Analytical Reliability Evaluation Framework of Three-Dimensional Engineering Slopes

Abstract

:1. Introduction

2. Implementation of 3DMPM

2.1. Assumptions

- (1)

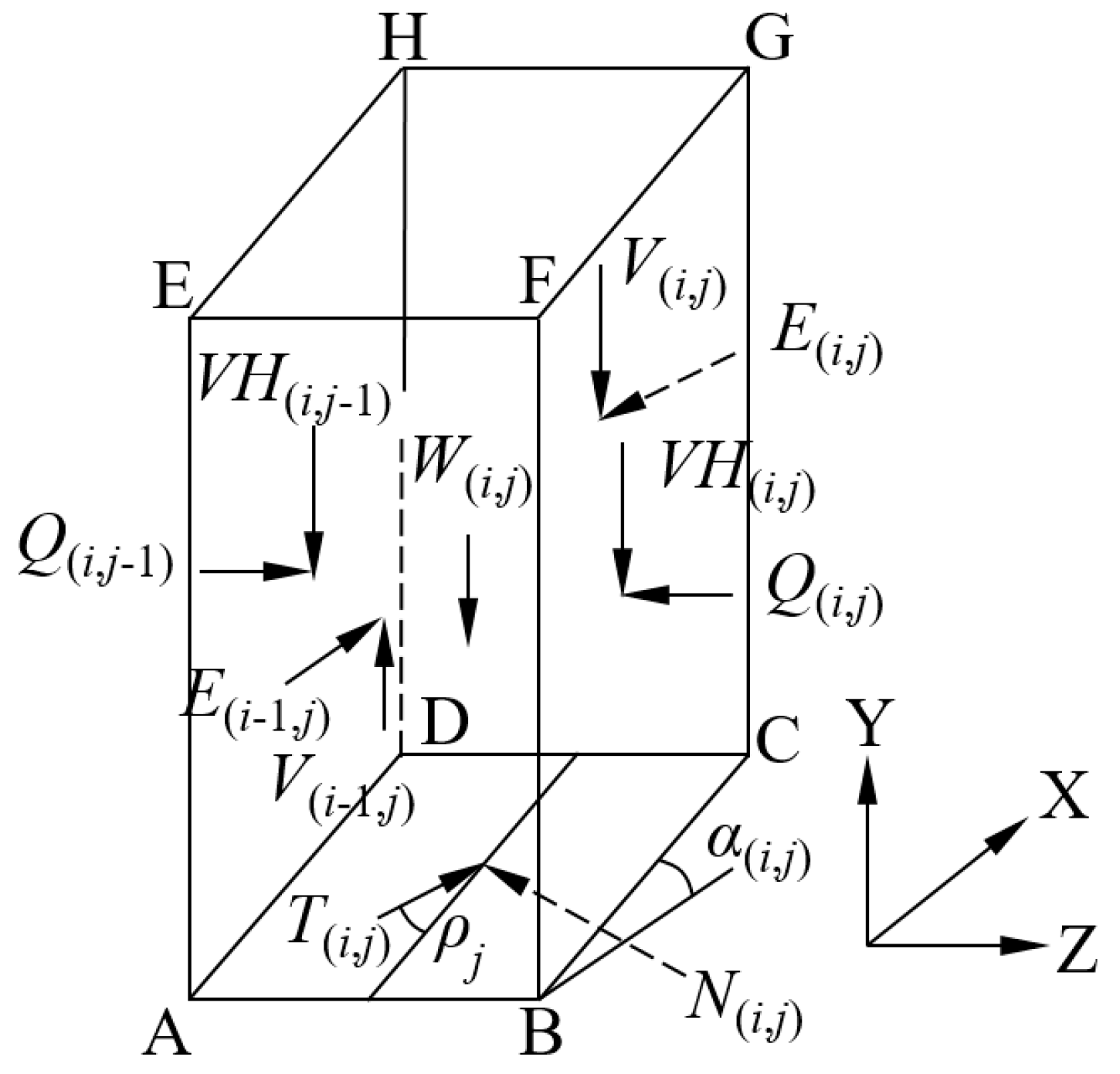

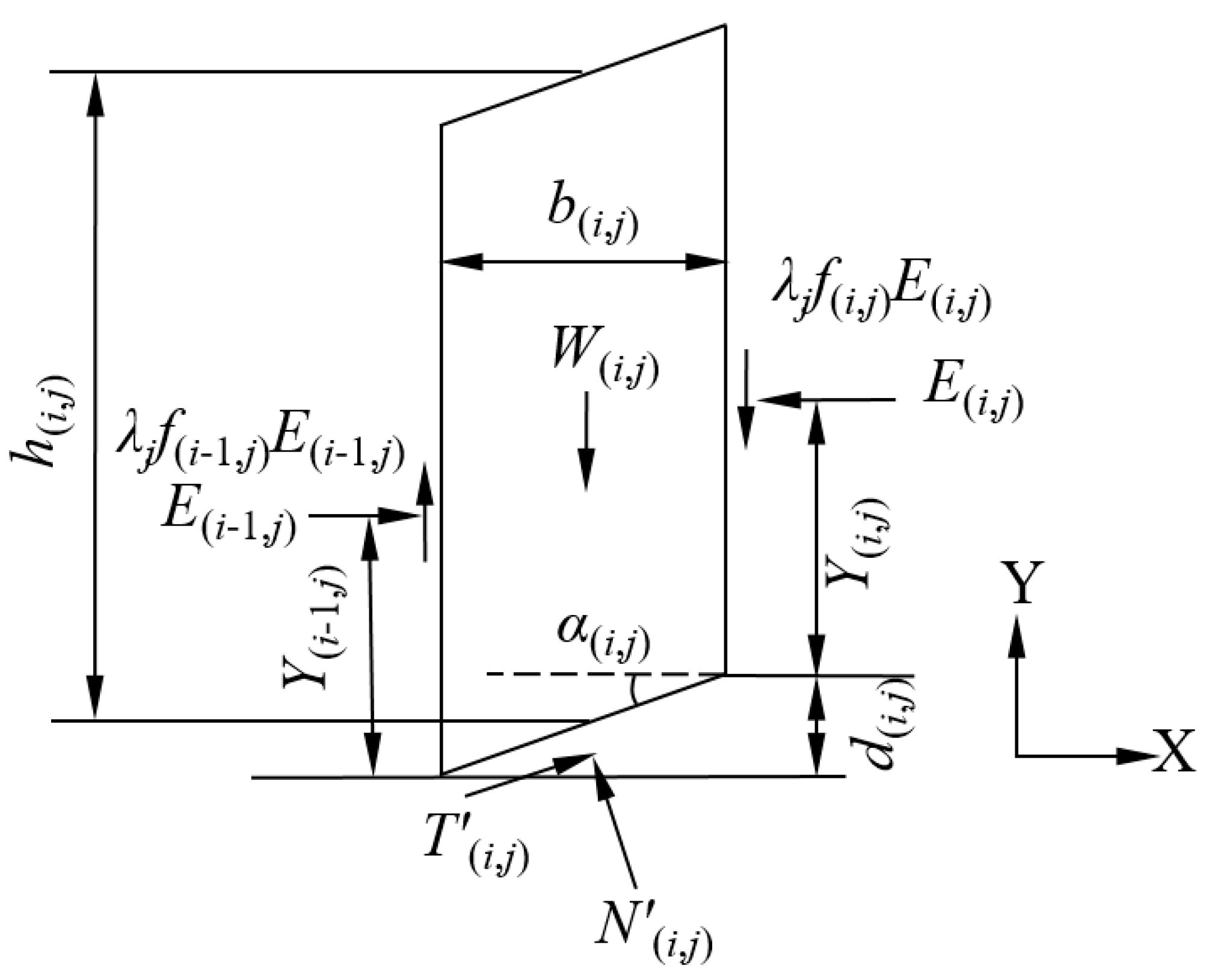

- The inter-column shear force and normal force exerting on the row face (parallel to plane, i.e., face in Figure 2) of the typical column labeled by conform to the equation [18] as:where is the proportional coefficient with the constant value for column group with the same column number (the subscript indicates the decisive variable on which the value of this coefficient is dependent, the same meaning applies to the definition of following coefficients), and is the inter-column force function [29] given by:in which is the shape coefficient for inter-column force function; is the function characterizing the relative position of this typical column against the column with maximum coordinate in the column group with the same column number :where is the normalized x coordinate of the center for the base of the column; is the maximum in the set of for the column group with the same column number .

- (2)

- The inter-column normal force in the axis direction and inter-column shear force in the axis direction exerts on the column face (parallel to plane, i.e., face in Figure 2) are neglected in accordance with the assumption in the 2D M-P method. This implies that the force equilibrium for each column is actually enforced in the axis direction, referred to as the main sliding direction.

- (3)

- Shear force applies to the column base integrating the whole slip surface, with an inclination angle over the plane.

- (a)

- , which means the whole sliding mass moves as a rigid body and generates shear force on each column base in a constant direction, as used in [31].

- (b)

