Life-Cycle Assessment of Sculptured Tiles for Building Envelopes in Mediterranean Climate

Abstract

:1. Introduction

2. Materials and Methods

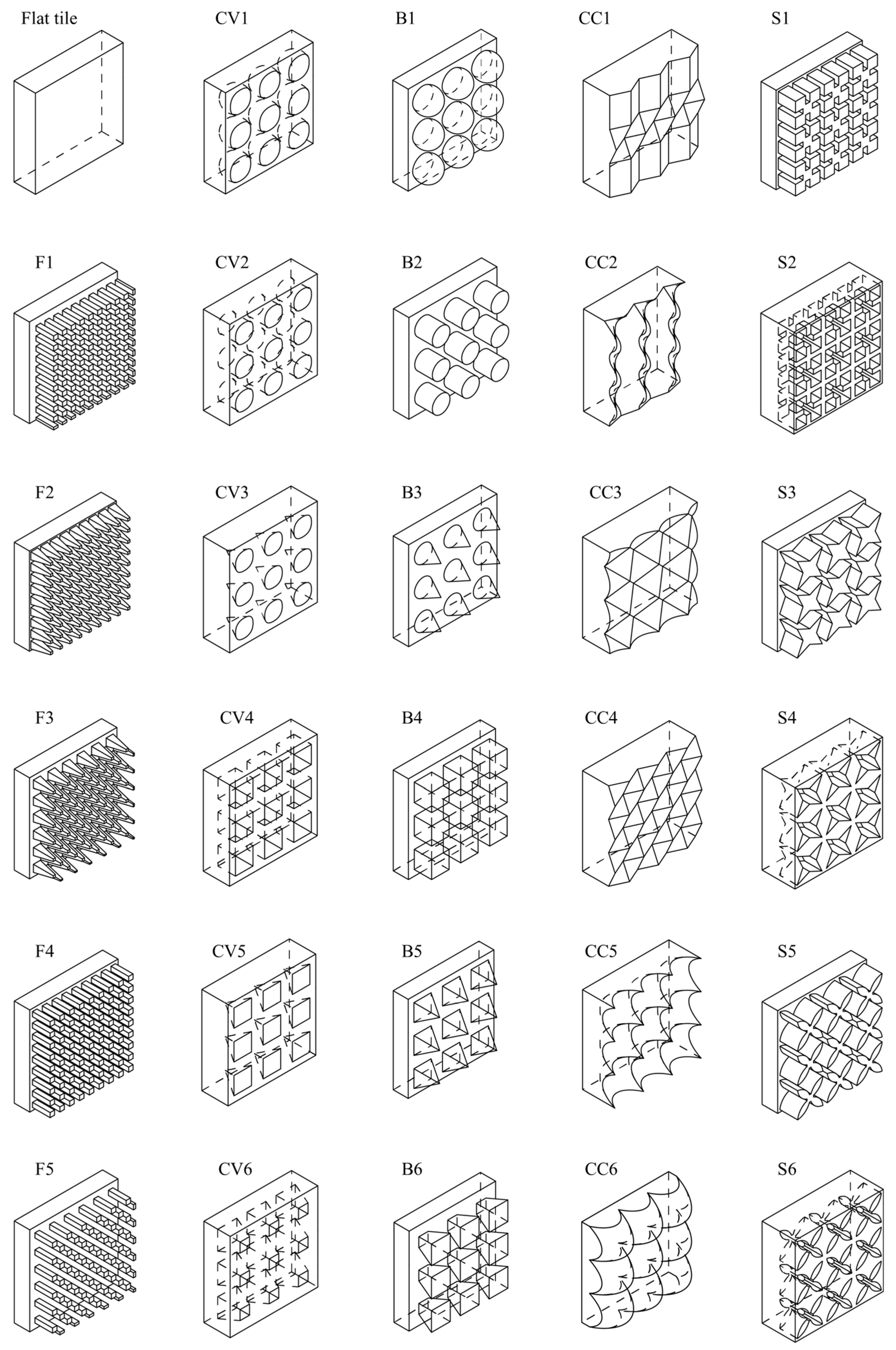

2.1. Design of Sculptured Tiles

2.2. Research Framework

2.2.1. Energy Assessment of the OE Stage

2.2.2. LCA of P and OE Stages

3. Results and Discussion

3.1. Energy Assessment of the OE Stage

3.2. LCA of P and OE Stages

3.2.1. Preparatory Results: Materials and Energy

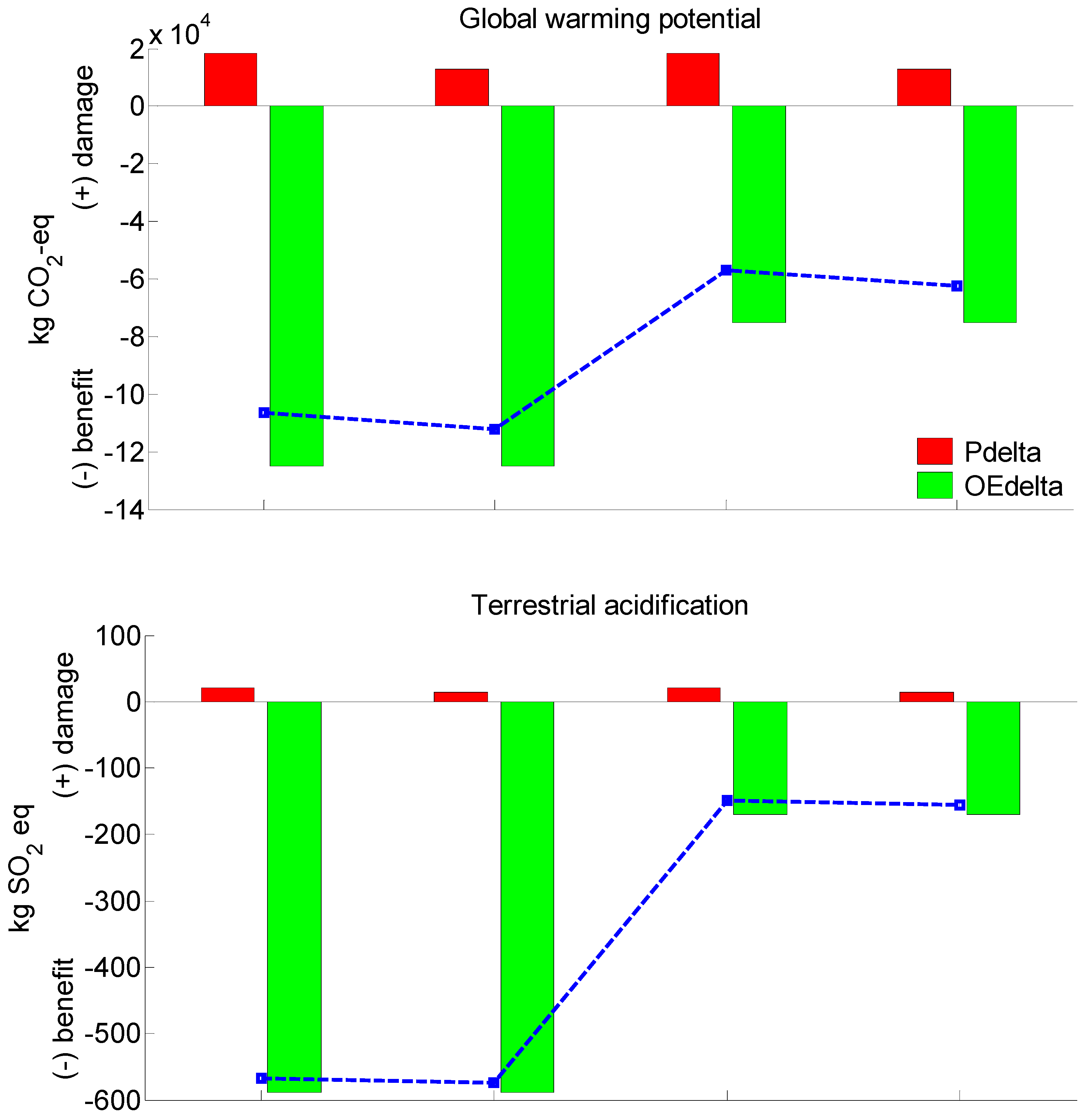

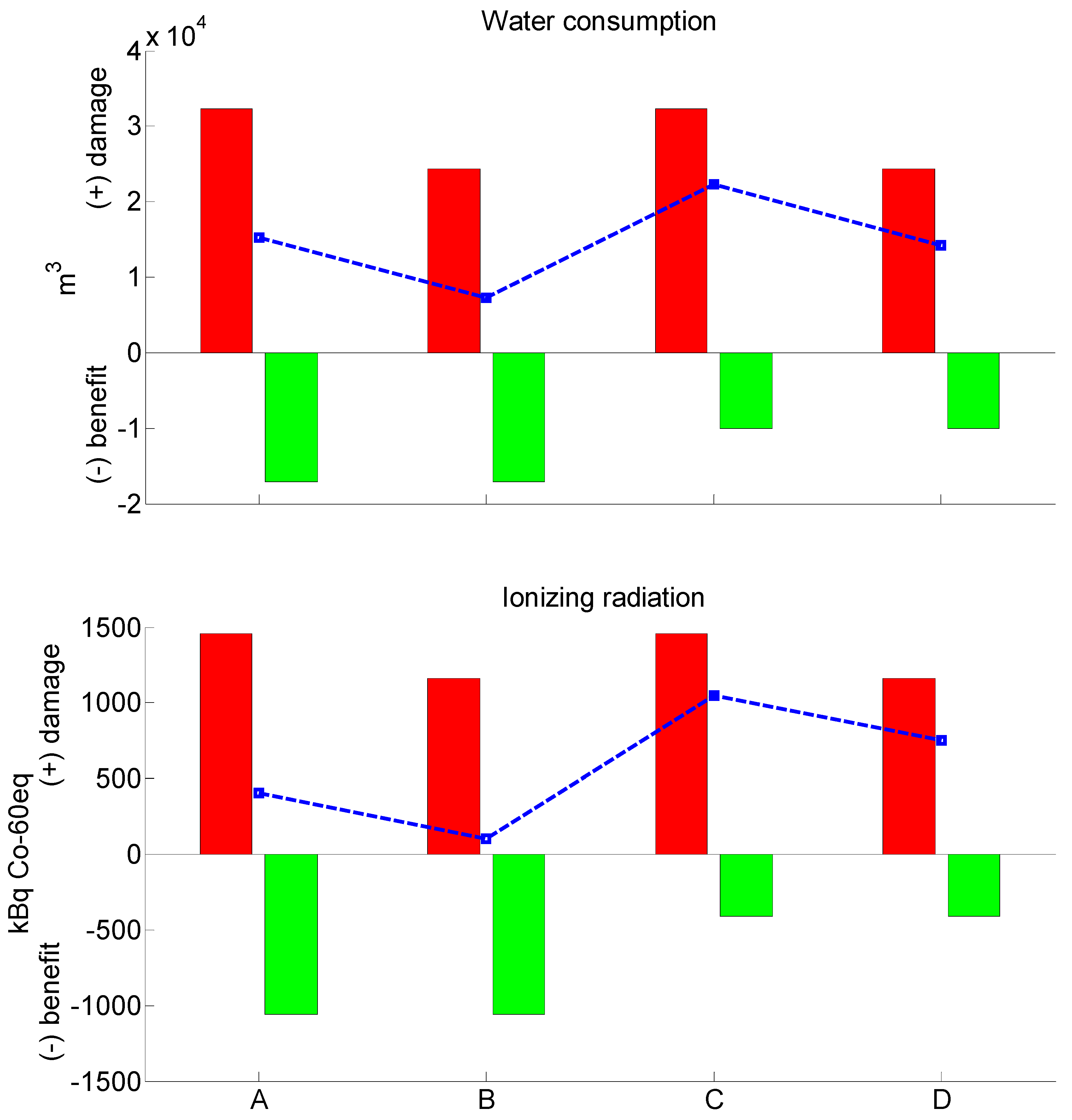

3.2.2. ReCiPe2016 Midpoint Results

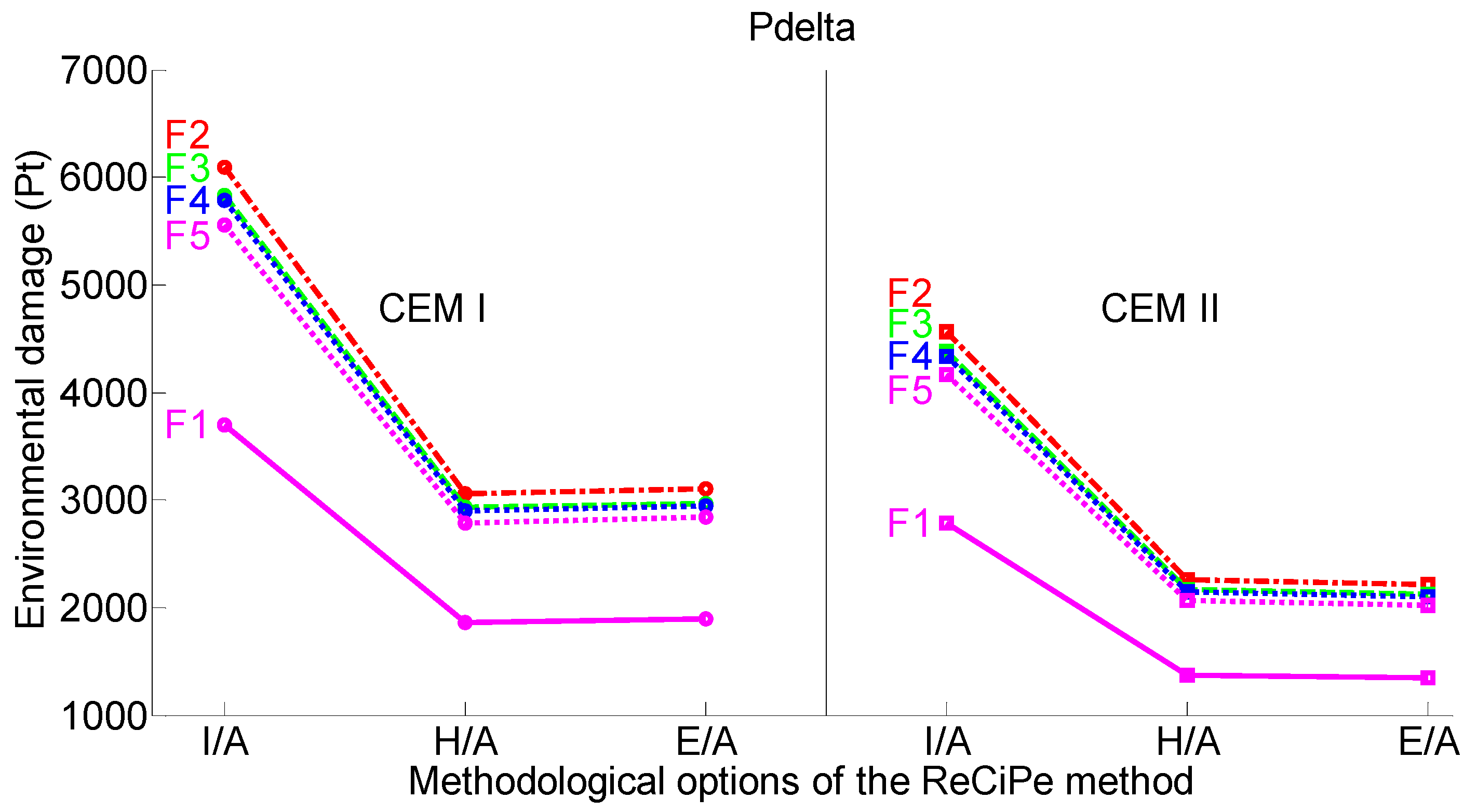

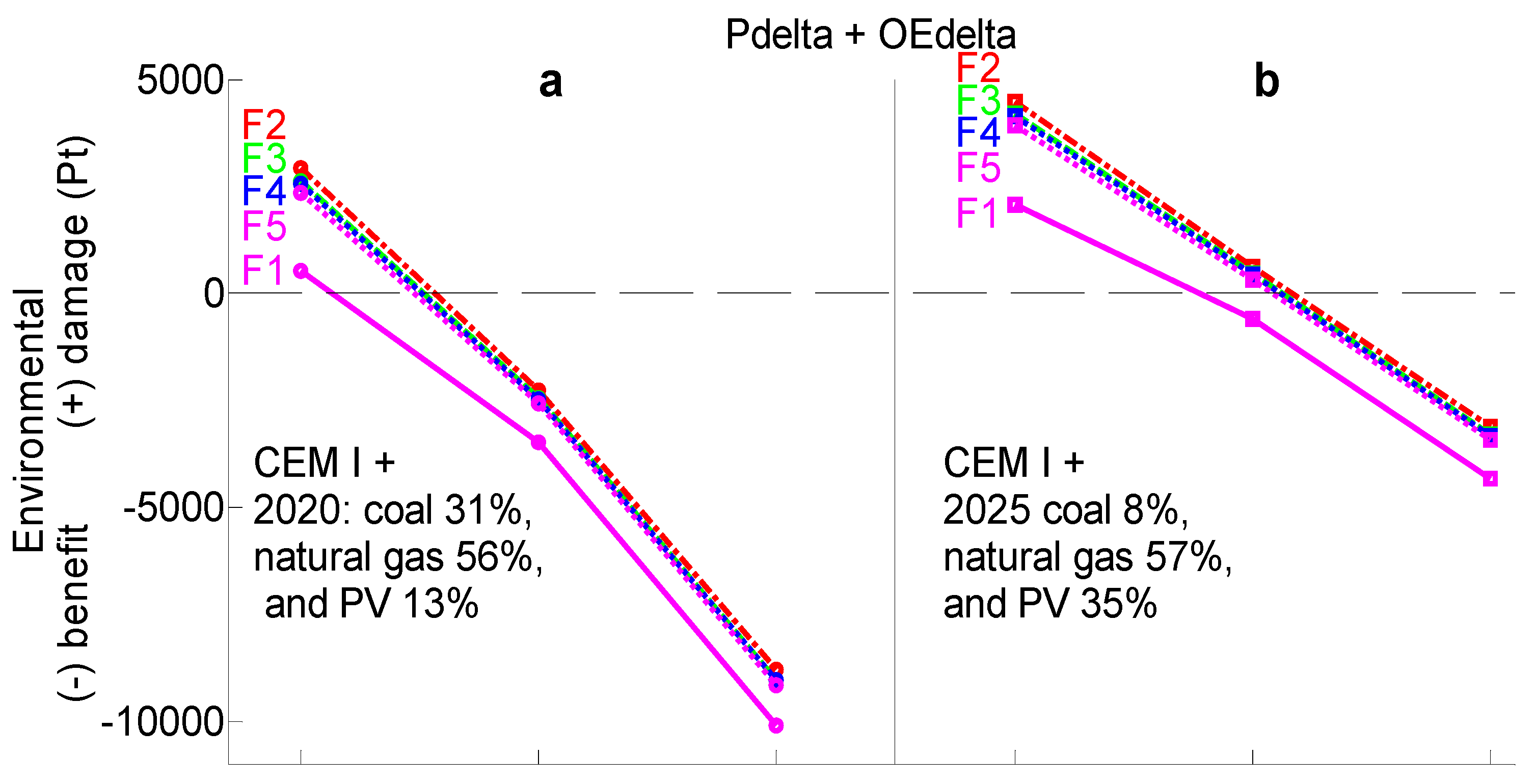

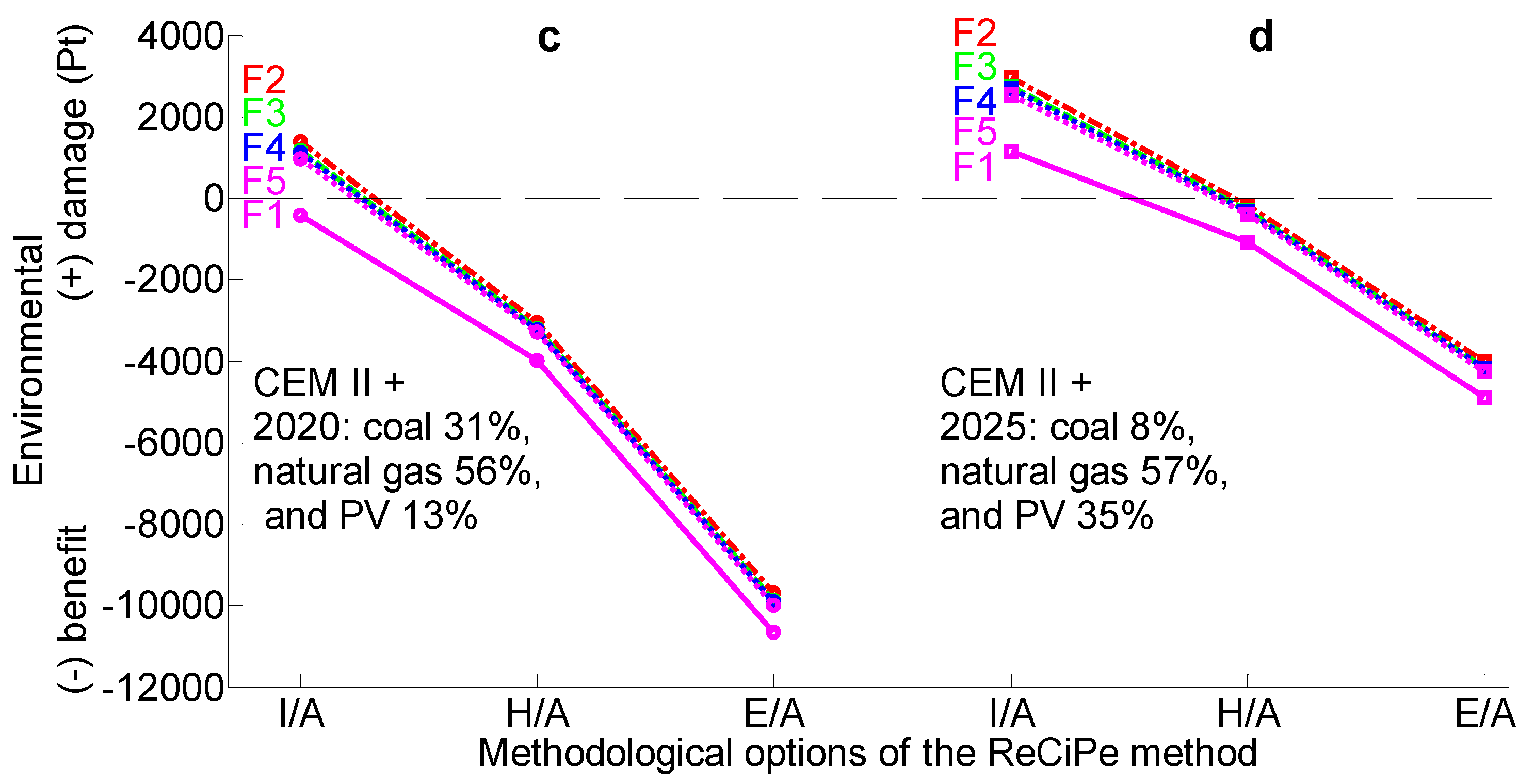

