Effect of Constructing a New Tunnel on the Adjacent Existed Tunnel in Weak Rock Mass: A Case Study

Abstract

:1. Introduction

2. Project Overviews

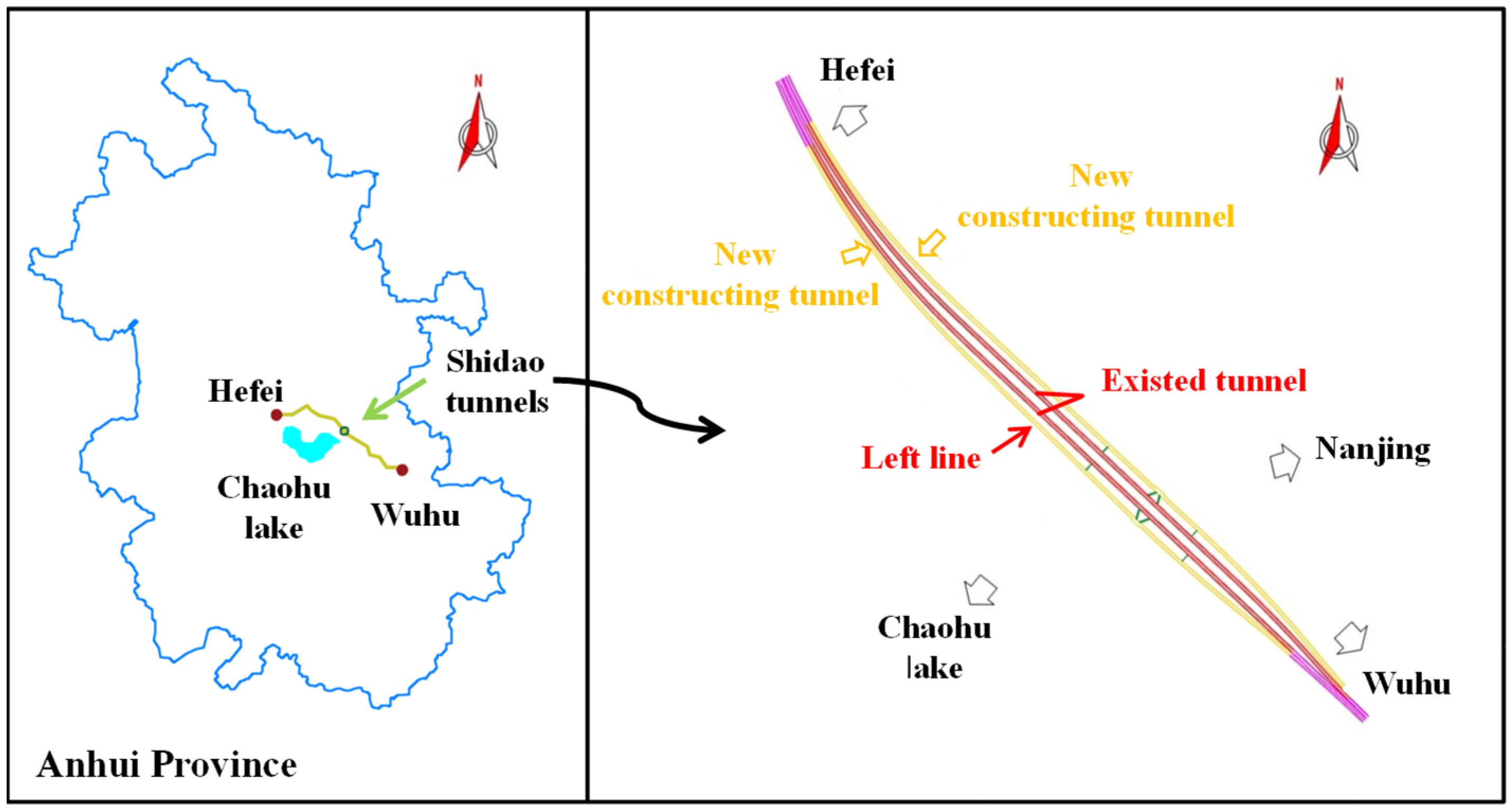

2.1. Expansion Project Site for Shidao Tunnels

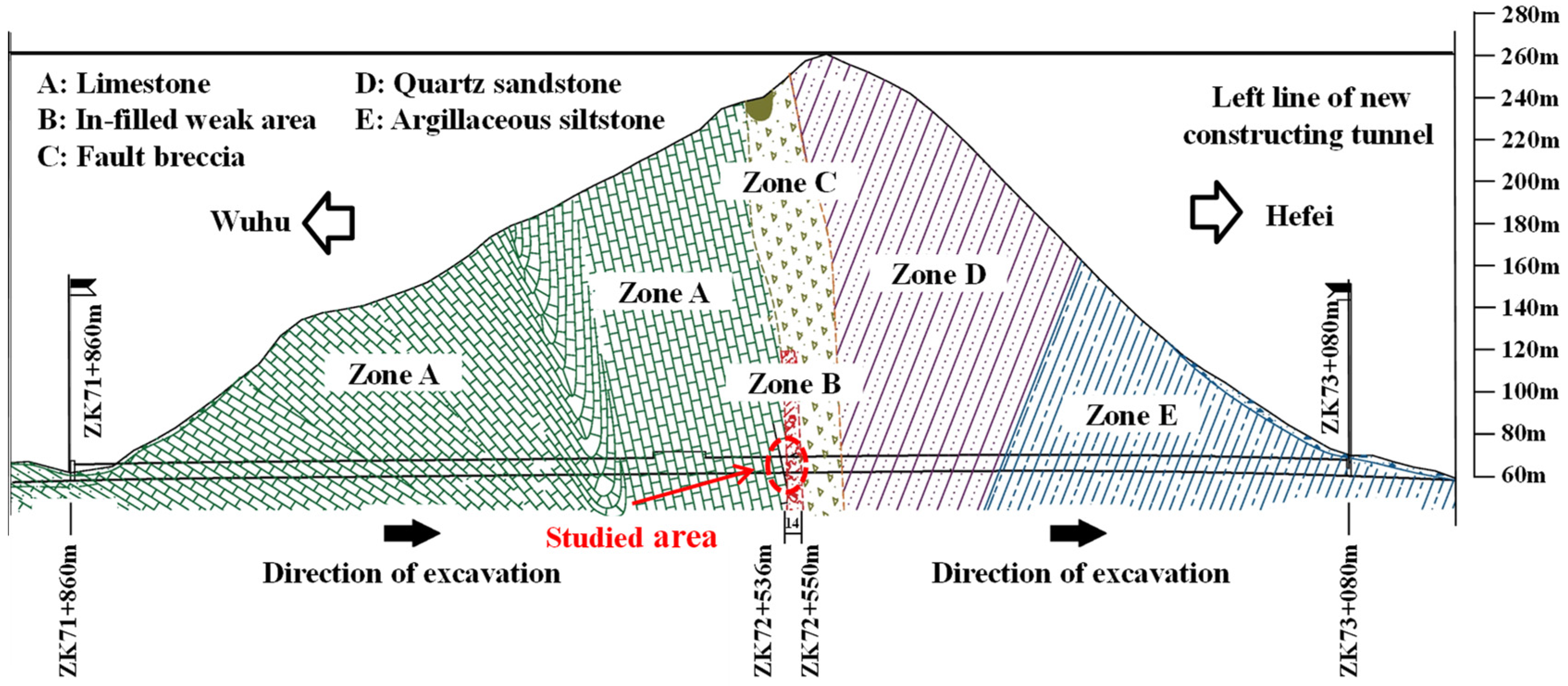

2.2. Geological Profile of Expansion Project for Shidao Tunnels

2.3. Excavation and Constructing Procedures

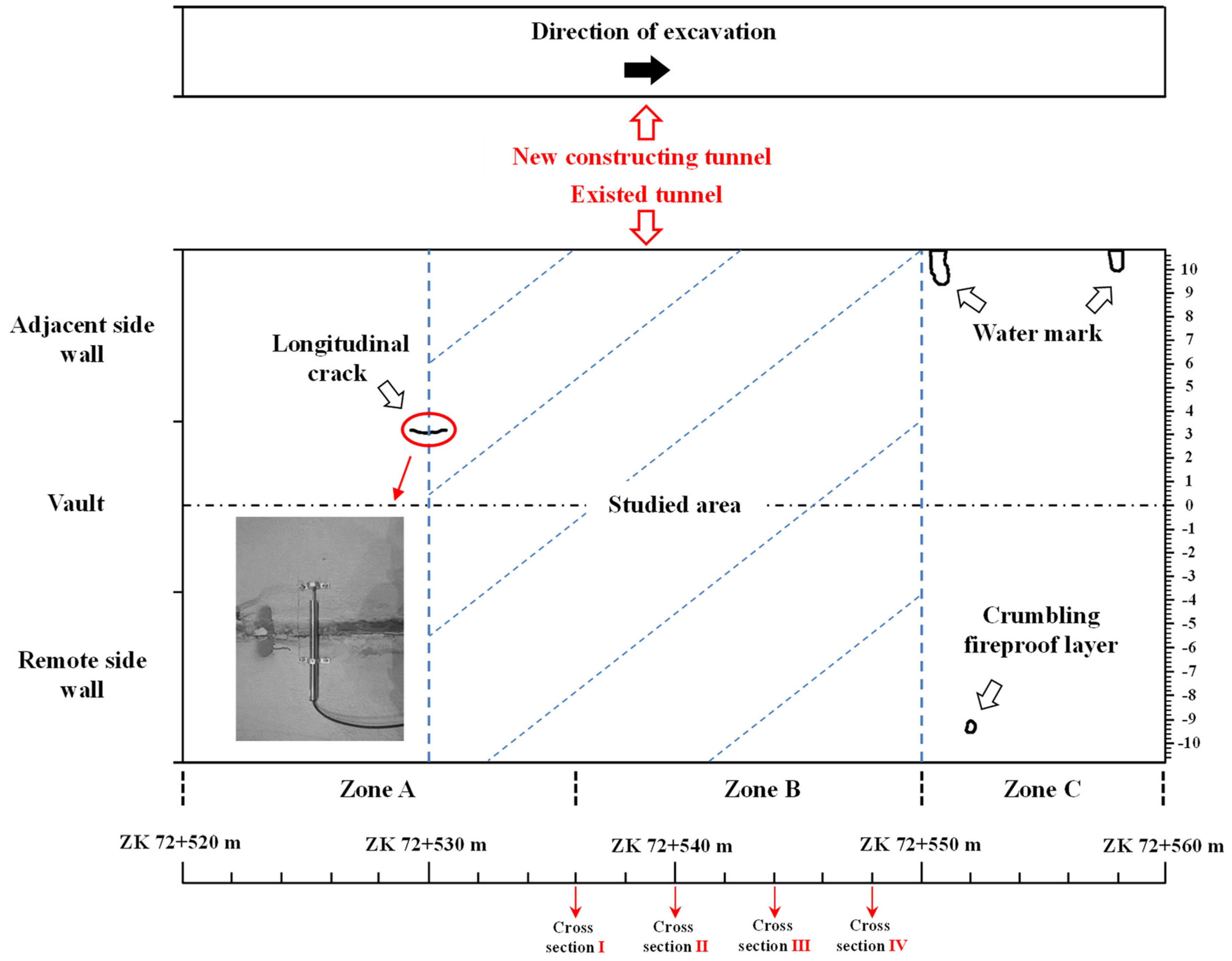

3. Field Investigations on New Constructing and Existed Tunnels

3.1. High-Precision Acquisitions on Excavation Surfaces of New Constructing Tunnel

3.2. Real-Time Monitoring Development of Crack in Existed Tunnel

4. Numerical Study on New Constructing and Existed Tunnels

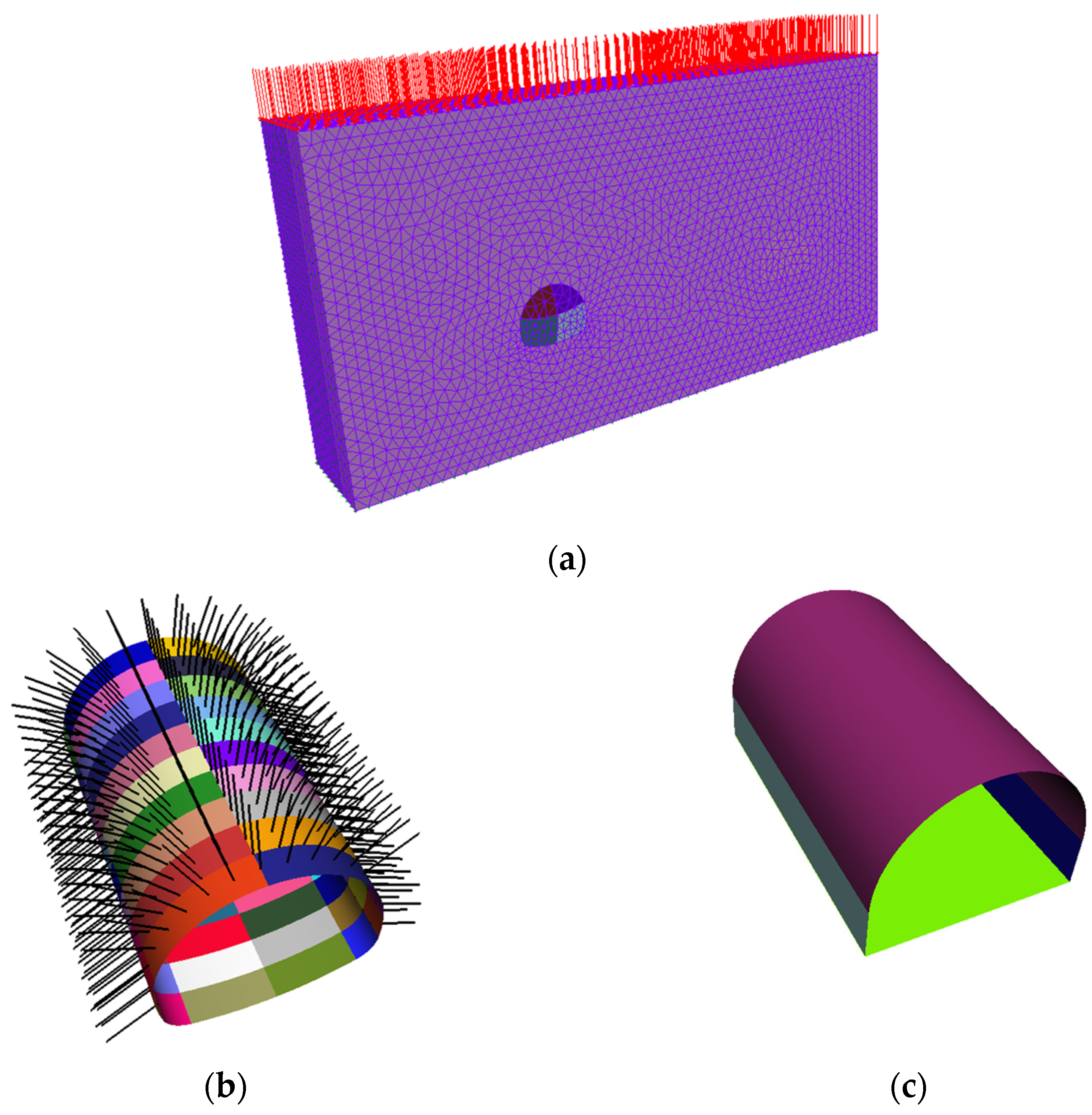

