A Systematic Review on Supply Chain Management in Prefabricated House-Building Research

Abstract

:1. Introduction

2. Research Methods

2.1. Systematic Retrieval of Articles

2.2. Rater-Based Approach

2.3. Extended Content Analysis for PCBs

2.4. Expert Judgment on Initial Review Findings

2.5. Extending Selection with Inclusion Consideration

2.6. Scientometric Analysis

2.7. Identification of Research Methods, Theories, and Frameworks

3. Results

3.1. Descriptive

3.1.1. Frequency of Published Articles by Year

3.1.2. Countries in Focus by Article Publication and Collaborative Networks

3.1.3. Publication Outlets and Citation Network

3.2. Research Focus, Methods, Theories, and Frameworks

3.2.1. Research Focus by PHB Material

3.2.2. Applied Research Methods

3.2.3. Applied Theories and Frameworks

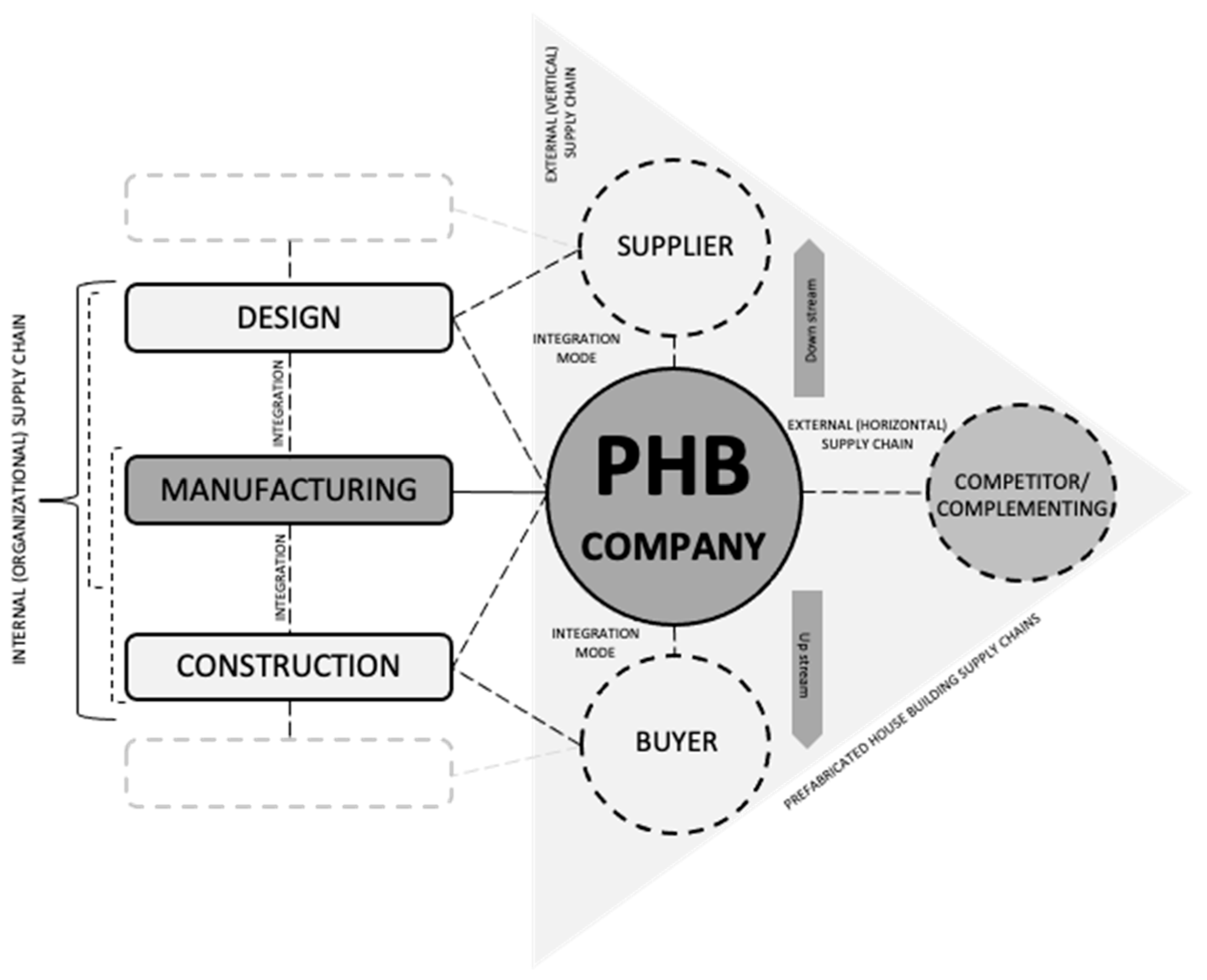

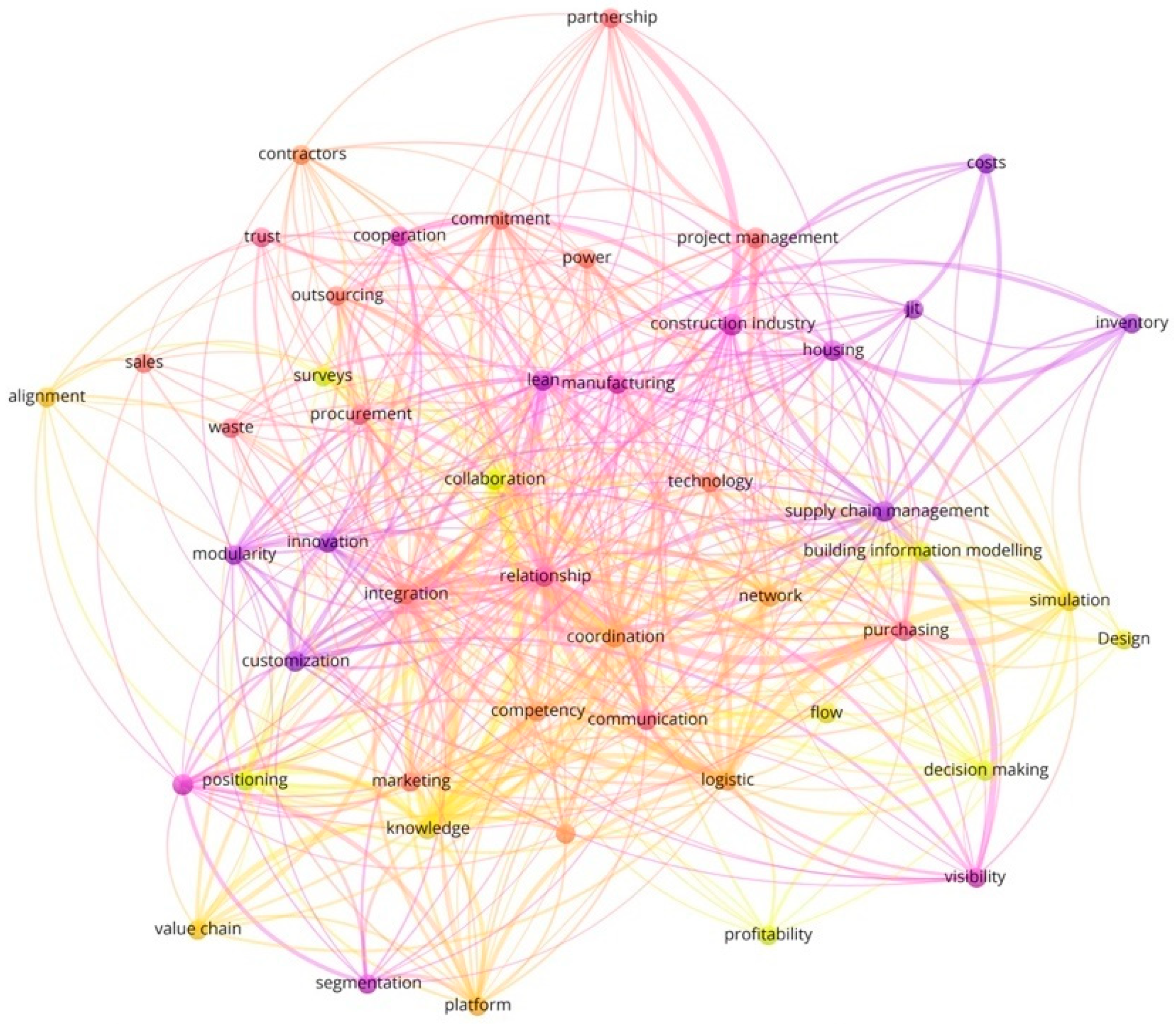

3.3. PHB-SCM Clustering and Thematic Coverage

3.4. Assessing PHB-SCM Themes by Product

4. Recent Developments in PHB-SCM by PCBs

5. Conclusions and Future Research

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Elnaas, E. The Decision to Use Off-Site Manufacturing (OSM) Systems for House Building Projects in the UK. Ph.D. Thesis, University of Brighton, Brighton, UK, 2014. [Google Scholar]

- Koebel, C.T. Innovation in Homebuilding and the Future of Housing. J. Am. Plan. Assoc. 2008, 74, 45–58. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.P. Holistic Review and Conceptual Framework for the Drivers of Offsite Construction: A Total Interpretive Structural Modelling Approach. Buildings 2019, 9, 117. [Google Scholar] [CrossRef] [Green Version]

- Koskela, L.; Vrijhoef, R. Is the current theory of construction a hindrance to innovation? Build. Res. Inf. 2001, 29, 197–207. [Google Scholar] [CrossRef]

- Sayed, E. Offsite manufacturing innovation in a biomimetic future. In Offsite Production and Manufacturing for Innovative Construction; Routledge: Oxfordshire, UK, 2019; pp. 419–448. [Google Scholar]