- The magnitude of increases linearly with the distance from the position of the neutral plane in the direction of axis , but with opposite directions indicated by the signs of coordinates and by different rates adjusted by the value of on two sides of the neutral plane, as characterized by functions:where indicates the coordinate of the base center for each column, of which the sign dictates the sign of the sliding direction, defined as a positive direction by the projection in the positive direction of the Z axis; the coefficient indicates the asymmetrically increasing rate of on two sides of the neutral plane; and is an unknown involved throughout the formulation to be solved. Note that the symmetricity of the slope geometry and the soil properties on two sides of the neutral plane can render the value of by zero and the value of by unit. This means that the sliding mass moves as a rigid body in the direction perpendicular to the rotational axis. With the solution of and obtained, the sliding orientation of each column is determinate, in addition to the shear force distribution on the slip surface for the whole sliding mass.

2.2. Formulation for Solving Factor of Safety in 3DMPM

- (1)

- The force equilibrium in the axis direction for each column gives:

- (2)

- The force equilibrium in the axis direction for each column by substituting Equation (1) gives:where denotes the normal force acting at the base center of each column and denotes the gravity of each column applying at its centroid.

- (3)

- The forces on the column base in compliance with the Mohr–Coulomb criterion, that the definition of the factor of safety by the mobilized proportion of the shear strength for each column base to maintain the limit equilibrium state is:in which represents the average pore water pressure on each column base, is the area of each column base, is the average cohesion on each column base, and denotes the factor of safety for the column group with the same column number .

- (4)