4.1. Numerical Model of Surrounding Rock and Tunnels

4.1.1. Overview of Numerical Model

4.1.2. Numerical Simulation of Excavating Process

4.2. Numerical Analysis on Performance of New Constructing Tunnel

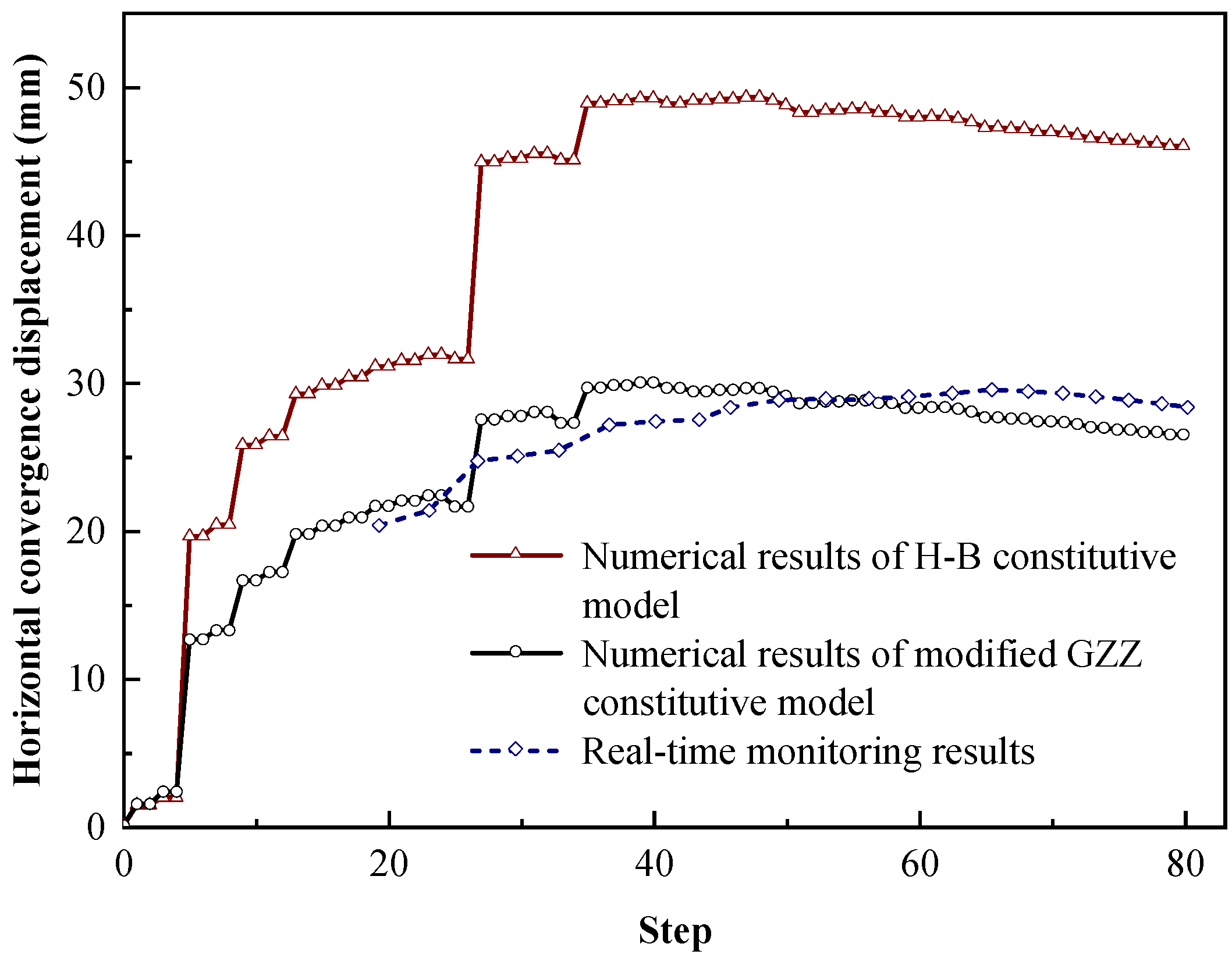

4.2.1. Validation of Horizontal Convergence Displacement of Side Walls by Real-Time Monitoring at ZK 72 + 530 m

4.2.2. Vertical Displacement of Vault and Horizontal Displacement of Adjacent Side Wall

4.2.3. Plastic Zone of Cross Section at ZK 72 + 550 m

4.3. Numerical Analysis on Effect of New Constructing Tunnel on Existed Tunnel

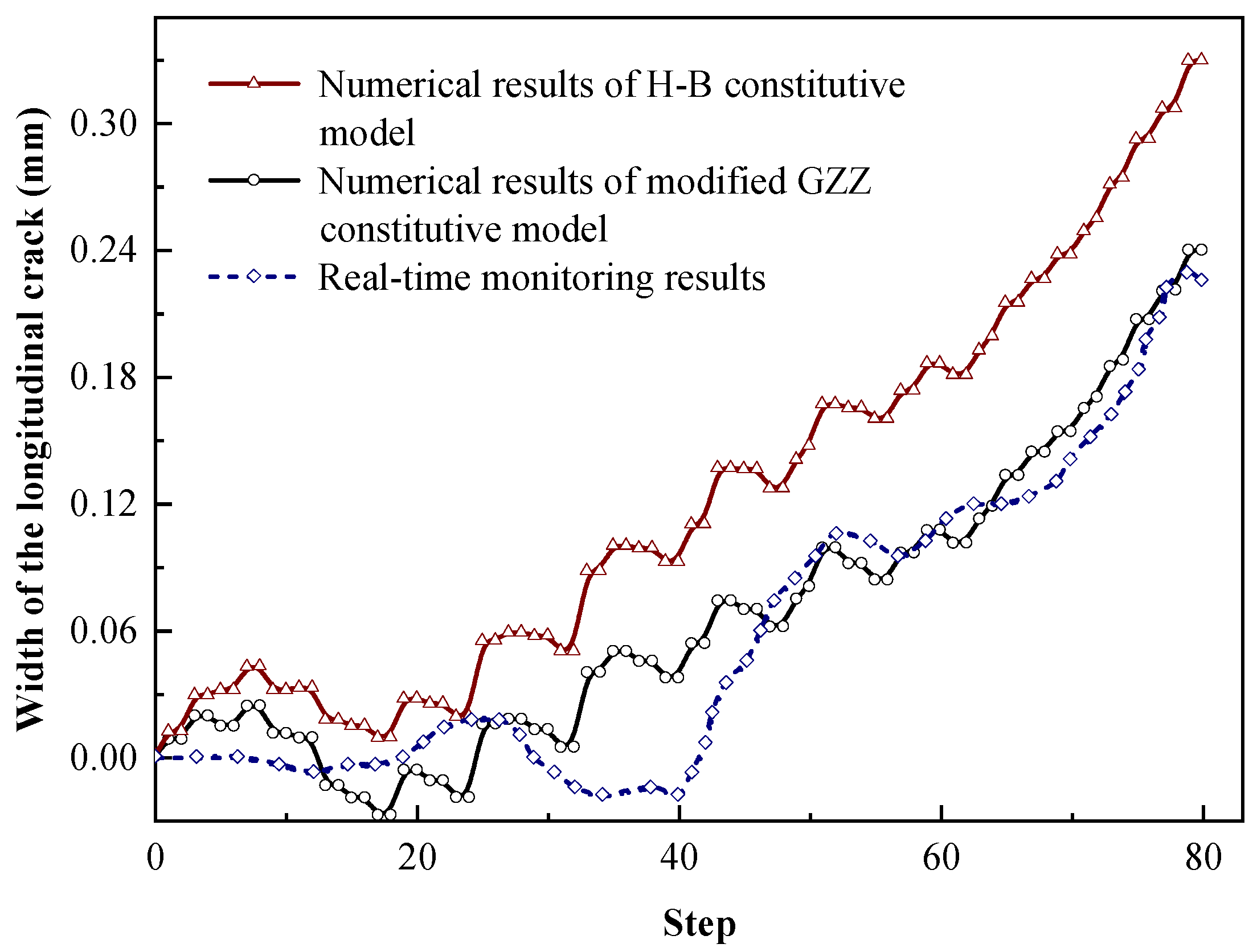

4.3.1. Validation of Width Variation of Longitudinal Crack in Existed Tunnel

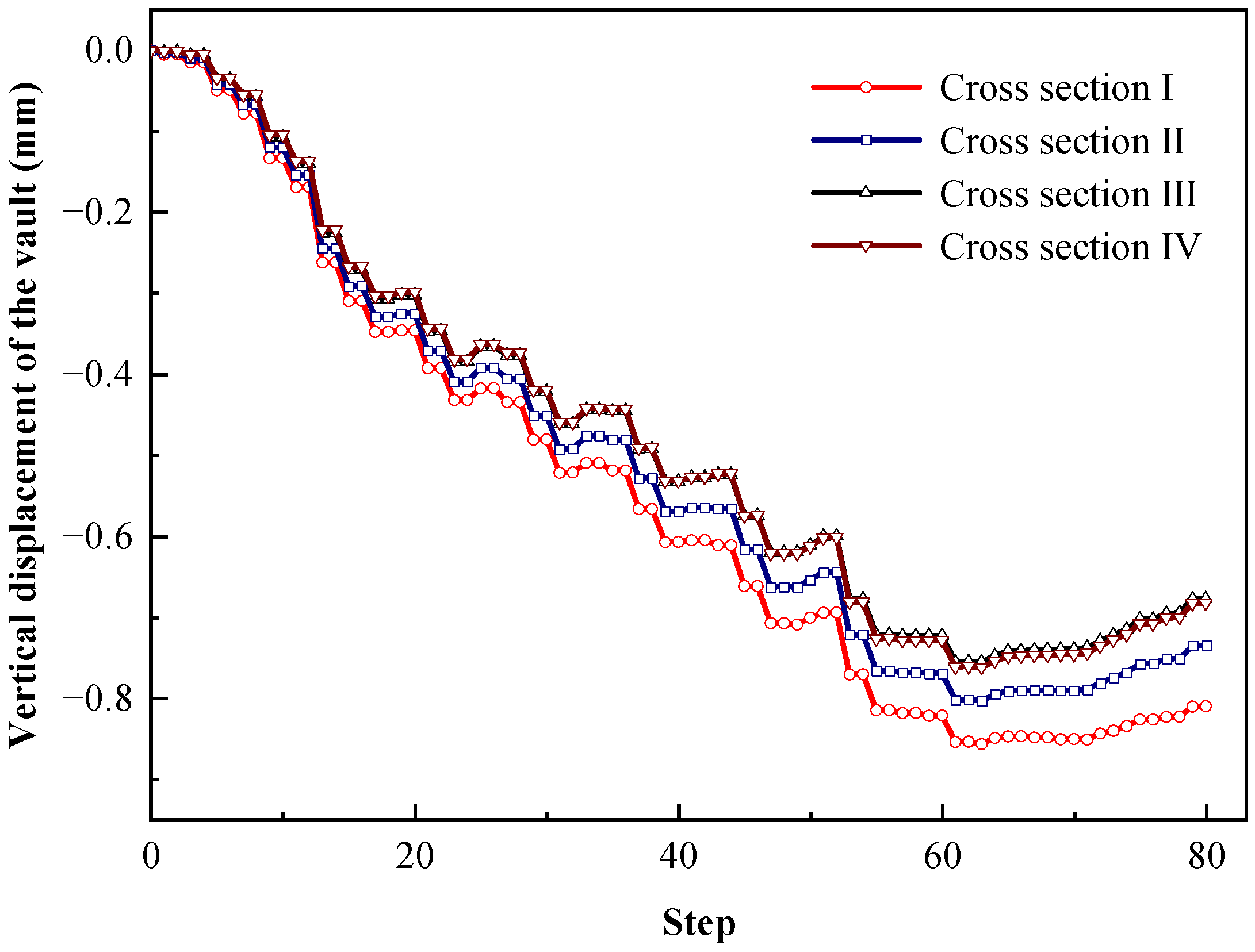

