Probabilistic Modeling for Cementitious Materials Based on Data of Nanoindentation

Abstract

:1. Introduction

2. Materials and Methods

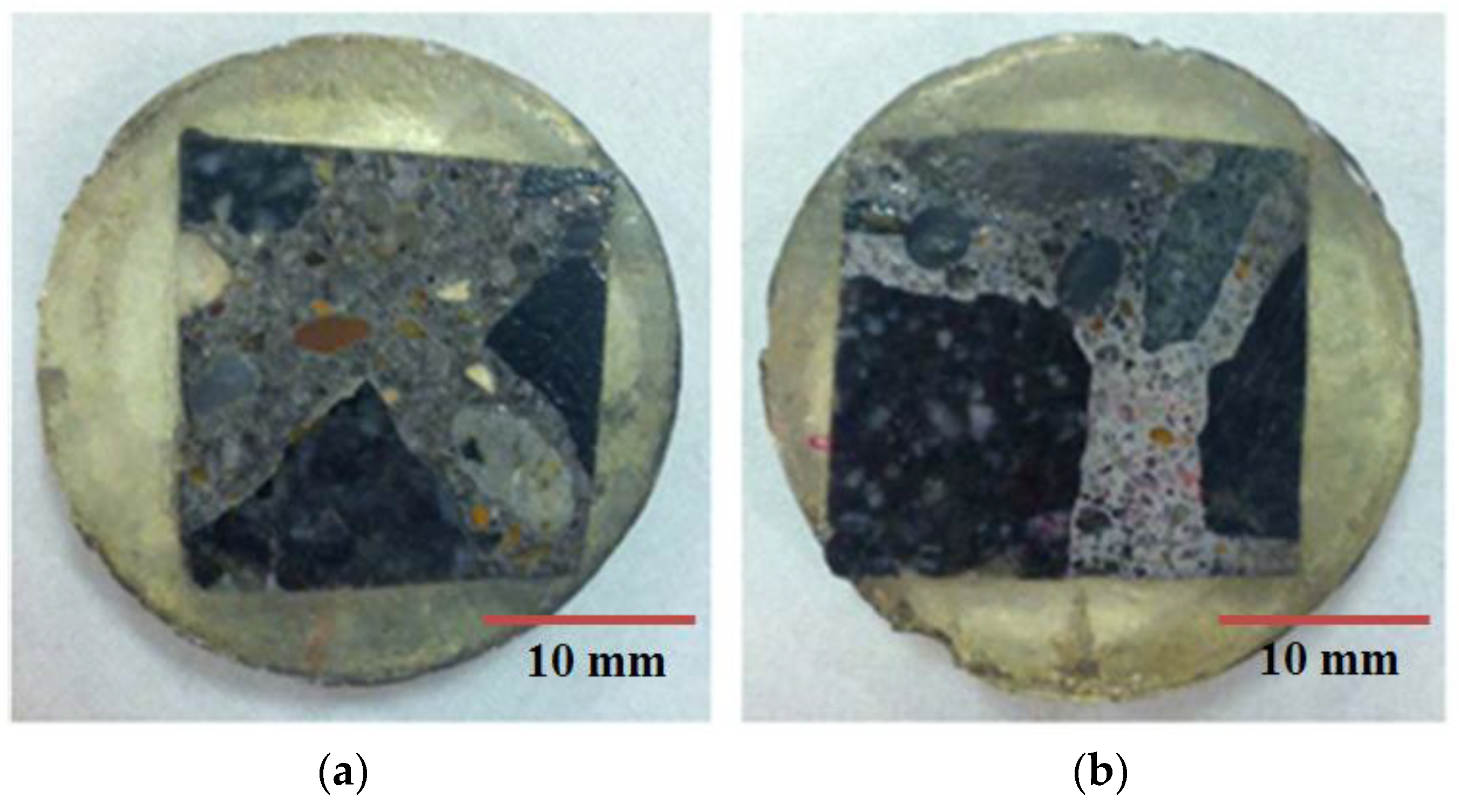

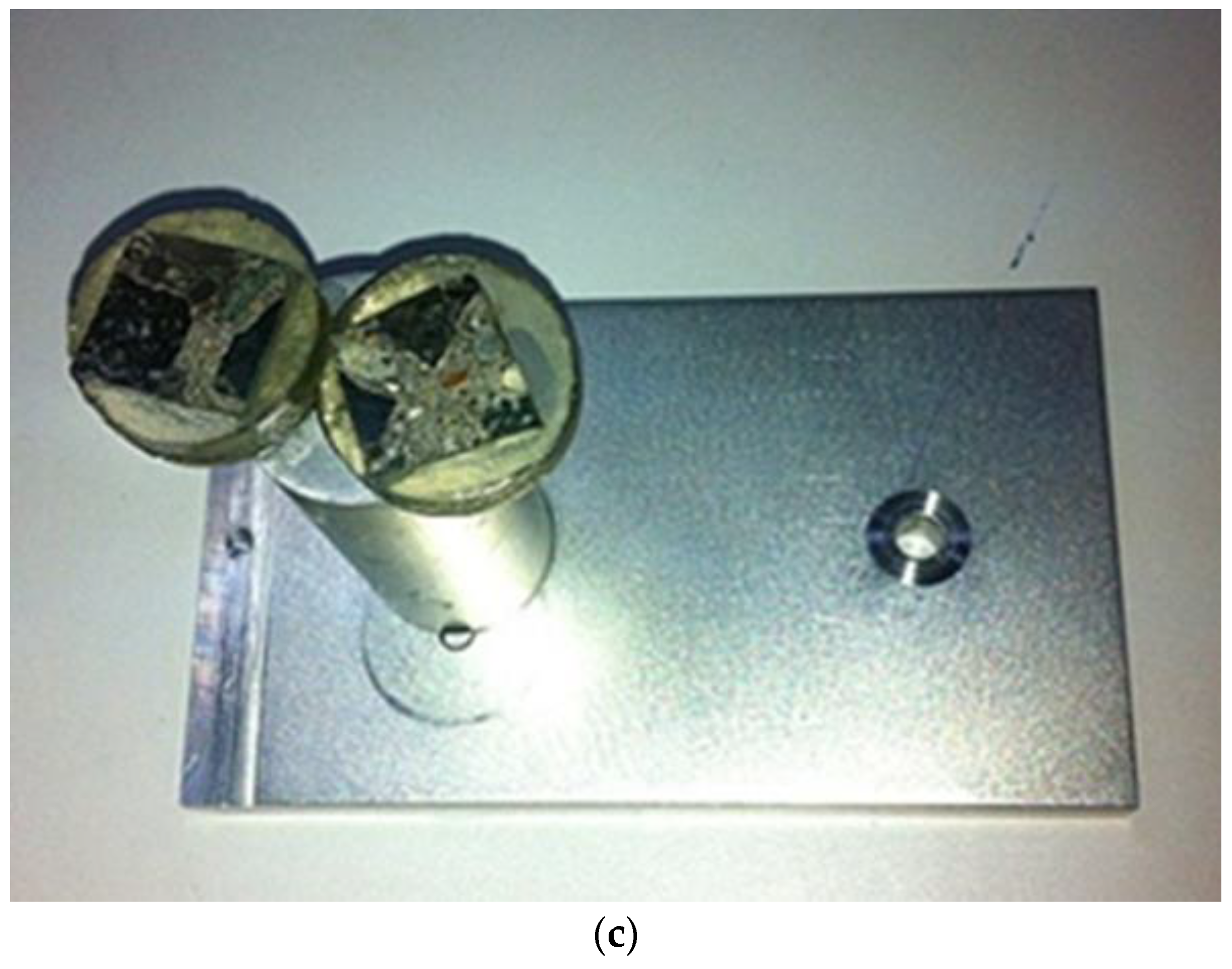

2.1. Concrete Mixes Used and Sample Preparation

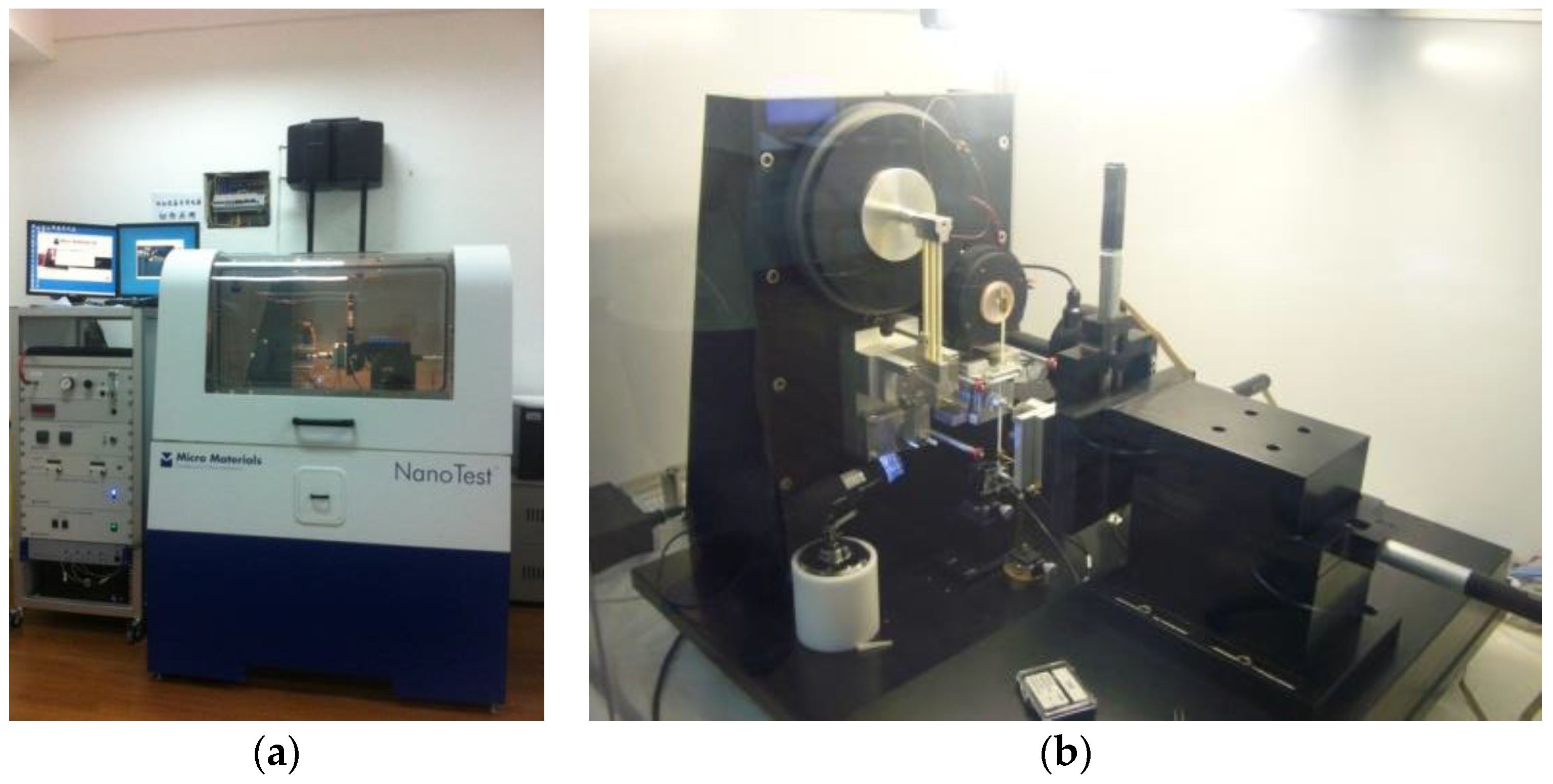

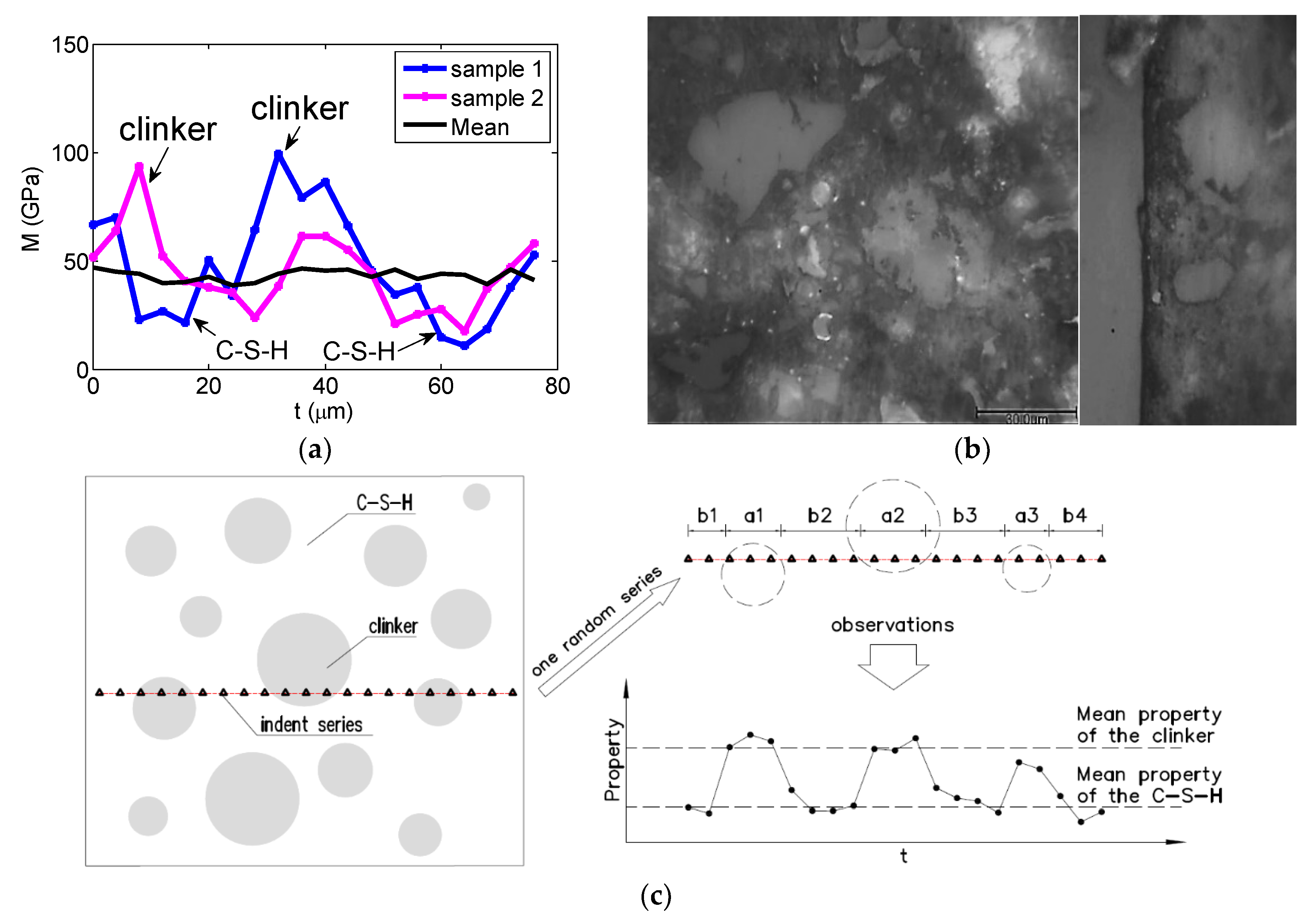

2.2. Nanoindentation

2.3. Random Field Modeling

