Finite Element Modelling to Predict the Fire Performance of Bio-Inspired 3D-Printed Concrete Wall Panels Exposed to Realistic Fire

Abstract

:1. Introduction

1.1. Three-Dimensional Concrete Printing (3DCP)

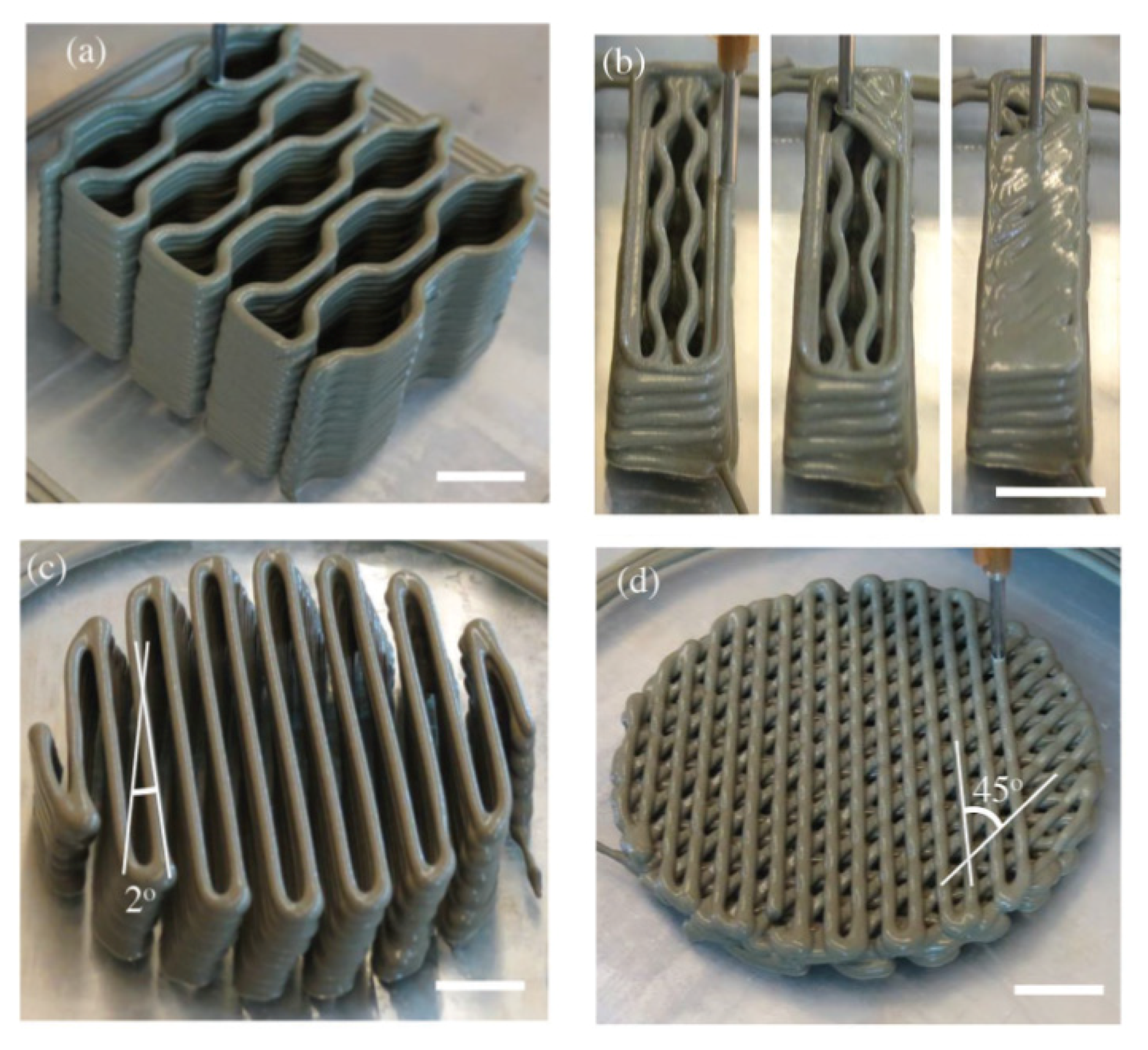

1.2. Bio-Inspired Design for 3DCP

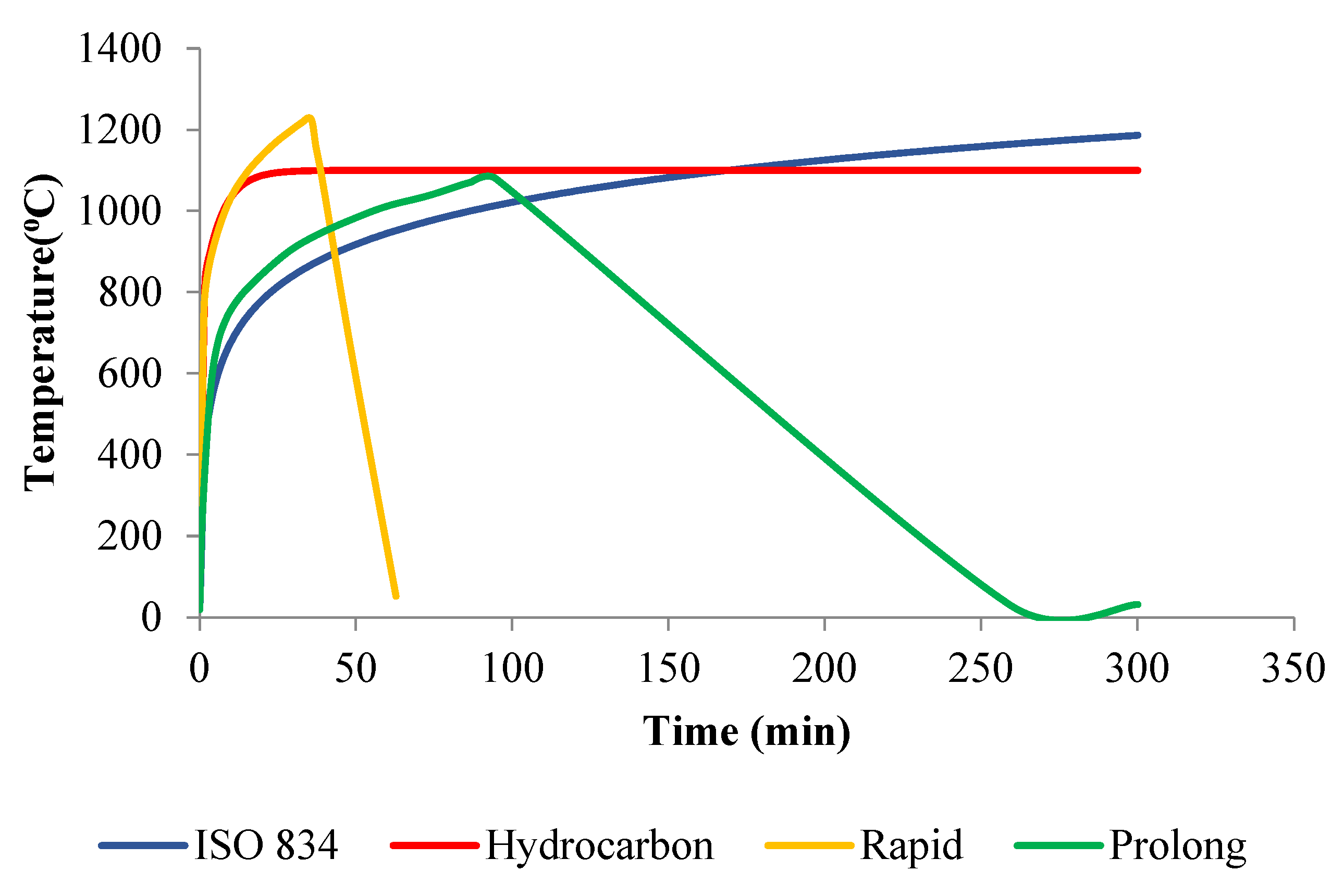

1.3. Fire Performance of Construction Materials

1.4. Performance of 3DCP Structures under Elevated Temperature

1.5. Scope of the Study

2. Finite Element Model Development

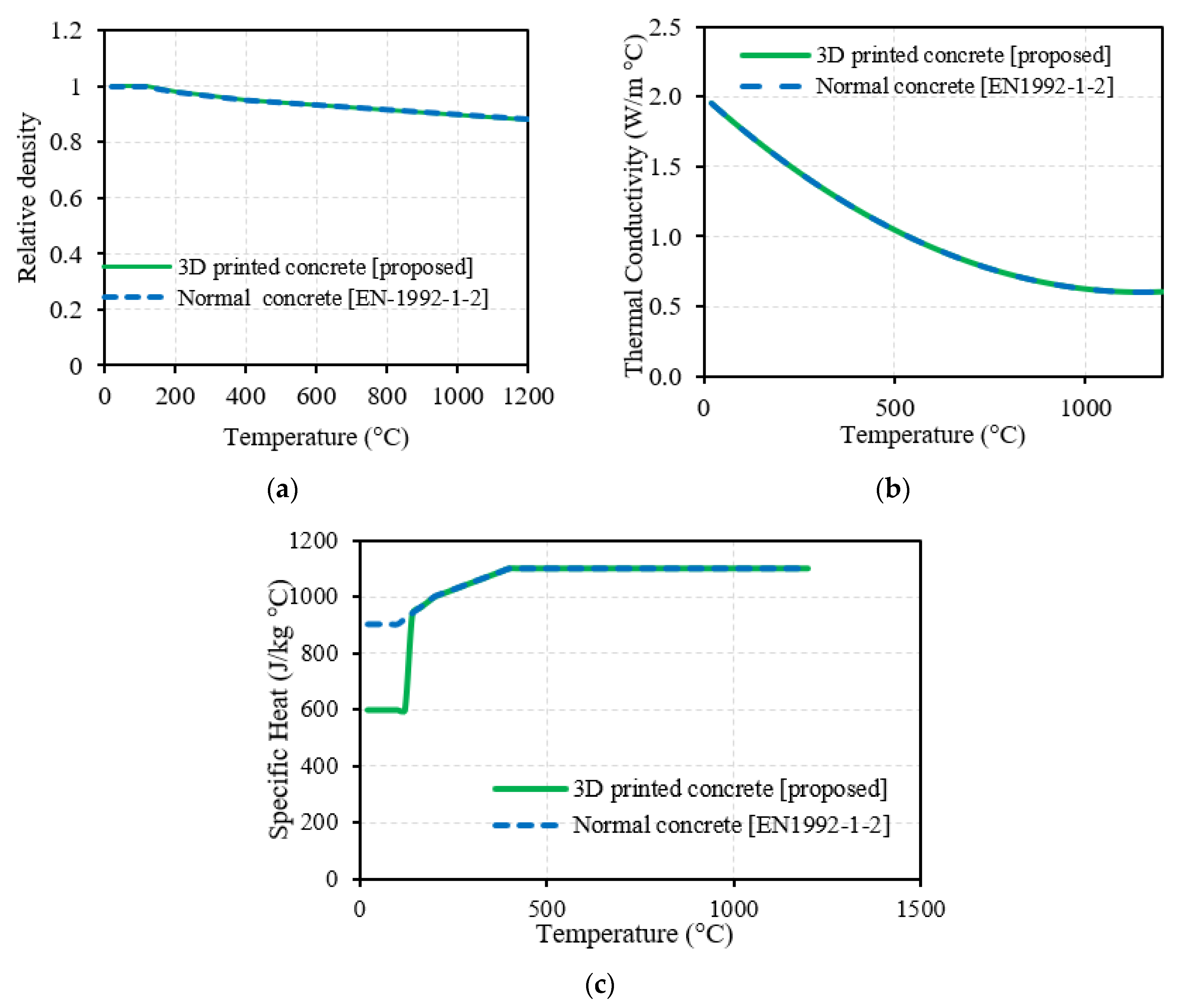

2.1. Thermal Properties of 3D-Printed Concrete at Elevated Temperature

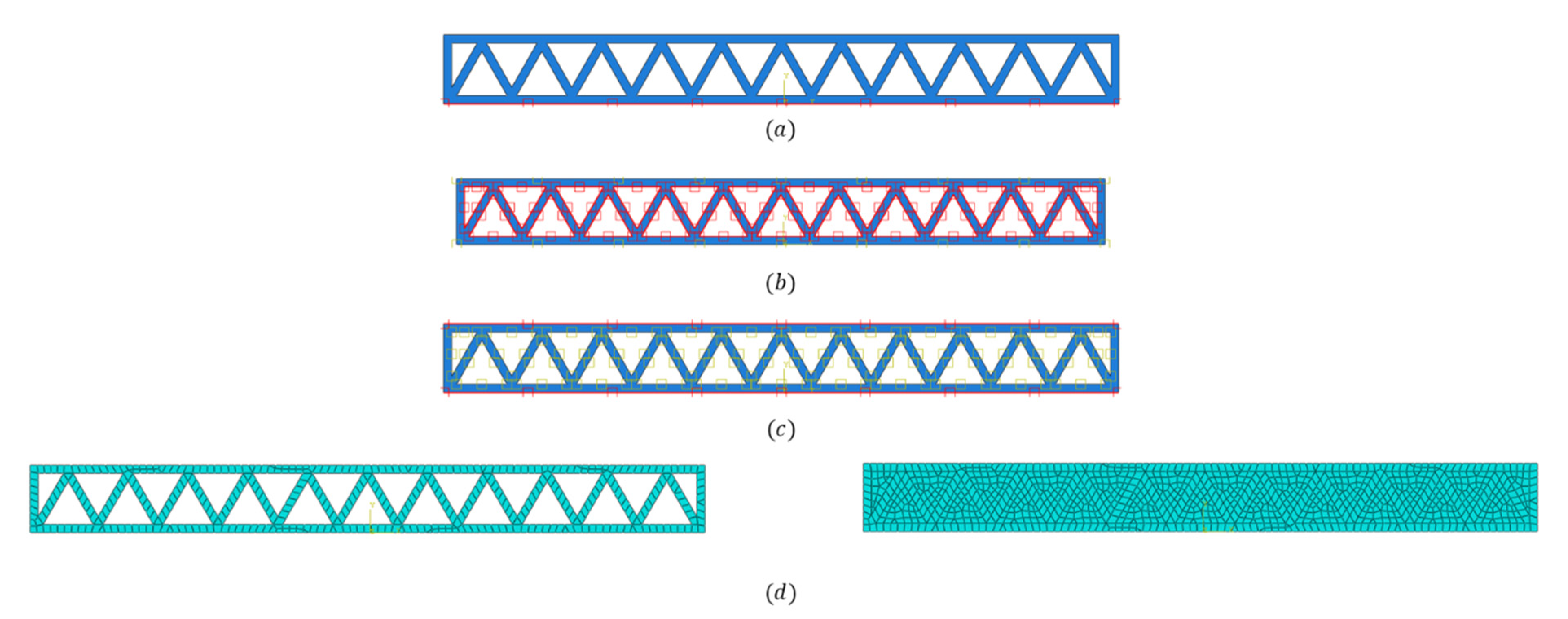

2.2. Heat Transfer FE Model

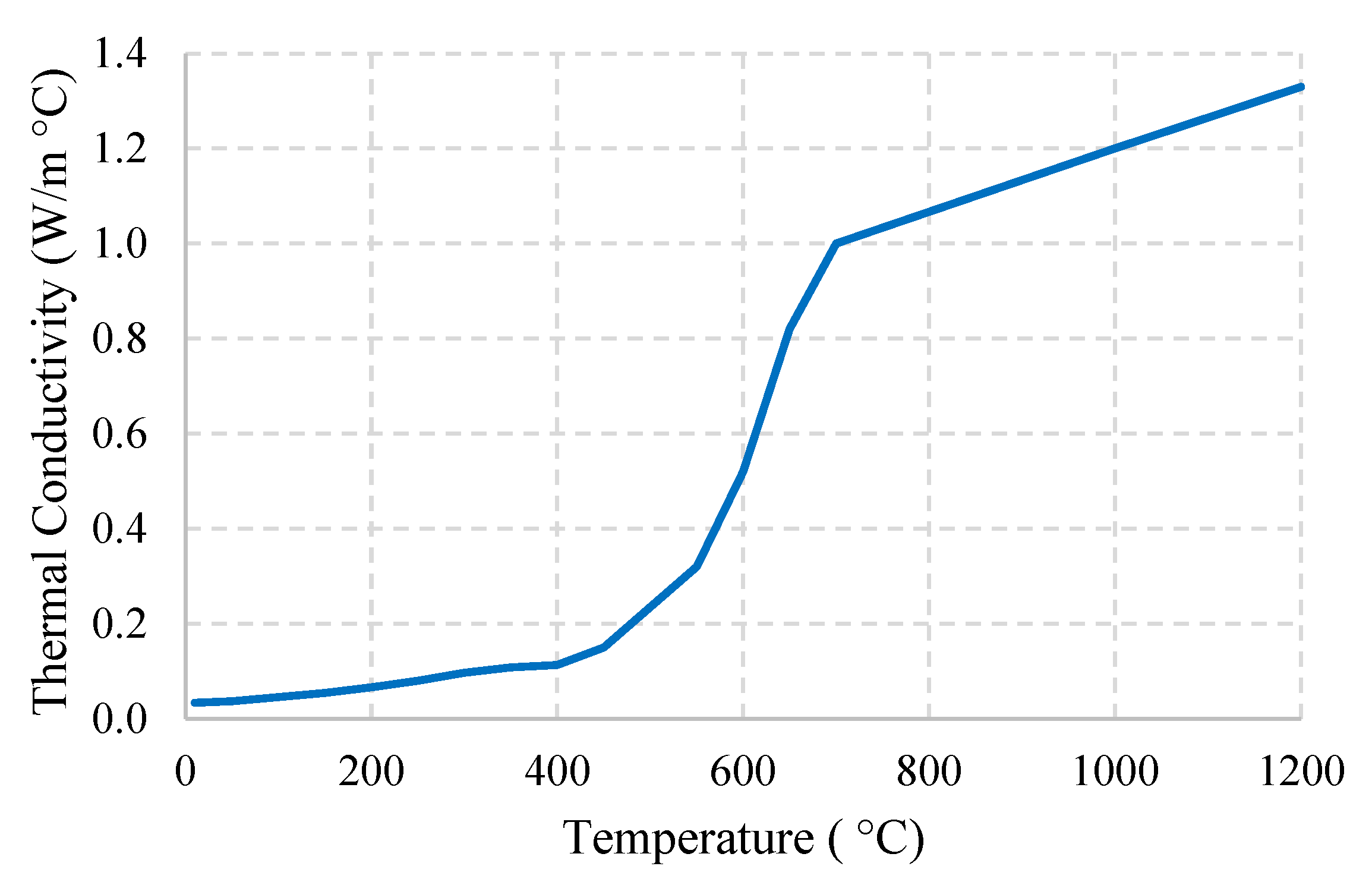

2.3. Elevated Temperature Properties Variation in a Real Fire

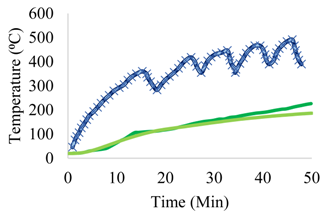

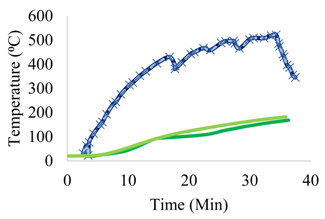

3. Validation

