Valorization of Dredged Sediments in Manufacturing Compressed Earth Blocks Stabilized by Alkali-Activated Fly Ash Binder

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

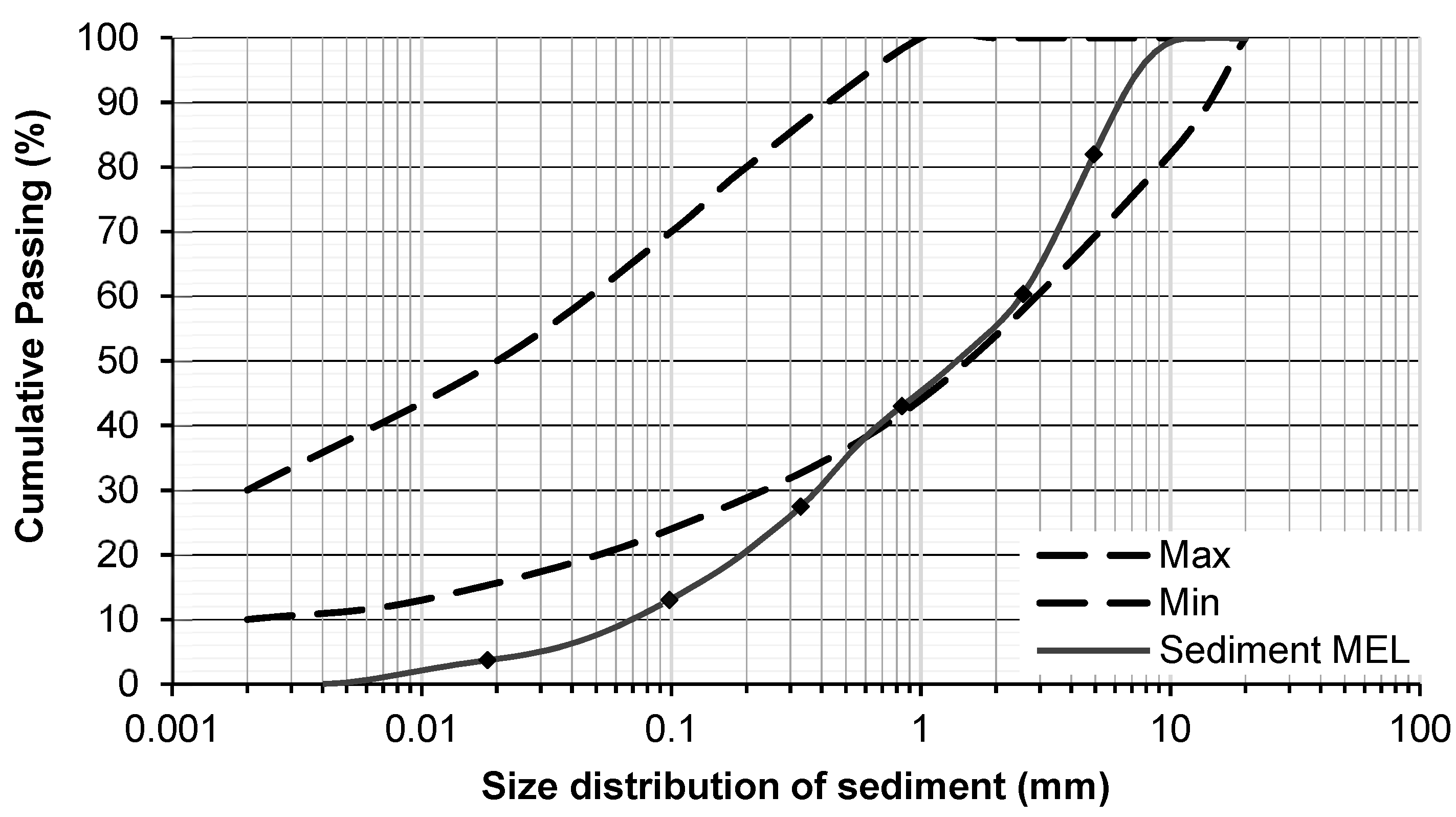

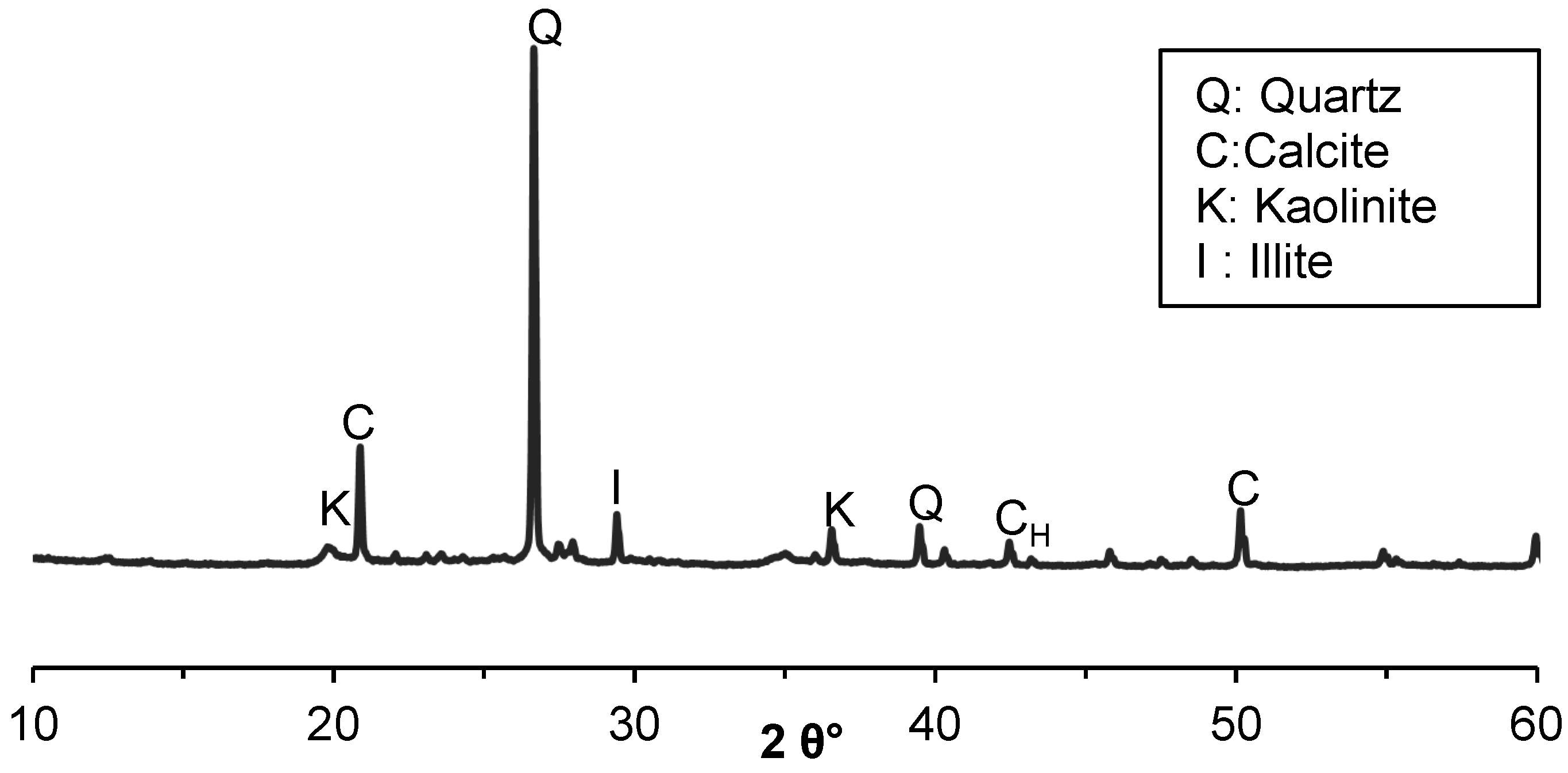

2.1.1. Dredged Sediments

2.1.2. Class F Fly Ash

2.1.3. Sodium Hydroxide Solution

2.2. Methods

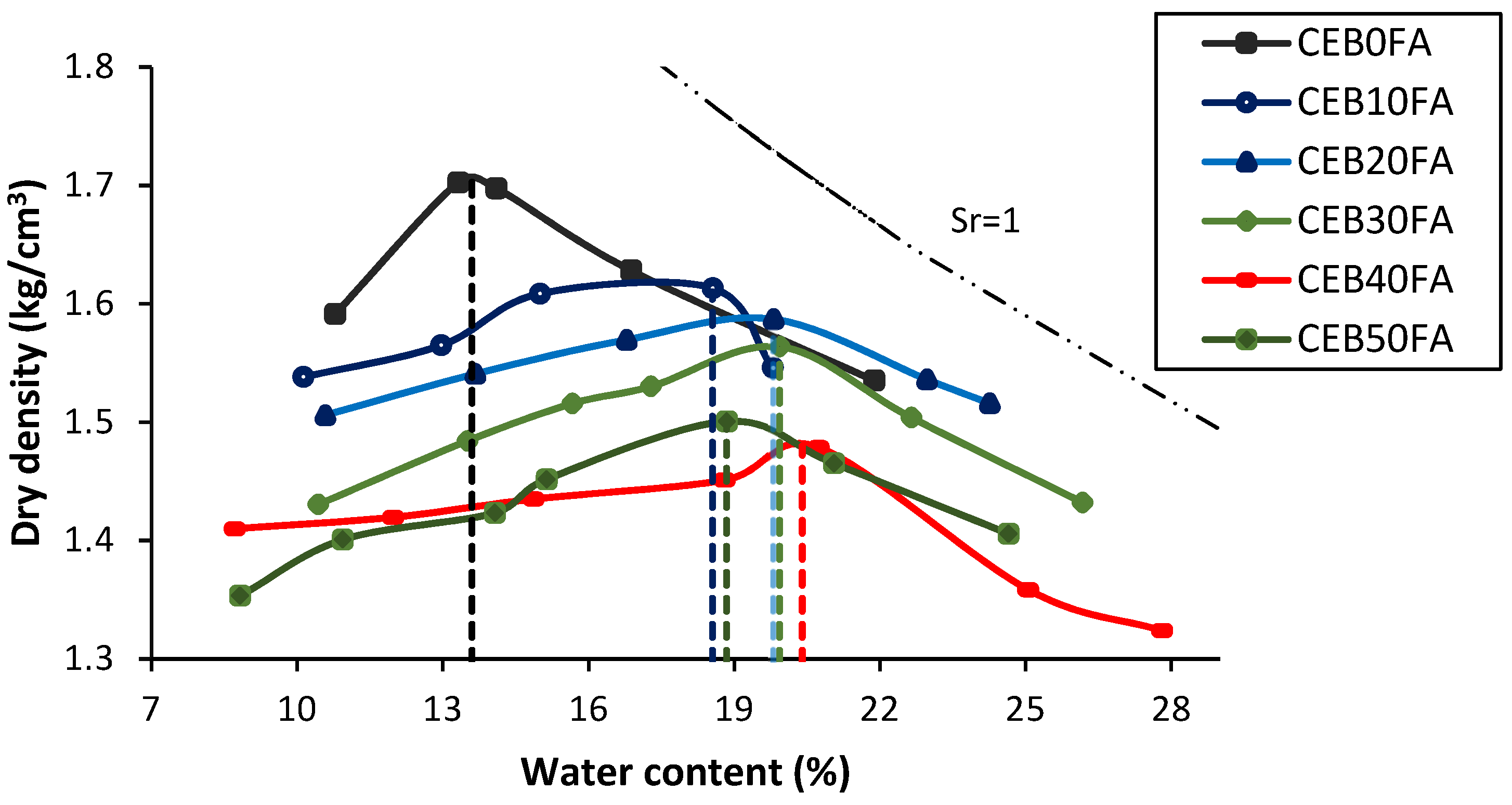

2.2.1. Optimal Water Content

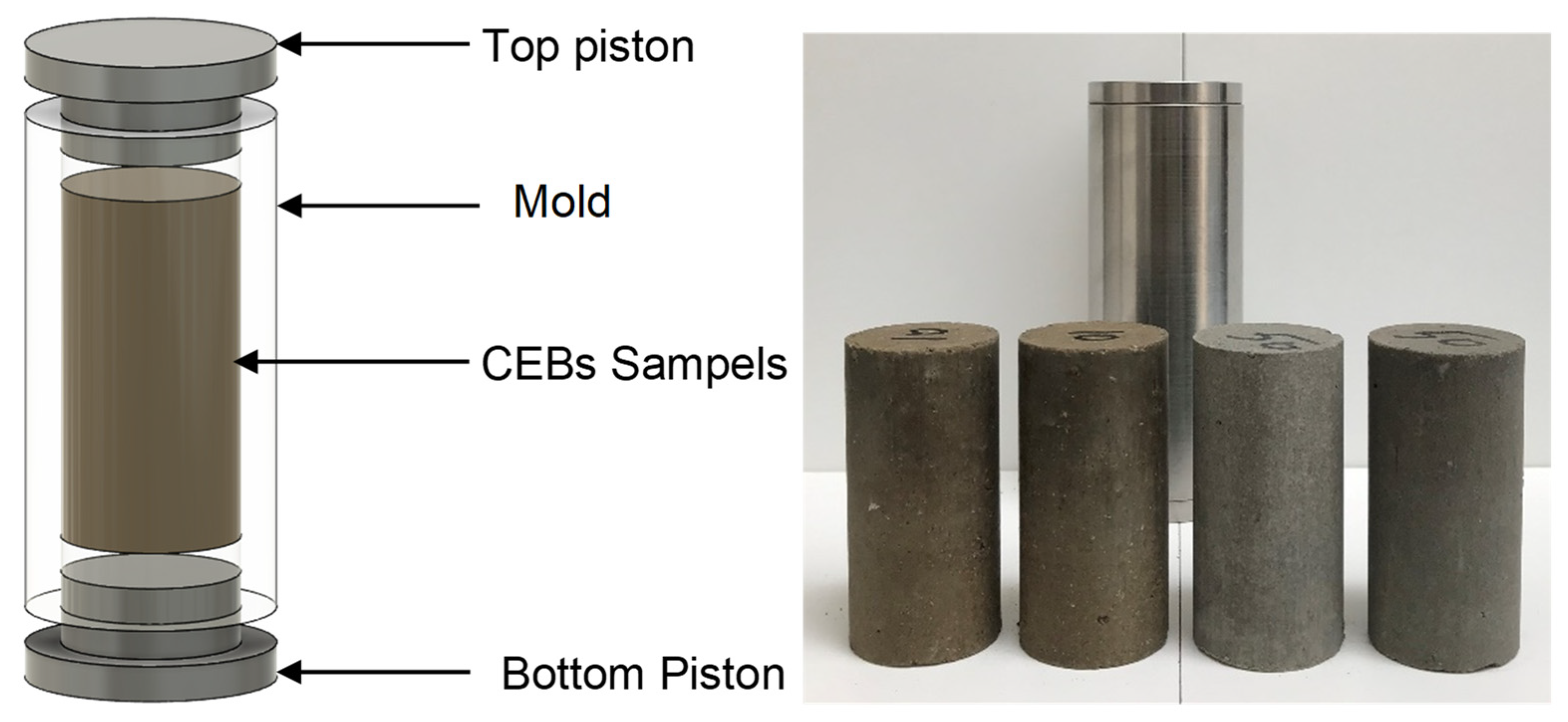

2.2.2. Preparation of CEBs

2.2.3. Experimental Techniques

3. Results

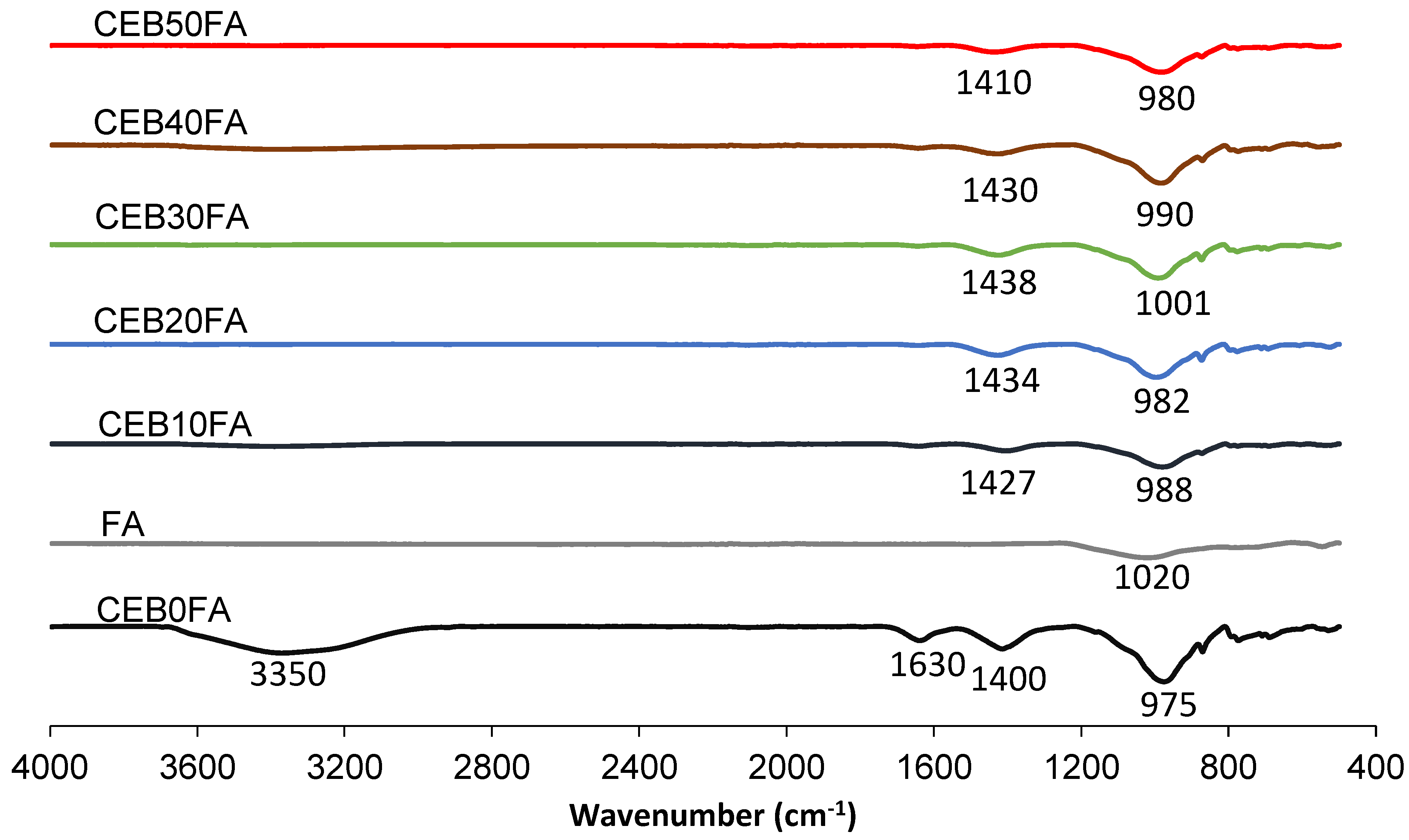

