Method for Designing Prequalified Connections Using Generative Design

Abstract

:1. Introduction

2. Background

2.1. Prequalified Connections

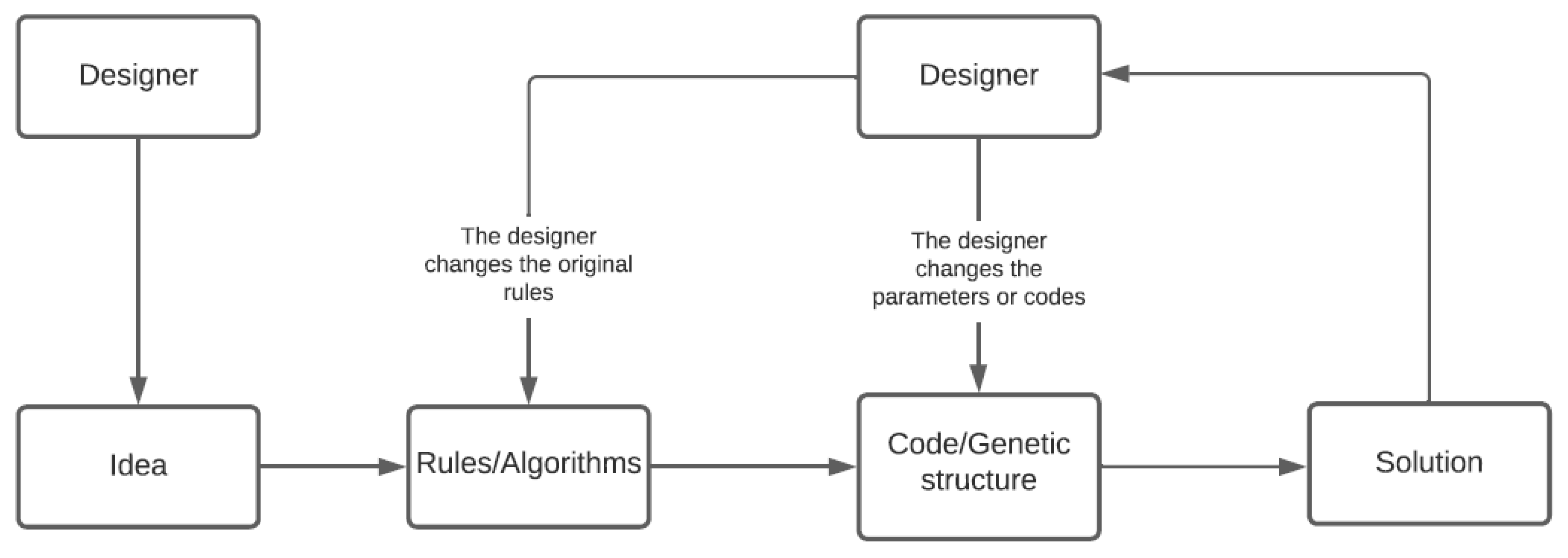

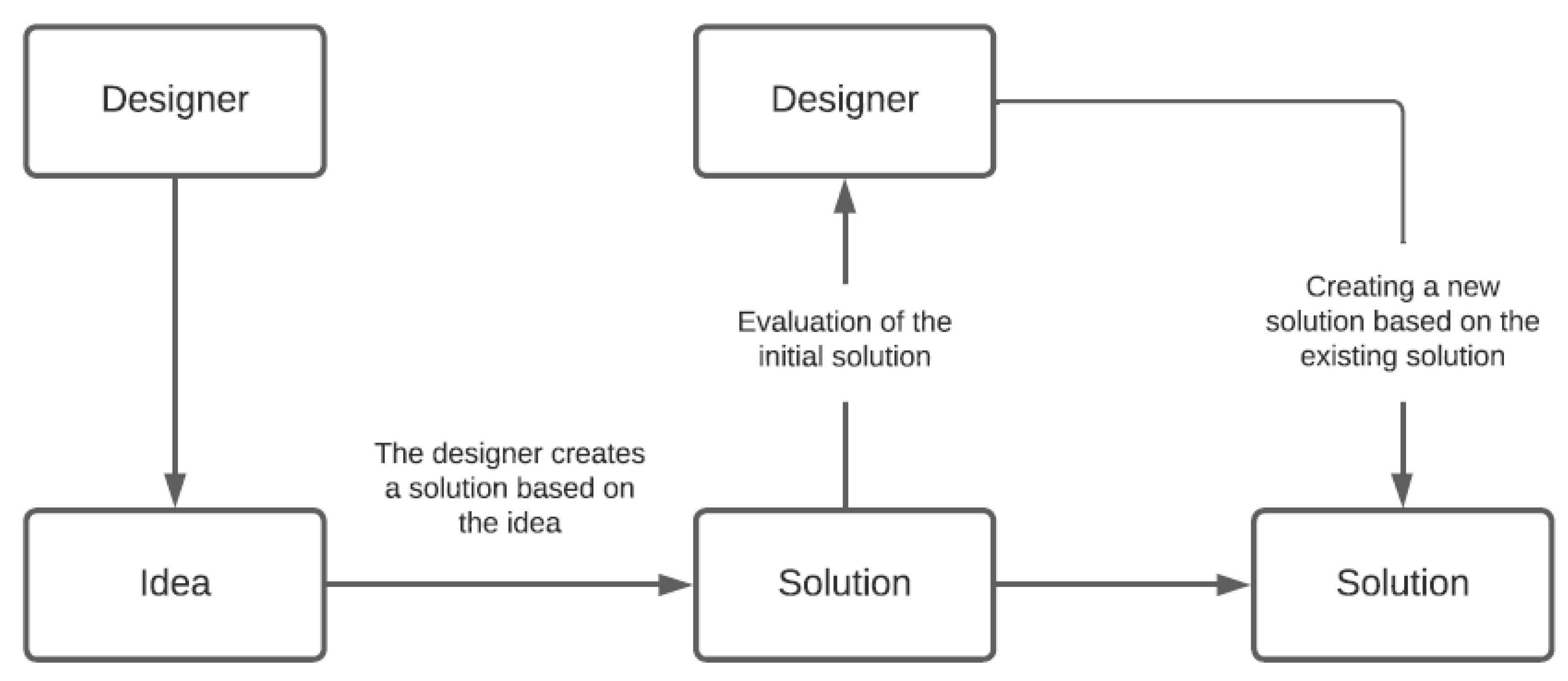

2.2. Comparison between Generative Design and Traditional Design

2.3. BIM in Process Automation

2.4. Traditional Methods and Software That Allow the Design of Prequalified Connections

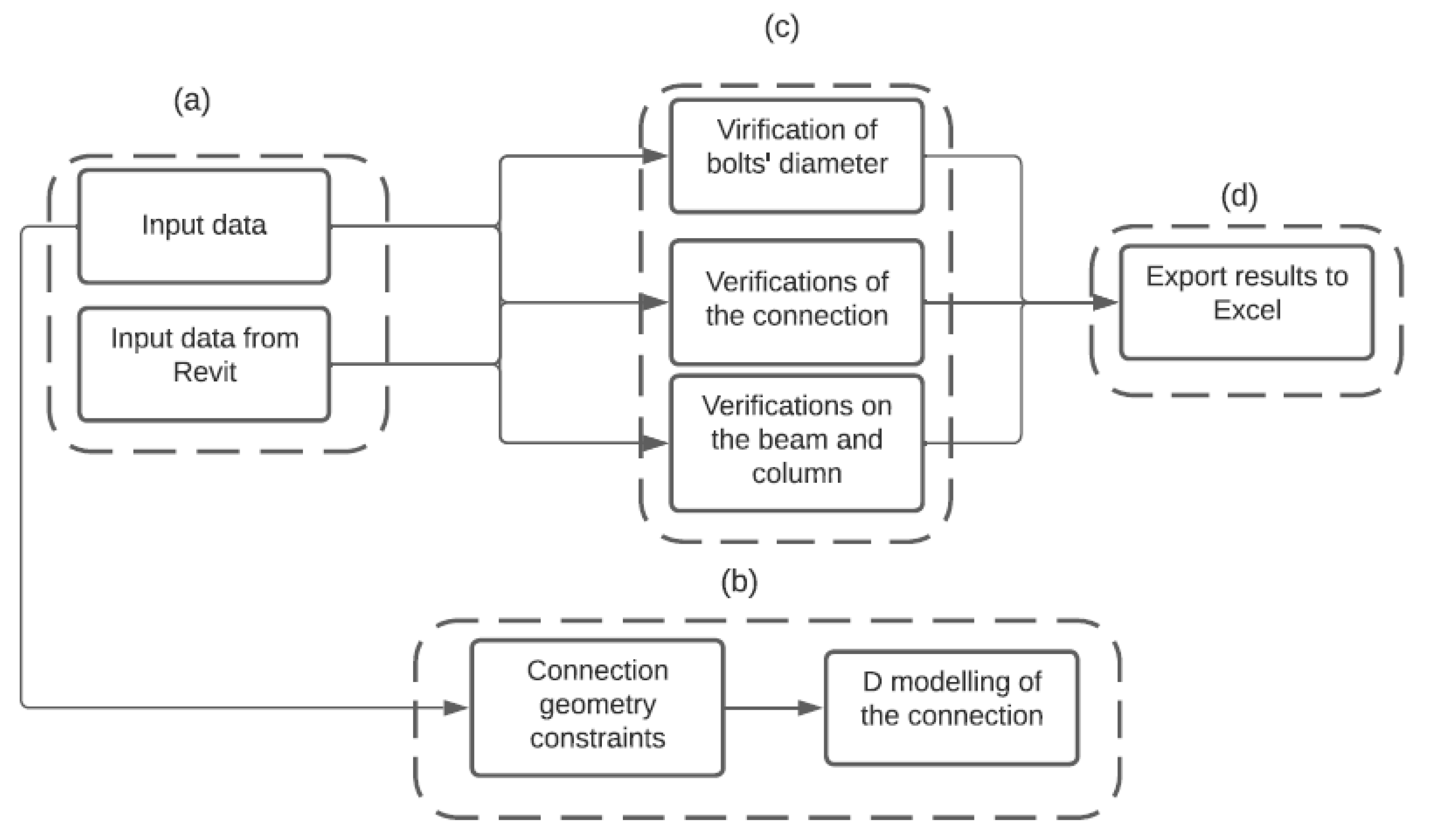

3. Methodology

4. Results and Discussion

- The material of the connection (plate, stiffeners, double-reinforcement plates and continuity plates) was the same as the material used for the beam; since Revit does not include this parameter in the element, this information cannot be imported to Dynamo.

- The information of some components of the connection cannot be transferred from Revit to Dynamo because they do not interact directly; that is, there is no node that allows the components of the connection to be brought into Dynamo, so it was decided to manually model the plates in Dynamo.

- It was necessary to add mechanical parameters for the beams and columns that were not included within the families of these elements, such as the plastic modulus of the section (Z) for both the beam and the column and the distance from the end face of the member flange to the tip of the fillet in the web (K) of the column.

- For purposes of generative design, the design of the plate reinforcements, such as continuity plates, stiffeners, and double-reinforcement plates, was not considered.

