Investigation of the Thermal Degradation of SBS Polymer in Long-Term Aged Asphalt Binder Using Confocal Laser Scanning Microscopy (CLSM)

Abstract

:1. Introduction

2. Materials

3. Methodologies

3.1. Aging Protocols

3.2. Confocal Laser Scanning Microscopy (CLSM) Analysis

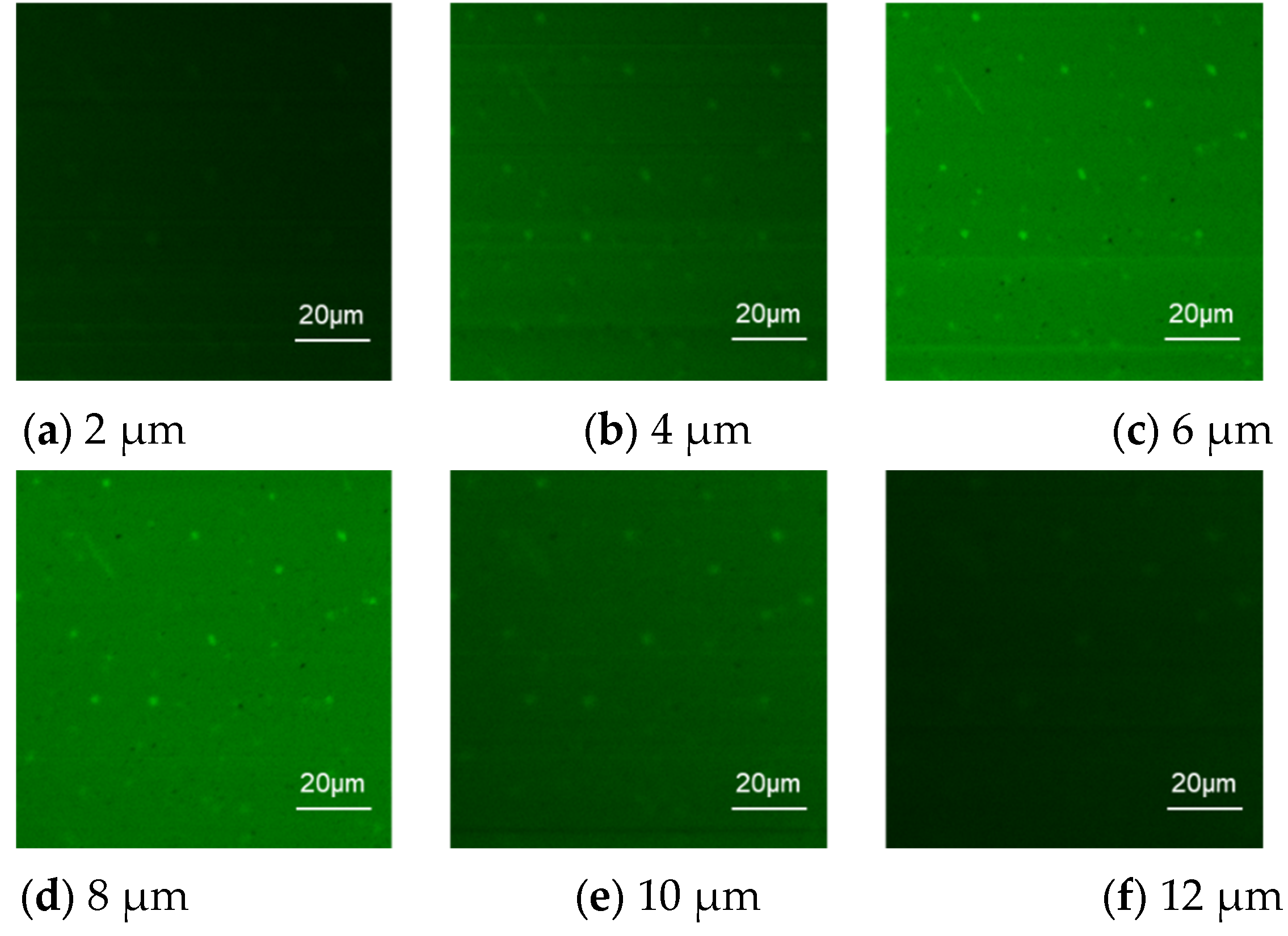

3.2.1. Polymer Fluorescence Image Acquisition

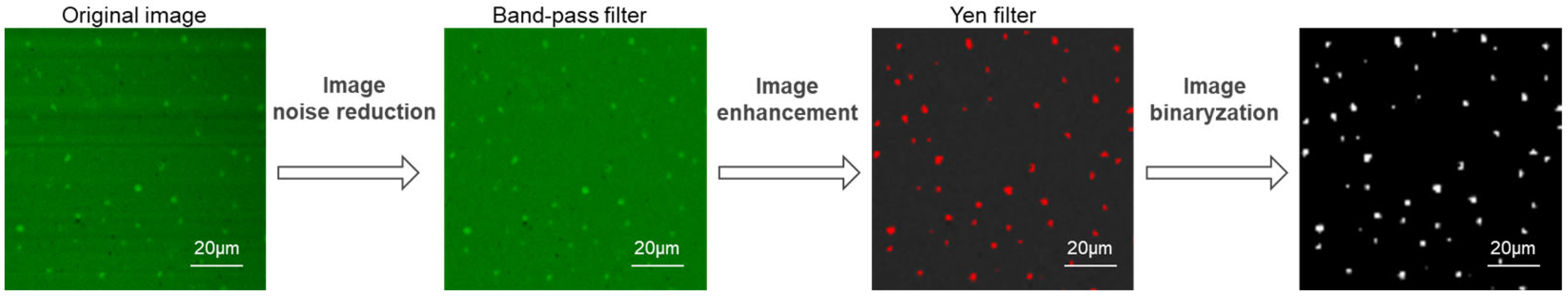

3.2.2. CLSM Image Pre-Processing

3.2.3. Semi-Quantitative Indicators of Stereology

3.2.4. Rheology Testing

4. Results and Discussion

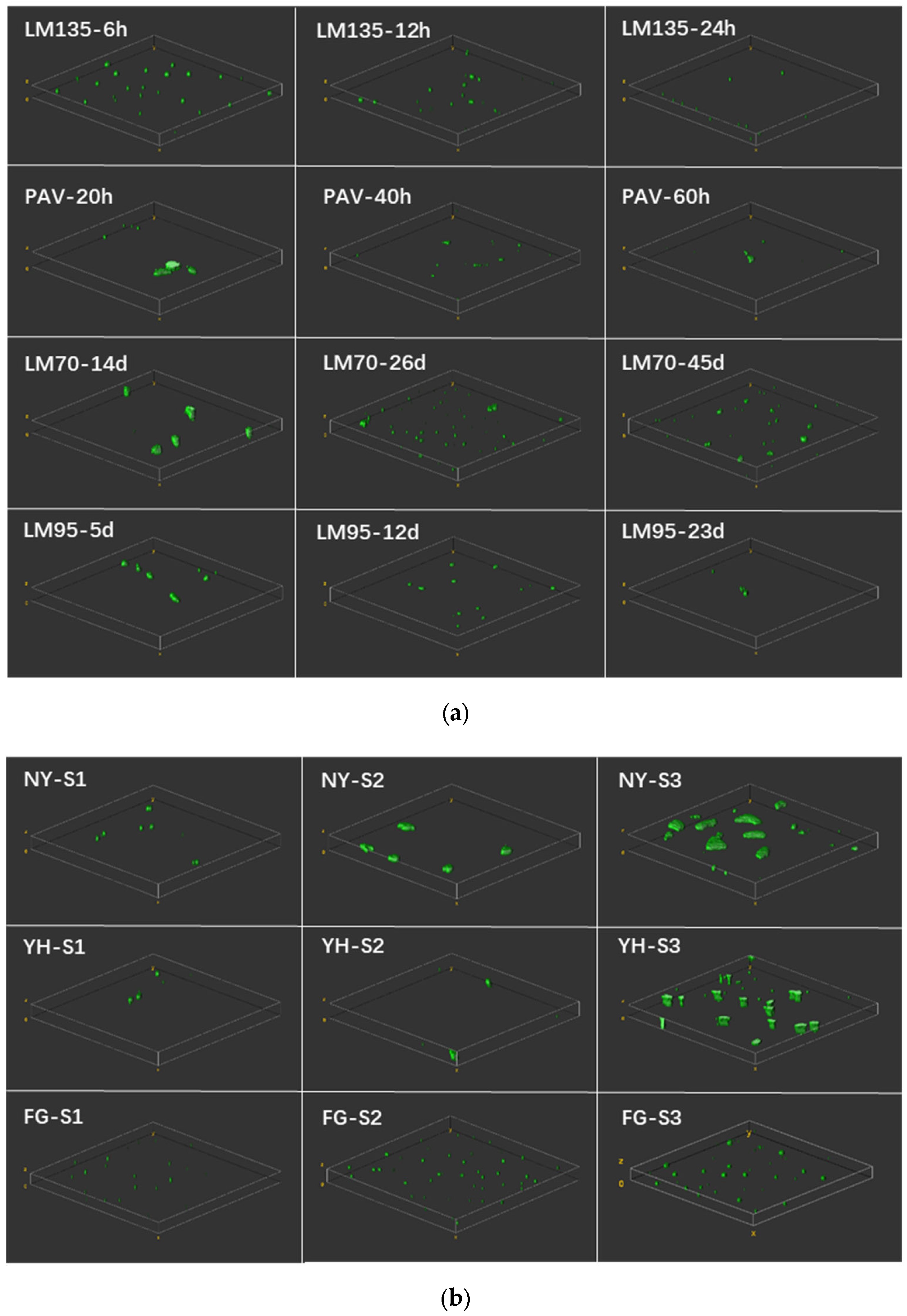

4.1. Visualization of SBS Polymer with Aging

4.1.1. Polymer Morphology Characterization

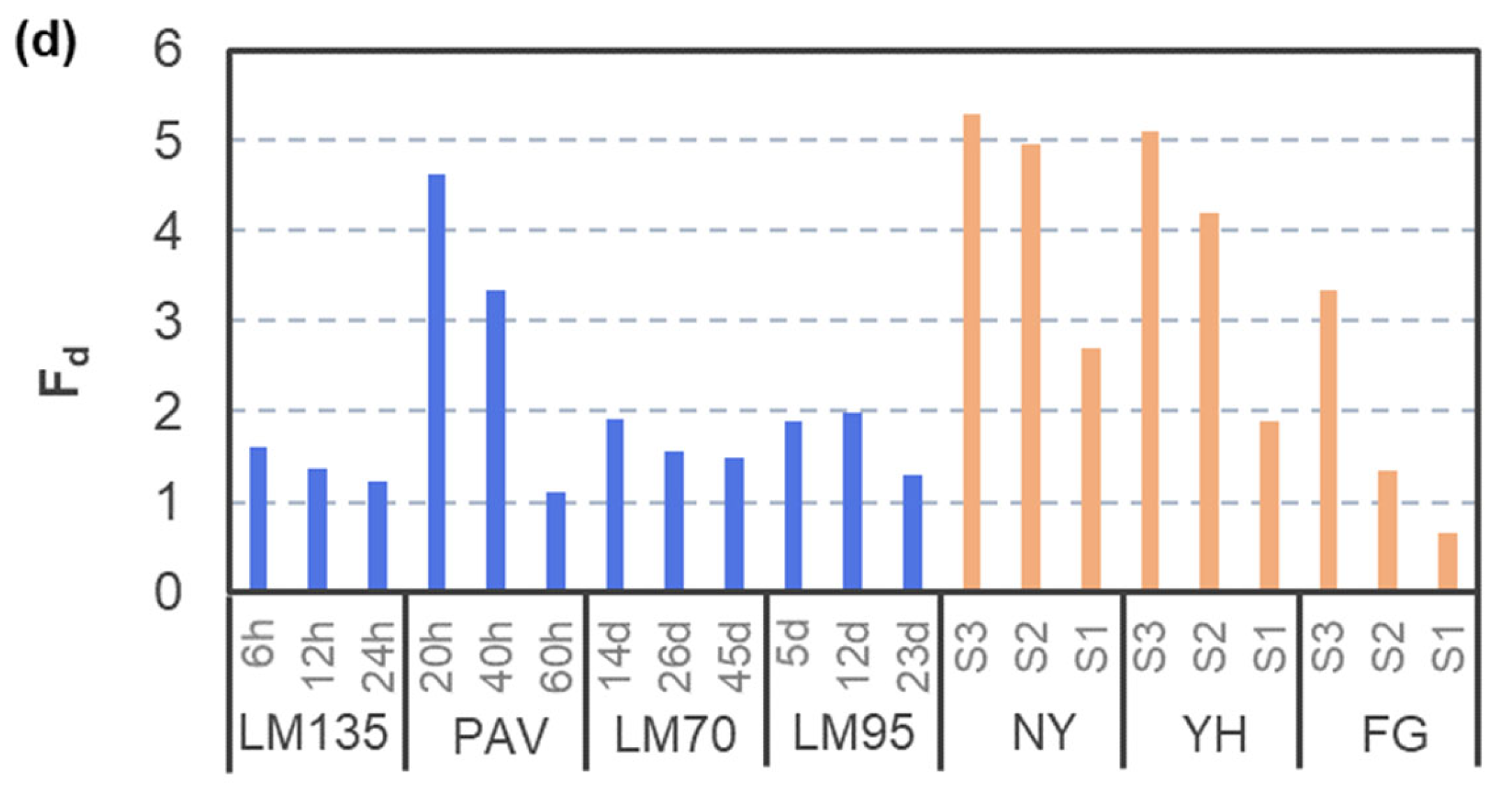

4.1.2. Quantitative Analysis

4.2. Correlation Analysis

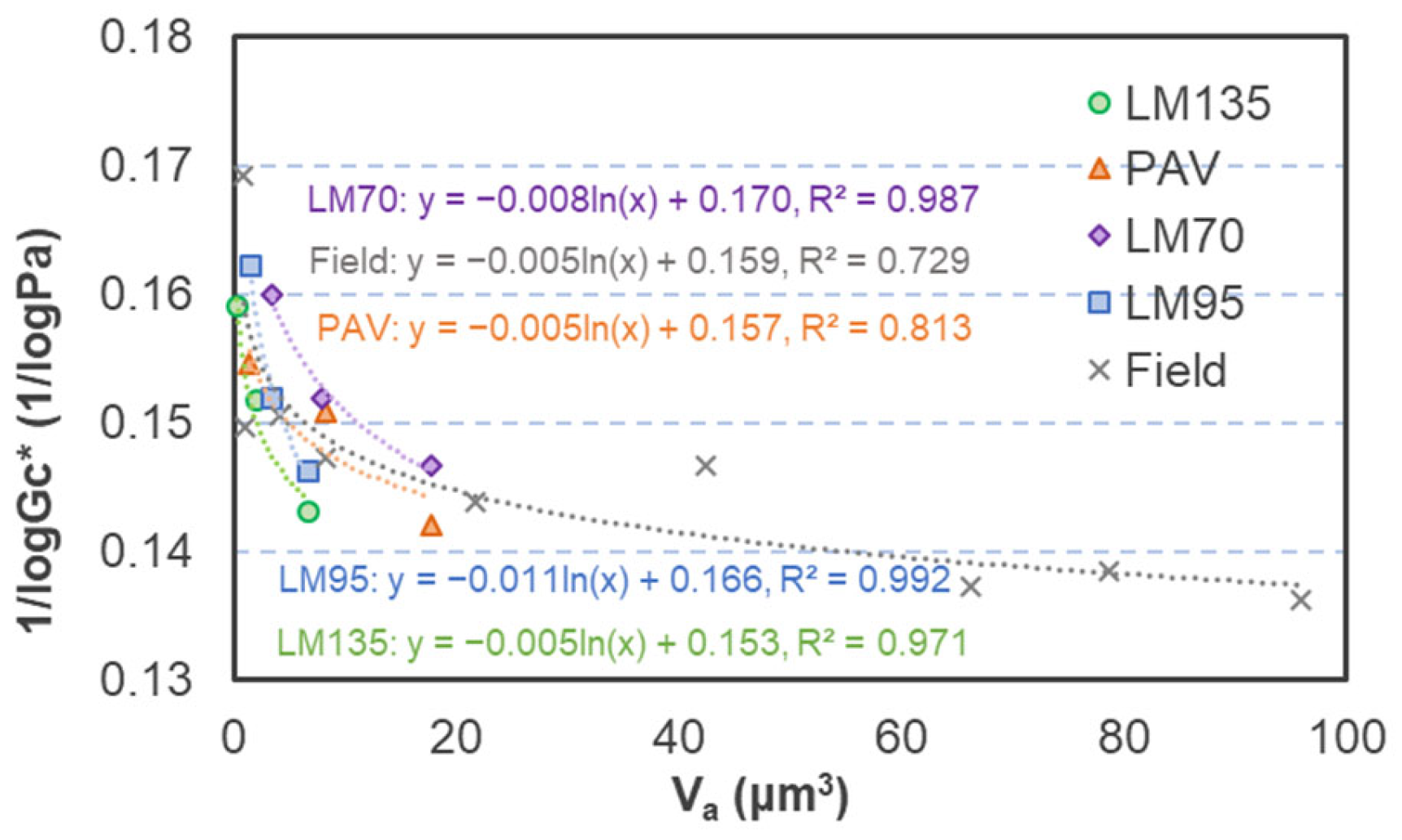

4.2.1. Effect of Aging Protocols on the Relationship between Stereology and Rheology

