Effects of the Design Parameters of Ridge Vents on Induced Buoyancy-Driven Ventilation

Abstract

:1. Introduction

2. Materials and Methods

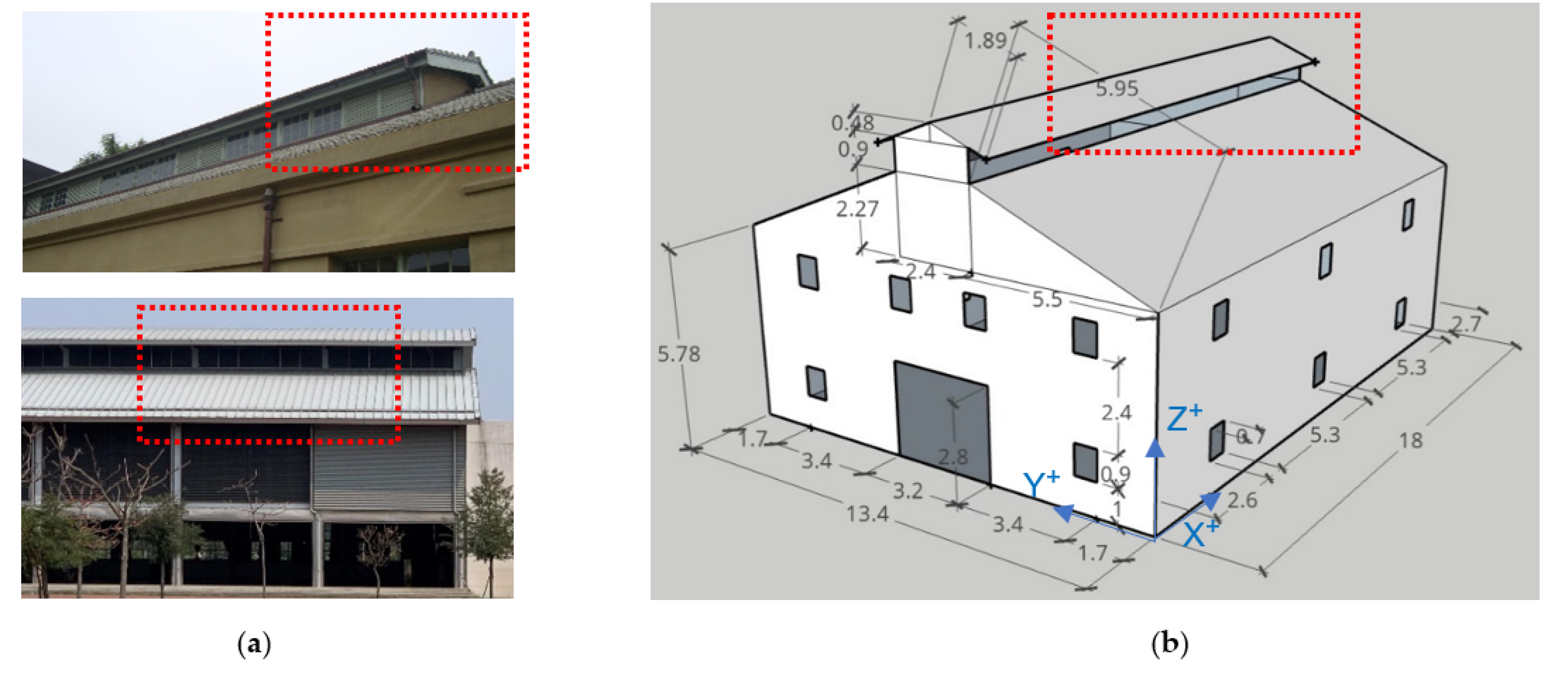

2.1. Research Object

- (1)