- Sooriyamudalige, N.; Domingo, N.; Shahzad, W.; Childerhouse, P. Barriers and enablers for supply chain integration in prefabricated elements manufacturing in New Zealand. Int. J. Constr. Supply Chain Manag. 2020, 10. [Google Scholar] [CrossRef]

- Childerhouse, P.; Lewis, J.; Naim, M.; Towill, D.R. Re-engineering a construction supply chain: A material flow control approach. Supply Chain Manag. Int. J. 2003, 8, 395–406. [Google Scholar] [CrossRef]

- Childerhouse, P.; Towill, D.R. Simplified material flow holds the key to supply chain integration. Omega 2003, 31, 17–27. [Google Scholar] [CrossRef]

- Sridhar, M. Industrialized Delivery Systems and the Future of Real Estate; McKinsey & Company: New York, NY, USA, 2017. [Google Scholar]

- Miltenburg, J. Manufacturing Strategy: How to Formulate and Implement a Winning Plan; Productivity Press: New York, NY, USA, 2005. [Google Scholar]

- Masood, R.; Lim, J.; Gonzalez, V.A. A Taxonomy of Construction Supply Chain for Affordable Housing in New Zealand. Int. J. Struct. Civ. Eng. Res. 2016. [Google Scholar] [CrossRef] [Green Version]

- Masood, R.; Lim, J.B.; González, V.A. Performance of the supply chains for New Zealand prefabricated house-building. Sustain. Cities Soc. 2020, 64, 102537. [Google Scholar] [CrossRef]

- Hubbard, B.; Hubbard, S.M. Stakeholder transformation in OSM infrastructure construction. In Offsite Production and Manufacturing for Innovative Construction; Routledge: Oxfordshire, UK, 2019; pp. 359–376. [Google Scholar]

- Xu, J.; Ye, M.; Lu, W.; Bao, Z.; Webster, C. A four-quadrant conceptual framework for analyzing extended producer responsibility in offshore prefabrication construction. J. Clean. Prod. 2020, 282, 124540. [Google Scholar] [CrossRef]

- Vrijhoef, R.; Koskela, L.; Howell, G. Understanding construction supply chains: An alternative interpretation. In Proceedings of the 9th International Group for Lean Construction Conference, Singapore, 6–8 August 2001; pp. 185–199. [Google Scholar]