3.2.3. ReCiPe2016 2016 Endpoint Single-Score Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sundaram, S.; Paul, M.C.; Mahmoudi, Y. Research on Hybrid Solar Photovoltaic/Thermal (PV/T) System. Energies 2022, 15, 886. [Google Scholar] [CrossRef]

- Sbrogiò, L.; Bevilacqua, C.; De Sordi, G.; Michelotto, I.; Sbrogiò, M.; Toniolo, A.; Tosato, C. Strategies for Structural and Energy Improvement in Mid-Rise Unreinforced Masonry Apartment Buildings. A Case Study in Mestre (Northeast Italy). Sustainability 2021, 13, 8819. [Google Scholar] [CrossRef]

- Al-Sakkaf, A.; Mohammed Abdelkader, E.; Mahmoud, S.; Bagchi, A. Studying Energy Performance and Thermal Comfort Conditions in Heritage Buildings: A Case Study of Murabba Palace. Sustainability 2021, 13, 12250. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pèreza, G.; Castella, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energ. Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Karimpour, M.; Belusko, M.; Xing, K.; Bruno, F. Minimising the life cycle energy of buildings: Review and analysis. Build. Environ. 2014, 73, 106–114. [Google Scholar] [CrossRef]

- Huberman, N.; Pearlmutter, D. A life-cycle energy analysis of building materials in the Negev desert. Energ. Build. 2008, 40, 837–848. [Google Scholar] [CrossRef]

- Huberman, N.; Pearlmutter, D.; Gal, E.; Meir, I.A. Optimizing structural roof form for life-cycle energy efficiency. Energy Build. 2015, 104, 336–349. [Google Scholar] [CrossRef]

