Large Panel System Technology in the Second Half of the Twentieth Century—Literature Review, Recycling Possibilities and Research Gaps

Abstract

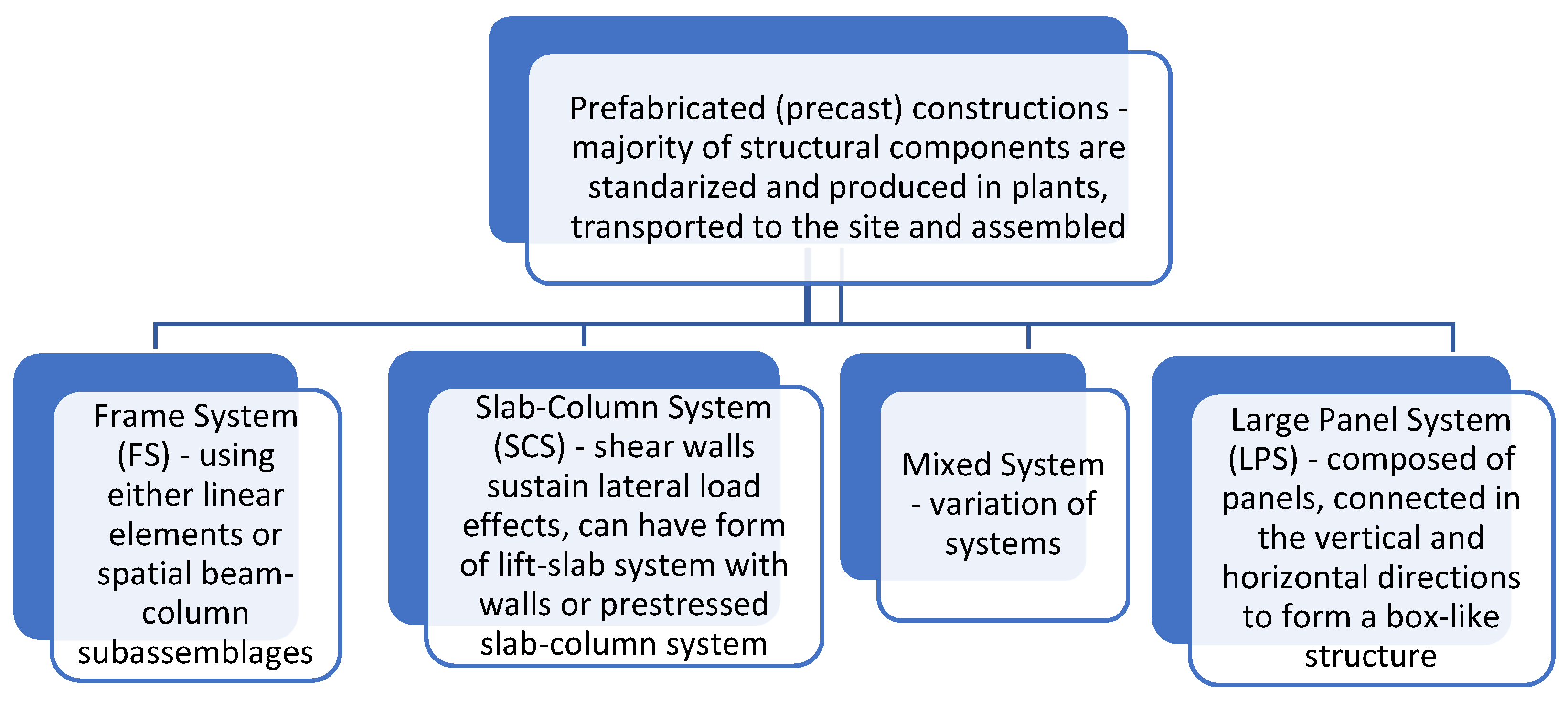

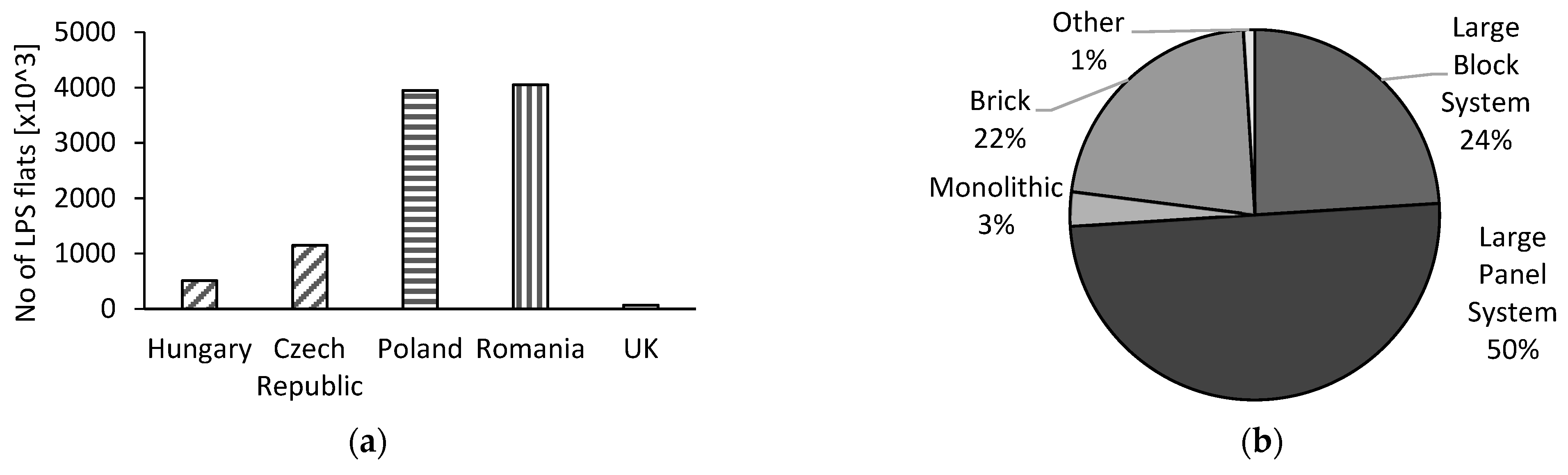

:1. Introduction

2. Scientometric Analysis of the Bibliometric Data

3. History of Large Panel System

4. Selected Characteristics of Large Panel System Technologies Having Impact on Their Durability

4.1. Seismic Resistance

4.2. Structural Integrity and Progressive Collapse

- direct approach (notional removal of structural elements, accurate but troublesome and time-consuming);

- indirect approach (seeking and verifying alternate load paths, allows to evaluate indirect design, can be applied to many forms of structure).

| Analysed Element | Testing | Results |

|---|---|---|

| Cantilever behaviour of walls while removing a panel | Scale model depicting a six-storey building where five of them acted as a cantilever over the removed wall. The loading included floor dead load, partition dead load and 1/3 of the live load for the catastrophic condition | The cantilever behaviour of the walls is the main mechanism for unfolding alternate load paths. The cantilever rest moment depends on the tension at the joints on each storey and the compression at the lowest level. |

| The slab suspension mechanism | Removal of the support between two full-size floor slabs (jointed in the centre) | The slab suspension provided an additional alternate load path. Tensile joints above the damaged area provided partial support for the load. |

| Horizontal joints, the transmission to the vertical loads and the potential for wall splitting | Horizontal joints with platform framing. The analysed properties: mortar strength, amount of wall transverse reinforcement, filled or unfilled slab cores, applied moment and rotation | Results enabled the design of guidelines for the joints based on the variables investigated. |

| Name of the Joint | Role | Characteristics |

|---|---|---|

| Transverse joint | To transfer vertical shear from the walls above the damage to adjacent walls in the line of the damaged wall by providing cantilever and beam action | To be installed in floor and roof systems and over interior wall supports and between members and exterior walls, the joints should provide a nominal strength of 2.03 kNm (1500 lb*ft) with enough shear strength to prevent horizontal panels from sliding. Spacing of bearing walls should also be the maximal spacing of joints perpendicular to floor or roof slab spans. |