4.2.2. Morphological Parameters Correlating with Rheological Indices

5. Conclusions

- (1)

- As aging proceeds, the SBS polymer particles showed a decrease in volume and an increase in specific surface area in the three-dimensional view. Moreover, a shortening of Feret’s diameter and a tendency to develop round shapes could be obtained in the two-dimensional plane.

- (2)

- Higher aging temperatures led to faster degradation rates of the polymer with a similar stiffness level. Air pressure had a negligible impact on the degradation rate of the SBS polymer.

- (3)

- CLSM could characterize the aging gradient of field-aged samples with different pavement depths. Compared to field-aged samples, laboratory-aged samples had a rapid SBS polymer degradation rate in the early stages of aging.

- (4)

- A certain correlation between the morphology changes in the polymer phase and the rheology changes in the binder phase could be observed for all aged samples, where the degradation of the polymer was strongly correlated with the diminution of the creep recovery rate of the SBS-modified asphalt binder.

6. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Q.; Sun, G.; Lu, Y.; Meng, Y.; Luo, S.; Gao, L. Effects of warm-mix asphalt technologies and modifiers on pavement performance of recycled asphalt binders. J. Clean. Prod. 2020, 282, 125435. [Google Scholar] [CrossRef]

- Sulyman, M.; Sienkiewicz, M.; Haponiuk, J. Asphalt Pavement Material Improvement: A Review. Int. J. Environ. Sci. Dev. 2014, 5, 444–454. [Google Scholar] [CrossRef] [Green Version]