- Navarro-Rubio, J.; Pineda, P.; García-Martínez, A. Sustainability, prefabrication and building optimization under different durability and re-using scenarios: Potential of dry precast structural connections. Sustain. Cities Soc. 2019, 44, 614–628. [Google Scholar] [CrossRef]

- Gibb, A.G.; Isack, F. Re-engineering through pre-assembly: Client expectations and drivers. Build. Res. Inf. 2003, 31, 146–160. [Google Scholar] [CrossRef] [Green Version]

- Steinhardt, D.; Manley, K.; Bildsten, L.; Widen, K. The structure of emergent prefabricated housing industries: A comparative case study of Australia and Sweden. Constr. Manag. Econ. 2019, 38, 483–501. [Google Scholar] [CrossRef]

- Goulding, J.; Pour Rahimian, F.; Arif, M.; Sharp, M. New offsite production and business models in construction: Priorities for the future research agenda. Arch. Eng. Des. Manag. 2014, 11, 163–184. [Google Scholar] [CrossRef]

- Pero, M.; Stößlein, M.; Cigolini, R. Linking product modularity to supply chain integration in the construction and shipbuilding industries. Int. J. Prod. Econ. 2015, 170, 602–615. [Google Scholar] [CrossRef]

- Barlow, J.; Childerhouse, P.; Gann, D.; Hong-Minh, S.; Naim, M.; Ozaki, R. Choice and delivery in housebuilding: Lessons from Japan for UK housebuilders. Build. Res. Inf. 2003, 31, 134–145. [Google Scholar] [CrossRef]

- Dainty, A.R.; Millett, S.J.; Briscoe, G.H. New perspectives on construction supply chain integration. Supply Chain Manag. Int. J. 2001, 6, 163–173. [Google Scholar] [CrossRef]

- Lessing, J.; Brege, S. Business models for product-oriented house-building companies—Experience from two Swedish case studies. Constr. Innov. 2015, 15, 449–472. [Google Scholar] [CrossRef]

- Björnfot, A.; Torjussen, L. Extent and Effect of Horizontal Supply Chain Collaboration among Construction SME. J. Eng. Proj. Prod. Manag. 2012, 2, 47–55. [Google Scholar] [CrossRef] [Green Version]

- Pothier, D.; Sawhney, A. What Will Industrialised Construction Mean for the Future of Work? Autodesk Education: Mill Valley, CA, USA; RICS: London, UK, 2020; Available online: https://www.rics.org/oceania/news-insight/future-of-surveying/talent-and-skills/what-will-industrialised-construction-mean-for-the-future-of-work/ (accessed on 27 May 2021).

- Mlecnik, E. Opportunities for supplier-led systemic innovation in highly energy-efficient housing. J. Clean. Prod. 2013, 56, 103–111. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, H.; Sher, W. A mixed method for measuring incompatibilities between manufacturing approaches and off-site construction. Eng. Constr. Arch. Manag. 2021, 28, 2516–2548. [Google Scholar] [CrossRef]

- London, K.; Kenley, R. An industrial organization economic supply chain approach for the construction industry: A review. Constr. Manag. Econ. 2001, 19, 777–788. [Google Scholar] [CrossRef]

- Smith, R.E. Off-Site and Modular Construction Explained; Off-Site Construction Council, National Institute of Building Sciences: Washington, DC, USA, 2014; pp. 1–6. [Google Scholar]

- Nguyen, B.N.; London, K.; Zhang, P. Stakeholder relationships in off-site construction: A systematic literature review. Smart Sustain. Built Environ. 2021. [Google Scholar] [CrossRef]

- Yashiro, T. Conceptual framework of the evolution and transformation of the idea of the industrialization of building in Japan. Constr. Manag. Econ. 2014, 32, 16–39. [Google Scholar] [CrossRef]

- Liu, K.; Su, Y.; Zhang, S. Evaluating Supplier Management Maturity in Prefabricated Construction Project-Survey Analysis in China. Sustainability 2018, 10, 3046. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.; Nzige, J.H.; Li, K. Trending topics and themes in offsite construction(OSC) research. Constr. Innov. 2019, 19, 343–366. [Google Scholar] [CrossRef]

- Poshdar, M.; Gonzalez, V.A.; Antunes, R.; Ghodrati, N.; Katebi, M.; Valasiuk, S.; Alqudah, H.; Talebi, S. Diffusion of Lean Construction in Small to Medium-Sized Enterprises of Housing Sector. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction (IGLC), Dublin, Ireland, 3–5 July 2019; pp. 383–392. [Google Scholar]

- Maqsoom, A.; Ashraf, H.; Choudhry, R.M.; Khan, S.Y.; Dawood, M.; Tariq, A. Extrinsic factors influencing the bid/no-bid decision of construction contracting firms: Impact of firm size and experience. Revista Construcción 2020, 19, 146–158. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Zhang, H.; Wang, Q.; Hua, T.; Xue, H. A Review and Scientometric Analysis of Global Research on Prefabricated Buildings. Adv. Civ. Eng. 2021, 2021, 8869315. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical evaluation of off-site construction research: A Scientometric analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Gosling, J.; Naim, M.M. Engineer-to-order supply chain management: A literature review and research agenda. Int. J. Prod. Econ. 2009, 122, 741–754. [Google Scholar] [CrossRef]

- Mostafa, S.; Chileshe, N.; Abdelhamid, T. Lean and agile integration within offsite construction using discrete-event simulation: A systematic literature review. Constr. Innov. 2016, 16, 4. [Google Scholar] [CrossRef]

- Sahin, O.; Miller, D.; Mohamed, S. Value-based modelling: An Australian case of off-site manufactured buildings. Int. J. Constr. Manag. 2016, 18, 34–52. [Google Scholar] [CrossRef]

- Fauzi, M.A.; Hassan, S.H.; Yunus, J.N.; Sulaiman, H.; Ramli, N.A. A Review of Supply Chain Management in IBS Construction IndustryL Challenges. J. Eng. Appl. Sci. 2017, 12, 6911–6915. [Google Scholar]