| Longitudinal joint | To develop membrane action of the floor | Spacing of the joints parallel to the span of the ceiling or the roof slab should be at intervals of maximum 3 m. It must be ensured that the forces are transmitted around the openings. |

| Vertical joint | To develop suspension action on ineffective walls to reduce debris load | To be installed in all walls and along the height of the building, the joints should provide a nominal tensile strength not less than 4.07 kNm (3000 lb*ft). Each panel should have at least two joints. |

4.3. Reliability and Fire Safety

4.4. Defects during Design, Execution and Exploitation Stages

4.5. Concrete Load-Bearing Elements

- Strengthening of hangers fixing external panels;

- Modernization of thermal insulation;

- Improvement of acoustic insulation;

- Replacement of improvement of old ironwork of balconies;

- Replacement of dry rises.

5. Possibilities of Recycling Concrete Panels

5.1. Concrete Load-Bearing Elements

- no publication of guidelines and instructions exists for various civil engineering sections;

- appropriate maintenance is the key factor in reaching the required durability of a residential building;

- maintenance is given up or not carried out in time and with no quality required, resulting in lowering the value of the building;

- expenditure on maintenance will increase in time;

- making an assessment of the pace of progressive degradation is of high importance.

5.2. The Amount of Waste and Its Localization

6. Research Gaps

7. Conclusions and Perspectives

- While LPS buildings were designed to last 50 years, it is assumed that properly managed maintenance can extend the service life for another 50 years. However, it only brings us inevitably to the prognosed end of service life;

- Research studies pay attention to, still, a lack of knowledge in retrofit techniques. A huge number of analysed blocks have undergone, more or less, unskilled renovation;

- Despite a number of catastrophes, weak connections at joints between panels are still the biggest concern.