- Yao, L.; Leng, Z.; Lan, J.; Chen, R.; Jiang, J. Environmental and economic assessment of collective recycling waste plastic and reclaimed asphalt pavement into pavement construction: A case study in Hong Kong. J. Clean. Prod. 2022, 336, 130405. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, H.; Chen, Z.; Shi, C. An improved method for separating styrene-butadiene-styrene triblock copolymer (SBS) and bitumen matrix from SBS modified bitumen. Fuel 2020, 286, 119314. [Google Scholar] [CrossRef]

- Yan, C.; Xiao, F.; Huang, W.; Lv, Q. Critical matters in using Attenuated Total Reflectance Fourier Transform Infrared to characterize the polymer degradation in Styrene–Butadiene–Styrene-modified asphalt binders. Polym. Test. 2018, 70, 289–296. [Google Scholar] [CrossRef]

- Ma, T.; Huang, X.; Zhao, Y.; Yuan, H. Aging Behaviour and Mechanism of SBS-Modified Asphalt. J. Test. Evaluation 2012, 40, 1186–1191. [Google Scholar] [CrossRef]

- Mouillet, V.; Lamontagne, J.; Durrieu, F.; Planche, J.-P.; Lapalu, L. Infrared microscopy investigation of oxidation and phase evolution in bitumen modified with polymers. Fuel 2008, 87, 1270–1280. [Google Scholar] [CrossRef]

- Ma, J.; Deng, Y.; Sun, D.; Hesp, S.A. Relationship between thermoreversible and irreversible aging in rejuvenated asphalt binder. Constr. Build. Mater. 2022, 358, 129463. [Google Scholar] [CrossRef]

- Ding, J.; Jiang, J.; Han, Y.; Ni, F.; Ma, X.; Chen, S. Chemical and rheological characterisation of in-situ SBS modified asphalt pavement considering the effect of aging gradient. Int. J. Pavement Eng. 2022. [Google Scholar] [CrossRef]

- Yan, C.; Huang, W.; Ma, J.; Xu, J.; Lv, Q.; Lin, P. Characterizing the SBS polymer degradation within high content polymer modified asphalt using ATR-FTIR. Constr. Build. Mater. 2019, 233, 117708. [Google Scholar] [CrossRef]