- Pushkar, S.; Verbitsky, O. Environmental damage from wall technologies for residential buildings in Israel. J. Green Build. 2016, 11, 98–106. [Google Scholar] [CrossRef]

- Hershcovich, C.; van Hout, R.; Rinsky, V.; Laufer, M.; Grobman, Y.J. Thermal performance of sculptured tiles for building envelopes. Build. Environ. 2021, 197, 107809. [Google Scholar] [CrossRef]

- Yezioro, A.; Capeluto, I.G. Energy Rating of Buildings to Promote Energy-Conscious Design in Israel. Buildings 2021, 11, 59. [Google Scholar] [CrossRef]

- SII. SI5282; Part 1. Energy Rating of Buildings: Residential Buildings. The Standards Institution of Israel (SII): Tel Aviv, Israel, 2017.

- US Department of Energy. EnergyPlus. Available online: https://energyplus.net/downloads (accessed on 12 December 2021).

- ISO 14040; Environmental Management Life Cycle Assessment Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- SII. SI1; Cement: Common Cements. The Standards Institution of Israel (SII): Tel Aviv, Israel, 2015.

- Nesher Israel Cement Enterprises. Ltd., Products Catalog. Available online: https://www.nesher.co.il/en/product-catalog/ (accessed on 10 December 2021).

- Israel Electricity Authority, Electricity Status Report. 2020. Available online: https://www.gov.il/BlobFolder/generalpage/dochmeshek/he/Files_Netunei_hashmal_doch_reshut_hasmal_2020_malle_n.xlsx.pdf (accessed on 14 December 2020). (In Hebrew)

- SII. SI1920; Plaster: Requirements and Test Methods. The Standards Institution of Israel (SII): Tel Aviv, Israel, 2021.

