Microclimate and Mould Growth Potential of Air Cavities in Ventilated Wooden Façade and Roof Systems—Case Studies from Norway

Abstract

1. Introduction

- What moisture and temperature conditions may be expected in ventilated air cavities behind façade cladding and roofing?

- What is the risk of mould growth in façades and roofs featuring dual-barrier weatherproofing?

2. Theoretical Framework

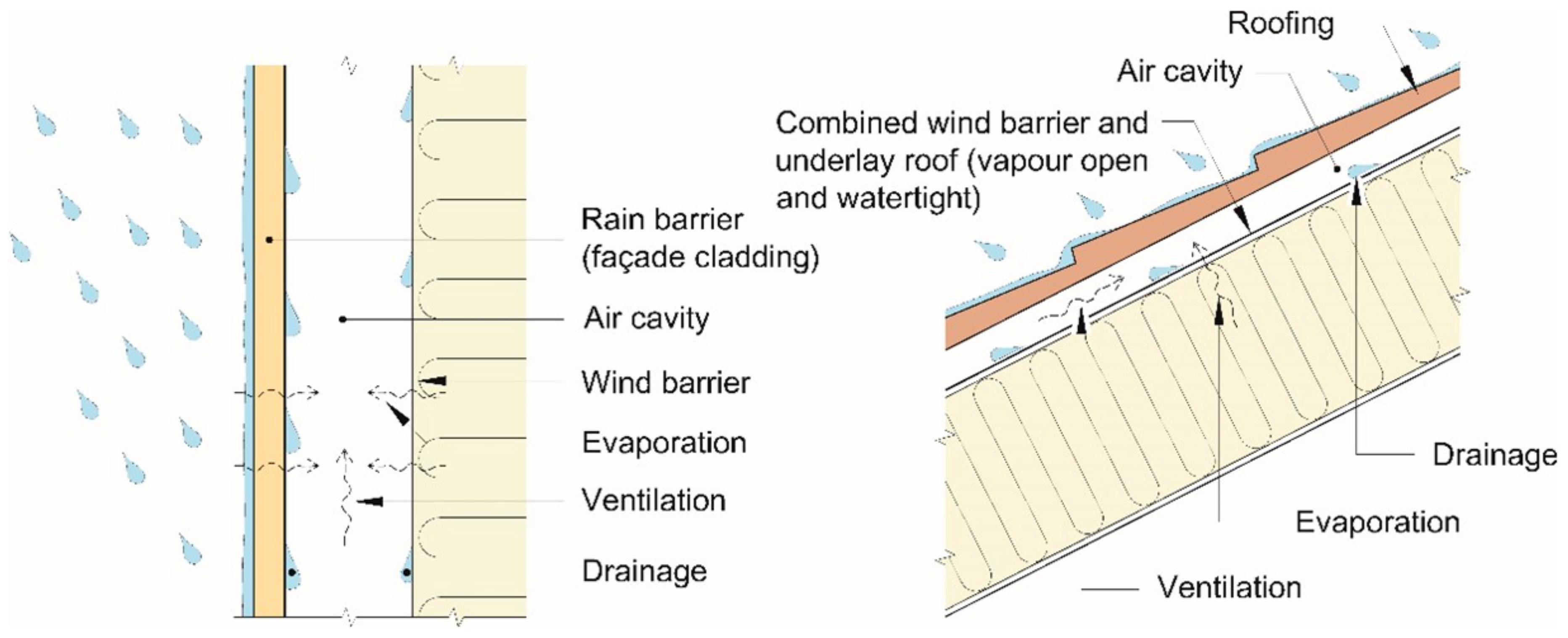

2.1. Air Cavities

- To work as a capillary break between the rain barrier and the wind barrier, so that wind-driven rain that soaks the rain screen cannot transfer through to the inner wall assembly by capillary action.

- To provide drainage for water that penetrates the rain screen.

- To remove excess moisture from the inner wall assembly and the interior side of the cladding through ventilation drying, to prevent mould growth and rot.