2.4. Statistical Modeling

3. Results and Discussion

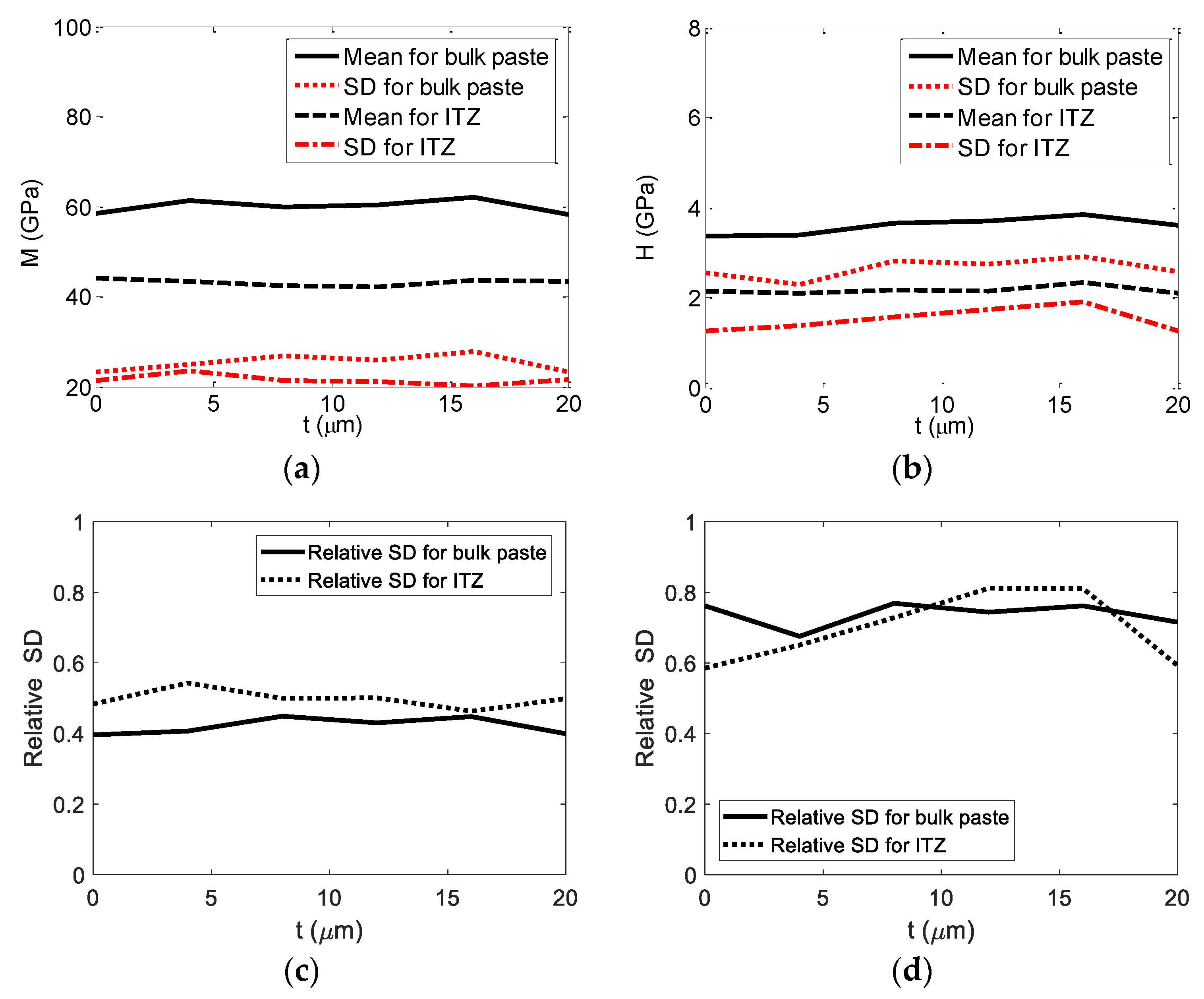

3.1. Mean and SD

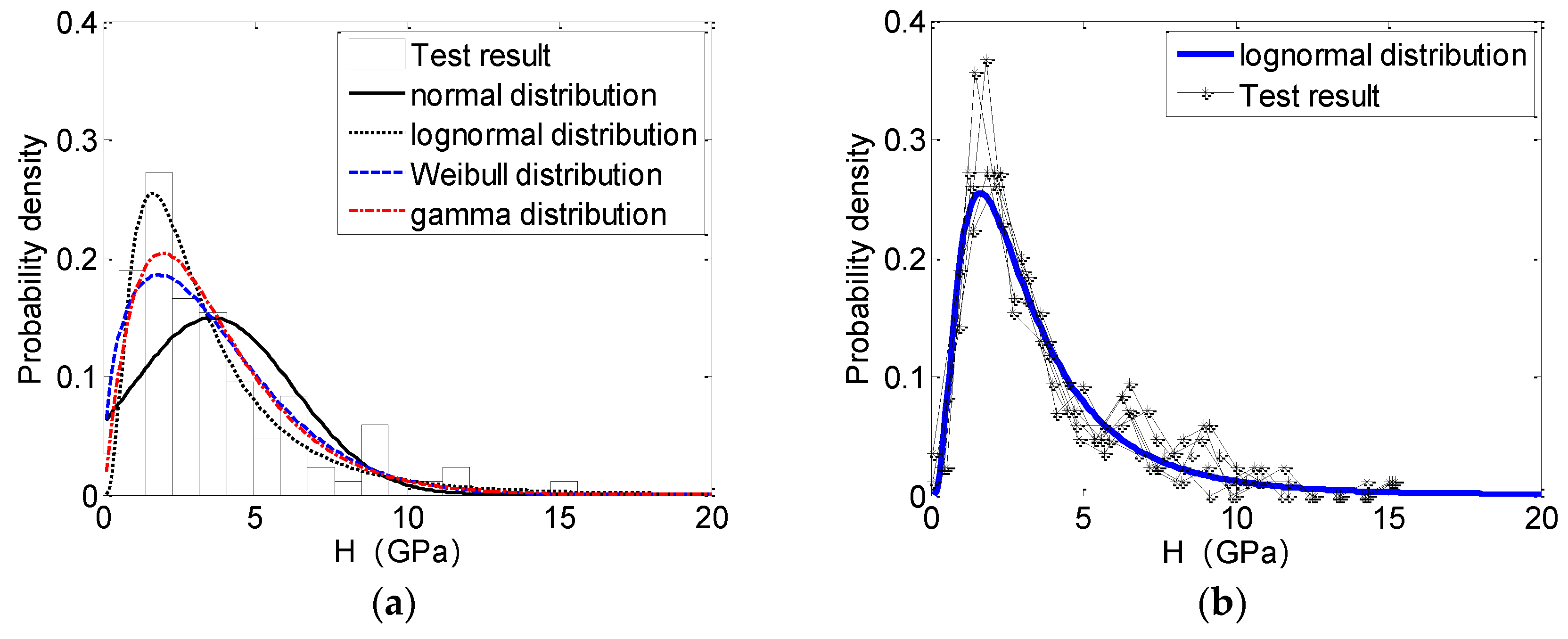

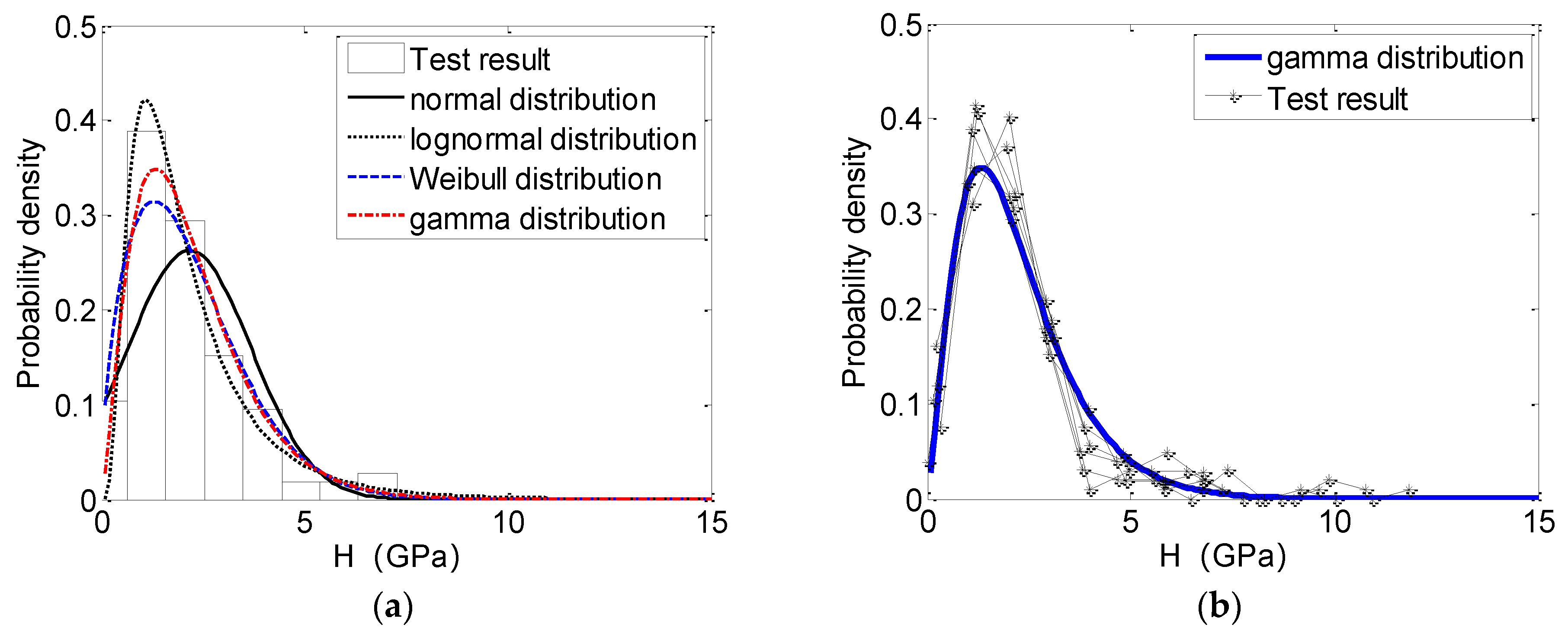

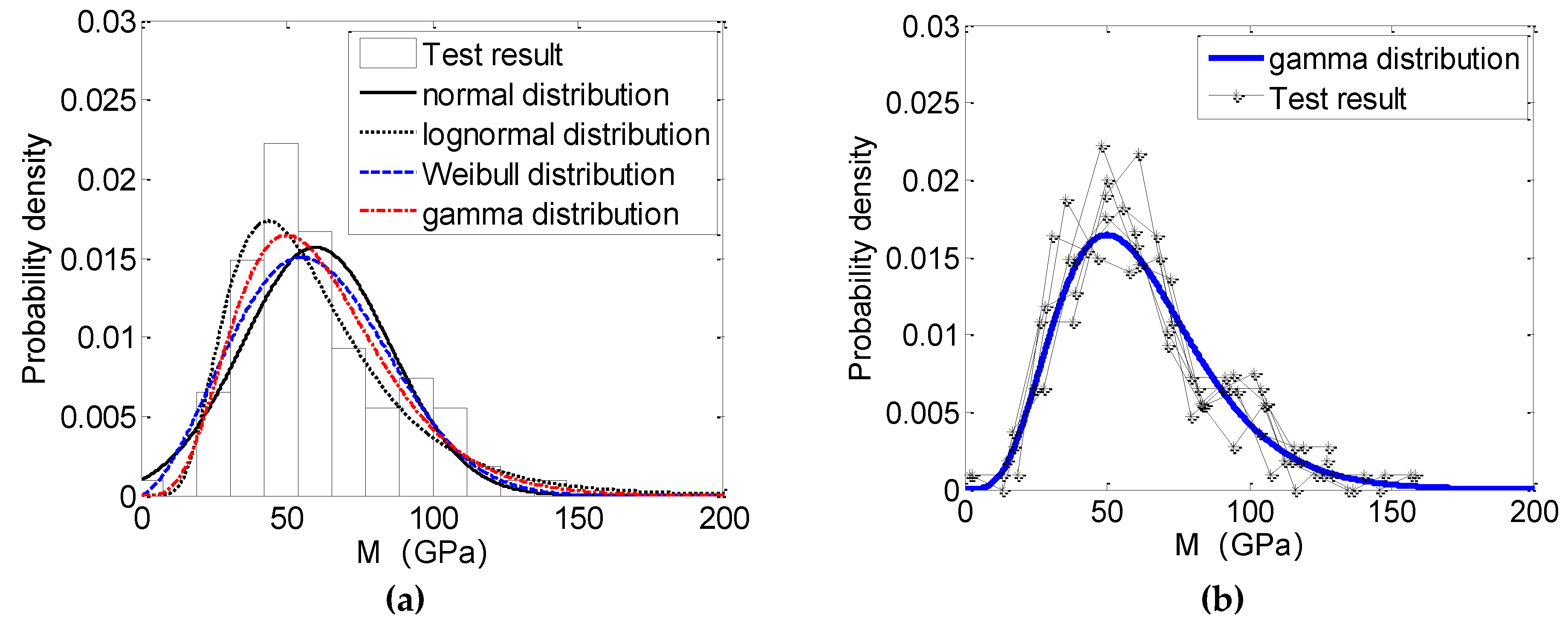

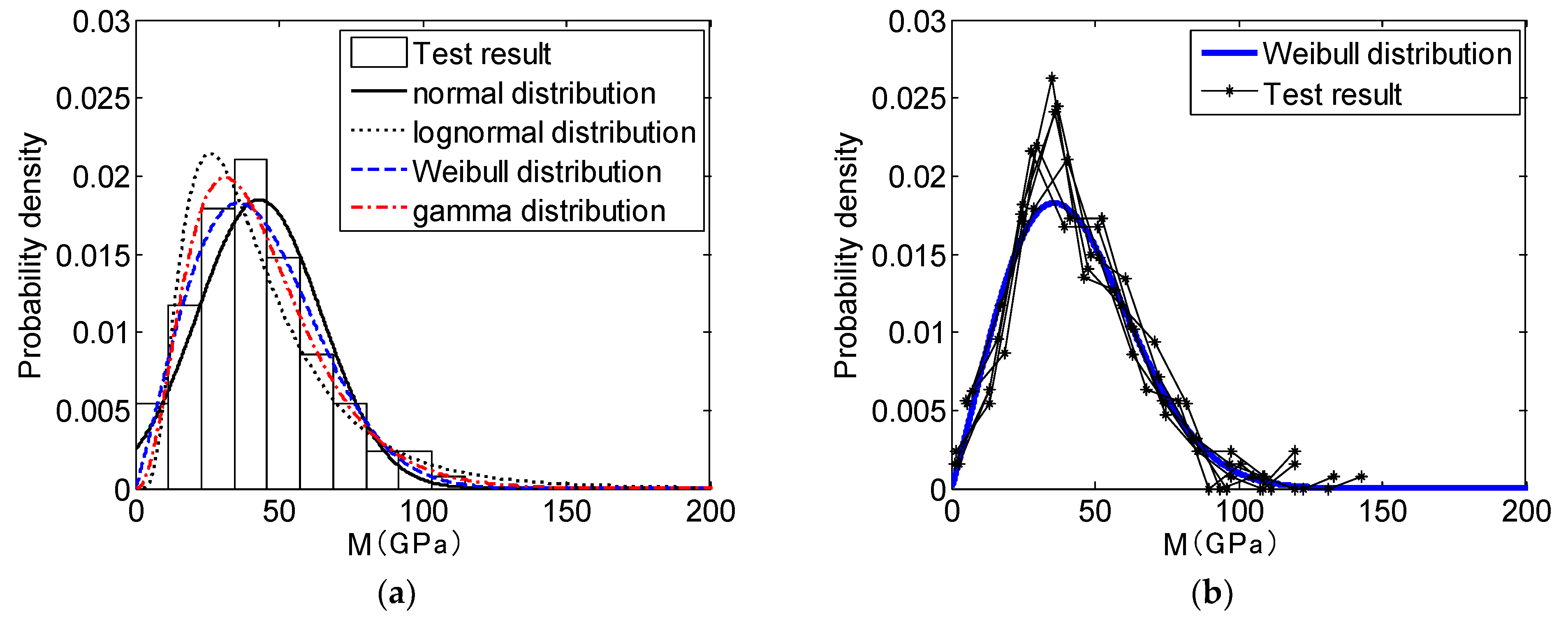

3.2. Probabilistic Distribution

3.3. Correlation Function

3.4. Scale of Fluctuation and Topology