Experimental and Numerical Study on the Heat Transfer Characteristics of a Newly-Developed Solar Active Thermal Insulation System

Abstract

:1. Introduction

- (a)

- In [7], it is concluded that glass honeycomb-type TIMs are fragile and thus not suitable for building applications.

- (b)

- High cutting temperatures resulted in melting at the cut edges of plastic TIMs, which negatively affects their transparency [24].

- (c)

- Solar transmittance of almost all experimentally investigated TIMs is almost constant over a wide range of incidence angles [6]. Accordingly, overheating problems are significant in summer due to excessive solar radiation absorption, either from a too large area of TI systems or large wall mass when applied to south-facing building facades [6,24,25].

- (d)

- Plastic-based TIMs represent a potential fire hazard, when attached to facades of high-rise buildings [26].

- (e)

- (f)

- The fragile structure of silica aerogel-based TIMs is one of the main problems that has prevented their wider application. It was not straightforward to fabricate large crack-free pieces of monolithic silica aerogels and the maximum size was limited to × . Accordingly, monolithic silica aerogel-based TIMs have only been used in research [28].

- (g)

- According to [10], most of the TIMs available on the market are made of plastic or glass. This implies that the thermal conductivity of the base material is much higher compared to conventional thermal insulation materials, which leads to excessive thermal losses during off-shine periods. In particular, plastic-based TIMs shall be associated with intensive efforts concerning their disposal upon recycling the building materials.