- PRé Consultants. SimaPro; Version 9.1. 0.35; PRé Consultants: Amersfoort, The Netherlands, 2019. [Google Scholar]

- Verbitsky, O.; Pushkar, S. Eco-Indicator 99, ReCiPe, and ANOVA for evaluating building technologies under LCA uncertainties. Environ. Eng. Manag. J. 2018, 17, 2549–2559. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Solano-Olivares, K.; Martínez, E.; García, E.O.; Santoyo, E. Life cycle assessment for a grid-connected multi-crystalline silicon photovoltaic system of 3 kWp: A case study for Mexico. J. Clean. Prod. 2021, 316, 128314. [Google Scholar] [CrossRef]

- Jia, X.; Lv, F.; Li, P.; Wang, W. Life-cycle assessment of p-type multi-Si back surface field (BSF) solar module in China of 2019. Sol. Energ. 2020, 196, 207–216. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Farquharson, D.; Jaramillo, P.; Schivley, G.; Klima, K.; Carlson, D.; Samaras, C. Beyond global warming potential: A comparative application of climate impact metrics for the life cycle assessment of coal and natural gas-based electricity. J. Ind. Ecol. 2017, 21, 857–873. [Google Scholar] [CrossRef]

- Pikon, K.; Bogacka, M.; Stanek, W.; Czarnowska, L. Energy, exergy and environmental quality of hard coal and natural gas in whole life cycle concerning home heating. Therm. Sci. 2016, 20, 1147–1159. [Google Scholar] [CrossRef] [Green Version]

- García-Gusano, D.; Garraín, D.; Herrera, I.; Cabal, H.; Lechón, Y. Life Cycle Assessment of applying CO2 post-combustion capture to the Spanish cement production. J. Clean. Prod. 2015, 104, 328–338. [Google Scholar] [CrossRef]

- Mack-Vergara, Y.L.; Vanderley, M.J. Life cycle water inventory in concrete production—A review. Resour. Conservat. Recycl. 2017, 122, 227–250. [Google Scholar] [CrossRef]

- Halasah, S.A.; Pearlmutter, D.; Feuermann, D. Field installation versus local integration of photovoltaic systems and their effect on energy evaluation metrics. Energ. Pol. 2013, 52, 462–471. [Google Scholar] [CrossRef]

- Pushkar, S.; Verbitsky, O. Life-Cycle Assessment of the Energy Code for Office Buildings Using the Prescriptive Approach in Israel. In Proceedings of the International Conference on Sustainable Infrastructure 2017 (ASCE) Methodology, New York, NY, USA, 26–28 October 2017; pp. 207–217. [Google Scholar] [CrossRef]

| Tile | Volume (cm3) | U-Value (W/m2K) | Tile | Volume (cm3) | U-Value (W/m2K) | Tile | Volume (cm3) | U-Value (W/m2K) | Tile | Volume (cm3) | U-Value (W/m2K) | Tile | Volume (cm3) | U-Value (W/m2K) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flat | 250 | 1.07 | CV1 | 642 | 0.61 | B1 | 538 | 0.62 | CC1 | 690 | 0.63 | S1 | 611 | 0.63 |

| F1 | 407 | 0.58 | CV2 | 660 | 0.62 | B2 | 520 | 0.61 | CC2 | 702 | 0.63 | S2 | 569 | 0.62 |

| F2 | 508 | 0.58 | CV3 | 720 | 0.62 | B3 | 460 | 0.63 | CC3 | 650 | 0.63 | S3 | 556 | 0.61 |

| F3 | 497 | 0.57 | CV4 | 635 | 0.61 | B4 | 545 | 0.62 | CC4 | 690 | 0.63 | S4 | 625 | 0.61 |

| F4 | 495 | 0.57 | CV5 | 712 | 0.62 | B5 | 468 | 0.62 | CC5 | 435 | 0.57 | S5 | 543 | 0.61 |

| F5 | 486 | 0.56 | CV6 | 671 | 0.62 | B6 | 509 | 0.59 | CC6 | 608 | 0.63 | S6 | 637 | 0.61 |

| Parameter | Setting | |

|---|---|---|

| Location | - | Tel Aviv |

| Structure (9 stories) | Typical floor | 655.18 m2 |

| Loads | People | 4 to 8, according to apartment size |

| Constant | 1 to 0.5 W/m2, according to apartment size | |

| Non-constant | 8 to 4 W/m2, according to apartment size | |

| Lighting | - | 5 W/m2 |

| Mechanical system | Ideal system heating/cooling load calculation | |

| Setpoint | Heating | 20 °C |

| Cooling | 24 °C | |

| Infiltration | - | 1 ach |

| Seasons | - | All |

| Component | External Wall Covering | |

|---|---|---|

| Flat Tiles | Sculptured Tiles | |

| Composite Materials (Thickness (m)) | ||

| Roof | Bitumen (0.05 m), light concrete (0.05 m), polystyrene (0.04 m), concrete (0.14 m), lime–cement mortar (0.02 m) | |

| Ground floor | Cement mortar (0.025 m), concrete (0.14 m), polystyrene (0.04 m), light concrete (0.05 m), sand (0.1 m), cement mortar (0.025), marble tile (0.04 m) | |

