–598. [Google Scholar] [CrossRef]

- Efinovatic. CE3X—Documento Reconocido Para la Certificación Energética de Edificios Existentes. Available online: http://www.efinova.es/CE3X (accessed on 28 October 2021).

- Arnold, P.J. Thermal conductivity of masonry materials. J. Inst. Heat. Vent. Eng. 1969, 37, 101–108. [Google Scholar]

- Chabriac, P.-A. Mesure du Comportement Hygrothermique du Pies; Université de Lyon: Lyon, France, 2014. [Google Scholar]

| Paper | Technical Specification of the Wall (Int-Ext) | Thickness (m) | U-Value (W/m2K) | |

|---|---|---|---|---|

| Estimated | Measured | |||

| [7] | Plaster on lath + solid sandstone wall + ashlar | 0.60 | 1.20–1.50 | 1.00 |

| [8] | Mortar + brick + plaster | 0.30 | 1.30–2.20 | 1.30 |

| Mortar + brick + bare painted brick | 0.30 | 1.30–2.40 | 1.20 | |

| [9] | thermal plaster + thermal block + plaster | 0.45 | 0.32 | 0.56 |

| [10] | gypsum plastering + brick | 0.31 | 1.60–2.39 | 1.16 ± 0.06 |

| [11] | Several cases (all solid walls: 40 brick walls and 18 stone walls) | - 1 | 2.10 | 1.30 ± 0.4 |

| [12] | plastering + solid brick | 0.25 | 2.07 | 1.48 |

| [13] | plaster + hollow clay brick + solid concrete block + hollow concrete block + plaster | 0.50 | 0.42–1.55 | 0.68 ± 0.07 |

| plaster + tuff block + plaster | 0.46 | 0.99–2.23 | 0.80 ± 0.09 | |

| [14] | lime and cement plastering + brick | 0.25 | 2.24 | 1.57 |

| [15] | plaster + solid brick | 0.70 | 0.88 | 0.52 |

| plaster + solid brick | 0.52 | 1.12 | 0.78 | |

| [16] | Gypsum mortar + rammed earth + cement mortar | 0.50 | 1.58 | 0.35 |

| [17] | Plaster + rammed earth + mortar | 0.72 | 1.01 | 0.58 |

| Building Level | Room Level: Office (Ground Floor) | |||

|---|---|---|---|---|

| Activity | Occupancy | Density | 0.03 people/m2 | Unoccupied |

| Schedule | Weekdays: 100% 0–8 h; 25% 8–16 h; 50% 16–24 h Weekends: 100% 0–24 h | Unoccupied | ||

| Metabolic | 117.2 W/person | Unoccupied | ||

| Environmental control | Heating | Setpoint: 20 °C Set back: 17 °C | Setpoint: 20 °C Set back: 18.5 °C | |

| Cooling | Setpoint: 25 °C Set back: 27 °C | No cooling system | ||

| Office equipment | Power density | 4.40 W/m2 | No activity | |

| Schedule | 50% 0–1 h; 10% 1–8 h; 30% 8–18 h; 50% 18–19 h; 100% 19–24 h | No activity | ||

| Construction | External walls | 0.01 m gypsum plaster + 0.70 m rammed earth 1,2 + 0.02 cement mortar | ||

| Pitched Roof | 0.05 m plywood + 0.15 m EPS (Expanded polystyrene insulation) + 0.01 m PU (Polyurethane) + 0.025 m air gap + 0.06 m clay tile | |||

| Partitions | 0.01 m gypsum plaster + 0.12 m adobe 2 + 0.01 gypsum plaster | |||

| Ground floor | 0.15 m cast concrete + 0.15 m gravel | |||

| Internal floor | 0.01 m gypsum plaster + 0.08 m plywood + 0.01 gypsum plaster + 0.03 m clay tile | |||

| Airtightness | Rate at 50 Pa: 10.49 h−1 | |||

| Openings | Glazing | 4 mm + 12 mm air + 4 mm | 4 mm | |

| Frame | PVC (polyvinyl chloride) | Wood | ||

| Lighting | Schedule | 50% 0–1 h; 10% 1–8 h; 30% 8–18 h; 50% 18–19 h; 100% 19–24 h | No lighting (no activity) | |