2.2. Parameters That Affect the Cavity Climate

2.3. Consequences of Air Cavity Climate

3. Methods

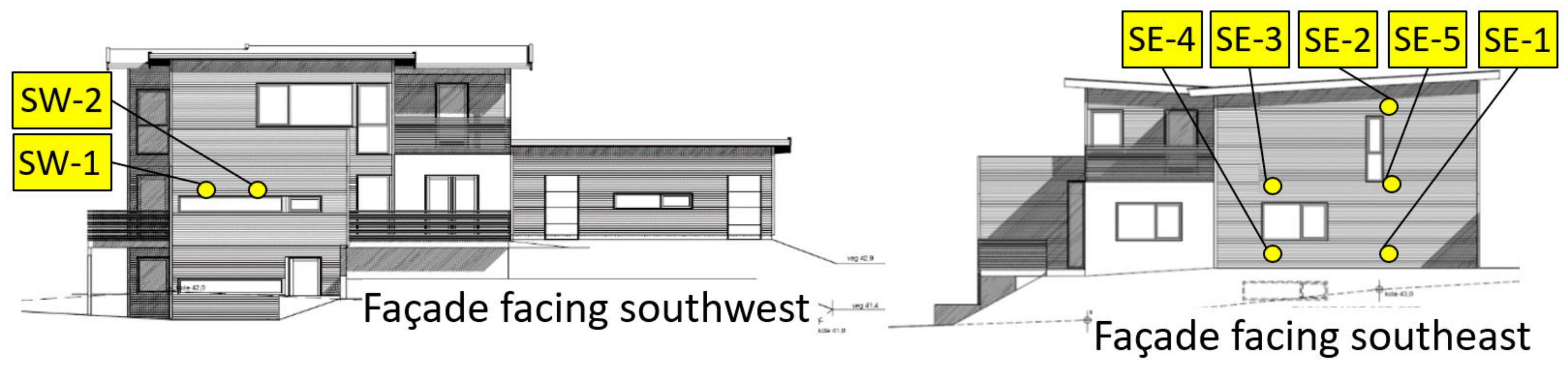

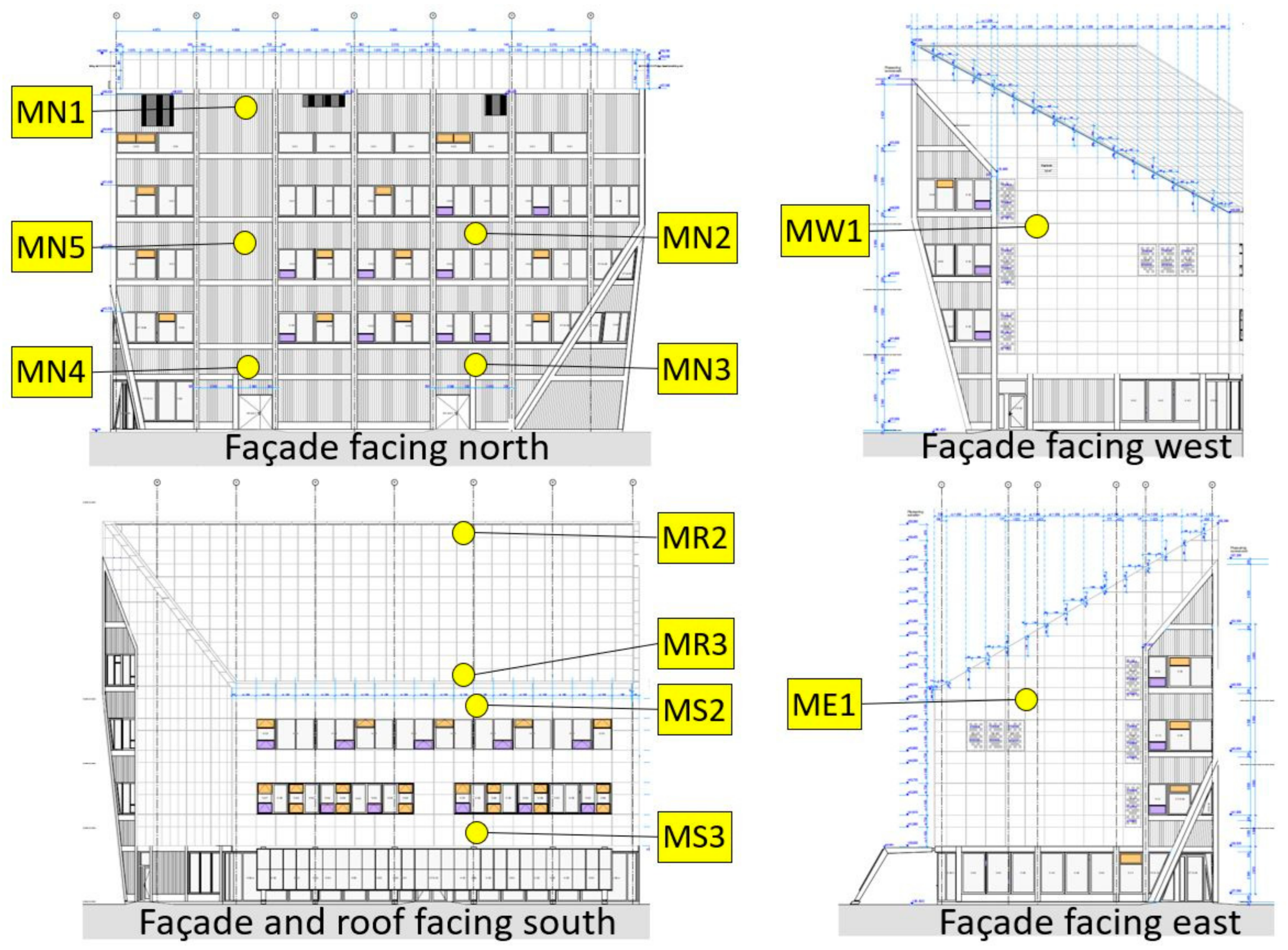

3.1. Instrumentation of the Case Buildings

3.2. Exterior Climate Data

3.3. Correction Formulas

3.4. Mould Growth Criteria

3.5. VTT Parametric Study

3.6. Other Analyses

- Temperature ≥ 0 °C and RH 80–85%

- Temperature ≥ 0 °C and RH 85–90%

- Temperature ≥ 0 °C and RH 90–95%

- Temperature ≥ 0 °C and RH 95–100%

- Temperature ≥ 5 °C and RH 80–85%

- Temperature ≥ 5 °C and RH 85–90%

- Temperature ≥ 5 °C and RH 90–95%

- Temperature ≥ 5 °C and RH 95–100%

4. Results

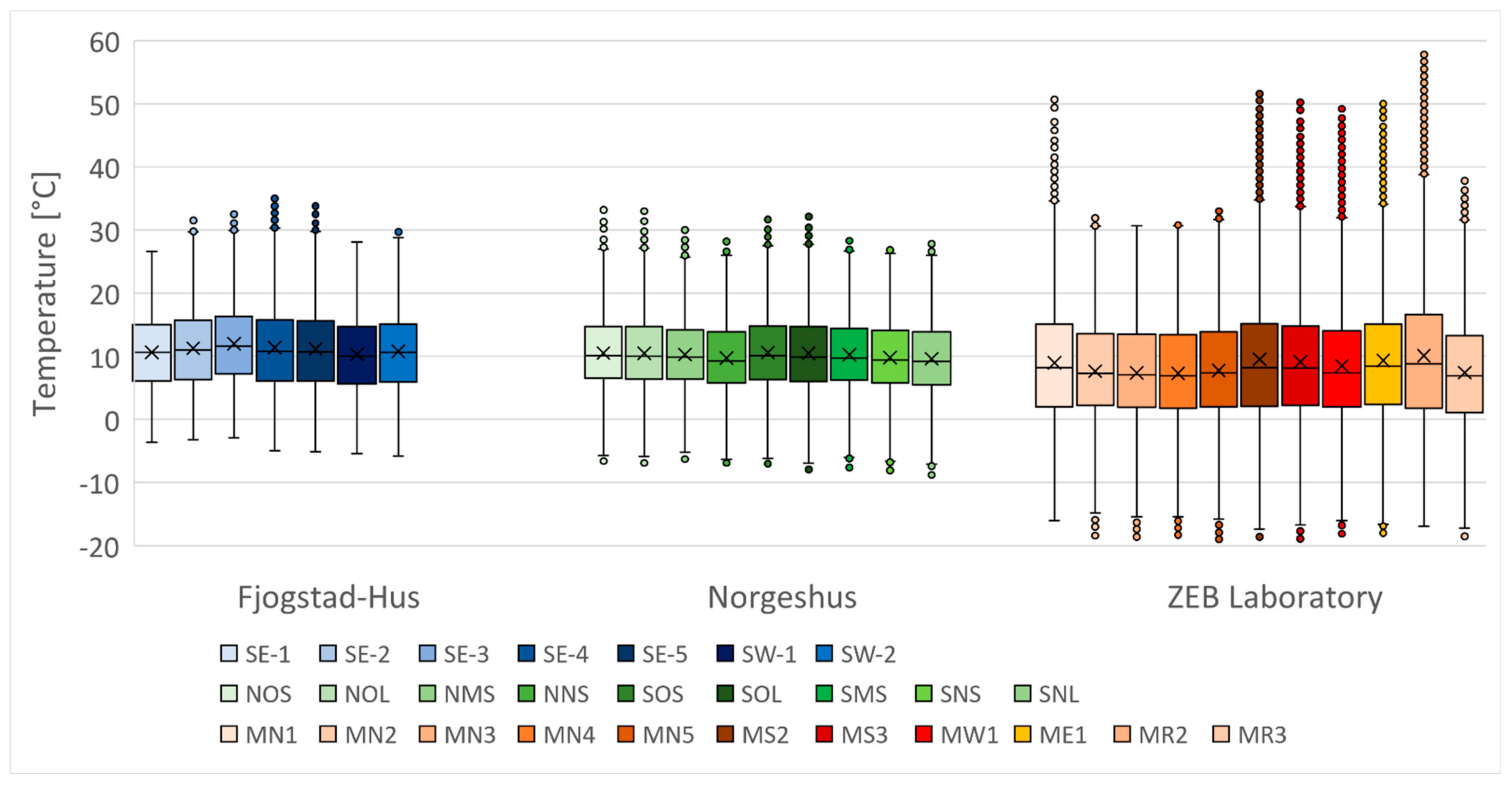

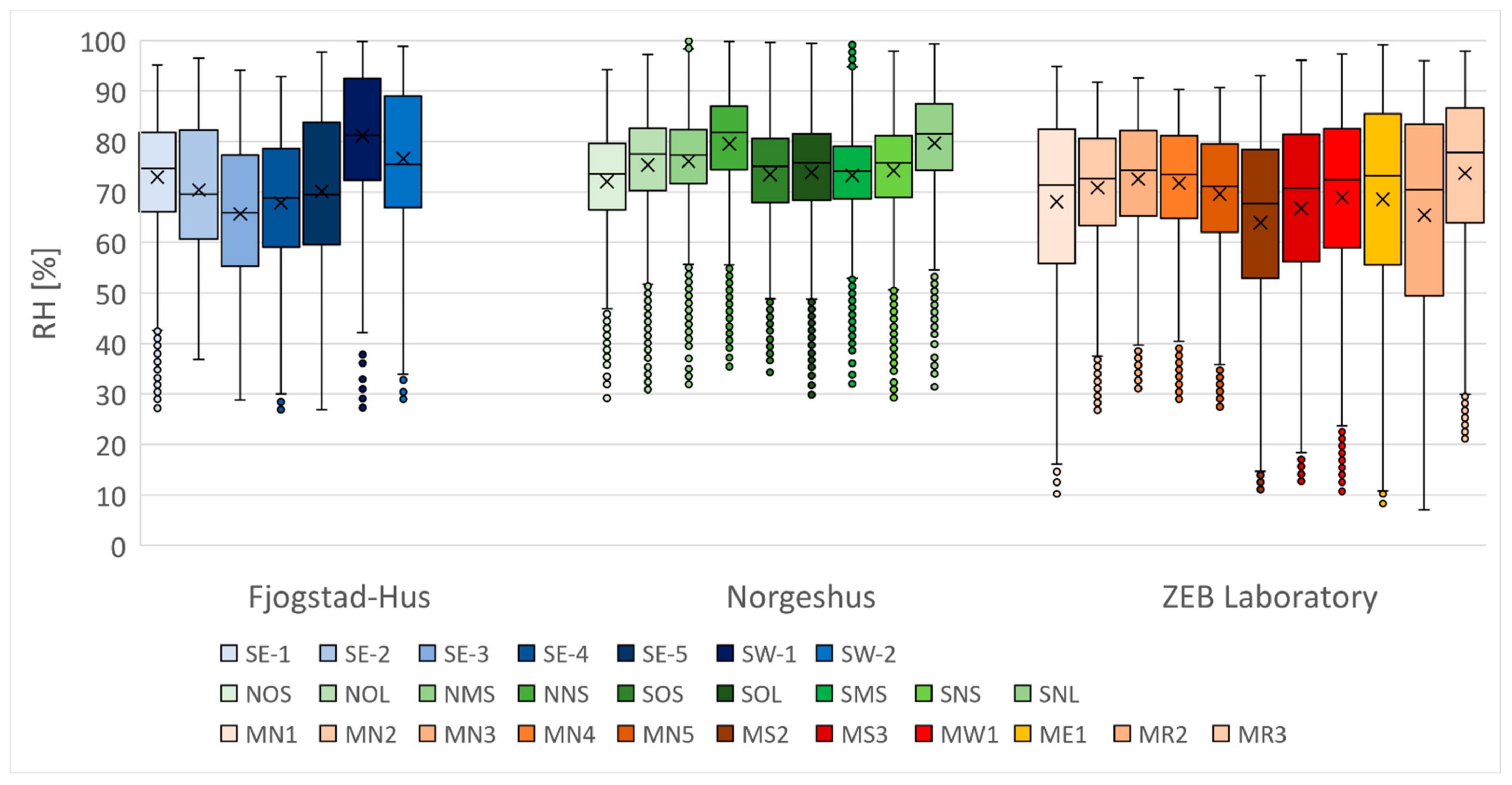

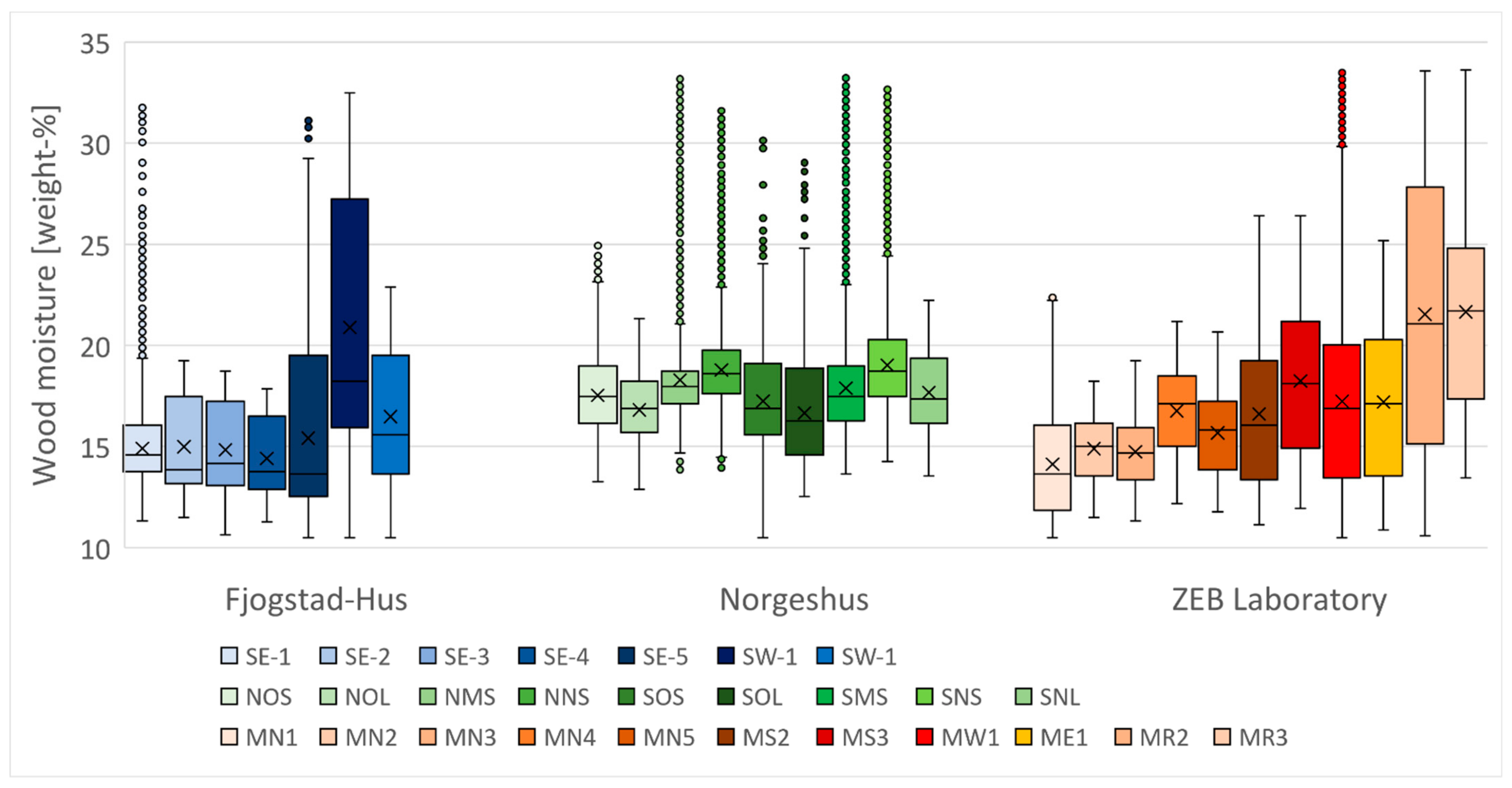

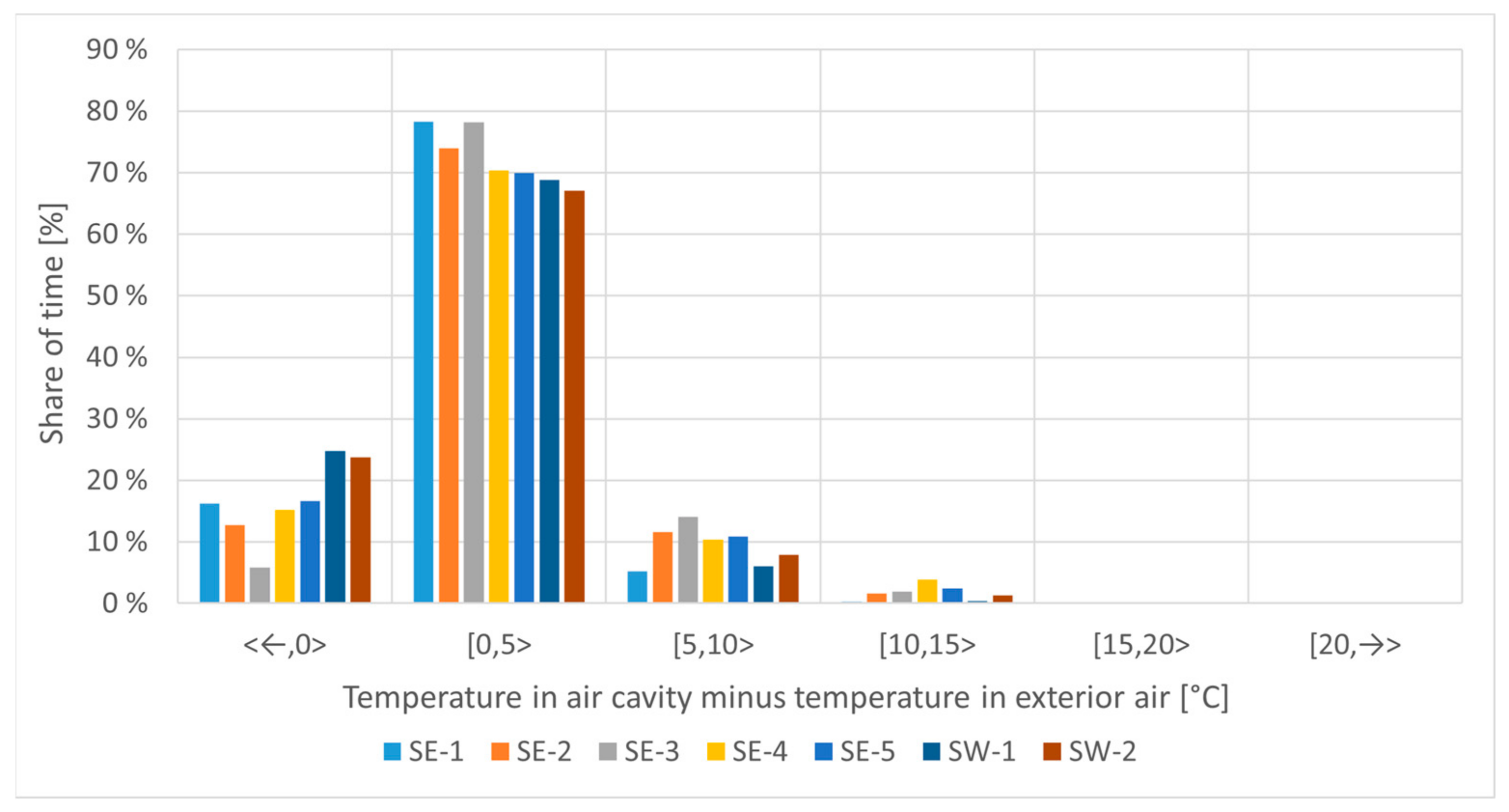

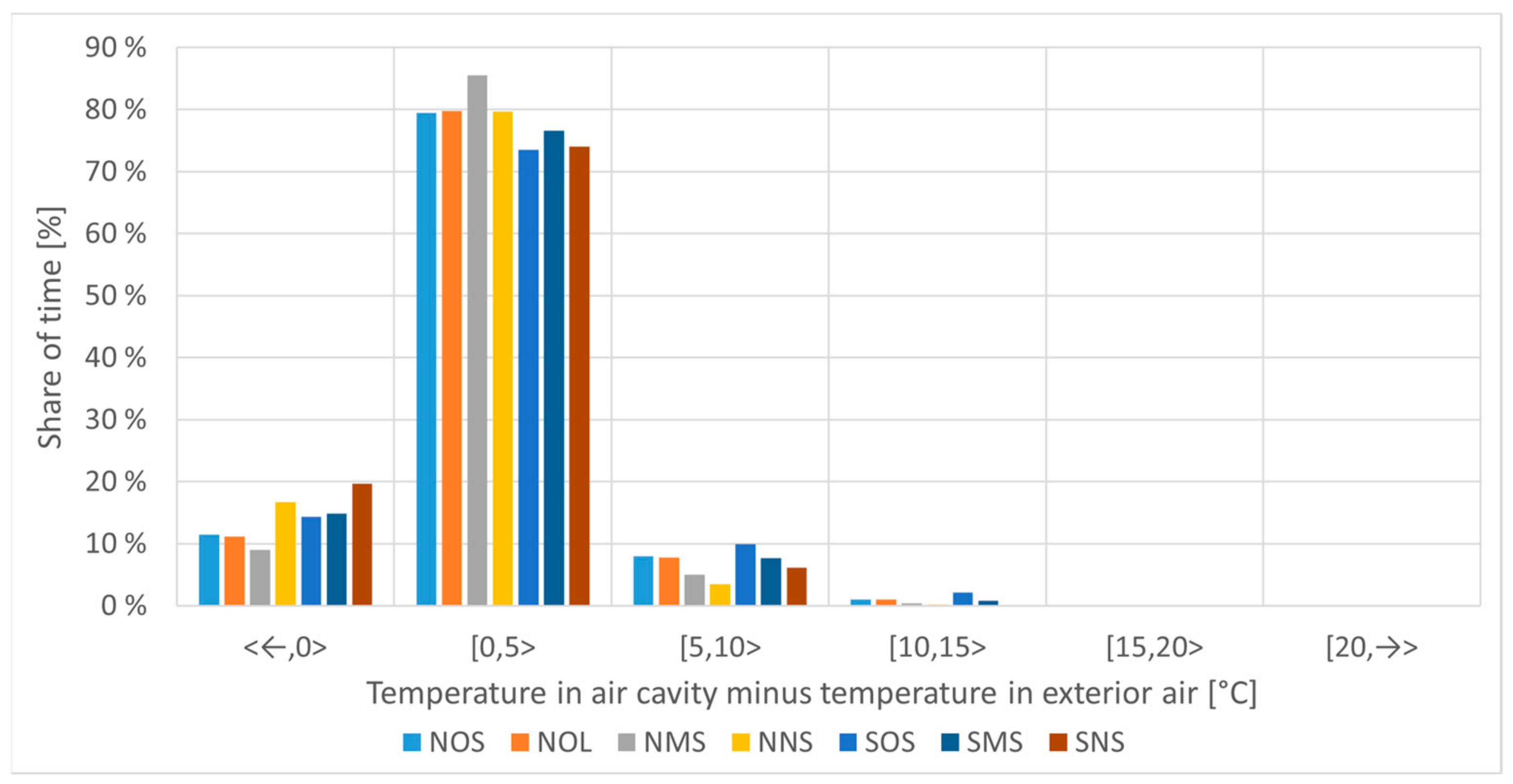

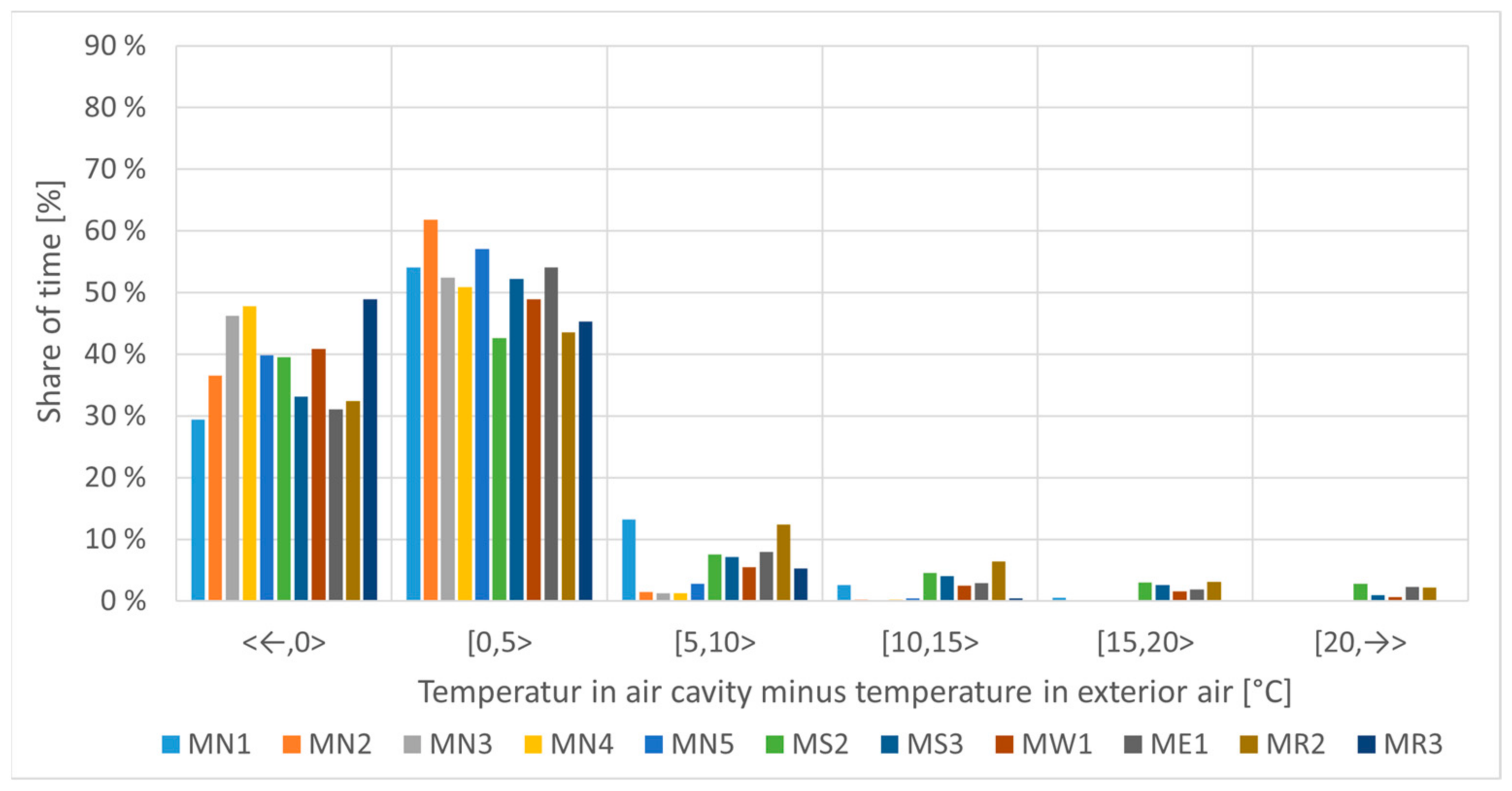

4.1. Temperature, RH, and Wood Moisture

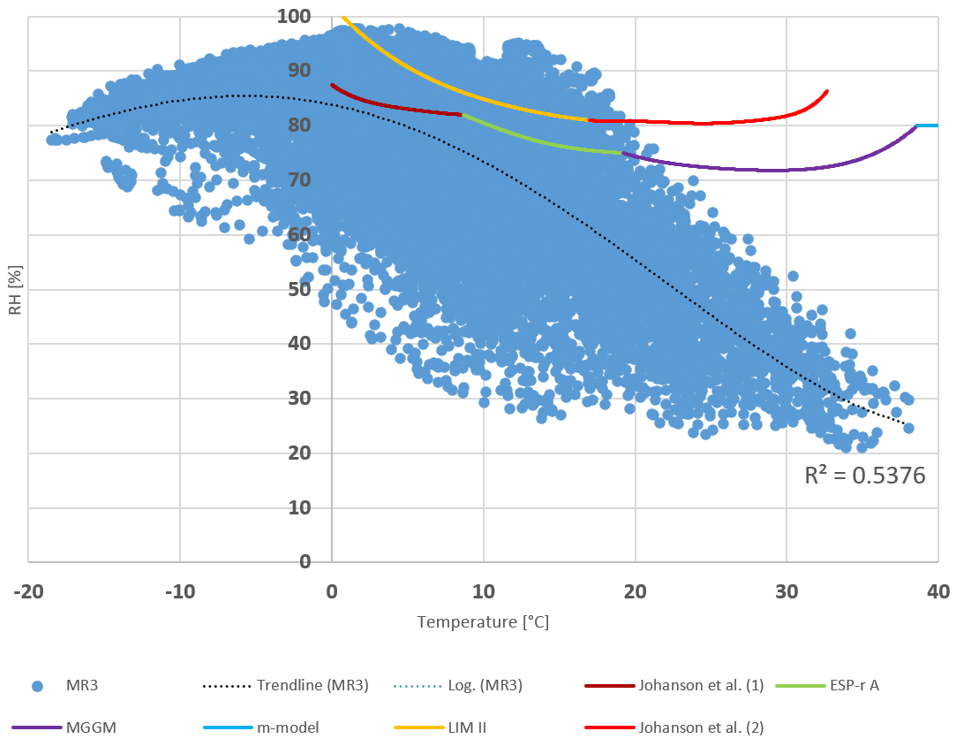

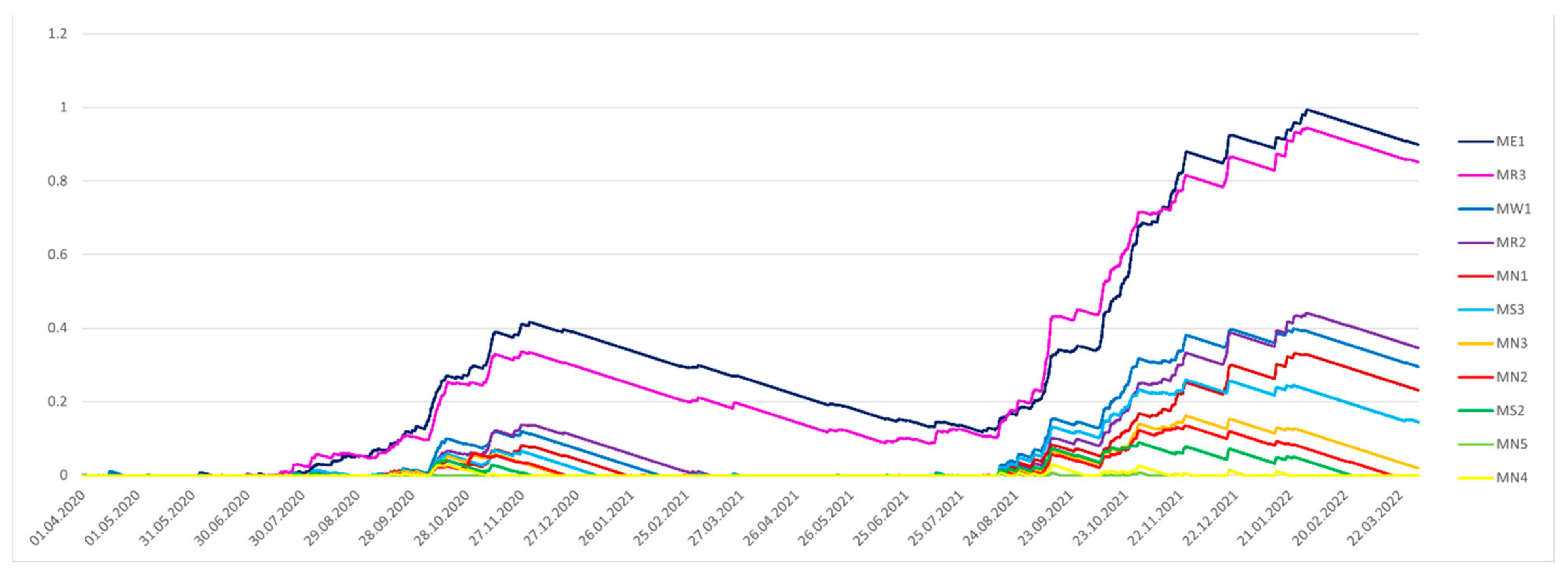

4.2. Mould Growth Criteria

5. Discussion

5.1. Expected Microclimate in the Air Cavity

5.2. Risk Assessment of Mould Growth

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- O’Brien, K.; Sygna, L.; Haugen, J.E. Vulnerable or Resilient? A Multi-Scale Assessment of Climate Impacts and Vulnerability in Norway. Clim. Chang. 2004, 64, 193–225. [Google Scholar] [CrossRef]

