Reinforced Concrete Corbels Shear Test: The Triangular-Truss Method Evaluation

Abstract

:1. Introduction

2. Experimental Program

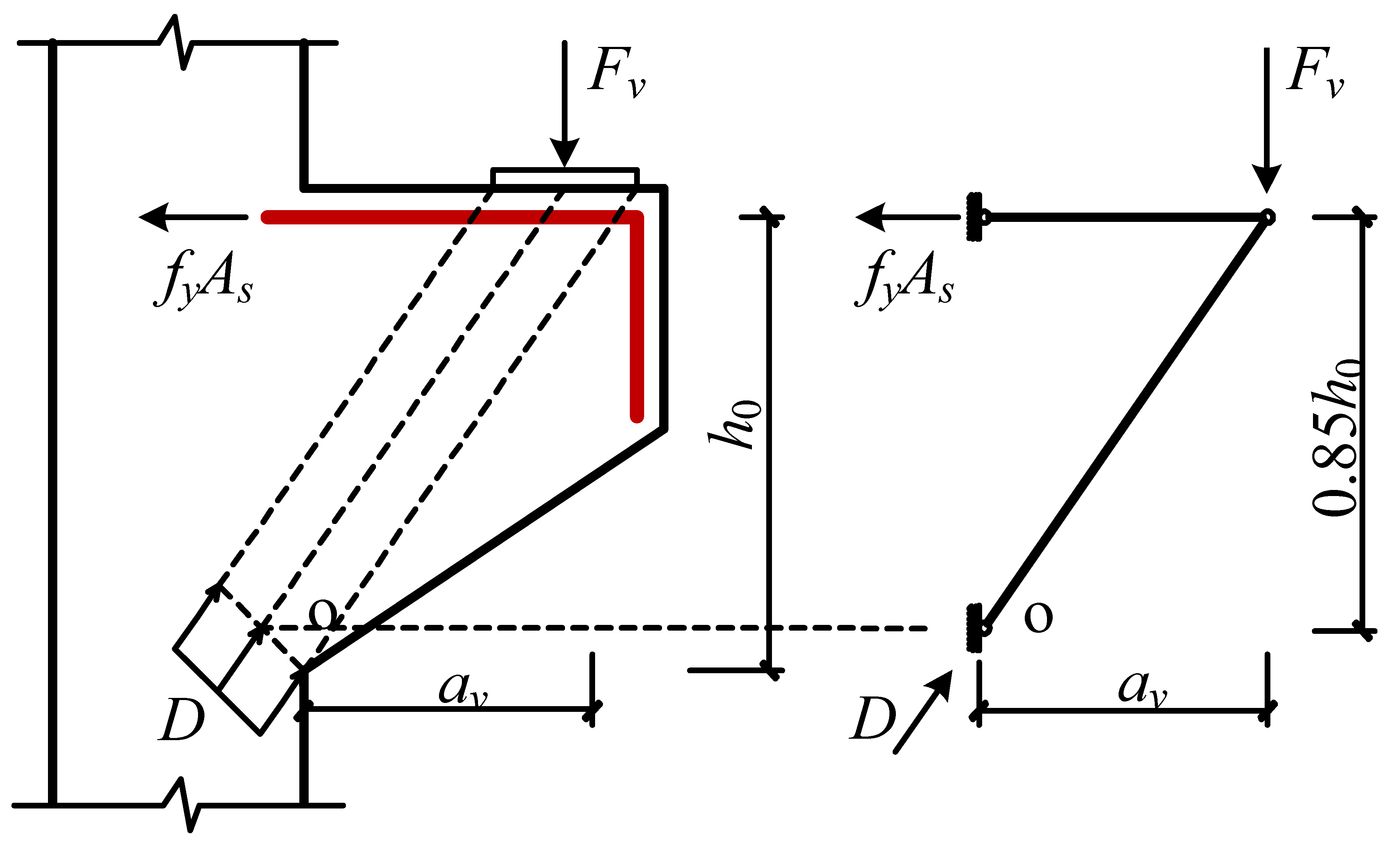

2.1. Design of Corbels

2.2. Material Properties

2.3. Testing Setup

3. Test Results and Analysis

3.1. Failure Mode and Process

3.2. Load–Displacement Curves

3.3. Crack Propagation

3.4. Strain Development of Reinforcements

4. Evaluation of the Triangular-Truss Method

4.1. Influence of Concrete Strength

4.2. Influence of Shear Span–Depth Ratio

5. Comparison of Calculation Methods

5.1. Multi-Country Strut-and-Tie Method

5.2. Softened Strut-and-Tie Method

5.3. Russo Strut-and-Tie Method

5.4. Comparison of Bearing Capacity Calculations

6. Conclusions

- (1)

- The safety level of the TTM becomes higher if the concrete compressive strength is improved. For example, when the concrete strength was improved from 20.8 MPa to 65.3 MPa, the safety factor of TTM was increased from 1.419 to 1.718.