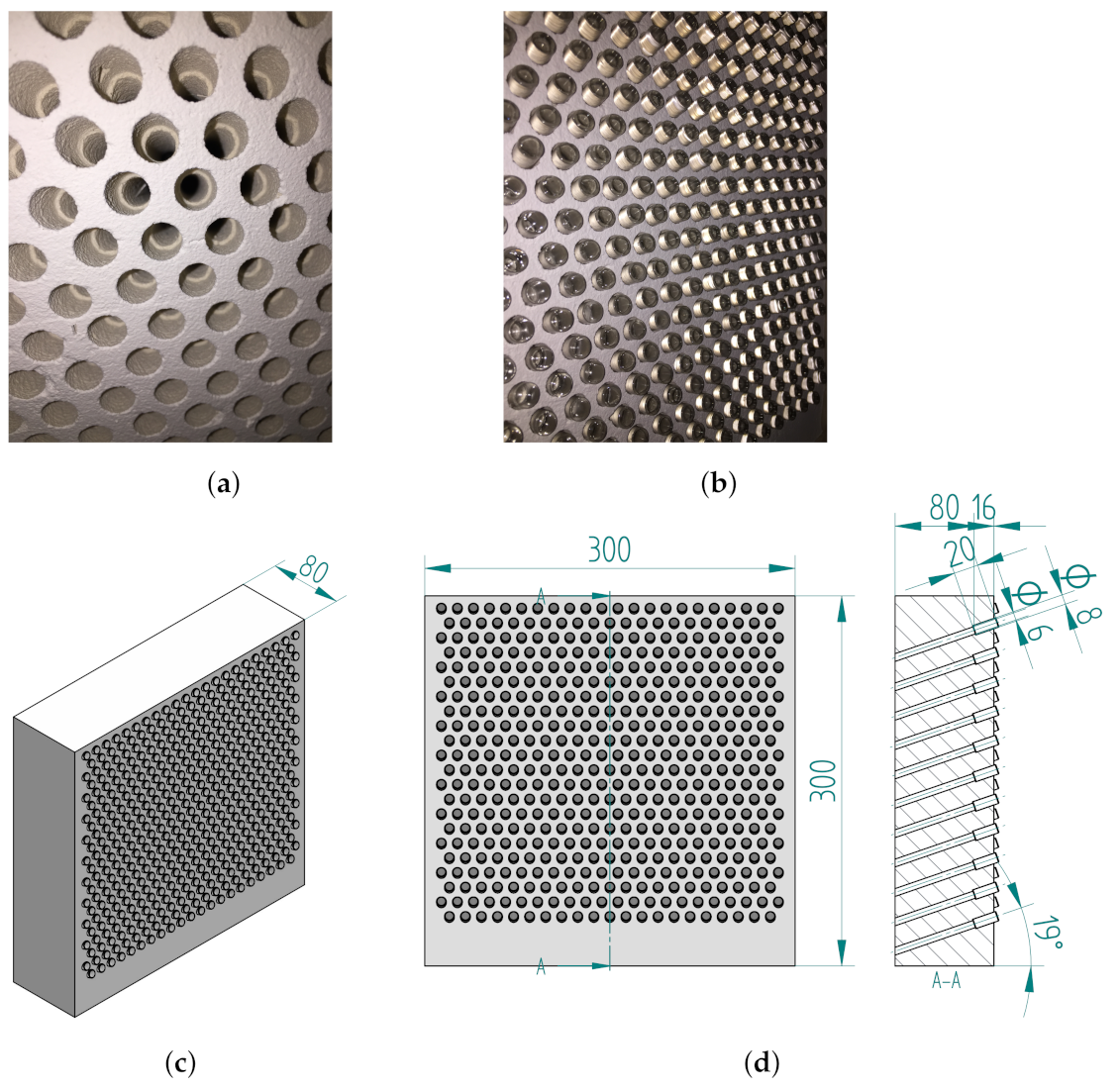

2. Materials and Methods

2.1. SATIS Concept

- To achieve maximum solar radiation transmittance at a defined angle of incidence typical for winter months or the transitional season.

- To considerably reduce solar transmittance at high summer irradiation angles to prevent summer overheating.

- To have an effective thermal conductivity compared to conventional thermal insulation materials (e.g., foamed plastics or mineral fiber insulation) in order to maintain a high thermal resistance during nighttime and cloudy periods.

- To develop a purely mineral, location-adaptable product that is readily recyclable and does not cause future disposal problems.

2.2. Experimental Setup

2.2.1. Test Specimen

2.2.2. Test Bench

2.2.3. Test Procedure and Conditions

Effective Thermal Conductivity

Total Solar Energy Transmittance

2.3. Numerical Modeling

2.3.1. Thermal and Fluid Flow Modeling

2.3.2. Short-Wave Radiation Transport Modeling

3. Results and Discussion

3.1. Effective Thermal Conductivity

Total Solar Energy Transmittance

4. Conclusions

- A maximum total solar energy transmittance of 11.2% has been measured at the irradiation angle of 19, which corresponds to a typical noon irradiation angle in wintertime in southern Germany.

- At an irradiation angle of 60, representing summer conditions in central Europe, a total solar energy transmittance of 2.9% has been measured, which represents a reduction of 75% compared to the obtained value at 19.

- The carried out ray tracing radiation simulations inside the LCEs has offered explanations for the obtained selectivity of the total transmittance. At an incidence angle of 19, 27% of the irradiated power is absorbed directly by the absorber surface at the backside of SATIS, while at the incidence angle of 60, 98% of the radiated power is absorbed by the surfaces adjacent to the glass cylinders, resulting in the remarkable reduction of the solar transmittance.

- The measured effective thermal conductivity of the base SATIS material amounts to 45 , which has been increased to 49 and 57 upon introducing the LCEs and then the closing elements out of borosilicate glass, respectively.

- The key parameters leading to the enhancement of the effective thermal conductivity of SATIS over that of the base material has been identified to be the length and the relatively high thermal conductivity of the applied closing elements in the investigated first SATIS prototype.

- The contribution of convection to the effective thermal conductivity of the SATIS prototype is proven to be negligible (below 1%), which has been attributed to the small diameter and the low inclination of the LCEs to the horizontal (19).

- On the other hand, thermal radiation contributes to 13% to the effective thermal conductivity of the SATIS prototype and cannot, therefore, be ignored.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Parliament and Council. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings; European Parliament and Council: Brussels, Belgium, 2010. [Google Scholar]

- Buildings Performance Institute Europe. 97% of Buildings in the EU Need to Be Upgraded; Buildings Performance Institute Europe: Brussels, Belgium, 2017. [Google Scholar]

- Buildings Performance Institute Europe. Future-Proof Buildings for All Europeans: A Guide to Implement the Energy Performance of Buildings Directive (2018/844); Buildings Performance Institute Europe: Brussels, Belgium, 2019. [Google Scholar]