| Internal floor | Cement mortar (0.025 m), concrete (0.15 m), cement mortar (0.025 m), ceramic tile (0.015 m) | |

| Interior walls | Cement mortar (0.025 m), concrete block (0.10 m), cement mortar (0.025 m) | |

| Exterior walls | Flat tiles (cement mortar) (0.025 m) 1, | Sculptured tiles (cement mortar) (0.075 m) 1, |

| concrete (0.15 m), | concrete (0.15 m), | |

| polystyrene (0.045 m), | polystyrene (0.045 m), | |

| Carton–gypsum boards (0.012 m) | Carton–gypsum boards (0.012 m) | |

| Window area | 29 m2/apartment | |

| Window type | Single Glazing | |

| Shading | External Blinds | |

| Materials/Energy | Data Source |

|---|---|

| Pdelta | - |

| Sand | Sand, at mine/CH 3 |

| Cement 1 | Portland calcareous cement, at plant/CH 3 |

| Water | Tap water, at user/CH 3 |

| OEdelta | - |

| Electricity 2 | Electricity, hard coal, at power plant/ES 4 |

| Electricity, natural gas, at power plant/ES 4 | |

| Electricity, PV, at 3 kWp flat roof installation, multi-Si/CH 3 |

| Materials/Energy | GWP (kg CO2 eq) | TA (kg SO2 eq) | WC (m3) | IR (kBq Co-60 eq) |

|---|---|---|---|---|

| Pdelta (1 kg) | ||||

| Sand | 0.00242 | 0.0000118 | 0.26 | 0.00179 |

| CEM I | 0.873 | 0.000972 | 1.46 | 0.0639 |

| CEM II | 0.6 | 0.000678 | 1.08 | 0.0495 |

| Water | 0.000171 | 0.000000546 | 0.00448 | 0.000294 |

| OEdelta (1 kWh) | ||||

| Coal | 1.14 | 0.00937 | 0.213 | 0.0151 |

| Natural gas | 0.519 | 0.000223 | 0.026 | 0.00122 |

| PV | 0.0969 | 0.00036 | 2.15 | 0.0231 |

| 2020 | 0.652 | 0.00306 | 0.266 | 0.00733 |

| 2025 | 0.41 | 0.000962 | 0.532 | 0.0072 |

| Tile | OE (kWh/m2∙yr) | Tile | OE (kWh/m2∙yr) | Tile | OE (kWh/m2∙yr) | Tile | OE (kWh/m2∙yr) | Tile | OE (kWh/m2∙yr) |

|---|---|---|---|---|---|---|---|---|---|

| Flat | 18.57 | CV1 | 17.94 | B1 | 17.95 | CC1 | 17.95 | S1 | 17.95 |

| F1 | 17.92 | CV2 | 17.94 | B2 | 17.94 | CC2 | 17.95 | S2 | 17.95 |

| F2 | 17.92 | CV3 | 17.95 | B3 | 17.95 | CC3 | 17.95 | S3 | 17.93 |

| F3 | 17.91 | CV4 | 17.94 | B4 | 17.95 | CC4 | 17.95 | S4 | 17.94 |

| F4 | 17.91 | CV5 | 17.95 | B5 | 17.95 | CC5 | 17.91 | S5 | 17.93 |

| F5 | 17.91 | CV6 | 17.95 | B6 | 17.92 | CC6 | 17.95 | S6 | 17.94 |

| Tile | Pdelta | OEdelta | Tile | Pdelta | OEdelta | Tile | Pdelta | OEdelta | Tile | Pdelta | OEdelta | Tile | Pdelta | OEdelta |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flat | - | - | CV1 | 261,968 | −187,585 | B1 | 192,780 | −185,421 | CC1 | 294,231 | −183,854 | S1 | 241,285 | −183,854 |

| F1 | 104,881 | −194,150 | CV2 | 274,256 | −186,373 | B2 | 180,881 | −188,401 | CC2 | 302,498 | −183,854 | S2 | 213,465 | −184,636 |

| F2 | 172,521 | −193,440 | CV3 | 314,205 | −184,636 | B3 | 140,544 | −183,466 | CC3 | 267,500 | −184,245 | S3 | 204,049 | −188,817 |

| F3 | 165,208 | −195,259 | CV4 | 257,335 | −187,179 | B4 | 197,415 | −184,636 | CC4 | 294,231 | −183,466 | S4 | 250,701 | −187,585 |

| F4 | 163,710 | −195,285 | CV5 | 308,695 | −184,636 | B5 | 146,055 | −185,421 | CC5 | 123,601 | −195,259 | S5 | 196,079 | −188,817 |

| F5 | 157,632 | −195,110 | CV6 | 281,632 | −185,421 | B6 | 173,116 | −191,973 | CC6 | 239,274 | −183,080 | S6 | 258,669 | −186,776 |

| Tile | I/A | H/A | E/A | Tile | I/A | H/A | E/A | Tile | I/A | H/A | E/A | Tile | I/A | H/A | E/A |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CEM I Pdelta + 2020 OEdelta | |||||||||||||||