- Hu, X.; Chong, H.-Y. Environmental sustainability of off-site manufacturing: A literature review. Eng. Constr. Arch. Manag. 2019, 28, 332–350. [Google Scholar] [CrossRef]

- Larsen, M.S.S.; Lindhard, S.M.; Brunoe, T.D.; Nielsen, K.; Larsen, J.K. Mass Customization in the House Building Industry: Literature Review and Research Directions. Front. Built Environ. 2019, 5, 115. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J.; Ma, X.; Xiong, W. Precast supply chain management in off-site construction: A critical literature review. J. Clean. Prod. 2019, 232, 1204–1217. [Google Scholar] [CrossRef]

- Ekanayake, E.M.A.C.; Shen, G.Q.P.; Kumaraswamy, M.M. Identifying supply chain capabilities of construction firms in industrialized construction. Prod. Plan. Control. 2020, 32, 303–321. [Google Scholar] [CrossRef]

- Ekanayake, E.M.A.C.; Shen, G.Q.P.; Kumaraswamy, M.M.; Owusu, E.K. Identifying supply chain vulnerabilities in industrialized construction: An overview. Int. J. Constr. Manag. 2020, 1–14. [Google Scholar] [CrossRef]

- Kedir, F.; Hall, D.M. Resource efficiency in industrialized housing construction–A systematic review of current performance and future opportunities. J. Clean. Prod. 2020, 286, 125443. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, J.; Shen, L. A Conceptual Development Framework for Prefabricated Construction Supply Chain Management: An Integrated Overview. Sustainability 2020, 12, 1878. [Google Scholar] [CrossRef] [Green Version]

- Hussein, M.; Eltoukhy, A.E.; Karam, A.; Shaban, I.A.; Zayed, T. Modelling in off-site construction supply chain management: A review and future directions for sustainable modular integrated construction. J. Clean. Prod. 2021, 310, 127503. [Google Scholar] [CrossRef]

- Tennant, S.; Fernie, S. Theory to practice: A typology of supply chain management in construction. Int. J. Constr. Manag. 2014, 14, 56–66. [Google Scholar] [CrossRef] [Green Version]

- Skjoett-Larsen, T. Supply Chain Management: A New Challenge for Researchers and Managers in Logistics. Int. J. Logist. Manag. 1999, 10, 41–54. [Google Scholar] [CrossRef]

- Saenz, M.J.; Koufteros, X. Special issue on literature reviews in supply chain management and logistics. Int. J. Phys. Distrib. Logist. Manag. 2015, 45. [Google Scholar] [CrossRef]

- Chen, I.J.; Paulraj, A. Towards a theory of supply chain management: The constructs and measurements. J. Oper. Manag. 2004, 22, 119–150. [Google Scholar] [CrossRef]

- Croom, S.; Romano, P.; Giannakis, M. Supply chain management: An analytical framework for critical literature review. Eur. J. Purch. Supply Manag. 2000, 6, 67–83. [Google Scholar] [CrossRef]

- Aloini, D.; Dulmin, R.; Mininno, V.; Ponticelli, S. Key antecedents and practices for Supply Chain Management adoption in project contexts. Int. J. Proj. Manag. 2015, 33, 1301–1316. [Google Scholar] [CrossRef]

- Soni, G.; Kodali, R. A critical analysis of supply chain management content in empirical research. Bus. Process. Manag. J. 2011, 17, 238–266. [Google Scholar] [CrossRef]

- Antunes, R.; Gonzalez, V. A Production Model for Construction: A Theoretical Framework. Buildings 2015, 5, 209–228. [Google Scholar] [CrossRef] [Green Version]

- Ketchen, D.J.; Giunipero, L.C. The intersection of strategic management and supply chain management. Ind. Mark. Manag. 2004, 33, 51–56. [Google Scholar] [CrossRef]

- Tan, K.C. A framework of supply chain management literature. Eur. J. Purch. Supply Manag. 2001, 7, 39–48. [Google Scholar] [CrossRef]

- Cooper, M.C.; Lambert, D.M.; Pagh, J.D. Supply Chain Management: More Than a New Name for Logistics. Int. J. Logist. Manag. 1997, 8, 1–14. [Google Scholar] [CrossRef]

- Lamming, R. Squaring lean supply with supply chain management. Int. J. Oper. Prod. Manag. 1996, 16, 183–196. [Google Scholar] [CrossRef]

- Min, S.; Mentzer, J.T. The role of marketing in supply chain management. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 765–787. [Google Scholar] [CrossRef]

- Holt, D.; Ghobadian, A. An empirical study of green supply chain management practices amongst UK manufacturers. J. Manuf. Technol. Manag. 2009, 20, 933–956. [Google Scholar] [CrossRef]

- Ayodele, O.A.; Chang-Richards, A.; González, V. Factors Affecting Workforce Turnover in the Construction Sector: A Systematic Review. J. Constr. Eng. Manag. 2020, 146, 03119010. [Google Scholar] [CrossRef]

- Gao, D.; Xu, Z.; Ruan, Y.Z.; Lu, H. From a systematic literature review to integrated definition for sustainable supply chain innovation (SSCI). J. Clean. Prod. 2017, 142, 1518–1538. [Google Scholar] [CrossRef]

- Welsh, E. Dealing with data: Using NVivo in the qualitative data analysis process. Forum Qual. Soz. Forum Qual. Soc. Res. 2020, 3, 2. [Google Scholar]

- Kim, M.C.; Chen, C. A scientometric review of emerging trends and new developments in recommendation systems. Scientometrics 2015, 104, 239–263. [Google Scholar] [CrossRef]

- Sinkovics, N. Enhancing the foundations for theorising through bibliometric mapping. Int. Mark. Rev. 2016, 33, 327–350. [Google Scholar] [CrossRef]