| HVAC 3 | Heating | Fuel | Oil | Oil |

| Schedule | October–May: 17 °C 0–8 h; 20 °C 8–24 h | October–May: 18.5 °C 0–7 h; 20 °C 7–15 h; 18.5 °C 15–24 h | ||

| Cooling | Fuel | Electricity | No cooling system | |

| Schedule | June–September: 27 °C 0–8 h; 25 °C 16–24 h | |||

| S1 in Situ λ | S2 Estim. λ | S3 in Situ λ—R | S4 Estim. λ—R | |

|---|---|---|---|---|

| Thermal mass consideration | YES | NO | ||

| λ-value (W/mK) | 0.46 | 1.10 | - | - |

| Specific Heat (J/kgK) | 1000 | - | - | |

| Density (kg/m3) | 1885 | - | - | |

| R-value (m2 K/W) | - | - | 1.52 (partitions: 0.26) | 0.64 (partitions: 0.11) |

| R2 Correlation | Graphical Correlation | RMSE and Max T. Deviation | Adaptative Model | |

|---|---|---|---|---|

| 24 h | 8 January 2018 and 29 July 2018 | - | 8 January 2018 and 29 July 2018 | - |

| 72 h | 8–10 January 2018 and 29–31 July 2018 | - | 8–10 January 2018 and 29–31 July 2018 | - |

| One Week | 8–14 January 2018 and 25–31 July 2018 | - | ||

| One month | - | July 2018 | ||

| Period | Winter (January) | Summer (July) | ||||||

|---|---|---|---|---|---|---|---|---|

| Mass (M) | No Mass (NM—R) | Mass (M) | No Mass (NM—R) | |||||

| S1: λ in Situ | S2: λ Estim. | S3: λ in Situ | S4: λ Estim. | S1: λ in Situ | S2: λ Estim. | S3: λ in Situ | S4: λ Estim. | |

| 24 h | 0.91 | 0.87 | 0.87 | 0.76 | 0.98 | 0.97 | 0.97 | 0.96 |

| 72 h | 0.81 | 0.72 | 0.75 | 0.65 | 0.90 | 0.84 | 0.89 | 0.88 |

| One week | 0.61 | 0.56 | 0.58 | 0.52 | 0.78 | 0.85 | 0.52 | 0.50 |

| Period | Winter (January) | Summer (July) | ||

|---|---|---|---|---|

| ρ = 1885 kg/m3 | ρ = 2500 kg/m3 | ρ = 1885 kg/m3 | ρ = 2500 kg/m3 | |

| 24 h | 0.91 | 0.91 | 0.98 | 0.98 |

| 72 h | 0.81 | 0.81 | 0.90 | 0.90 |

| One week | 0.61 | 0.61 | 0.78 | 0.78 |

| Period | Winter (January) | Summer (July) | ||||||

|---|---|---|---|---|---|---|---|---|

| Mass (M) | No Mass (NM—R) | Mass (M) | No Mass (NM—R) | |||||

| S1: λ in Situ | S2: λ Estim. | S3: λ In Situ | S4: λ Estim. | S1: λ In Situ | S2: λ Estim. | S3: λ in Situ | S4: λ Estim. | |

| 24 h | 0.19 | 0.33 | 0.33 | 0.49 | 0.11 | 0.34 | 0.37 | 0.47 |

| 72 h | 0.25 | 0.37 | 0.40 | 0.54 | 0.12 | 0.30 | 0.46 | 0.59 |

| One week | 0.39 | 0.42 | 0.49 | 0.55 | 0.17 | 0.34 | 0.49 | 0.65 |

| Period | Winter (January) | Summer (July) | ||||||

|---|---|---|---|---|---|---|---|---|

| Mass (M) | No Mass (NM—R) | Mass (M) | No Mass (NM—R) | |||||

| S1: λ in Situ | S2: λ Estim. | S3: λ in Situ | S4: λ Estim. | S1: λ in Situ | S2: λ Estim. | S3: λ in Situ | S4: λ Estim. | |