4.3.2. Vertical Displacement of Vault of Existed Tunnel

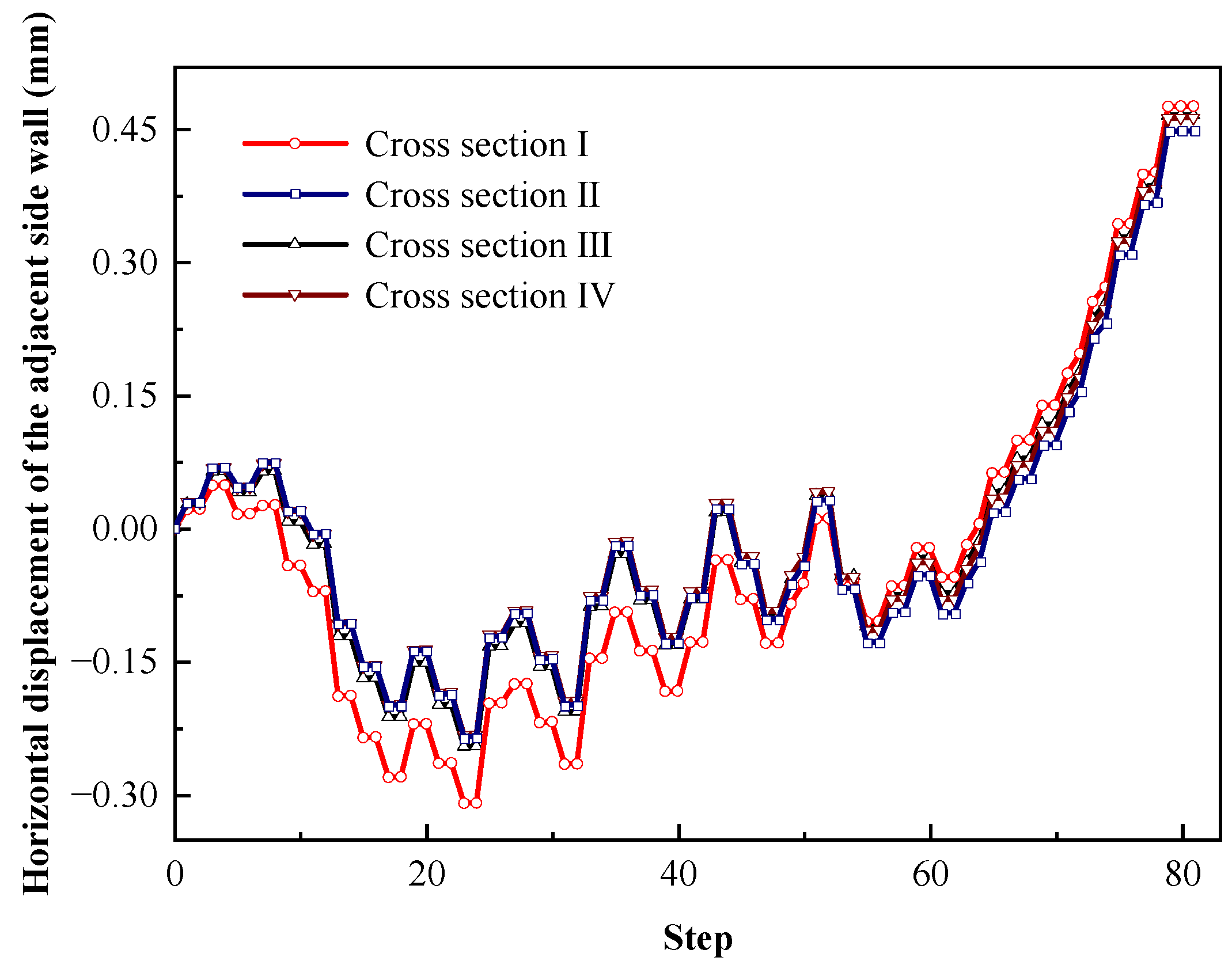

4.3.3. Horizontal Displacement of Adjacent Side Wall of Existed Tunnel

5. Numerical Analysis on Constructing Influence of Tunnel Spacing and Geological Condition

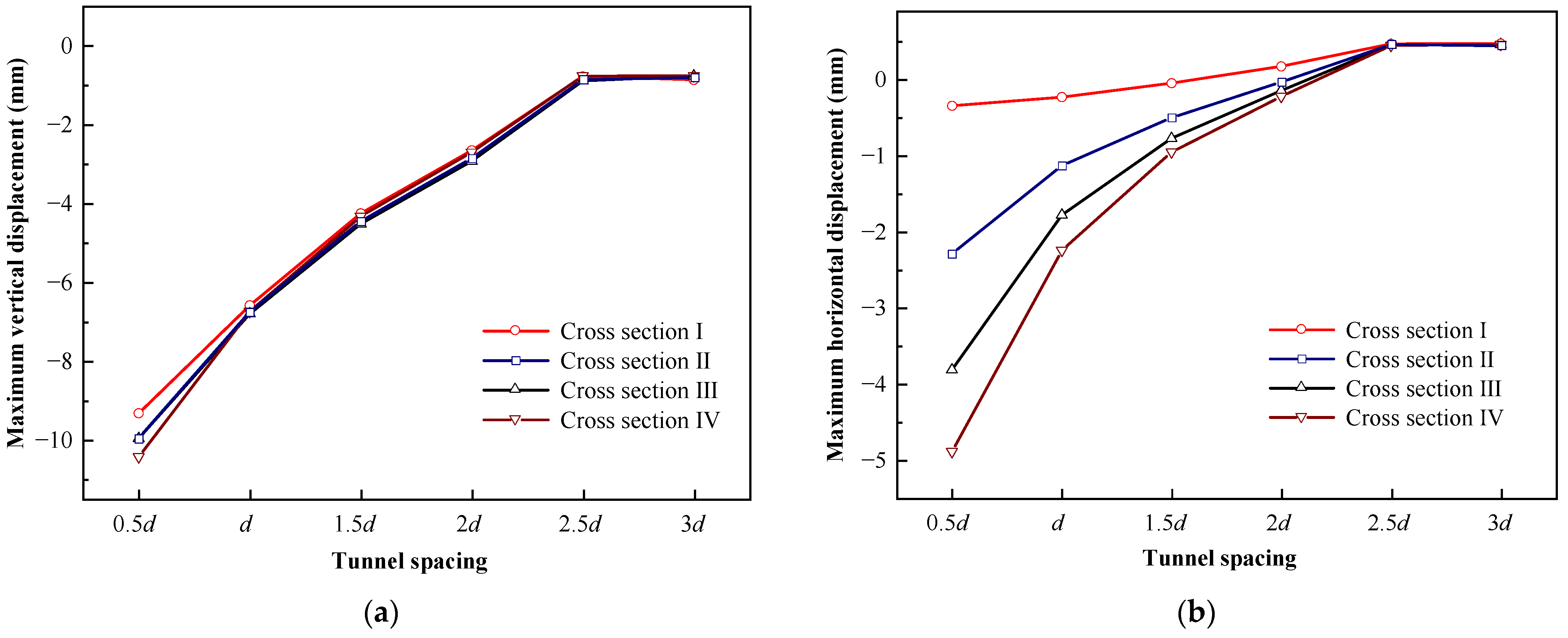

5.1. Spacing between New Constructing Tunnel and Existed Tunnel

5.2. Geological Strength Index of Surrounding Rock Mass

6. Summary and Conclusions

- The numerical analysis results based on modified GZZ constitutive model are in good agreement with real-time monitoring results. In new constructing tunnel, the vertical displacement of the vault keeps increasing in the constructing process. The horizontal displacement of the adjacent side wall has a