- Hanssen-Bauer, I.; Førland, E.J.; Haddeland, I.; Hisdal, H.; Mayer, S.; Nesje, A.; Nilsen, J.E.Ø.; Sandven, S.; Sandø, A.B.; Sorteberg, A.; et al. Klima i Norge 2100—Kunnskapsgrunnlag for Klimatilpasning Oppdatert i 2015; Norwegian Environmental Agency/Norwegian Climate Service Center: Oslo, Norway, 2015. [Google Scholar]

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental Benefits of Using Hybrid CLT Structure in Midrise Non-Residential Construction: An LCA Based Comparative Case Study in the U.S. Pacific Northwest. J. Build. Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- Gullbrekken, L.; Kvande, T.; Time, B. Roof-Integrated PV in Nordic Climate—Building Physical Challenges. In Proceedings of the 6th International Building Physics Conference, IBPC 2015, Turin, Italy, 14–17 June 2015; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; Volume 78, pp. 1962–1967. [Google Scholar]

- Ingebretsen, S.B.; Andenæs, E.; Kvande, T. Microclimate of Air Cavities in Ventilated Roof and Façade Systems in Nordic Climates. Buildings 2022, 12, 683. [Google Scholar] [CrossRef]

- Svendsen, S.D. The Principle of One-Stage and Two-Stage Seals. In Proceedings of the International Symposium on Weathertight Joints for Walls, Oslo, Norway, 25 September 1967; pp. 298–301. [Google Scholar]

- Birkeland, Ø. The Mechanism of Rain Penetration; CIB Report No. 11; CIB: Oslo, Norway, 1967; pp. 33–34. [Google Scholar]

- Lexico Dictionaries. Microclimate, English, Meaning & Definition for UK English, Lexico Dictionaries–English. Available online: https://www.dictionary.com/browse/microclimate (accessed on 19 April 2022).