- Dixon-Woods, M.; Agarwal, S.; Jones, D.; Young, B.; Sutton, A. Synthesising qualitative and quantitative evidence: A review of possible methods. J. Health Serv. Res. Policy 2005, 10, 45–53. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Wang, G.; Luo, L.; Shi, Q.; Xie, J.; Meng, X. Mapping the managerial areas of Building Information Modeling (BIM) using scientometric analysis. Int. J. Proj. Manag. 2017, 35, 670–685. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a Systematic Review. In The Sage Handbook of Organizational Research Methods; Buchanan, D., Bryman, A., Eds.; Sage: London, UK, 2009; pp. 671–689. [Google Scholar]

- Jaillon, L.C.; Poon, C.S. Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- Li, Z.; Shen, Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef] [Green Version]

- Abanda, F.; Tah, J.; Cheung, F.K.T. BIM in off-site manufacturing for buildings. J. Build. Eng. 2017, 14, 89–102. [Google Scholar] [CrossRef] [Green Version]

- Fleiss, J.L.; Levin, B.; Paik, M.C. Statistical Methods for Rates and Proportions, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Gwet, K.L. Benchmarking Inter-Rater Reliability Coefficients. In Handbook of Inter-Rater Reliability: The Definitive Guide to Measuring the Extent of Agreement Among Raters, 4th ed.; Advanced Analytics, LLC: Oxford, MS, USA, 2014. [Google Scholar]

- Gibb, A.G. Off-Site Fabrication: Prefabrication, Pre-Assembly and Modularisation; John Wiley & Sons: New York, NY, USA, 1999. [Google Scholar]

- Lawson, M.; Ogden, R.; Goodier, C. Design in Modular Construction; Taylor & Francis: London, UK, 2014. [Google Scholar]

- Halldórsson, Á.; Arlbjørn, J.S. Research methodologies in supply chain management—What do we know? In Research Methodologies in Supply Chain Management; Springer: Berlin, Germany, 2005; pp. 107–122. [Google Scholar]

- Giannakis, M.; Croom, S.R. Toward the Development of a Supply Chain Management Paradigm: A Conceptual Framework. J. Supply Chain Manag. 2004, 40, 27–37. [Google Scholar] [CrossRef]

- Plisson, J.; Lavrac, N.; Mladenić, D. A rule based approach to word lemmatization. In Proceedings of the 7th International Multi Conference Information Society IS, Ljubljana, Slovenia, 11–15 October 2004. [Google Scholar]

- Elo, S.; Kääriäinen, M.; Kanste, O.I.; Pölkki, T.; Utriainen, K.; Kyngäs, H. Qualitative Content Analysis. SAGE Open 2014, 4. [Google Scholar] [CrossRef]

- Kassarjian, H.H. Content Analysis in Consumer Research. J. Consum. Res. 1977, 4, 8–18. [Google Scholar] [CrossRef]

- Yalcinkaya, M.; Singh, V. Patterns and trends in Building Information Modeling (BIM) research: A Latent Semantic Analysis. Autom. Constr. 2015, 59, 68–80. [Google Scholar] [CrossRef]

- Tan, W. Practical Research Methods; Prentice Hall: Singapore, 2002. [Google Scholar]

- Wohlin, C. Guidelines for snowballing in systematic literature studies and a replication in software engineering. In Proceedings of the 18th International Conference on Evaluation and Assessment in Software Engineering, London, UK, 13–14 May 2014; pp. 1–10. [Google Scholar]

- Bom, S.; Jorge, J.; Ribeiro, H.M.; Marto, J. A step forward on sustainability in the cosmetics industry: A review. J. Clean. Prod. 2019, 225, 270–290. [Google Scholar] [CrossRef]

- Pollack, J.; Adler, D. Emergent trends and passing fads in project management research: A scientometric analysis of changes in the field. Int. J. Proj. Manag. 2015, 33, 236–248. [Google Scholar] [CrossRef]

- Glenisson, P.; Glänzel, W.; Janssens, F.; De Moor, B. Combining full text and bibliometric information in mapping scientific disciplines. Inf. Process. Manag. 2005, 41, 1548–1572. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Basu, P.K. Mapping a research area at the micro level using co-word analysis. Scientometrics 1998, 43, 359–372. [Google Scholar] [CrossRef]

- Chen, C. Mapping Scientific Frontiers: The Quest for Knowledge Visualization; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Cherven, K. Mastering Gephi Network Visualization; Packt Publishing Ltd.: Birmingham, UK, 2015. [Google Scholar]

- Vom-Brocke, J.; Simons, A.; Niehaves, B.; Riemer, K.; Plattfaut, R.; Cleven, A. Reconstructing the giant: On the importance of rigour in documenting the literature search process. In Proceedings of the ECIS, Verona, Italy, 8 June 2009; pp. 2206–2217. [Google Scholar]

- Purdum, J. Arduino Libraries. In Beginning C for Arduino: Learn C Programming for the Arduino; Purdum, J., Ed.; Apress: Berkeley, CA, USA, 2015; pp. 277–298. [Google Scholar] [CrossRef]

- Opsahl, T.; Agneessens, F.; Skvoretz, J. Node centrality in weighted networks: Generalizing degree and shortest paths. Soc. Netw. 2010, 32, 245–251. [Google Scholar] [CrossRef]

- Jenkins, L.D.; Dreyer, S.J.; Polis, H.J.; Beaver, E.; Kowalski, A.A.; Linder, H.L.; McMillin, T.N.; McTiernan, K.L.; Rogier, T.T.; Wiesebron, L.E. Human dimensions of tidal energy: A review of theories and frameworks. Renew. Sustain. Energy Rev. 2018, 97, 323–337. [Google Scholar] [CrossRef]

- Lessing, J.; Stehn, L.; Ekholm, A. Industrialised house-building—Development and conceptual orientation of the field. Constr. Innov. 2015, 15, 378–399. [Google Scholar] [CrossRef]

- Hunt, S.D. Modern Marketing Theory: Critical Issues in Philosophy of Marketing Science; South-Western: Cincinnati, OH, USA, 1991. [Google Scholar]

- Defee, C.C.; Williams, B.; Randall, W.S.; Thomas, R. An inventory of theory in logistics and SCM research. Int. J. Logist. Manag. 2010, 21, 404–489. [Google Scholar] [CrossRef]