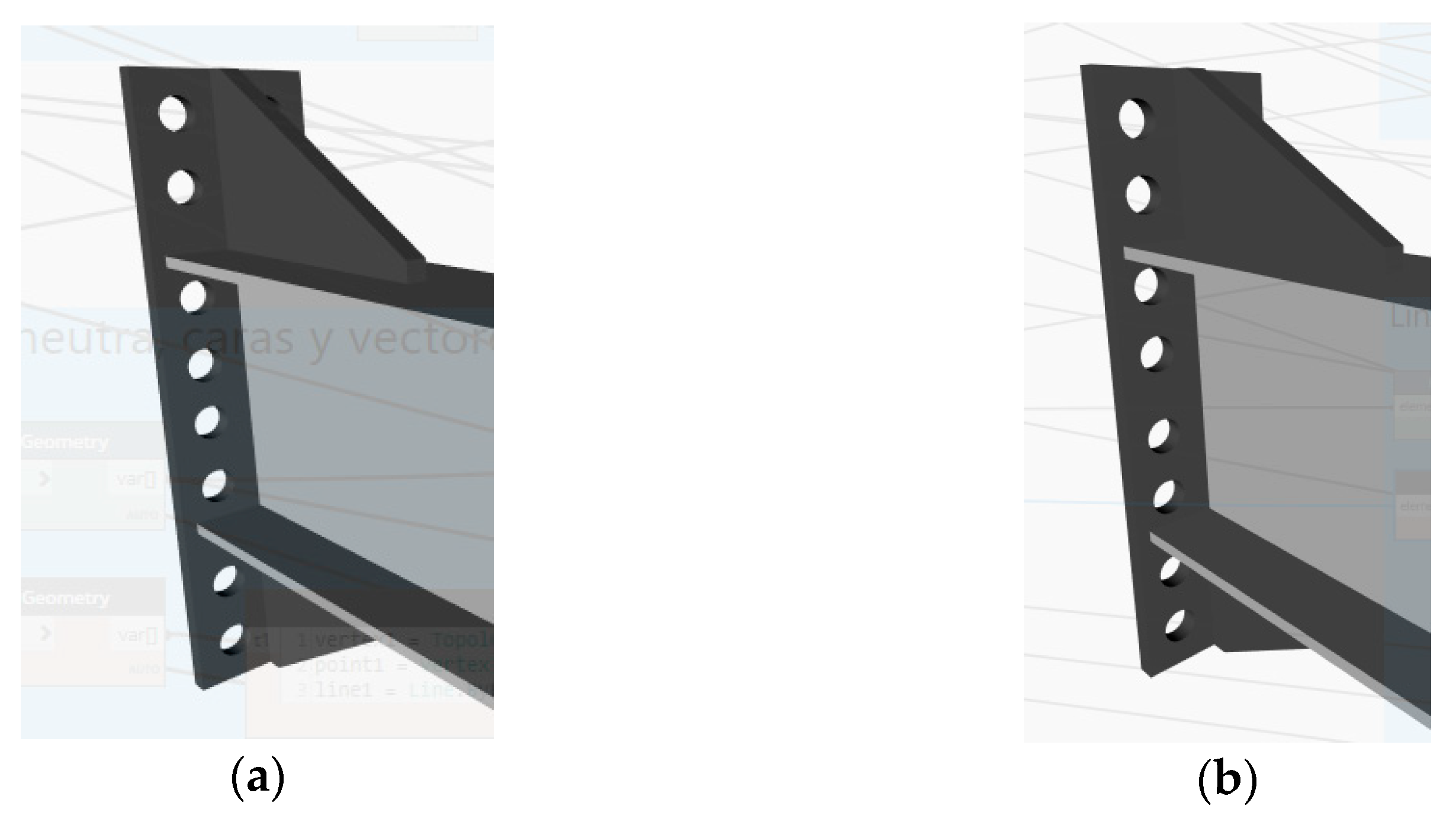

4.1. Design and Development of the Solution

- vertical distance between the outer end bolts and the edge of the end plate

- vertical distance between the inner and outer bolt rows

- vertical distance from the outside of the tension flange to the nearest outside bolt row

- vertical distance from the inside of the tension flange to the nearest inside bolt row

- vertical distance between the rows of interior and exterior bolts, which for the purposes of the investigation will be equal to the variable b

- horizontal distance between the outer bolts and the edge of the end plate

- horizontal distance between bolts

- bolt diameter

- plate thickness

- : number of connection bolts in the compression flange, i.e., 8 for the purposes of this study;

- nominal strength of the bolts;

- gross bolt area in , represented in Equation (2).

- ø: resistance factor, i.e., 0.9 for the purposes of this study;

- shear force at the center of the plastic hinge.

4.2. Verification and Validation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guerrero, S.; Angarita, C. Creación de una Herramienta de Chequeo de Conexiones Precalificadas con Verificación de la Norma Vigente. Bachlor’s Thesis, Franciso Jose de Caldas University, Bogotá, Colombia, 2019. [Google Scholar]

- Pannillo, G.; Vielma, E.; Ocanto, W.; Vielma, J.C. Development and programming of end-plate 4E and 8ES connections in accordance with the ANSI/AISC 358-16 regulations. Rev. Int. Ing. Estruct. 2020, 25, 39–60. [Google Scholar] [CrossRef]

- Pannillo, G.; Gutiérrez, O.; Vielma, J.C. Development and programming of double-tee earthquake-resistant connections (double-tee moment connections) in accordance with the ANSI/AISC 358-16 code. Rev. Int. Ing. Estruct. 2018, 23, 189–207. [Google Scholar] [CrossRef]

- Pannillo, G. Development and programming of seismic-resistant connections type BFP and RBS in accordance with the Ansi/Aisc 358-16 code. Gac. Técnica 2018, 19, 51–68. [Google Scholar] [CrossRef]

- Gallegos, M.; Nuñez, E.; Herrera, R. Numerical study on cyclic response of end-plate biaxial moment connection in box columns. Metals 2020, 10, 523. [Google Scholar] [CrossRef]

