Bending Performance of Precast Ceramsite-Concrete-Insulated Sandwich Panel with Stainless Steel Shear Connectors

Abstract

1. Introduction

2. Experimental Design

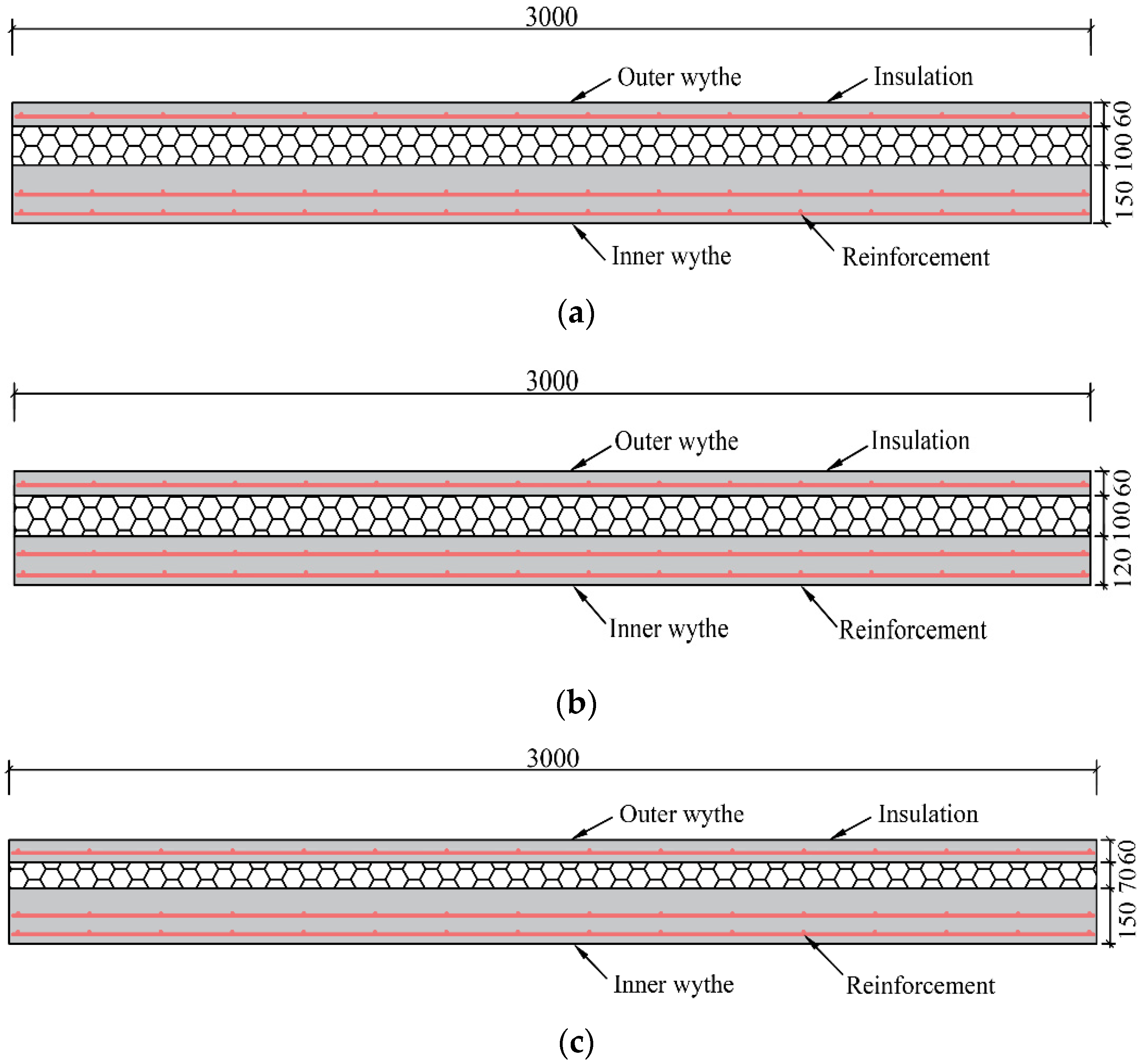

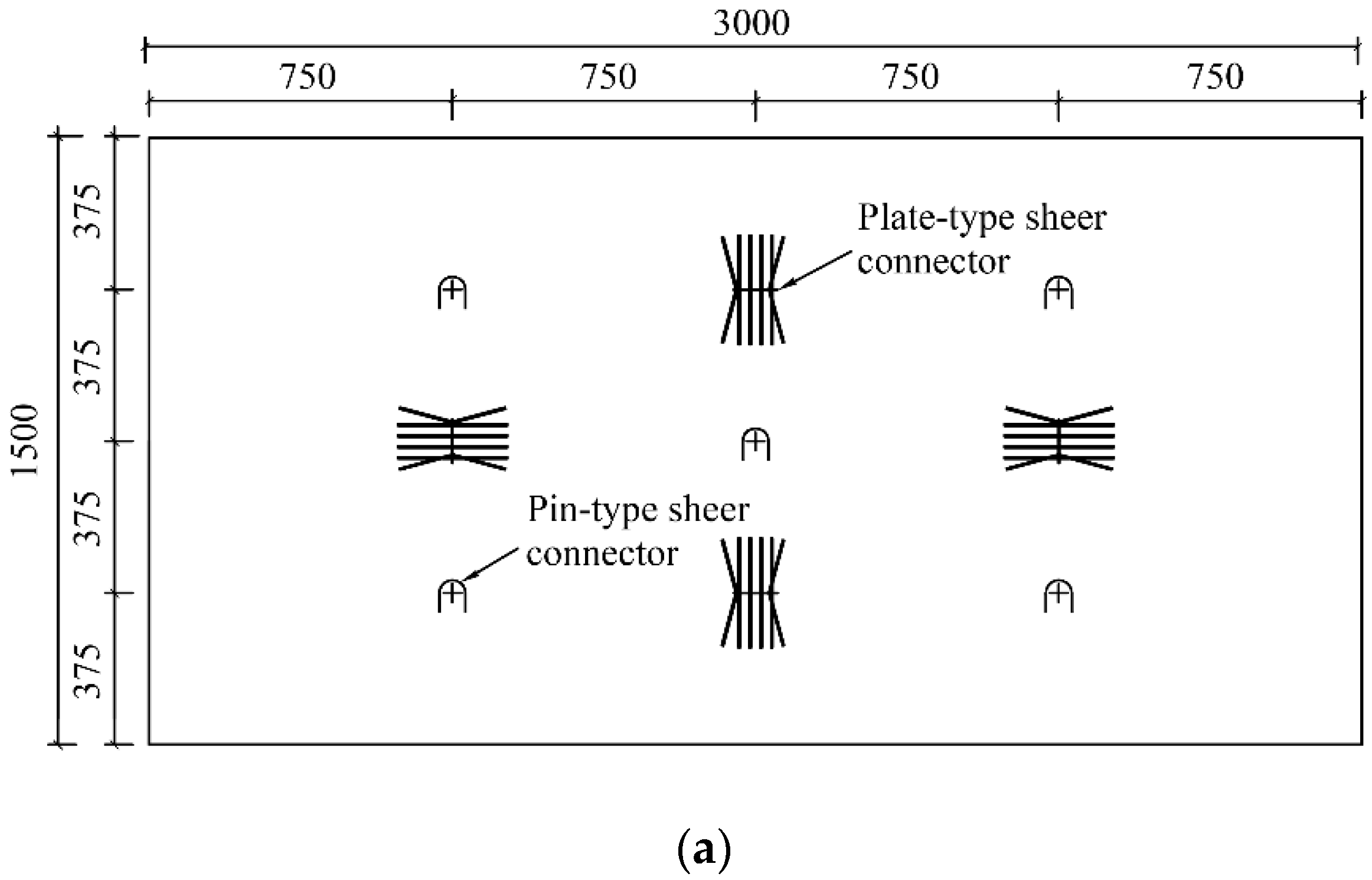

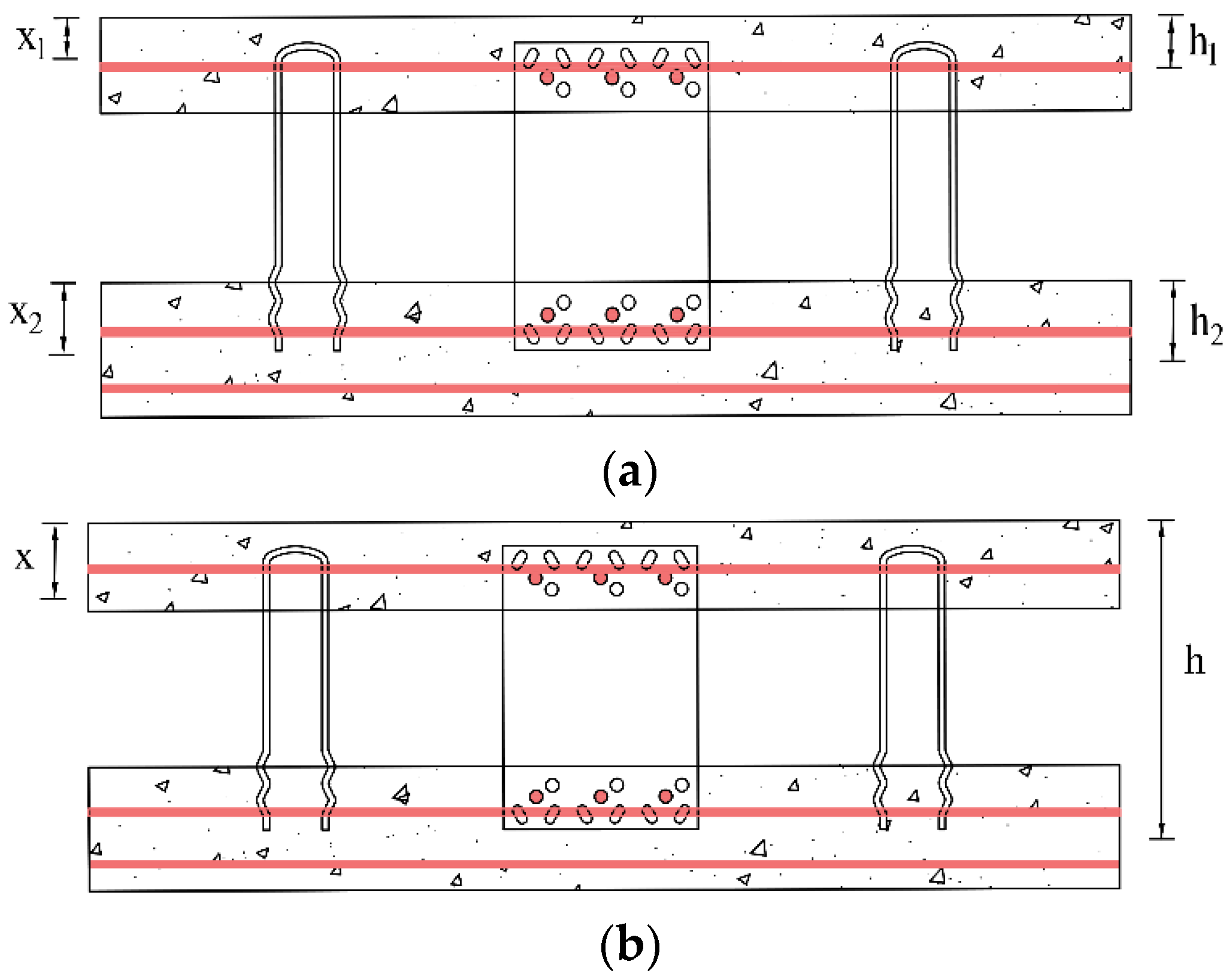

2.1. Description of the Test Specimens

2.2. Material Mechanical Properties

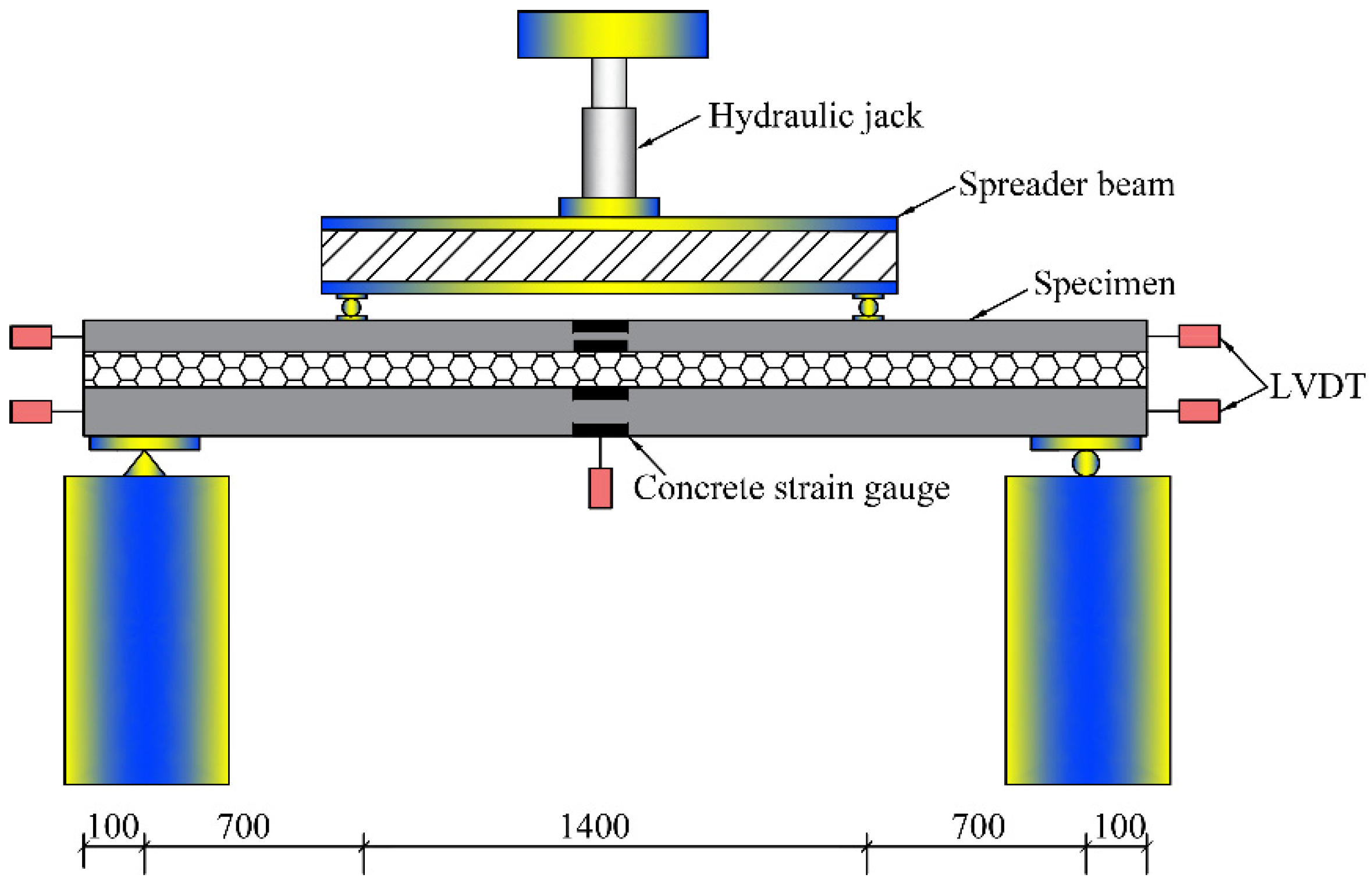

2.3. Loading Scheme and Measuring Point Arrangement

3. Test Results and Analysis

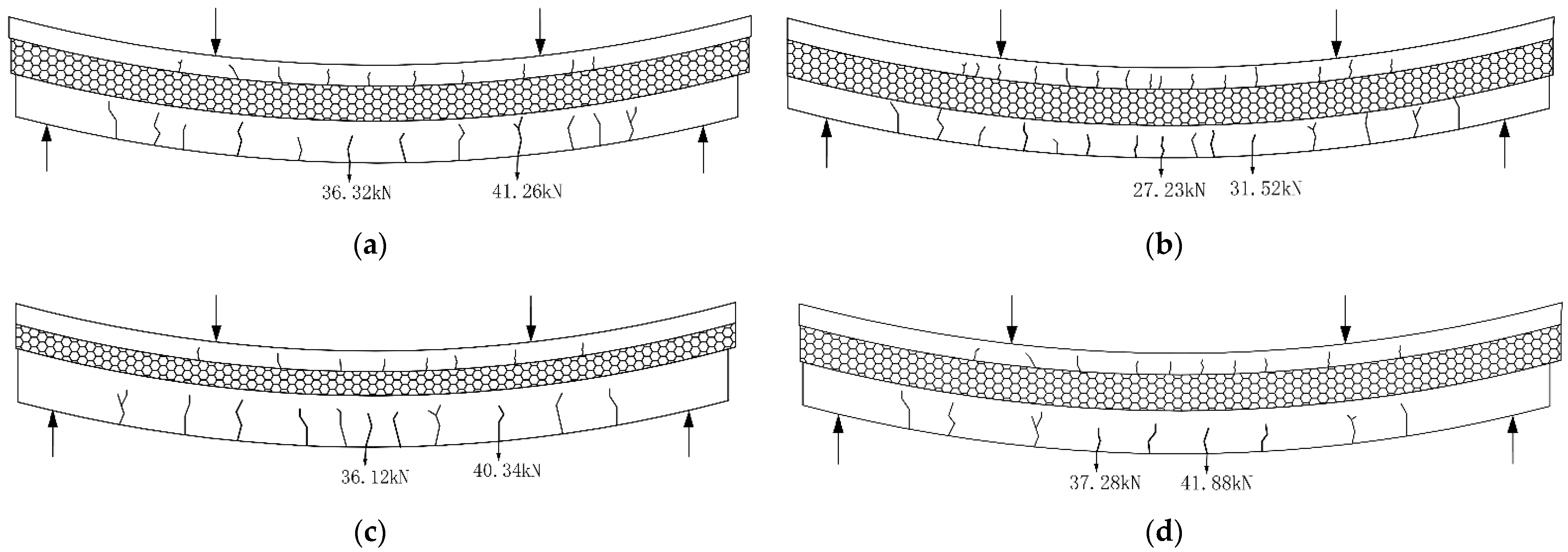