- Gann, D. Construction as a manufacturing process? Similarities and differences between industrialized housing and car production in Japan. Constr. Manag. Econ. 1996, 14, 437–450. [Google Scholar] [CrossRef]

- Gosling, J.; Purvis, L.; Naim, M. Supply chain flexibility as a determinant of supplier selection. Int. J. Prod. Econ. 2010, 128, 11–21. [Google Scholar] [CrossRef]

- Voordijk, H.; Meijboom, B.; de Haan, J. Modularity in supply chains: A multiple case study in the construction industry. Int. J. Oper. Prod. Manag. 2006, 26, 600–618. [Google Scholar] [CrossRef]

- Naim, M.M.; Barlow, J. An innovative supply chain strategy for customized housing. Constr. Manag. Econ. 2003, 21, 593–602. [Google Scholar] [CrossRef]

- Höök, M.; Stehn, L. Applicability of lean principles and practices in industrialized housing production. Constr. Manag. Econ. 2008, 26, 1091–1100. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.F.; Dainty, A.R.J. Strategies for Integrating the Use of Off-Site Production Technologies in House Building. J. Constr. Eng. Manag. 2012, 138, 1331–1340. [Google Scholar] [CrossRef] [Green Version]

- Stehn, L.; Höök, M. Lean principles in industrialized housing production: The need for a cultural change. Lean Constr. J. 2008, 2008, 20–33. [Google Scholar]

- Pan, W.; Goodier, C.I. House-Building Business Models and Off-Site Construction Take-Up. J. Arch. Eng. 2012, 18, 84–93. [Google Scholar] [CrossRef]

- Aram, S.; Eastman, C.; Sacks, R. Requirements for BIM platforms in the concrete reinforcement supply chain. Autom. Constr. 2013, 35, 1–17. [Google Scholar] [CrossRef]

- Bakhtiarizadeh, E.; Shahzad, W.M.; Poshdar, M.; Khalfan, M.; Rotimi, J.O.B. Blockchain and Information Integration: Applications in New Zealand’s Prefabrication Supply Chain. Buildings 2021, 11, 608. [Google Scholar] [CrossRef]

- Dowsett, R.; Green, M.; Sexton, M.; Harty, C. Projecting at the project level: MMC supply chain integration roadmap for small housebuilders. Constr. Innov. 2019, 19, 193–211. [Google Scholar] [CrossRef]

- Zhai, Y.; Fu, Y.; Xu, G.; Huang, G. Multi-period hedging and coordination in a prefabricated construction supply chain. Int. J. Prod. Res. 2018, 57, 1949–1971. [Google Scholar] [CrossRef]

- Yang, Y.; Pan, M.; Pan, W.; Zhang, Z. Sources of Uncertainties in Offsite Logistics of Modular Construction for High-Rise Building Projects. J. Manag. Eng. 2021, 37, 04021011. [Google Scholar] [CrossRef]

- Uusitalo, P.; Lavikka, R. Overcoming Path Dependency in an Industrialised House-Building Company through Entrepreneurial Orientation. Buildings 2020, 10, 45. [Google Scholar] [CrossRef] [Green Version]

- Koppenhagen, F.; Held, T. The implications of product modularisation on the development process, supplier integration and supply chain design in collaborative product development. Adv. Prod. Eng. Manag. 2021, 16, 82–98. [Google Scholar] [CrossRef]

- Grenzfurtner, W.; Gronalt, M. Developing a continuous improvement perspective for subcontractor involvement in the industrialised housebuilding supply chain. Supply Chain Manag. Int. J. 2020, 26, 174–191. [Google Scholar] [CrossRef]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modeling. Autom. Constr. 2018, 98, 248–264. [Google Scholar] [CrossRef]

- Li, Y.; Song, Y.; Wang, J.; Li, C. Intellectual Capital, Knowledge Sharing, and Innovation Performance: Evidence from the Chinese Construction Industry. Sustainability 2019, 11, 2713. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Wang, X.; Rao, Z. Automated Optimization for the Production Scheduling of Prefabricated Elements Based on the Genetic Algorithm and IFC Object Segmentation. Processes 2020, 8, 1593. [Google Scholar] [CrossRef]

- Chen, W.; Zhao, Y.; Yu, Y.; Chen, K.; Arashpour, M. Collaborative Scheduling of On-Site and Off-Site Operations in Prefabrication. Sustainability 2020, 12, 9266. [Google Scholar] [CrossRef]

- Dharmapalan, V.; O’Brien, W.J.; Morrice, D.; Jung, M. Assessment of visibility in industrial construction projects: A viewpoint from supply chain stakeholders. Constr. Innov. 2021, 21, 782–799. [Google Scholar] [CrossRef]

- Luo, L.; Jin, X.; Shen, G.Q.; Wang, Y.; Liang, X.; Li, X.; Li, C.Z. Supply Chain Management for Prefabricated Building Projects in Hong Kong. J. Manag. Eng. 2020, 36, 05020001. [Google Scholar] [CrossRef]

- Li, X.; Shen, G.Q.; Wu, P.; Yue, T. Integrating Building Information Modeling and Prefabrication Housing Production. Autom. Constr. 2019, 100, 46–60. [Google Scholar] [CrossRef]

- Mossman, A. Just-in-Time Delivery Requires Just-in-Time Production X2—Sychronising Factory and Site for Successful Prefabrication. Modul. Offsite Constr. (MOC) Summit Proc. 2019, 124–132. [Google Scholar] [CrossRef] [Green Version]

- Li, C.Z.; Chen, Z.; Xue, F.; Kong, X.T.; Xiao, B.; Lai, X.; Zhao, Y. A blockchain-and IoT-based smart product-service system for the sustainability of prefabricated housing construction. J. Clean. Prod. 2021, 286, 125391. [Google Scholar] [CrossRef]

- Ekanayake, E.; Shen, G.; Kumaraswamy, M.M. Critical capabilities of improving supply chain resilience in industrialized construction in Hong Kong. Eng. Constr. Arch. Manag. 2020. [Google Scholar] [CrossRef]

