An Experimental Study of Granular Material Using Recycled Concrete Waste for Pavement Roadbed Construction

Abstract

1. Introduction

2. Experimental Work

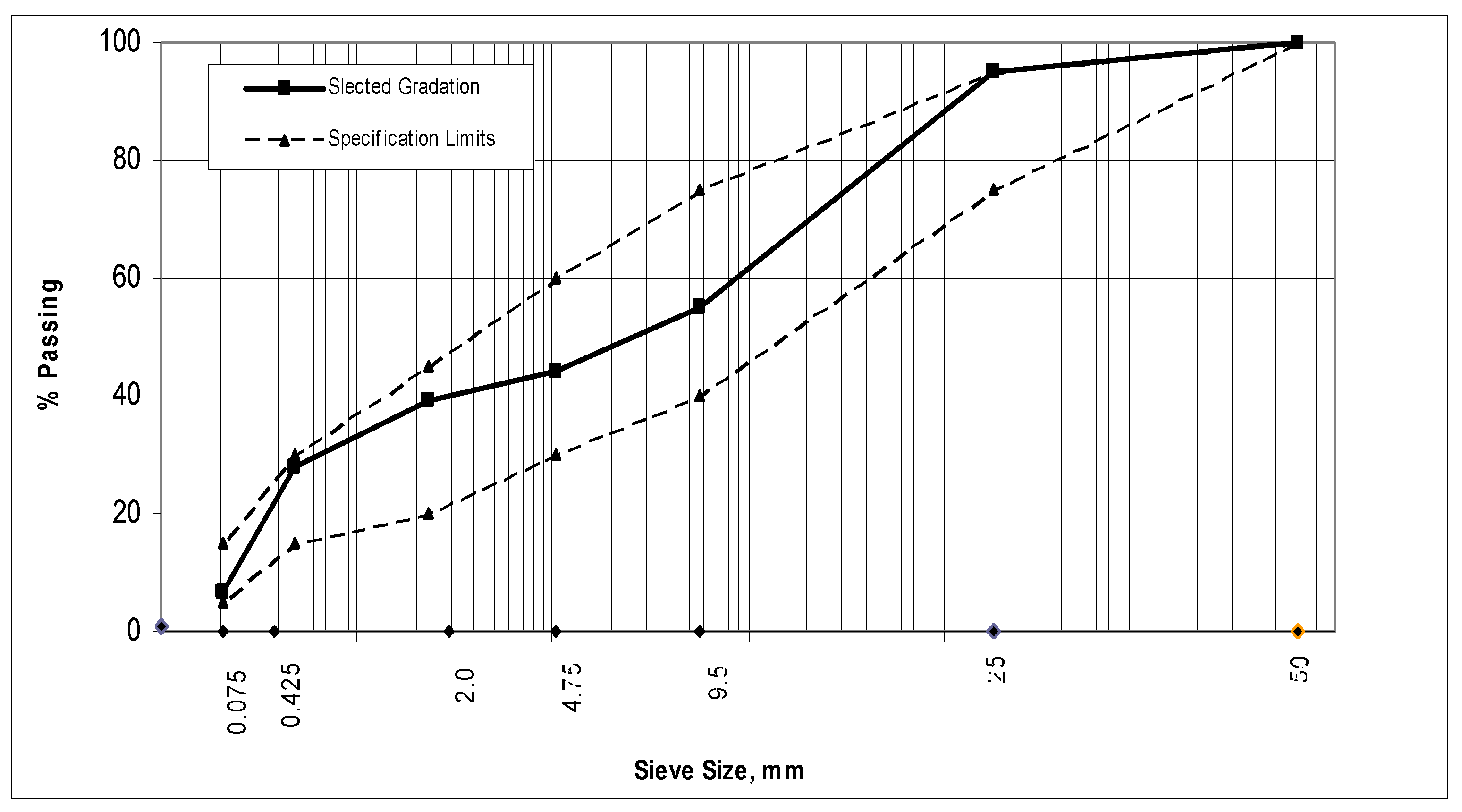

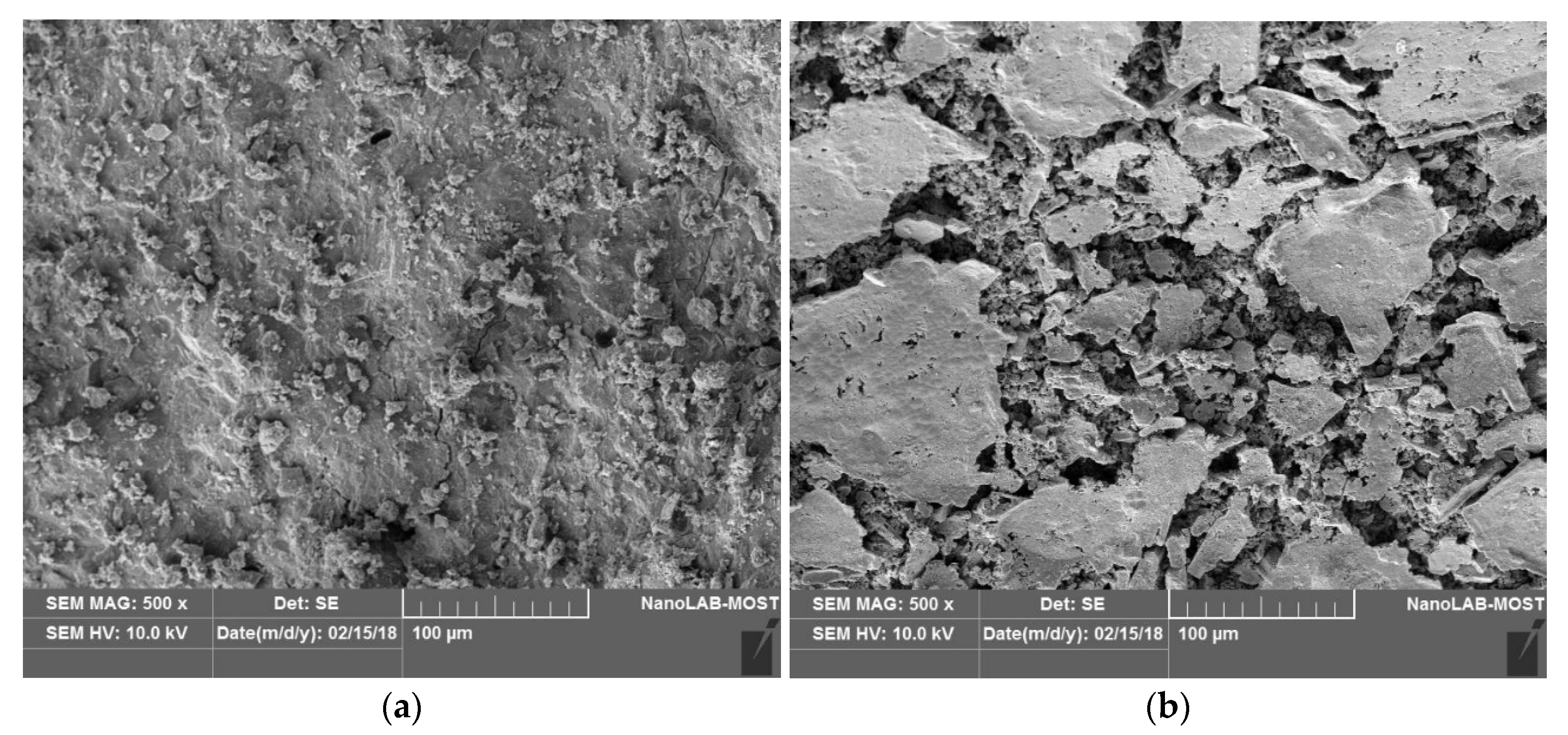

Raw Materials

3. Experimental Tests

3.1. Mositure–Density Test

3.2. California Bearing Ratio (CBR) test

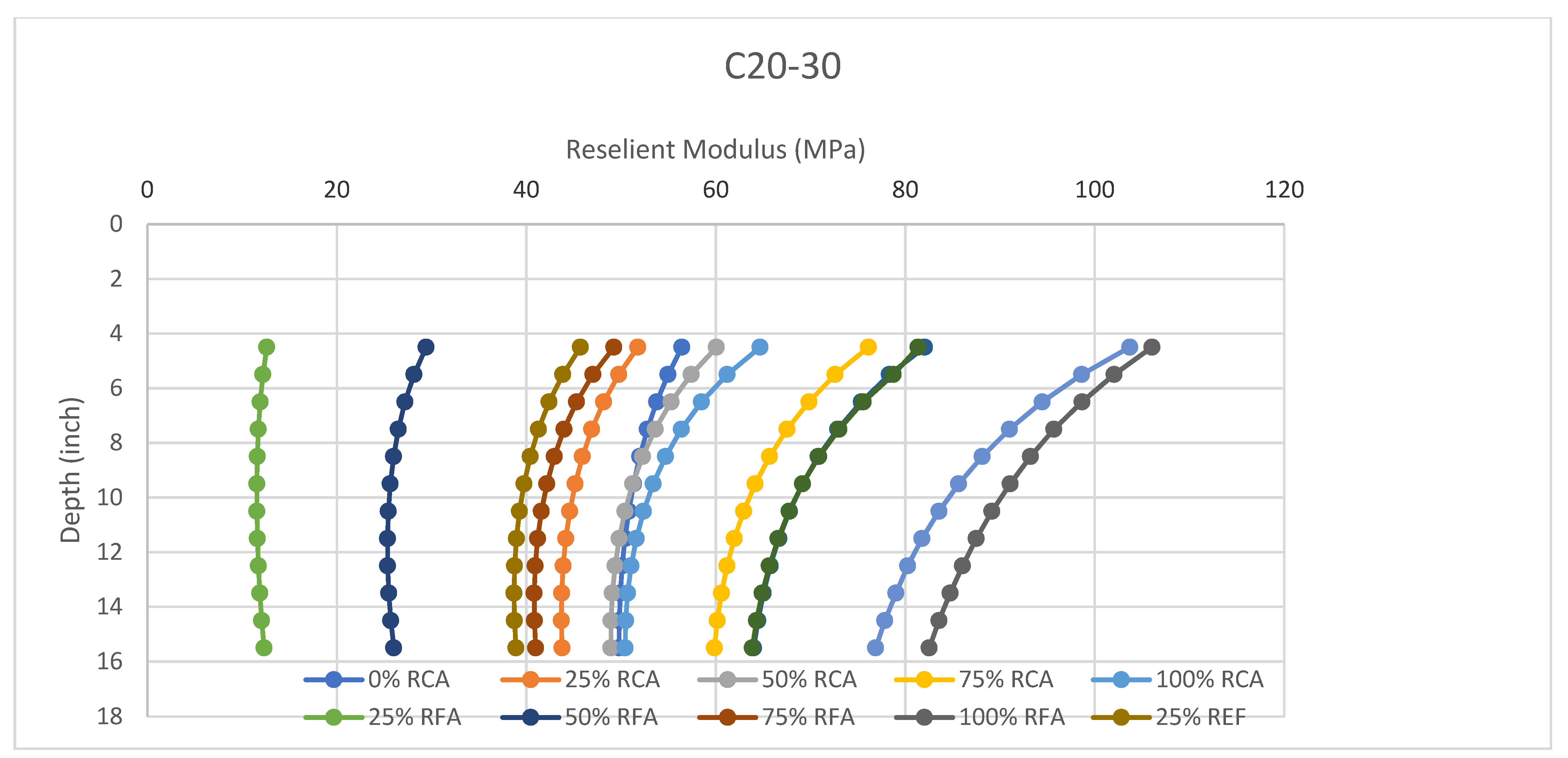

3.3. Resilient Modulus Test

4. Results and Discussion

4.1. Optimum Moisture Content (OMC %)

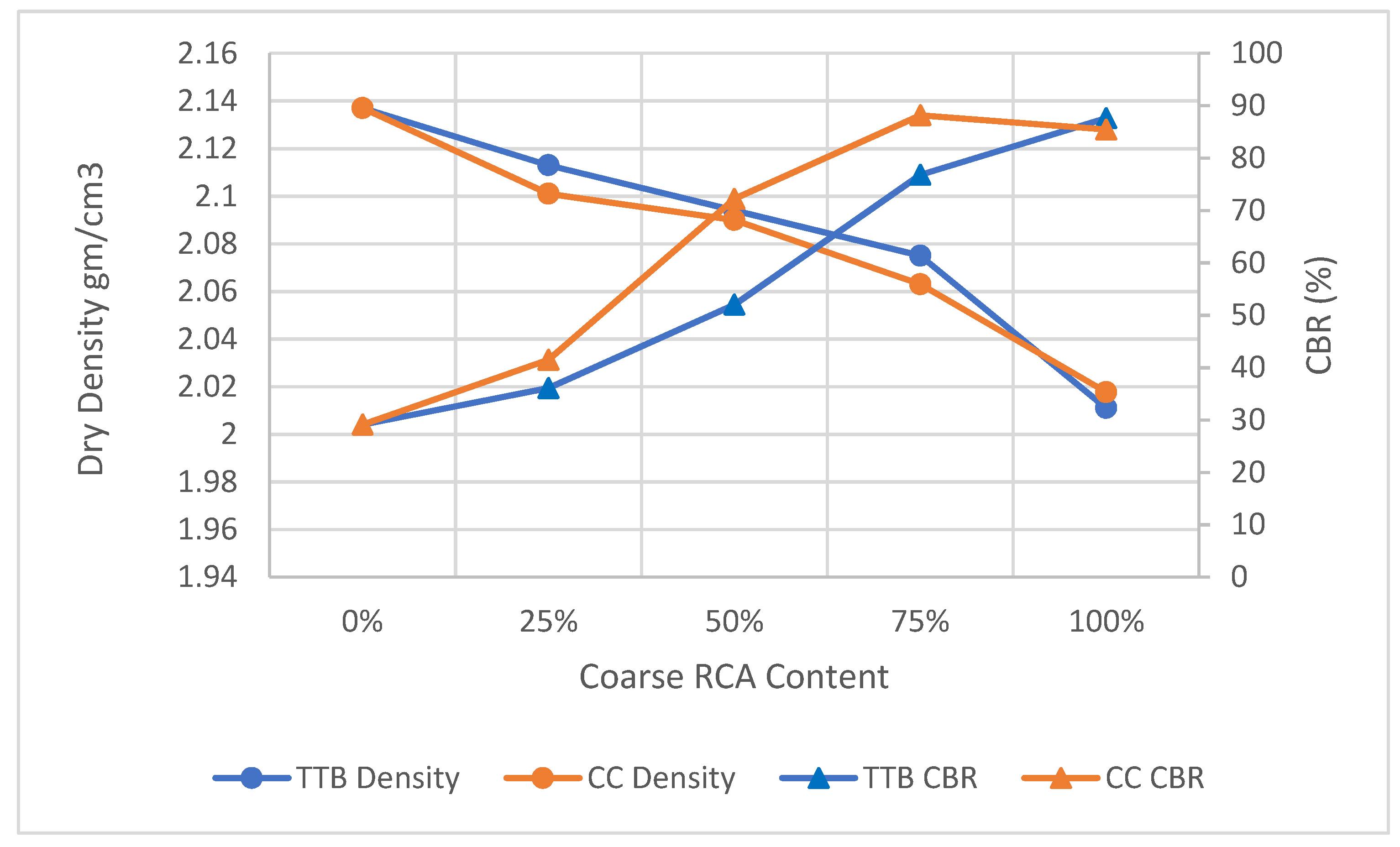

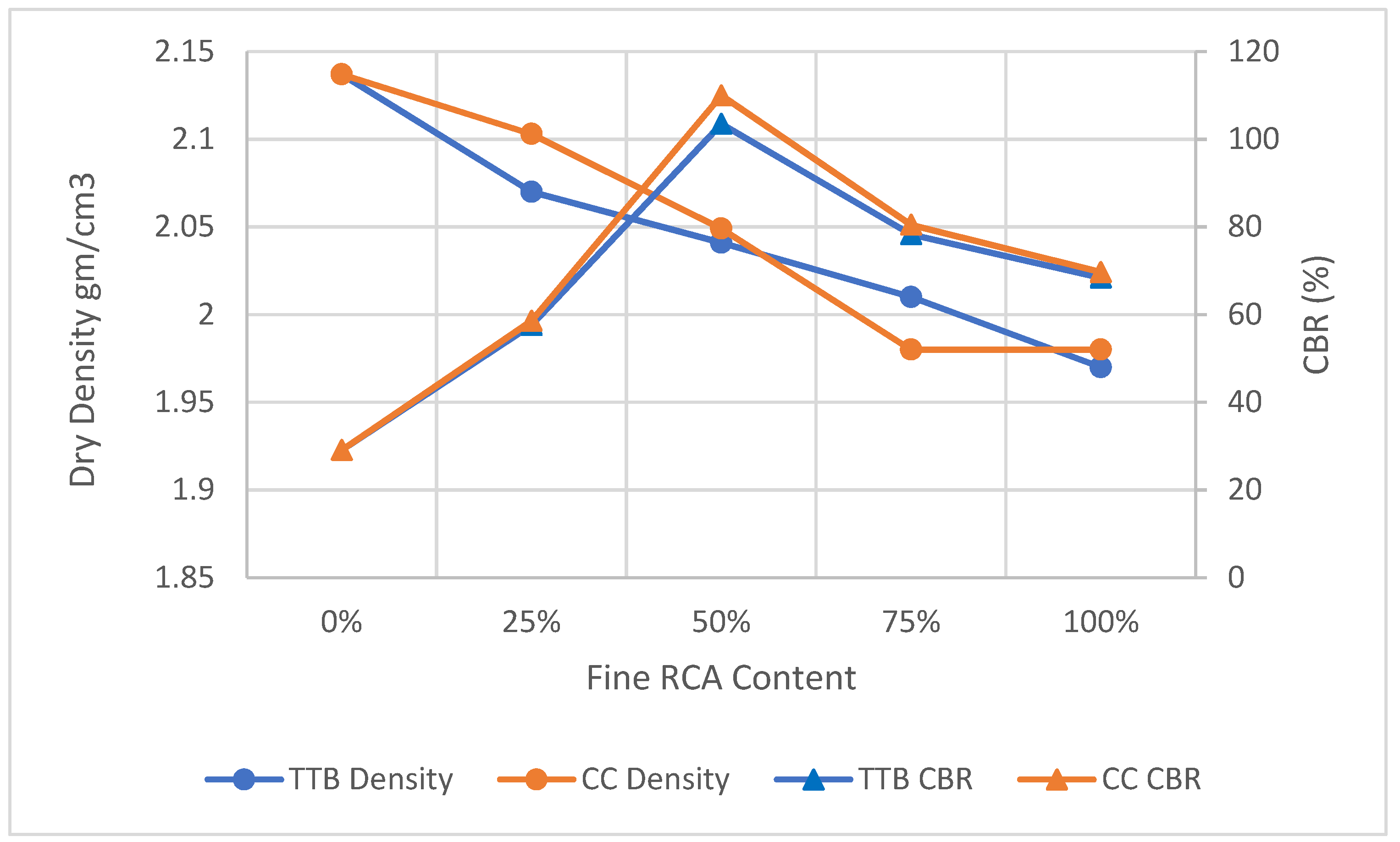

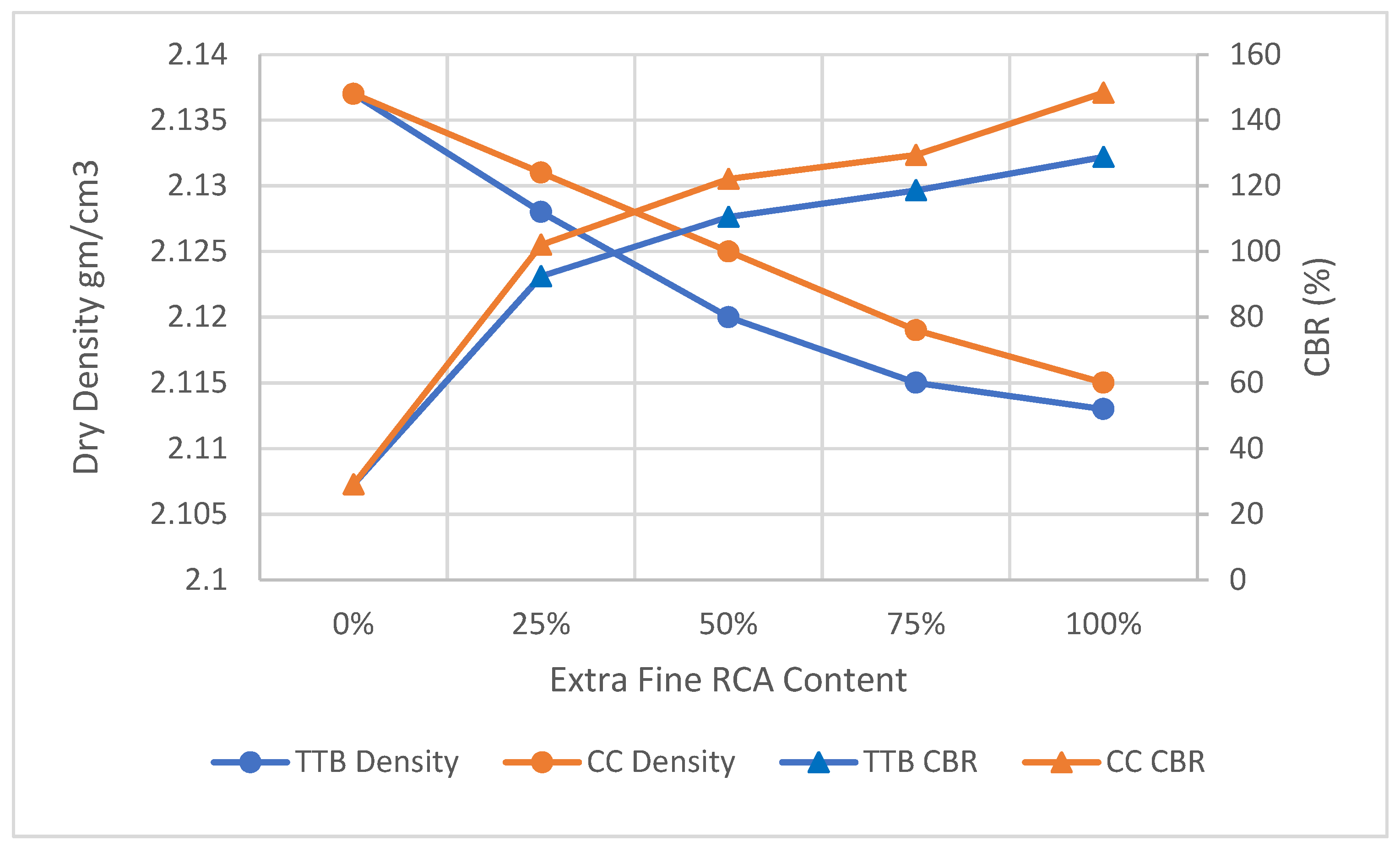

4.2. Density and CBR

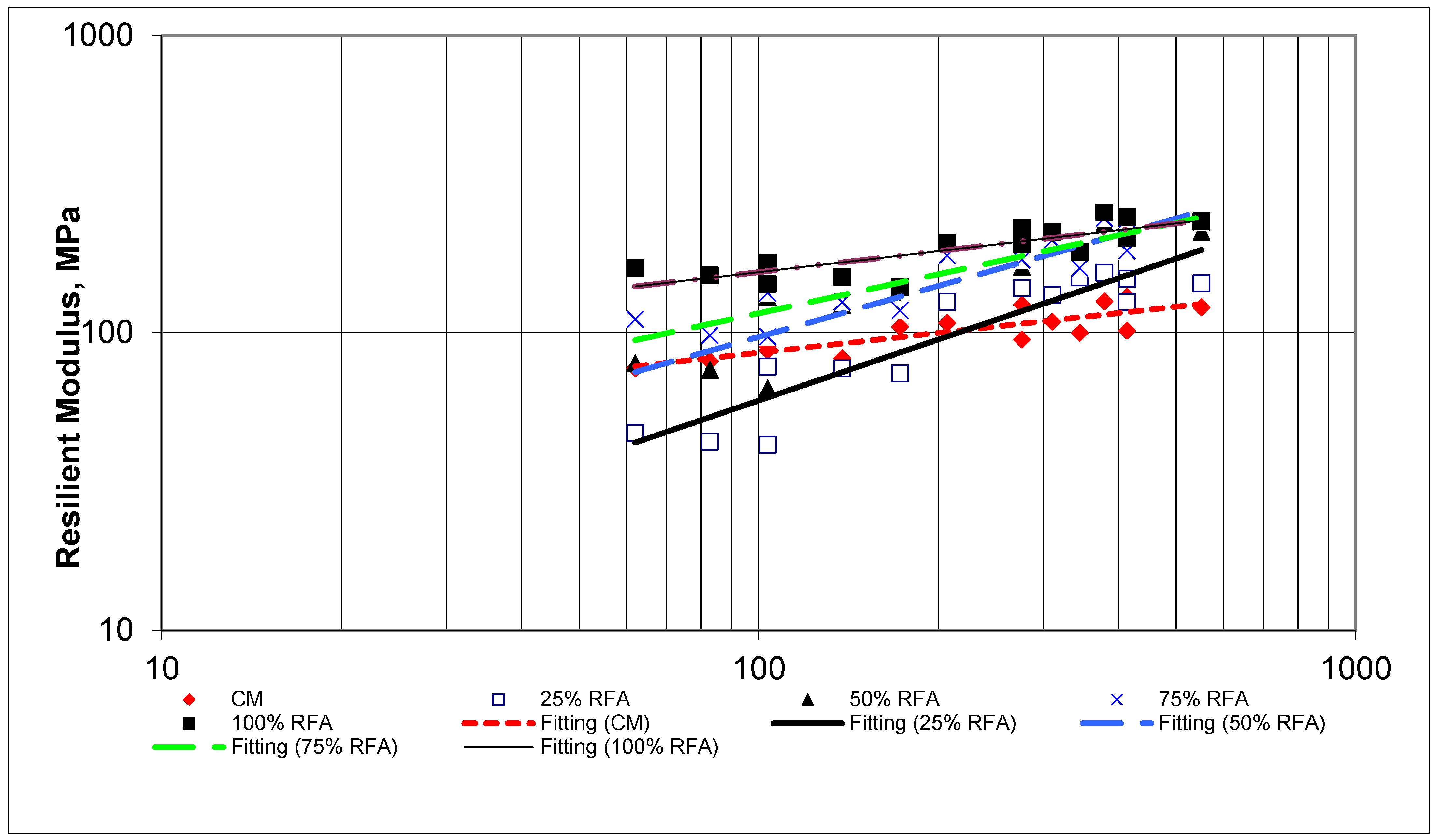

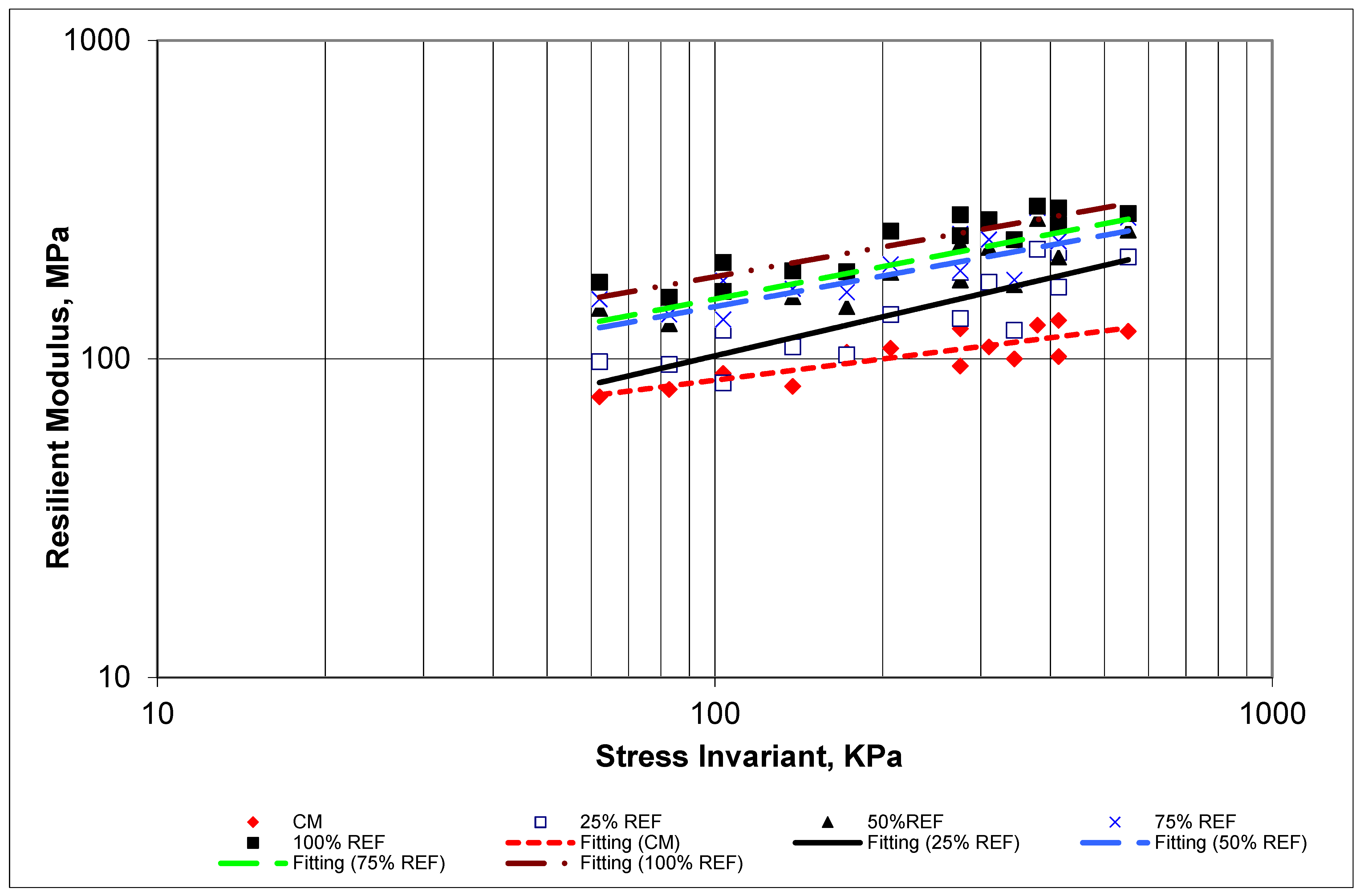

4.3. Resilient Modulus

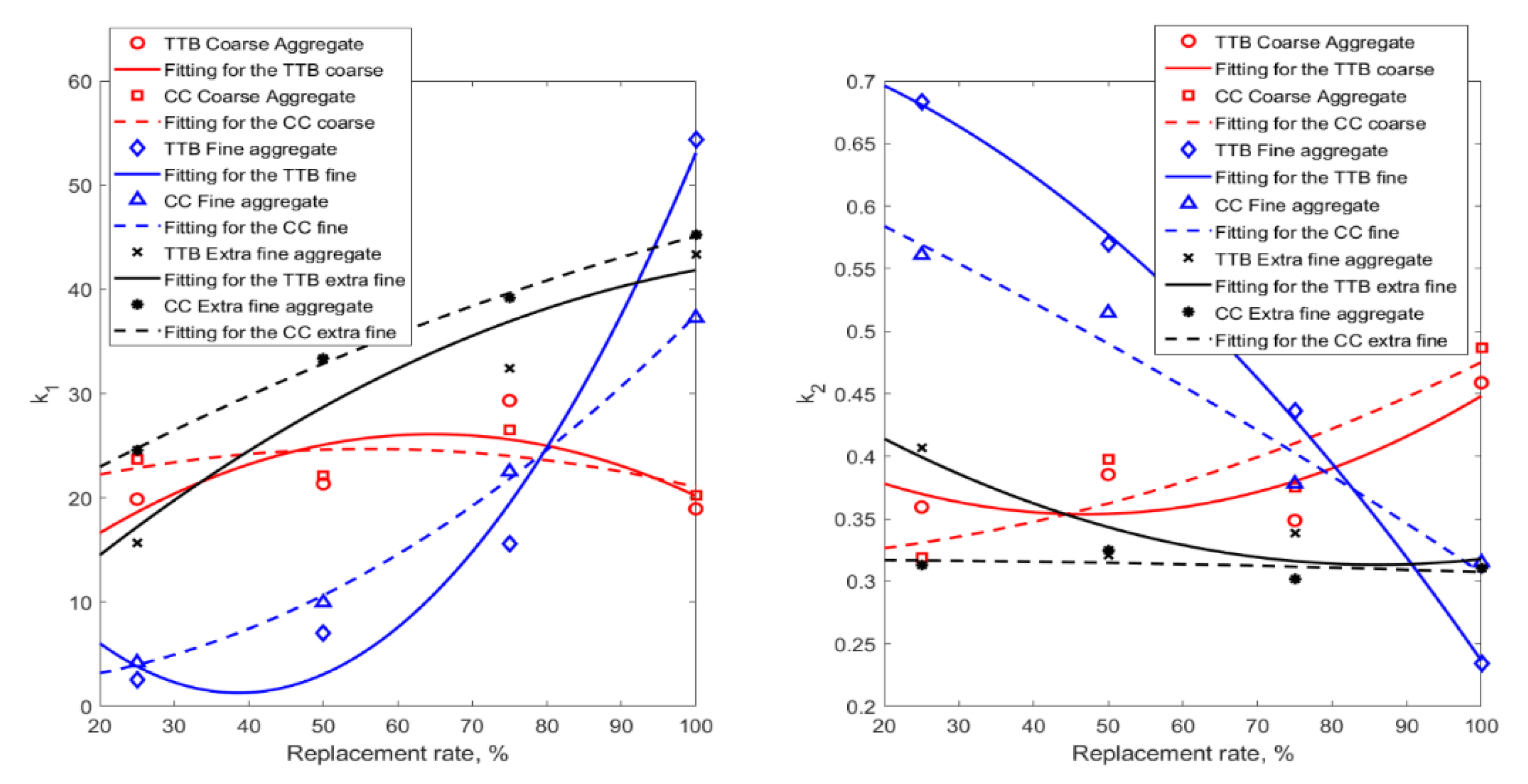

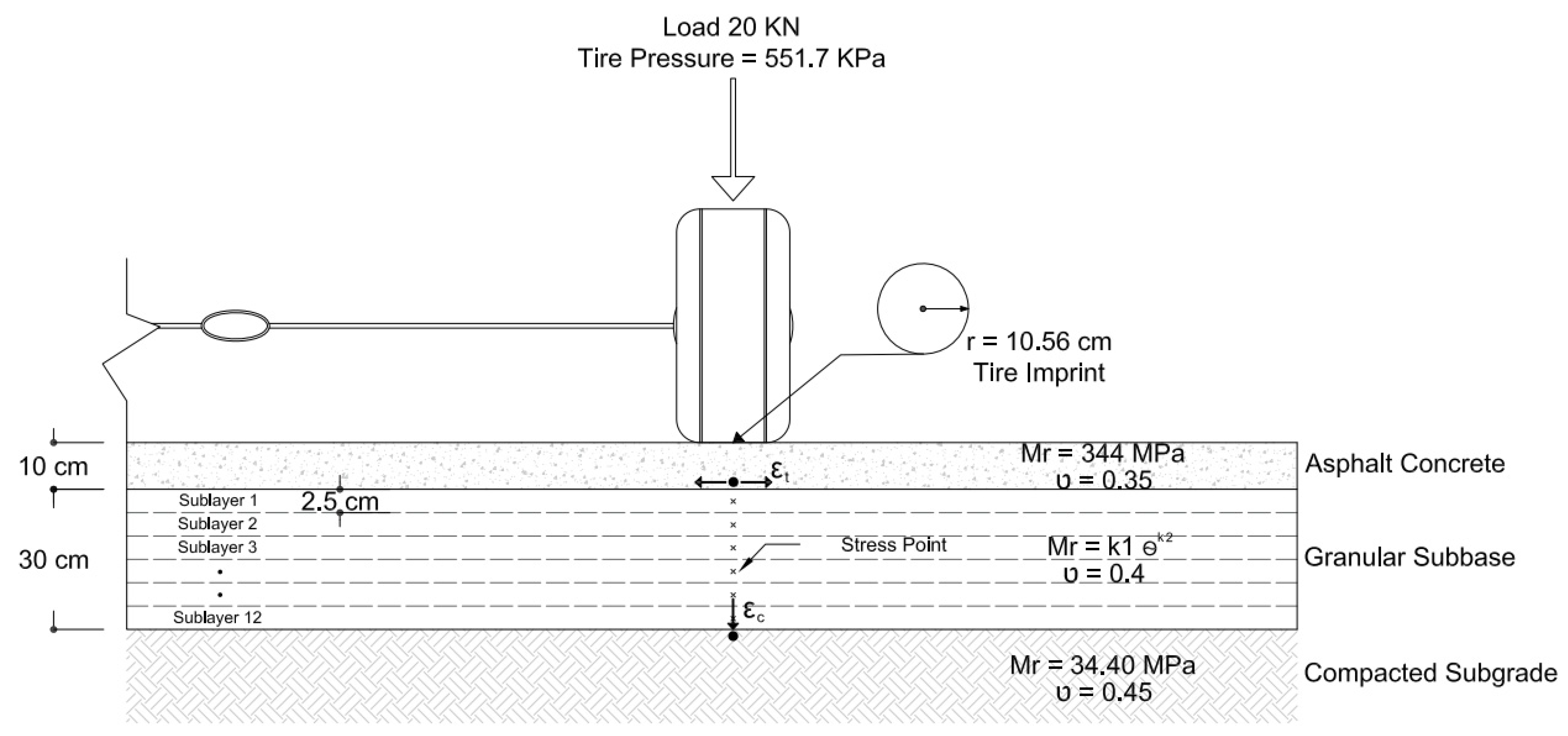