| CV1 | 7380 | 150 | −6000 | B1 | 3750 | −1680 | −7930 | CC1 | 7380 | 150 | −6000 | S1 | 5490 | −780 | −6960 |

| CV2 | 7680 | 300 | −5850 | B2 | 3280 | −1970 | −8340 | CC2 | 7680 | 300 | −5850 | S2 | 4490 | −1300 | −7560 |

| CV3 | 6410 | −330 | −6580 | B3 | 1940 | −2560 | −8770 | CC3 | 6410 | −330 | −6580 | S3 | 4090 | −1570 | −7930 |

| CV4 | 7380 | 160 | −6000 | B4 | 3930 | −1580 | −7850 | CC4 | 7380 | 160 | −6000 | S4 | 5760 | −720 | −7090 |

| CV5 | 1150 | −3540 | −9770 | B5 | 2100 | −2510 | −8770 | CC5 | 1150 | −3540 | −9770 | S5 | 3810 | −1720 | −8070 |

| CV6 | 5430 | −800 | −6990 | B6 | 2950 | −2210 | −8680 | CC6 | 5430 | −800 | −6990 | S6 | 6060 | −560 | −6840 |

| CEM II Pdelta + 2020 OEdelta | |||||||||||||||

| CV1 | 3850 | −1730 | −8240 | B1 | 2060 | −2570 | −8920 | CC1 | 4770 | −1200 | −7520 | S1 | 3370 | −1900 | −8200 |

| CV2 | 4190 | −1540 | −7980 | B2 | 1690 | −2810 | −9280 | CC2 | 4990 | −1090 | −7410 | S2 | 2610 | −2280 | −8660 |

| CV3 | 5280 | −960 | −7360 | B3 | 700 | −3210 | −9490 | CC3 | 4050 | −1560 | −7960 | S3 | 2290 | −2520 | −8980 |

| CV4 | 3740 | −1780 | −8190 | B4 | 2190 | −2490 | −8860 | CC4 | 4770 | −1190 | −7520 | S4 | 3550 | −1870 | −8380 |

| CV5 | 5140 | −1030 | −7440 | B5 | 820 | −3190 | −9520 | CC5 | 60 | −4110 | −10410 | S5 | 2080 | −2620 | −9080 |

| CV6 | 4410 | −1410 | −7780 | B6 | 1420 | −3010 | −9580 | CC6 | 3330 | −1900 | −8230 | S6 | 3780 | −1750 | −8180 |

| CEM I Pdelta + 2025 OEdelta | |||||||||||||||

| CV1 | 7670 | 2260 | −1310 | B1 | 5240 | 1070 | −2490 | CC1 | 8860 | 2880 | −610 | S1 | 6970 | 1950 | −1570 |

| CV2 | 8120 | 2500 | −1050 | B2 | 4800 | 820 | −2800 | CC2 | 9160 | 3030 | −460 | S2 | 5980 | 1440 | −2100 |

| CV3 | 9550 | 3230 | −280 | B3 | 3420 | 170 | −3370 | CC3 | 7890 | 2410 | −1100 | S3 | 5620 | 1230 | −2400 |

| CV4 | 7510 | 2190 | −1390 | B4 | 5420 | 1160 | −2390 | CC4 | 8860 | 2890 | −600 | S4 | 7280 | 2060 | −1520 |

| CV5 | 9350 | 3130 | −380 | B5 | 3590 | 240 | −3330 | CC5 | 2720 | −280 | −4050 | S5 | 5340 | 1080 | −2540 |

| CV6 | 8380 | 2640 | −890 | B6 | 4500 | 640 | −3050 | CC6 | 6900 | 1920 | −1580 | S6 | 7560 | 2210 | −1340 |

| CEM II Pdelta + 2025 OEdelta | |||||||||||||||

| CV1 | 5370 | 1050 | −2670 | B1 | 3550 | 180 | −3480 | CC1 | 6250 | 1530 | −2130 | S1 | 4850 | 830 | −2810 |

| CV2 | 5700 | 1230 | −2470 | B2 | 3210 | −20 | −3740 | CC2 | 6470 | 1640 | −2020 | S2 | 4100 | 460 | −3200 |

| CV3 | 6770 | 1780 | −1900 | B3 | 2180 | −480 | −4090 | CC3 | 5530 | 1180 | −2480 | S3 | 3820 | 280 | −3450 |

| CV4 | 5250 | 1000 | −2710 | B4 | 3680 | 250 | −3400 | CC4 | 6250 | 1540 | −2120 | S4 | 5070 | 910 | −2810 |

| CV5 | 6630 | 1710 | −1980 | B5 | 2310 | −440 | −4080 | CC5 | 1630 | −850 | −4690 | S5 | 3610 | 180 | −3550 |

| CV6 | 5900 | 1340 | −2340 | B6 | 2970 | −160 | −3950 | CC6 | 4800 | 820 | −2820 | S6 | 5280 | 1020 | −2680 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pushkar, S.; Yezioro, A.; Hershcovich, C.; Grobman, Y.J. Life-Cycle Assessment of Sculptured Tiles for Building Envelopes in Mediterranean Climate. Buildings 2022, 12, 165. https://doi.org/10.3390/buildings12020165

Pushkar S, Yezioro A, Hershcovich C, Grobman YJ. Life-Cycle Assessment of Sculptured Tiles for Building Envelopes in Mediterranean Climate. Buildings. 2022; 12(2):165. https://doi.org/10.3390/buildings12020165

Chicago/Turabian StylePushkar, Svetlana, Abraham Yezioro, Cheli Hershcovich, and Yasha J. Grobman. 2022. "Life-Cycle Assessment of Sculptured Tiles for Building Envelopes in Mediterranean Climate" Buildings 12, no. 2: 165. https://doi.org/10.3390/buildings12020165