- (2)

- The safety level of the TTM becomes higher if the shear span–depth ratio is increased. For example, when the shear span–depth ratio was increased from 0.25 to 0.67, the safety factor was increased from 1.414 to 1.859.

- (3)

- When using the TTM to design a corbel under a certain designed capacity, increasing the concrete strength or decreasing the shear span–depth ratio are both effective in reducing the crack width at the serviceability limit state.

- (4)

- The horizontal stirrups distributed in the up half of corbel′s section depth can be fully utilized for their yield strength.

- (5)

- Compared to GB 50010-2010, ACI 318-19, and EC 2, the predictions of CSA A23.3-04 for corbels are closer to the test values. The safety level of codes GB 50010-2010, ACI 318-19, and EC 2 is essentially the same. In addition, the SSTM and Russo STM are more accurate, and even the Russo method tends to overestimate the result.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kaloop, M.R.; Roy, B.; Chaurasia, K.; Kim, S.-M.; Jang, H.-M.; Hu, J.-W.; Abdelwahed, B.S. Shear Strength Estimation of Reinforced Concrete Deep Beams Using a Novel Hybrid Metaheuristic Optimized SVR Models. Sustainability 2022, 14, 5238. [Google Scholar] [CrossRef]

- Mansour, M.; El-Ariss, B.; El-Maaddawy, T. Effect of Support Conditions on Performance of Continuous Reinforced Concrete Deep Beams. Buildings 2020, 10, 212. [Google Scholar] [CrossRef]

- Kachouh, N.; El-Maaddawy, T.; El-Hassan, H.; El-Ariss, B. Shear Behavior of Steel-Fiber-Reinforced Recycled Aggregate Concrete Deep Beams. Buildings 2021, 11, 423. [Google Scholar] [CrossRef]

- Hsu, T.T.C. Unified theory of reinforced concrete-A summary. Struct. Eng. Mech. 1994, 2, 1–16. [Google Scholar] [CrossRef]

- Khosravikia, F.; Kim, H.s.; Yi, Y.; Wilson, H.; Yousefpour, Y.H.H.; Hrynyk, T.; Bayrak, O. Experimental and Numerical Assessment of Corbels Designed Based on Strut-and-Tie Provisions. J. Struct. Eng. 2018, 144, 04018138. [Google Scholar] [CrossRef]

- Hwang, S.-J.; Tsa, R.-J.; Lam, W.-K.; Moehle, J.P. Simplification of softened strut-and-tie model for strength prediction of discontinuity regions. ACI Struct. J. 2017, 114, 1569–1579. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2015.

- Ding, B. Culculation of reinforced concrete corbels. Ind. Constr. 1974, 31–36+51. [Google Scholar]

- Canha, R.M.F.; Kuchma, D.A.; Debs, M.K.E.; Souza, R.A.d. Numerical analysis of reinforced high strength concrete corbels. Eng. Struct. 2014, 74, 130–144. [Google Scholar] [CrossRef]

- Yun, Y.M.; Lee, Y. Strengths of Struts and Nodal Zones for Strut-and-Tie Model Design of Reinforced Concrete Corbels. Civil Eng. J. 2021, 7, 1275–1289. [Google Scholar] [CrossRef]

- Hamoodi, A.Z.; Chkheiwer, A.H.; Kadim, J.A. Shear Strength of Reinforced Recycled Aggregate Concrete Corbels. J. Eng. 2021, 2021, 6652647. [Google Scholar] [CrossRef]

- Yuan, H.; Wenmeng, Y.; Weijian, Y. Study on Design Modification Factor for Shear Capacity of Reinforced Concrete Corbels. J. Hunan Univ. 2021, 48, 61–70. [Google Scholar] [CrossRef]