- Bouchair, A. Solar Induced Ventilation in the Algerian and Similar Climates. Ph.D. Thesis, University of Leeds, Leeds, UK, 1989. [Google Scholar]

- Van Belleghem, M.; Steeman, M.; Janssens, A.; De Paepe, M. Heat, Air and Moisture Transport Modelling in Ventilated Cavity Walls. J. Build. Phys. 2015, 38, 317–349. [Google Scholar] [CrossRef]

- Viitanen, H.; Vinha, J.; Salminen, K.; Ojanen, T.; Peuhkuri, R.; Paajanen, L.; Lähdesmäki, K. Moisture and Bio-Deterioration Risk of Building Materials and Structures. J. Build. Phys. 2010, 33, 201–224. [Google Scholar] [CrossRef]

- Brischke, C.; Bayerbach, R.; Rapp, A.O. Decay-Influencing Factors: A Basis for Service Life Prediction of Wood and Wood-Based Products. Wood Mater. Sci. Eng. 2006, 1, 91–107. [Google Scholar] [CrossRef]

- Bunkholt, N.S.; Time, B.; Kvande, T. Luftede Kledninger—Anbefalinger for Klimatilpasning; SINTEF Community: Trondheim, Norway, 2021. [Google Scholar]

- Gullbrekken, L.; Time, B.; Harboe, T.; Kvande, T. Trekledning—Instrumentering Av Luftede Trefasader Hos Fjogstad Hus; SINTEF Community: Trondheim, Norway, 2021. [Google Scholar]

- Edvardsen, K.I.; Ramstad, T.Ø. Trehus Håndbok 5, 4th ed.; SINTEF Akademisk Forlag: Oslo, Norway, 2018. [Google Scholar]

- Gradeci, K.; Labonnote, N.; Time, B.; Köhler, J. Mould Growth Criteria and Design Avoidance Approaches in Wood-Based Materials—A Systematic Review. Constr. Build. Mater. 2017, 150, 77–88. [Google Scholar] [CrossRef]

- Nocente, A.; Time, B.; Mathisen, H.M.; Kvande, T.; Gustavsen, A. The ZEB Laboratory: The Development of a Research Tool for Future Climate Adapted Zero Emission Buildings. J. Phys. Conf. Ser. 2021, 2069, 012109. [Google Scholar] [CrossRef]