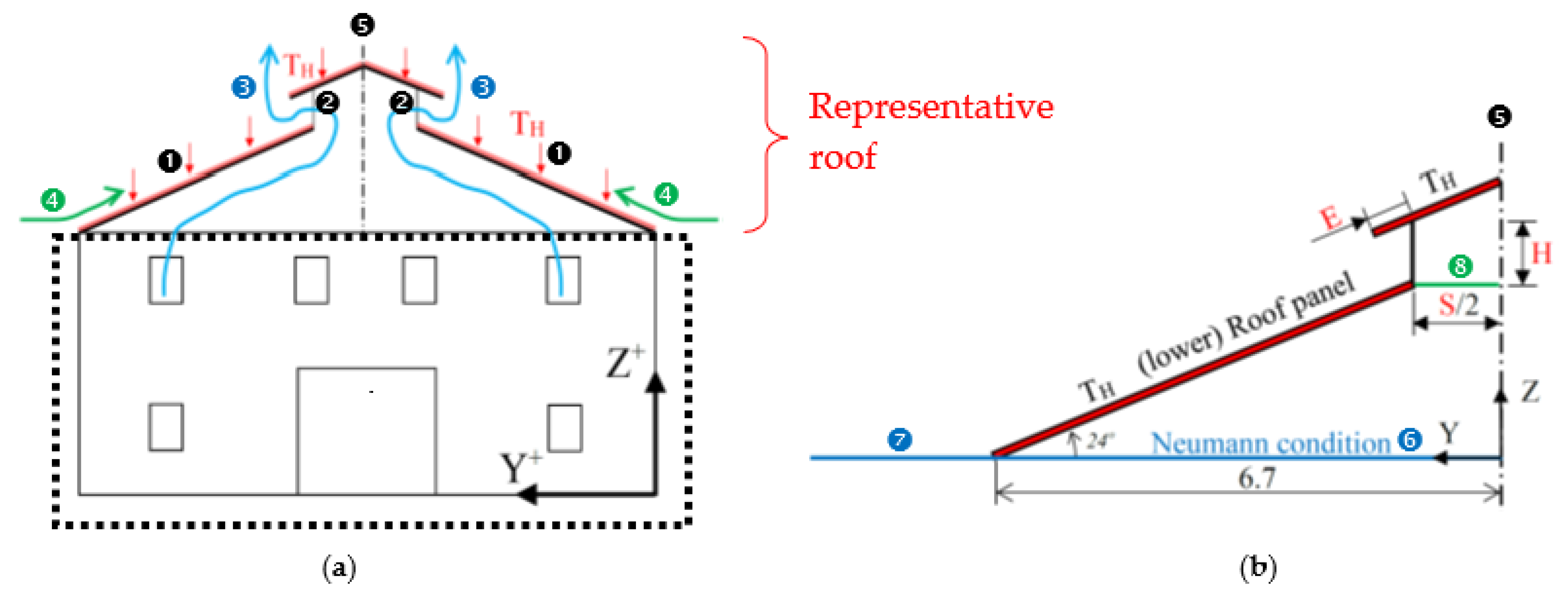

- The plane Y = 0 (❺ in Figure 2b) is set at the boundary of the computational domain to a wall with no-slip conditions to realize symmetry of the flow fields.

- (2)

- The lower boundary of the computational domain below the roof is given Neumann conditions (blue line ❻, Y = 0–6.7 m; Z = 0 m) so that the fluid can flow freely into or out of the computational domain. This represents that air can flow into and out of the roof space from and to the workshop space.

- (3)

- For the external flow field, the lower boundary of the computational domain is also given Neumann conditions (blue line ❼, Y > 6.7 m; Z = 0 m) to represent the free flow of outdoor air (symbol ❹ in Figure 2a).

- Width S: 1.2, 1.8, 2.4, and 3 m;

- Height H: 0.3, 0.6, 0.9, and 1.2 m;

- Eave overhang E: 0, 0.3, and 0.6 m.

2.2. Numerical Methods

3. Results and Discussion

3.1. Flow Patterns and Temperature Distribution Observations

3.2. Edge Effects

3.3. Design Parameter Effects

4. Conclusions

- (1)

- The flow patterns and temperature distributions in each case are similar. Two buoyancy-driven boundary layer flows that move obliquely upward form inside and outside of the roof panel occur under solar heating. The indoor buoyancy-driven flow moves toward the upper right underneath the roof panel and then turns upward and moves outside via the opening of the ridge vent. Later, this airflow combines with the outdoor buoyancy-driven flow from above the panel and separates again at the top end of the upper roof panel. The separated airflow flows vertically upward under the influence of thermal buoyancy and a symmetric flow pattern. High-temperature air accumulates at the indoor side of the upper roof panel of the ridge vent.