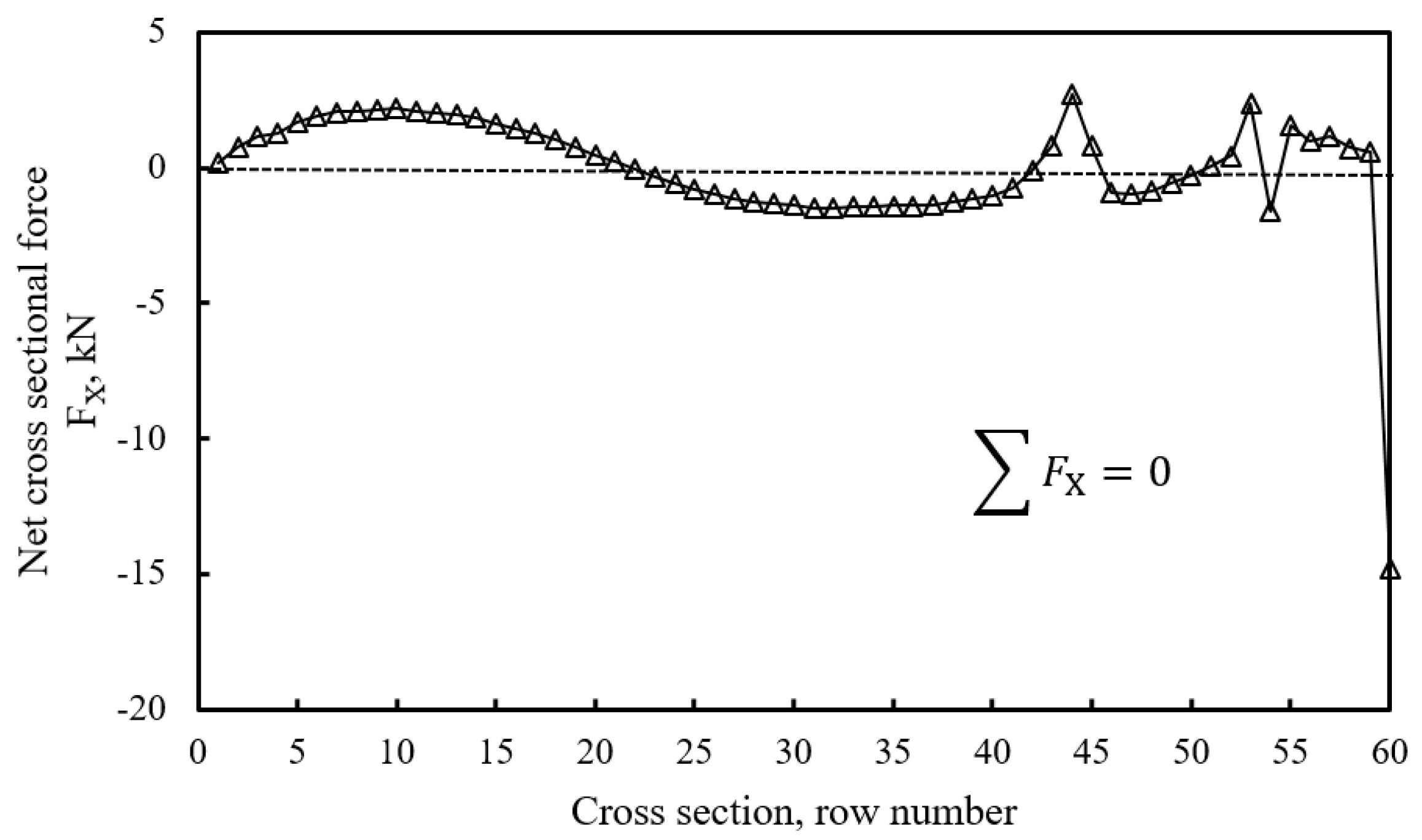

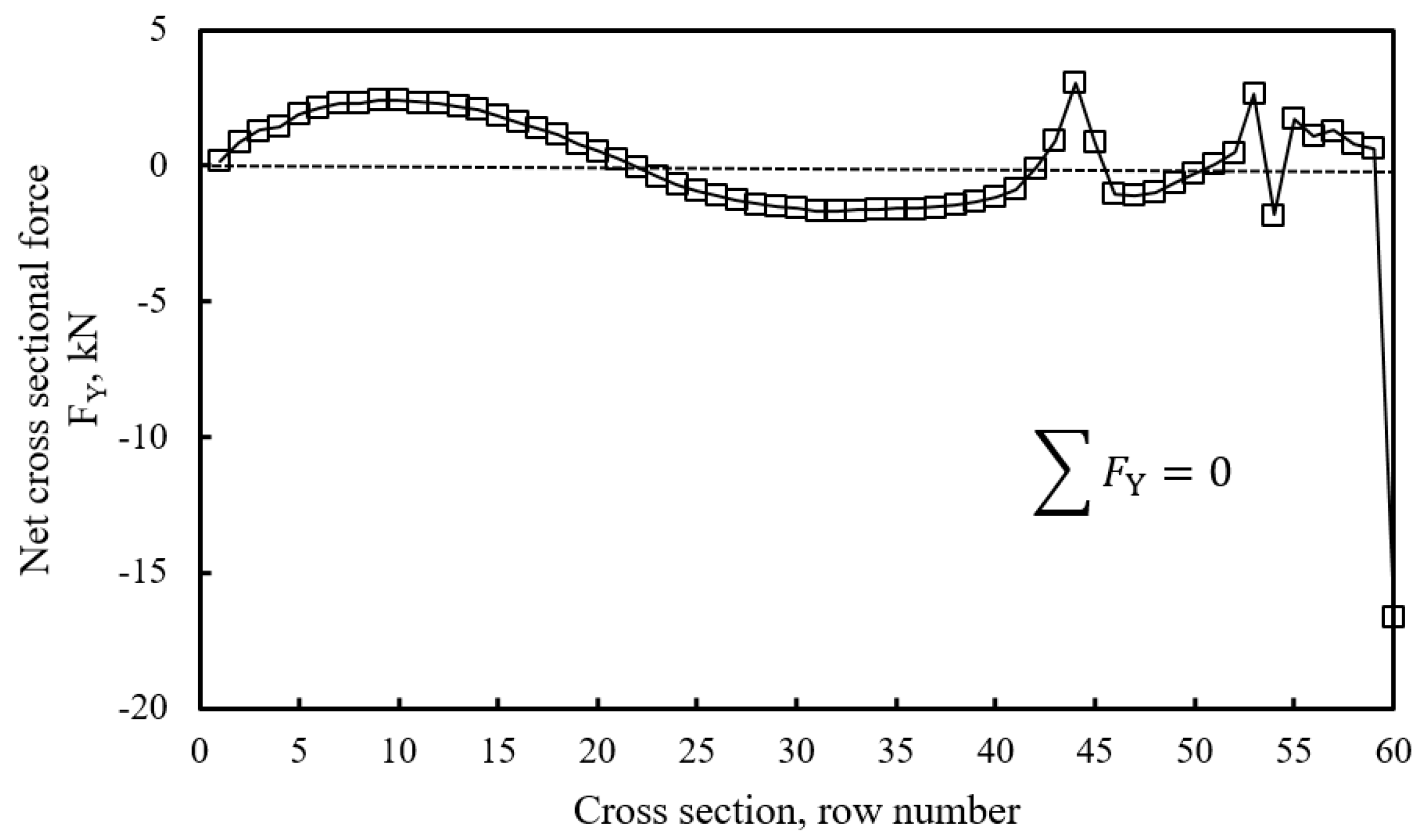

- Establishment of the force equilibrium equation in the axis direction for the whole sliding mass:

- (a)

- If constant for each column is assumed, summation of Equation (24) for all columns in column group with number gives:in which denotes the constant direction derivative in the axis for the whole sliding mass.

- (b)

- Columns with centroid coordinate (denoted by ) in the column group with number j were labeled by row number in the range ; thus Equation (24) can be rewritten as:

- (c)

- Columns with centroid coordinate denoted by in the column group with column number were labeled by row number from 1 through ; thus, the procedure of deriving value of was repeated to obtain the value of :

2.3. The Programming Implementation of 3DMPM

- (1)

- Establish the Cartesian coordinate system upon the sliding mass by aligning the Z axis with the rotational axis, the plane with the neutral plane with the largest cross-section area, and the origin set at the toe of the neutral plane.