- Concrete used in the construction of panels seems to be in satisfactory condition with a possibility to re-use it as a recycled coarse aggregate in new structures;

- The influence of RCA on the homogeneity of concrete along the thickness of concrete should be studied in more depth, especially with regards to the properties of concrete at its early stage;

- To the best of the authors’ knowledge, there is no publication concerning concrete with recycled coarse aggregate from large panel system buildings from the second half of the twentieth century.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alcocer, S.M.; Carranza, R.; Perez-Navarrete, D.; Martinez, R. Seismic tests of beam-to-column connections in a precast concrete frame. PCI J. 2002, 47, 70–89. [Google Scholar] [CrossRef]

- Pittore, M.; Bindi, D.; Tyagunov, S.; Wieland, M.; Picozzi, M.; Pilz, M.; Mikhailova, N. Seismic Hazard and Risk in Central Asia STR11/14; Deutsches GeoForschungsZentrum GFZ: Potsdam, Germany, 2011. [Google Scholar]

- King, S.A.; Khalturin, V.I.; Tucker, B.E. Seismic Hazard and Building Vulnerability in Post-Soviet Central Asian Republics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 52. [Google Scholar]

- Types of Precast Systems . Available online: https://db.world-housing.net/ (accessed on 7 January 2022).

- Baghchesaraei, O.R.; Lavasani, H.H.; Baghchesaraei, A. Behavior of prefabricated structures in developed and developing countries. Bull. Société Sci. Liège 2016, 85, 1229–1234. [Google Scholar] [CrossRef]

- Jovanović, J. From Yugoslavia to Angola: Housing as Postcolonial Technical Assistance City Building through IMS Žeželj Housing Technology. Archit. Urban. 2019, 53, 170–181. [Google Scholar]

- Nikolic, J. New challenging approach for analysis and upgrading of massive building structure: Case study of New Belgrade post-war mega blocks. In CESB 2013 PRAGUE-Central Europe Towards Sustainable Building 2013: Sustainable Building and Refurbishment for Next Generations; Grada for Faculty of Civil Engineering; Czech Technical University in Prague: Prague, Czechia, 2013; pp. 1–10. [Google Scholar]

- Jovanović, J.; Grbić, J.; Petrović, D. Prefabricated construction in former Yugoslavia. Visual and aesthetic features and technology of prefabrication. In Graue Reihe des Instituts für Stadt-Und Regionalplanung; Technische Universität Berlin: Berlin, Germany, 2012; p. 175. [Google Scholar]

- Alfirević, Đ.; Simonović Alfirević, S. Urban housing experiments in Yugoslavia 1948–1970. Spatium 2015, 1, 1–9. [Google Scholar] [CrossRef]

- Jule, L.; Zhuye, H.; Cedric, M.; Xiaosheng, J. Structural Installation of Precast Concrete Elements. J. Eng. 2020, 8, 1–8. [Google Scholar] [CrossRef]

- Brzev, S.; Guevara-Perez, T. Precast Concrete Construction; British Columbia Institute of Technology: Burnaby, BC, Canada, 2010. [Google Scholar]

- Shemie, M. Bolted connections in large panel system buildings. PCI J. 1973, 18, 27–33. [Google Scholar] [CrossRef]

- Berkowski, P.; Barański, J. 3D Fem Analysis of Precast Concrete Apartment Buildings Under Mining Tremors–A Case Study. In Proceedings of the 6th International Conference on Mechanics and Materials in Design, Porta Delgada, Portugal, 26–30 July 2015. [Google Scholar]

- Trzcińska, M. Add, Transform, and Utilize. Possibilities of Applying Druot, Lacaton, and Vassal’s Modernization Strategies and Solutions in Polish Large-Panel Housing Estates. Land 2021, 10, 1308. [Google Scholar] [CrossRef]

- Salnikov, V.A.; Mikheeva, O.M. Analysis and Forecast of Russian Housing Stock Based on New Data Sources. Stud. Russ. Econ. Dev. 2019, 30, 442–450. [Google Scholar] [CrossRef]

- Thanoon, W.A.; Peng, L.W.; Kadir, M.R.A.; Jaafar, M.S.; Salit, M.S. The Experiences of Malaysia and other countries in industrialised building system. In Proceedings of the International Conference on Industrialised Building Systems, Kuala Lumpur, Malaysia, 10–11 September 2003; Volume 10, pp. 255–261. [Google Scholar]

- Peshkov, V.V.; Gorbach, P.S.; Shcherbin, S.A.; Savenkov, A.I. Some aspects of the organization of the processes of renovation of the housing stock in Irkutsk. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 751, p. 012078. [Google Scholar]

- Romano, E.; Iuorio, O.; Nikitas, N.; Negro, P. A review of retrofit strategies for Large Panel System buildings. In Proceedings of the Sixth International Symposium on Life-Cycle Civil Engineering, Ghent, Belgium, 28–31 October 2018. [Google Scholar]

- Ostanska, A. Basics of the methodology of creating programs for revitalization of large housing estates erected in industrialized technology on the example of the housing estate St. Moniuszki in Lublin. In Monographs of the Faculty of Building and Sanitary Engineering; Lublin University of Technology: Lublin, Poland, 2009; Volume 1, pp. 1–173. [Google Scholar]

