Asphalt Mixture with Scrap Tire Rubber and Nylon Fiber from Waste Tires: Laboratory Performance and Preliminary M-E Design Analysis

Abstract

:1. Introduction

2. Materials and Methods

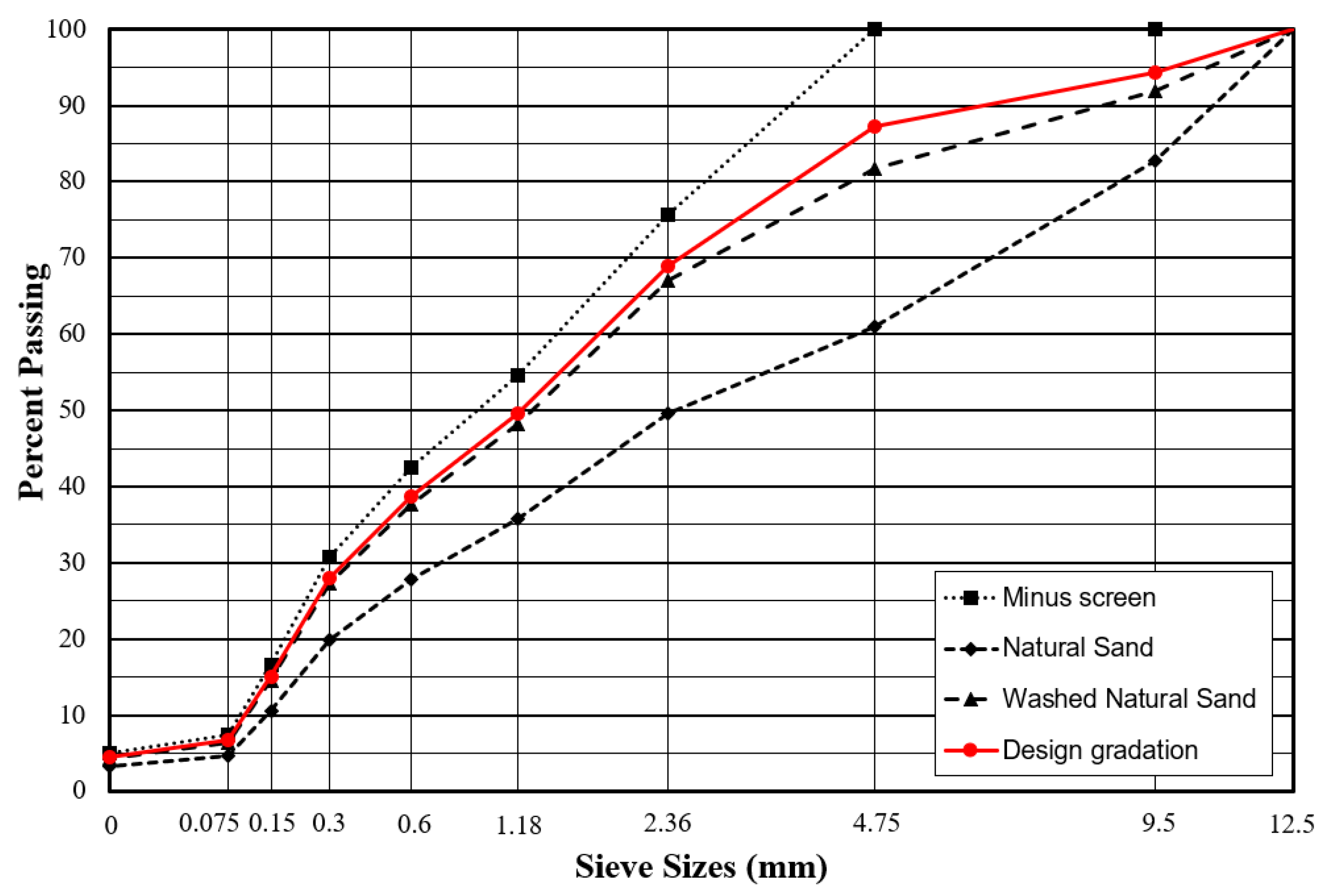

2.1. Materials and Mixture Design

2.2. Scrap Rubber and Nylon Fiber Modified WMA Preparation

2.3. Traffic Inputs and Local Calibration Factors

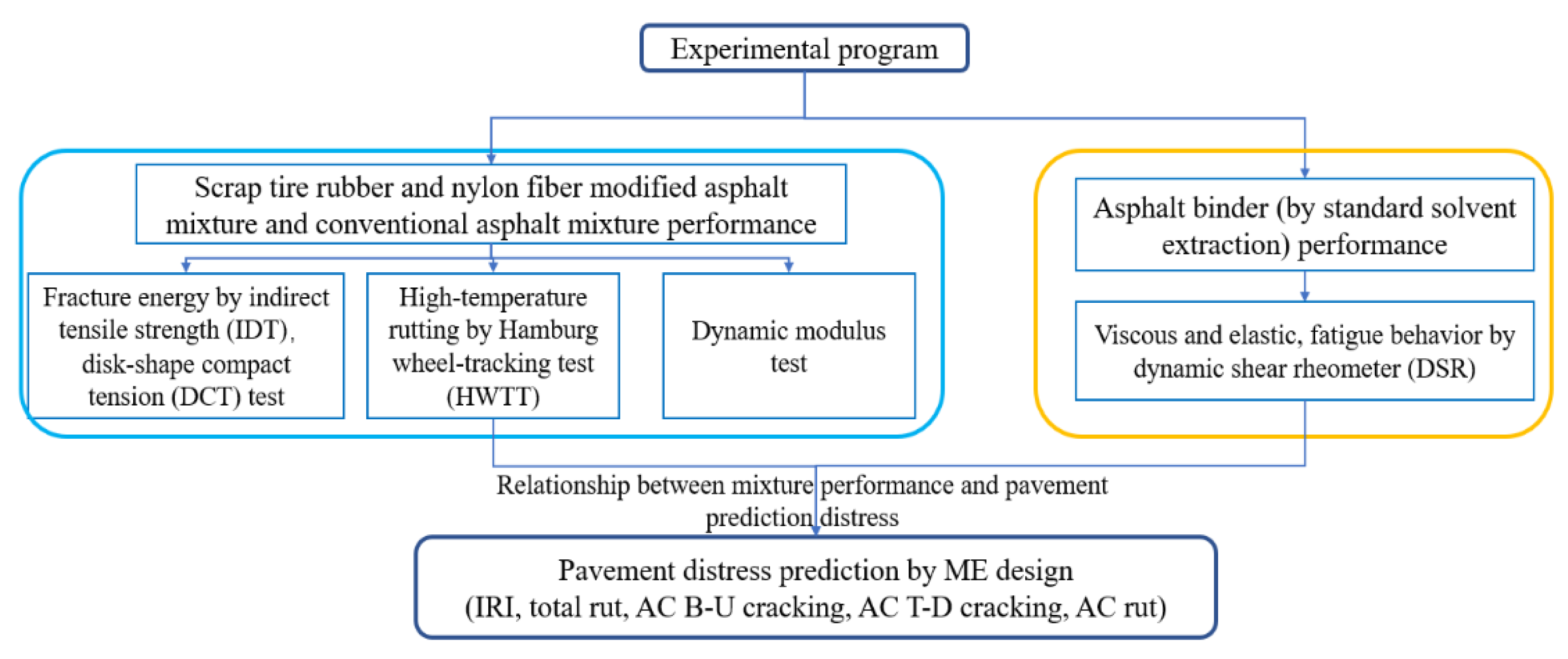

2.4. Research Methodology

2.5. Test Program

2.5.1. Dynamic Modulus

2.5.2. Disk-Shaped Compact Tension (DCT) Test

2.5.3. Hamburg Wheel-Track Testing (HWTT) Test

2.5.4. Indirect Tensile Strength (IDT)

2.5.5. Dynamic Shear Rheometer (DSR)

2.5.6. Pavement M-E Distress Prediction

3. Results and Discussions

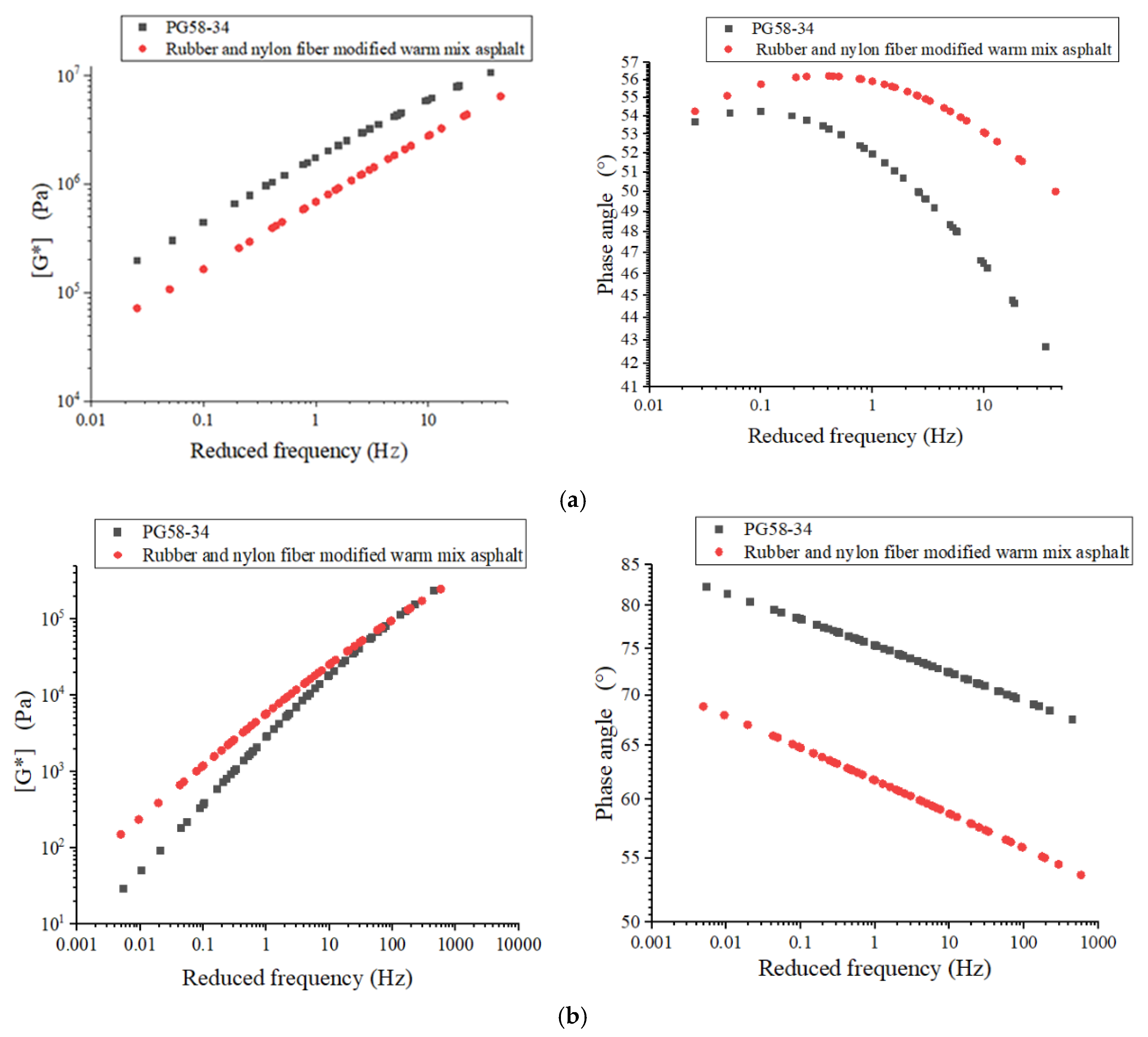

3.1. Complex Shear Modulus (|G*|) of Binders

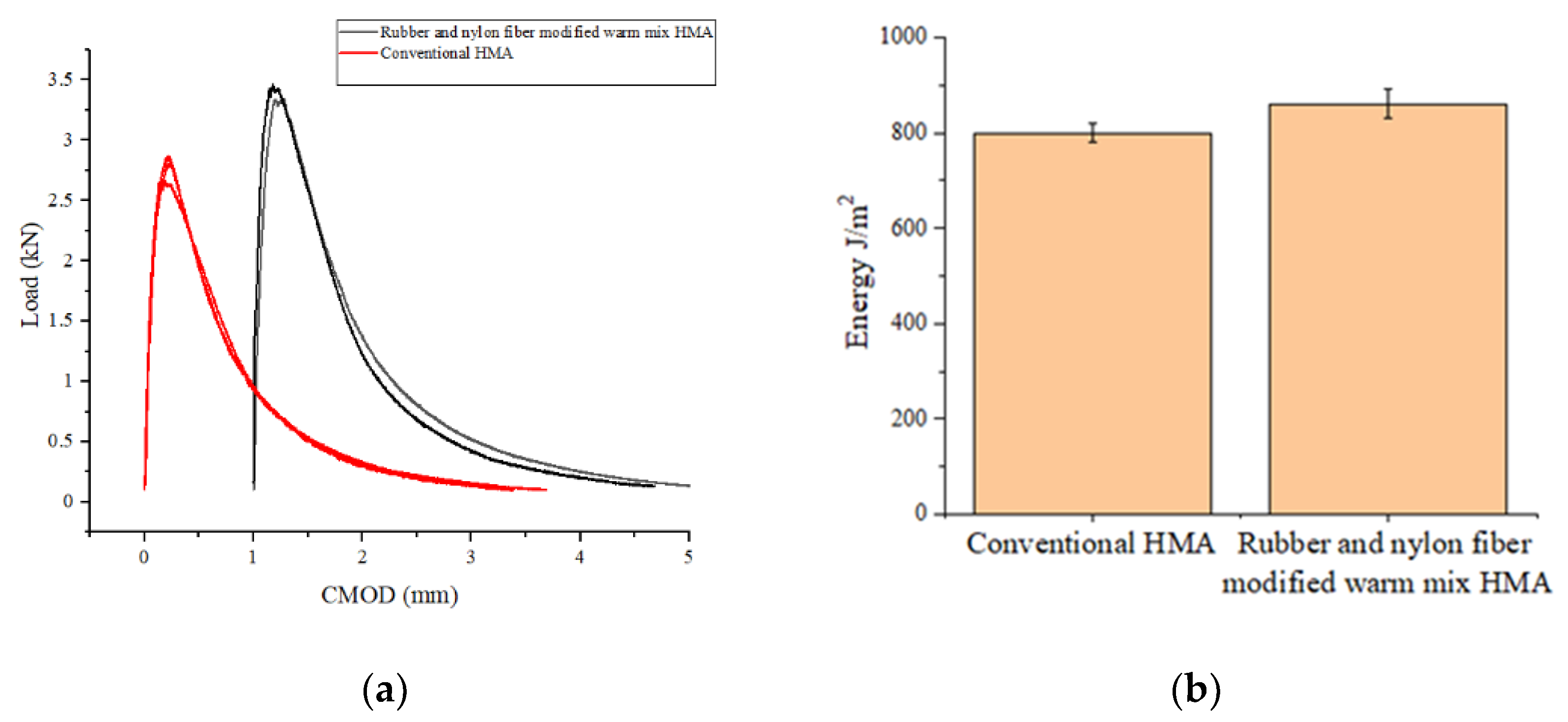