- (2)

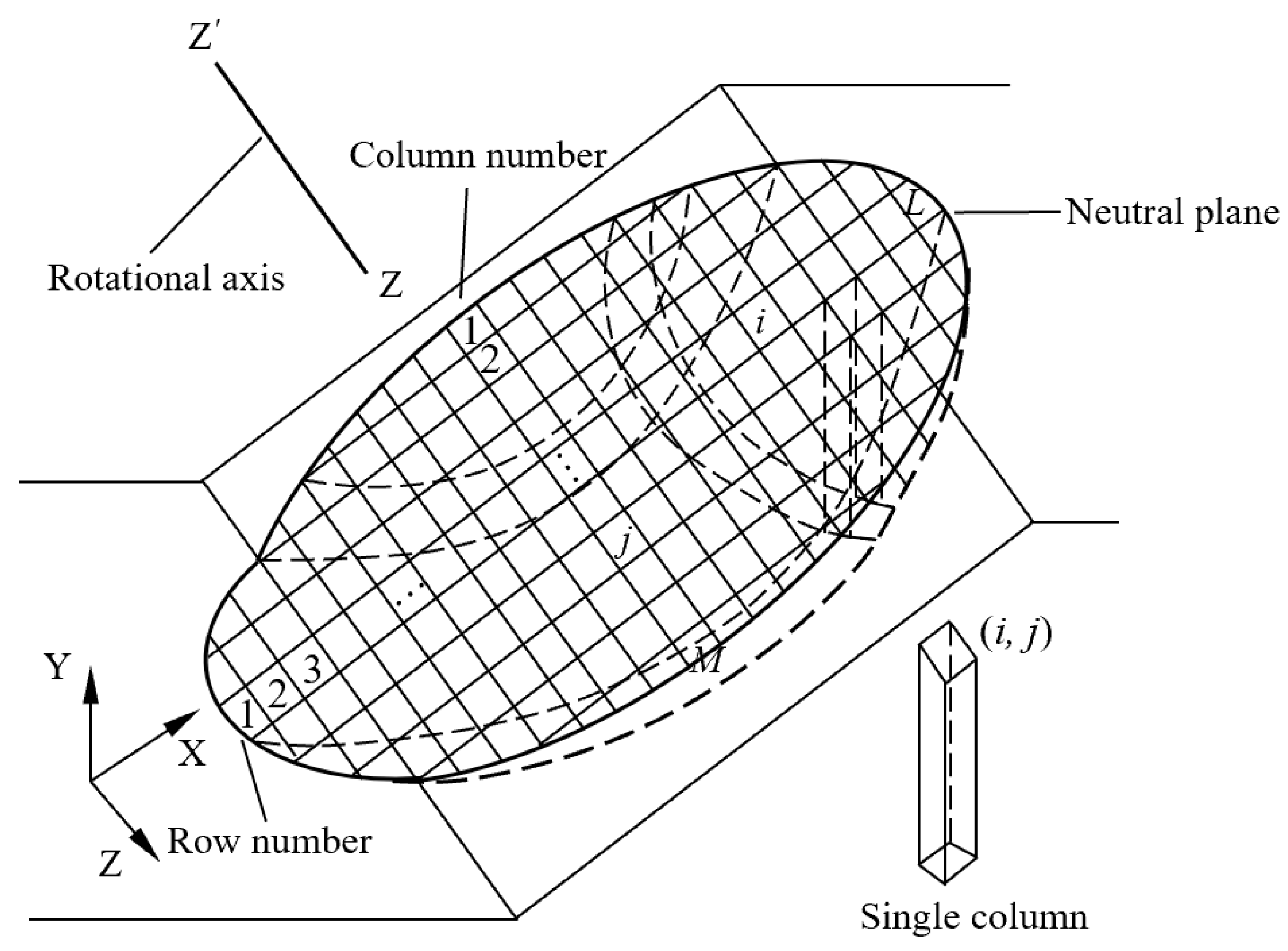

- Mesh the sliding mass into element columns by the prescribed grid density on the slip surface, label each column by row number along the X axis and column number along the axis illustrated in Figure 1.

- (3)

- Prescribe the soils’ properties, including unit weight and shear strength parameters, and pore water pressure distribution, to each column according to the information by geological survey.

- (4)

- Prescribe the initial estimate of unknowns , and for constant pattern (or and for linear pattern) by rough evaluation of the geometric and mechanic characteristics of the object sliding mass.

- (5)

- Gravity and gravity-related intermediate forces and can be calculated in Equations (16) and (17) for each column.

- (6)

- Angle-related intermediate variables and can be obtained by substituting and into Equations (13)–(15) with direction derivatives solved in Equations (5) and (6) by or and .

- (7)

- The value of evolved by substitution of and into Equation (21).

- (8)

- Solve in Equation (12) by the updated and the precedent and .

- (9)

- Update the value of by substituting into Equation (35).

- (10)

- Solve and by using , , and in Equations (9) and (10).

- (11)

- Update the value of or and by calculation of Equations (25) and (26) or Equations (27)–(30) with and .

- (12)

- The initial values of , , or and are updated by the above computed results.

- (13)

- The evolution of prescribed unknowns continues by repeating step (4) through step (12) until the termination criterion are achieved, which were defined by , , or , where , and denote the tolerance prescribed for unknowns.

- (14)

- Output the solution of , , or and .