- Säwén, T.; Stockhaus, M.; Hagentoft, C.E.; Bunkholt, N.S.; Wahlgren, P. Model of Thermal Buoyancy in Cavity-Ventilated Roof Constructions. J. Build. Phys. 2021, 45, 413–431. [Google Scholar] [CrossRef]

- Gullbrekken, L. Climate Adaption of Piched Wooden Roofs. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2018. [Google Scholar]

- Kvande, T. Byggforskserien 542.003 Totrinnstetning Mot Slagregn På Fasader. Luftede Kledninger Og Fuger; SINTEF Community: Oslo, Norway, 2013. [Google Scholar]

- Lisø, K.R.; Kvande, T. Klimatilpasning Av Bygninger, 1st ed.; SINTEF Community: Trondheim, Norway, 2007; ISBN 978-82-536-0960-7. [Google Scholar]

- Bunkholt, N.S.; Gullbrekken, L.; Kvande, T. Influence of Local Weather Conditions on Ventilation of a Pitched Wooden Roof. J. Civ. Eng. Arch. 2020, 14, 37–45. [Google Scholar] [CrossRef]

- Gaarder, J.E. Byggforskserien 525.101 Skrå, Luftede Tretak Med Isolerte Takflater; SINTEF Community: Oslo, Norway, 2021. [Google Scholar]

- Blom, P. Venting of Attics and Pitched, Insulated Roofs. J. Therm. Envel. Build. Sci. 2001, 25, 32–50. [Google Scholar] [CrossRef]

- Andenæs, E.; Skagseth, V.A.; Bunkholt, N.S.; Kvande, T.; Lohne, J. Experiences with External Drainage Systems from Compact Roofs in Norwegian Climates. E3S Web Conf. 2020, 172, 21010. [Google Scholar] [CrossRef]

- Noreng, K. Byggforskserien 525.207 Kompakte Tak; SINTEF Community: Oslo, Norway, 2018. [Google Scholar]