3.2. DCT Test Results

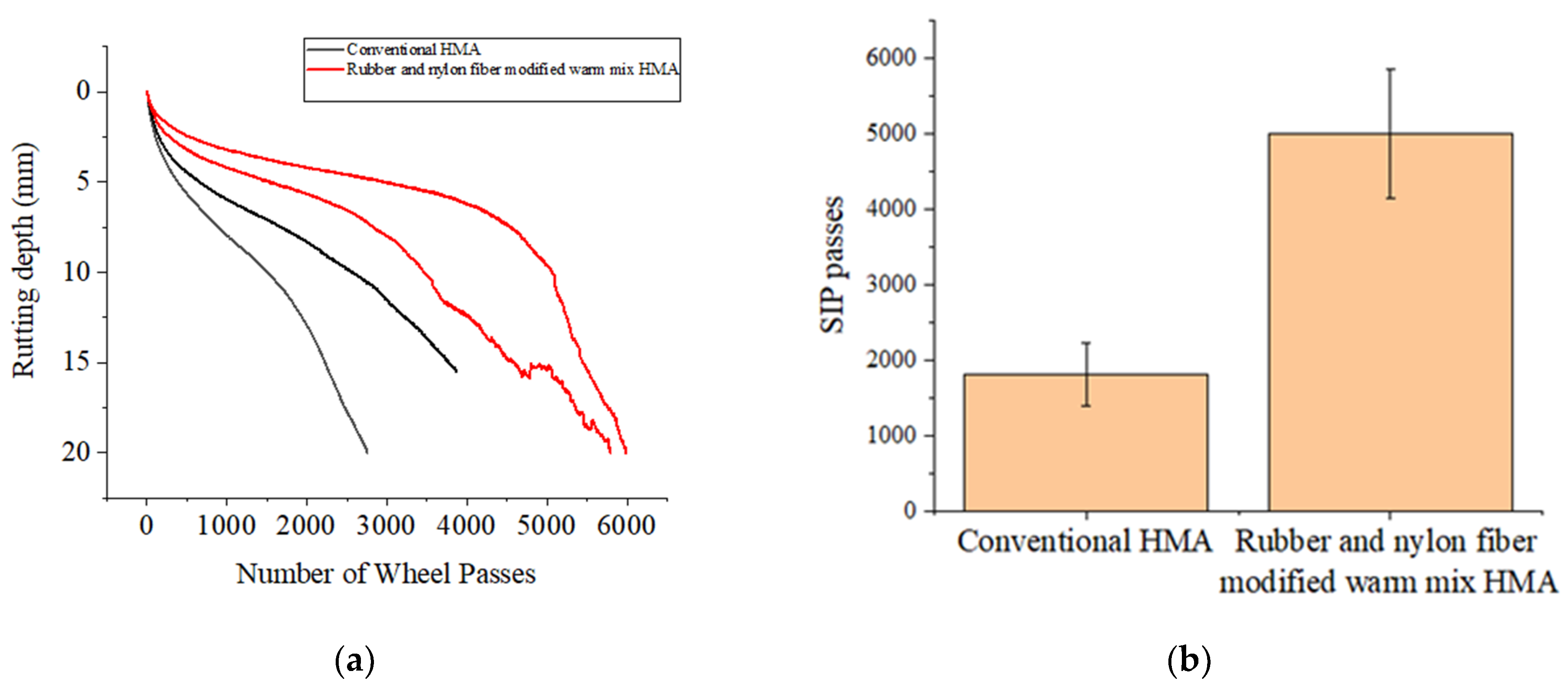

3.3. HWDT Test Results

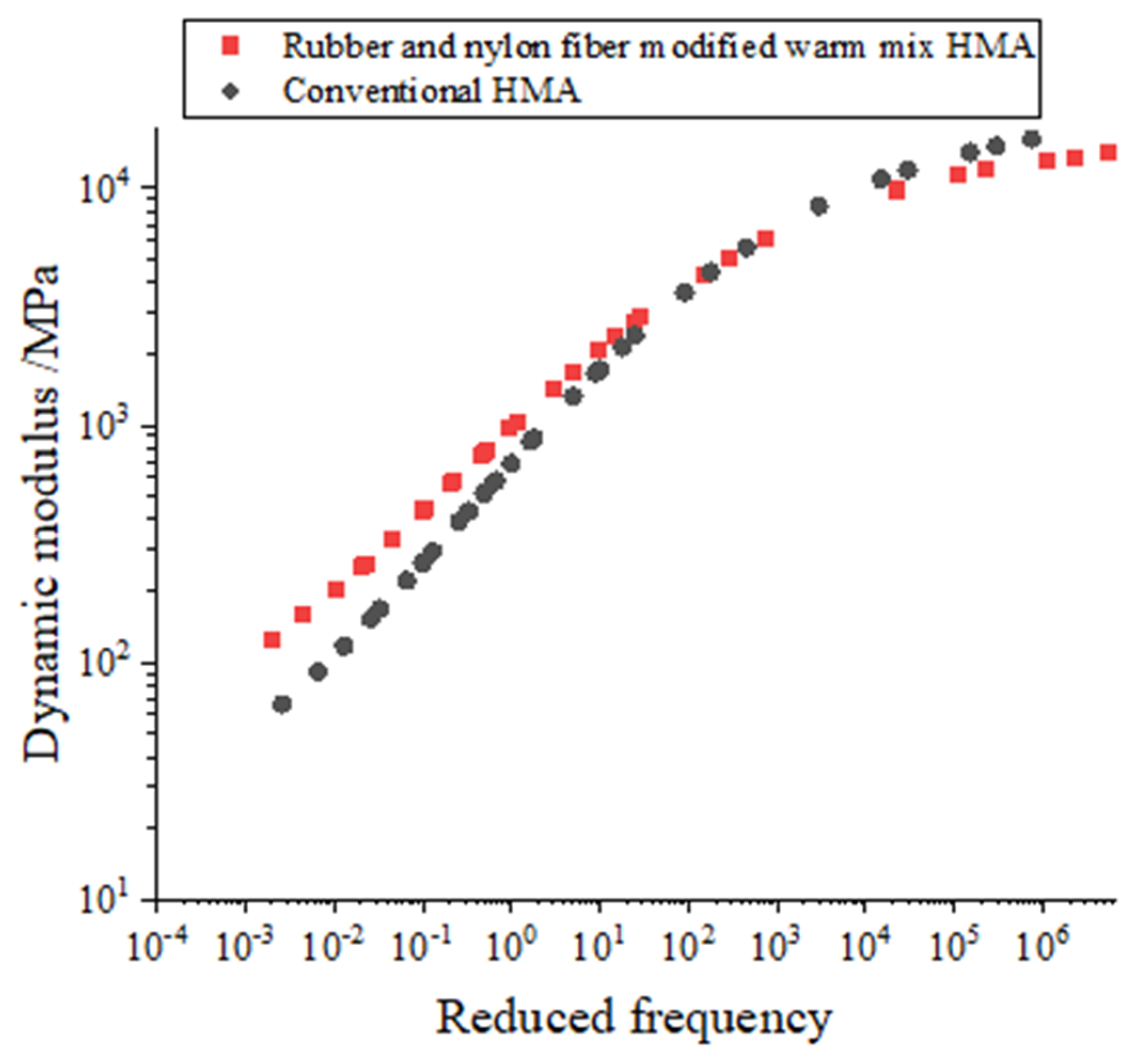

3.4. Dynamic Modulus Results

3.5. IDT Strength and Failure Energy

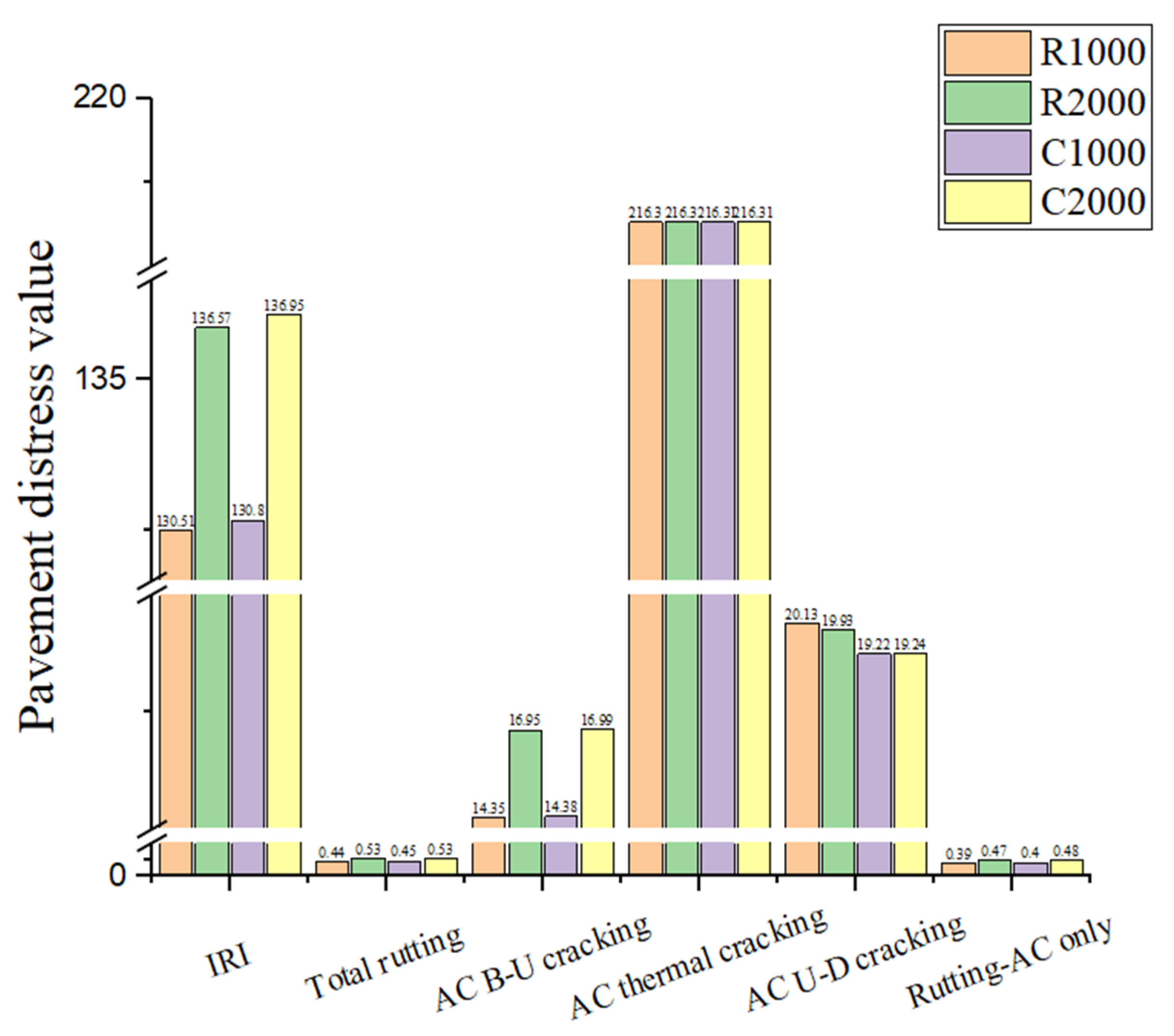

3.6. Pavement Distress Prediction Results

4. Summary and Conclusions

- (1)

- The test of dynamic modulus revealed that the rubber and nylon fiber modified WMA had higher stiffness compared with the conventional asphalt mixture at high temperature, which increases the rutting resistance at high temperatures. The dynamic modulus of conventional HMA was 21.8~103% lower than that of rubber and nylon fiber modified WMA at high temperatures.

- (2)

- The dynamic shear rheometer test results show that the rubber and nylon fiber modified warm mix asphalt has better rutting resistance and