3. Examination of 3DMPM by Reported Example Cases

3.1. Power Plant Slope of the Tianshengqiao II Project

3.2. Hypothetic Slope Example with Spherical Slip Surface

4. Reliability Evaluation on Hypothetic Slope Example by 3DMPM and RSM

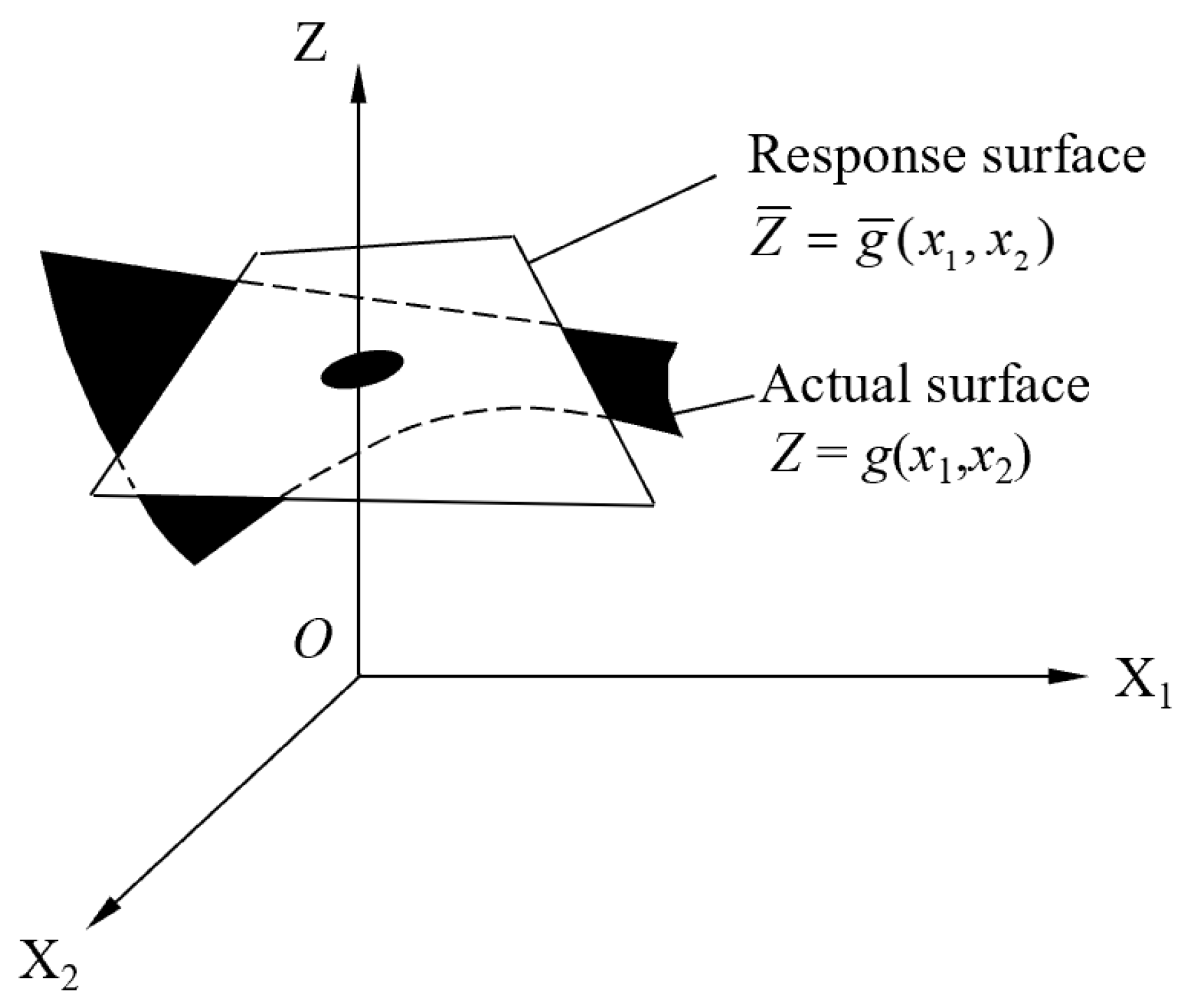

4.1. Fundamentals of the Response Surface Method

4.2. Establishment of Response Surface Model Based on 3DMPM

4.2.1. Determination of Random Variables

4.2.2. Establishment of Performance Function

4.2.3. Computation of Slope Reliability Index

- (1)

- Give the mean value , variation coefficient and correlation coefficient for each random variable according to the distribution pattern used in computation, and prescribe an initial minimum reliability index .

- (2)

- Prescribe the mean value of random vector to the initial sample denoted by .

- (3)

- Update the by interpolation close to the sample with and obtain samples, where coefficient is a value in the range of .

- (4)

- Obtain estimates of by Equation (38) and solve the undetermined coefficients , and in the response surface function.

- (5)

- Solve the checking point and reliability index ( indicates the iteration) using the first-order second-moment method.

- (6)

- Examine the value of by comparing it with the prescribed tolerance; if it is larger than the tolerance, update the by and update the response surface approaching the limit state by looping with steps (3)–(5); if the tolerance is achieved, output the failure probability by and final reliability ; then, the minimum reliability index should be evolved in the next loop by if .