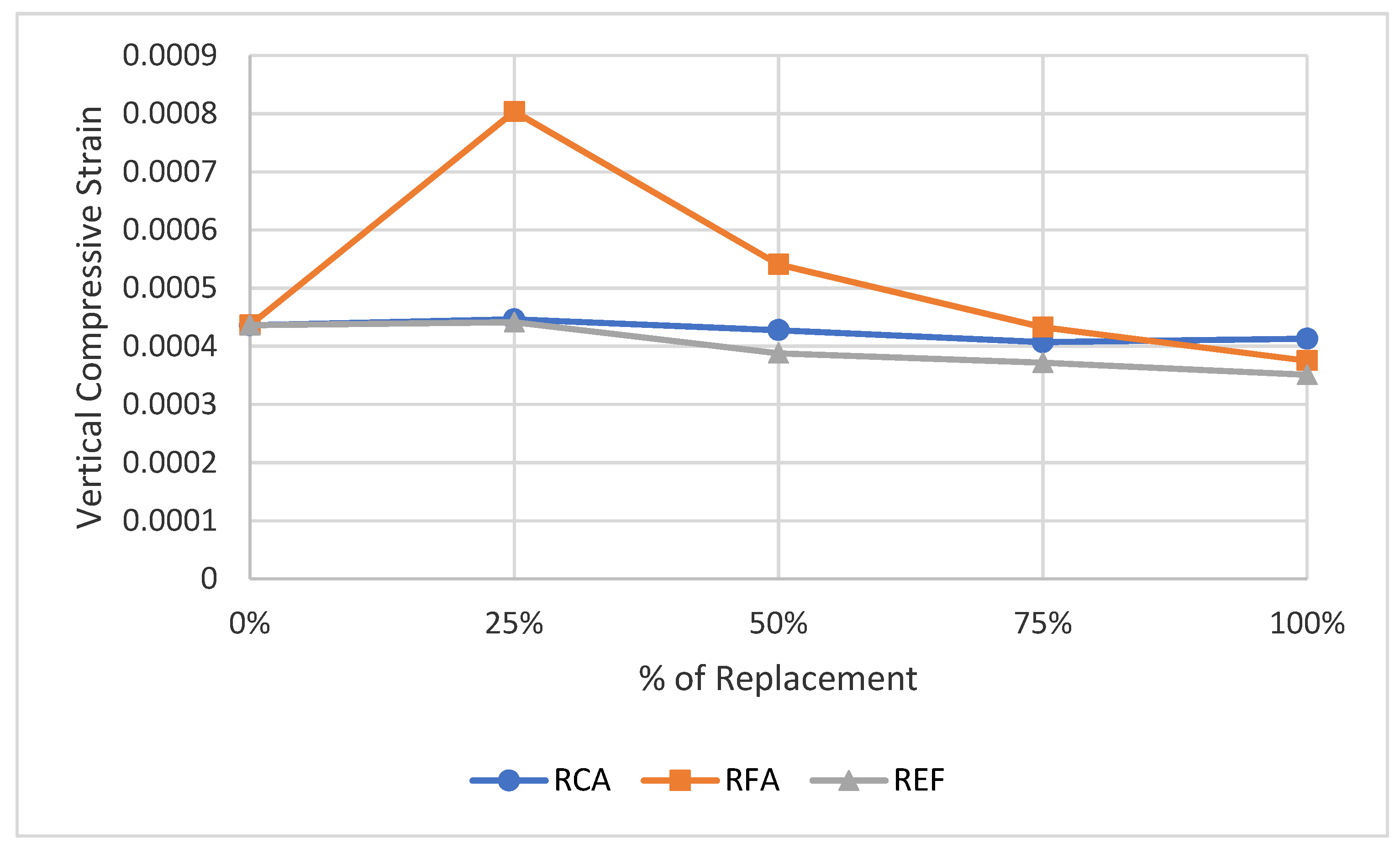

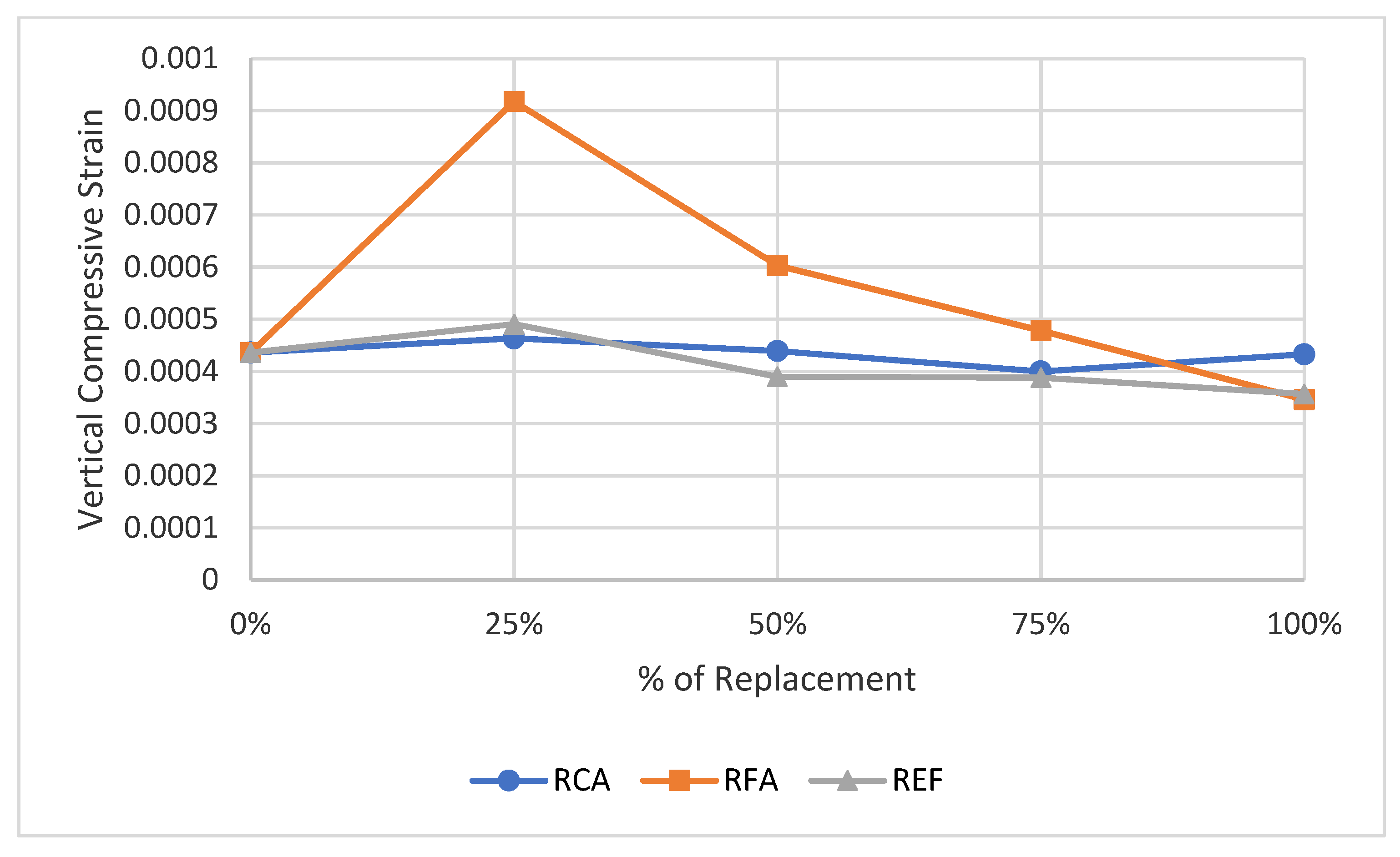

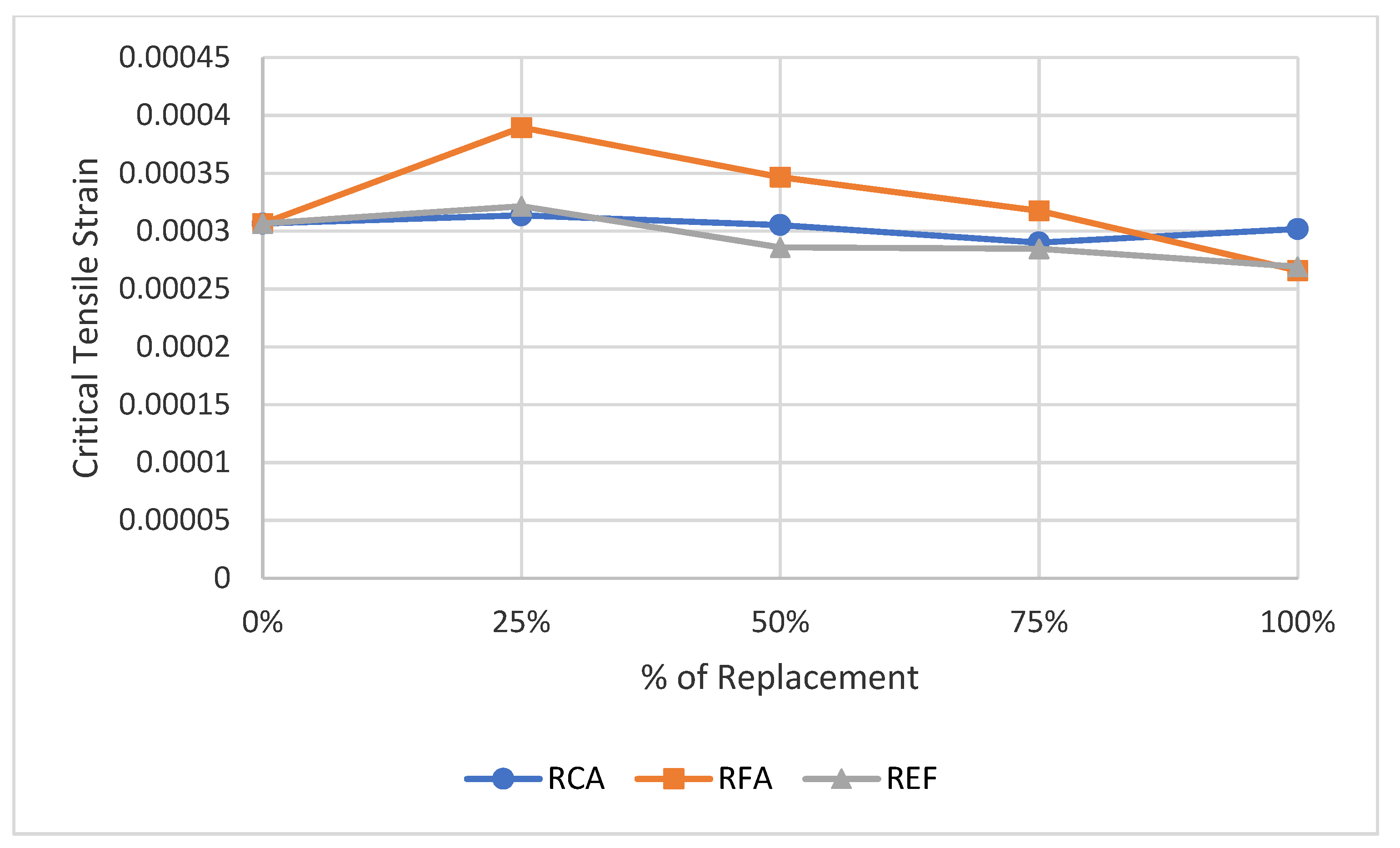

4.4. Non-Linear Pavement Analysis

5. Conclusions

- ○

- RCA can be used to replace ordinary gravel materials at full scale to meet the requirement for pavement subbase layer construction in terms of the material specification.

- ○

- RCA materials have a higher optimum moisture content in comparison with ordinary gravel material. If linearity is implied, the constant proportions would be 0.026%, 0.471%, and 0.373% for the coarse, fine, and extra fine materials, respectively.

- ○

- In general, using RCA to replace the ordinary gravel material for subbase course construction will enhance the bearing capacity and rigidness of the whole pavement structure, and the benefit would be particularly pronounced in the pavement surface layer with asphalt.