3.1. Failure Phenomenon of Specimen

3.2. Bearing Capacity Analysis

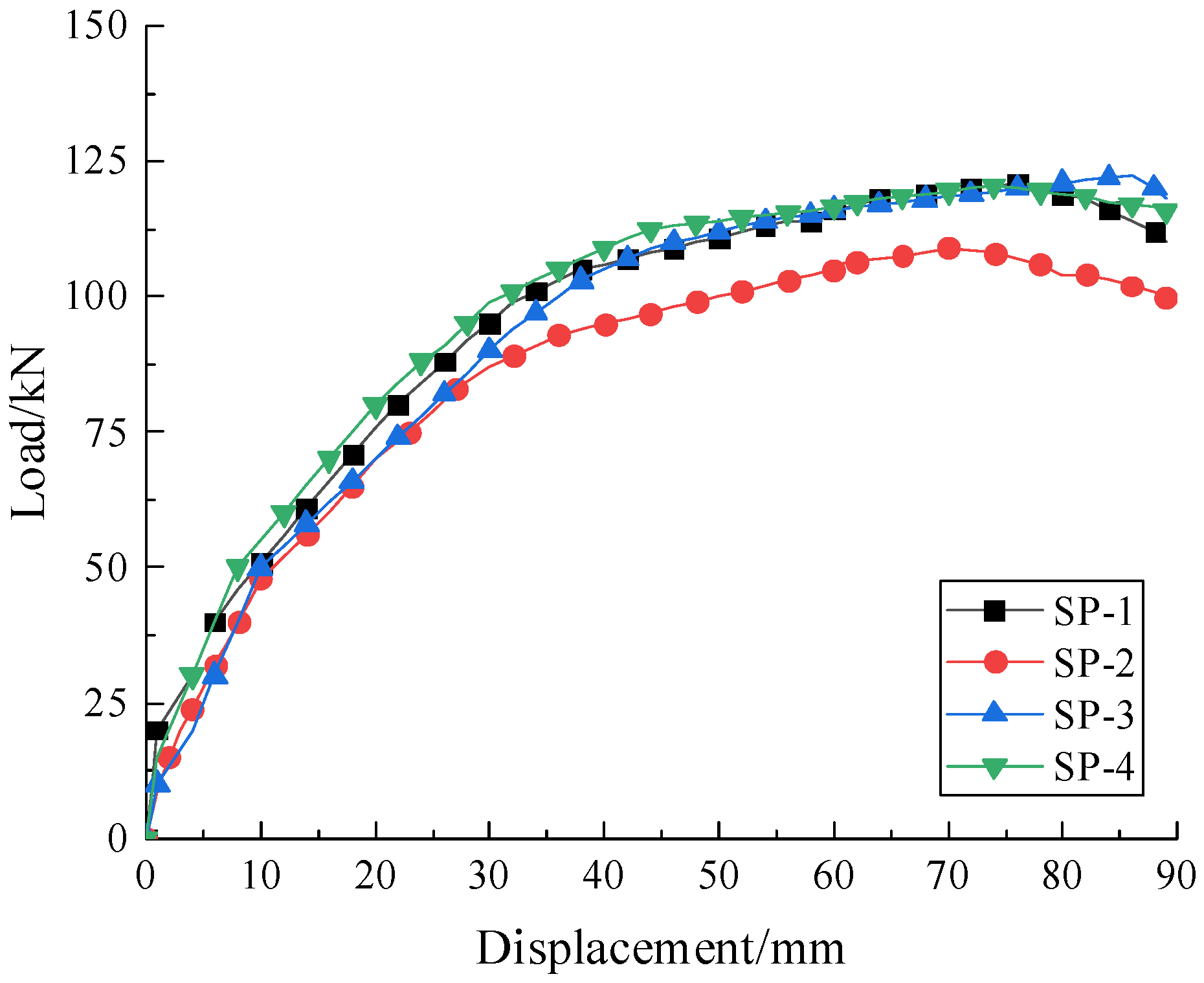

3.3. Load-Deflection Curve

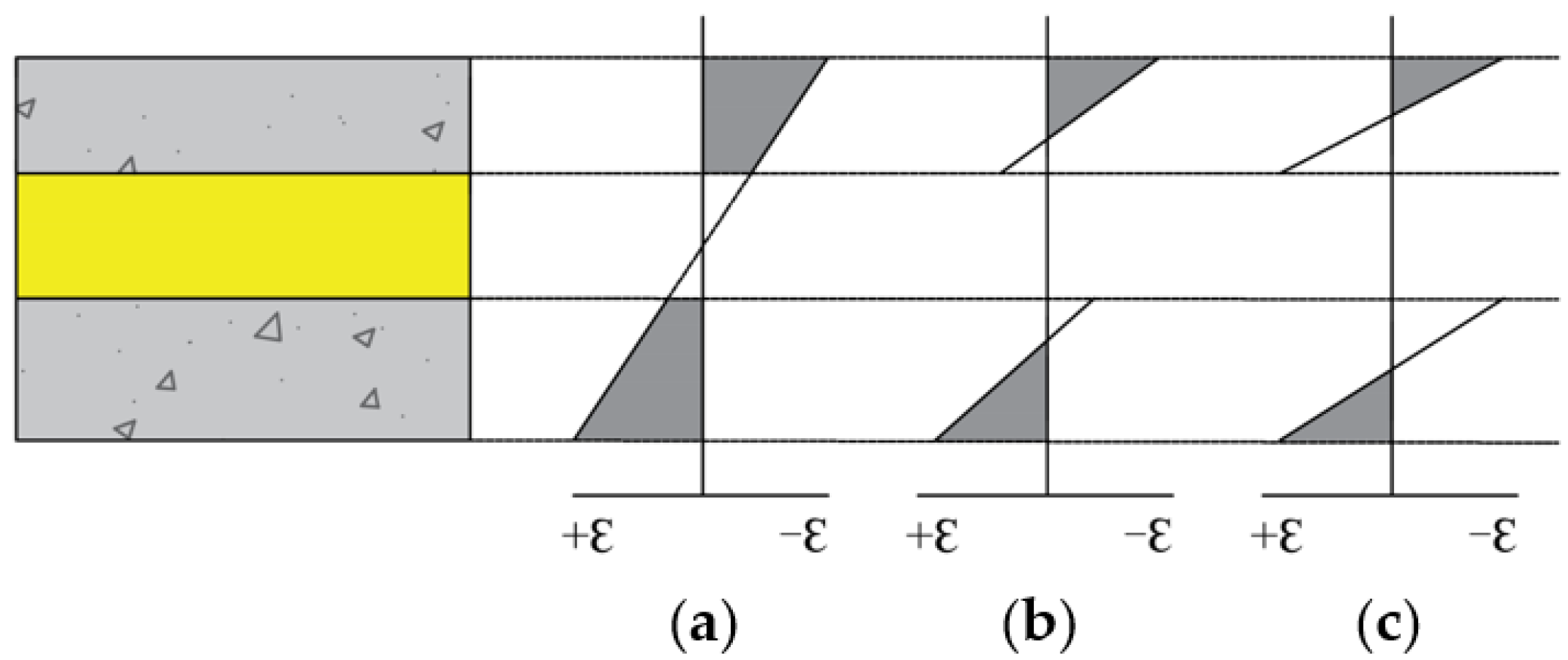

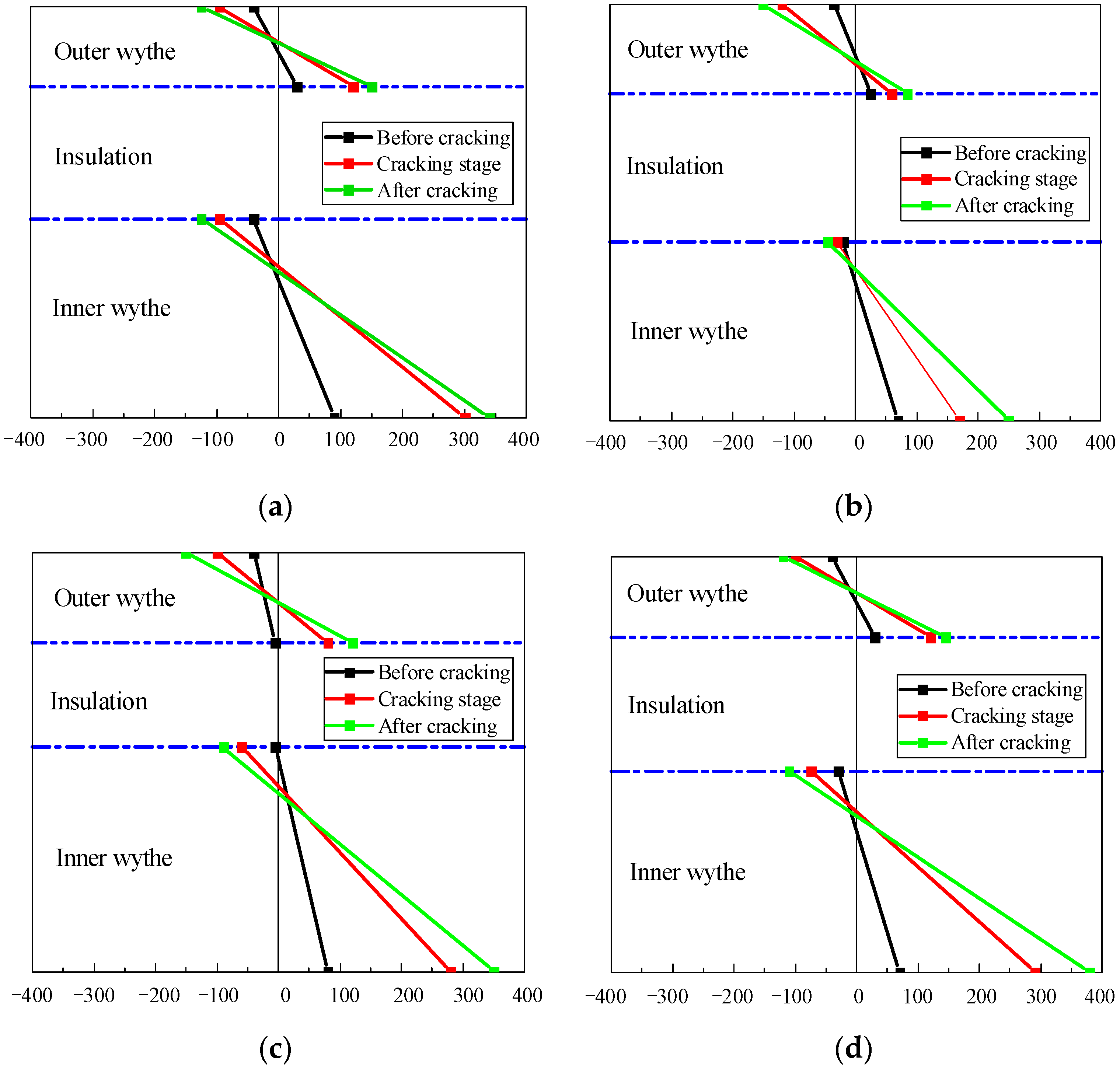

3.4. Concrete Strain Analysis

4. Finite-Element Analysis

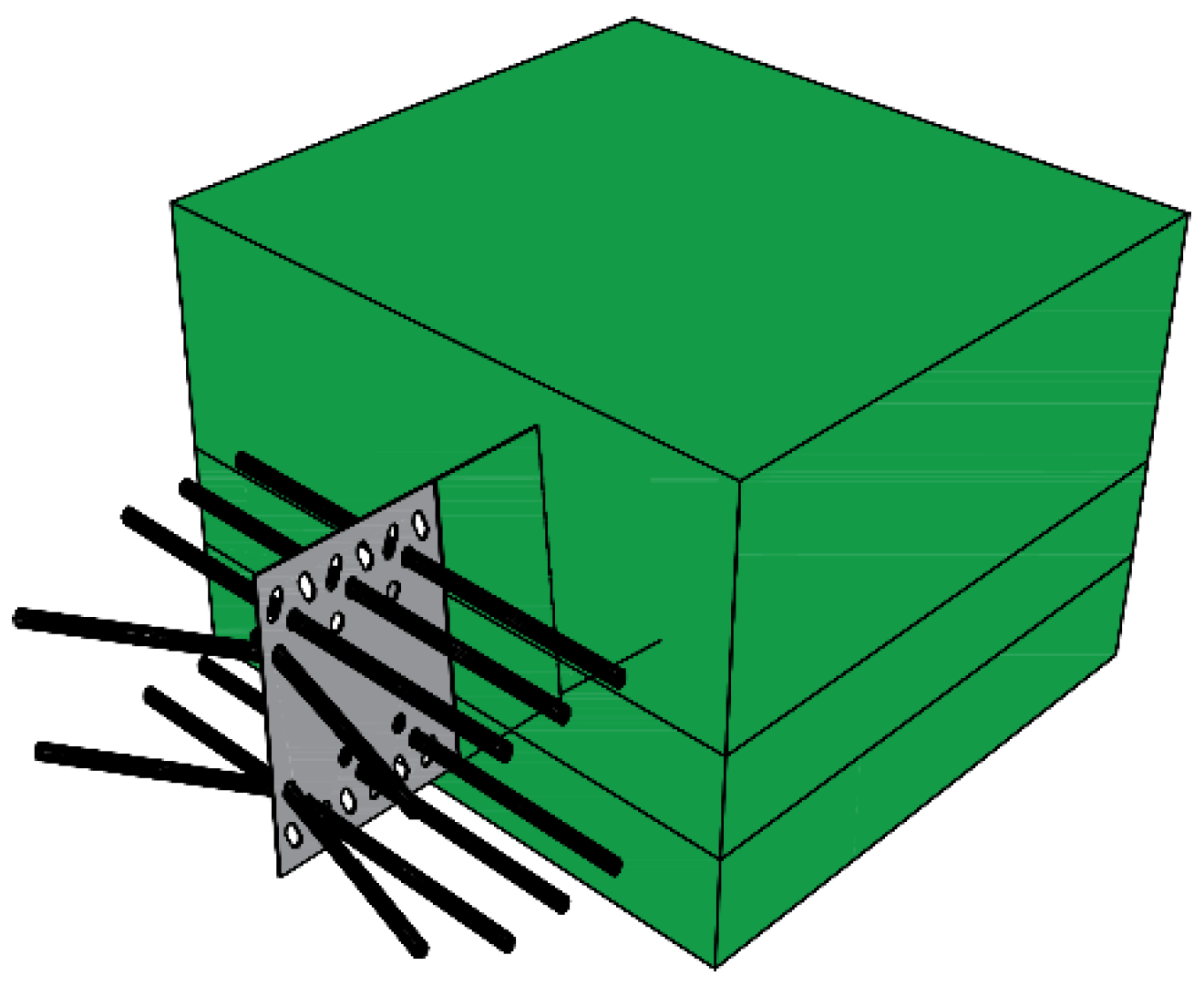

4.1. Model Description

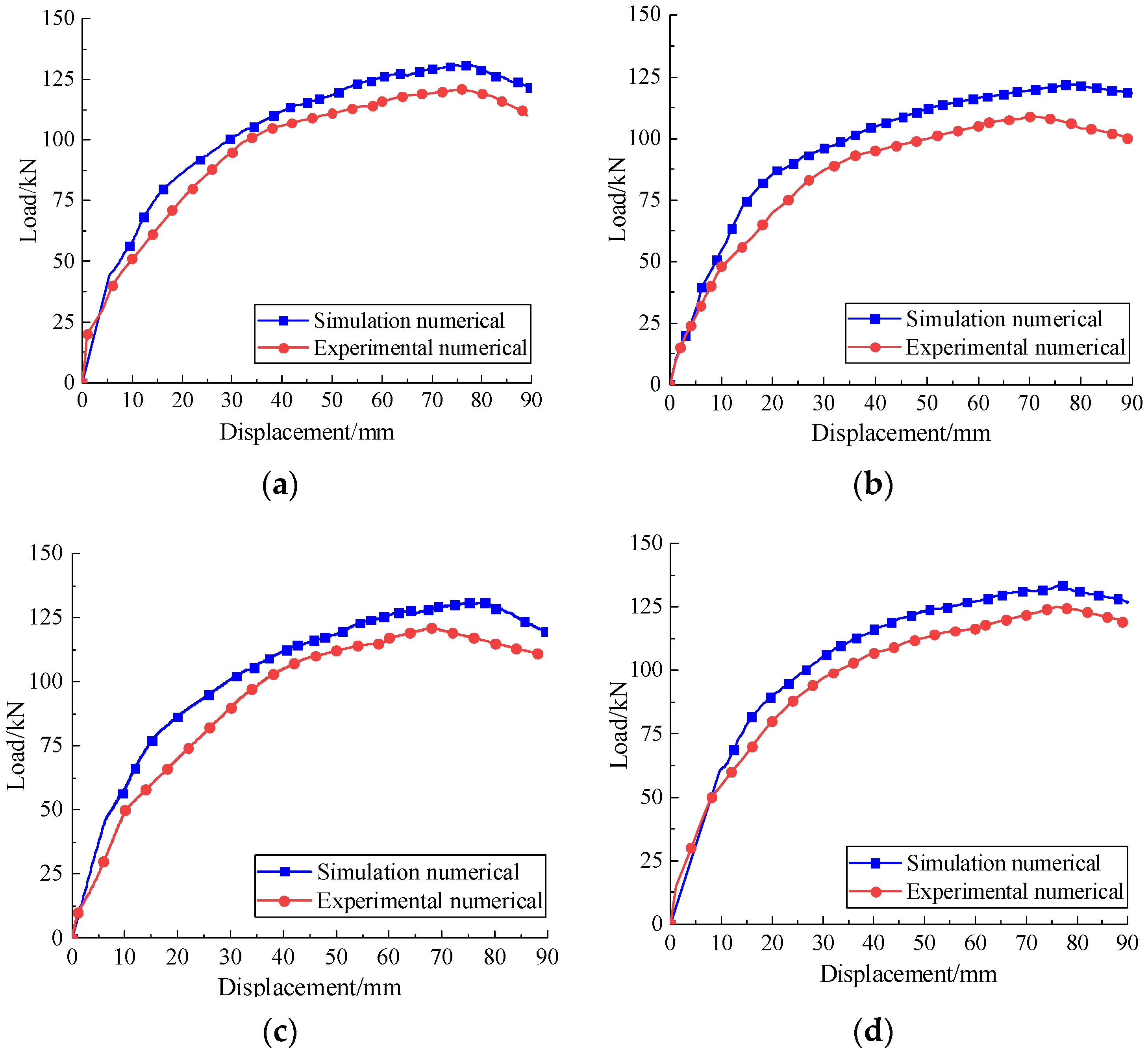

4.2. Finite-Element Model Validation

4.3. Parameter Analysis

5. Analysis of Composite Degree

6. Conclusions