- Ramstad, T.; Thommesen, J.E. Byggforskserien 525.002 Takformer, Taktyper Og Oppbygning; SINTEF Community: Oslo, Norway, 2018. [Google Scholar]

- Lee, S.; Park, S.H.; Yeo, M.S.; Kim, K.W. An Experimental Study on Airflow in the Cavity of a Ventilated Roof. Build. Environ. 2009, 44, 1431–1439. [Google Scholar] [CrossRef]

- Hagentoft, C.-E. Introduction to Building Physics; 1:7; Studentlitteratur: Gothenburg, Sweden, 2001; ISBN 91-44-01896-7. [Google Scholar]

- Nore, K.; Blocken, B.; Thue, J.V. On CFD Simulation of Wind-Induced Airflow in Narrow Ventilated Facade Cavities: Coupled and Decoupled Simulations and Modelling Limitations. Build. Environ. 2010, 45, 1834–1846. [Google Scholar] [CrossRef]

- Mundt-Petersen, S.O.; Harderup, L.E. Predicting Hygrothermal Performance in Cold Roofs Using a 1D Transient Heat and Moisture Calculation Tool. Build. Environ. 2015, 90, 215–231. [Google Scholar] [CrossRef]

- Gullbrekken, L.; Uvsløkk, S.; Geving, S.; Kvande, T. Local Loss Coefficients inside Air Cavity of Ventilated Pitched Roofs. J. Build. Phys. 2018, 42, 197–219. [Google Scholar] [CrossRef]

- Falk, J.; Sandin, K. Ventilated Rainscreen Cladding: A Study of the Ventilation Drying Process. Build. Environ. 2013, 60, 173–184. [Google Scholar] [CrossRef]

- Mundt-Petersen, S.O.; Harderup, L.E.; Arfvidsson, J. Important Factors Affecting the Risk of Mold Growth in Well-Insulated Wood Frame Walls in Northern European Climates. In Proceedings of the Thermal Performance of the Exterior Envelopes of Whole Buildings XII International Conference, Clearwater, FL, USA, 1–5 December 2013. [Google Scholar]

- Støver, E.A.; Sundsøy, M.H.; Andenæs, E.; Geving, S.; Kvande, T. Rain Intrusion through Horizontal Joints in Façade Panel Systems—Experimental Investigation. Buildings 2022, 12, 1497. [Google Scholar] [CrossRef]

- Geving, S.; Thue, J.V. Fukt i Bygninger; Håndbok 50; Norsk Byggforskningsinstitutt: Oslo, Norway, 2002. [Google Scholar]

- Blocken, B.; Carmeliet, J. A Review of Wind-Driven Rain Research in Building Science. J. Wind Eng. Ind. Aerodyn. 2004, 92, 1079–1130. [Google Scholar] [CrossRef]

- Kvande, T.; Lisø, K.R.; Time, B. Luftede Kledninger. Klimapåkjenninger, Erfaringer Og Anbefalinger; SINTEF Community: Oslo, Norway, 2007. [Google Scholar]

- Falk, J.; Molnár, M.; Larsson, O. Investigation of a Simple Approach to Predict Rainscreen Wall Ventilation Rates for Hygrothermal Simulation Purposes. Build. Environ. 2014, 73, 88–96. [Google Scholar] [CrossRef]

- Jaakkola, M.S.; Jaakkola, J.J.K. Indoor Molds and Asthma in Adults. In Advances in Applied Microbiology; Academic Press: Cambridge, MA, USA, 2004; Volume 55, pp. 309–338. [Google Scholar]

- Sauni, R.; Uitti, J.; Jauhiainen, M.; Kreiss, K.; Sigsgaard, T.; Verbeek, J.H. Remediating Buildings Damaged by Dampness and Mould for Preventing or Reducing Respiratory Tract Symptoms, Infections and Asthma (Review). Evid.-Based Child Health 2013, 8, 944–1000. [Google Scholar] [CrossRef]

- Bornehag, C.G.; Sundell, J.; Bonini, S.; Custovic, A.; Malmberg, P.; Skerfving, S.; Sigsgaard, T.; Verhoeff, A. EUROEXPO Dampness in Buildings as a Risk Factor for Health Effects, EUROEXPO: A Multidisciplinary Review of the Literature (1998–2000) on Dampness and Mite Exposure in Buildings and Health Effects. Indoor Air 2004, 14, 243–257. [Google Scholar] [CrossRef]

- Park, J.-H.; Cox-Ganser, J.M.; Kreiss, K.; White, S.K.; Rao, C.Y. Hydrophilic Fungi and Ergosterol Associated with Respiratory Illness in a Water-Damaged Building. Environ. Health Perspect. 2008, 116, 45–50. [Google Scholar] [CrossRef]

- Evans, F.G. Soppskader På Tre; Fokus På Tre; TreFokus AS Og Norsk Treteknisk Institutt: Oslo, Norway, 2009. [Google Scholar]

- Thue, J.V. Bygningsfysikk Grunnlag; Fagbokforlaget: Bergen, Norway, 2016; ISBN 978-82-450-1994-0. [Google Scholar]

- Tronstad, S. Tre Og Fuktighet—Fra Produsent Til Forbruker. In Teknisk Håndbok, 4th ed.; Norsk Treteknisk Institutt: Oslo, Norway, 2013. [Google Scholar]

- Viitanen, H. Factors Affecting the Development of Biodeterioration in Wooden Constructions. Mater. Struct. 1994, 27, 483–493. [Google Scholar] [CrossRef]

- Geving, S. Fuktskader: Årsaker, Utredning Og Tiltak—Håndbok 3; SINTEF Akademisk Forlag: Oslo, Norway, 2011. [Google Scholar]

- Clarke, J.A.; Johnstone, C.M.; Kelly, N.J.; McLean, R.C.; Anderson, J.A.; Rowan, N.J.; Smith, J.E. A Technique for the Prediction of the Conditions Leading to Mould Growth in Buildings. Build. Environ. 1999, 34, 515–521. [Google Scholar] [CrossRef]

- Johansson, S.; Wadsö, L.; Sandin, K. Estimation of Mould Growth Levels on Rendered Façades Based on Surface Relative Humidity and Surface Temperature Measurements. Build. Environ. 2010, 45, 1153–1160. [Google Scholar] [CrossRef]

- Sedlbauer, K. Prediction of Mould Fungus Formation on the Surface of and inside Building Components; Fraunhofer Institute: Munich, Germany, 2001. [Google Scholar]

- Sedlbauer, K. Prediction of Mould Growth by Hygrothermal Calculation. J. Therm. Envel. Build. Sci. 2002, 25, 321–336. [Google Scholar] [CrossRef]

- Ayerst, G. The Effects of Moisture and Temperature on Growth and Spore Germination in Some Fungi. J. Stored Prod. Res. 1969, 5, 127–141. [Google Scholar] [CrossRef]

- Smith, S.L.; Hill, S.T. Influence of Temperature and Water Activity on Germination and Growth of Aspergillus Restrictus and A. Versicolor. Trans. Br. Mycol. Soc. 1982, 79, 558–560. [Google Scholar] [CrossRef]

- Moon, H.J.; Augenbroe, G.L.M. Towards a Practical Mould Growth Risk Indicator. Build. Serv. Eng. Res. Technol. 2004, 25, 317–326. [Google Scholar] [CrossRef]

- Togerö, Å.; Tengberg, C.S.; Bengtsson, B. M-Model: A Method to Assess the Risk for Mould Growth in Wood Structures with Fluctuating Hygrothermal Conditions; Tampere University of Technology: Tampere, Finland, 2011; Volume 2, pp. 883–890. [Google Scholar]

- Viitanen, H.; Bjurman, J. Mould Growth on Wood under Fluctuating Humidity Conditions. Mater. Org. 1995, 29, 27–46. [Google Scholar]

- Hukka, A.; Viitanen, H.A. A Mathematical Model of Mould Growth on Wooden Material. Wood Sci. Technol. 1999, 33, 475–485. [Google Scholar] [CrossRef]

- Viitanen, H.; Ritschkoff, A.-C. Mould Growth in Pine and Spruce Sapwood in Relation to Air Humidity and Temperature; Swedish University of Agricultural Sciences, Department of Forest Products: Uppsala, Sweden, 1991. [Google Scholar]

- Viitanen, H. Modelling the Time Factor in the Development of Mould Fungi: The Effect of Critical Humidity and Temperature Conditions on Pine and Spruce Sapwood. Holzforschung 1997, 51, 6–14. [Google Scholar] [CrossRef]

- Viitanen, H.; Ojanen, T. Improved Model to Predict Mould Growth in Building Materials. In Proceedings of the Thermal Performance of the Exterior Envelopes of Whole Buildings XI Conference, Clearwater, FL, USA, 1–5 December 2007. [Google Scholar]

- Ojanen, T.; Viitanen, H.; Peuhkuri, R.; Lähdesmäki, K.; Vinha, J.; Salminen, K. Mold Growth Modeling of Building Structures Using Sensitivity Classes of Materials. In Proceedings of the 11th International Conference on Thermal Performance of the Exterior Envelopes of Whole Buildings, Buildings XI, Clearwater, FL, USA, 4–8 November 2010; pp. 1–10. [Google Scholar]

- Ojanen, T.; Peuhkuri, R.; Viitanen, H.; Lähdesmäki, K.; Vinha, J.; Salminen, K. Classification of Material Sensitivity: New Approach for Mould Groeth Modeling. In Proceedings of the 9th Nordic Symposium on Building Physics, Tampere, Finland, 29 May–2 June 2011; Volume 2, pp. 867–874. [Google Scholar]

- Fraunhofer IBP WUFI Mould Index VTT. Available online: https://wufi.de/en/2017/03/31/wufi-mould-index-vtt/ (accessed on 23 September 2022).