4. Parametric Study of 3D-Printed Concrete Wall Section Specimens

5. Results and Discussion

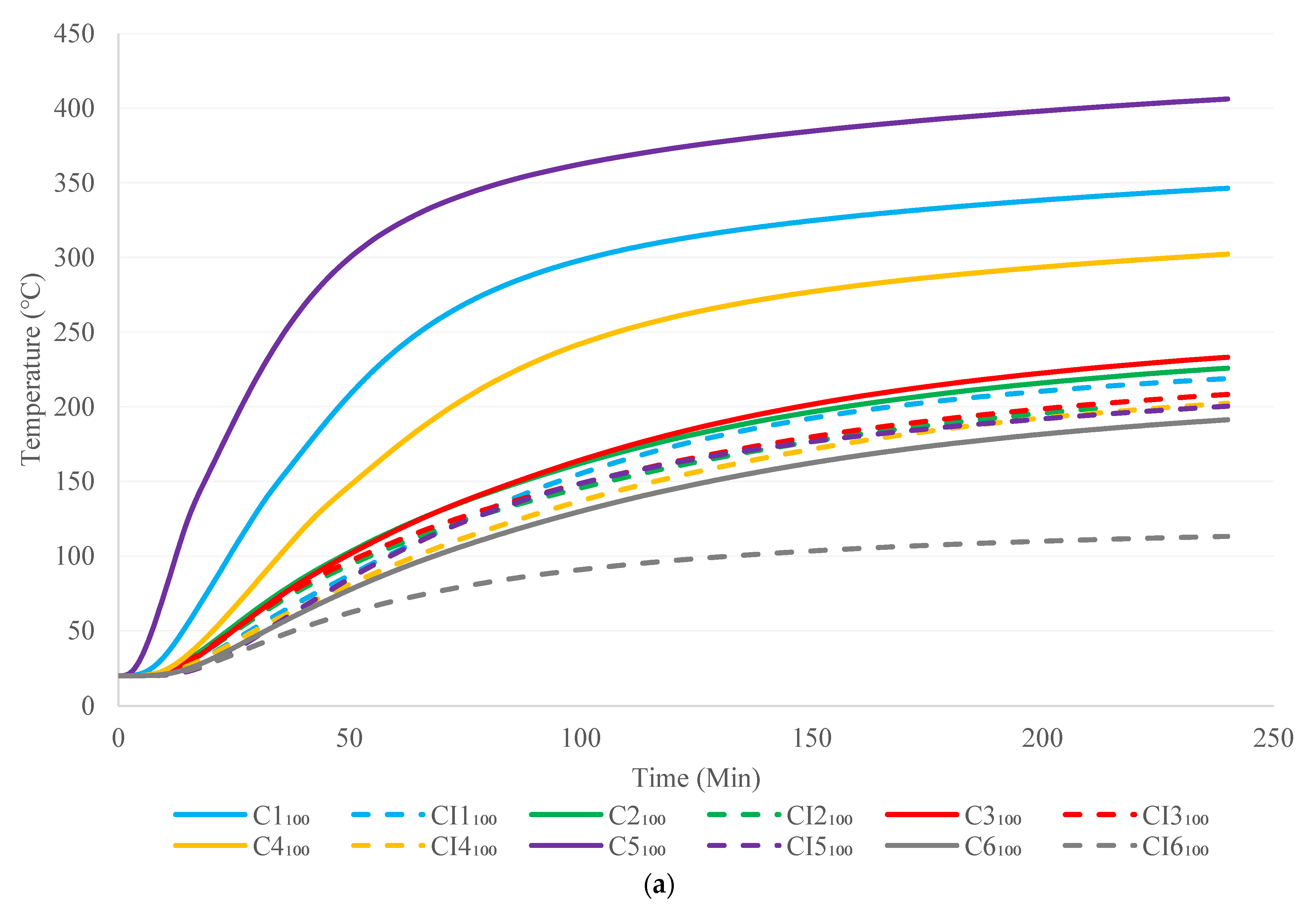

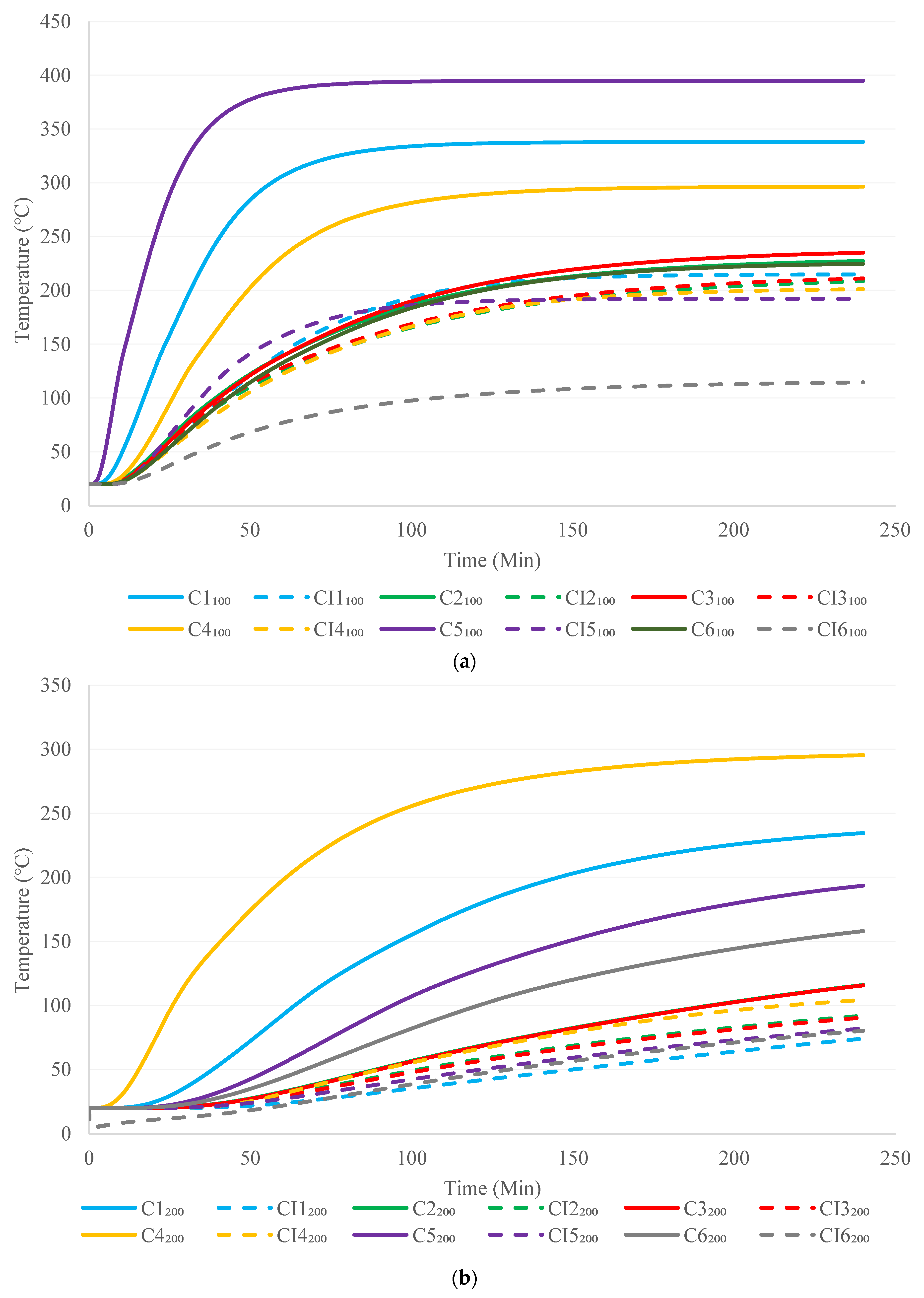

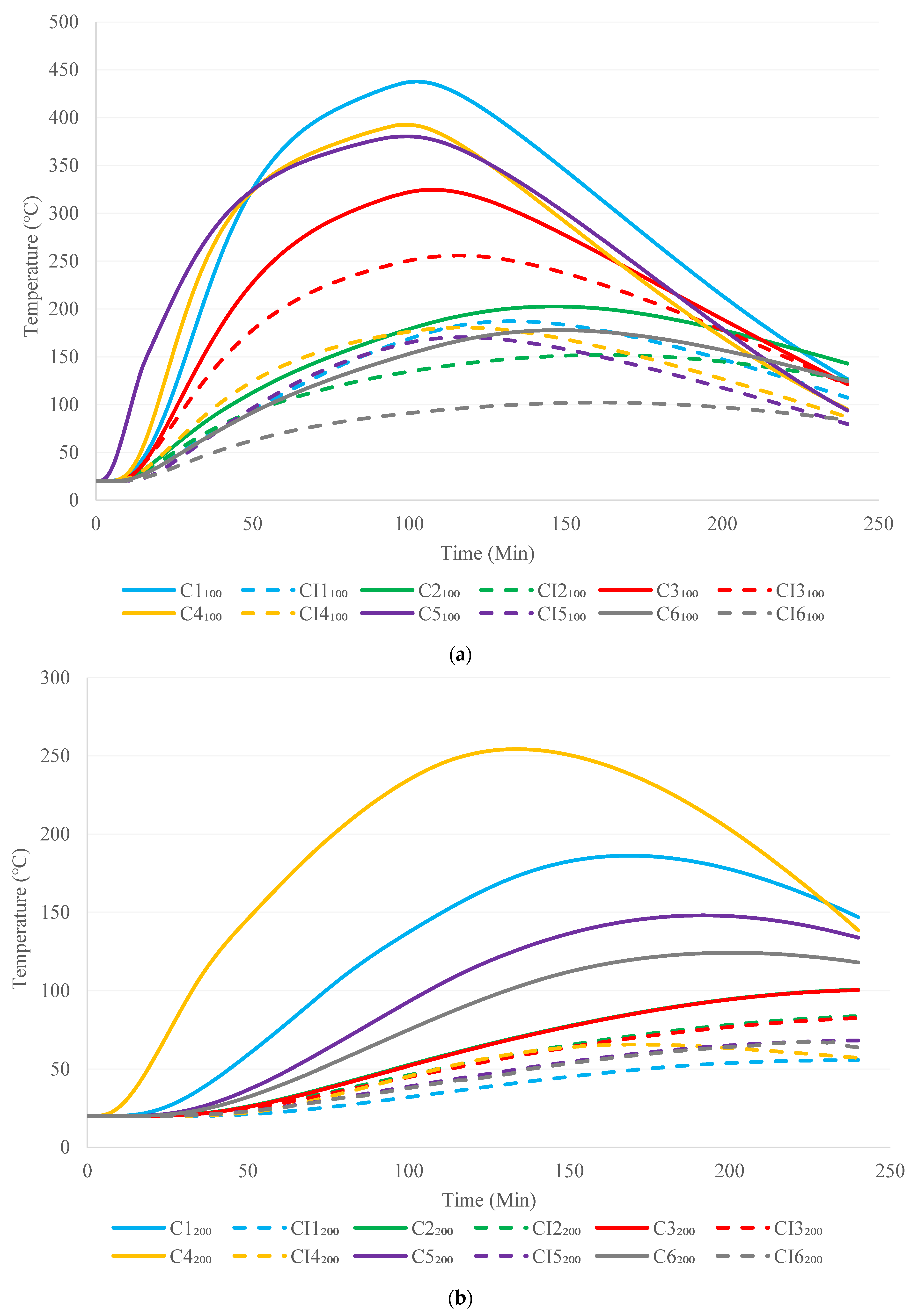

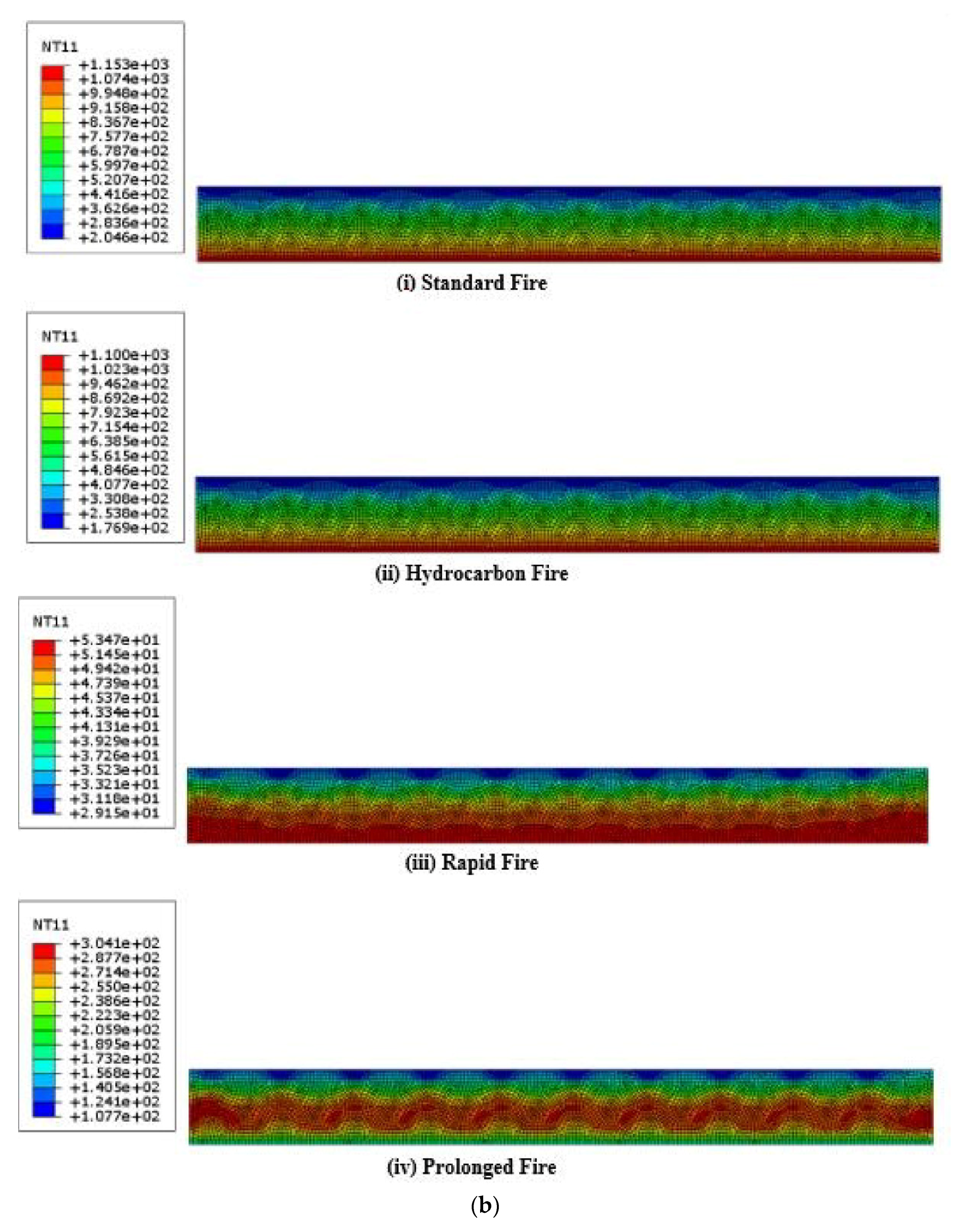

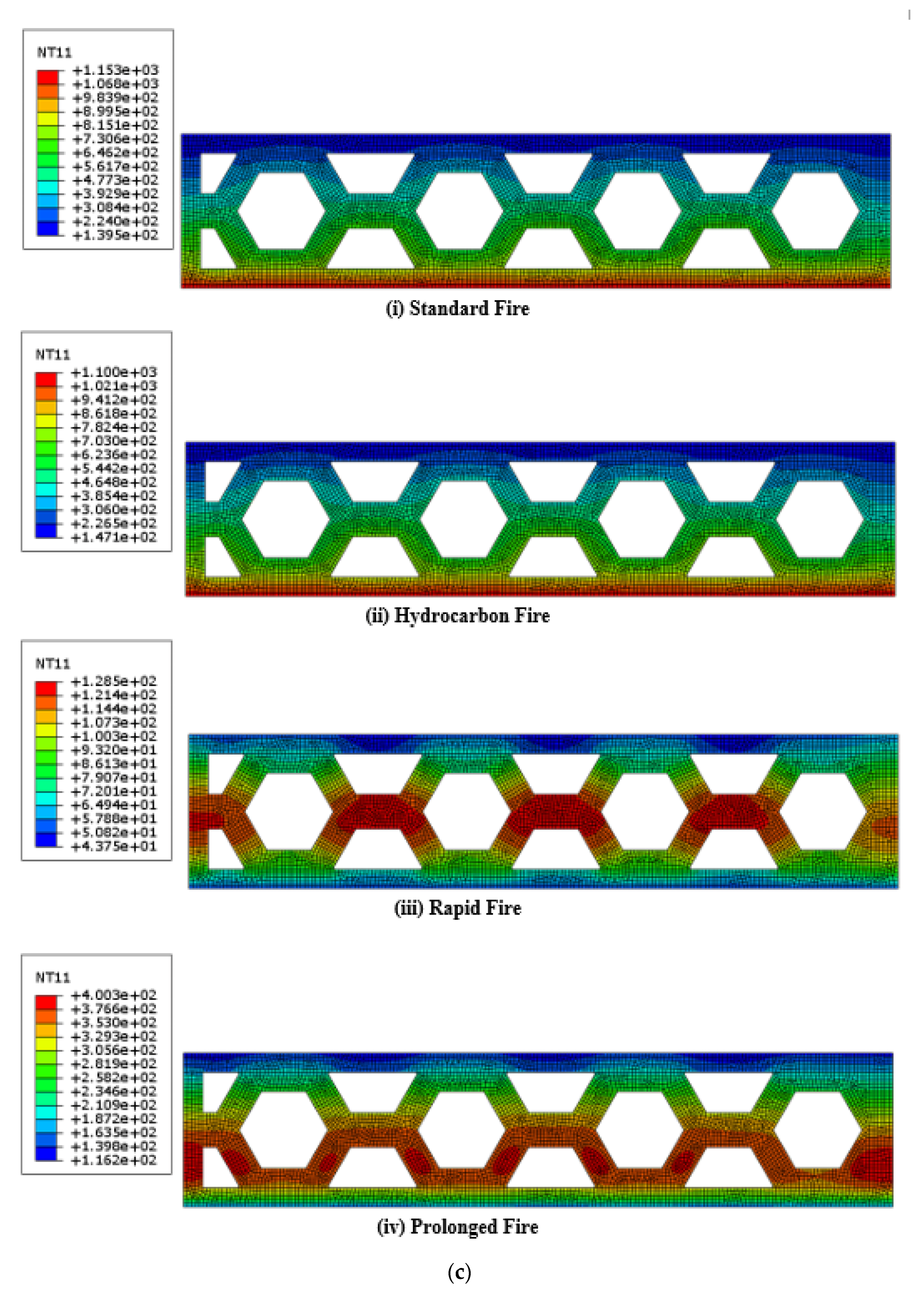

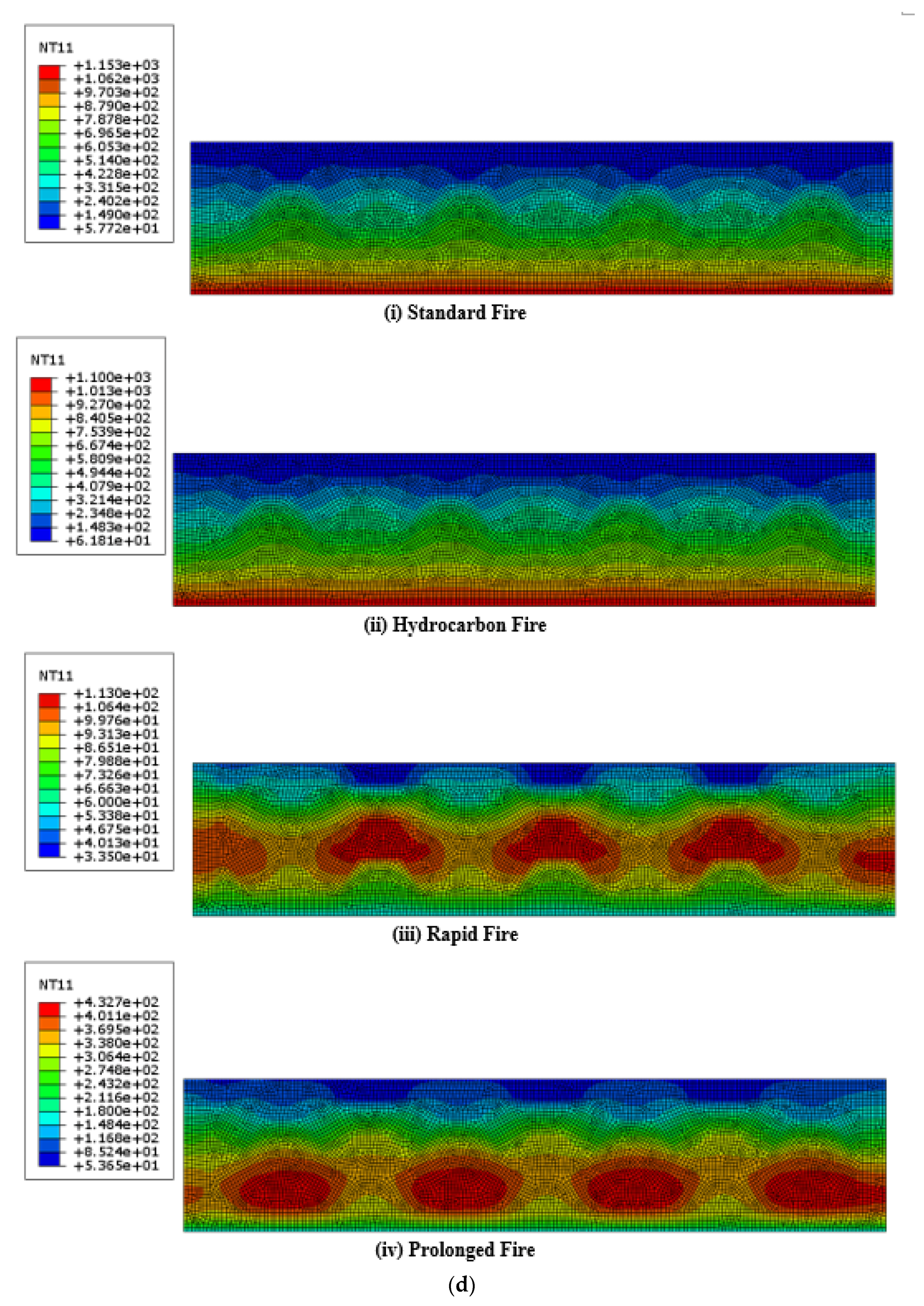

5.1. Standard Fire

5.2. Hydrocarbon Fire

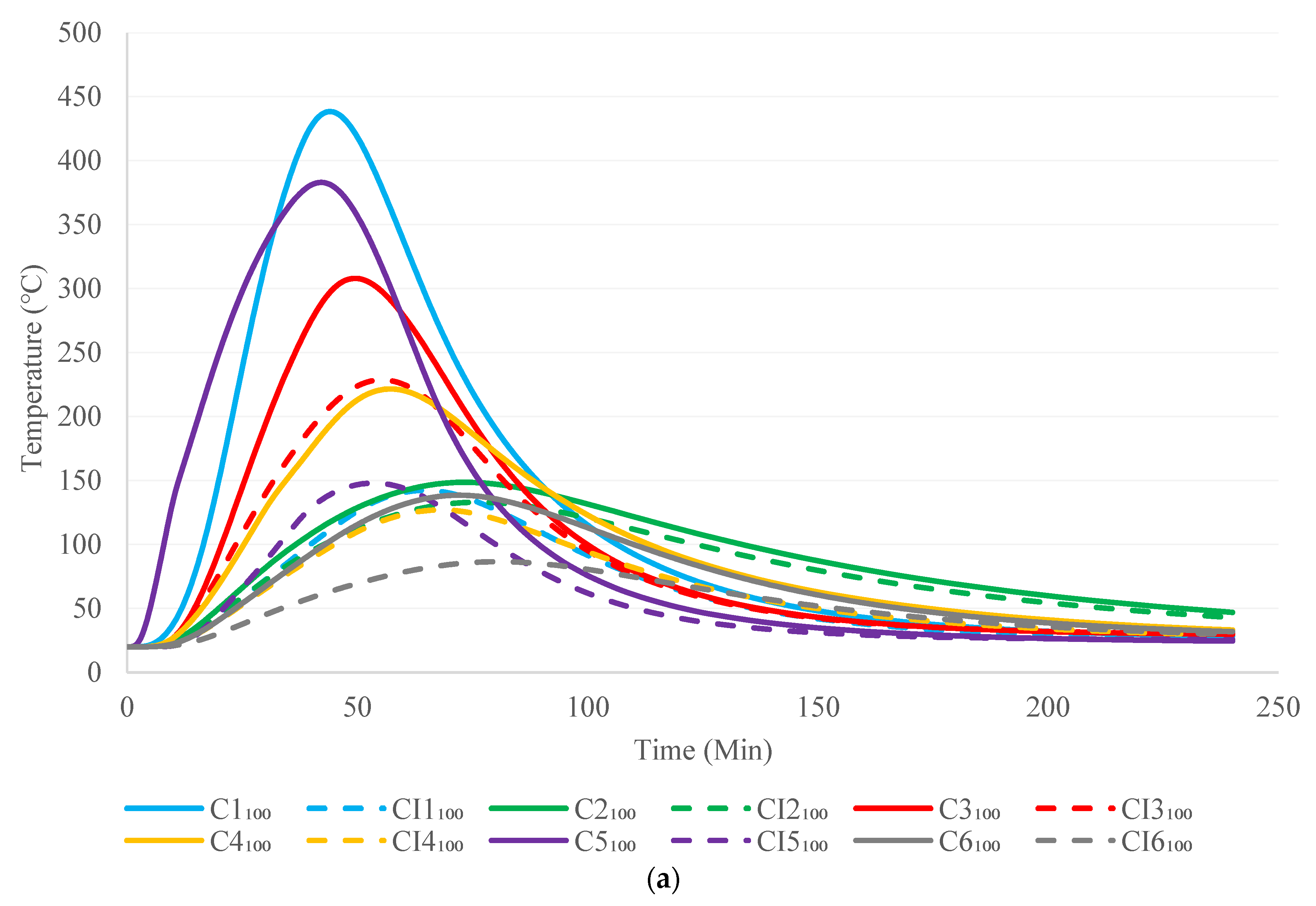

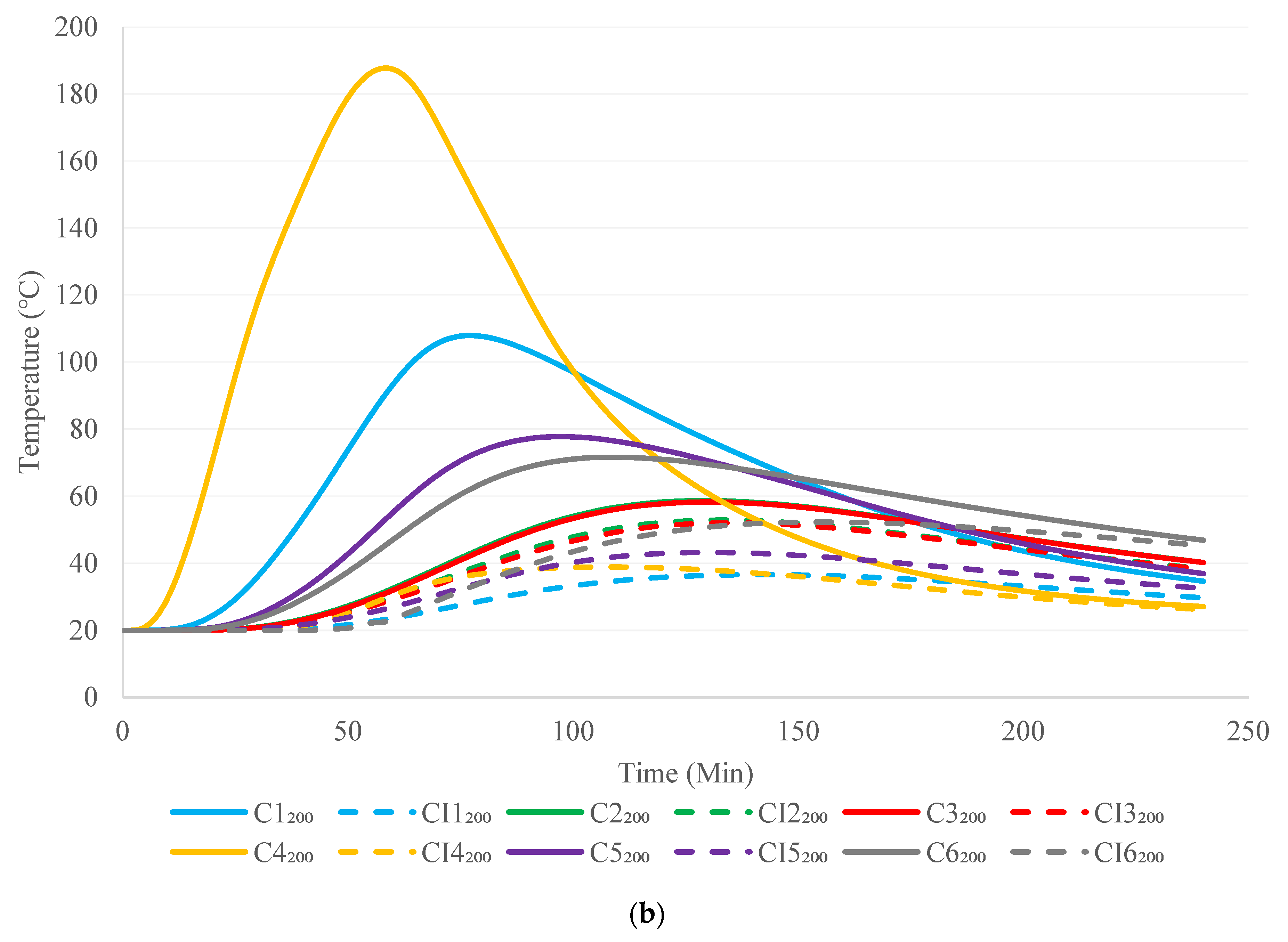

5.3. Rapid Fire

5.4. Prolonged Fire

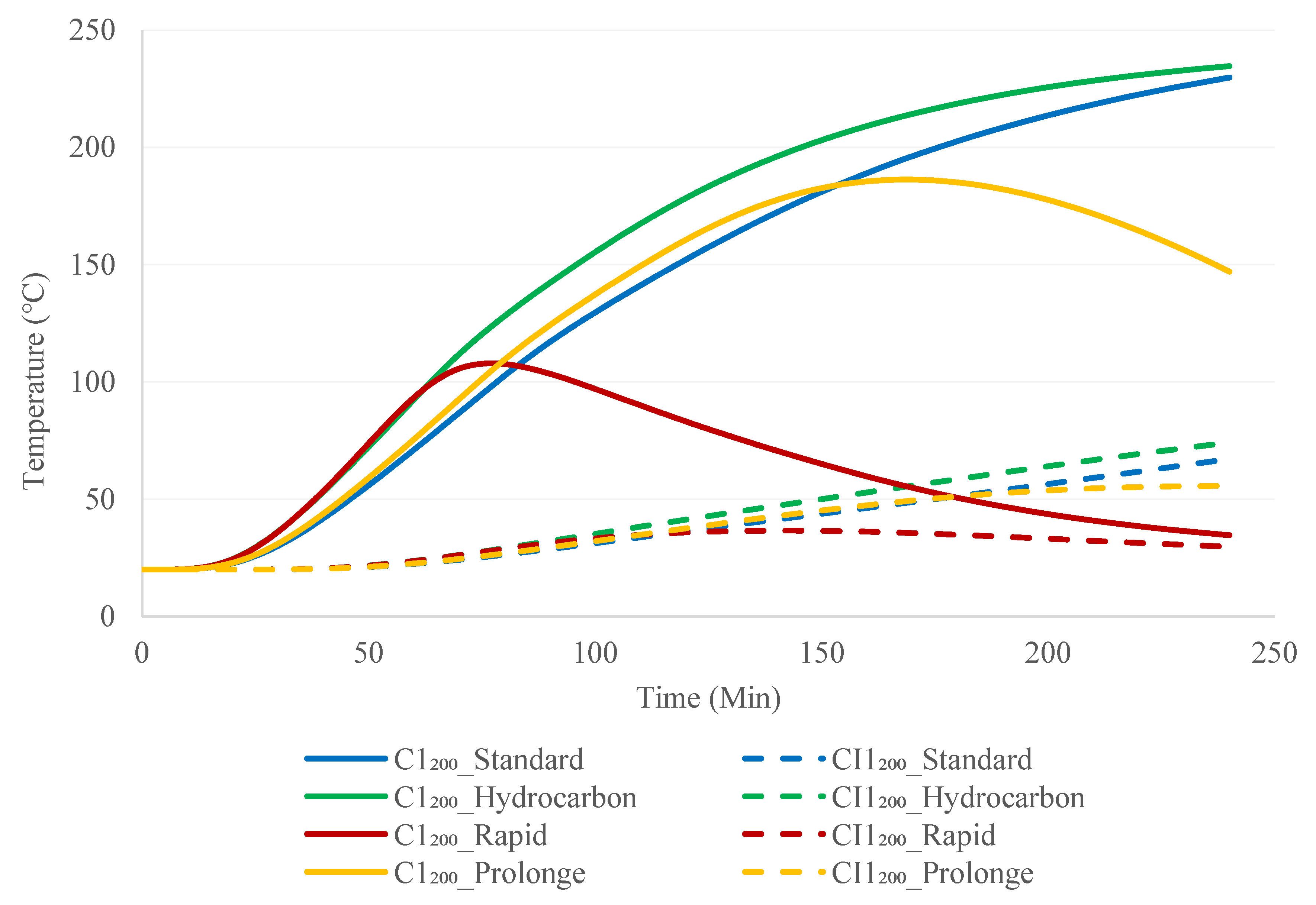

5.5. Effect of Individual Real Fire on Different Wall Configurations

6. Conclusions

- Non-load-bearing 3D-printed concrete cavity walls showed a lower insulation failure fire rating, whereas 3D-printed concrete cavity walls insulated with mineral wool had an excellent fire rating.