- Li, S.; Zhang, F.; Zhang, Z.; Huang, F.; Jia, M.; Liu, Z.; Xie, W. Experimental study on shear behavior of high-strength steel fiber reinforced concrete corbel. J. Build. Struct. 2020, 41, 151–159. [Google Scholar] [CrossRef]

- Ritter, W. Die bauweise hennebique (Hennebiques construction method). Schweiz. Bauztg. 1899, 33, 59–61. [Google Scholar]

- Wilson, H.R.; Hossein, Y.; Michael, B.D.; Oguzhan, B. Investigation of corbels designed according to strut-and-tie and empirical methods. ACI Struct. J. 2018, 115, 813–824. [Google Scholar] [CrossRef]

- Hwang, S.-J.; Lu, W.-Y.; Lee, H.-J. Shear strength prediction for reinforced concrete corbels. ACI Struct. J. 2000, 97, 543–552. [Google Scholar] [CrossRef]

- Hwang, S.-J.; Lee, H.-J. Strength prediction for discontinuity regions by softened strut-and-tie model. J. Struct. Eng. 2002, 128, 1519–1526. [Google Scholar] [CrossRef]

- Russo, G.; Venir, R.; Pauletta, M.; Somma, G. Reinforced concrete corbels-shear strength model and design formula. ACI Struct. J. 2006, 103, 3–9. [Google Scholar] [CrossRef]

- ACI 318-19; Building code requirements for structural concrete. American Concrete Institute: Farmington Hills, MI, USA, 2019; pp. 436–449.

- Eurocode 2: Design of concrete structures. In Part 1-1: General Rules and Rules for Buildings: BS EN 1992-1-1; British Standards Institution: London, UK, 2004; pp. 107–109.

- CSA A23.3-04; Design of Concrete Structures. Canadian Standards Association: Toronto, ON, Canada, 2004; pp. 62–66.

- Yao, J.; Gu, H.; Li, Q.; Huang, B. Research on bearing capacity design reliability of RC crane beams. J. Hunan Univ. 2019, 46, 21–30. [Google Scholar] [CrossRef]

- Shen, P. Design of Concrete Structures, 3rd ed.; Higher Education Press: Beijing, China, 2007; pp. 107–136. [Google Scholar]

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2011.

- Deifalla, A.; Awad, A.; Seleem, H.; Abdelrahman, A. Experimental and numerical investigation of the behavior of LWFC L-girders under combined torsion. Structures 2020, 26, 362–377. [Google Scholar] [CrossRef]

- Tariq, M.; Khan, A.; Ullah, A.; Shayanfar, J.; Niaz, M. Improved Shear Strength Prediction Model of Steel Fiber Reinforced Concrete Beams by Adopting Gene Expression Programming. Materials 2022, 15, 3758. [Google Scholar] [CrossRef]

- Deifalla, A.; Awad, A.; Seleem, H.; Abdelrahman, A. Investigating the behavior of lightweight foamed concrete T-beams under torsion, shear, and flexure. Eng. Struct. 2020, 219, 110741. [Google Scholar] [CrossRef]

- Kriz, L.B.; Raths, C.H. Connections in precast concrete structures-strength of corbels. PCI J. 1965, 10, 16–61. [Google Scholar] [CrossRef]

- Al-Shaarbaf, I.A.; Al-Azzawi, A.A.; Farahan, R.S. Experimental Investigation on the Behavior of Reinforced Concrete Corbels under Repeated Loadings. J. Eng. Dev. 2015, 19, 126–147. [Google Scholar]

- Foster, S.J.; Powell, R.E.; Selim, H.S. Performance of High-Strength Concrete Corbels. ACI Struct. J. 1996, 93, 555–563. [Google Scholar] [CrossRef]

- Li, G. Experimental Study on Design Method of Reinforced Concrete Corbel with Small Shear Span Ratio. Master Thesis, Hohai University, Jiangsu, China, 2008. [Google Scholar]

| ID | h (mm) | av (mm) | λ | fcu,D (MPa) | Longitudinal Bars | ρs (%) | Stirrups | ρst (%) | b (mm) |