- Gullbrekken, L.; Kvande, T.; Time, B. Instrumentering Av Luftede Trefasader På Orre for Norgeshus Varhaug; SINTEF Community: Trondheim, Norway, 2021. [Google Scholar]

- Rønningen, E.S. Feltstudie Av Klimatiske Forhold i Luftespalter Bak Kledning Og Taktekning. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2020. [Google Scholar]

- Thodesen, B.; Kvande, T.; Tajet, H.T.T.; Time, B.; Lohne, J. Adapting Green-Blue Roofs to Nordic Climate. Nord. J. Archit. Res. 2018, 30, 99–128. [Google Scholar]

- NCCS Norwegian Centre for Climate Services. Available online: https://seklima.met.no/ (accessed on 19 May 2022).

- Bunkholt, N.S.; Time, B.; Kvande, T. Trefuktmålinger: Litteraturundersøkelse Og Korrelasjonskurver; Klima 2050: Trondheim, Norway, 2022. [Google Scholar]

- Lie, S.K.; Thiis, T.K.; Vestøl, G.I.; Høibø, O.; Gobakken, L.R. Can Existing Mould Growth Models Be Used to Predict Mould Growth on Wooden Claddings Exposed to Transient Wetting? Build. Environ. 2019, 152, 192–203. [Google Scholar] [CrossRef]

- Gullbrekken, L.; Kvande, T.; Time, B. Ventilated Wooden Roofs: Influence of Local Weather Conditions—Measurements. Energy Procedia 2017, 132, 777–782. [Google Scholar] [CrossRef]

- Viljanen, K.; Lü, X.; Puttonen, J. Factors Affecting the Performance of Ventilation Cavities in Highly Insulated Assemblies. J. Build. Phys. 2021, 45, 67–110. [Google Scholar] [CrossRef]

- Sandberg, M.; Moshfegh, B. Buoyancy-Induced Air Flow in Photovoltaic Facades—Effect of Geometry of the Air Gap and Location of Solar Cell Modules. Build. Environ. 2002, 37, 211–218. [Google Scholar] [CrossRef]

- Lie, S.K.; Vestøl, G.I.; Høibø, O.; Gobakken, L.R. Surface Mould Growth on Wooden Claddings—Effects of Transient Wetting, Relative Humidity, Temperature and Material Properties. Wood Mater. Sci. Eng. 2019, 14, 129–141. [Google Scholar] [CrossRef]

| Building | Sensor | Orientation (Façade/Roof) | Description of Placement |

|---|---|---|---|

| Fjogstad-Hus | SE-1 | South-east | 560 mm from east corner, 430 mm from lower edge of siding board. |

| SE-2 | Top, 600 mm from eave height, 540 mm from east corner, 460 mm from eave. | ||

| SE-3 | Above window, 170 mm from head, 2820 mm from east corner. | ||

| SE-4 | Below window, approx. 300 mm from sill, 2250 mm from east corner, 420 mm from lower edge of siding board. | ||

| SE-5 | 560 mm from east corner, 2950 mm from lower siding board. | ||

| SW-1 | South-west | Above middle window, 230 mm above head, 310 mm from west corner. Frame partially covered by window. | |

| SW-2 | Above middle window, 250 mm above head, 1720 mm from west corner. | ||

| Norgeshus | NOS | North-east | Batten, top of façade. Sensor at 500 mm from lower edge of rafter. |

| NOL | Counter-batten top of façade. Sensor at 780 mm from corner. | ||

| NMS | Counter-batten, approx. middle of façade height. | ||

| NNS | Counter-batten, bottom of façade. | ||

| SOS | South-west | Counter-batten, top of façade. Sensor at 4960 mm from lower edge of sill plate. | |

| SOL | Batten, top of façade. Sensor at 5010 mm from lower edge of sill plate. | ||

| SMS | Counter-batten approx. middle of façade height, 2400 mm from lower edge of sill plate. | ||

| SNS | Counter-batten, bottom of façade. | ||

| SNL | Batten, bottom of façade. Mounted 2400 mm from west corner. 63 mm from lower edge of sill plate (~500 mm above terrain). | ||

| ZEB Laboratory | MN1 | North | Batten, approx. 300 mm below top of façade. |

| MN2 | Batten below window, approx. 850 mm below sill. | ||

| MN3 | Batten below window, approx. 1250 mm below sill. | ||

| MN4 | Batten middle of wall, same elevation as MN3. | ||

| MN5 | Batten, middle of wall, same elevation as MN2. | ||

| MS2 | South | Batten, top of facade. Approx. 700 mm above head. | |

| MS3 | Batten, above glass facade. Approx. 1150 mm above head. | ||

| MW1 | West | Batten, approx. 350 mm below and 1150 mm south of edge of sill. | |

| ME1 | East | Batten, approx. 1100 mm above and 600 mm south of edge of head. | |

| MR2 | Roof (south) | Batten, top of shed roof. | |

| MR3 | Batten, bottom of shed roof. |

| Parameter | Setting |

|---|---|

| Material category: | Wood or natural material |

| Material sub-category: | Untreated pine or spruce (heartwood) |

| Sensitivity class: | Very sensitive |

| Reduction factor: | Nearly no reduction |

| Type of surface: | Rough |

| Type of wood: | Conifer |

| Building | Position | Maximum | Minimum | ||||

|---|---|---|---|---|---|---|---|

| Value | Sensor | Date | Value | Sensor | Date | ||

| Fjogstad-Hus | Air cavity | 35.3 °C | SE-4 | 01 Jul 2021 | −5.8 °C | SW-2 | 24 Dec 2021 |

| Exterior air | 26.7 °C | - | 25 Jul 2021 | −4.5 °C | - | 24 Dec 2021 | |

| Norgeshus | Air cavity | 33.5 °C | NOL | 01 Jul 2021 | −8.8 °C | SNL | 24 Dec 2021 |

| Exterior air | 22.8 °C | - | 25 Jul 2021 | −8.4 °C | - | 24 Dec 2021 | |

| ZEB Laboratory | Air cavity (facade) | 51.0 °C | ME1 | 21 Aug 2020 | −19.0 °C | MN5 | 11 Feb 2021 |

| Air cavity (roof) | 58.0 °C | MR2 | 27 Jun 2020 | −18.5 °C | MR3 | 11 Feb 2021 | |

| Exterior air | 31.0 °C | - | 20 Jun 2020 | −18.8 °C | - | 11 Feb 2021 | |

| Fjogstad-Hus | Temperature | Wood Moisture | Norges-Hus | Temperature | Wood Moisture | ZEB Laboratory | Temperature | Wood Moisture |

|---|---|---|---|---|---|---|---|---|

| SEA-SE1 | 0.9821 | 0.8719 | NOS-SNL | 0.9299 | 0.8956 | MNA-MN1 | 0.9786 | 0.9734 |

| SEA-SE2 | 0.9954 | 0.9856 | SOS-SOL | 0.9980 | 0.9413 | MNA-MN2 | 0.9978 | 0.9850 |

| SEA-SE3 | 0.9978 | 0.9778 | SNS-SNL | 0.9990 | 0.8016 | MNA-MN3 | 0.9966 | 0.9858 |

| SEA-SE4 | 0.9960 | 0.9762 | NOS-SOS | 0.9168 | 0.9365 | MNA-MN4 | 0.9976 | 0.9878 |

| SEA-SE5 | 0.9976 | 0.9859 | MNA-MN5 | 0.9983 | 0.9853 | |||

| SW1-SW2 | 0.9960 | 0.9410 | MR2-MR3 | 0.9534 | 0.8377 | |||

| MS2-MS3 | 0.9746 | 0.9803 | ||||||

| Våland-SEA | 0.9178 | Obrestad-NOS | 0.9192 | Ext.-MNA | 0.9748 | |||

| Våland-SW2 | 0.9176 | Obrestad-SNL | 0.9274 | Ext.-MN1 | 0.9385 | |||

| Ext.-MN2 | 0.9790 | |||||||

| Ext.-MR2 | 0.8945 | |||||||

| Ext.-MR3 | 0.9686 | |||||||

| Ext.-MS2 | 0.8737 |

| Building | Sensor | Curve Fitting Analysis | Simplified Mould Growth Criteria | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| % of Data Points Exceeding Lower Curve | % of Data Points Exceeding Upper Curve | T ≥ 0 °C | T ≥ 5 °C | ||||||||