- Díaz, C.; Victoria, M.; Martí, P.; Querin, O.M. FE model of beam-to-column extended endplate joints. J. Constr. Steel Res. 2011, 67, 1578–1590. [Google Scholar] [CrossRef]

- American Institute of Steel Construction. Prequalified Connections for Special and Intermediate Steel Moment Frames for Seismic Applications; No. 1; American Institute of Steel Construction: Chicago, IL, USA, 2020. [Google Scholar]

- Delgado, C.; Garza, L.; Cruz, R. Conexiones Precalificadas en COLOMBIA. Master’s Thesis, Universidad Industrial De Santander, Bucaramanga, Colombia, 2017. [Google Scholar]

- Zhou, F. Model-Based Simulation of Steel Frames with Endplate Connections. Ph.D. Thesis, University of Cincinnati, Cincinnati, OH, USA, 2005. [Google Scholar]

- Shi, G.; Shi, Y.; Wang, Y.; Bradford, M.A. Numerical simulation of steel pretensioned bolted end-plate connections of different types and details. Eng. Struct. 2008, 30, 2677–2686. [Google Scholar] [CrossRef]

- Muñoz-La Rivera, F.; Vielma, J.C.; Herrera, R.F.; Carvallo, J. Methodology for Building Information Modeling (BIM) Implementation in Structural Engineering Companies (SECs). Adv. Civ. Eng. 2019, 8452461. [Google Scholar] [CrossRef]

- Morrison, M.; Quayyum, S.; Hassan, T. Performance enhancement of eight bolt extended end-plate moment connections under simulated seismic loading. Eng. Struct. 2017, 151, 444–458. [Google Scholar] [CrossRef]

- Hong, J.K.; Park, Y.C.; Sim, H.B. Cyclic Perfrmance of Easy Quality (EQ) Moment Connections as an Intermediate Steel Moment Frame. Int. J. Steel Struct. 2019, 19, 1272–1282. [Google Scholar] [CrossRef]

- Incelli, F.; Cardellicchio, L. Designing a steel connection with a high degree of disassembly: A practice-based experience. J. Technol. Archit. Environ. 2021, 104–113. [Google Scholar] [CrossRef]

- Maini, D. Up and Running with Autodesk Advance Steel 2021: Volume 1; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2020. [Google Scholar]

- Ismail, R.E.S.; Fahmy, A.S.; Khalifa, A.M.; Mohamed, Y.M. Numerical study on ultimate behavior of bolted end-plate steel connections. Lat. Am. J. Solids Struct. 2016, 13, 1–22. [Google Scholar] [CrossRef]

- Ghassemieh, M.; Jalalpour, M.; Gholampour, A.A. Numerical evaluation of the extended endplate moment connection subjected to cyclic loading. Curr. Adv. Civil. Eng. 2014, 2, 35–43. [Google Scholar]

- Díaz, G. Aplicaciones del Diseño Generativo en la Ingeniería Estructural. Bachelor’s Thesis, Pontificia Universidad Católica de Valparapiso, Valparaíso, Chile, 2020. [Google Scholar]

- Buonamici, F.; Carfagni, M.; Furferi, R.; Volpe, Y.; Governi, L. Generative Design: An Explorative Study. Comput. Aided Des. Appl. 2020, 18, 144–155. [Google Scholar] [CrossRef]

- Cascone, F.; Faiella, D.; Tomei, V.; Mele, E. A Structural Grammar Approach for the Generative Design of Diagrid-Like Structures. Buildings 2021, 11, 90. [Google Scholar] [CrossRef]

- Dzwierzynska, J. Rationalized Algorithmic-Aided Shaping a Responsive Curvilinear Steel Bar Structure. Buildings 2019, 9, 61. [Google Scholar] [CrossRef]

- Li, B.; Tang, W.; Ding, S.; Hong, J. A generative design method for structural topology optimization via transformable triangular mesh (TTM) algorithm. Struct. Multidisc.Optim. 2020, 62, 1159–1183. [Google Scholar] [CrossRef]

- Liao, W.; Lu, X.; Huang, Y.; Zheng, Z.; Lin, Y. Automated structural design of shear wall residential buildings using generative adversarial networks. Autom. Constr. 2021, 132, 103931. [Google Scholar] [CrossRef]