- The individual fire curves considerably affected the unexposed surface temperature increase in wall panels. The outcomes prove that rapid fire and prolonged fire are crucial in terms of the fire performance associated with standard and hydrocarbon fire curves.

- Ample enhancement on fire performance was observed when the wall thicknesses of 3D-printed concrete walls were increased from 100 mm to 200 mm.

- The cellular configuration (C6) showed greater fire performance with mineral wool insulation compared to the other wall configurations, regardless of the fire scenario.

- The fluctuating fire behaviour of these wall configurations needs to be investigated further considering the measured thermal properties of 3D-printable concrete at higher temperatures and with the incorporation of structural failures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Adaloudis, M.; Bonnin Roca, J. Sustainability tradeoffs in the adoption of 3D Concrete Printing in the construction industry. J. Clean. Prod. 2021, 307, 127201. [Google Scholar] [CrossRef]

- Khan, M.S.; Sanchez, F.; Zhou, H. 3-D printing of concrete: Beyond horizons. Cem. Concr. Res. 2020, 133, 106070. [Google Scholar] [CrossRef]

- Xiao, J.; Ji, G.; Zhang, Y.; Ma, G.; Mechtcherine, V.; Pan, J.; Wang, L.; Ding, T.; Duan, Z.; Du, S. Large-scale 3D printing concrete technology: Current status and future opportunities. Cem. Concr. Compos. 2021, 122, 104115. [Google Scholar] [CrossRef]

- Pessoa, S.; Guimarães, A.S.; Lucas, S.S.; Simões, N. 3D printing in the construction industry—A systematic review of the thermal performance in buildings. Renew. Sustain. Energy Rev. 2021, 141, 110794. [Google Scholar] [CrossRef]

- Menna, C.; Mata-Falcón, J.; Bos, F.P.; Vantyghem, G.; Ferrara, L.; Asprone, D.; Salet, T.; Kaufmann, W. Opportunities and challenges for structural engineering of digitally fabricated concrete. Cem. Concr. Res. 2020, 133, 106079. [Google Scholar] [CrossRef]