- Wang, S.; Huang, W. Investigation of aging behavior of terminal blend rubberized asphalt with SBS polymer. Constr. Build. Mater. 2020, 267, 120870. [Google Scholar] [CrossRef]

- Lin, P.; Yan, C.; Huang, W.; Li, Y.; Zhou, L.; Tang, N.; Xiao, F.; Zhang, Y.; Lv, Q. Rheological, chemical and aging characteristics of high content polymer modified asphalt. Constr. Build. Mater. 2019, 207, 616–629. [Google Scholar] [CrossRef]

- Kou, C.; Xiao, P.; Kang, A.; Mikhailenko, P.; Baaj, H.; Wu, Z. Protocol for the morphology analysis of SBS polymer modified bitumen images obtained by using fluorescent microscopy. Int. J. Pavement Eng. 2017, 20, 585–591. [Google Scholar] [CrossRef]

- Soenen, H.; Lu, X.; Redelius, P. The Morphology of Bitumen-SBS Blends by UV Microscopy. An Evaluation of Preparation Methods. Road Mater. Pavement Des. 2008, 9, 97–110. [Google Scholar] [CrossRef]

- Cuciniello, G.; Leandri, P.; Losa, M.; Airey, G. Effects of ageing on the damage tolerance of polymer modified bitumens investigated through the LAS test and fluorescence microscopy. Int. J. Pavement Eng. 2020, 23, 1083–1094. [Google Scholar] [CrossRef]

- Pipintakos, G.; Hasheminejad, N.; Lommaert, C.; Bocharova, A.; Blom, J. Application of Atomic Force (AFM), Environmental Scanning Electron (ESEM) and Confocal Laser Scanning Microscopy (CLSM) in bitumen: A review of the ageing effect. Micron 2021, 147, 103093. [Google Scholar] [CrossRef]

- Li, R.; Leng, Z.; Zhang, Y.; Ma, X. Preparation and characterization of waterborne epoxy modified bitumen emulsion as a potential high-performance cold binder. J. Clean. Prod. 2019, 235, 1265–1275. [Google Scholar] [CrossRef]

- Hao, G.; Wang, Y. 3D Reconstruction of Polymer Phase in Polymer-Modified Asphalt Using Confocal Fluorescence Microscopy. J. Mater. Civ. Eng. 2021, 33, 04020400. [Google Scholar] [CrossRef]

- Handle, F.; Füssl, J.; Neudl, S.; Grossegger, D.; Eberhardsteiner, L.; Hofko, B.; Hospodka, M.; Blab, R.; Grothe, H. Understanding the microstructure of bitumen: A CLSM and fluorescence approach to model bitumen ageing behavior. In Proceedings to the 12th ISAP International Conference on Asphalt Pavements, Raleigh, NC, USA, 1–5 June 2014. [Google Scholar]

- Pipintakos, G.; Blom, J.; Soenen, H.; Bergh, W.V.D. Coupling AFM and CLSM to investigate the effect of ageing on the bee structures of bitumen. Micron 2021, 151, 103149. [Google Scholar] [CrossRef]

- Mirwald, J.; Hofko, B.; Grothe, H. Utilising fluorescence spectroscopy and optical microscopy to investigate bitumen long-term ageing. Road Mater. Pavement Des. 2020, 22, S23–S36. [Google Scholar] [CrossRef]

- Kaya, D.; Topal, A.; McNally, T. Correlation of processing parameters and ageing with the phase morphology of styrene-butadiene-styrene block co-polymer modified bitumen. Mater. Res. Express 2019, 6, 105309. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Modification of road bitumens with thermoplastic polymers. Polym. Test. 2000, 20, 77–86. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, H.; Duan, H.; Wu, C. Determination of time-temperature superposition relationship of SBS modified asphalt based on special rheological phenomenon caused by SBS-formed structure in asphalt matrix. Constr. Build. Mater. 2020, 260, 119835. [Google Scholar] [CrossRef]

| Code | Depth | Region | Service Year | Gradation Type | Binder Content (%) | Air Void (%) |