- Shen, Q.; Vahdatikhaki, F.; Voordijk, H.; van der Gucht, J.; van der Meer, L. Metamodel-based generative design of wind turbine foundations. Autom. Constr. 2022, 138, 104233. [Google Scholar] [CrossRef]

- Silveira, M.V.G.; Paini, B.; Bitencourt, L.A.G., Jr.; Das, S. Design and experimental investigation of deep beams based on the Generative Tie Method. Eng. Struct. 2022, 255, 113913. [Google Scholar] [CrossRef]

- Korus, K.; Salamak, M.; Jasiński, M. Optimization of geometric parameters of arch bridges using visual programming FEM components and genetic algorithm. Eng. Struct. 2021, 241, 112465. [Google Scholar] [CrossRef]

- Herath, S.; Haputhanthri, U. Topologically optimal design and failure prediction using conditional generative adversarial networks. Numer. Meth Eng. 2021, 122, 6867–6887. [Google Scholar] [CrossRef]

- Ma, X.; Wang, F.; Aage, N.; Tian, K.; Hao, P.; Wang, B. Generative design of stiffened plates based on homogenization method. Struct. Multidisc. Optim. 2021, 64, 3951–3969. [Google Scholar] [CrossRef]

- Wang, H.; Du, W.; Zhao, Y.; Wang, Y.; Hao, R.; Yang, M. Joints for treelike column structures based on generative design and additive manufacturing. J. Constr. Steel Res. 2021, 184, 106794. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y.; Lei, Z.; Li, H.X.; Han, S. Design for Manufacturing and Assembly: A BIM-Enabled Generative Framework for Building Panelization Design. Adv. Civ. Eng. 2021, 13, 5554551. [Google Scholar] [CrossRef]

- Tafraout, S.; Bourahla, N.; Bourahla, Y.; Mebarki, A. Automatic structural design of RC wall-slab buildings using a genetic algorithm with application in BIM environment. Autom. Constr. 2019, 106, 102901. [Google Scholar] [CrossRef]

- Angulo, C.; Díaz, K.; Gutiérrez, J.M.; Prado, A.; Casadey, R.; Pannillo, G.; Muñoz-La Rivera, F.; Herrera, R.; Vielma, J.C. Using BIM for the assessment of the seismic performance of educational buildings. Int. J. Saf. Secur. Eng. 2020, 10, 77–82. [Google Scholar] [CrossRef]

- Muñoz-La Rivera, F.; Vielma, J.C.; Herrera, R.F.; Gallardo, E. Waste Identification in the Operation of Structural Engineering Companies (SEC) According to Lean Management. Sustainability 2021, 13, 4249. [Google Scholar] [CrossRef]

- Ambiado, E. Automatización y Optimización de Diseño de Conexión de Placa Extrema Extendida 8ES a Través de los Análisis Lineal y no Lineal. Bachelor’s Thesis, Pontificia Universidad Católica de Valparaíso, Valparaíso, Chile, 2020. [Google Scholar]

- Velasco, R. Estudio de la Aplicación del Diseño Generativo al Diseño Conceptual Arquitectónico. Bachelor’s Thesis, Universitat Politècnica de València, Valencia, Spain, 2015. [Google Scholar]

- Bohnacker, H.; Gross, B.; Laub, J. Generative Design: Visualize, Program, and Create with Processing; Princeton Architectural Press: New York, NY, USA, 2012. [Google Scholar]

- ASCENT. Autodesk Advance Steel 2021 Fundamentals: Autodesk Authorized Publisher; ASCENT Center for Technical Knowledge: Carlottesville, VA, USA, 2020. [Google Scholar]

- Acuña, J.; Sotelo, H. Software libre para el diseño de conexiones metálicas de acuerdo con la NSR-10. J. Chem. Inf. Model 2014, 138. [Google Scholar]

- Bentley. RAM Connection. Available online: https://www.bentley.com/en/products/product-line/structural-analysis-software/ram-connection (accessed on 20 December 2021).

- IDEA Statica. Available online: https://www.ideastatica.com/ (accessed on 20 December 2021).

- Autodesk. Revit. Available online: https://www.autodesk.com/products/revit/ (accessed on 20 December 2021).

- Autodesk. Fusion 360. 2015. Available online: http://www.autodesk.com/products/3ds-max/overview (accessed on 20 December 2021).

- Grasshopper. Available online: https://grasshopper.app/es_419/ (accessed on 20 December 2021).