4.3. Application to Hypothetic Example Case

4.3.1. Example Case

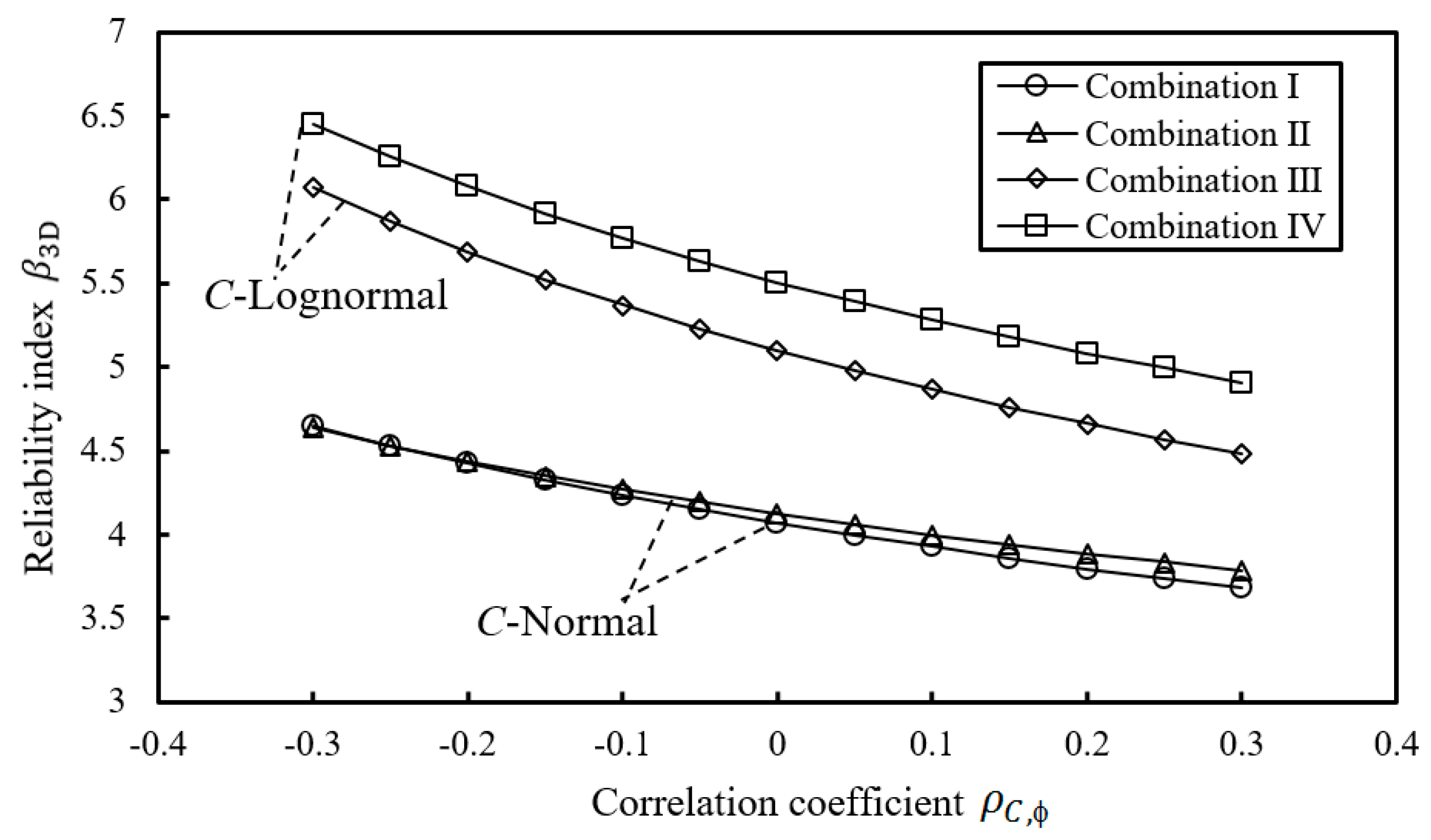

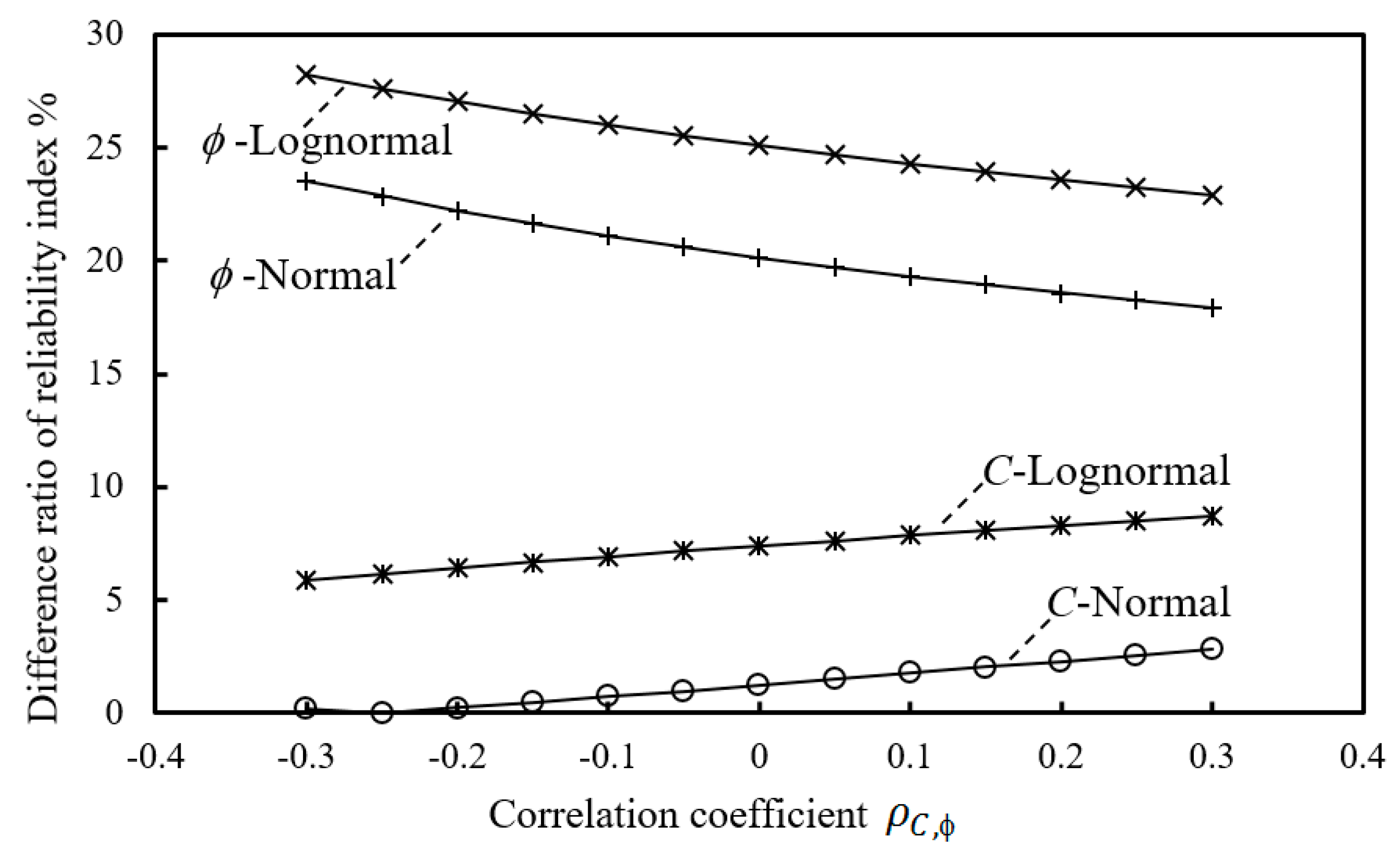

4.3.2. Discussion

5. Conclusions

- The extended three-dimensional stability analysis method is capable of accounting for the inter-column forces along the main sliding direction and the sliding direction variation on each column, and is applicable to slope cases with highly asymmetric or symmetric slip surfaces.

- The reliability evaluation framework was found to attain better efficiency by incorporating the above stability analysis into the response surface method than that using Monte-Carlo technique.

- The increasing correlation coefficient between the cohesion and the friction angle can reduce the slope reliability index.