fatigue performance than the base asphalt binder. The rubber and nylon fiber particle in the asphalt increases the strength inside of the asphalt binder, which improves the deformation resistance and fatigue property under the load.

- (3)

- The IDT and DCT test results show that the rubber and nylon fiber modified WMA had a higher crack resistance when compared with traditional asphalt mixtures. According to the findings of the DCT test, the failure energy of the rubber and nylon fiber modified WMA was 24.3% higher than that of the conventional HMA, and the fracture energy of the rubber and nylon fiber modified WMA was 7.7% higher than the conventional asphalt mixture. This may be caused by the rubber and nylon fiber increasing the cracking resistance of the asphalt mixture.

- (4)

- The HWDT test results show that the rubber and nylon fiber modified WMA has better rutting resistance and anti-striping than the conventional HMA. The number of wheel passes of rubber and nylon fiber modified WMA was 2.17 times higher than that of conventional HMA. Meanwhile, the stripping point of rubber and nylon fiber modified WMA was 5.8 times higher than that of conventional HMA. The main reason behind this is that the rubber and nylon fiber in the asphalt mixture improves the stiffness and anti-stripping properties.

- (5)

- The pavement distress prediction results show that the rubber and nylon fiber modified WMA helps to improve the IRI and AC cracking and rutting performance at the same or increased traffic level compared with the conventional asphalt mixture. The results from the pavement M-E analysis show the same trend compared with the laboratory testing performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.; Zhou, Z.; Ye, J.; Zhang, X.; Wang, S.; Diab, A. High-temperature creep and low-temperature relaxation of recycled asphalt mixtures: Evaluation and balanced mix design. Constr. Build. Mater. 2021, 310, 125222. [Google Scholar] [CrossRef]

- Chen, J.; Dan, H.; Ding, Y.; Gao, Y.; Guo, M.; Guo, S.; Han, B.; Hong, B.; Hou, Y.; Hu, C.; et al. New innovations in pavement materials and engineering: A review on pavement engineering research 2021. J. Traffic Transp. Eng. (Engl. Ed.) 2021, 8, 815–999. [Google Scholar] [CrossRef]

- Marconi, M.; Landi, D.; Meo, I.; Germani, M. Reuse of tires textile fibers in plastic compounds: Is this scenario environmentally sustainable? Procedia Cirp 2018, 69, 944–949. [Google Scholar] [CrossRef]

- Ge, D.; Zhou, X.; Chen, S.; Jin, D.; You, Z. Laboratory Evaluation of the Residue of Rubber-Modified Emulsified Asphalt. Sustainability 2020, 12, 8383. [Google Scholar] [CrossRef]

- Ogunbiyi, A.W.; Openibo, A.O.; Ojowuro, O.M. Smelting of Waste Nylon and Low-density Plastics (ldps) in a Fluidized Bed System. Procedia Environ. Sci. 2016, 35, 491–497. [Google Scholar] [CrossRef]

- Wang, W.; Meng, L.; Leng, K.; Huang, Y. Hydrolysis of waste monomer casting nylon catalyzed by solid acids. Polym. Degrad. Stab. 2017, 136, 112–120. [Google Scholar] [CrossRef]

- Yin, J.; Wu, W. Utilization of waste nylon wire in stone matrix asphalt mixtures. Waste Manag. 2018, 78, 948–954. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.J.; Rust, J.P.; Hamouda, H.; Kim, Y.R.; Borden, R.H. Fatigue Cracking Resistance of Fiber-Reinforced Asphalt Concrete. Text. Res. J. 2005, 75, 123–128. [Google Scholar] [CrossRef]