- Autodesk. Robot Structural Analysis Professional. 2015. Available online: http://www.autodesk.com/products/3ds-max/overview (accessed on 20 December 2021).

- Trimble. Tekla Structures. Available online: https://www.tekla.com/la/productos/tekla-structures (accessed on 20 December 2021).

- Dynamobim. Dynamo. Available online: https://primer.dynamobim.org/es/ (accessed on 20 December 2021).

- Ambiado, E.; López, A.; Vielma, J.C. Numerical evaluation of prequalified end-plate connections used in a framed steel industrial structure. Metals 2021, 11, 243. [Google Scholar] [CrossRef]

| Software | Generative Design | BIM | Description |

|---|---|---|---|

| Advance Steel | No | Yes | Automates the process of designing structural steel connections based on preconfigured parametric connections. Allows interaction with other software [15]. |

| RAM Connection | No | No | Analyzes, designs and optimizes any type of connection for structural steel joints [39]. |

| IDEA Statica Connection | No | Yes | Performs analysis and structural design of metallic connections and calculation of connections based on finite elements. Allows interaction with other software [40]. |

| Revit | Yes | Yes | Produces 3D modeling; architectural, structural and MEP design; documentation; and coordination. Allows interaction with other software [41]. |

| Fusion 360 | Yes | Yes | Creates mechanical and technical 3D models to meet the needs of industrial designers. Offers parametric, direct, and free-form modeling [42]. |

| Grasshopper | Yes | No | Different types of design and 3D modeling can be generated, as well as programming and performing highly complex algorithms. Allows parametric and generative design [43]. |

| Robot Structural Analysis | Yes | Yes | Creates strong, buildable designs, enables structural load analysis, and verifies regulatory compliance. Can design steel connections [44]. |

| Tekla | No | Yes | Allows collaborative work between different disciplines in construction projects, with all the information included in a 3D model. It is used in the design, detailing and information management of projects [45]. |

| Variable | Restrictions |

|---|---|

| Variable | Range [mm] |

|---|---|

| [22, 150] | |

| [42.67, 300] | |

| [29, 150] | |

| [29, 150] | |

| [42.67, 190] |

| Variable | Range [mm] |

|---|---|

| [30, 50] | |

| [50, 70] | |

| [30, 60] | |

| [30, 60] | |

| [70, 80] |

| Variable | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 40 | 40 | 45 | 40 | 30 | 45 | 35 | 40 | 40 | 40 | |

| 65 | 70 | 60 | 65 | 60 | 55 | 70 | 70 | 55 | 55 | 55 | |

| 60 | 50 | 55 | 40 | 40 | 40 | 50 | 55 | 40 | 40 | 40 | |

| 35 | 45 | 45 | 55 | 30 | 45 | 50 | 35 | 35 | 60 | 55 | |

| 65 | 70 | 60 | 65 | 60 | 55 | 70 | 70 | 55 | 55 | 55 | |

| 42.5 | 40 | 37.5 | 32.5 | 45 | 35 | 35 | 40 | 42.5 | 42.5 | 42.5 | |

| 75 | 80 | 75 | 80 | 70 | 80 | 80 | 75 | 70 | 75 | 75 | |

| 18 | 18 | 18 | 20 | 18 | 20 | 20 | 20 | 20 | 18 | 20 | |

| 16 | 16 | 16 | 16 | 16 | 16 | 20 | 20 | 20 | 20 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Henríquez, D.; Herrera, R.F.; Vielma, J.C. Method for Designing Prequalified Connections Using Generative Design. Buildings 2022, 12, 1579. https://doi.org/10.3390/buildings12101579

Henríquez D, Herrera RF, Vielma JC. Method for Designing Prequalified Connections Using Generative Design. Buildings. 2022; 12(10):1579. https://doi.org/10.3390/buildings12101579

Chicago/Turabian StyleHenríquez, Daniela, Rodrigo F. Herrera, and Juan Carlos Vielma. 2022. "Method for Designing Prequalified Connections Using Generative Design" Buildings 12, no. 10: 1579. https://doi.org/10.3390/buildings12101579

APA StyleHenríquez, D., Herrera, R. F., & Vielma, J. C. (2022). Method for Designing Prequalified Connections Using Generative Design. Buildings, 12(10), 1579. https://doi.org/10.3390/buildings12101579