- Agudelo-Vera, C.M.; Leduc, W.R.; Mels, A.R.; Rijnaarts, H.H. Harvesting urban resources towards more resilient cities. Resour. Conserv. Recycl. 2012, 64, 3–12. [Google Scholar] [CrossRef]

- Huuhka, S.; Kaasalainen, T.; Hakanen, J.H.; Lahdensivu, J. Reusing concrete panels from buildings for building: Potential in Finnish 1970s mass housing. Resour. Conserv. Recycl. 2015, 101, 105–121. [Google Scholar] [CrossRef]

- Kibert, C.J.; Chini, A.R. Overview of Deconstruction in Selected Countries; CIB Publication: Rotterdam, The Netherlands, 2000; Volume 252. [Google Scholar]

- Kadela, M.; Cincio, A.; Fedorowicz, J.; Gerylo, R. Attempt at Numerical Representation of Gas Explosion in a Large Panel Building. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 603, p. 052023. [Google Scholar]

- Niemelä, T.; Kosonen, R.; Jokisalo, J. Energy performance and environmental impact analysis of cost-optimal renovation solutions of large panel apartment buildings in Finland. Sustain. Cities Soc. 2017, 32, 9–30. [Google Scholar] [CrossRef]

- Deilmann, C.; Effenberger, K.H.; Banse, J. Housing stock shrinkage: Vacancy and demolition trends in Germany. Build. Res. Inf. 2009, 37, 660–668. [Google Scholar] [CrossRef]

- Mah, C.M.; Fujiwara, T.; Ho, C.S. Construction and demolition waste generation rates for high-rise buildings in Malaysia. Waste Manag. Res. 2016, 34, 1224–1230. [Google Scholar] [CrossRef] [PubMed]

- Perron, B.E.; Victor, B.G.; Hodge, D.R.; Salas-Wright, C.P.; Vaughn, M.G.; Taylor, R.J. Laying the foundations for scientometric research: A data science approach. Res. Soc. Work. Pract. 2017, 27, 802–812. [Google Scholar] [CrossRef]

- Zitt, M.; Bassecoulard, E. Challenges for scientometric indicators: Data demining, knowledge-flow measurements and diversity issues. Ethics Sci. Environ. Politics 2008, 8, 49–60. [Google Scholar] [CrossRef]

- Singh, V.K.; Banshal, S.K.; Singhal, K.; Uddin, A. Scientometric mapping of research on ‘Big Data’. Scientometrics 2015, 105, 727–741. [Google Scholar] [CrossRef]

- Gile, D. Analyzing translation studies with scientometric data: From CIRIN to citation analysis. Perspectives 2015, 23, 240–248. [Google Scholar] [CrossRef]

- Ahmad, W.; Ahmad, A.; Ostrowski, K.A.; Aslam, F.; Joyklad, P.A. scientometric review of waste material utilization in concrete for sustainable construction. Case Stud. Constr. Mater. 2021, 15, e00683. [Google Scholar] [CrossRef]

- Falagas, M.E.; Pitsouni, E.I.; Malietzis, G.A.; Pappas, G. Comparison of PubMed, Scopus, web of science, and Google scholar: Strengths and weaknesses. FASEB J. 2008, 22, 338–342. [Google Scholar] [CrossRef]

- Vieira, E.; Gomes, J. A comparison of Scopus and Web of Science for a typical university. Scientometrics 2009, 81, 587–600. [Google Scholar] [CrossRef]

- Analysis of Titles and Publishers. Available online: https://www.scopus.com/ (accessed on 7 January 2022).

- Visualising Scientific Landscapes. Available online: https://www.vosviewer.com/ (accessed on 7 January 2022).

- Heinemann, H.A.; Nijland, T.G. Concrete in the Netherlands: Historic use of components and conservation. In Proceedings of the Third International Congress on Construction History, Cottbus, Germany, 20–24 May 2009. [Google Scholar]

- MacCarthy, F. Walter Gropius: Visionary Founder of the Bauhaus; Faber & Faber: London, UK, 2019. [Google Scholar]

- Gropius, W.; Gropius WA, G. The New Architecture and the Bauhaus; MIT Press: Cambridge, MA, USA, 1965; Volume 21. [Google Scholar]

- Boesiger, W.; Girsberger, H. Le Corbusier 1910–65; Editorial Gustavo Gili: Barcelona, Spain, 2000. [Google Scholar]

- Millais, M. A critical appraisal of the design, construction and influence of the Unité d’Habitation, Marseilles, France. J. Archit. Urban. 2015, 39, 103–115. [Google Scholar] [CrossRef]

- Pearson, C.; Delatte, N. Ronan point apartment tower collapse and its effect on building codes. J. Perform. Constr. Facil. 2005, 19, 172–177. [Google Scholar] [CrossRef] [Green Version]

- Newland, P. After Ronan Point: Re-imagining the Territory. In The Cultural Construction of London’s East End; Brill Rodopi: Paderborn, Germany, 2008; pp. 149–182. [Google Scholar]

