1. Introduction

With the advancement of urbanization, a large number of buildings and other structures have been built. These structures inevitably degenerate during service. The continuous accumulation of damage significantly reduces the safety and durability of structures, and likely causes engineering accidents and personnel/property losses [

1,

2]. It is of great practical significance to accurately detect the damage at the initial stage to maintain the health of the structure and ensure the safety of life and property. In recent decades, vibration-based damage diagnosis methods have received extensive attention as representatives of global damage identification technology.

Damage identification based on vibration monitoring data is one of the core problems in determining the characteristic parameters that are closely related to the structural dynamic characteristics and sensitivity to damage [

3]. In previous studies, changes in vibration characteristics (such as natural frequency, modal curvature, and flexibility) have been proven to be useful for damage identification [

4]. Compared with the natural frequency, the mode shape is more sensitive to local damage and robust to noise measurement signals [

5]. To improve the sensitivity of the damage index to small damage, Pandey et al. [

6] proposed the concept of the curvature mode shape. The second derivative of the structural mode shape curve is the modal curvature, which is more sensitive to structural damage than the mode shape [

6] and is widely used in the damage location [

6,

7,

8]. Because the modal curvatures corresponding to lower-order modal vibrations are more reliable, Wahab et al. suggested using low-order modal curvature for damage location [

7].

The damage index is often represented by the difference between the identified modal curvature and theoretical structural modal curvature in a healthy state. Because the modal curvature in the healthy state is usually unknown, Ratcliffe et al. [

9] proposed a gap-smoothing method, which uses a third-order polynomial function to reconstruct the modal curvature reference data from four adjacent data points. However, the gap-smoothing method also has some limitations [

5]: (1) the fitting baseline has poor accuracy at the boundary; and (2) because of the smoothing effect of local curve fitting, the gap-smoothing method can only locate high-degree damage.

Machine learning methods have been widely accepted as tools for feature extraction and damage detection. Aydin and Kisi [

10] applied a multi-layer perceptron (MLP) and a radial basis function (RBF) neural network to identify the structural damage of a Timoshenko beam. The results show that the trained network can be used as a diagnostic method for beam-like structure health monitoring. Zhang et al. [

11] used a one-dimensional convolutional neural network (CNN) to locate damage to a plate structure based on time-varying characteristics. This method allows the accurate location of damage in the plate with fewer sensors. Li et al. [

12] used acoustic emission waves as model inputs and neural networks to monitor rail cracks more accurately and comprehensively. Nguyen et al. [

7] used CNN to convert the first three order modal curvatures into images for training. The results showed that if the severity of the damage exceeded 30%, the accuracy of this method would reach 100%.

On the other hand, from the perspective of the model, the damage quantification problem can be defined as the optimization problem of an objective function. A large number of studies have also investigated the feasibility of optimization algorithms in the field of structural damage detection. Mehrjoo et al. [

13] used a genetic algorithm (GA) to effectively determine the location and extent of beam structure cracks. Daei et al. [

14] proposed a continuous ant colony algorithm (ACO) to detect structural damage using a dynamically measured flexibility matrix. Huang et al. [

15] combined particle swarm optimization (PSO) and cuckoo search (CA), and introduced the hybrid algorithm into the damage identification performance test of the actual steel–concrete composite bridge I-40 to effectively distinguish the actual damage and temperature effect. Kang et al. [

16] combined an artificial immune system with a PSO algorithm and proposed an immune-enhanced particle swarm optimization (IEPSO) algorithm to effectively identify the location and extent of damage. However, for practical engineering structures, to obtain more accurate damage information, the structure must be divided into smaller elements, which means that the search dimension is increased in the optimization algorithm. To overcome the curse of dimensionality [

17,

18], one solution is to consider the location and quantification of the damage as a two-stage problem. References [

19,

20] verified the feasibility of the two-stage damage-identification method. Applying the optimization algorithm to the quantitative analysis of damage based on the determined damage location can significantly reduce the search dimension and calculation time of the algorithm.