- ○

- The optimum use of replacement to obtain a higher CBR value was achieved by using 75% coarse RCA replacement, 50% fine RCA replacement, or 100% extra fine replacement.

- ○

- The 100% REF replacement minimized the critical tensile strain and maximum compressive strain when using the CC RCA type. On the other hand, the 100% RFA replacement enhanced these two parameters when using the TTB RCA type. These two recommended replacements also maximized the value of the resilient modulus.

- ○

- The use of the proposed replacement would cause the number of allowable load repetitions to increase, resulting in a longer design life of the pavement structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stone Cycling, 2021, 28 Incredible Statistics About Waste Generation: Global, US, UK & European Union. Available online: https://www.stonecycling.com/news/statistics-about-waste-generation/ (accessed on 14 September 2022).

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; The World Bank: Washington, DC, USA, 2018; Available online: https://datatopics.worldbank.org/what-a-waste/ (accessed on 21 September 2022).

- Karalar, M.; Özkılıç, Y.O.; Deifalla, A.F.; Aksoylu, C.; Arslan, M.H.; Ahmad, M.; Sabri, M.M.S. Improvement in Bending Performance of Reinforced Concrete Beams Produced with Waste Lathe Scraps. Sustainability 2022, 14, 12660. [Google Scholar] [CrossRef]

- Aksoylu, C.; Özkılıç, Y.O.; Hadzima-Nyarko, M.; Işık, E.; Arslan, M.H. Investigation on Improvement in Shear Performance of Reinforced-Concrete Beams Produced with Recycled Steel Wires from Waste Tires. Sustainability 2022, 14, 13360. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Özdöner, N.; Tayeh, B.A. Performance Assessment of Fiber-Reinforced Concrete Produced with Waste Lathe Fibers. Sustainability 2022, 14, 11817. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef] [PubMed]

- Özkılıç, Y.O.; Karalar, M.; Bilir, T.; Çavuşli, M.; Sabri, M. Use of Recycled Coal Bottom Ash in Reinforced Concrete Beams as Replacement for Aggregate. Frontiers in Materials 675, in press. Available online: https://www.frontiersin.org/articles/10.3389/fmats.2022.1064604/abstract (accessed on 21 September 2022).

- Tam, V.W. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef]

- Arabani, M.; Azarhoosh, A.R. The effect of recycled concrete aggregate and steel slag on the dynamic properties of asphalt mixtures. Constr. Build. Mater. 2012, 35, 1–7. [Google Scholar] [CrossRef]

- Marinković, S.B.; Ignjatović, I.S.; Radonjanin, V.S.; Malešev, M.M. Recycled aggregate concrete for structural use—An overview of technologies, properties and applications. In Innovative Materials and Techniques in Concrete Construction: ACES Workshop; Springer Science+Business Media B.V.: Dordrecht, The Netherlands, 2012; pp. 115–130. [Google Scholar]

- Pourkhorshidi, S.; Sangiorgi, C.; Torreggiani, D.; Tassinar, P. Using Recycled Aggregates from Construction and DemolitionWaste in Unbound Layers of Pavements. Sustainability 2020, 12, 9386. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate–A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Courard, L.; Michel, F.; Delhez, P. Use of concrete road recycled aggregates for roller compacted concrete. Constr. Build. Mater. 2010, 24, 390–395. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Y.; Wang, R.; Li, Y.; Wu, X.; Si, Z. Experimental investigation on the properties of the interface between RCC layers subjected to early-age frost damage. Cem. Concr. Compos. 2022, 134, 104745. [Google Scholar] [CrossRef]

- Seferoğlu, A.G.; Seferoğlu, M.T.; Akpınar, M.V. Investigation of the effect of recycled asphalt pavement material on permeability and bearing capacity in the base layer. Adv. Civ. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Toka, E.B.; Olgun, M. Performance of granular road base and sub-base layers containing recycled concrete aggregate in different ratios. Int. J. Pavement Eng. 2021, 1–14. [Google Scholar] [CrossRef]