- MacAskill, S.; Mostafa, S.; Stewart, R.A.; Sahin, O.; Suprun, E. Offsite construction supply chain strategies for matching affordable rental housing demand: A system dynamics approach. Sustain. Cities Soc. 2021, 73, 103093. [Google Scholar] [CrossRef]

- Innella, F.; Arashpour, M.; Bai, Y. Lean Methodologies and Techniques for Modular Construction: Chronological and Critical Review. J. Constr. Eng. Manag. 2019, 145, 04019076. [Google Scholar] [CrossRef]

- Broft, R.D. Lean Supply Chain Management in Construction: Implementation at the ‘Lower Tiers’ of the Construction Supply Chain. In Successful Construction Supply Chain Management: Concepts and Case Studies; John Wiley & Sons: New York, NY, USA, 2020. [Google Scholar]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef] [Green Version]

- Costa, F.; Granja, A.D.; Fregola, A.; Picchi, F.; Staudacher, A.P. Understanding Relative Importance of Barriers to Improving the Customer–Supplier Relationship within Construction Supply Chains Using DEMATEL Technique. J. Manag. Eng. 2019, 35, 04019002. [Google Scholar] [CrossRef]

- Hentschke, C.D.S.; Formoso, C.T.; Echeveste, M. A Customer Integration Framework for the Development of Mass Customised Housing Projects. Sustainability 2020, 12, 8901. [Google Scholar] [CrossRef]

- Wu, H.; Qian, Q.K.; Straub, A.; Visscher, H. Exploring transaction costs in the prefabricated housing supply chain in China. J. Clean. Prod. 2019, 226, 550–563. [Google Scholar] [CrossRef] [Green Version]

- Ekanayake, E.M.A.C.; Shen, G.Q.P.; Kumaraswamy, M.M. A fuzzy synthetic evaluation of capabilities for improving supply chain resilience of industrialised construction: A Hong Kong case study. Prod. Plan. Control. 2021, 1–18. [Google Scholar] [CrossRef]

- Das, P.; Perera, S.; Senaratne, S.; Osei-Kyei, R. Developing a construction business model transformation canvas. Eng. Constr. Arch. Manag. 2020, 28, 1423–1439. [Google Scholar] [CrossRef]

- Thuesen, C.; Bekdik, B. The impact of organisational learning and change on offsite manufacturing. In Offsite Production and Manufacturing for Innovative Construction; Routledge: London, UK, 2019; pp. 337–358. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Exploring the critical success determinants for supply chain management in modular integrated construction projects. Smart Sustain. Built Environ. 2021. [Google Scholar] [CrossRef]

- Briscoe, G.; Dainty, A. Construction supply chain integration: An elusive goal? Supply Chain Manag. Int. J. 2005, 10, 319–326. [Google Scholar] [CrossRef]

- Lessing, J.; Stehn, L.; Ekholm, A. Industrialised Housing: Definition and Categorisation of the Concept. In Proceedings of the 13th International Group for Lean Construction Conference, Sydney, Australia, 19–21 July 2005; pp. 471–480. [Google Scholar]

| Main Keywords and Sub Keywords | Scopus | WOS | EV | Sc.Dir | ProQuest |

|---|---|---|---|---|---|

| Offsite manufacturing (OSM): off-site/offsite + manufacture/manufactured/manufacturing | 6 | 2 | 2 | 1 | 2 |

| Offsite construction (OSC): off-site/offsite + construction/constructed | 3 | 3 | 3 | 0 | 4 |

| Offsite production (OSP): off-site/offsite + production | 3 | 3 | 4 | 0 | 4 |

| Offsite fabrication: prefab/prefabrication/prefabricated | 4 | 2 | 3 | 2 | 1 |

| Prefabrication (Prefab) | 33 | 37 | 40 | 10 | 56 |

| Manufactured (Manu) | 61 | 14 | 40 | 11 | 26 |

| Industrialized: industrialized/industrialised/Industrialized building(IB)/Industrialized building system (IBS) | 22 | 35 | 22 | 3 | 14 |

| Modular: modular/modularity/modularisation/modularization | 13 | 25 | 38 | 79 | 43 |

| Customization | 37 | 73 | 25 | 26 | 29 |

| Factory-built: factory built/factory-built/factory assembled/factory-assembled | 2 | 1 | 2 | 2 | 2 |

| Transportable: transportable/relocatable/movable | 22 | 8 | 1 | 7 | 2 |

| Pre-assembled: pre-assembled/preassembled/pre-assembly/preassembly | 3 | 2 | 2 | 1 | 2 |

| Pre-built | 0 | 0 | 0 | 0 | 0 |

| Pre-cast | 24 | 5 | 14 | 8 | 11 |

| Ready-made | 11 | 4 | 3 | 2 | 2 |

| Containerized: containerised/containerized | 1 | 1 | 1 | 5 | 1 |

| Panelized: panel/panelised | 341 | 68 | 14 | 128 | 29 |

| Modern methods of construction (MMC) | 7 | 4 | 5 | 0 | 4 |

| Total | 593 | 287 | 219 | 285 | 232 |

| S# | Paper Title | Authors | Journal | Citations |

|---|---|---|---|---|

| A1 | Construction as a manufacturing process? Similarities and differences between industrialized housing and car production in Japan | [103] | CME | 568 |

| A2 | Supply chain flexibility as a determinant of supplier selection | [104] | IJPE | 294 |

| A3 | Choice and delivery in house-building: lessons from Japan for UK housebuilders | [21] | BRI | 279 |

| A4 | Modularity in SCs: a multiple case study in the construction industry | [105] | IJOPM | 191 |

| A5 | An innovative SC strategy for customized housing | [106] | CME | 173 |

| A6 | Applicability of lean principles and practices in industrialized housing production | [107] | CME | 155 |

| A7 | Strategies for Integrating the Use of Off-Site Production Technologies in House Building | [108] | JCEM | 187 |

| A8 | Lean principles in industrialized housing production: the need for a cultural change | [109] | LCJ | 126 |

| A9 | House-Building Business Models and Off-Site Construction Take-Up | [110] | JAE | 141 |