Nanostructure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Scrivener, K.L.; Crumbie, A.K.; Laugesen, P. The interfacial transition zone (ITZ) between cement paste and aggregate in concrete. Interface. Sci. 2004, 12, 411–421. [Google Scholar] [CrossRef]

- Ramesh, G.; Sotelino, E.D.; Chen, W.F. Effect of transition zone on elastic moduli of concrete materials. Cem. Concr. Res. 1996, 26, 611–622. [Google Scholar] [CrossRef]

- Perry, C.; Gillott, J.E. The influence of mortar-aggregate bond strength on the behaviour of concrete in uniaxial compression. Cem. Concr. Res. 1977, 7, 553–564. [Google Scholar] [CrossRef]

- Igarashi, S.; Bentur, A.; Mindess, S. Microhardness testing of cementitious materials. Adv. Cem. Based. Mater. 1996, 4, 48–57. [Google Scholar] [CrossRef]

- Zhu, W.; Sonebi, M.; Bartos, P.J.M. Bond and interfacial properties of reinforcement in self-compacting concrete. Mater. Struct. 2004, 37, 442–448. [Google Scholar] [CrossRef]

- Mondal, P.; Shah, S.P.; Marks, L.D. Nanoscale characterization of cementitious materials. ACI Mater. J. 2008, 105, 174–179. [Google Scholar]

- Mondal, P.; Shah, S.P.; Marks, L.D. Nanomechanical Properties of Interfacial Transition Zone in Concrete. In Nanotechnology in Construction 3; Springer: Berlin/Heidelberg, Germany, 2009; pp. 315–320. [Google Scholar]

- Zimbelmann, R. A contribution to the problem of cement-aggregate bond. Cem. Concr. Res. 1985, 15, 801–808. [Google Scholar] [CrossRef]

- Tasong, W.A.; Lynsdale, C.J.; Cripps, J.C. Aggregate-cement paste interface: Part I. Influence of aggregate geochemistry. Cem. Concr. Res. 1999, 29, 1019–1025. [Google Scholar] [CrossRef]