| RH 80–85% | RH 85–90% | RH 90–95% | RH 95–100% | RH 80–85% | RH 85–90% | RH 90–95% | RH 95–100% | ||||

| Fjogstad-Hus | SE-1 | 32% | 17% | 15.4% | 12.5% | 2.6% | 0.0% | 10.4% | 11.2% | 2.6% | 0.0% |

| SE-2 | 31% | 8% | 16.1% | 13.4% | 0.6% | 0.0% | 9.5% | 9.9% | 0.6% | 0.0% | |

| SE-3 | 19% | 6% | 14.1% | 4.9% | 0.1% | 0.0% | 12.3% | 4.8% | 0.1% | 0.0% | |

| SE-4 | 21% | 5% | 15.2% | 5.3% | 0.2% | 0.0% | 10.8% | 5.1% | 0.2% | 0.0% | |

| SE-5 | 30% | 13% | 9.6% | 17.7% | 2.6% | 0.1% | 5.6% | 12.4% | 2.5% | 0.1% | |

| SW-1 | 52% | 37% | 10.8% | 9.8% | 18.7% | 11.5% | 9.5% | 7.9% | 9.3% | 7.6% | |

| SW-2 | 39% | 22% | 6.9% | 10.6% | 19.7% | 0.7% | 6.2% | 7.3% | 9.8% | 0.6% | |

| Norgeshus | NOS | 24% | 8% | 19.6% | 2.6% | 0.7% | 0.0% | 17.9% | 2.5% | 0.6% | 0.0% |

| NOL | 40% | 18% | 26.6% | 10.0% | 1.9% | 0.3% | 23.3% | 9.7% | 1.5% | 0.3% | |

| NMS | 38% | 23% | 22.8% | 10.7% | 2.2% | 1.0% | 22.2% | 10.5% | 1.9% | 1.0% | |

| NNS | 57% | 36% | 20.5% | 24.6% | 9.7% | 1.0% | 16.6% | 21.1% | 9.4% | 0.8% | |

| SOS | 29% | 11% | 18.2% | 7.3% | 1.2% | 0.7% | 15.0% | 7.1% | 1.2% | 0.6% | |

| SOL | 31% | 12% | 19.4% | 9.0% | 1.5% | 0.8% | 15.1% | 8.8% | 1.3% | 0.6% | |

| SMS | 22% | 8% | 15.2% | 3.7% | 1.1% | 1.0% | 14.4% | 3.7% | 1.0% | 0.8% | |

| SNS | 31% | 12% | 19.5% | 8.7% | 1.0% | 0.6% | 15.9% | 8.5% | 0.9% | 0.4% | |

| SNL | 55% | 33% | 20.1% | 18.2% | 13.3% | 2.2% | 16.2% | 13.7% | 11.3% | 2.1% | |

| ZEB Laboratory | MN1 | 22% | 3% | 8.6% | 8.5% | 4.3% | 0.0% | 4.7% | 2.9% | 0.8% | 0.0% |

| MN2 | 19% | 2% | 11.3% | 6.8% | 0.1% | 0.0% | 5.6% | 2.6% | 0.0% | 0.0% | |

| MN3 | 21% | 3% | 11.0% | 8.9% | 0.9% | 0.0% | 5.9% | 3.1% | 0.2% | 0.0% | |

| MN4 | 18% | 1% | 12.2% | 5.6% | 0.0% | 0.0% | 5.8% | 1.6% | 0.0% | 0.0% | |

| MN5 | 14% | 0% | 9.8% | 3.7% | 0.0% | 0.0% | 3.7% | 0.7% | 0.0% | 0.0% | |

| MS2 | 16% | 2% | 8.3% | 6.3% | 0.9% | 0.0% | 4.1% | 2.3% | 0.2% | 0.0% | |

| MS3 | 20% | 4% | 9.0% | 8.4% | 2.4% | 0.0% | 5.0% | 3.4% | 0.5% | 0.0% | |

| MW1 | 23% | 5% | 9.0% | 9.1% | 4.1% | 0.1% | 4.9% | 3.6% | 1.1% | 0.0% | |

| ME1 | 26% | 9% | 8.6% | 8.7% | 7.6% | 0.9% | 5.6% | 4.3% | 2.7% | 0.3% | |

| MR2 | 22% | 4% | 7.6% | 8.4% | 5.9% | 0.2% | 4.2% | 3.0% | 0.9% | 0.2% | |

| MR3 | 31% | 9% | 10.3% | 10.3% | 8.9% | 1.0% | 6.5% | 4.8% | 2.4% | 0.2% | |

| Building | Sensor | Data Completeness | Wood Moisture [weight-%] | % of Hours Wherein 1RH > RHcrit | % of Hours Wherein 2T < Text | Yearly Mould Growth(VTT) | |||

|---|---|---|---|---|---|---|---|---|---|

| [←, 15> | [15, 20> | [20, 25> | [25, →> | ||||||

| Fjogstad-Hus | SE-1 | 100.00% | 58% | 40% | 1% | 0% | 19% | 16% | 0.84 |

| SE-2 | 100.00% | 58% | 42% | 0% | 0% | 14% | 13% | 0.55 | |

| SE-3 | 100.00% | 56% | 44% | 0% | 0% | 10% | 6% | 0.27 | |

| SE-4 | 100.00% | 63% | 37% | 0% | 0% | 10% | 15% | 0.26 | |

| SE-5 | 100.00% | 59% | 27% | 14% | 0% | 17% | 17% | 0.94 | |

| SW-1 | 100.00% | 6% | 48% | 10% | 36% | 40% | 25% | 4.95 | |

| SW-2 | 95.10% | 47% | 35% | 18% | 0% | 27% | 24% | 4.02 | |

| Norgeshus | NOS | 99.58% | 8% | 86% | 6% | 0% | 11% | 11% | 0.15 |

| NOL | 99.59% | 13% | 84% | 2% | 0% | 25% | 11% | 0.83 | |

| NMS | 99.77% | 5% | 87% | 4% | 4% | 27% | 9% | 2.77 | |

| NNS | 99.69% | 4% | 76% | 16% | 4% | 41% | 17% | 3.42 | |

| SOS | 99.98% | 12% | 77% | 11% | 0% | 16% | 14% | 0.40 | |

| SOL | 99.82% | 35% | 57% | 9% | 0% | 17% | 17% | 0.50 | |

| SMS | 99.43% | 7% | 86% | 5% | 3% | 12% | 15% | 0.40 | |

| SNS | 99.67% | 3% | 66% | 28% | 3% | 17% | 20% | 0.43 | |

| SNL | 99.77% | 6% | 80% | 14% | 0% | 38% | 25% | 3.71 | |

| ZEB Laboratory | MN1 | 99.86% | 61% | 39% | 0% | 0% | 7% | 29% | 0.33 |

| MN2 | 99.73% | 49% | 51% | 0% | 0% | 4% | 37% | 0.14 | |

| MN3 | 98.65% | 55% | 45% | 0% | 0% | 6% | 46% | 0.16 | |

| MN4 | 98.48% | 24% | 69% | 8% | 0% | 3% | 48% | 0.03 | |

| MN5 | 99.69% | 41% | 57% | 3% | 0% | 1% | 40% | 0.01 | |

| MS2 | 99.86% | 41% | 41% | 16% | 2% | 4% | 40% | 0.09 | |

| MS3 | 99.86% | 26% | 38% | 33% | 3% | 6% | 33% | 0.26 | |

| MW1 | 99.77% | 37% | 37% | 22% | 3% | 7% | 41% | 0.40 | |

| ME1 | 99.88% | 37% | 35% | 28% | 0% | 12% | 31% | 0.99 | |

| MR2 | 99.78% | 24% | 23% | 14% | 39% | 7% | 32% | 0.44 | |

| MR3 | 99.58% | 6% | 34% | 35% | 24% | 12% | 49% | 0.95 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ingebretsen, S.B.; Andenæs, E.; Gullbrekken, L.; Kvande, T. Microclimate and Mould Growth Potential of Air Cavities in Ventilated Wooden Façade and Roof Systems—Case Studies from Norway. Buildings 2022, 12, 1739. https://doi.org/10.3390/buildings12101739

Ingebretsen SB, Andenæs E, Gullbrekken L, Kvande T. Microclimate and Mould Growth Potential of Air Cavities in Ventilated Wooden Façade and Roof Systems—Case Studies from Norway. Buildings. 2022; 12(10):1739. https://doi.org/10.3390/buildings12101739

Chicago/Turabian StyleIngebretsen, Sara Bredal, Erlend Andenæs, Lars Gullbrekken, and Tore Kvande. 2022. "Microclimate and Mould Growth Potential of Air Cavities in Ventilated Wooden Façade and Roof Systems—Case Studies from Norway" Buildings 12, no. 10: 1739. https://doi.org/10.3390/buildings12101739

APA StyleIngebretsen, S. B., Andenæs, E., Gullbrekken, L., & Kvande, T. (2022). Microclimate and Mould Growth Potential of Air Cavities in Ventilated Wooden Façade and Roof Systems—Case Studies from Norway. Buildings, 12(10), 1739. https://doi.org/10.3390/buildings12101739