- Russell, J.M.; Sagaseta, J.; Cormie, D.; Jones, A.E.K. Historical review of prescriptive design rules for robustness after the collapse of Ronan Point. In Structures; Elsevier: Amsterdam, The Netherlands, 2019; Volume 20, pp. 365–373. [Google Scholar]

- Crowley, D. Building the world anew: Design in Stalinist and post-Stalinist Poland. J. Des. Hist. 1994, 7, 187–203. [Google Scholar] [CrossRef]

- Nowakowski, P. Functional and aesthetic aspects of modernization of large panel residential buildings. In International Conference on Applied Human Factors and Ergonomics; Springer: Cham, Switzerland, 2019; pp. 335–346. [Google Scholar]

- Górski, W. Problems of Early Large Panel Structures in Poland. Acta Sci. Pol. Archit. 2021, 20, 45–53. [Google Scholar] [CrossRef]

- Szymańska, D.; Matczak, A. Urbanization in Poland: Tendencies and transformation. Eur. Urban Reg. Stud. 2002, 9, 39–46. [Google Scholar] [CrossRef]

- Apostolska, R.; Necevska-Cvetanovska, G.; Bojadjiev, J.; Bojadjieva, J. Seismic performance of RC high-rise buildings–a case study of 44 storey structure in Skopje (Macedonia). Tech. Gaz. 2016, 23, 1177–1183. [Google Scholar]

- Pall, A.S.; Marsh, C.; Fazio, P. Friction joints for seismic control of large panel structures. J. Prestress. Concr. Inst. 1980, 25, 38–61. [Google Scholar] [CrossRef]

- Pall, A.S. Limited slip bolted joints: A device to control the seismic response of large panel structures. Ph.D. Thesis, Concordia University, Montreal, QC, Canada, 1979. [Google Scholar]

- Ademović, N.; Oliveira, D.V.; Lourenço, P.B. Seismic evaluation and strengthening of an existing masonry building in Sarajevo, B&H. Buildings 2019, 9, 30. [Google Scholar]

- Lintz, C.A.; Bulka, L. Skopje, Macedonia 1965 to 2014: In Search of a Modern European Capital. In Planning Forum; The University of Texas at Austin: Austin, TX, USA, 2015; p. 19. [Google Scholar]

- Stojkov, T. State of the Art: FYR of Macedonia. In Cost C16, Improving the Quality of Existing Urban Building Envelopes; State of the Art; COST (European Cooperation in Science and Technology): Brussels, Belgium, 2007; p. 195. [Google Scholar]

- Folić, R.; Laban, M.; Milanko, V. Reliability and sustainability analysis of large panel residential buildings in Sofia, Skopje and Novi Sad. Facta Univ.-Ser. Archit. Civ. Eng. 2011, 9, 161–176. [Google Scholar] [CrossRef]

- Home, R. Reconstructing Skopje, Macedonia, after the 1963 earthquake: The Master Plan forty years on. Pap. Land Manag. 2007, 7, 660–663. [Google Scholar]

- Ellingwood, B.; Leyendecker, E.V. Approaches for design against progressive collapse. J. Struct. Div. 1978, 104, 413–423. [Google Scholar] [CrossRef]

- Cleland, N.M. Structural integrity and progressive collapse in large-panel precast concrete structural systems. PCI J. 2008, 53, 55. [Google Scholar] [CrossRef]

- Fintel, M.; Schultz, D.M.; Iqbal, M. Philosophy of Structural Response to Normal and Abnormal Loads; Portland Cement Association: Skokie, IL, USA, 1976. [Google Scholar]

- Hanson, N.W.; Burnett, E.F. Wall Cantilevers and Slab Suspension Tests; US Department of Housing and Urban Development, Office of Policy Development and Research: Washington, DC, USA, 1978.

- Kripanarayanan, K.M. Wall Panels: Analysis and Design Criteria; US Department of Housing and Urban Development, Office of Policy Development and Research: Washington, DC, USA, 1976; Volume 3.

- Fintel, M.; Schultz, D.M. A philosophy for structural integrity of large panel buildings. PCI J. 1976, 21, 46–69. [Google Scholar] [CrossRef]

- Johal, L.S.; Hanson, N.W. Design for vertical load on horizontal connections in large panel structures. PCI J. 1982, 27, 62–79. [Google Scholar] [CrossRef]

- Breen, J.E. Developing structural integrity in bearing wall buildings. PCI J. 1980, 25, 42–73. [Google Scholar] [CrossRef]

- Palmisano, F. Mitigation of progressive collapse by the activation of the elasto-plastic catenary behaviour of RC slab structures. Open Constr. Build. Technol. J. 2014, 8, 122–131. [Google Scholar] [CrossRef]

- Currie, R.J.; Reeves, B.R.; Moore JF, A. The Structural Adequacy and Durability of Large Panel System Dwellings; Building Research Establishment: Watford, UK, 1987. [Google Scholar]

- Gramatikov, K.; Bozinovski, Z.L. Enlargement of Balconies of Existing Residential Building “Karpos” in Skopje. Cost C16 Improv. Qual. Exist. Urban Build. Envel. Struct. 2007, 3, 91. [Google Scholar]

- Laban, M.; Milanko, V. Fire safety assessment in urban environment. Int. Sci. Publ. Ecol. Saf. 2008, 2, 121–133. [Google Scholar]

- Building Research Institute. Available online: https://www.itb.pl/en (accessed on 7 January 2022).