|---|---|---|---|---|---|---|

| NY | S1 (0.65 mm) | Yangzhou | 9 | SMA-13 | 5.7 | 3.4 |

| S2 (1.95 mm) | 5.8 | 3.6 | ||||

| S3 (3.25 mm) | 5.8 | 4.4 | ||||

| YH-2 | S1 (0.65 mm) | Yancheng | 15 | SMA-13 | 5.7 | 3.6 |

| S2 (1.95 mm) | 5.9 | 3.6 | ||||

| S3 (3.25 mm) | 5.9 | 4.2 | ||||

| FG | S1 (0.65 mm) | Lianyungang | 19 | AK-13 | 5.2 | 3.7 |

| S2 (1.95 mm) | 5.0 | 3.6 | ||||

| S3 (3.25 mm) | 5.2 | 4.2 |

| Items | SBS-Modified Asphalt Binder | Specification Limits | Test Method |

|---|---|---|---|

| Penetration (25 °C, 0.1 mm) | 68 | 60–80 | ASTM D5 |

| Softening point (°C) | 67 | ≥46 | ASTM D36 |

| Ductility (5 °C, cm) | 38.1 | / | ASTM D113 |

| Viscosity (135 °C, Pa·s) | 1.59 | / | ASTM D4402 |

| Binder grade | PG 70-22 | / | / |

| SBS polymer content | 3 wt% | / | / |

| ID | Short-Term Aging | Long-Term Aging | ||

|---|---|---|---|---|

| Temp (°C) | Duration | Temp (°C) | Duration | |

| PAV | 163 | 85 min | 100 | 20, 40, and 60 h |

| LM70 | 135 | 4 h | 70 | 14, 26, and 45 days |

| LM95 | 135 | 4 h | 95 | 5, 12, and 23 days |

| LM135 | 135 | 4 h | 135 | 6, 12, and 24 h |

| 1/log() | log(G–R) | R3.2 | Jnr3.2 | ||

|---|---|---|---|---|---|

| Lab aging | |||||

| PAV | 20 h | 0.142 | 0.594 | 43.848 | 0.598 |

| 40 h | 0.151 | 1.200 | 30.186 | 0.381 | |

| 60 h | 0.155 | 1.490 | 14.254 | 0.252 | |

| LM70 | 14 d | 0.147 | 0.541 | 41.084 | 0.428 |

| 26 d | 0.152 | 0.831 | 32.396 | 0.351 | |

| 45 d | 0.160 | 1.602 | 29.920 | 0.312 | |

| LM95 | 5 d | 0.146 | 0.843 | 38.007 | 0.507 |

| 12 d | 0.152 | 1.342 | 29.746 | 0.361 | |

| 23 d | 0.162 | 1.604 | 20.729 | 0.305 | |

| LM135 | 6 h | 0.143 | 0.912 | 38.354 | 0.534 |

| 12 h | 0.152 | 1.274 | 18.546 | 0.352 | |

| 24 h | 0.159 | 1.908 | 13.564 | 0.254 | |

| Field aging | |||||

| NY | S1 | 0.136 | 0.506 | 70.153 | 1.290 |

| S2 | 0.137 | 0.627 | 50.777 | 0.780 | |

| S3 | 0.147 | 1.188 | 34.745 | 0.502 | |

| YH | S1 | 0.138 | 0.512 | 54.041 | 0.716 |

| S2 | 0.144 | 0.744 | 35.758 | 0.679 | |

| S3 | 0.151 | 1.275 | 15.402 | 0.380 | |

| FG | S1 | 0.147 | 0.992 | 19.783 | 1.012 |

| S2 | 0.150 | 0.455 | 10.885 | 0.576 | |

| S3 | 0.169 | 1.391 | 6.464 | 0.183 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, J.; Jiang, J.; Ni, F.; Zheng, J. Investigation of the Thermal Degradation of SBS Polymer in Long-Term Aged Asphalt Binder Using Confocal Laser Scanning Microscopy (CLSM). Buildings 2022, 12, 2110. https://doi.org/10.3390/buildings12122110

Ding J, Jiang J, Ni F, Zheng J. Investigation of the Thermal Degradation of SBS Polymer in Long-Term Aged Asphalt Binder Using Confocal Laser Scanning Microscopy (CLSM). Buildings. 2022; 12(12):2110. https://doi.org/10.3390/buildings12122110

Chicago/Turabian StyleDing, Jitong, Jiwang Jiang, Fujian Ni, and Junqiu Zheng. 2022. "Investigation of the Thermal Degradation of SBS Polymer in Long-Term Aged Asphalt Binder Using Confocal Laser Scanning Microscopy (CLSM)" Buildings 12, no. 12: 2110. https://doi.org/10.3390/buildings12122110