- Taherkhani, H. Investigating the effects of nanoclay and nylon fibers on the mechanical properties of asphalt concrete. Civ. Eng. Infrastruct. J. 2016, 49, 235–249. [Google Scholar]

- Yang, X.; You, Z.; Hasan, M.R.M.; Diab, A.; Shao, H.; Chen, S.; Ge, D. Environmental and mechanical performance of crumb rubber modified warm mix asphalt using Evotherm. J. Clean. Prod. 2017, 159, 346–358. [Google Scholar] [CrossRef]

- Oliveira, J.R.; Silva, H.M.; Abreu, L.P.; Fernandes, S.R. Use of a warm mix asphalt additive to reduce the production temperatures and to improve the performance of asphalt rubber mixtures. J. Clean. Prod. 2013, 41, 15–22. [Google Scholar] [CrossRef]

- Dinis-Almeida, M. and M.L. Afonso, Warm mix recycled asphalt–a sustainable solution. J. Clean. Prod. 2015, 107, 310–316. [Google Scholar] [CrossRef]

- Airey, G.D.; Rahman, M.M.; Collop, A.C. Absorption of Bitumen into Crumb Rubber Using the Basket Drainage Method. Int. J. Pavement Eng. 2003, 4, 105–119. [Google Scholar] [CrossRef]

- Rahman, M.M.; Airey, G.D.; Collop, A.C. Moisture Susceptibility of High and Low Compaction Dry Process Crumb Rubber–Modified Asphalt Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2010, 2180, 121–129. [Google Scholar] [CrossRef]

- Chen, S.; Ge, D.; Jin, D.; Zhou, X.; Liu, C.; Lv, S.; You, Z. Investigation of hot mixture asphalt with high ground tire rubber content. J. Clean. Prod. 2020, 277, 124037. [Google Scholar] [CrossRef]

- Xie, Z.; Shen, J. Fatigue Performance of Rubberized Stone Matrix Asphalt by a Simplified Viscoelastic Continuum Damage Model. J. Mater. Civ. Eng. 2016, 28, 04015162. [Google Scholar] [CrossRef]

- Jin, D.; Ge, D.; Chen, S.; Che, T.; Liu, H.; Malburg, L.; You, Z. Cold In-Place Recycling Asphalt Mixtures: Laboratory Performance and Preliminary M-E Design Analysis. Materials 2021, 14, 2036. [Google Scholar] [CrossRef] [PubMed]

- Buch, N.; Haider, S.W.; Brown, J.; Chatti, K. Characterization of Truck Traffic in Michigan for the New Mechanistic Empirical Pavement Design Guide; Michigan Department of Transportation, Construction and Technology Division: Lansing, MI, USA, 2009.

- AASHTO T 342Standard Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt (HMA), American Association of State Highway Transportation Officials: Washington, DC, USA, 2011.

- ASTM D7313-20Standard Test Method for Determining Fracture Energy of Asphalt Mixtures Using the Disk-Shaped Compact Tension Geometry, American Society for Testing and Materials International: West Conshohocken, PA, USA, 2021.

- AASHTO T 324Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures, American Association of State Highway Transportation Officials: Washington, DC, USA, 2019.

- AASHTO T 322Standard Method of Test for Determining the Creep Compliance and Strength of Hot Mix Asphalt (HMA) Using the Indirect Tensile Test Device, American Association of State Highway Transportation Officials: Washington, DC, USA, 2007.

- Jin, D.; Wang, J.; You, L.; Ge, D.; Liu, C.; Liu, H.; You, Z. Waste cathode-ray-tube glass powder modified asphalt materials: Preparation and characterization. J. Clean. Prod. 2021, 314, 127949. [Google Scholar] [CrossRef]

- AASHTO T 315Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer, American Association of State Highway Transportation Officials: Washington, DC, USA, 2020.

- AASHTO T 240Standard Method of Test for Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-Film Oven Test), American Association of State Highway Transportation Officials: Washington, DC, USA, 2009.

- AASHTO R 28Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV), American Association of State Highway Transportation Officials: Washington, DC, USA, 2009.

- MDOT. Michigan DOT User Guide for Mechanistic-Empirical Pavement Design; Michigan Department of Transportation: Lansing, MI, USA, 2021.

- Park, S.; Schapery, R. Methods of interconversion between linear viscoelastic material functions. Part I—a numerical method based on Prony series. Int. J. Solids Struct. 1999, 36, 1653–1675. [Google Scholar] [CrossRef]

| Layer Types and Thickness | Pavement Structure |

|---|---|

| Surface layer (3.8 cm) | Conventional or rubber and nylon fiber modified warm mix asphalt (WMA) |