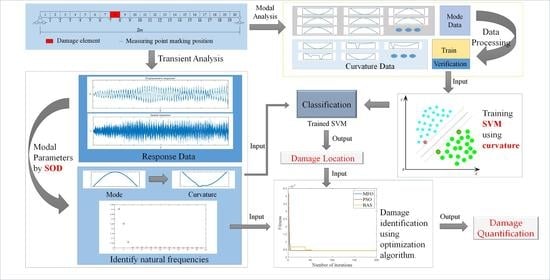

Following the idea of two-stage damage identification, this study investigated the damage identification of beam structures. Based on the analysis of the mapping relationship between the damage location and modal curvature of the beam structure, a support vector machine (SVM) is trained to locate the damage. Compared with other data-driven machine learning methods, the support vector machine can use a limited number of samples to achieve the best generalization effect [

21]; it is also favored by a large number of scholars. At the same time, studies [

21,

22,

23,

24] have shown that the SVM performs well in damage locations, but it is difficult to quantify damage. The swarm intelligence optimization algorithm can solve this problem well when it is used to identify the degree of damage. Considering the damage degree as an unknown quantity, this study uses the particle swarm optimization (PSO), moth-flame algorithm (MFO), and mayfly algorithm (MA) to calculate the damage degree. Through a large number of simulations and analyses, it is verified that the intelligent optimization algorithm can calculate the damage degree quickly and effectively. To further study the robustness of the method, four levels of noise are set for comparative analysis: no noise, 0.2% noise, 0.5% noise, and 1% noise. The uncertainty of the damage degree identification under different noise levels is analyzed using the Monte-Carlo method.

The remainder of this paper is organized as follows. The second section introduces the principle of the smooth orthogonal decomposition (SOD) and the SVM and the calculation method of normalized curvature. In

Section 3, the three swarm intelligent optimization algorithms are introduced in combination with the damage quantification problem, and the fitness function used in this study is proposed. In

Section 4, numerical examples of simply supported beams with different damage scenarios are used to verify the proposed method. In

Section 5, an uncertainty analysis of the damage degree identification of swarm intelligence algorithms is carried out using the Monte-Carlo method. Finally, this study provides a summary in

Section 6.

2. Damage Location

Damage identification is a typical inverse mathematical problem. The two-stage damage identification method divides the damage identification problem into two parts: damage location and damage quantification. Determining the location of damage is the first step. Only when the location of the damage is clear can the damage degree of the damaged part of the structure be identified, and the structure can be better warned, maintained, or replaced. In this study, using the SOD method, the observable response data are transformed into the frequency and mode shape information determined by the structural characteristics we are concerned about, and the modal curvature is obtained. After normalization, it is used as the input of the SVM model to predict the damage location.

2.1. Smooth Orthogonal Decomposition (SOD)

In the field of vibration engineering, the SOD is suitable for identifying lightly damped vibration systems with multiple degrees of freedom [

25]. Compared to the proper orthogonal decomposition (POD) method, the SOD method does not require a uniform distribution of the structural mass and can directly identify natural frequencies.

Let the matrix

denote an

ensemble of displacements obtained from

sampling time points from

sensors. The speed dataset can be represented by

. The displacement covariance matrix and velocity covariance matrix can then be expressed as

The SOD can extract mode shapes and natural frequencies from the following generalized eigenvalue problems:

where the generalized eigenvalue

is the smooth orthogonal value, and the generalized eigenvector

represents the smooth orthogonal mode corresponding to

. The generalized eigenvalue problem defined in Equation (2) can be expressed in the matrix form as follows:

where

and

. As the sampling frequency increases,

approaches the square of the natural frequency

, that is,

. The system modal matrix

is the inverse transpose of the smooth orthogonal modal matrix

, that is,

.

According to the modal superposition principle, we know that

where

denotes the ensemble data of the modal coordinate responses. The covariance matrices in Equation (1) are congruent matrices of the covariance matrices of the modal coordinate responses, as follows:

where

and

.

For undamped free vibration systems, the covariance matrices of the modal coordinate responses are diagonal. Solving the generalized eigenvalue decomposition of Equation (3) is equivalent to the eigenvalue decomposition of the

. By introducing Equation (5), we obtain

Using the transpose and symmetry of matrices, Hu et al. improved Equation (6) and proposed the following new expression [

26]:

Thus far, the estimated modal matrix can be directly obtained by the eigenvalue decomposition of the . The obtained mode shape vectors are normalized to ensure that their lengths are equal to one.

In practical applications, only low-order modes can be excited with a sufficient energy. Thus, we cannot identify all mode shape vectors completely. It is also very important to determine the order

of the identifiable mode shapes. Take the diagonal elements of

and arrange them in descending order

. Because the order of magnitude of the noise eigenvalue is much smaller than the modal eigenvalue, when

, we believe that the order of the exact modal shape is

[

20]. In this paper, when

, we consider

.

2.2. Modal Curvature

The curvature

is the second derivative of a curve [

27]:

where

is the displacement mode shape function and

is the position coordinate.