- The failure modes of four precast ceramsite-concrete-insulated sandwich panels were all ductile failures of concrete flexural members, and all of them were partial composite panels.

- The load-deflection curve of PCCISP simulated by finite-element was in good agreement with the test curve, the simulated value of ultimate bearing capacity was close to the test value, and the finite-element model established was more accurate, which can be used as the basis for analyzing other working conditions of the same type of sandwich panel.

- With the decrease in the inner concrete wythe thickness, the overall rigidity and ductility of the PCCISP can decrease. When the thickness of the inner concrete wythe decreased by 20%, the cracking load decreased by 25.03% and the ultimate bearing capacity decreased by 9.41%. The ultimate bearing capacity was not significantly affected by reducing the thickness of the insulation layer. The ultimate bearing capacity can be slightly increased by increasing the length of the plate-type shear connector and the number of pin-type shear connectors.

- The composite degree of the rigidity and bearing capacity of PCCISP are increased when the thickness of the inner concrete wythe decreases. The thickness of the insulation layer was reduced, which can greatly improve the composite degree of rigidity, and the composite degree of the bearing capacity can be increased slightly. Increasing the length of the stainless steel plate-type shear connector had no obvious effect on the composite degree of rigidity and bearing capacity of PCCISP.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mobaraki, B.; Komarizadehasl, S.; Castilla Pascual, F.J.; Lozano-Galant, J.A.; Porras Soriano, R. A Novel Data Acquisition System for Obtaining Thermal Parameters of Building Envelopes. Buildings 2022, 12, 670. [Google Scholar] [CrossRef]

- Konstantinou, T.; Knaack, U. Refurbishment of Residential Buildings: A Design Approach to Energy-Efficiency Upgrades. Procedia Eng. 2011, 21, 666–675. [Google Scholar] [CrossRef]

- Ma, S.; Gu, Y.; Bao, P. Seismic performance of ceramsite concrete T-shaped composite wallboard joints under cyclic loading. Structures 2021, 33, 4433–4445. [Google Scholar] [CrossRef]