slight rebound at last stage. This is due to the settlement of the surrounding rock at the vault, which squeezes outward the surrounding rock on the adjacent side of the new constructing tunnel. The development of the plastic zone of cross section at ZK 72 + 550 m of the new constructing tunnel indicates the divided excavation method can obviously reduce the constructing influence in weak rock mass.

- The monitoring results show that the maximum width variation of the longitudinal crack in the existed tunnel is less than 0.3 mm during the constructing process of the new tunnel. Numerical analysis shows that the maximum vertical displacement of vault is less than 1 mm, and the maximum horizontal displacement of the adjacent side wall is less than 0.5 mm. The numerical analysis indicates that the vertical displacement of the vault and the horizontal displacement of the side wall of existed tunnel show varying degrees of rebound in the later period of excavation. The main reason is that in the constructing process the redistribution of stress field causes the rock at its adjacent side wall to be squeezed and deformed toward the existed tunnel.

- Tunnel spacing between the new constructing and existed tunnels has an obvious influence on the maximum vertical displacements of the vault and the maximum horizontal displacement of the adjacent side wall of the existed tunnel. When the distance is larger than 2.5 d, the influence on existed tunnel because of excavation is not remarkable, while the effect increases rapidly with its decrease when it is less than 2 d. Therefore, it is suggested that new constructing tunnels should be kept at least 2 d away from the existed tunnel, so that the influence of excavation can be minimized. In general, poor geological conditions lead to an increase in the constructing effect of the new constructing tunnel on the existed tunnel. Therefore, it is suggested to strengthen the support of the surrounding rock when constructing a new tunnel in the weak rock mass.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Index No. 000019713O04/2022-00119; Statistical Bulletin on the Development of the Transport Industry in 2021. Ministry of Transport of the People’s Republic of China: Beijing, China, 2022.