- Khan, S.A.; Koç, M.; Al-Ghamdi, S.G. Sustainability assessment, potentials and challenges of 3D printed concrete structures: A systematic review for built environmental applications. J. Clean. Prod. 2021, 303, 127027. [Google Scholar] [CrossRef]

- Ooms, T.; Vantyghem, G.; Van Coile, R.; De Corte, W. A parametric modelling strategy for the numerical simulation of 3D concrete printing with complex geometries. Addit. Manuf. 2021, 38, 101743. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Bos, F.P.; Perrot, A.; da Silva, W.R.L.; Nerella, V.N.; Fataei, S.; Wolfs, R.J.M.; Sonebi, M.; Roussel, N. Extrusion-based additive manufacturing with cement-based materials—Production steps, processes, and their underlying physics: A review. Cem. Concr. Res. 2020, 132, 106037. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P.A.G.; Tan, M.J.; Gibson, I. A review of 3D concrete printing systems and materials properties: Current status and future research prospects. Rapid Prototyp. J. 2018, 24, 784–798. [Google Scholar] [CrossRef] [Green Version]

- Yazyev, B.; Karpova, E.; Skripkiunas, G.; Sedova, A.; Tsimbalyuk, Y. Additive manufacturing of concrete wall structures. E3S Web Conf. 2021, 281, 03007. [Google Scholar] [CrossRef]

- Nguyen-Van, V.; Panda, B.; Zhang, G.; Nguyen-Xuan, H.; Tran, P. Digital design computing and modelling for 3-D concrete printing. Autom. Constr. 2021, 123, 103529. [Google Scholar] [CrossRef]

- Ahmed, A.; Azam, A.; Aslam Bhutta, M.M.; Khan, F.A.; Aslam, R.; Tahir, Z. Discovering the technology evolution pathways for 3D printing (3DP) using bibliometric investigation and emerging applications of 3DP during COVID-19. Clean. Environ. Syst. 2021, 3, 100042. [Google Scholar] [CrossRef]