When the measuring points are arranged at equal intervals, each element

in the modal curvature matrix

can be expressed as [

27]:

where

represents the modal displacement of the

j-th measuring point for the

i-th mode, and

h represents the distance between the measuring points. Because the measuring points are arranged at equal intervals, the nominal curvature of all modes is multiplied by the

:

Simultaneously, analogous to the normalization of the mode shape vectors, the modal curvature is also normalized. We call this process normalizing, which ensures that the required modal curvature characteristics are guaranteed to be of the same order of magnitude.

The modal curvature components of the first and last measuring points cannot be calculated using Equation (10) and can be estimated by the following equation (assuming there are

measuring points):

2.3. Support Vector Machine (SVM)

The SVM is a generalized linear classifier that classifies the labeled training sample dataset. Its learning strategy is to solve the hyperplane of the optimal (maximized) margin (the minimum distance between the hyperplane and any point of the sample) of the training sample and binary classification of the training dataset [

28,

29]. A conceptual example of an SVM is shown in

Figure 1. However, it is unrealistic to expect only two damage categories for damage locations in practical engineering applications. The damage location problem is a typical multi-classification problem. When an SVM is applied to multi-classification problems, it can be considered as a series of binary classification problems, and the corresponding multi-step binary classification machines should be established.

Suppose we have a training dataset of damaged structures that has only two damage categories:

where

is the set of damage characteristic vectors and

(

) is the label corresponding to the damage eigenvector.

represents the vector under the

i-th damage condition, which refers to the normalized curvature under the

i-th damage condition. The hyperplane can be defined as:

where

is the normal vector that controls the normal direction of the hyperplane and

controls the marginal size. The

category can be judged using a hyperplane. If

, it is determined that it belongs to damage category

I. Conversely, if

, it is determined that it belongs to damage category

II. The binary classification can be expressed as the following discriminant:

where

is the sign discriminant function. If

, then

; if

, then

.

When

is determined, adjusting

can cause some sample points of damage conditions to fall on

and

. These characteristic vectors are called the support vectors. The functional margin from the sample point

to the hyperplane under any damage condition can be defined as follows:

There is significant uncertainty in the function margin. If the parameters

and

are synchronously magnified, the hyperplane will not change, but the function margin

will be magnified. Therefore, it is necessary to normalize

and

to obtain the geometric margin:

The geometric margin that passes through the plane of the two support vectors and is consistent with the normal direction of the optimal hyperplane, that is, the geometric interval between

and

, can be expressed as:

The hyperplane for solving the optimal (maximized) margin of the training sample can be transformed into the following equivalent convex quadratic problem:

The Lagrange function is introduced to solve Equation (18):

where

denotes the Lagrange multiplier vector. According to the Karush–Kuhn–Tucker condition for the differentiable convex problem, the dual problem of Equation (19) can be obtained as [

30]:

Assuming that the optimal solution determined by Equation (20) is

, the two parameters that control the hyperplane can be determined by:

where

is the index set of all support vectors and

denotes the cardinality of the set

.

However, in practical engineering applications, the data are usually linearly indivisible. In this case, the kernel SVM is constructed using a nonlinear mapping function:

where

is a nonlinear mapping function. Similarly, it can be transformed into a convex quadratic problem:

The dual problem of Equation (23), similar to Equation (20), can also be constructed as follows:

If the kernel function is defined as

, then Equation (24) can be expressed as:

For the real Euclidean space, the Mercer condition guarantees the arbitrariness of the kernel function

[

31]. In this manner, we map the linearly indivisible data from the low-dimensional feature space to the high-dimensional feature space. In a high-dimensional space, the original nonlinear separable data will become linearly separable. In this study, because the data are linearly separable, we use the simplest linear kernel function, whose expression is:

By substituting Equation (26) into Equation (25), we find that it is the same as in Equation (20). Therefore, these two parameters are obtained from Equation (21).

4. Numerical Example

The beam structure is divided into 20 elements, and the model is established and simulated using finite element analysis software. The beam model is shown in

Figure 3. The span of the simply supported beam is

and the section size is

, the Young’s Modulus is

, the density is

, and the Poisson’s ratio is

.

The local damage of this simply supported beam is simulated by reducing the elastic modulus of a specific element [

20], as follows:

where

represents the elastic modulus of the

i-th damaged element, and

represents the percentage of stiffness reduction of the

i-th element (represented as the degree of damage in this study). Gaussian white noise is used as random excitation, and the transient dynamic analysis of the model is carried out to obtain the displacement and velocity response data of each node. At the same time, in order to study the noise robustness of the proposed damage identification method, 0.2%, 0.5%, and 1% noise are added to the extracted displacement and velocity response data, respectively. The signal is contaminated by white noise in terms of:

where

indicates the noise level,

is the covariance of the original signal,

is sequence length of the original signal,

is a subroutine to generate normal distribution random numbers,

X represents the original signal, and

indicates the signal polluted by white noise.