3.1. Microstructural Properties

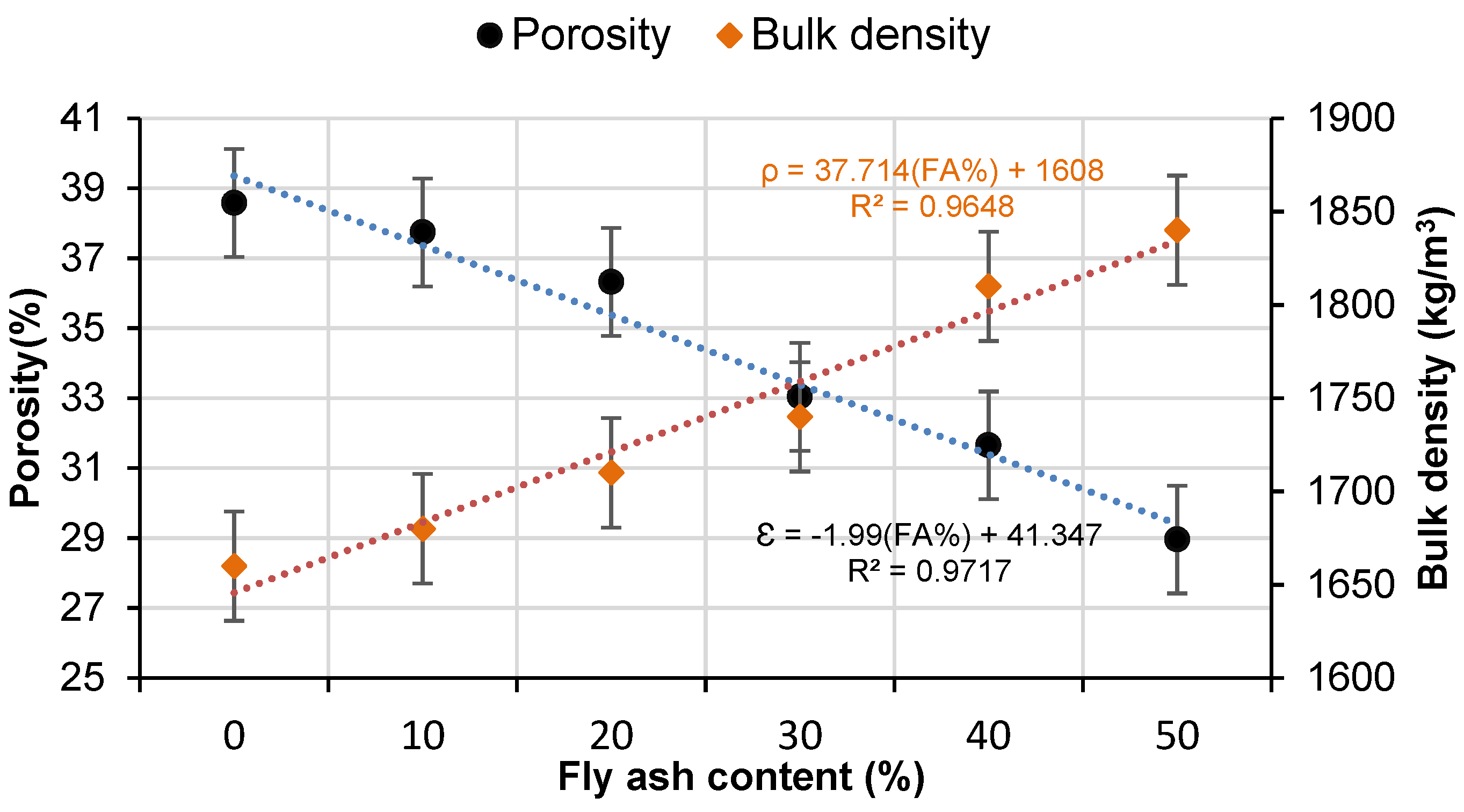

3.2. Physical Properties

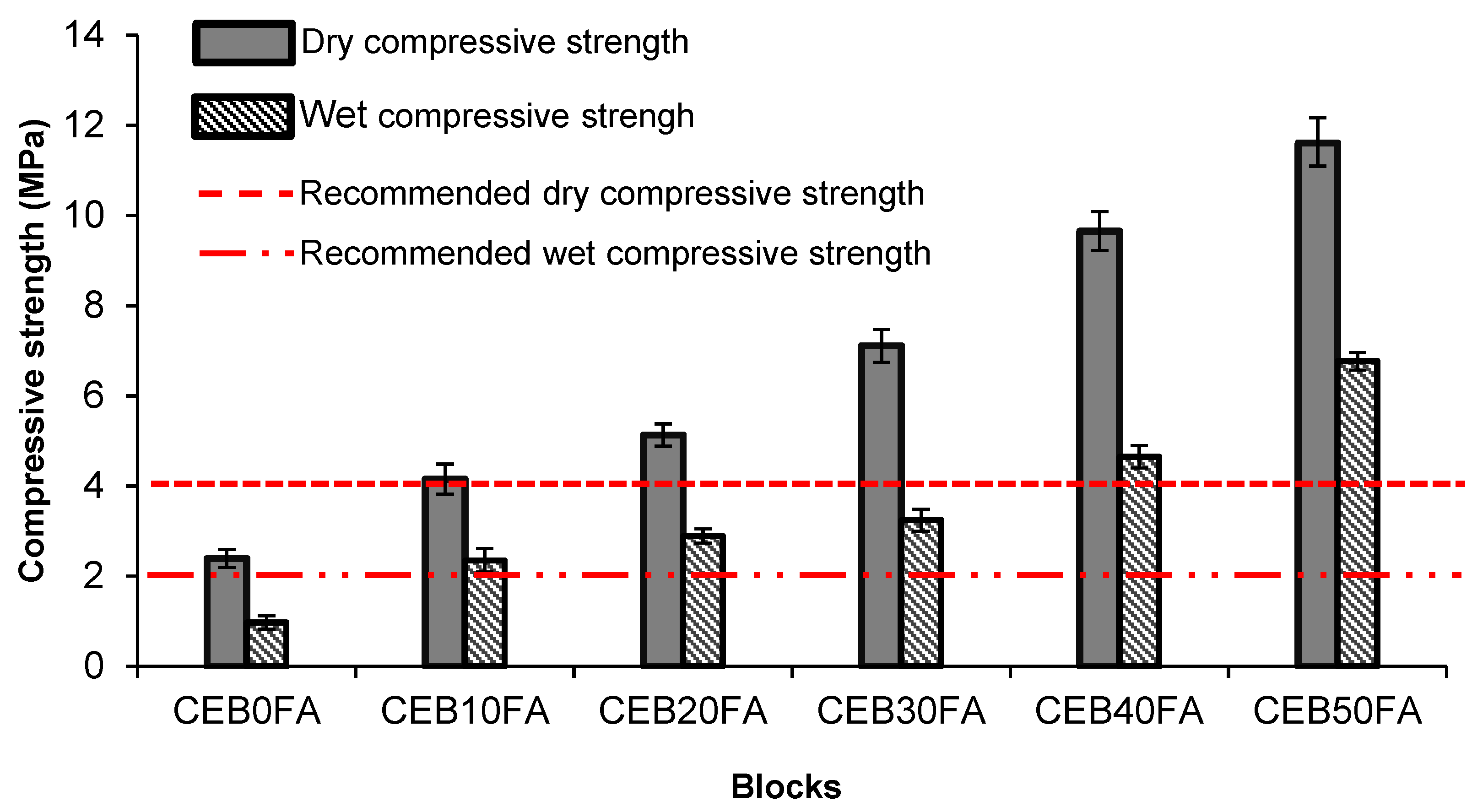

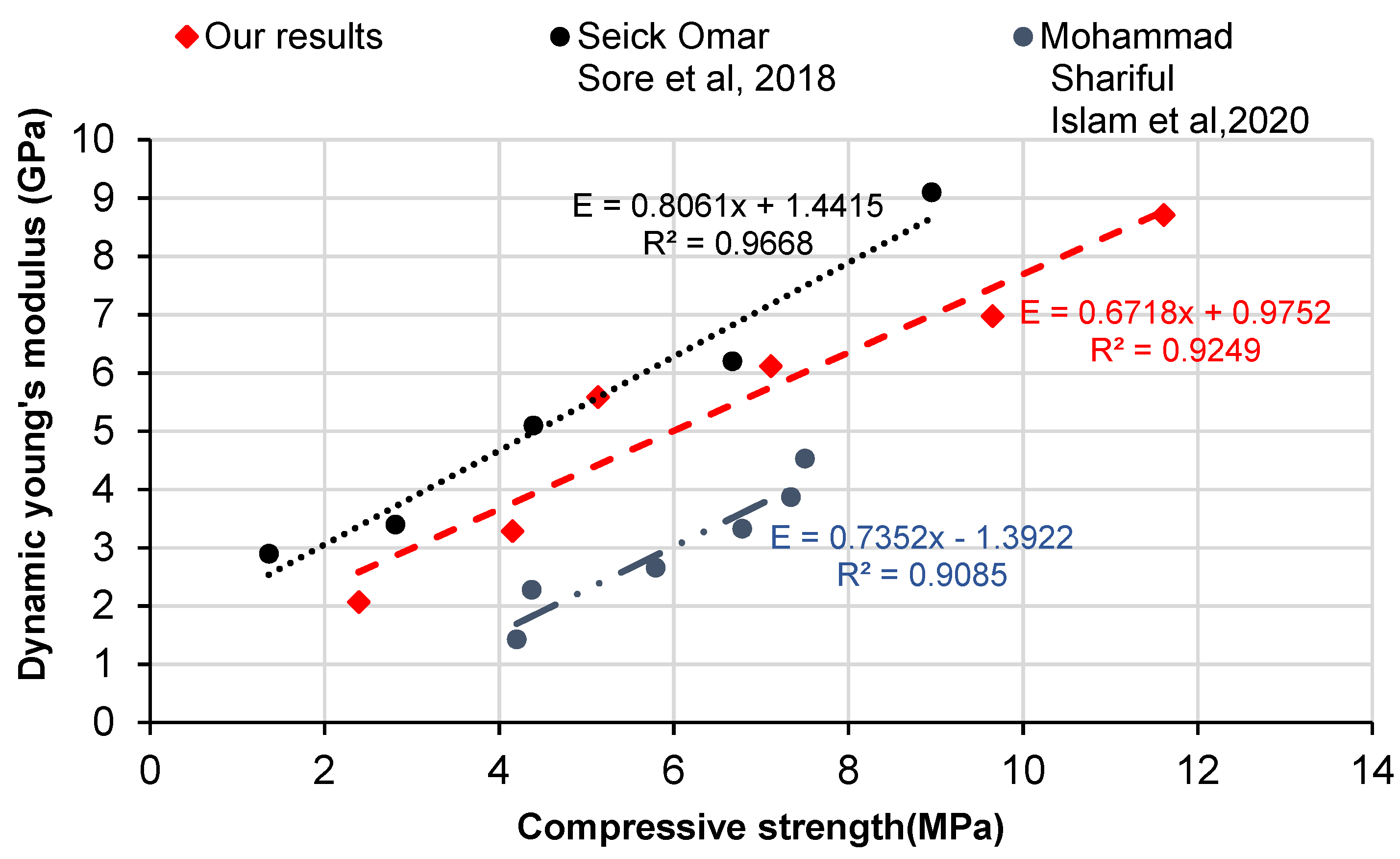

3.3. Mechanical Properties

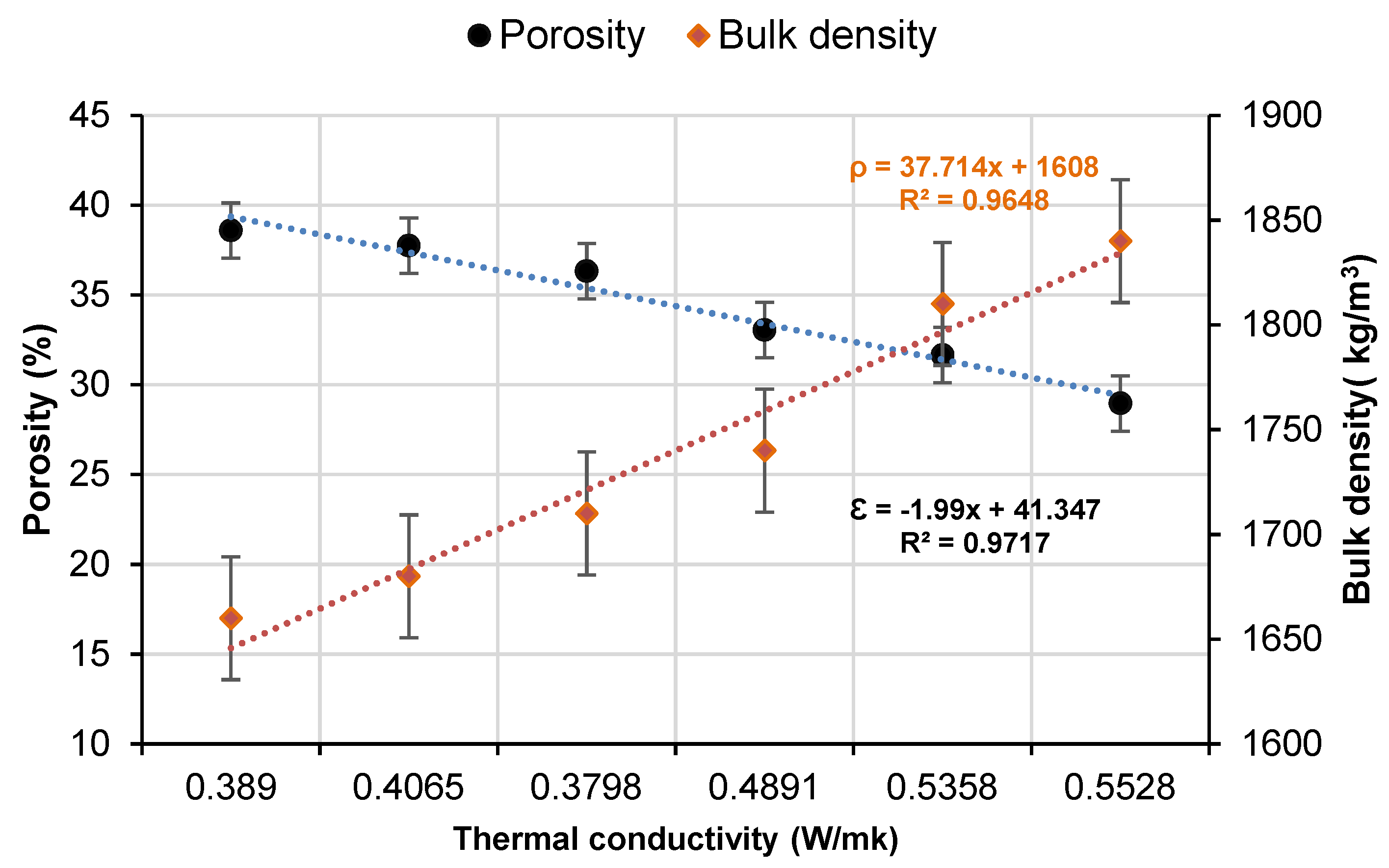

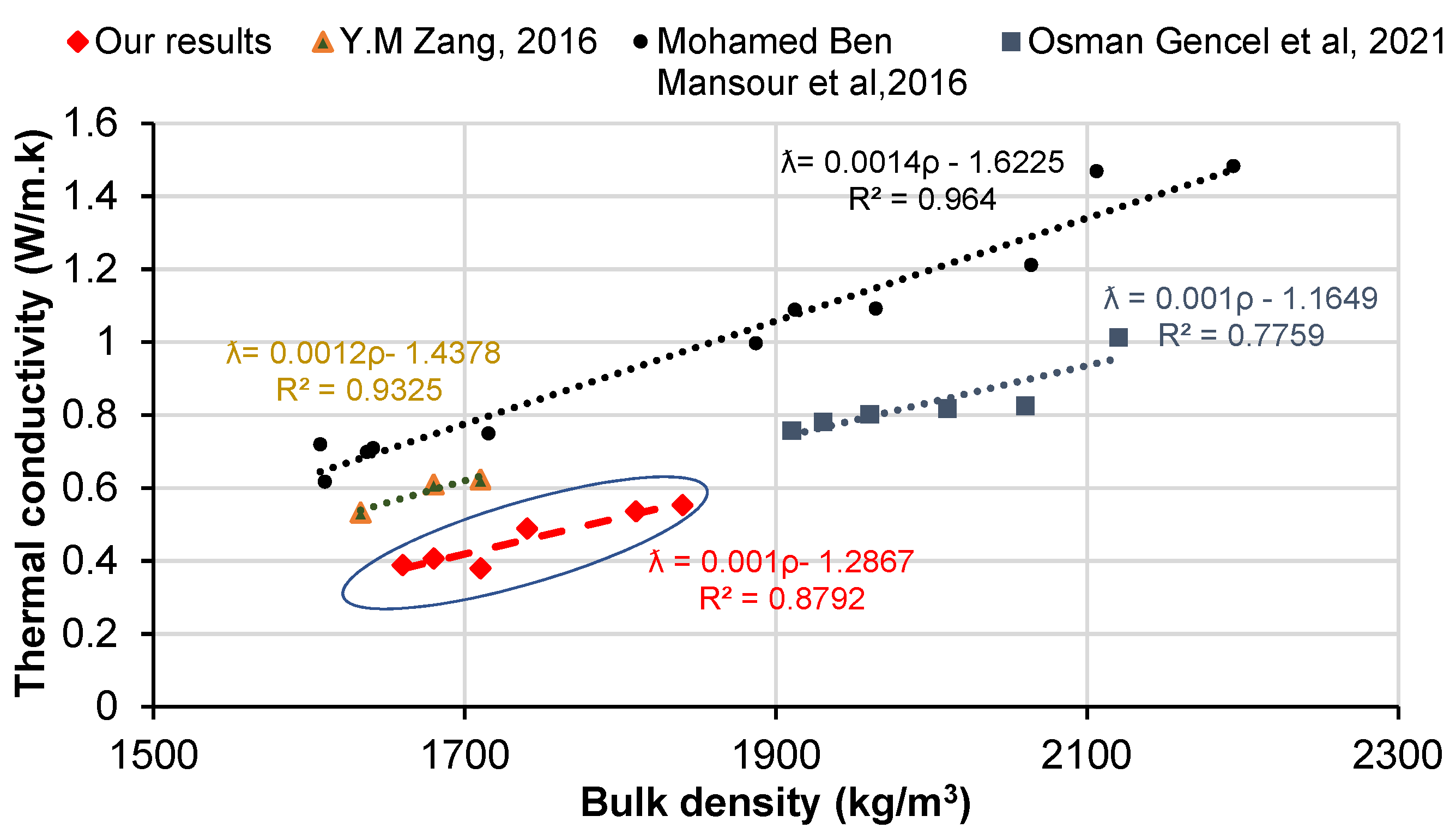

3.4. Thermal Properties

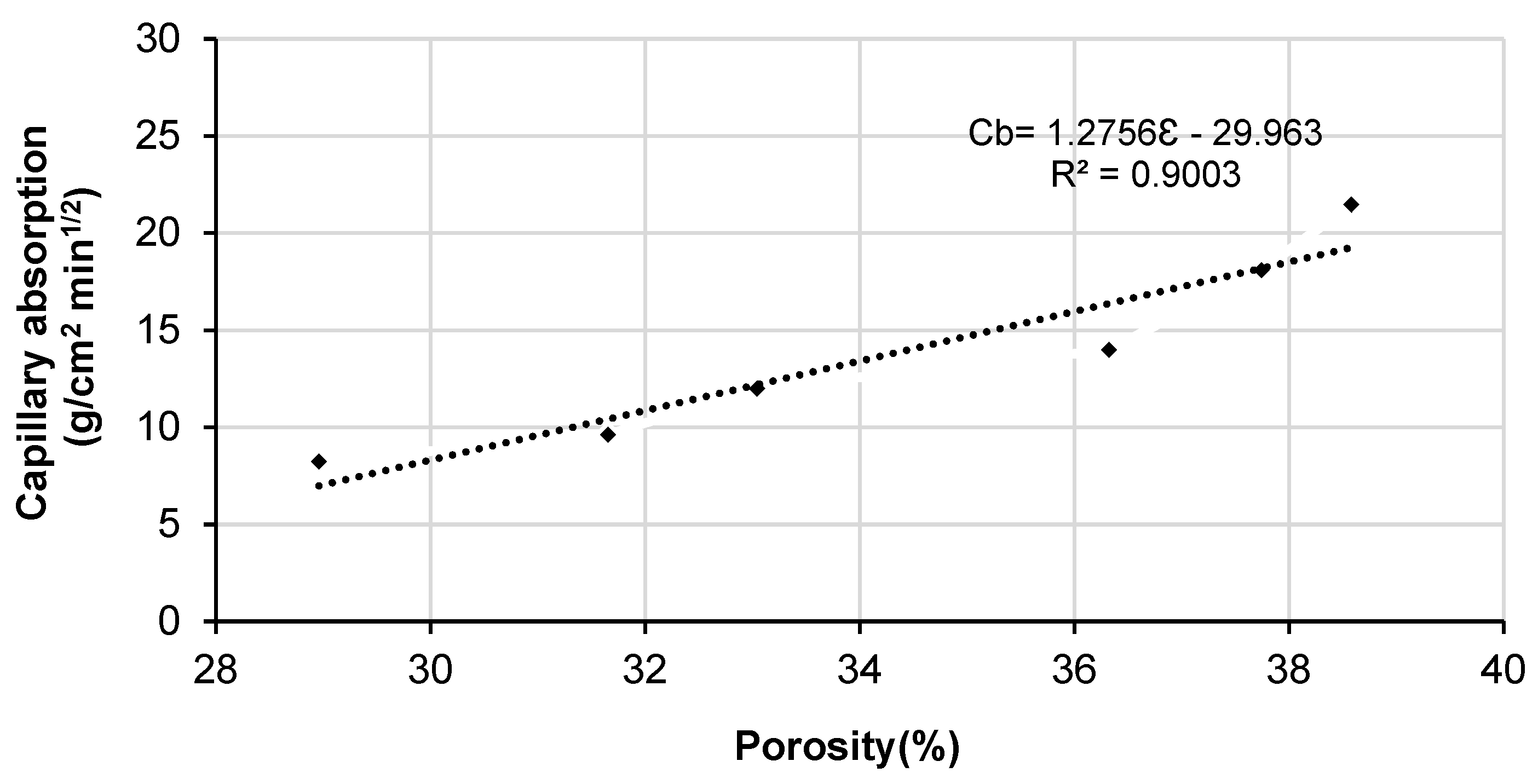

3.5. Water Capillary Absorption

4. Conclusions

- The most important factor affecting the mechanical properties was the porosity, since the microstructure of the blocks is modified by the addition of fly ash, as