| Leveling course (5 cm) | Dense mix asphalt mixture |

| Asphalt base course (17.8 cm) | Dense mix asphalt mixture |

| Aggregate base (15.2 cm) | Sandwich granular |

| Aggregate base (25.4 cm) | Crushed stone |

| Aggregate subbase (15.2 cm) | Crushed gravel |

| subgrade | Semi-infinite |

| |E*| (MPa) Average Value Rubber and Nylon Fiber Modified WMA | |||||||

|---|---|---|---|---|---|---|---|

| F (Hz) | 0.1 | 0.5 | 1 | 5 | 10 | 25 | |

| T (°C) | |||||||

| −10 | 6463.2 | 8848.3 | 10,010.1 | 12,667.3 | 14,253.0 | 15,521.3 | |

| 10 | 2180.8 | 3261.2 | 3935.8 | 5773.4 | 6679.5 | 7673.6 | |

| 21 | 511.5 | 718.1 | 947.1 | 1620.4 | 2061.0 | 2645.0 | |

| 37 | 210.9 | 261.8 | 321.9 | 492.2 | 610.3 | 862.9 | |

| 54 | 120.0 | 181.0 | 309.0 | 498.1 | 606.6 | 773.3 | |

| |G*| (MPa) Average Value | Creep Compliance | ||||||

| Temperature (°C) | Binder G* (Pa) | Phase angle (°) | Time (s) | Temperature (°C) | |||

| 16 | 1,430,000 | 54.38 | −20 | −10 | 0 | ||

| 34 | 97,216 | 58.89 | 1 | 5.32 × 10−7 | 1.04 × 10−6 | 2.25 × 10−6 | |

| 46 | 25,659 | 58.27 | 2 | 5.87 × 10−7 | 1.21 × 10−6 | 2.69 × 10−6 | |

| 64 | 4435 | 60.38 | 5 | 6.86 × 10−7 | 1.46 × 10−6 | 3.50 × 10−6 | |

| 76 | 1629 | 64.83 | 10 | 7.75 × 10−7 | 1.74 × 10−6 | 4.24 × 10−6 | |

| (−10 °C) IDT strength: 2.676 MPa | 20 | 8.75 × 10−7 | 2.07 × 10−6 | 5.18 × 10−6 | |||

| 50 | 1.06 × 10−6 | 2.59 × 10−6 | 6.94 × 10−6 | ||||

| 100 | 1.22 × 10−6 | 3.15 × 10−6 | 8.56 × 10−6 | ||||

| |E*| (MPa) Average Value Conventional HMA | |||||||

|---|---|---|---|---|---|---|---|

| F (Hz) | 0.1 | 0.5 | 1 | 5 | 10 | 25 | |

| T (°C) | |||||||

| −10 | 6821.2 | 9806.8 | 11,183.8 | 14,234.0 | 15,584.8 | 16,782.7 | |

| 10 | 2548.0 | 4570.4 | 5806.5 | 8961.4 | 10,779.7 | 12,600.4 | |

| 21 | 296.5 | 512.7 | 600.3 | 1081.1 | 1476.7 | 2032.4 | |

| 37 | 142.6 | 182.0 | 219.4 | 444.7 | 532.5 | 755.6 | |

| 54 | 60.0 | 100.0 | 152.0 | 352.0 | 498.0 | 582.0 | |

| |G*| (MPa) Average Value | Creep Compliance | ||||||

| Temperature (°C) | Binder G* (Pa) | Phase angle (°) | Time (s) | Temperature (°C) | |||

| 16 | 3,146,800 | 48.63 | −20 | −10 | 0 | ||

| 34 | 78,249.67 | 68.16 | 1 | 4.35 × 10−7 | 7.94 × 10−7 | 1.95 × 10−6 | |

| 46 | 16,972.33 | 71.25 | 2 | 4.64 × 10−7 | 8.93 × 10−7 | 2.35 × 10−6 | |

| 64 | 2042.63 | 75.98 | 5 | 5.05 × 10−7 | 1.05 × 10−6 | 3.02 × 10−6 | |

| 76 | 594.66 | 79.63 | 10 | 5.43 × 10−7 | 1.21 × 10−6 | 3.74 × 10−6 | |

| (−10 °C) IDT strength: 2.18 MPa | 20 | 5.92 × 10−7 | 1.41 × 10−6 | 4.69 × 10−6 | |||

| 50 | 6.65 × 10−7 | 1.74 × 10−6 | 6.32 × 10−6 | ||||

| 100 | 7.34 × 10−7 | 2.09 × 10−6 | 8.12 × 10−6 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, D.; Ge, D.; Zhou, X.; You, Z. Asphalt Mixture with Scrap Tire Rubber and Nylon Fiber from Waste Tires: Laboratory Performance and Preliminary M-E Design Analysis. Buildings 2022, 12, 160. https://doi.org/10.3390/buildings12020160

Jin D, Ge D, Zhou X, You Z. Asphalt Mixture with Scrap Tire Rubber and Nylon Fiber from Waste Tires: Laboratory Performance and Preliminary M-E Design Analysis. Buildings. 2022; 12(2):160. https://doi.org/10.3390/buildings12020160

Chicago/Turabian StyleJin, Dongzhao, Dongdong Ge, Xiaodong Zhou, and Zhanping You. 2022. "Asphalt Mixture with Scrap Tire Rubber and Nylon Fiber from Waste Tires: Laboratory Performance and Preliminary M-E Design Analysis" Buildings 12, no. 2: 160. https://doi.org/10.3390/buildings12020160

APA StyleJin, D., Ge, D., Zhou, X., & You, Z. (2022). Asphalt Mixture with Scrap Tire Rubber and Nylon Fiber from Waste Tires: Laboratory Performance and Preliminary M-E Design Analysis. Buildings, 12(2), 160. https://doi.org/10.3390/buildings12020160