- Diamond, S. Considerations in image analysis as applied to investigations of the ITZ in concrete. Cem. Concr. Comp. 2001, 23, 171–178. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Nemati, K.M. The percolation of pore space in the cement paste/aggregate interfacial zone of concrete. Cem. Concr. Res. 1996, 26, 35–40. [Google Scholar] [CrossRef]

- Liao, K.Y.; Chang, P.K.; Peng, Y.N.; Yang, C.C. A study on characteristics of interfacial transition zone in concrete. Cem. Concr. Res. 2004, 34, 977–989. [Google Scholar] [CrossRef]

- Akçaoğlu, T.; Tokyay, M.; Çelik, T. Assessing the ITZ microcracking via scanning electron microscope and its effect on the failure behavior of concrete. Cem. Concr. Res. 2005, 35, 358–363. [Google Scholar] [CrossRef]

- Tasong, W.A.; Lynsdale, C.J.; Cripps, J.C. Aggregate-cement paste interface: Part II. influence of aggregate physical properties. Cem. Concr. Res. 1998, 28, 1453–1465. [Google Scholar] [CrossRef]

- Liu, H.K.; Ren, X.D.; Li, J. Indentation tests based multi-scale random media modeling of concrete. Constr. Build. Mater. 2018, 168, 209–220. [Google Scholar] [CrossRef]

- Liu, H.K.; Ren, X.D.; Liang, S.X.; Li, J. Physical Mechanism of Concrete Damage under Compression. Materials 2019, 12, 3295. [Google Scholar] [CrossRef]

- Liu, H.K.; Qi, N.P. Discussions on Physical Mechanism of “Inspecting of Concrete Compressive Strength by Rebound Method”. Sichuan Build. Sci. 2017, 43, 117–119. (In Chinese) [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Pharr, G.M.; Oliver, W.C.; Brotzen, F.R. On the generality of the relationship between contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 1992, 7, 613–617. [Google Scholar] [CrossRef]

- Vanmarcke, E. Random Fields: Analysis and Synthesis; The MIT Press: Cambridge, MA, USA; London, England, 2010. [Google Scholar]

- Jennings, H.M. A model for the microstructure of calcium silicate hydrate in cement paste. Cem. Concr. Res. 2000, 30, 101–116. [Google Scholar] [CrossRef]

- Vandamme, M.; Ulm, F.J.; Bazant, Z.P. Nanogranular Origin of Concrete Creep. Proc. Natl. Acad. Sci. USA 2009, 106, 10552–10557. [Google Scholar] [CrossRef]

- Barnes, B.D.; Diamond, S.; Dolch, W.L. The contact zone between Portland cement paste and glass “aggregate” surfaces. Cem. Concr. Res. 1978, 8, 233–243. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman Group Limited: Essex, England, 1995. [Google Scholar]

- Mondal, P. Nanomechanical Properties of Cementitious Materials. Ph.D. Thesis, Northwestern University, Evanston, IL, USA, 2008. [Google Scholar]

| Probability Distribution | Parameters and p-Value | p-Values for 6 Sections of 1D Random Field | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | Mean Value | ||

| normal distribution | Location parameter | 3.365 | 3.400 | 3.664 | 3.690 | 3.837 | 3.598 | 3.592 |

| Scale parameter | 2.576 | 2.307 | 2.831 | 2.758 | 2.936 | 2.586 | 2.666 | |

| p-value | 0.002 | 0.011 | 0.023 | 0.007 | 0.002 | 0.010 | 0.009 | |

| log-normal distribution | Location parameter | 0.970 | 1.013 | 0.996 | 1.040 | 1.074 | 1.055 | 1.025 |

| Scale parameter | 0.707 | 0.653 | 0.862 | 0.778 | 0.746 | 0.678 | 0.737 | |

| p-value | 0.964 | 0.766 | 0.570 | 0.336 | 0.748 | 0.846 | 0.705 | |

| Weibull distribution | Location parameter | 3.746 | 3.824 | 4.027 | 4.094 | 4.251 | 4.028 | 3.995 |

| Scale parameter | 1.457 | 1.602 | 1.379 | 1.446 | 1.417 | 1.529 | 1.472 | |

| p-value | 0.183 | 0.289 | 0.446 | 0.174 | 0.128 | 0.346 | 0.261 | |

| gamma distribution | Shape parameter | 2.205 | 2.526 | 1.803 | 2.034 | 1.996 | 2.369 | 2.155 |

| Scale parameter | 1.526 | 1.346 | 2.033 | 1.814 | 1.923 | 1.519 | 1.693 | |

| p-value | 0.365 | 0.428 | 0.424 | 0.165 | 0.181 | 0.353 | 0.319 | |

| Probability Distribution | Parameters and p-Value | p-Values for 6 Sections of 1D Random Field | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | Mean Value | ||

| normal distribution | Location parameter | 2.133 | 2.103 | 2.157 | 2.150 | 2.342 | 2.105 | 2.165 |

| Scale parameter | 1.253 | 1.374 | 1.576 | 1.751 | 1.905 | 1.252 | 1.519 | |

| p-value | 0.058 | 0.049 | 0.009 | 0.001 | 0.000 | 0.044 | 0.027 | |

| log-normal distribution | Location parameter | 0.569 | 0.528 | 0.537 | 0.524 | 0.594 | 0.577 | 0.555 |

| Scale parameter | 0.701 | 0.700 | 0.700 | 0.698 | 0.724 | 0.598 | 0.687 | |

| p-value | 0.307 | 0.682 | 0.687 | 0.296 | 0.336 | 0.864 | 0.529 | |

| Weibull distribution | Location parameter | 2.400 | 2.361 | 2.409 | 2.387 | 2.593 | 2.380 | 2.421 |