shown in the SEM analysis. The stabilized CEBs showed high mechanical performance which increased significantly with the fly ash content, although the performance evaluation of these CEBs under unfavorable conditions (wet compressive strength) showed a decrease in compressive strengths of about 50% compared to dry compressive strengths. In addition, all blocks meet the current criteria, which require a minimum compressive strength of 2 MPa.

- The thermal conductivities of the blocks were low, ranging from 0.38 to 0.58 W/m·K. All the blocks fall within the previously documented thermal conductivity range of compressed earth blocks. These CEBs have a good thermal inertia capable to ensure the comfort of the occupants.

- The stabilized blocks with less than 10% fly ash in this study met the criteria indicated in the standards for low-capillary blocks and were perfectly suitable for severe climatic conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Junakova, N.; Junak, J. Sustainable Use of Reservoir Sediment through Partial Application in Building Material. Sustainability 2017, 9, 852. [Google Scholar] [CrossRef] [Green Version]

- Amar, M.; Benzerzour, M.; Safhi, A.E.M.; Abriak, N.-E. Durability of a cementitious matrix based on treated sediments. Case Stud. Constr. Mater. 2018, 8, 258–276. [Google Scholar] [CrossRef]

- Marmin, S.; Dauvin, J.-C.; Lesueur, P. Collaborative approach for the management of harbour-dredged sediment in the Bay of Seine (France). Ocean. Coast. Manag. 2014, 102, 328–339. [Google Scholar] [CrossRef]

- Hadj Sadok, R.; Maherzi, W.; Benzerzour, M.; Lord, R.; Torrance, K.; Zambon, A.; Abriak, N.-E. Mechanical Properties and Microstructure of Low Carbon Binders Manufactured from Calcined Canal