- Li, X.G.; Yuan, D.J. Response of a double-decked metro tunnel to shield driving of twin closely under-crossing tunnels. Tunn. Undergr. Space Technol. 2012, 28, 18–30. [Google Scholar] [CrossRef]

- Do, N.A.; Dias, D.; Oreste, P. 3D numerical investigation of mechanized twin tunnels in soft ground—Influence of lagging distance between two tunnel faces. Eng. Struct. 2016, 109, 117–125. [Google Scholar] [CrossRef]

- Trinh, N.Q.; Holmøy, K.H.; Wiig, H.E. Challenging infrastructure project assisted by monitoring and numerical modelling as the follo line tunnels were excavated below existing tunnels. Rock Mech. Rock Eng. 2021, 54, 1671–1685. [Google Scholar] [CrossRef]

- Bauduin, C.; Kirstein, A.A. Design, construction and monitoring of an underwater retaining wall close to an existing immersed tunnel. Tunn. Undergr. Space Technol. 2022, 120, 104311. [Google Scholar] [CrossRef]

- Lv, J.; Lin, D.; Wu, W.; Huang, J.; Li, Z.; Fu, H.; Li, H. Mechanical responses of slurry shield underpassing existing bridge piles in upper-soft and lower-hard composite strata. Buildings 2022, 12, 1000. [Google Scholar] [CrossRef]

- Li, J.; Fang, Q.; Liu, X.; Du, J.; Wang, G.; Wang, J. Mechanical behaviors of existing large-diameter tunnel induced by horseshoe-shaped undercrossing twin tunnels in Gravel. Appl. Sci. 2022, 12, 7344. [Google Scholar] [CrossRef]

- Jin, D.; Yuan, D.; Ng, Y.C.H.; Pan, Y. Effect of an undercrossing tunnel excavation on an existing tunnel considering nonlinear soil-tunnel interaction. Tunn. Undergr. Space Technol. 2022, 130, 104571. [Google Scholar] [CrossRef]

- Charles, W.W.; Wong, Y.Y.A.; Shakeel, M. Effects of the skew angle of new tunneling on an existing tunnel: Three-dimensional centrifuge and numerical modeling. Can. Geotech. J. 2022, 59, 1728–1742. [Google Scholar]

- Fu, J.; Zhao, N.; Qu, Y.; Yang, J.; Wang, S. Effects of twin tunnel undercrossing excavation on the operational high speed railway tunnel with ballastless track. Tunn. Undergr. Space Technol. 2022, 124, 104470. [Google Scholar] [CrossRef]

- Gan, X.; Yu, J.; Gong, X.; Liu, N.; Zheng, D. Behaviours of existing shield tunnels due to tunnelling underneath considering asymmetric ground settlements. Undergr. Space 2022, 7, 882–897. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Tarifard, A.; Moridi, M.A. Time-dependent behavior of tunnel lining in weak rock mass based on displacement back analysis method. Tunn. Undergr. Space Technol. 2013, 38, 348–356. [Google Scholar] [CrossRef]

- Paltrinieri, E.; Sandrone, F.; Dudt, J.P.; Zhao, J. Probabilistic simulations of TBM tunnelling in highly fractured and faulted rocks. Tunn. Undergr. Space Technol. 2016, 57, 183–194. [Google Scholar] [CrossRef]

- Abdollahi, M.S.; Najafi, M.; Bafghi, A.Y.; Marji, M.F. A 3D numerical model to determine suitable reinforcement strategies for passing TBM through a fault zone, a case study: Safaroud water transmission tunnel, Iran. Tunn. Undergr. Space Technol. 2019, 88, 186–199. [Google Scholar] [CrossRef]

- Sharafat, A.; Tanoli, W.A.; Raptis, G.; Seo, J.W. Controlled blasting in underground construction: A case study of a tunnel plug demolition in the Neelum Jhelum hydroelectric project. Tunn. Undergr. Space Technol. 2019, 93, 103098. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, M.; Zhang, D.; Huang, H.; Chapman, D. Random evolution of multiple cracks and associated mechanical behaviors of segmental tunnel linings using a multiscale modeling method. Tunn. Undergr. Space Technol. 2019, 90, 220–230. [Google Scholar] [CrossRef]

- Iasiello, C.; Guerra, T.; Juan, C.; Torrero Fernández, C. Large deformations in deep tunnels excavated in weak rocks: Study on Y-Basque high-speed railway tunnels in northern Spain. Undergr. Space 2021, 6, 636–649. [Google Scholar] [CrossRef]

- Luo, Y.; Chen, J.; Chen, Y.; Diao, P.; Qiao, X. Longitudinal deformation profile of a tunnel in weak rock mass by using the back analysis method. Tunn. Undergr. Space Technol. 2018, 71, 478–493. [Google Scholar] [CrossRef]

- Sakcali, A.; Yavuz, H. Estimation of radial deformations around circular tunnels in weak rock masses through numerical modelling. Int. J. Rock Mech. Min. Sci. 2019, 123, 104092. [Google Scholar] [CrossRef]

- Deng, H.; Fu, H.; Shi, Y.; Zhao, Y.; Hou, W. Countermeasures against large deformation of deep-buried soft rock tunnels in areas with high geostress: A case study. Tunn. Undergr. Space Technol. 2022, 119, 104238. [Google Scholar] [CrossRef]

- Zhu, H.H.; Wu, W.; Chen, J.; Ma, G.; Liu, X.; Zhuang, X. Integration of three dimensional discontinuous deformation analysis (DDA) with binocular photogrammetry for stability analysis of tunnels in blocky rockmass. Tunn. Undergr. Space Technol. 2016, 51, 30–40. [Google Scholar] [CrossRef]

- Chen, J.Q.; Zhu, H.H.; Li, X.J. Automatic extraction of discontinuity orientation from rock mass surface 3D point cloud. Comput. Geotech. 2016, 95, 18–31. [Google Scholar] [CrossRef]

- Li, X.; Chen, J.; Zhu, H. A new method for automated discontinuity trace mapping on rock mass 3D surface model. Comput. Geotech. 2016, 89, 118–131. [Google Scholar] [CrossRef]