| Scale parameter | 1.791 | 1.634 | 1.508 | 1.420 | 1.399 | 1.809 | 1.593 | |

| p-value | 0.660 | 0.607 | 0.413 | 0.057 | 0.075 | 0.477 | 0.381 | |

| gamma distribution | Shape parameter | 2.814 | 2.472 | 2.312 | 2.226 | 2.099 | 3.140 | 2.510 |

| Scale parameter | 0.758 | 0.851 | 0.933 | 0.966 | 1.116 | 0.670 | 0.882 | |

| p-value | 0.947 | 0.827 | 0.618 | 0.189 | 0.119 | 0.904 | 0.601 | |

| Probability Distribution | Parameters and p-Value | p-Values for 6 Sections of 1D Random Field | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | Mean Value | ||

| normal distribution | Location parameter | 58.436 | 61.355 | 59.839 | 60.289 | 62.147 | 58.225 | 60.049 |

| Scale parameter | 23.253 | 25.074 | 26.990 | 26.055 | 27.963 | 23.352 | 25.447 | |

| p-value | 0.639 | 0.368 | 0.557 | 0.067 | 0.322 | 0.518 | 0.412 | |

| log-normal distribution | Location parameter | 3.983 | 4.034 | 3.970 | 3.989 | 4.028 | 3.983 | 3.998 |

| Scale parameter | 0.432 | 0.413 | 0.560 | 0.548 | 0.464 | 0.415 | 0.472 | |

| p-value | 0.283 | 0.965 | 0.167 | 0.276 | 0.917 | 0.967 | 0.596 | |

| Weibull distribution | Location parameter | 65.781 | 69.215 | 67.419 | 67.851 | 70.270 | 65.599 | 67.689 |

| Scale parameter | 2.712 | 2.627 | 2.334 | 2.432 | 2.370 | 2.674 | 2.525 | |

| p-value | 0.760 | 0.541 | 0.601 | 0.248 | 0.763 | 0.814 | 0.621 | |

| gamma distribution | Shape parameter | 6.021 | 6.229 | 4.278 | 4.684 | 5.098 | 6.286 | 5.433 |

| Scale parameter | 9.706 | 9.850 | 13.989 | 12.871 | 12.190 | 9.263 | 11.312 | |

| p-value | 0.696 | 0.936 | 0.551 | 0.726 | 0.956 | 1.000 | 0.811 | |

| Probability Distribution | Parameters and p-Value | p-Values for 6 Sections of 1D Random Field | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | Mean Value | ||

| normal distribution | Location parameter | 44.100 | 43.399 | 42.465 | 42.096 | 43.523 | 43.268 | 43.142 |

| Scale parameter | 21.413 | 23.660 | 21.295 | 21.171 | 20.236 | 21.668 | 21.574 | |

| p-value | 0.169 | 0.304 | 0.612 | 0.153 | 0.199 | 0.192 | 0.272 | |

| log-normal distribution | Location parameter | 3.645 | 3.604 | 3.605 | 3.596 | 3.633 | 3.628 | 3.618 |

| Scale parameter | 0.610 | 0.626 | 0.579 | 0.594 | 0.606 | 0.569 | 0.597 | |

| p-value | 0.089 | 0.224 | 0.120 | 0.230 | 0.075 | 0.390 | 0.188 | |

| Weibull distribution | Location parameter | 49.677 | 48.998 | 48.007 | 47.506 | 49.032 | 48.907 | 48.687 |

| Scale parameter | 2.146 | 1.934 | 2.115 | 2.088 | 2.268 | 2.114 | 2.111 | |

| p-value | 0.457 | 0.879 | 0.924 | 0.746 | 0.723 | 0.685 | 0.735 | |

| gamma distribution | Shape parameter | 3.691 | 3.155 | 3.635 | 3.627 | 3.722 | 3.736 | 3.594 |

| Scale parameter | 11.948 | 13.756 | 11.684 | 11.607 | 11.693 | 11.582 | 12.045 | |

| p-value | 0.452 | 0.733 | 0.555 | 0.788 | 0.398 | 0.758 | 0.614 | |

| Phase | Indentation Properties | Correlation Function 1 | Correlation Function 2 | Correlation Function 3 |

|---|---|---|---|---|

| Bulk paste | H | 0.0185 | 0.0235 | 0.0533 |

| M | 0.0214 | 0.0729 | 0.1406 | |

| ITZ | H | 0.0055 | 0.0456 | 0.1054 |

| M | 0.0083 | 0.0569 | 0.1198 |

| Phase | Indentation Properties | ||||

|---|---|---|---|---|---|

| Bulk paste | H | 19.99 | 20.05 | 0.997 | 10–35 |

| M | 19.71 | 18.80 | 1.048 | ||

| ITZ | H | 17.88 | 16.32 | 1.096 | |

| M | 23.79 | 17.35 | 1.371 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Ren, X.; Li, J.; Luo, L.; Li, H. Probabilistic Modeling for Cementitious Materials Based on Data of Nanoindentation. Buildings 2023, 13, 416. https://doi.org/10.3390/buildings13020416

Liu H, Ren X, Li J, Luo L, Li H. Probabilistic Modeling for Cementitious Materials Based on Data of Nanoindentation. Buildings. 2023; 13(2):416. https://doi.org/10.3390/buildings13020416

Chicago/Turabian StyleLiu, Hankun, Xiaodan Ren, Jie Li, Linglong Luo, and Hongbing Li. 2023. "Probabilistic Modeling for Cementitious Materials Based on Data of Nanoindentation" Buildings 13, no. 2: 416. https://doi.org/10.3390/buildings13020416

APA StyleLiu, H., Ren, X., Li, J., Luo, L., & Li, H. (2023). Probabilistic Modeling for Cementitious Materials Based on Data of Nanoindentation. Buildings, 13(2), 416. https://doi.org/10.3390/buildings13020416