Sediments and Ground Granulated Blast Furnace Slag (GGBS). Sustainability 2021, 13, 9057. [Google Scholar] [CrossRef]

- Couvidat, J.; Benzaazoua, M.; Chatain, V.; Bouzahzah, H. Environmental evaluation of dredged sediment submitted to a solidification stabilization process using hydraulic binders. Environ. Sci. Pollut. Res. 2016, 23, 17142–17157. [Google Scholar] [CrossRef] [PubMed]

- Akcil, A.; Erust, C.; Ozdemiroglu, S.; Fonti, V.; Beolchini, F. A review of approaches and techniques used in aquatic contaminated sediments: Metal removal and stabilization by chemical and biotechnological processes. J. Clean. Prod. 2015, 86, 24–36. [Google Scholar] [CrossRef]

- Lirer, S.; Liguori, B.; Capasso, I.; Flora, A.; Caputo, D. Mechanical and chemical properties of composite materials made of dredged sediments in a fly-ash based geopolymer. J. Environ. Manag. 2017, 191, 1–7. [Google Scholar] [CrossRef]

- Bianchi, V.; Masciandaro, G.; Ceccanti, B.; Doni, S.; Iannelli, R. Phytoremediation and Bio-physical Conditioning of Dredged Marine Sediments for Their Re-use in the Environment. Water Air Soil Pollut. 2010, 210, 187–195. [Google Scholar] [CrossRef]