- European Parliament and Council. Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency; European Parliament and Council: Brussels, Belgium, 2018. [Google Scholar]

- Crawley, D.B.; Hand, J.W.; Kummert, M.; Griffith, B.T. Contrasting the capabilities of building energy performance simulation programs. Build. Environ. 2008, 43, 661–673. [Google Scholar] [CrossRef] [Green Version]

- Wong, I.L.; Eames, P.C.; Perera, R.S. A review of transparent insulation systems and the evaluation of payback period for building applications. Sol. Energy 2007, 81, 1058–1071. [Google Scholar] [CrossRef]

- Kaushika, N.D.; Sumathy, K. Solar transparent insulation materials: A review. Renew. Sustain. Energy Rev. 2003, 7, 317–351. [Google Scholar] [CrossRef]

- Sun, Y.; Wilson, R.; Wu, Y. A Review of Transparent Insulation Material (TIM) for building energy saving and daylight comfort. Appl. Energy 2018, 226, 713–729. [Google Scholar] [CrossRef]

- Liang Wong, I.; Eames, P.; Perera, S. Energy simulations of a transparent insulated office facade retrofit in London, UK. Smart Sustain. Built Environ. 2012, 1, 253–276. [Google Scholar] [CrossRef] [Green Version]

- Paneri, A.; Wong, I.L.; Burek, S. Transparent insulation materials: An overview on past, present and future developments. Sol. Energy 2019, 184, 59–83. [Google Scholar] [CrossRef] [Green Version]

- Platzer, W.J. Bestimmung des solaren Energiegewinns durch Massivwände mit transparenter Wärmedämmung. Richtlinie Fachverbandes Transparente Wärmedämmung. 2000. Available online: http://www.umwelt-wand.de/twd/service/hilfen/richtlinie0006.pdf (accessed on 16 March 2021).

- Russ, C. Einsatz transparenter Wärmedämmung zur Gebäudesanierung. In Energie; Hoffmann, V.U., Thiele, R., Eds.; Vieweg+Teubner: Wiesbaden, Germany, 1994; Volume 3, pp. 82–94. [Google Scholar] [CrossRef]

- Wittwer, V.; Platzer, W. Transparent thermal insulation materials and systems: State of the art and potential for the future. High Temp. High Press. 2000, 32, 143–158. [Google Scholar] [CrossRef]

- Čekon, M.; Slávik, R.; Zach, J. Experimental Analysis of Transparent Insulation Based on Poly-carbonate Multi-Wall Systems: Thermal and Optical Performance. Energy Procedia 2017, 132, 502–507. [Google Scholar] [CrossRef]

- Platzer, W.J. Total heat transport data for plastic honeycomb-type structures. Sol. Energy 1992, 49, 351–358. [Google Scholar] [CrossRef]

- Platzer, W.J. Solar transmission of transparent insulation material. Sol. Energy Mater. 1987, 16, 275–287. [Google Scholar] [CrossRef]

- Symons, J.G. The Solar Transmittance of Some Convection Suppression Devices for Solar Energy Applications: An Experimental Study. J. Sol. Energy Eng. 1982, 104, 251–256. [Google Scholar] [CrossRef]

- Platzer, W.J. Directional-hemispherical solar transmittance data for plastic honeycomb-type structures. Sol. Energy 1992, 49, 359–369. [Google Scholar] [CrossRef]

- Kuhn, T.E. Calorimetric determination of the solar heat gain coefficient g with steady-state laboratory measurements. Energy Build. 2014, 84, 388–402. [Google Scholar] [CrossRef]

- Świrska-Perkowska, J.; Kucharczyk, A.; Wyrwał, J. Energy Efficiency of a Solar Wall with Transparent Insulation in Polish Climatic Conditions. Energies 2020, 13, 859. [Google Scholar] [CrossRef] [Green Version]

- Čekon, M.; Čurpek, J. A transparent insulation façade enhanced with a selective absorber: A cooling energy load and validated building energy performance prediction model. Energy Build. 2019, 183, 266–282. [Google Scholar] [CrossRef]

- Čekon, M.; Čurpek, J. A Transparent Insulation Solar Façade Coupled with a Selective Absorber: An Experimentally Validated Building Energy Simulation Model. In Healthy, Intelligent and Resilient Buildings and Urban Environments; International Association of Building Physics (IABP): Syracuse, NY, USA, 2018; pp. 361–365. [Google Scholar] [CrossRef]