- Rybka, A. Large-panel dwelling building, current state-ways of construction and architectural modifications. In COST Action C; COST (European Cooperation in Science and Technology): Brussels, Belgium, 2003; Volume 12, pp. 207–216. [Google Scholar]

- Podawca, K.; Pawłat-Zawrzykraj, A.; Dohojda, M. Analysis of the possibilities for improvement of thermal comfort of living quarters located in multi-family large-panel prefabricated buildings. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 44, p. 00145. [Google Scholar]

- Ligęza, W. Renovation of Large-Panel Buildings in Context of Urban Renewal/Remonty Budynków Wielkopłytowych, Jako Element Rewitalizacji Miast. Civ. Environ. Eng. Rep. 2015, 17, 83–95. [Google Scholar] [CrossRef] [Green Version]

- Jasiczak, J.; Girus, K. Maintenance and Durability of the Concrete External Layer of Curtain Walls in Prefabricated Technological Poznan Large Panel System. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 245, p. 032015. [Google Scholar]

- Jasiczak, J. Influence of technological processes on homogeneity and strength of concrete. Build. Eng. 1985, 12, 561–564. [Google Scholar]

- Girus, K. Evaluation of the condition of the external layer of walls in the national technological system″ S-Sz″ (Szczecin System) of large-panel prefabricated construction. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 284, p. 07003. [Google Scholar]

- Bacharz, K.; Raczkiewicz, W.; Bacharz, M.; Grzmil, W. Manufacturing Errors of Concrete Cover as a Reason of Reinforcement Corrosion in a Precast Element—Case Study. Coatings 2019, 9, 702. [Google Scholar] [CrossRef] [Green Version]

- Knyziak, P. The quality and reliability in the structural design, production, execution and maintenance of the precast residential buildings in Poland in the past and now. In Key Engineering Materials; Trans Tech Publications Ltd: Wollerau, Switzerland, 2016; Volume 691, pp. 420–431. [Google Scholar]

- The Rules for Determining the Technical Deterioration of Buildings; WACETOB: Warsaw, Poland, 1998; pp. 43–44. Available online: https://wacetob.com.pl/en/ (accessed on 7 January 2022).

- Knyziak, P.; Krentowski, J.R.; Bieranowski, P. Risks of the durability of large-panel buildings elevations in reference to the conclusions from technical conditions audits. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 117, p. 00080. [Google Scholar]

- Tofiluk, A.; Knyziak, P.; Krentowski, J. Revitalization of twentieth-century prefabricated housing estates as interdisciplinary issue. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 471, p. 112096. [Google Scholar]

- Krentowski, J.R.; Knyziak, P.; Mackiewicz, M. Durability of interlayer connections in external walls in precast residential buildings. Eng. Fail. Anal. 2021, 121, 105059. [Google Scholar] [CrossRef]

- Tomaszewicz, D.; Jablonska-Krysiewicz, A.; Gryniewicz, M. Pull-Out Tests and Numerical Simulations of Bonded Threaded Anchors in Concrete Blocks with Thermal Insulation Layer. In International Scientific Conference Environmental Challenges in Civil Engineering; Springer: Cham, Switzerland, 2020; pp. 45–61. [Google Scholar]

- Botici, A.A.; Ungureanu, V.; Ciutina, A.; Botici, A.; Dubina, D. Sustainable retrofitting of large panel prefabricated concrete residential buildings. In Proceedings of the Central Europe towards Sustainable Building 2013 Conference–Sustainable Building and Refurbishment for Next Generations, Prague, Czech Republic, 26–28 June 2013; pp. 39–42. [Google Scholar]

- Muntean, D.M.; Ungureanu, V.; Petran, I.; Georgescu, M. Large Prefabricated Concrete Panels Collective Dwellings from the 1970s: Context and Improvements. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 245, p. 052050. [Google Scholar]

- Todut, C.; Stoian, V.; Demeter, I.; Nagy-György, T.; Ungureanu, V. Retrofitting strategy for earthquake damaged precast concrete wall using FRP composites. In Proceedings Engineering a Concrete Future: Technology, Modeling & Construction; Tel-Aviv; Technion-Israel Institute of Technology: Haifa, Israel, 2013; pp. 573–576. [Google Scholar]

- Lyublinskiy, V.A. The deformability of shear bonds in the load-bearing systems of panel buildings. J. Phys. Conf. Ser. 2019, 1425, 012159. [Google Scholar] [CrossRef]