- Luhar, S.; Suntharalingam, T.; Navaratnam, S.; Luhar, I.; Thamboo, J.; Poologanathan, K.; Gatheeshgar, P. Sustainable and Renewable Bio-Based Natural Fibres and Its Application for 3D Printed Concrete: A Review. Sustainability 2020, 12, 10485. [Google Scholar] [CrossRef]

- Delgado Camacho, D.; Clayton, P.; O’Brien, W.J.; Seepersad, C.; Juenger, M.; Ferron, R.; Salamone, S. Applications of additive manufacturing in the construction industry—A forward-looking review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Gatheeshgar, P.; Upasiri, I.; Poologanathan, K.; Nagaratnam, B.; Rajanayagam, H.; Navaratnam, S. Numerical Study of Fire and Energy Performance of Innovative Light-Weight 3D Printed Concrete Wall Configurations in Modular Building System. Sustainability 2021, 13, 2314. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Upasiri, I.; Gatheeshgar, P.; Poologanathan, K.; Nagaratnam, B.; Santos, P.; Rajanayagam, H. Energy Performance of 3D-Printed Concrete Walls: A Numerical Study. Buildings 2021, 11, 432. [Google Scholar] [CrossRef]

- Hayes, S.; Desha, C.; Baumeister, D. Learning from nature—Biomimicry innovation to support infrastructure sustainability and resilience. Technol. Forecast. Soc. Chang. 2020, 161, 120287. [Google Scholar] [CrossRef]

- du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and Functional: A Review of Biomimetic Design in Additive Manufacturing. Addit. Manuf. 2019, 27, 408–427. [Google Scholar] [CrossRef]

- Islam, M.K.; Hazell, P.J.; Escobedo, J.P.; Wang, H. Biomimetic armour design strategies for additive manufacturing: A review. Mater. Des. 2021, 205, 109730. [Google Scholar] [CrossRef]

- Jia, Z.; Wang, L. 3D printing of biomimetic composites with improved fracture toughness. Acta Mater. 2019, 173, 61–73. [Google Scholar] [CrossRef]

- Ko, K.; Jin, S.; Lee, S.E.; Lee, I.; Hong, J.-W. Bio-inspired bimaterial composites patterned using three-dimensional printing. Compos. Part B: Eng. 2019, 165, 594–603. [Google Scholar] [CrossRef]

- du Plessis, A.; Babafemi, A.J.; Paul, S.C.; Panda, B.; Tran, J.P.; Broeckhoven, C. Biomimicry for 3D concrete printing: A review and perspective. Addit. Manuf. 2021, 38, 101823. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, H.; Li, Z.; Ma, G. Mechanical behaviors of 3D printed lightweight concrete structure with hollow section. Arch. Civ. Mech. Eng. 2020, 20, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Panda, B.; Leite, M.; Biswal, B.B.; Niu, X.; Garg, A. Experimental and numerical modelling of mechanical properties of 3D printed honeycomb structures. Measurement 2018, 116, 495–506. [Google Scholar] [CrossRef]

- Moini, M.; Olek, J.; Youngblood, J.P.; Magee, B.; Zavattieri, P.D. Additive Manufacturing and Performance of Architectured Cement-Based Materials. Adv. Mater. 2018, 30, e1802123. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rashid, M.H.; Molla, M.; Taki, I.M. Effect of Elevated Temperature on Bond Strength of Concrete. In Materials Science Forum; Trans Tech Publications Ltd.: Freinbach, Switzerland, 2019; Volume 972, pp. 26–33. [Google Scholar]

- Upasiri, I.R.; Konthesigha, K.M.C.; Nanayakkara, S.M.A.; Poologanathan, K.; Gatheeshgar, P.; Nuwanthika, D. Finite element analysis of lightweight composite sandwich panels exposed to fire. J. Build. Eng. 2021, 40, 102329. [Google Scholar] [CrossRef]

- Mohd Ali, A.Z.; Sanjayan, J.; Guerrieri, M. Performance of geopolymer high strength concrete wall panels and cylinders when exposed to a hydrocarbon fire. Constr. Build. Mater. 2017, 137, 195–207. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Gatheeshgar, P.; Upasiri, I.; Poologanathan, K.; Nagaratnam, B.; Corradi, M.; Nuwanthika, D. Fire performance of innovative 3D printed concrete composite wall panels—A Numerical Study. Case Stud. Constr. Mater. 2021, 15, e00586. [Google Scholar] [CrossRef]

- del Coz-Díaz, J.J.; Martínez-Martínez, J.E.; Alonso-Martínez, M.; Álvarez Rabanal, F.P. Comparative study of LightWeight and Normal Concrete composite slabs behaviour under fire conditions. Eng. Struct. 2020, 207, 110196. [Google Scholar] [CrossRef]

- Banerji, S.; Kodur, V.; Solhmirzaei, R. Experimental behavior of ultra high performance fiber reinforced concrete beams under fire conditions. Eng. Struct. 2020, 208, 110316. [Google Scholar] [CrossRef]

- Weerasinghe, P.; Nguyen, K.; Mendis, P.; Guerrieri, M. Large-scale experiment on the behaviour of concrete flat slabs subjected to standard fire. J. Build. Eng. 2020, 30, 101255. [Google Scholar] [CrossRef]

- Cao, V.D.; Bui, T.Q.; Kjøniksen, A.-L. Thermal analysis of multi-layer walls containing geopolymer concrete and phase change materials for building applications. Energy 2019, 186, 115792. [Google Scholar] [CrossRef]

- Steau, E.; Mahendran, M.; Poologanathan, K. Elevated temperature thermal properties of carbon steels used in cold-formed light gauge steel frame systems. J. Build. Eng. 2020, 28, 101074. [Google Scholar] [CrossRef]

- Gunalan, S.; Mahendran, M. Fire performance of cold-formed steel wall panels and prediction of their fire resistance rating. Fire Saf. J. 2014, 64, 61–80. [Google Scholar] [CrossRef] [Green Version]

- Steau, E.; Mahendran, M.; Poologanathan, K. Experimental study of fire resistant board configurations under standard fire conditions. Fire Saf. J. 2020, 116, 103153. [Google Scholar] [CrossRef]

- Gunalan, S.; Kolarkar, P.; Mahendran, M. Experimental study of load bearing cold-formed steel wall systems under fire conditions. Thin-Walled Struct. 2013, 65, 72–92. [Google Scholar] [CrossRef] [Green Version]

- Ariyanayagam, A.; Mahendran, M. Experimental Study of Load-Bearing Cold-Formed Steel Walls Exposed to Realistic Design Fires. J. Struct. Fire Eng. 2014, 5, 291–330. [Google Scholar] [CrossRef] [Green Version]

- Ariyanayagam, A.D.; Mahendran, M. Fire design rules for load bearing cold-formed steel frame walls exposed to realistic design fire curves. Fire Saf. J. 2015, 77, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Ariyanayagam, A.D.; Mahendran, M. Influence of cavity insulation on the fire resistance of light gauge steel framed walls. Constr. Build. Mater. 2019, 203, 687–710. [Google Scholar] [CrossRef]

- Ariyanayagam, A.D.; Mahendran, M. Experimental study of non-load bearing light gauge steel framed walls in fire. J. Constr. Steel Res. 2018, 145, 529–551. [Google Scholar] [CrossRef] [Green Version]

- Dias, Y.; Keerthan, P.; Mahendran, M. Fire performance of steel and plasterboard sheathed non-load bearing LSF walls. Fire Saf. J. 2019, 103, 1–18. [Google Scholar] [CrossRef]

- Kesawan, S.; Mahendran, M. Fire tests of load-bearing LSF walls made of hollow flange channel sections. J. Constr. Steel Res. 2015, 115, 191–205. [Google Scholar] [CrossRef]

- Kesawan, S.; Mahendran, M. Fire design rules for LSF walls made of hollow flange channel sections. Thin-Walled Struct. 2016, 107, 300–314. [Google Scholar] [CrossRef]

- Perera, D.; Poologanathan, K.; Gillie, M.; Gatheeshgar, P.; Sherlock, P.; Nanayakkara, S.M.A.; Konthesingha, K.M.C. Fire performance of cold, warm and hybrid LSF wall panels using numerical studies. Thin-Walled Struct. 2020, 157, 107109. [Google Scholar] [CrossRef]

- Ariyanayagam, A.D.; Mahendran, M. Numerical modelling of load bearing light gauge steel frame wall systems exposed to realistic design fires. Thin-Walled Struct. 2014, 78, 148–170. [Google Scholar] [CrossRef] [Green Version]

- Gunalan, S.; Mahendran, M. Finite element modelling of load bearing cold-formed steel wall systems under fire conditions. Eng. Struct. 2013, 56, 1007–1027. [Google Scholar] [CrossRef] [Green Version]

- Keerthan, P.; Mahendran, M. Thermal Performance of Composite Panels Under Fire Conditions Using Numerical Studies: Plasterboards, Rockwool, Glass Fibre and Cellulose Insulations. Fire Technol. 2012, 49, 329–356. [Google Scholar] [CrossRef] [Green Version]

- Suntharalingam, T.; Upasiri, I.; Gatheeshgar, P.; Poologanathan, K.; Nagaratnam, B.; Rajanayagam, H.; Navaratnam, S. Fire resistance of 3D printed concrete composite wall panels exposed to various fire scenarios. J. Struct. Fire Eng. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Xiao, J.; Han, N.; Zhang, L.; Zou, S. Mechanical and microstructural evolution of 3D printed concrete with polyethylene fiber and recycled sand at elevated temperatures. Constr. Build. Mater. 2021, 293, 123524. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Liu, Z.; Lao, W.; Lu, B.; Zhang, D.; Tan, M.J. Printability and fire performance of a developed 3D printable fibre reinforced cementitious composites under elevated temperatures. Virtual Phys. Prototyp. 2018, 14, 284–292. [Google Scholar] [CrossRef]