- Sun, Y.; Liang, R.; Wu, Y.; Wilson, R.; Rutherford, P. Glazing systems with Parallel Slats Transparent Insulation Material (PS-TIM): Evaluation of building energy and daylight performance. Energy Build. 2018, 159, 213–227. [Google Scholar] [CrossRef]

- Lien, A.G.; Hestnes, A.G.; Aschehoug, Ø. The use of transparent insulation in low energy dwellings in cold climates. Sol. Energy 1997, 59, 27–35. [Google Scholar] [CrossRef]

- Manz, H.; Egolf, P.; Suter, P.; Goetzberger, A. TIM–PCM external wall system for solar space heating and daylighting. Sol. Energy 1997, 61, 369–379. [Google Scholar] [CrossRef]

- Twidell, J.W.; Johnstone, C.; Zuhdy, B.; Scott, A. Strathclyde University’s passive solar, low-energy, residences with transparent insulation. Sol. Energy 1994, 52, 85–109. [Google Scholar] [CrossRef]

- Braun, P.O.; Goetzberger, A.; Schmid, J.; Stahl, W. Transparent insulation of building facades—Steps from research to commercial applications. Sol. Energy 1992, 49, 413–427. [Google Scholar] [CrossRef]

- Berardi, U. The development of a monolithic aerogel glazed window for an energy retrofitting project. Appl. Energy 2015, 154, 603–615. [Google Scholar] [CrossRef]

- Franken Maxit GmbH. maxit eco 72. 2020. Available online: https://docs.maxit.de:8443/procat/assets/images/TM-DE-GEECO72.pdf (accessed on 16 March 2021).

- Lehmann, S.; Schwinger, L.; Scharfe, B.; Gerdes, T.; Ehrhardt, M.; Riechert, C.; Fischer, H.B.; Schmidt-Rodenkirchen, A.; Scharfe, F.; Wolff, F. Mikro-Hohlglaskugeln als Basis energieeffizienter Dämmung von Gebäuden. In Beiträge der Konferenz für neue Materialien im Bauwesen am 31. Januar 2018 in Berlin; Deutscher Ausschuss für Stahlbeton, e.V., Ed.; Fraunhofer IRB: Berlin, Germany, 2018; pp. 21–25. [Google Scholar]

- Steininger, P.; Gaderer, M.; Dawoud, B. Experimental and numerical study on the solar gain and heat loss of typical existing and refurbished German buildings. iCRBE Procedia 2020, 1, 75–93. [Google Scholar] [CrossRef]

- Franken Maxit GmbH.maxit Siliconharzfarbe A 7030. 2020. Available online: https://docs.maxit.de:8443/procat/assets/images/TM-DE-FDSILICOFA%20A.pdf (accessed on 16 March 2021).

- Schott, A.G. DURAN®: Tubing, Rods and Capillaries Made of Borosilicate Glass 3.3. 2016. Available online: https://www.schott.com/d/tubing/66ee849c-cad9-42a3-97cb-67fd0534e3fb/schott_duran_brochure_gb_final.pdf (accessed on 16 March 2021).

- DIN Deutsches Institut für Normung e.V. Fundamentals of Metrology—Part 3: Evaluation of Measurements of a Single Measurand, Measurement Uncertain-ty; DIN1319-3; DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 1996. [Google Scholar] [CrossRef]

- Fachverband Transparente Wärmedämmung, e.V. Transparente Wärmedämmung: Planerische Grundlagen und Hinweise. Available online: http://www.umwelt-wand.de/twd/service/infos/info3.pdf (accessed on 16 March 2021).

- Baehr, H.D.; Stephan, K. Wärme- und Stoffübertragung, 8th ed.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- COMSOL. Material Library User’s Guide; COMSOL: Stockholm, Sweden, 2018; Available online: https://doc.comsol.com/5.4/doc/com.comsol.help.matlib/MaterialLibraryUsersGuide.pdf (accessed on 16 March 2021).