- Qiu, J.; Xing, M.; Yang, Z.; Zhang, C.; Guan, X. Micro-pore structure characteristics and macro-mechanical properties of PP fibre reinforced coal gangue ceramsite concrete. J. Build. Eng. 2020, 8, 1192–1197. [Google Scholar] [CrossRef]

- Bu, C.; Zhu, D.; Liu, L.; Lu, X.; Sun, Y.; Yan, Z.; Yu, L.; Wei, Q. A Study on the Mechanical Properties and Microcosmic Mechanism of Basalt Fiber Modified Rubber Ceramsite Concrete. Buildings 2022, 12, 103. [Google Scholar] [CrossRef]

- Xie, J.; Zhao, J.; Wang, J.; Huang, P.; Liu, J. Investigation of the high-temperature resistance of sludge ceramsite concrete with recycled fine aggregates and GGBS and its application in hollow blocks. J. Build. Eng. 2020, 34, 101954. [Google Scholar] [CrossRef]

- Li, X.; Yan, F.; Yue, X. Research progress of ceramsite concrete. J. Bull. Chin. Ceram. Soc. 2020, 39, 3407–3418, 3452. [Google Scholar]

- Ma, S.C.; Li, L.H.; Bao, P. Seismic Performance Test of Double-Row Reinforced Ceramsite Concrete Composite Panels with Cores. J. Appl. Sci. 2021, 11, 2688. [Google Scholar] [CrossRef]

- Aksakal, B.; Ulutaş, A.; Balo, F.; Karabasevic, D. A New Hybrid MCDM Model for Insulation Material Evaluation for Healthier Environment. Buildings 2022, 12, 655. [Google Scholar] [CrossRef]

- Gama, N.V.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef]

- Yin, X.; Li, H.; Bo, H.; Ke, H. Weatherability studies on external insulation thermal system of expanded polystyrene board, polystyrene granule and polyurethane foam. J. Wuhan Univ. Technol. Sci. Ed. 2010, 25, 1027–1032. [Google Scholar] [CrossRef]

- Kinnane, O.; West, R.; Hegarty, R.O. Structural shear performance of insulated precast concrete sandwich panels with steel plate connectors. J. Eng. Struct. 2020, 215, 110691. [Google Scholar] [CrossRef]

- Einea, A.; Salmon, D.C.D.C.; Tadros, M.K.; Culp, T. A new structurally and thermally efficient precast sandwich panel system. PCI J. 1994, 39, 90–101. [Google Scholar] [CrossRef]

- Portal, N.W.; Flansbjer, M.; Zandi, K.; Wlasak, L.; Malaga, K. Bending behaviour of novel Textile Reinforced Concrete-foamed concrete (TRC-FC) sandwich elements, Compos. J. Struct. 2017, 177, 104–118. [Google Scholar]

- Huang, J.; Dai, J. Direct shear tests of glass fiber reinforced polymer connectors for use in precast concrete sandwich panels. Compos. Struct. 2019, 207, 136–147. [Google Scholar] [CrossRef]

- Hassan, T.K.; Rizkalla, S.H. Analysis and design guidelines of precast, prestressed concrete, composite load-bearing sandwich panels reinforced with CFRP grid. PCI J. 2010, 55, 147–162. [Google Scholar] [CrossRef]

- Kazem, H.; Bunn, W.G.; Seliem, H.M.; Rizkalla, S.H.; Gleich, H. Durability and long term behavior of FRP/foam shear transfer mechanism for concrete sandwich panels. J. Constr. Build. Mater. 2015, 98, 722–734. [Google Scholar] [CrossRef]

- Carbonari, G.; Cavalaro, S.H.P.; Cansario, M.M. Flexural behavior of light-weight sandwich panels composed by concrete and EPS. J. Constr. Build. Mater. 2012, 35, 792–799. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, Q.; Ai, W.; Li, H.; Wang, T.J. The failure behavior of geometrically asymmetric metal foam core sandwich beams under three-point bending. J. Appl. Mech. 2014, 81, 071008. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, Q.; Han, X.; Ai, W. The initial plastic failure of fully clamped geometrical asymmetric metal foam core sandwich beams. Compos. Part B Eng. 2016, 87, 233–244. [Google Scholar] [CrossRef]

- Zhang, J.; Ye, Y.; Qin, Q. Large deflections of multilayer sandwich beams with metal foam cores under transverse loading. Acta Mech. 2018, 229, 3585–3599. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, H.; Du, J. Large deflection of multilayer sandwich beams with foam-filled trapezoidal corrugated and foam cores. Thin Walled Struct. 2022, 179, 109755. [Google Scholar] [CrossRef]

- Bush, T.; Stine, G. Flexural behavior of composite precast concrete sandwich panels with continuous truss connectors. PCI J. 1994, 3, 112–121. [Google Scholar] [CrossRef]

- Huang, J.; Jiang, Q.; Chong, X. Experimental study on precast concrete sandwich panel with cross-shaped GFRP connectors. Adv. Struct. Eng. 2020, 72, 149–162. [Google Scholar] [CrossRef]

- Zhi, Q.; Guo, Z. Experimental evaluation of precast concrete sandwich panels with steel–glass fiber–reinforced polymer shear connectors. Adv. Struct. Eng. 2017, 20, 1476–1492. [Google Scholar] [CrossRef]

- O′Hegarty, R.; West, R.; Reilly, A.; Kinnane, O. Composite behaviour of fibre-reinforced concrete sandwich panels with FRP shear connectors. J. Eng. Struct. 2019, 198, 109475. [Google Scholar] [CrossRef]

- Choi, I.; Kim, J.; Kim, H.-R. Composite behavior of insulated concrete sandwich panels subjected to wind pressure and suction. Materials 2015, 8, 1264–1282. [Google Scholar] [CrossRef]

- Frankl, B. Behavior of insulated precast prestressed concrete sandwich panels reinforced with CFRP grid–Masters Thesis. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2008. [Google Scholar]

- Pessiki, S.; Mlynarczyk, A. Experimental evaluation of the composite behavior of precast concrete sandwich panels. PCI J. 2003, 48, 54–71. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, T.; Zhang, L.; Yin, L.; Wu, Y.; Chen, B. Fatigue Performance of Rib Beam Bridge Slabs Reinforced with Polyurethane Concrete Based on the Damage Theory. Buildings 2022, 12, 704. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, X.; Ren, Y.; Bai, F.; Li, C.; Li, Z. Finite Element Modelling of Bolt Shear Connections in Precast Steel Lightweight Aggregate–Concrete Composite Beams. Buildings 2022, 12, 758. [Google Scholar] [CrossRef]