|---|---|---|---|---|---|---|---|---|---|

| C30-S0.42 | 500 | 200 | 0.42 | 30 | 5Ø10 | 0.275 | Ø8@100 | 0.212 | 300 |

| C45-S0.50 | 425 | 200 | 0.50 | 45 | 4Ø12 | 0.377 | Ø10@100 | 0.262 | 300 |

| C60-S0.57 | 375 | 200 | 0.57 | 60 | 5Ø12 | 0.538 | Ø10@100 | 0.299 | 300 |

| C45-S0.31 | 350 | 100 | 0.31 | 45 | 4Ø10 | 0.322 | Ø8@100 | 0.206 | 300 |

| C45-S0.67 | 475 | 300 | 0.67 | 45 | 4Ø14 | 0.456 | Ø10@100 | 0.349 | 300 |

| Concrete Strength Grades | Ingredient (kg/m3) | fcu (MPa) | fc (MPa) | |||||

|---|---|---|---|---|---|---|---|---|

| Water | Cement | Sand | Gravel | Fly Ash | Superplasticizer | |||

| C30 | 185 | 345 | 670 | 1195 | 0 | 0 | 38.6 | 23.8 |

| C45 | 150 | 500 | 612 | 1188 | 0 | 7.5 | 65.3 | 54.2 |

| C60 | 164 | 459 | 649 | 1086 | 114.3 | 7.1 | 59.7 | 44.2 |

| Bar Diameter (mm) | As (mm2) | fy (MPa) | fu (MPa) | Es (GPa) | εy (10−6) |

|---|---|---|---|---|---|

| 8 | 50.2 | 539 | 687 | 206 | 2617 |

| 10 | 78.5 | 473 | 609 | 206 | 2296 |

| 12 | 113.0 | 453 | 636 | 206 | 2199 |

| 14 | 153.9 | 454 | 611 | 206 | 2204 |

| 20 | 314.0 | 425 | 615 | 206 | 2063 |

| ID | Vcr (kN) | Vy,st (kN) | Vy,al (kN) | Vt (kN) | w in (mm) | w0 (mm) | Failure Mode |

|---|---|---|---|---|---|---|---|

| C30-S0.42 | 149 | 467 | 506 | 573 | 0.02 | 0.14 | DC |

| C45-S0.50 | 175 | 450 | 622 | 624 | 0.02 | 0.05 | DC |

| C60-S0.57 | 100 | 414 | 496 | 593 | 0.02 | 0.09 | DC |

| C45-S0.31 | 175 | 449 | 613 | 632 | 0.02 | 0.05 | DC |

| C45-S0.67 | 124 | 446 | 566 | 679 | 0.02 | 0.11 | DC |

| Source | ID | h0 (mm) | b (mm) | av (mm) | fcu (MPa) | fy (MPa) | As (mm2) | Vt (kN) | αt |

|---|---|---|---|---|---|---|---|---|---|

| This paper | C30-S0.42 | 475 | 300 | 200 | 38.6 | 473 | 393 | 375 | 1.527 |

| C45-S0.50 | 400 | 300 | 200 | 65.3 | 453 | 452 | 348 | 1.793 | |

| C60-S0.57 | 350 | 300 | 200 | 59.7 | 453 | 565 | 381 | 1.558 | |

| C45-S0.31 | 325 | 300 | 100 | 65.3 | 473 | 314 | 410 | 1.541 | |

| C45-S0.67 | 450 | 300 | 300 | 65.3 | 453 | 615 | 356 | 1.907 | |

| Al-Shaarbaf et al. [29] | LNC7 | 215 | 150 | 108 | 42.7 | 532 | 339 | 160 | 1.638 |