4.1. Single Damage Condition

The damage degree of each element of the established simply supported beam from 1% to 90% (increasing by 1%) is simulated separately, the first-order mode of each damage model is extracted, and the modal curvature is calculated. Through the above operations, we obtain groups of data. Another 90 groups of data calculated for the undamaged beam are added to the dataset, and a total of 1890 groups of data are used as the dataset. Using a 75–25 split, the training and verification sets contained 1417 and 473 groups of data, respectively. The SVM model is trained using these data. The damage location of the above datasets is identified using the SVM. The results show that the recognition accuracy of the damage location of the training and verification sets reaches 100%. It can be seen that the SVM can make a good judgment on the location of a single point of damage in the simulated cases.

To further determine the accuracy and robustness of the SVM model, 10%, 15%, 20%, and 25% damage is preset for each element of the simply supported beam. White noise excitation is used to excite the damage model for transient dynamic analysis, and the displacement and velocity response data are obtained. White noise with different degrees is added to the responses (the noise levels are 0.2%, 0.5%, or 1%). The mode shapes and natural frequencies of the structure are extracted using the SOD. As shown in

Figure 4, for the eighth element with 20% damage, under the influence of 0.5% noise degree, we can determine and extract the modal parameters of the

mode order. The frequencies identified by the SOD and those extracted using ANSYS are compared in

Table 1. The results show that under different noise levels, the differences between the first three frequency identification values and the extracted values are within 0.15%, indicating that the SOD method can accurately identify the frequencies of a single damaged simply supported beam.

The modal energies of each excitation order are often different. To accurately evaluate the performance of the established SVM model, the test set is composed of the identified modal shape curvatures with the largest modal energy, which is the first-order modal parameter obtained by the SOD method. The statistical verification results for the test set are shown in

Figure 5. The results show that the localization accuracy of the SVM for the damage location increases with an increase in the damage degree. The more serious the damage, the easier it is to detect. When the damage is 10% and the noise level reaches 1%, the accuracy of the SVM model is more than 85%. When the noise level is reduced to 0.5%, the recognition accuracy reaches 97.56%, which is significantly improved. When the noise level drops to 0.2%, the position recognition accuracy reaches 100%, even if the local damage is 10%. When the degree of damage reaches 15%, the accuracy is still above 95%, even in the case of high-level noise. At the same time, when the damage degree reaches 20%, even under the influence of 0.5% noise, the localization accuracy reaches 100%. The statistical results show that the damage location method based on the SOD-SVM can effectively identify the damage location under a single damage condition. After the location of the damage element is determined, the subsequent damage degree optimization model is reduced to a one-dimensional search problem.

The eighth element is chosen as the damaged element to illustrate the performance of the searching algorithm. After the SVM determines that the damage element is the eighth element, the stiffness loss ratio of the eighth element is set as an unknown parameter and the first three frequencies are substituted into the fitness function. The search range of the stiffness loss ratio of the element is set to [0, 1]. The fitness evolution of the three swarm intelligent optimization algorithms with an increase in the iteration number is shown in

Figure 6. It can be observed that after the dimension is reduced, all three algorithms can converge quickly. The results of the stiffness loss ratio of the damaged element calculated by the three algorithms under different noise levels are listed in

Table 2. The results demonstrate that swarm intelligence algorithms have good accuracy in the damage identification of simple supported beams with single damage. It should also be noted that the greater the noise level, the greater the deviation in the predicted damage degree. At a noise level of 1%, the maximum error is 8.70%.

4.2. Multiple Damage Condition

Two-element damage is used to represent multi-element damage. The structural damage of each element of the simply supported beam from 10% to 90% (increased by 10%) is simulated separately, the first-order mode of each damage model is extracted, and the modal curvature is calculated. Through the above operations, we can obtain 15,390 groups of data. Another 81 groups of data for calculated undamaged and 1620 groups of data for single damage of each element are added to the dataset, and a total of 17,091 groups of data are used as the dataset. Using a 75–25 split, the training and verification set had 12,818 and 4273 groups of data, respectively. The SVM model is trained using these data. The damage location of the above datasets is identified using the SVM. The results show that the recognition accuracy of the damage location of the training set is 100%, and that of the verification set is 99.91%. It can be seen that the SVM can also make a good judgment on the location of multiple damages in the simulated cases.