- Cicione, A.; Kruger, J.; Walls, R.S.; Van Zijl, G. An experimental study of the behavior of 3D printed concrete at elevated temperatures. Fire Saf. J. 2021, 120, 103075. [Google Scholar] [CrossRef]

- Cicione, A.; Mazolwana, K.; Kruger, J.; Walls, R.; Sander, Z.; Van Zijl, G. Effect of transverse and longitudinal confinement on the interlayer bond in 3D printed concrete at elevated temperatures: An experimental study. In Proceedings of Proceedings of the 11th International Conference on Structures in Fire (SiF2020), Brisbane, Australia, 30 November–2 December 2020. [Google Scholar]

- Sun, J.; Xiao, J.; Li, Z.; Feng, X. Experimental study on the thermal performance of a 3D printed concrete prototype building. Energy Build. 2021, 241, 110965. [Google Scholar] [CrossRef]

- Kaszynka, M.; Olczyk, N.; Techman, M.; Skibicki, S.; Zielinski, A.; Filipowicz, K.; Wroblewski1, T.; Hoffmann, M. Thermal-humidity parameters of 3D printed wall. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 471, p. 082018. [Google Scholar]

- Yang, S.; Wi, S.; Park, J.H.; Cho, H.M.; Kim, S. Novel proposal to overcome insulation limitations due to nonlinear structures using 3D printing: Hybrid heat-storage system. Energy Build. 2019, 197, 177–187. [Google Scholar] [CrossRef]

- Alchaar, A.S.; Al-Tamimi, A.K. Mechanical properties of 3D printed concrete in hot temperatures. Constr. Build. Mater. 2021, 266, 120991. [Google Scholar] [CrossRef]

- Marais, H.; Christen, H.; Cho, S.; De Villiers, W.; Van Zijl, G. Computational assessment of thermal performance of 3D printed concrete wall structures with cavities. J. Build. Eng. 2021, 41, 102431. [Google Scholar] [CrossRef]

- Mahadevan, M.; Francis, A.; Thomas, A. A simulation-based investigation of sustainability aspects of 3D printed structures. J. Build. Eng. 2020, 32, 101735. [Google Scholar] [CrossRef]

- Hibbett; Karlsson; Sorensen. ABAQUS/Standard: User’s Manual; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 1998; Volume 1. [Google Scholar]

- EN 1993-1-2; Eurocode 3: Design of Steel Structures—Part 1-2: General Rules—Structural Fire Design. European Committee for Standardisation: London, UK, 2007.

- Upasiri, I.; Konthesingha, C.; Nanayakkara, A.; Poologanathan, K.; Nagaratnam, B.; Perampalam, G. Evaluation of fire performance of lightweight concrete wall panels using finite element analysis. J. Struct. Fire Eng. 2021, 12, 328–362. [Google Scholar] [CrossRef]

- Upasiri, I.; Konthesingha, C.; Poologanathan, K.; Nanayakkara, A.; Nagaratnam, B. Review on Fire Performance of Cellular Lightweight Concrete. In ICSBE 2018; Dissanayake, R., Mendis, P., Eds.; Springer: Singapore, 2020; pp. 470–478. [Google Scholar]

- Tan, X.; Chen, W.; Wang, J.; Yang, D.; Qi, X.; Ma, Y.; Wang, X.; Ma, S.; Li, C. Influence of high temperature on the residual physical and mechanical properties of foamed concrete. Constr. Build. Mater. 2017, 135, 203–211. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Kunhanandan Nambiar, E.K.; Indu Siva Ranjani, G. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- EN 1991-1-2; Eurocode 1: Actions on Structures—Part 1–2: General Actions—Actions on Structures Exposed to Fire. British Standards: London, UK, 1991.

- American Society for Testing and Materials. ASTM E119: Standard Test Methods for Fire Tests of Building Construction and Materials; ASTM: West Conshohocken, PA, USA, 2021. [Google Scholar] [CrossRef]

- Ariyanayagam, A.D.; Mahendran, M. Development of realistic design fire time-temperature curves for the testing of cold-formed steel wall systems. Front. Struct. Civ. Eng. 2014, 8, 427–447. [Google Scholar] [CrossRef] [Green Version]

| Fire Curve | Rapid Fire | Prolonged Fire |

|---|---|---|

| Opening Factor (m1/2) | 0.08 | 0.03 |

| Area of Ventilation (m2) | 2.85 | 1.44 |

| Compartment’s Thermal Inertia (J/m2 S1/2 K) | 715 | 702 |

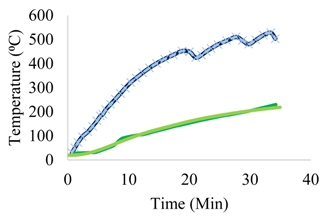

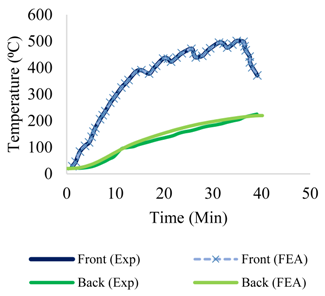

| Comparison of Experimental Results of 3DPC Samples with 2D FEA in Abaqus | Comparison of Experimental Results of C3DPC Samples with 2D FEA in Abaqus |

|---|---|

3DPC(S1) |  C3DPC(S1) |

3DPC(S2) |  C3DPC(S2) |

3DPC(S3) |  C3DPC(S3) |

| Wall Configuration (1 m Length) | 100 mm (12 mm Layer) | 200 mm (25 mm Layer) |

|---|---|---|

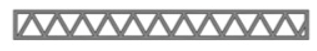

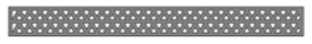

| C1 Truss |  |  |

| C2 Triangular |  |  |

| C3 Triangular |  |  |

| C4 Lattice |  |  |

| C5 Lattice |  |  |

| C6 Cellular |  |  |

| Fire Scenario | Density (kg/m3) | Thickness of the Wall (mm) | Wall Configuration | Models |

|---|---|---|---|---|

| ISO Fire | 2400 | 100 200 | C1, C2, C3, C4, C5, C6 CI1, CI2, CI3, CI4, CI5, CI6 | 24 |

| Hydrocarbon | 2400 | 100 200 | C1, C2, C3, C4, C5, C6 CI1, CI2, CI3, CI4, CI5, CI6 | 24 |

| Rapid Fire | 2400 | 100 200 | C1, C2, C3, C4, C5, C6 CI1, CI2, CI3, CI4, CI5, CI6 | 24 |

| Prolonged Fire | 2400 | 100 200 | C1, C2, C3, C4, C5, C6 CI1, CI2, CI3, CI4, CI5, CI6 | 24 |

| Total | 96 |

| Configurations | Insulation Failure Time under Different Fire Exposure (min) | ||||

|---|---|---|---|---|---|

| Standard Fire | Hydrocarbon Fire | Rapid Fire | Prolonged Fire | ||

| Cavity walls | C1100 | 37 | 25 | 20 | 29 |

| C2100 | 97 | 75 | - | 82 | |

| C3100 | 95 | 74 | 27 | 35 | |

| C4100 | 53 | 38 | 36 | 25 | |

| C5100 | 20 | 12 | 12 | 17 | |

| C6100 | 144 | 78 | - | 106 | |

| Mineral wool-infilled walls | CI1100 | 104 | 70 | - | 92 |

| CI2100 | 120 | 93 | - | - | |

| CI3100 | 116 | 89 | 33 | 44 | |

| CI4100 | 128 | 91 | - | 76 | |

| CI5100 | 112 | 61 | - | 94 | |

| CI6100 | - | - | - | - | |

| Configurations | Insulation Failure Time under Different Fire Exposure (min) | ||||

|---|---|---|---|---|---|

| Standard Fire | Hydrocarbon Fire | Rapid Fire | Prolonged Fire | ||

| Cavity walls | C1200 | 125 | 101 | - | 119 |

| C2200 | - | - | - | - | |

| C3200 | - | - | - | - | |

| C4200 | 60 | 44 | 42 | 56 | |

| C5200 | 187 | 159 | - | - | |

| C6200 | - | - | - | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suntharalingam, T.; Upasiri, I.; Nagaratnam, B.; Poologanathan, K.; Gatheeshgar, P.; Tsavdaridis, K.D.; Nuwanthika, D. Finite Element Modelling to Predict the Fire Performance of Bio-Inspired 3D-Printed Concrete Wall Panels Exposed to Realistic Fire. Buildings 2022, 12, 111. https://doi.org/10.3390/buildings12020111

Suntharalingam T, Upasiri I, Nagaratnam B, Poologanathan K, Gatheeshgar P, Tsavdaridis KD, Nuwanthika D. Finite Element Modelling to Predict the Fire Performance of Bio-Inspired 3D-Printed Concrete Wall Panels Exposed to Realistic Fire. Buildings. 2022; 12(2):111. https://doi.org/10.3390/buildings12020111

Chicago/Turabian StyleSuntharalingam, Thadshajini, Irindu Upasiri, Brabha Nagaratnam, Keerthan Poologanathan, Perampalam Gatheeshgar, Konstantinos Daniel Tsavdaridis, and Dilini Nuwanthika. 2022. "Finite Element Modelling to Predict the Fire Performance of Bio-Inspired 3D-Printed Concrete Wall Panels Exposed to Realistic Fire" Buildings 12, no. 2: 111. https://doi.org/10.3390/buildings12020111

APA StyleSuntharalingam, T., Upasiri, I., Nagaratnam, B., Poologanathan, K., Gatheeshgar, P., Tsavdaridis, K. D., & Nuwanthika, D. (2022). Finite Element Modelling to Predict the Fire Performance of Bio-Inspired 3D-Printed Concrete Wall Panels Exposed to Realistic Fire. Buildings, 12(2), 111. https://doi.org/10.3390/buildings12020111