- Tran, D.V.P.; Allawi, A.; Albayati, A.; Cao, T.N.; El-Zohairy, A.; Nguyen, Y.T.H. Recycled concrete aggregate for medium-quality structural concrete. Materials 2021, 14, 4612. [Google Scholar] [CrossRef]

- Alnedawi, A.; Md, A.R. Recycled concrete aggregate as alternative pavement materials: Experimental and parametric study. J. Transp. Eng. Part B Pavements 2021, 147, 04020076. [Google Scholar] [CrossRef]

- Farhan, O.S. Effect of Use Recycled Coarse Aggregate on the Behavior of Axially Loaded Reinforced Concrete Columns. J. Eng. 2019, 25, 88–107. [Google Scholar] [CrossRef][Green Version]

- Albayati, A.H.; Al-Mosawe, H.M.; Allawi, A.A.; Oukaili, N. Moisture susceptibility of sustainable warm mix asphalt. Adv. Civ. Eng. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Albayati, A.; Wang, Y.; Wang, Y.; Haynes, J. A sustainable pavement concrete using warm mix asphalt and hydrated lime treated recycled concrete aggregates. Sustain. Mater. Technol. 2018, 18, e00081. [Google Scholar] [CrossRef]

- Hama, S.M.; Hama, S.M.; Mhana, M.H. Improving Strengths of Porcelanite Aggregate Concrete by Adding Chopped Carbon Fibers. Al-Nahrain J. Eng. Sci. 2018, 21, 161–165. [Google Scholar]

- Haynes, J.H. Effects of Repeated Loading on Gravel and Crushed Stone Base Course Materials Used in the AASHO Road Test; Report; Purdue University: Lafayette, IN, USA, 1963. [Google Scholar]

- Barksdale, R.D. Laboratory evaluation of rutting in base course materials. In Proceedings of the Third International Conference on the Structural Design of Asphalt Pavements, Grosvenor House, Park Lane, London, UK, 11–15 September 1972. [Google Scholar]

- Lekarp, F.; Isacsson, U.; Dawson, A. State of the art. II: Permanent strain response of unbound aggregates. J. Transp. Eng. 2000, 126, 76–83. [Google Scholar] [CrossRef]

- Abid, A.N.; Salih, A.O.; Nawaf, E.A. The influence of fines content on the mechanical properties of aggregate subbase course material for highway construction using repeated load CBR test. Al-Nahrain J. Eng. Sci. 2017, 20, 615–624. [Google Scholar]

- Poon, C.S.; Chan, D. Feasible use of recycled concrete aggregates and crushed clay brick as unbound road sub-base. Constr. Build. Mater. 2006, 20, 578–585. [Google Scholar] [CrossRef]

- Dunlap, W.A. Deformation Characteristics of Granular Materials Subjected to Rapid, Repetitive Loading; Texas A&M University: College Station, TX, USA, 1966. [Google Scholar]

- Thai, H.N.; Nguyen, T.D.; Nguyen, V.T.; Nguyen, H.G.; Kawamoto, K. Characterization of compaction and CBR properties of recycled concrete aggregates for unbound road base and subbase materials in Vietnam. J. Mater. Cycles Waste Manag. 2022, 24, 34–48. [Google Scholar] [CrossRef]

- Signes, C.H.; Fernández, P.M.; Garzón-Roca, J.; de la Torre, M.E.G.; Franco, R.I. An evaluation of the resilient modulus and permanent deformation of unbound mixtures of granular materials and rubber particles from scrap tyres to be used in subballast layers. Transp. Res. Procedia 2016, 18, 384–391. [Google Scholar] [CrossRef]

| Property | ASTM Design | Test Results | ASTM D 1241 Specification Limit | ||

|---|---|---|---|---|---|

| CGSM | TTB RCA | CC RCA | |||

| Coarse aggregates (2 mm) | |||||

| Bulk specific gravity | C-127 | 2.631 | 2.314 | 2.332 | Not limited |

| Apparent specific gravity | 2.634 | 2.482 | 2.502 | Not limited | |

| Water absorption (%) | 0.271 | 2.98 | 2.73 | Not limited | |

| Percent wear by Los Angeles abrasion (%) | C-131 | 19 | 31 | 27 | 50 max. |

| Soundness loss by sodium sulfate solution (%) | C-88 | 4.1 | 6.9 | 6.4 | Not limited |

| Fine aggregates (<2 mm) | |||||

| Bulk specific gravity | C-128 | 2.561 | 2.092 | 2.102 | Not limited |

| Apparent specific gravity | 2.622 | 2.223 | 2.241 | Not limited | |

| Water absorption (%) | 0.809 | 4.953 | 4.303 | Not limited | |

| Plasticity index (%) | D2419 | Non Plastic | Non Plastic | Non Plastic | Max. 6 |

| Replacement Rate % | RCA of TTB | RCA of CC | ||||

|---|---|---|---|---|---|---|

| Coarse ≥2 mm | Fine 2–0.075 mm | Extra fine >0.075 mm | Coarse ≥2 mm | Fine 2–0.075 mm | Extra fine >0.075 mm | |

| 0 | Control Mix (CM) | |||||

| 25 | TTB_RCA/25 | TTB_RFA/25 | TTB_EFA/25 | CC_RCA/25 | CC_RFA/25 | CC_REF/25 |

| 50 | TTB_RCA/50 | TTB_RFA/50 | TTB_EFA/50 | CC_RCA/50 | CC_RFA/50 | CC_REF/50 |

| 75 | TTB_RCA/75 | TTB_RFA/75 | TTB_EFA/75 | CC_RCA/75 | CC_RFA/75 | CC_REF/75 |

| 100 | TTB_RCA/100 | TTB_RFA/100 | TTB_EFA/100 | CC_RCA/100 | CC_RFA/100 | CC_REF/100 |

| k1 | k2 | |

|---|---|---|

| TTB_RCA | −4.75x2 + 0.61x + 6.24 | 3.36ex2 − 3.16x + 4.28 |

| CC_RCA | −1.89x2 + 0.21x + 18.76 | 1.34x2 + 2.50x + 3.16 |

| TTB_RFA | 1.37x2 − 1.06x + 21.78 | −3.56x2 − 1.48x + 7.4 |

| CC_RFA | 3.60x2 − 3.40x + 1.82 | −6.68x2 − 2.66 x + 6.4 |

| TTB_EFA | −2.64x2 + 6.59x + 2.39 | 2.30x2 − 3.97x + 4.84 |

| CC_EFA | −1.08x2 + 4.06x + 15.3 | −1.0x2 + 6.0x + 3.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Mosawe, H.; Albayati, A.; Wang, Y.; Mashaan, N.S. An Experimental Study of Granular Material Using Recycled Concrete Waste for Pavement Roadbed Construction. Buildings 2022, 12, 1926. https://doi.org/10.3390/buildings12111926

Al-Mosawe H, Albayati A, Wang Y, Mashaan NS. An Experimental Study of Granular Material Using Recycled Concrete Waste for Pavement Roadbed Construction. Buildings. 2022; 12(11):1926. https://doi.org/10.3390/buildings12111926

Chicago/Turabian StyleAl-Mosawe, Hasan, Amjad Albayati, Yu Wang, and Nuha S. Mashaan. 2022. "An Experimental Study of Granular Material Using Recycled Concrete Waste for Pavement Roadbed Construction" Buildings 12, no. 11: 1926. https://doi.org/10.3390/buildings12111926

APA StyleAl-Mosawe, H., Albayati, A., Wang, Y., & Mashaan, N. S. (2022). An Experimental Study of Granular Material Using Recycled Concrete Waste for Pavement Roadbed Construction. Buildings, 12(11), 1926. https://doi.org/10.3390/buildings12111926