| A10 | Requirements for BIM platforms in the concrete reinforcement SC. | [111] | AUTC | 118 |

| Strategic Management |

| supply chain integration [integration (2)]; process integration in supply chain [integration (2)]; supply chain coordination [coordination (6)]; mass customization [customization (11), design (42)]; product range management [customization (11)]; flexibility [customization (11)]; control in the supply chain [procurement (12), strategy (14), power (23)]; strategic purchasing [purchasing (13)]; strategic planning [strategy (14), positioning (19), decision making (39)]; supply chain configuration [strategy (14), segmentation (24)]; agility and responsiveness [strategy (14), alignment (45)]; global strategy [construction industry (4), strategy (14), competency (22)]; implementation of lean thinking [lean (15)]; product standardization [modularity (16)]; modularization [modularity (16)]; network structure design [network (17)]; platform (18); capability development [competency (22), continuous improvement (38)]; power and governance [power (23)]; supply chain modelling [segmentation (24), simulation (32)]; production technology [technology (31)]; production system optimization [simulation (32), manufacturing (37)]; cashflow analysis [sales, (33), profitability (44), costs (47)]; business process re-engineering [innovation (36), continuous improvement (38)]; design flexibility [design (42)]; sustainability [value chain (43)]; risk management [profitability (44)]; and supply chain alignment [alignment (45)]. |

| Relationships |

| supply or distribution base integration [integration (2)]; collaboration [collaboration (5)]; relationships development [relationship (3), cooperation (25), value chain (43)]; relationships management [relationship (3), decision making (39)]; commitment [commitment (10)]; partnering [commitment (10), partnering (46)]; supplier management [procurement (12), decision making (39)]; supplier development [procurement (12), competency (22), outsourcing (26)]; supply chain efficiency [strategy (14), competency (22); flow (35); value chain (43), profitability (44)]; merger [positioning (19), decision making (39)]; acquisition [positioning (19), decision making (39)]; outsourcing [outsourcing (26), manufacturing (37)]; trust [trust (34)]; and alliance [decision making (39); value chain (43); alignment (45)]. |

| Logistics |

| integration of material and information flow [integration (2), network (17), communication (20), segmentation (24), flow (35)]; knowledge base [knowledge (7), communication (20)]; pre-assembly [logistic (9), customization (11), modularity (16)]; modularization [logistic (9), modularity (16)]; planning and control of material flow [logistic (9), flow (35); decision making (39)]; postponement [logistic (9), decision making (39)]; inventory control and management [logistic (9), decision making (39), inventory (49)]; reposition [logistic (9), positioning (19), alignment (45)]; order policies [customization (11), decision making (39)]; demand management [procurement (12), purchasing (13), marketing (29), sales (33)]; capacity planning [strategy (14), competency (22), innovation (36), decision making (39)]; distribution channel management [network (17), just in time (40), value chain (43)]; information sharing [communication (20), building information modeling (27), visibility (48)]; quality [continuous improvement (38), waste (41)]; production scheduling [manufacturing (37), decision making (39), just in time (40)]; and visibility [visibility (48)]. |

| Best practices |

| synchronized supply chain management [integration (2), flow (35), value chain (43)]; framework [strategy (14), continuous improvement (38)]; waste removal with value analysis [lean (15), waste (41)]; performance measurement [project management (21), continuous improvement (38), profitability (44), costs (47)]; enterprise resource planning [communication (20), project management (21), technology (31), flow (35), decision making (39)]; material requirements planning [communication (20), technology (31), flow (35), decision making (39)]; information technology [communication (20), technology (31)]; radio frequency identification [communication (20), technology (31), flow (35), continuous improvement (38)]; material resource planning [communication (20), technology (31), flow (35), decision making (39)]; production planning [communication (20), technology (31), manufacturing (37), decision making (39)]; system thinking [simulation (32), decision making (39)]; continuous improvement [continuous improvement (38)]; reverse supply chain [continuous improvement (38), manufacturing (37), waste (41)]; and just in time [just in time (40)]. |

| Marketing |

| customer focus [relationship (3), commitment (10), customization (11), communication (20); contractor (28), marketing (29), sales (33), trust (34), profitability (44), costs (47)]; relationship marketing [relationship (3), communication (20), marketing (29), value chain (43)]; sales management [marketing (29), sales (33), just in time (40), inventory (49)]. |

| Organizational Behaviour |

| Organisational structure [integration (2), relationship (3), customization (11), strategy (14), network (17), project management (21), flow (35), manufacturing (37), decision making (39); value chain (43), visibility (48)]; technology integration ([integration (2), technology (31), flow (35)]; power in relationships [relationship (3), power (23), value chain (43)]; organisational learning [knowledge (7), communication (20), contractors (28), technology (31), innovation (36), continuous improvement (38)]; culture [commitment (10), communication (20), cooperation (25), trust (34)]; communication [communication (20)]; HR development [competency (22), technology (31), manufacturing (37), continuous improvement (38)]; joint ventures [trust (34), partnering (46)]. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masood, R.; Lim, J.B.P.; González, V.A.; Roy, K.; Khan, K.I.A. A Systematic Review on Supply Chain Management in Prefabricated House-Building Research. Buildings 2022, 12, 40. https://doi.org/10.3390/buildings12010040

Masood R, Lim JBP, González VA, Roy K, Khan KIA. A Systematic Review on Supply Chain Management in Prefabricated House-Building Research. Buildings. 2022; 12(1):40. https://doi.org/10.3390/buildings12010040

Chicago/Turabian StyleMasood, Rehan, James B. P. Lim, Vicente A. González, Krishanu Roy, and Khurram Iqbal Ahmad Khan. 2022. "A Systematic Review on Supply Chain Management in Prefabricated House-Building Research" Buildings 12, no. 1: 40. https://doi.org/10.3390/buildings12010040

APA StyleMasood, R., Lim, J. B. P., González, V. A., Roy, K., & Khan, K. I. A. (2022). A Systematic Review on Supply Chain Management in Prefabricated House-Building Research. Buildings, 12(1), 40. https://doi.org/10.3390/buildings12010040