Similarly, 10%, 15%, 20%, and 25% damages are preset for each of the two elements of the simply supported beam. White noise excitation is used to excite the damage model for transient dynamic analysis, and displacement and velocity response data are obtained. White noise with different degrees is added to the responses (the noise levels are 0.2%, 0.5%, or 1%). As shown in

Figure 7, for the fifth element with 30% damage and the tenth element with 20% damage, under the influence of 1% noise degree, we can determine and extract the modal parameters of the

mode order. The frequencies identified by the SOD and those extracted using ANSYS are compared in

Table 3. The results show that under different noise levels, the differences between the first three frequency identification values and the extracted values are within 0.15%, which indicates that the SOD method can accurately identify the frequencies of multiple damaged simply supported beams.

Similarly, the test set is composed of the identified modal shape curvatures with the largest modal energy, which is the first-order modal parameter obtained using the SOD method. The statistical verification results for the test set are shown in

Figure 8. The results show that the localization accuracy of the SVM for the damage location increases with an increase in the damage degree. The more serious the damage, the easier it is to detect. When the damage is 10% and the noise level reaches 1%, the accuracy of the SVM model is only 60%; however, when the noise level is reduced to 0.5%, the recognition accuracy reaches 93.2%, which is significantly improved. When the noise level drops to 0.2%, the position recognition accuracy reaches 98%, even if the local damage is 10%. When the damage degree reaches 20%, the accuracy is still above 83.2% even in the case of high-level noise. When the damage degree reaches 25%, the accuracy is still above 91.2%, even in the case of high-level noise. At the same time, when the damage degree reaches 20%, even under the influence of 0.5% noise, the localization accuracy reaches 99%. The statistical results show that the damage location method based on the SOD-SVM can effectively identify the damage location under multiple damage conditions. After the location of the damage elements is determined, the subsequent damage degree optimization model is reduced to a two-dimensional search problem.

To illustrate the performance of the search algorithm, the fifth and tenth elements are selected as the damaged elements. After the SVM determines that the damage elements are the fifth and tenth elements, the stiffness loss ratios of the fifth and tenth elements are set as unknown parameters, and the first two frequencies are substituted into the fitness function. The search range of the stiffness loss ratios of the element is set to [0, 1]. The fitness evolution of the three swarm intelligent optimization algorithms with an increase in the iteration number is shown in

Figure 9. It can be observed that after the dimension is reduced, all three algorithms can converge quickly. The results of the stiffness loss ratio of the damaged element calculated by the three algorithms under different noise levels are listed in

Table 4. The results demonstrate that swarm intelligence algorithms have good accuracy in the damage identification of simple supported beams with single damage. It should also be noted that the greater the noise level, the greater the deviation in the predicted damage degree. At a noise level of 1%, the maximum error is 10.20%.

6. Conclusions

In this study, a two-stage damage identification method for beam structures based on an SVM and swarm intelligence algorithms is studied, and the method is verified by a simple supported beam example. First, the normalized modal curvature is calculated, the mapping relationship between the damage location and modal curvature of the beam structures is established, and the SVM model for the damage location is trained. Based on the pre-trained SVM damage location model, the SOD method is introduced to identify the mode shape of the damaged structure. The modal curvature, which is used as the input data of the SVM model for damage location, is calculated using the second-order central difference of the identified mode shapes. The SOD-SVM damage location method is affected by noise when the degree of damage is low. Nevertheless, at a noise level of 0.5% and below, it can accurately locate the damage, even in the case of small damage. In the second step, the stiffness loss of the damaged element located by the SVM is considered as the optimization objective of the swarm intelligence algorithms. Combined with the frequencies obtained by the SOD method, the three swarm intelligent algorithms (PSO, MFO, and MA) are used to calculate the stiffness loss of the damaged element. The results show that all three swarm intelligence algorithms can converge quickly. Even in the case of strong noise pollution, the deviation in the calculated damage is still small (mean deviation within 3%). The Monte-Carlo method is used to calculate the degree of damage under the influence of different noise levels. It is found that the greater the noise, the more dispersed the calculation of damage degree and the greater the uncertainty; the greater the degree of damage, the more accurate the value of the damage calculation results, and the smaller the uncertainty. In summary, the method proposed in this study can accurately identify damage to beam structures. Even under the influence of noise, this method is reliable. In the future, it is necessary to study the application of this algorithm in the damage identification of complex structures.