| HNC7 | 215 | 150 | 108 | 56.1 | 532 | 339 | 175 | 1.542 | |

| Kriz and Raths [28] | 12 | 411 | 203 | 152 | 35.4 | 352 | 259 | 314 | 1.499 |

| 13 | 513 | 203 | 152 | 39.0 | 352 | 261 | 427 | 1.620 | |

| 16 | 411 | 203 | 152 | 29.3 | 331 | 401 | 350 | 1.479 | |

| 17 | 411 | 203 | 152 | 34.1 | 661 | 401 | 381 | 1.479 | |

| 24 | 409 | 203 | 152 | 35.4 | 326 | 773 | 396 | 1.519 | |

| 25 | 409 | 203 | 152 | 53.7 | 322 | 773 | 579 | 1.766 | |

| 27 | 511 | 203 | 152 | 36.6 | 326 | 778 | 512 | 1.411 | |

| 31 | 610 | 203 | 152 | 34.1 | 322 | 1016 | 668 | 1.505 | |

| 41 | 409 | 203 | 241 | 35.4 | 306 | 773 | 347 | 1.663 | |

| 42 | 612 | 203 | 241 | 40.2 | 362 | 771 | 668 | 1.635 | |

| 43 | 612 | 203 | 241 | 35.4 | 315 | 771 | 534 | 1.403 | |

| 44 | 612 | 203 | 241 | 31.7 | 313 | 771 | 499 | 1.393 | |

| 76 | 1059 | 203 | 318 | 34.1 | 322 | 2045 | 1112 | 1.542 | |

| 80 | 513 | 203 | 152 | 20.7 | 300 | 511 | 370 | 1.386 | |

| 85 | 406 | 203 | 216 | 18.3 | 308 | 1016 | 282 | 1.854 | |

| 89 | 513 | 203 | 152 | 34.1 | 309 | 511 | 490 | 1.395 | |

| 101 | 411 | 203 | 216 | 53.7 | 319 | 401 | 347 | 1.677 | |

| Foster et al. [30] | SC1–3 | 600 | 125 | 300 | 109 | 430 | 762 | 700 | 1.829 |

| PF1 | 500 | 150 | 150 | 128 | 420 | 762 | 750 | 1.440 | |

| Li [31] | N04 | 410 | 200 | 123 | 24.4 | 378 | 452 | 330 | 1.443 |

| DN10 | 760 | 400 | 228 | 20.7 | 359 | 1520 | 1140 | 1.470 | |

| DN11 | 760 | 400 | 228 | 20.7 | 359 | 1520 | 1110 | 1.431 | |

| DN12 | 760 | 400 | 228 | 20.7 | 359 | 1520 | 1150 | 1.483 |

| Codes | λ | θ | Effective Coefficient of Concrete Strength | ||

|---|---|---|---|---|---|

| Concrete Strut AB | Node A (A′) | Node B (B′) | |||

| ACI 318-19 | λ ≤ 2 | 25° ≤ θ | 0.64 βc (under ρh ≥ 0.0025/(sin θ)2) | 0.68 βc | 0.85 βc |

| 0.34 βc (under ρh < 0.0025/(sin θ)2) | |||||

| EC 2 | λ ≤ 1 | 1 ≤ tan θ ≤ 2 | 0.6 × (1-fc/250) | 0.85 × (1-fc/250) | 1.0 × (1-fc/250) |

| CSA A23.3-04 | λ ≤ 1 | - | 1/(0.8 + 170 ε1) ≤ 0.85 | 0.75 | 0.85 |

| ID | GB 50010 | ACI 318 | EC 2 | CSA | SSTM | Russo STM | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vca (kN) | Vca/Vt | Vca (kN) | Vca/Vt | Vca (kN) | Vca/Vt | Vca (kN) | Vca/Vt | Vca (kN) | Vca/Vt | Vca (kN) | Vca/Vt | |

| C30-S0.42 | 375 | 0.655 | 301 | 0.526 | 314 | 0.548 | 314 | 0.548 | 552 | 0.963 | 565 | 0.986 |

| C45-S0.50 | 348 | 0.558 | 295 | 0.474 | 272 | 0.436 | 295 | 0.474 | 561 | 0.899 | 749 | 1.200 |

| C60-S0.57 | 381 | 0.642 | 319 | 0.537 | 308 | 0.52 | 319 | 0.537 | 520 | 0.877 | 659 | 1.111 |

| C45-S0.31 | 410 | 0.649 | 283 | 0.448 | 261 | 0.413 | 283 | 0.448 | 572 | 0.905 | 652 | 1.031 |

| C45-S0.67 | 356 | 0.524 | 331 | 0.488 | 305 | 0.449 | 331 | 0.488 | 613 | 0.903 | 843 | 1.241 |

| LNC7 | 98 | 0.610 | 223 | 1.394 | 191 | 1.194 | 223 | 1.394 | 162 | 1.013 | 197 | 1.231 |

| HNC7 | 114 | 0.649 | 229 | 1.309 | 219 | 1.251 | 229 | 1.309 | 192 | 1.097 | 233 | 1.331 |

| 12 | 210 | 0.667 | 161 | 0.513 | 161 | 0.513 | 161 | 0.513 | 268 | 0.854 | 296 | 0.943 |

| 13 | 264 | 0.617 | 202 | 0.473 | 202 | 0.473 | 202 | 0.473 | 329 | 0.770 | 364 | 0.852 |