- (2)

- The ventilated airflow velocity significantly changes at both sides of the roof, resulting in edge effects. The influence range varies with the design parameters. When S = 3 m, H = 0.3 m and E = 0 m, the ventilation rate in the unit length along the X-axis (long axis of the roof) within the edge effect zone is 0.163 (m3/s)/m, while that within the non-edge effect zone is 0.144 (m3/s)/m, with no significant differences between the two.

- (3)

- For the design parameters of ridge vents, when there is thermal buoyancy-driven ventilation, height is the dominant design parameter. When there are high temperatures and low wind velocities over a long period of time, the designer can raise the ridge vent as high as possible to increase the ventilation efficiency.

- (4)

- The thermal buoyancy-driven ventilation rate (m3/s) induced by ridge vents can be expressed as follows: . The correlation equation deviates 5.36% from the simulation result. The applicable parameter ranges are S = 1.2–3.0 m, H = 0.3–1.2 m, and E = 0.3–0.6 m.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aflaki, A.; Mahyuddin, N.; Al-Cheikh Mahmoud, Z.; Baharum, M.R. A review on natural ventilation applications through building façade components and ventilation openings in tropical climates. Energy Build. 2015, 101, 153–162. [Google Scholar] [CrossRef]

- Jomehzadeh, F.; Hussen, H.M.; Calautit, J.K.; Nejat, P.; Ferwati, M.S. Natural ventilation by windcatcher (Badgir): A review on the impacts of geometry, microclimate and macroclimate. Energy Build. 2020, 226, 110396. [Google Scholar] [CrossRef]

- Izadyar, N.; Miller, W.; Rismanchi, B.; Garcia-Hansen, V. Impacts of façade openings’ geometry on natural ventilation and occupants’ perception: A review. Build. Environ. 2020, 170, 106613. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, D.; Tam, V.W.Y.; Tao, Y.; Zhang, G.; Setunge, S.; Shi, L. A critical review of combined natural ventilation techniques in sustainable buildings. Renew. Sustain. Energy Rev. 2021, 141, 110795. [Google Scholar] [CrossRef]

- Tariku, F.; Iffa, E. Temperature and air flow patterns in attic roof. J. Archit. Eng. 2017, 23, 04017014. [Google Scholar] [CrossRef]

- Wang, S.; Shen, Z. Impacts of ventilation ratio and vent balance on cooling load and air flow of naturally ventilated attics. Energies 2012, 5, 3218–3232. [Google Scholar] [CrossRef]

- Iffa, E.; Tariku, F. Attic baffle size and vent configuration impacts on attic ventilation. Build. Environ. 2015, 89, 28–37. [Google Scholar] [CrossRef]

- Wen, I.J.; Chang, P.C.; Lai, C.M.; Chiang, C.M. Numerical investigation on flow structures of two double roofs collocating with covered ridge with sidewall opening (CRSO). J. Inst. Eng. Archit. Eng. Div. 2008, 89, 20–25. [Google Scholar]

- Kang, J.H.; Lee, S.J. Improvement of natural ventilation in a large factory building using a louver ventilator. Build. Environ. 2008, 43, 2132–2141. [Google Scholar] [CrossRef]

- Cruz-Salas, M.V.; Castillo, A.; Huelsz, G. Experimental study on natural ventilation of a room with a windward window and different windexchangers. Energy Build. 2014, 84, 458–465. [Google Scholar] [CrossRef]

- Van Overbeke, P.; De Vogeleer, G.; Mendes, L.; Brusselman, E.; Demeyer, P.; Pieters, J. Methodology for airflow rate measurements in a naturally ventilated mock-up animal building with side and ridge vents. Build. Environ. 2016, 105, 153–163. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, T.; Cao, Z.; Zhai, C.; Wu, S.; Zhang, C.; Zhang, Q.; Lv, W. The influence of indoor thermal conditions on ventilation flow and pollutant dispersion in downstream industrial workshop. Build. Environ. 2021, 187, 107400. [Google Scholar] [CrossRef]