- COMSOL. Ray Optics Module User’s Guide; COMSOL: Stockholm, Sweden, 2018; Available online: https://doc.comsol.com/5.4/doc/com.comsol.help.roptics/RayOpticsModuleUsersGuide.pdf (accessed on 16 March 2021).

- Landau, L.D.; Lifšic, E.M. The Classical Theory of Fields, 4th ed.; Pergamon International Library of Science: Oxford, UK; Technology: New York, NY, USA; Engineering: Toronto, ON, Canada; Social Studies: Sydney, Australia; Pergamon Press: Braunschweig, Germay, 1975. [Google Scholar]

| SATIS State | in | in | in |

|---|---|---|---|

| 1—exp. 1 | 19.0 | −0.7 | 19.7 |

| 1—exp. 2 | 23.7 | −5.6 | 29.3 |

| 1—exp. 3 | 28.3 | −10.6 | 38.9 |

| 2—exp. 1 | 19.0 | −0.6 | 19.6 |

| 2—exp. 2 | 23.7 | −5.4 | 29.1 |

| 2—exp. 3 | 28.3 | −10.6 | 38.9 |

| 3—exp. 1 | 19.0 | −0.4 | 19.4 |

| 3—exp. 2 | 23.6 | −5.2 | 28.8 |

| 3—exp. 3 | 28.3 | −10.3 | 38.6 |

| in | in | in | in |

|---|---|---|---|

| 0 | 1070 | 24 | 1090 |

| 14 | 1110 | 30 | 1100 |

| 17 | 1100 | 35 | 1060 |

| 19 | 1060 | 45 | 1040 |

| 21 | 1090 | 60 | 940 |

| No. | Material | in | in | in | n | Reference |

|---|---|---|---|---|---|---|

| (1) | Steel | 31 | 7870 | 435 | - | [36] |

| (2) | Thermal insulation plaster | 0.045 | 125 | 1150 | - | [29,31] |

| (3) and (5) | Air (COMSOL ref. material) | 1 | [37] | |||

| (4) | Borosilicate glass | 1.2 | 2230 | 830 | 1.473 | [33] |

| Frame color | Red | Green | ||||

| Boundary condition | ||||||

| Frame color | Blue | Violet | ||||

| Boundary condition | ||||||

| Notation | Boundary Condition |

|---|---|

| a | Ray inlet |

| b | [33] |

| c | |

| d | |

| e | Wall; [36] |

| SATIS State | in | in | in | in | in |

|---|---|---|---|---|---|

| 1—exp. 1 | 17.61 | 2.14 | 8.4 | 8.9 | 45 |

| 1—exp. 2 | 21.46 | −2.30 | 13.2 | 13.7 | 45 |

| 1—exp. 3 | 25.29 | −6.80 | 18.1 | 18.6 | 46 |

| 2—exp. 1 | 17.47 | 2.07 | 9.0 | 9.3 | 48 |

| 2—exp. 2 | 21.34 | −2.09 | 14.0 | 14.5 | 49 |

| 2—exp. 3 | 25.15 | −6.47 | 19.5 | 19.8 | 50 |

| 3—exp. 1 | 17.22 | - | 10.7 | - | (57 + 57)/2 = 57 |

| 3—exp. 2 | 20.88 | - | 16.4 | - | (57 + 56)/2 = 57 |

| 3—exp. 3 | 24.56 | - | 22.6 | - | (58 + 57)/2 = 58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Steininger, P.; Gaderer, M.; Steffens, O.; Dawoud, B. Experimental and Numerical Study on the Heat Transfer Characteristics of a Newly-Developed Solar Active Thermal Insulation System. Buildings 2021, 11, 123. https://doi.org/10.3390/buildings11030123

Steininger P, Gaderer M, Steffens O, Dawoud B. Experimental and Numerical Study on the Heat Transfer Characteristics of a Newly-Developed Solar Active Thermal Insulation System. Buildings. 2021; 11(3):123. https://doi.org/10.3390/buildings11030123

Chicago/Turabian StyleSteininger, Peter, Matthias Gaderer, Oliver Steffens, and Belal Dawoud. 2021. "Experimental and Numerical Study on the Heat Transfer Characteristics of a Newly-Developed Solar Active Thermal Insulation System" Buildings 11, no. 3: 123. https://doi.org/10.3390/buildings11030123