| 24 h | −0.61 | −0.90 | −0.81 | −1.07 | −0.20 | −0.41 | 0.69 | 0.85 |

| 72 h | −0.69 | −0.95 | −0.89 | −1.09 | −0.29 | −0.46 | 0.97 | 1.18 |

| One week | 0.96 | −1.08 | −1.09 | −1.32 | −0.39 | −0.51 | −0.97 | −1.32 |

| Value | Mass | No Mass | ||

|---|---|---|---|---|

| S1: λ in Situ | S2: λ Estim. | S3: λ in Situ | S4: λ Estim. | |

| Maximum | 15.16 | 14.03 | 14.64 | 13.57 |

| Median | 14.66 | 13.31 | 14.14 | 12.93 |

| Mean | 14.69 | 13.40 | 14.12 | 12.91 |

| Minimum | 14.38 | 13.07 | 13.51 | 12.14 |

| Difference max—min | 0.78 | 0.96 | 1.13 | 1.43 |

| Difference minimum—Tiol | −3.02 | −4.33 | −3.89 | −5.26 |

| Period of Time | Mass | No Mass | |||||

|---|---|---|---|---|---|---|---|

| S1: λ in Situ | S2: λ Estim. | S3: λ In Situ | S4: λ Estim. | ||||

| kWh/m2 | kWh/m2 | dif. | kWh/m2 | dif. | kWh/m2 | dif. | |

| 8–14 January | 5.38 | 7.72 | +43% | 5.74 | +7% | 7.81 | +45% |

| 25–31 July | −0.67 | −1.37 | +102% | −1.03 | +53% | −1.56 | +131% |

| Mean diff. weeks | +73% | +30% | +88% | ||||

| Total heating year | 90.61 | 128.95 | +42% | 96.07 | +6% | 137.28 | +52% |

| Total cooling year | −5.13 | −9.82 | +91 | −9.03 | +76% | −13.83 | +170% |

| Mean diff. year | +67% | +41% | +111% | ||||

| Condition | Limit (Zone D3) | S1: λ in Situ 1 | S2: λ Estim. 1 | |||

|---|---|---|---|---|---|---|

| Value | Difference | Value | Difference | |||

| Energy demand 2 (kWh/m2 per year) | Heating | 30.29 3 | 57.89 | +91% | 77.12 | +155% |

| Cooling | 15.00 3 | 10.81 | −28% | 12.77 | −15% | |

| U (W/m2K) | 0.41 5 | 0.65 | +25% | 1.35 | +160% | |

| K2,4 (W/m2K) | 0.64 5 | 0.61 | −5% | 0.87 | +36% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mellado Mascaraque, M.Á.; Castilla Pascual, F.J.; Pérez Andreu, V.; Gosalbo Guenot, G.A. Evaluation of the Thermal Comfort and Energy Demand in a Building with Rammed Earth Walls in Spain: Influence of the Use of In Situ Measured Thermal Conductivity and Estimated Values. Buildings 2021, 11, 635. https://doi.org/10.3390/buildings11120635

Mellado Mascaraque MÁ, Castilla Pascual FJ, Pérez Andreu V, Gosalbo Guenot GA. Evaluation of the Thermal Comfort and Energy Demand in a Building with Rammed Earth Walls in Spain: Influence of the Use of In Situ Measured Thermal Conductivity and Estimated Values. Buildings. 2021; 11(12):635. https://doi.org/10.3390/buildings11120635

Chicago/Turabian StyleMellado Mascaraque, Miguel Ángel, Francisco Javier Castilla Pascual, Víctor Pérez Andreu, and Guillermo Adrián Gosalbo Guenot. 2021. "Evaluation of the Thermal Comfort and Energy Demand in a Building with Rammed Earth Walls in Spain: Influence of the Use of In Situ Measured Thermal Conductivity and Estimated Values" Buildings 11, no. 12: 635. https://doi.org/10.3390/buildings11120635