- Li, X.; Chen, Z.; Chen, J.; Zhu, H.H. Automatic characterization of rock mass discontinuities using 3D point clouds. Eng. Struct. 2019, 259, 105131. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Zhu, H.H. Three-dimensional Hoek-Brown strength criterion for rocks. J. Geotech. Geoenviron. Eng. 2007, 133, 1128–1135. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. Empirical strength criterion for rock masses. J. Geotech. Engrg. Div. 1980, 106, 1013–1035. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. The Hoek-Brown failure criterion: A 1988 update. In Proceedings of the 15th Canadian Rock Mechanics Symposium, University of Toronto, Toronto, ON, Canada, 3–4 October 1988; pp. 31–38. [Google Scholar]

- Hoek, E.; Brown, E.T. Practical estimates of rock mass strength. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1997, 34, 1165–1186. [Google Scholar] [CrossRef]

- Zhang, L.Y. A generalized three-dimensional Hoek–Brown strength criterion. Rock Mech. Rock Eng. 2008, 41, 893–915. [Google Scholar] [CrossRef]

- Priest, S. Three-dimensional failure criteria based on the Hoek–Brown criterion. Rock Mech. Rock Eng. 2012, 45, 989–993. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Zhu, H.H.; Zhang, L.Y. Modification of a generalized three-dimensional Hoek–Brown strength criterion. Int. J. Rock Mech. Min. Sci. 2013, 59, 80–96. [Google Scholar] [CrossRef]

- Zhu, H.H.; Zhang, Q.; Huang, B.Q.; Zhang, L.Y. A constitutive model based on the modified generalized three-dimensional Hoek–Brown strength criterion. Int. J. Rock Mech. Min. Sci. 2017, 98, 78–87. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Kolivand, F.; Ghorbani, M.; Yasrobi, S. Design of sequential excavation method for large span urban tunnels in soft ground–Niayesh tunnel. Tunn. Undergr. Space Technol. 2013, 35, 178–188. [Google Scholar] [CrossRef]

- Sonmez, H.; Ulusay, R. Modifications to the geological strength index (GSI) and their applicability to stability of slopes. Int. J. Rock Mech. Min. Sci. 1999, 36, 743–760. [Google Scholar] [CrossRef]

- Sonmez, H.; Ulusay, R. A discussion on the Hoek-Brown failure criterion and suggested modifications to the criterion verified by slope stability case studies. Yerbilimleri 2002, 26, 77–99. [Google Scholar]

- Hoek, E.; Carranza-Torres, C.; Corkum, B. Hoek-Brown failure criterion-2002 edition. In Proceedings of the Mining and Tunnelling Innovation and Opportunity: The 5th North American Rock Mechanics Symposium and 17th Tunnelling Association of Canada Conference, University of Toronto, Toronto, ON, Canada, 7–10 July 2002; pp. 267–273. [Google Scholar]

- Marinos, P.; Hoek, E. Estimating the geotechnical properties of heterogeneous rock masses such as flysch. Bull. Eng. Geol. Environ. 2001, 60, 85–92. [Google Scholar] [CrossRef]

| Surrounding Rock | Structure Rating (SR) | Roughness (Rr) | Weathering (Rw) | Infilling (Rf) | Surface Condition Rating (SCR = Rr + Rw + Rf) | GSI |

|---|---|---|---|---|---|---|

| Zone A | Blocky /Disturbed | Slightly rough | Moderate~Highly weathered | Soft <5 mm | 7 | 30 |

| 24 | 3 | 2 | 2 | |||

| Zone B | Disintegrated | Slickensided | Highly weathered | Soft <5 mm | 3 | 15 |

| 10 | 0 | 1 | 2 |

| Surrounding Rock | ρ (kg/m3) | Em (GPa) | v | UCS (MPa) | GSI | D | mi |

|---|---|---|---|---|---|---|---|

| Zone A | 2700 | 2.1095 | 0.4 | 44.5 | 30 | 0 | 7 |

| Zone B | 2660 | 0.6023 | 0.4 | 20.4 | 15 | 0 | 6 |

| Tunnel | Structures | Material | Density (kg/m3) | E (GPa) | Poisson Ratio v | Thickness (cm) |

|---|---|---|---|---|---|---|

| Existed tunnel | Primary lining | Plain concrete | 2200 | 25.5 | 0.25 | 30 |

| Secondary lining | Reinforced concrete | 2500 | 31.5 | 0.25 | 50 | |

| Floor backfilling | Plain concrete | 2400 | 28 | 0.25 | 70 | |

| New constructing tunnel | Primary lining | Plain concrete | 2200 | 25.5 | 0.25 | 26 |

| Secondary lining | Reinforced concrete | 2500 | 31.5 | 0.25 | 60 | |

| Floor backfilling | Plain concrete | 2400 | 28 | 0.25 | 60 | |

| Bolts | Steel | 7800 | 210 | 0.25 | − |

| Construction Step | 1~26 | 27~34 | 35~42 | 43~50 | 51~58 | 59~64 | 65~68 | 69~72 | 73~76 | 77~78 | 79~80 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Excavation distance (m) | 0 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Mileage of part IV [ZK (m)] | 72 + 530 | 72 + 532 | 72 + 534 | 72 + 536 | 72 + 538 | 72 + 540 | 72 + 542 | 72 + 544 | 72 + 546 | 72 + 548 | 72 + 550 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Guo, X.; Yu, T.; Shen, Y.; Liu, X. Effect of Constructing a New Tunnel on the Adjacent Existed Tunnel in Weak Rock Mass: A Case Study. Buildings 2022, 12, 1845. https://doi.org/10.3390/buildings12111845

Zhang Q, Guo X, Yu T, Shen Y, Liu X. Effect of Constructing a New Tunnel on the Adjacent Existed Tunnel in Weak Rock Mass: A Case Study. Buildings. 2022; 12(11):1845. https://doi.org/10.3390/buildings12111845

Chicago/Turabian StyleZhang, Qi, Xiaokang Guo, Tao Yu, Yixin Shen, and Xingen Liu. 2022. "Effect of Constructing a New Tunnel on the Adjacent Existed Tunnel in Weak Rock Mass: A Case Study" Buildings 12, no. 11: 1845. https://doi.org/10.3390/buildings12111845