| 16 | 237 | 0.676 | 230 | 0.657 | 230 | 0.657 | 230 | 0.657 | 275 | 0.786 | 305 | 0.871 |

| 17 | 258 | 0.676 | 367 | 0.963 | 288 | 0.756 | 391 | 1.026 | 309 | 0.811 | 340 | 0.892 |

| 24 | 261 | 0.658 | 400 | 1.010 | 311 | 0.785 | 424 | 1.071 | 422 | 1.066 | 457 | 1.154 |

| 25 | 328 | 0.566 | 427 | 0.737 | 413 | 0.713 | 427 | 0.737 | 565 | 0.976 | 595 | 1.028 |

| 27 | 363 | 0.709 | 410 | 0.801 | 319 | 0.623 | 467 | 0.912 | 503 | 0.982 | 549 | 1.072 |

| 31 | 444 | 0.664 | 388 | 0.581 | 304 | 0.455 | 457 | 0.684 | 600 | 0.898 | 660 | 0.988 |

| 41 | 209 | 0.601 | 228 | 0.657 | 287 | 0.827 | 287 | 0.827 | 330 | 0.951 | 406 | 1.170 |

| 42 | 409 | 0.612 | 320 | 0.479 | 488 | 0.731 | 517 | 0.774 | 588 | 0.880 | 635 | 0.951 |

| 43 | 380 | 0.713 | 273 | 0.511 | 427 | 0.800 | 450 | 0.843 | 520 | 0.974 | 570 | 1.067 |

| 44 | 358 | 0.718 | 254 | 0.509 | 400 | 0.802 | 446 | 0.894 | 491 | 0.984 | 540 | 1.082 |

| 76 | 721 | 0.649 | 481 | 0.433 | 329 | 0.296 | 567 | 0.510 | 1098 | 0.987 | 1200 | 1.079 |

| 80 | 267 | 0.721 | 250 | 0.676 | 266 | 0.719 | 326 | 0.881 | 271 | 0.732 | 305 | 0.824 |

| 85 | 152 | 0.539 | 152 | 0.539 | 213 | 0.755 | 261 | 0.926 | 221 | 0.784 | 274 | 0.972 |

| 89 | 351 | 0.717 | 343 | 0.700 | 343 | 0.700 | 343 | 0.700 | 399 | 0.814 | 442 | 0.902 |

| 101 | 207 | 0.596 | 177 | 0.510 | 172 | 0.496 | 177 | 0.510 | 351 | 1.012 | 427 | 1.231 |

| SC1–3 | 383 | 0.547 | 477 | 0.681 | 359 | 0.513 | 477 | 0.681 | 619 | 0.884 | 840 | 1.200 |

| PF1 | 521 | 0.694 | 625 | 0.833 | 426 | 0.568 | 625 | 0.833 | 708 | 0.944 | 798 | 1.064 |

| N04 | 229 | 0.693 | 214 | 0.648 | 174 | 0.527 | 257 | 0.779 | 317 | 0.96 | 326 | 0.988 |

| DN10 | 775 | 0.680 | 951 | 0.834 | 533 | 0.468 | 809 | 0.710 | 1135 | 0.996 | 1208 | 1.060 |

| DN11 | 775 | 0.699 | 951 | 0.857 | 533 | 0.480 | 809 | 0.729 | 1135 | 1.023 | 1208 | 1.088 |

| DN12 | 775 | 0.674 | 951 | 0.827 | 533 | 0.463 | 809 | 0.703 | 1135 | 0.987 | 1208 | 1.050 |

| Mean | 0.646 | 0.687 | 0.631 | 0.752 | 0.924 | 1.055 | ||||||

| DEV | 0.054 | 0.246 | 0.220 | 0.226 | 0.099 | 0.129 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Han, B.; Yin, W. Reinforced Concrete Corbels Shear Test: The Triangular-Truss Method Evaluation. Buildings 2022, 12, 1619. https://doi.org/10.3390/buildings12101619

Huang Y, Han B, Yin W. Reinforced Concrete Corbels Shear Test: The Triangular-Truss Method Evaluation. Buildings. 2022; 12(10):1619. https://doi.org/10.3390/buildings12101619

Chicago/Turabian StyleHuang, Yuan, Bing Han, and Wenmeng Yin. 2022. "Reinforced Concrete Corbels Shear Test: The Triangular-Truss Method Evaluation" Buildings 12, no. 10: 1619. https://doi.org/10.3390/buildings12101619