- Espinoza, K.; López, A.; Valera, D.L.; Molina-Aiz, F.D.; Torres, J.A.; Peña, A. Effects of ventilator configuration on the flow pattern of a naturally-ventilated three-span mediterranean greenhouse. Biosyst. Eng. 2017, 164, 13–30. [Google Scholar] [CrossRef]

- Chu, C.-R.; Lan, T.-W. Effectiveness of ridge vent to wind-driven natural ventilation in monoslope multi-span greenhouses. Biosyst. Eng. 2019, 186, 279–292. [Google Scholar] [CrossRef]

- Munar, E.V.; Bojacá, C. Study using a CFD approach of the efficiency of a roof ventilation closure system in a multi-tunnel greenhouse for nighttime microclimate optimization. Rev. Ceres 2020, 67, 345–356. [Google Scholar] [CrossRef]

- Spalding, D.B. The Phoenics Encyclopedia; CHAM Ltd.: London, UK, 1994. [Google Scholar]

| Parts of the Model | Geometric Data |

|---|---|

| Coordinates (X+, Y+, Z+) | For illustration of the factory case and representative roof (Figure 1 and Figure 2a) |

| Coordinates (X, Y, Z) | For illustration of the physical model (Figure 2b) |

| Coordinates (X’, Y’, Z’) | For illustration of the computational domain (Figure 3a) |

| Representative roof (Figure 2a) | 18 m × 13.4 m × (Z+ − 5.78) m (H) |

| Physical model (CFD model) (Figure 2b) | 18 m × 6.7 m × Z m (H) This Z value is determined by S and H; when S = 1.2 m and H = 1.2 m, Z reaches the maximum value, 3.9 m |

| Material and thickness of the roof panel | Steel, 0.06 m |

| Angle between the roof panel and ground (Figure 2b) | 24° |

| Other building materials | Adiabatic plates |

| Width of the ridge vent S (m) (Figure 2b) | 1.2, 1.8, 2.4, 3 |

| Height of the ridge vent H (m) (Figure 2b) | 0.3, 0.6, 0.9, 1.2 |

| Eave overhang of the ridge vent E (m) (Figure 2b) | 0, 0.3, 0.6 |

| Distance between the physical model and computational domain | Lx (= 18 m), Ly (6.7 m), 2Lz |

| Computational domain | 54 m × 13.4 m × 3Lz |

| Direction of gravitational acceleration | −Z’ |

| Plane Y’ = 0 in the computational domain (Figure 3a) | Wall with no-slip conditions (realizing symmetry of the physical model) |

| Plane Z’ = 0 in the computational domain (Figure 3a) | Neumann conditions (realizing free indoor and outdoor airflow induced by solar-heated roof panel) |

| Other planes | Neumann conditions (realizing free flow of the outdoor air) |

| Temperature of the roof surface (TH) | 70 °C |

| Environment temperature | 28 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.-M.; Lin, Y.-P.; Chung, S.-C.; Lai, C.-M. Effects of the Design Parameters of Ridge Vents on Induced Buoyancy-Driven Ventilation. Buildings 2022, 12, 112. https://doi.org/10.3390/buildings12020112

Chen C-M, Lin Y-P, Chung S-C, Lai C-M. Effects of the Design Parameters of Ridge Vents on Induced Buoyancy-Driven Ventilation. Buildings. 2022; 12(2):112. https://doi.org/10.3390/buildings12020112

Chicago/Turabian StyleChen, Ching-Mei, Yi-Pin Lin, Sung-Chin Chung, and Chi-Ming Lai. 2022. "Effects of the Design Parameters of Ridge Vents on Induced Buoyancy-Driven Ventilation" Buildings 12, no. 2: 112. https://doi.org/10.3390/buildings12020112

APA StyleChen, C.-M., Lin, Y.-P., Chung, S.-C., & Lai, C.-M. (2022). Effects of the Design Parameters of Ridge Vents on Induced Buoyancy-Driven Ventilation. Buildings, 12(2), 112. https://doi.org/10.3390/buildings12020112