- Kuusk, K.; Kalamees, T.; Link, S.; Ilomets, S.; Mikola, A. Case-study analysis of concrete large-panel apartment building at pre-and post low-budget energy-renovation. J. Civ. Eng. Manag. 2017, 23, 67–75. [Google Scholar] [CrossRef] [Green Version]

- Antonini, E.; Boeri, A.; Lauria, M.; Giglio, F. Reversibility and durability as potential indicators for Circular building Technologies. Sustainability 2020, 12, 7659. [Google Scholar] [CrossRef]

- Nowogońska, B. Prognosis of the technical condition of masonry walls in residential buildings. Bud. I Archit. 2014, 13, 027–032. [Google Scholar] [CrossRef]

- Konior, J. Overdurability and Technical Wear of Materials Used in the Construction of Old Buildings. Materials 2021, 14, 378. [Google Scholar] [CrossRef]

- Lee, S.; Lee, S.; Kim, J. Evaluating the impact of defect risks in residential buildings at the occupancy phase. Sustainability 2018, 10, 4466. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://stat.gov.pl/en/ (accessed on 7 January 2022).

- Błaszczyński, T. Eco-Cities; Inżynieria i Budownictwo: Warsaw, Poland, 2022; pp. 436–444. [Google Scholar]

- Available online: http://www.abc.tychy.pl/en/mapa (accessed on 7 January 2022).

- Available online: https://polska.geoportal2.pl/map/www/mapa.php?mapa=polska (accessed on 7 January 2022).

- Tošić, N.; Torrenti, J.M.; Sedran, T.; Ignjatović, I. Toward a codified design of recycled aggregate concrete structures: Background for the new fib Model Code 2020 and Eurocode 2. Struct. Concr. 2020, 22, 2916–2938. [Google Scholar] [CrossRef]

- Ostrowski, K.; Stefaniuk, D.; Sadowski, Ł.; Krzywiński, K.; Gicala, M.; Różańska, M. Potential use of granite waste sourced from rock processing for the application as coarse aggregate in high-performance self-compacting concrete. Constr. Build. Mater. 2020, 238, 117794. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.P.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; (No. 2544); PBL Publishers: Lemesos, Cyprus, 2017. [Google Scholar]

- Kwan, W.H.; Ramli, M.; Kam, K.J.; Sulieman, M.Z. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater. 2012, 26, 565–573. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, C.; Ding, T.; Akbarnezhad, A. A recycled aggregate concrete high-rise building: Structural performance and embodied carbon footprint. J. Clean. Prod. 2018, 199, 868–881. [Google Scholar] [CrossRef]

- Jiménez, L.F.; Dominguez, J.A.; Vega-Azamar, R.E. Carbon footprint of recycled aggregate concrete. Adv. Civ. Eng. 2018, 2018, 1–6. [Google Scholar] [CrossRef]

- Panda, K.C.; Bal, P.K. Properties of self compacting concrete using recycled coarse aggregate. Procedia Eng. 2013, 51, 159–164. [Google Scholar] [CrossRef] [Green Version]

- Duan, Z.; Singh, A.; Xiao, J.; Hou, S. Combined use of recycled powder and recycled coarse aggregate derived from construction and demolition waste in self-compacting concrete. Constr. Build. Mater. 2020, 254, 119323. [Google Scholar] [CrossRef]

- Salesa, Á.; Pérez-Benedicto, J.Á.; Esteban, L.M.; Vicente-Vas, R.; Orna-Carmona, M. Physico-mechanical properties of multi-recycled self-compacting concrete prepared with precast concrete rejects. Constr. Build. Mater. 2017, 153, 364–373. [Google Scholar] [CrossRef]

- Fiol, F.; Thomas, C.; Muñoz, C.; Ortega-López, V.; Manso, J.M. The influence of recycled aggregates from precast elements on the mechanical properties of structural self-compacting concrete. Constr. Build. Mater. 2018, 182, 309–323. [Google Scholar] [CrossRef]

- Pereira-de Oliveira, L.A.; Nepomuceno, M.; Rangel, M. An eco-friendly self-compacting concrete with recycled coarse aggregates. Inf. Constr. 2013, 65, 31–41. [Google Scholar] [CrossRef] [Green Version]

- Kou, S.C.; Poon, C.S. Properties of self-compacting concrete prepared with coarse and fine recycled concrete aggregates. Cem. Concr. Compos. 2009, 31, 622–627. [Google Scholar] [CrossRef]

- Conde Silva, J.; Serra, C. A Review on Cement-Based Materials and Practices for Rehabilitation, Retrofitting, and Strengthening of Hydraulic Structures. Pract. Period. Struct. Des. Constr. 2022, 27, 03122002. [Google Scholar] [CrossRef]