- Gombeda, M.; Trasborg, P.; Naito, C.J. Simplified model for partially-composite precast concrete insulated panels subjected to lateral loading. J. Eng. Struct. 2017, 138, 367–380. [Google Scholar] [CrossRef]

- Hodicky, K.; Sopal, G.; Rizkalla, S.; Hulin, T.; Stang, H. Experimental and numerical investigation of the FRP shear mechanism for concrete sandwich panels. Compos. Constr. 2015, 19, 04014083. [Google Scholar] [CrossRef]

- Tomlinson, D.; Fam, A. Analytical approach to flexural response of partially composite insulated concrete sandwich walls used for cladding. J. Eng. Struct. 2016, 122, 251–266. [Google Scholar] [CrossRef]

- Chen, A.; Yossef, M.; Hopkins, P. A comparative study of differ-rent methods to calculate degrees of composite action for insulated concrete sandwich panels. J. Eng. Struct. 2020, 212, 110423. [Google Scholar] [CrossRef]

- Insub, C.; Jun-Hee, K.; Young-Chan, Y. Effect of cyclic loading on composite behavior of insulated concrete sandwich panels with GFRP shear connectors. Compos. Part B Eng. 2016, 96, 7–19. [Google Scholar]

- Benayoune, A.; Samad, A.A.; Trikha, D.; Ali, A.A.; Ellinna, S. Flexural behaviour of pre-cast concrete sandwich composite panel–experimental and theoretical investigations. Constr. Build. Mater. 2008, 22, 580–592. [Google Scholar] [CrossRef]

- Huang, J.; Dai, J. Flexural performance of precast geopolymer concrete sandwich panel enabled by FRP connector. Compos. Struct. 2020, 248, 112563. [Google Scholar] [CrossRef]

| Panels | Thickness/mm | Length/mm | ||

|---|---|---|---|---|

| Outer Concrete Wythe | Insulation Layer | Inner Concrete Wythe | Plate-Type Shear Connector | |

| SP-1 | 60 | 100 | 150 | 120 |

| SP-2 | 60 | 100 | 120 | 120 |

| SP-3 | 60 | 70 | 150 | 120 |

| SP-4 | 60 | 100 | 150 | 200 |

| Type of Shear Connector | Standard Value of Tensile Strength/MPa | The Yield Strength/MPa |

|---|---|---|

| Plate-type shear connector | 661 | 405 |

| Pin-type shear connector | 858 | 713 |

| Panels | Cracking Load/kN | Yield Load/kN | Ultimate Load/kN |

|---|---|---|---|

| SP-1 | 36.32 | 82.46 | 113.82 |

| SP-2 | 27.23 | 73.18 | 103.11 |

| SP-3 | 36.12 | 81.78 | 114.54 |

| SP-4 | 37.28 | 83.67 | 115.58 |

| Dilation Angle | Eccentricity | fb0/fc0 | K | Viscosity Parameter |

|---|---|---|---|---|

| 30 | 0.1 | 1.16 | 0.667 | 0.0001 |

| Panels | Test Value/kN | Simulation Value/kN | The Relative Difference |

|---|---|---|---|

| SP-1 | 113.82 | 123.79 | 8.76% |

| SP-2 | 103.11 | 114.86 | 11.40% |

| SP-3 | 114.54 | 124.21 | 9.67% |

| SP-4 | 115.67 | 125.58 | 8.57% |

| Panels | Thickness/mm | Length/mm | Number | Ultimate Load/kN | ||

|---|---|---|---|---|---|---|

| Outer Concrete Wythe | Insulation Layer | Inner Concrete Wythe | Plate-Type Shear Connector | Pin-Type Shear Connector | ||

| SP-2-1 | 60 | 100 | 160 | 120 | 5 | 126.92 |

| SP-2-2 | 60 | 100 | 140 | 120 | 5 | 120.13 |

| SP-2-3 | 60 | 100 | 100 | 120 | 5 | 108.74 |

| SP-3-1 | 60 | 160 | 150 | 120 | 5 | 121.28 |

| SP-3-2 | 60 | 130 | 150 | 120 | 5 | 122.35 |

| SP-3-3 | 60 | 50 | 150 | 120 | 5 | 125.87 |

| SP-4-1 | 60 | 100 | 150 | 80 | 5 | 123.03 |

| SP-4-2 | 60 | 100 | 150 | 160 | 5 | 124.72 |

| SP-4-3 | 60 | 100 | 150 | 240 | 5 | 126.11 |

| SP-5-1 | 60 | 100 | 150 | 120 | 10 | 125.68 |

| SP-5-2 | 60 | 100 | 150 | 120 | 15 | 127.04 |

| SP-5-3 | 60 | 100 | 150 | 120 | 20 | 128.65 |

| Panels | Inc/107 mm4 | Ic/108 mm4 | Iexp/108 mm4 | k1/% | Pnc/kN | Pc/kN | Pe/kN | k2/% |

|---|---|---|---|---|---|---|---|---|

| SP-1 | 9.31 | 7.58 | 2.09 | 17.43 | 86.94 | 294.22 | 113.82 | 12.97 |

| SP-2 | 7.09 | 5.38 | 1.78 | 22.94 | 65.03 | 263.46 | 103.11 | 18.70 |

| SP-3 | 9.31 | 5.38 | 2.10 | 26.28 | 86.94 | 263.46 | 114.54 | 15.64 |

| SP-4 | 9.31 | 7.58 | 2.13 | 17.96 | 86.94 | 294.22 | 115.67 | 13.86 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Kang, C.; Wu, Y.; Qian, Z. Bending Performance of Precast Ceramsite-Concrete-Insulated Sandwich Panel with Stainless Steel Shear Connectors. Buildings 2022, 12, 1640. https://doi.org/10.3390/buildings12101640

Chen Y, Kang C, Wu Y, Qian Z. Bending Performance of Precast Ceramsite-Concrete-Insulated Sandwich Panel with Stainless Steel Shear Connectors. Buildings. 2022; 12(10):1640. https://doi.org/10.3390/buildings12101640

Chicago/Turabian StyleChen, Yingjie, Chaofeng Kang, Yunfeng Wu, and Zhenxiao Qian. 2022. "Bending Performance of Precast Ceramsite-Concrete-Insulated Sandwich Panel with Stainless Steel Shear Connectors" Buildings 12, no. 10: 1640. https://doi.org/10.3390/buildings12101640

APA StyleChen, Y., Kang, C., Wu, Y., & Qian, Z. (2022). Bending Performance of Precast Ceramsite-Concrete-Insulated Sandwich Panel with Stainless Steel Shear Connectors. Buildings, 12(10), 1640. https://doi.org/10.3390/buildings12101640