- The switch of the probability distribution pattern for the cohesion leads to more significant degradation of the reliability index than that for the friction angle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Notations

| maximum row number labeling soil columns | |

| maximum column number labeling soil columns | |

| inter-column shear force exerting on row face | |

| inter-column normal force exerting on row face | |

| the proportional coefficient relating inter-column forces | |

| the inter-column force function | |

| the shape coefficient for inter-column force function | |

| the function characterizing the relative position | |

| the normalized coordinate of the center for the base of the column | |

| the maximum in the set of | |

| inter-column normal force exerting on column face | |

| inter-column shear force exerting on column face | |

| shear force exerting on the column base | |

| the inclination angle formed by over axis | |

| coefficient in equation characterizing | |

| coefficient in equation characterizing | |

| directional derivative of normal direction of column base over axis | |

| directional derivative of normal direction of column base over axis | |

| directional derivative of normal direction of column base over axis | |

| directional derivative of shear force over axis | |

| directional derivative of shear force over axis | |

| directional derivative of shear force over axis | |

| normal force exerting on the column base | |

| the gravity of each column applying at its centroid | |

| the average pore water pressure on each column base | |

| the area of each column base | |

| the average cohesion on each column base | |

| the factor of safety for column group with the same column number | |

| the factor of safety for the whole sliding mass | |

| centroid coordinate for each column with | |

| centroid coordinate for each column with | |

| the maximum row number of columns with | |

| the average height of each column | |

| projective length of each column base in -axis direction | |

| projective length of each column base in -axis direction | |

| the application height of started from the base side | |

| moment formed by as | |

| identical for all columns | |

| the intermedia function defined in Equation (13) | |

| the intermedia function defined in Equation (15) | |

| the intermedia function defined in Equation (16) | |

| the intermedia function defined in Equation (17) | |

| the number of random variables | |

| random vector defined by | |

| response surface | |

| performance function | |

| , and | undetermined coefficients in |

| mean value for random variable | |

| variation coefficient for random variable | |

| correlation coefficient for random variables | |

| initial minimum reliability index | |

| updated sample in iteration | |

| updated reliability index in iteration | |

| cohesion in slope example | |

| friction angle in slope example | |

| correlation coefficient for and | |

| reliability index of slope example |

References

- Duncan, J.M. State of the art: Limit equilibrium and finite-element analysis of slopes. J. Geotech. Eng. 1996, 122, 577–596. [Google Scholar] [CrossRef]

- Liu, J.; Wu, C.; Wu, G.; Wang, X. A novel differential search algorithm and applications for structure design. Appl. Math. Comput. 2015, 268, 246–269. [Google Scholar] [CrossRef]

- Kalatehjari, R.; Ali, N. A review of three-dimensional slope stability analyses based on limit equilibrium method. Electron. J. Geotech. Eng. 2013, 18, 119–134. [Google Scholar]

- Zhang, J.; Li, M.; Ke, L.; Yi, J. Distributions of lateral earth pressure behind rock-socketed circular diaphragm walls considering radial deflection. Comput. Geotech. 2022, 143, 104604. [Google Scholar] [CrossRef]

- Lam, L.; Fredlund, D. A general limit equilibrium model for three-dimensional slope stability analysis. Can. Geotech. J. 1993, 30, 905–919. [Google Scholar] [CrossRef]

- Dong, H.; Zhao, B.; Deng, Y. Instability phenomenon associated with two typical high speed railway vehicles. Int. J. Non-Lin. Mech. 2018, 105, 130–145. [Google Scholar] [CrossRef]

- Hungr, O.; Salgado, F.; Byrne, P. Evaluation of a three-dimensional method of slope stability analysis. Can. Geotech. J. 1989, 26, 679–686. [Google Scholar] [CrossRef]

- Huang, C.-C.; Tsai, C.-C. New method for 3D and asymmetrical slope stability analysis. J. Geotech. Geoenviron. Eng. 2000, 126, 917–927. [Google Scholar] [CrossRef]

- Hovland, H.J. Three-dimensional slope stability analysis method. J. Geotech. Eng. Div. 1977, 103, 971–986. [Google Scholar] [CrossRef]

- Lu, K.; Wang, L.; Yang, Y.; Zhou, G. Three-dimensional method for slope stability with the curvilinear route of the main sliding. Bull. Eng. Geol. Environ. 2022, 81, 67. [Google Scholar] [CrossRef]

- Michalowski, R. Three-dimensional analysis of locally loaded slopes. Géotechnique 1989, 39, 27–38. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, X.; Haberfield, C.; Yin, J.; Wang, Y. A three-dimensional slope stability analysis method using the upper bound theorem: Part I: Theory and methods. Int. J. Rock Mech. Min. 2001, 38, 369–378. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, F.; Lei, G.; Li, D. An extended limit analysis of three-dimensional slope stability. Géotechnique 2013, 63, 518–524. [Google Scholar] [CrossRef]

- Zheng, H. A three-dimensional rigorous method for stability analysis of landslides. Eng. Geol. 2012, 145–146, 30–40. [Google Scholar] [CrossRef]

- Kalatehjari, R.; Arefnia, A.; Rashid, A.; Ali, N.; Hajihassani, M. Determination of three-dimensional shape of failure in soil slopes. Can. Geotech. J. 2015, 52, 1283–1301. [Google Scholar] [CrossRef]

- Fang, Q.; Wang, G.; Yu, F.; Du, J. Analytical algorithm for longitudinal deformation profile of a deep tunnel. J. Rock Mech. Geotech. Eng. 2021, 13, 845–854. [Google Scholar] [CrossRef]

- Morgenstern, N.; Price, V. The analysis of the stability of general slip surfaces. Géotechnique 1965, 15, 79–93. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, J. A three-dimensional slope stability analysis procedure based on Morgenstern-Price method. Chin. J. Rock Mech. Eng. 2010, 29, 1473–1480. [Google Scholar]

- Ling, D.; Qi, S.; Chen, F.; Li, N. A limit equilibrium method based on Morgenstern-Price method for 3D slope stability analysis. Chin. J. Rock Mech. Eng. 2013, 32, 107–116. [Google Scholar]

- Xiao, T.; Li, D.; Cao, Z.; Au, S.; Phoon, K. Three-dimensional slope reliability and risk assessment using auxiliary random finite element method. Comput. Geotech. 2016, 79, 146–158. [Google Scholar] [CrossRef] [Green Version]

- Song, L.; Xu, B.; Kong, X.; Zou, D.; Pang, R.; Yu, X.; Zhang, Z. Three-dimensional slope dynamic stability reliability assessment based on the probability density evolution method. Soil Dyn. Earthq. Eng. 2019, 120, 360–368. [Google Scholar] [CrossRef]

- Cho, S. Effects of spatial variability of soil properties on slope stability. Eng. Geol. 2007, 92, 97–109. [Google Scholar] [CrossRef]