- Pečur, I.B.; Bagarić, M.; Milovanović, B. Development and Application of a Prefabricated Façade Panel Containing Recycled Construction and Demolition Waste. J. Facade Des. Eng. 2020, 8, 101–126. [Google Scholar]

| Name | Description |

|---|---|

| Based on the location within the building | |

| Vertical joints | Connect the vertical faces of adjoining wall panels and resist vertical seismic shear forces. |

| Horizontal joints | Connect the horizontal faces of adjoining wall and floor panels, resist gravity and seismic loads. Examples: between floor slabs, between the floor slab and cross-wall, between floor slab and external wall. |

| Based on the construction method | |

| Wet joints | Protruding reinforcing bars from panels (dowels) are connected in the joint. Then cast in-situ concrete is poured between panels. |

| Dry joints | Constructed by bolting or welding together steel plates cast into the ends of the prefabricated panels. |

| Country | City | Building | Built in [Year] | Fire Safety |

|---|---|---|---|---|

| Bulgaria | Sofia | Mladost 3 | 1980 | Unsatisfactory |

| Serbia | Novi Sad | Detelinara | 1987 | Unsatisfactory |

| North Macedonia | Skopje | Karpos | 1966 | Unsatisfactory |

| Stage | Occurring Problem | Characteristics |

|---|---|---|

| Implementation | Errors during design stage | Poor knowledge of guidelines governing the design in LPS technology. Adopting weld dimensions based only on theoretical assumptions and sometimes impossible to install later on site. Lack of knowledge on material’s parameters and incorrect solutions enabling water penetration and corrosion. Wrong selection of technical solutions for designing construction details and finishing elements. Incompetent design of structures under unusual loads (e.g., paraseismic shocks, ground deformation, mining damage). |

| Poor quality in prefabricate production | Material flaws, poor quality of the produced elements and use of building materials without confirming their quality. Damages during storage and transportation. Wrong preparation of concrete mix: low quality of the applied aggregate, using various aggregate fractions, incorrect recipes and addition of water for better workability. Omitted or imprecise vibration of concrete. | |

| Errors, flaws during construction | No control of element’s quality on site, assembling parts that had dimension deviation and shape errors. Design changes without consulting the designer. Incorrect execution of joints and too large dimensional tolerances. Lack of contractors who could assemble proper interconnections and welds. Vertical and horizontal displacements of load-bearing walls and slabs. Execution of flashing enabling water to penetrate into inner parts. Excessively thin layer of foam glass and sealing welds with tarred rope. | |

| Exploitation | Flaws during exploitation and maintenance | Temperature and material shrinkage influence. Mildew and fungus caused by neglecting problems with ventilation. Failure to perform periodic technical inspections and assessments. Insufficient quality of maintenance and repair works. |

| Material ageing, corrosion | Low durability of curtain walls due to incorrect kind of steel used for joints between panels. Allowing for scratches, cracks without adequate protection against corrosion. Changing norms and standards, residents’ expectations over time caused LPS structures to not meet the current demands and have to be technically upgraded. |

| Action | UK | France | Netherlands | Germany | Poland | Denmark | Sweden | Norway | Finland |

|---|---|---|---|---|---|---|---|---|---|

| Demolition | Yes | ||||||||

| Partial demolition | Yes | Yes | Yes | ||||||

| Repair works—preventing further deterioration | Yes | Yes | |||||||

| Modernization works—improving standard of equipment, residential functions | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |

| Modernization including improvement of building’s surroundings | Yes | Yes | Yes | Yes | Yes | Yes | |||

| Preserving the structure of the estate, taking into account cultural activities | Yes | Yes | |||||||

| Revalorization of the estate | Yes | Yes | Yes | ||||||

| Supplementing services on the estate | Yes |

| No | Keyword | Articles |

|---|---|---|

| 1 keyword | Concrete | 364,206 |

| Large Panel System Building | 1333 | |

| Recycled Coarse Aggregate | 2841 | |

| 2 keywords | Concrete + Recycled Coarse Aggregate | 2727 |

| Large Panel System Building + Recycled Coarse Aggregate | 1 | |

| 3 keywords | Large Panel System Building + Recycled Coarse Aggregate + Concrete | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malazdrewicz, S.; Ostrowski, K.A.; Sadowski, Ł. Large Panel System Technology in the Second Half of the Twentieth Century—Literature Review, Recycling Possibilities and Research Gaps. Buildings 2022, 12, 1822. https://doi.org/10.3390/buildings12111822

Malazdrewicz S, Ostrowski KA, Sadowski Ł. Large Panel System Technology in the Second Half of the Twentieth Century—Literature Review, Recycling Possibilities and Research Gaps. Buildings. 2022; 12(11):1822. https://doi.org/10.3390/buildings12111822

Chicago/Turabian StyleMalazdrewicz, Seweryn, Krzysztof Adam Ostrowski, and Łukasz Sadowski. 2022. "Large Panel System Technology in the Second Half of the Twentieth Century—Literature Review, Recycling Possibilities and Research Gaps" Buildings 12, no. 11: 1822. https://doi.org/10.3390/buildings12111822

APA StyleMalazdrewicz, S., Ostrowski, K. A., & Sadowski, Ł. (2022). Large Panel System Technology in the Second Half of the Twentieth Century—Literature Review, Recycling Possibilities and Research Gaps. Buildings, 12(11), 1822. https://doi.org/10.3390/buildings12111822