- Low, B.; Gilbert, R.; Wright, S. Slope reliability analysis using generalized method of slices. J. Geotech. Geoenviron. Eng. 1998, 124, 350–362. [Google Scholar] [CrossRef]

- Wong, F. Slope reliability and response surface method. J. Geotech. Eng. 1985, 111, 32–53. [Google Scholar] [CrossRef]

- Zhu, B.; Pei, H.; Yang, Q. An intelligent response surface method for analyzing slope reliability based on Gaussian process regression. Int. J. Numer. Methods Eng. 2019, 43, 2431–2448. [Google Scholar] [CrossRef]

- Li, L.; Chu, X. Comparative study on response surfaces for reliability analysis of spatially variable soil slope. China Ocean Eng. 2015, 29, 81–90. [Google Scholar] [CrossRef]

- Li, D.; Zheng, D.; Cao, Z.; Tang, X.; Phoon, K. Response surface methods for slope reliability analysis: Review and comparison. Eng. Geol. 2016, 203, 3–14. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, J.; Gong, X. Calculation method of earth slope reliability based on response surface method and Morgenstern-price procedure. Eng. Mech. 2008, 25, 166–172. [Google Scholar]

- Chen, C. Bionic algorithm and its application to slope and excavation engineering. Chin. J. Rock Mech. Eng. 2001, 22, 1578. [Google Scholar]

- Chen, Z.; Mi, H.; Zhang, F.; Wang, X. A simplified method for 3D slope stability analysis. Can. Geotech. J. 2003, 40, 675–683. [Google Scholar] [CrossRef]

- Cheng, Y.; Yip, C. Three-dimensional asymmetrical slope stability analysis extension of Bishop’s, Janbu’s, and Morgenstern–Price’s techniques. J. Geotech. Geoenviron. Eng. 2007, 133, 1544–1555. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, J.; Wang, Y.; Yin, J.; Haberfield, C. A three-dimensional slope stability analysis method using the upper bound theorem Part II: Numerical approaches, applications and extensions. Int. J. Rock Mech. Min. Sci. 2001, 38, 379–397. [Google Scholar] [CrossRef]

- Chen, F.; Zhong, Y.; Gao, X.; Jin, Z.; Wang, E.; Zhu, F.; Shao, X.; He, X. Non-uniform model of relationship between surface strain and rust expansion force of reinforced concrete. Sci. Rep. 2021, 11, 8741. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Z.; Au, S. Practical reliability analysis of slope stability by advanced Monte Carlo simulations in a spreadsheet. Can. Geotech. J. 2011, 48, 162–172. [Google Scholar] [CrossRef]

- Jiang, S.; Li, D.; Zhang, L.; Zhou, C. Slope reliability analysis considering spatially variable shear strength parameters using a non-intrusive stochastic finite element method. Eng. Geol. 2014, 168, 120–128. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, C.; Zhao, H. An approach to assess the stability of unsaturated multilayered coastal-embankment slope during rainfall infiltration. J. Mar. Sci. Eng. 2019, 7, 165. [Google Scholar] [CrossRef] [Green Version]

| Iteration Count | Unknowns | ||||

|---|---|---|---|---|---|

| 0 | Initial value | 1 | 0.1 | 0.5 | 1 |

| 1 | Updated value | 0.92904658 | 0.343899892 | 0.002694623 | 1.760167704 |

| 2 | 0.935328933 | 0.355620079 | 0.002003866 | 2.191196578 | |

| 3 | 0.941684448 | 0.353126985 | 0.00220214 | 2.011046151 | |

| 4 | 0.939967021 | 0.353642088 | 0.002155628 | 2.049847772 | |

| 5 | 0.940380074 | 0.353515887 | 0.002166378 | 2.040912157 | |

| 6 | 0.940282089 | 0.353545864 | 0.002163924 | 2.042938779 | |

| 7 | 0.940304766 | 0.353538998 | 0.002164479 | 2.042479728 | |

| 8 | 0.94029961 | 0.35354055 | 0.002164355 | 2.04258301 |

| Statistic Properties | ||

|---|---|---|

| Cohesion | 24.5 kPa | 0.15 |

| Friction angle | 20° | 0.15 |

| Establishment of Performance Function | Method Solving Reliability | Error, % | Running Time, Seconds | |

|---|---|---|---|---|

| 3DMPM&RSM | First-order second-moment | 4.073 | 0.37 | 2 |

| 3DMPM | Monte-Carlo | 4.057 | -- | 16,292 |

| Combination | Probability Distribution Pattern | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| −0.3 | −0.2 | −0.1 | 0 | 0.1 | 0.2 | 0.3 | |||

| Ⅰ | Normal | Normal | 4.645 | 4.426 | 4.237 | 4.073 | 3.927 | 3.796 | 3.677 |

| Ⅱ | Normal | Lognormal | 4.635 | 4.436 | 4.268 | 4.122 | 3.997 | 3.885 | 3.785 |

| Ⅲ | Lognormal | Normal | 6.075 | 5.690 | 5.370 | 5.099 | 4.865 | 4.662 | 4.482 |

| Ⅳ | Lognormal | Lognormal | 6.454 | 6.080 | 5.769 | 5.507 | 5.280 | 5.083 | 4.909 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Zhu, J.; Chen, C.; Tang, R.; Zhu, S.; Luo, X. Analytical Reliability Evaluation Framework of Three-Dimensional Engineering Slopes. Buildings 2022, 12, 268. https://doi.org/10.3390/buildings12030268

Zhang G, Zhu J, Chen C, Tang R, Zhu S, Luo X. Analytical Reliability Evaluation Framework of Three-Dimensional Engineering Slopes. Buildings. 2022; 12(3):268. https://doi.org/10.3390/buildings12030268

Chicago/Turabian StyleZhang, Genbao, Jianfeng Zhu, Changfu Chen, Renhua Tang, Shimin Zhu, and Xiao Luo. 2022. "Analytical Reliability Evaluation Framework of Three-Dimensional Engineering Slopes" Buildings 12, no. 3: 268. https://doi.org/10.3390/buildings12030268

APA StyleZhang, G., Zhu, J., Chen, C., Tang, R., Zhu, S., & Luo, X. (2022). Analytical Reliability Evaluation Framework of Three-Dimensional Engineering Slopes. Buildings, 12(3), 268. https://doi.org/10.3390/buildings12030268