- Caplat, C.; Texier, H.; Barillier, D.; Lelievre, C. Heavy metals mobility in harbour contaminated sediments: The case of Port-en-Bessin. Mar. Pollut. Bull. 2005, 50, 504–511. [Google Scholar] [CrossRef]

- Casado-Martínez, M.C.; Buceta, J.L.; Belzunce, M.J.; DelValls, T.A. Using sediment quality guidelines for dredged material management in commercial ports from Spain. Environ. Int. 2006, 32, 388–396. [Google Scholar] [CrossRef]

- Dalton, J.L.; Gardner, K.H.; Seager, T.P.; Weimer, M.L.; Spear, J.C.M.; Magee, B.J. Properties of Portland cement made from contaminated sediments. Resour. Conserv. Recycl. 2004, 41, 227–241. [Google Scholar] [CrossRef]

- Aouad, G.; Laboudigue, A.; Gineys, N.; Abriak, N.E. Dredged sediments used as novel supply of raw material to produce Portland cement clinker. Cem. Concr. Compos. 2012, 34, 788–793. [Google Scholar] [CrossRef]

- Bouchikhi, A.; Maherzi, W.; Benzerzour, M.; Mamindy-Pajany, Y.; Peys, A.; Abriak, N.-E. Manufacturing of Low-Carbon Binders Using Waste Glass and Dredged Sediments: Formulation and Performance Assessment at Laboratory Scale. Sustainability 2021, 13, 4960. [Google Scholar] [CrossRef]

- Liu, M. Effects of sintering temperature on the characteristics of lightweight aggregate made from sewage sludge and river sediment. J. Alloys Compd. 2018, 6, 522–527. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, C.; Xu, B.; Ruan, X.; Wei, Z. The use of urban river sediments as a primary raw material in the production of highly insulating brick. Ceram. Int. 2014, 40, 8833–8840. [Google Scholar] [CrossRef]

- Hamer, K.; Karius, V. Brick production with dredged harbour sediments. An industrial-scale experiment. Waste Manag. 2002, 22, 521–530. [Google Scholar] [CrossRef]

- Samara, M.; Lafhaj, Z.; Chapiseau, C. Valorization of stabilized river sediments in fired clay bricks: Factory scale experiment. J. Hazard. Mater. 2009, 163, 701–710. [Google Scholar] [CrossRef]

- Serbah, B.; Abou-Bekr, N.; Bouchemella, S.; Eid, J.; Taibi, S. Dredged sediments valorisation in compressed earth blocks: Suction and water content effect on their mechanical properties. Constr. Build. Mater. 2018, 158, 503–515. [Google Scholar] [CrossRef]

- Larbi, S.; Khaldi, A.; Maherzi, W.; Abriak, N.-E. Formulation of Compressed Earth Blocks Stabilized by Glass Waste Activated with NaOH Solution. Sustainability 2021, 14, 102. [Google Scholar] [CrossRef]

- Achour, R.; Abriak, N.-E.; Zentar, R.; Rivard, P.; Gregoire, P. Valorization of unauthorized sea disposal dredged sediments as a road foundation material. Environ. Technol. 2014, 35, 1997–2007. [Google Scholar] [CrossRef]

- Serlet, M. Blocs de Terre Comprimée. In Manuel de Conception et de Construction; CRAterre: Villefontaine, France, 1995; Volume II, Available online: https://craterre.hypotheses.org/281 (accessed on 14 November 2021).

- XP P13-901: Compressed Earth Blocks for Walls and Partitions: Definitions—Specifications—Test Methods—Delivery Acceptance Conditions 2001. Available online: https://www.boutique.afnor.org/fr-fr/norme/xp-p13901/blocs-de-terre-comprimee-pourmurs-et-cloisons-definitions-specifications-m/fa120503/487 (accessed on 14 November 2021).

- Houben, H.; Guillaud, H. Notice “Earth Construction. A Comprehensive Guide”; Intermediate Technology Development Group Publications: London, UK, 1994; Volume 13. [Google Scholar]

- Jiménez Delgado, M.C.; Guerrero, I.C. The selection of soils for unstabilised earth building: A normative review. Constr. Build. Mater. 2007, 21, 237–251. [Google Scholar] [CrossRef]

- Muntohar, A.S. Engineering characteristics of the compressed-stabilized earth brick. Constr. Build. Mater. 2011, 25, 4215–4220. [Google Scholar] [CrossRef]

- Yu, H.; Zheng, L.; Yang, J.; Yang, L. Stabilised compressed earth bricks made with coastal solonchak. Constr. Build. Mater. 2015, 77, 409–418. [Google Scholar] [CrossRef]

- Omar Sore, S.; Messan, A.; Prud’homme, E.; Escadeillas, G.; Tsobnang, F. Stabilization of compressed earth blocks (CEBs) by geopolymer binder based on local materials from Burkina Faso. Constr. Build. Mater. 2018, 165, 333–345. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef] [Green Version]

- Rivera, J.; Coelho, J.; Silva, R.; Miranda, T.; Castro, F.; Cristelo, N. Compressed earth blocks stabilized with glass waste and fly ash activated with a recycled alkaline cleaning solution. J. Clean. Prod. 2021, 284, 124783. [Google Scholar] [CrossRef]

- Davidovits, J. Properties of geopolymer cements. In First International Conference on Alkaline Cements and Concretes; Kiev State Technical University Kiev: Kiev, Ukraine, 1994; p. 19. Available online: https://www.geopolymer.org/wp-content/uploads/KIEV.pdf (accessed on 14 November 2021).

- Arrêté du 12 Décembre 2014 Relatif aux Conditions d’Admission des Déchets Inertes dans les Installations Relevant des Rubriques et dans les Installations de Stockage de Déchets Inertes Relevant de la Rubrique 2760 de la Nomenclature des Installations Classées—Légifrance. Available online: https://www.legifrance.gouv.fr/loda/id/JORFTEXT000029893828/ (accessed on 14 November 2021).

- EN 450-1; Fly Ash Definition, Specifications and Conformity Criteria. European Committee for Standardization: Brussels, Belgium, 2012.

- Rifaai, Y.; Yahia, A.; Mostafa, A.; Aggoun, S.; Kadri, E.-H. Rheology of fly ash-based geopolymer: Effect of NaOH concentration. Constr. Build. Mater. 2019, 223, 583–594. [Google Scholar] [CrossRef]

- Namango, S.S. Development of Cost-Effective Earthen Building Material for Housing Wall Construction: Investigations into the Properties of Compressed Earth Blocks Stabilized with Sisal Vegetable Fibres, Cassava Powder and Cement Compositions. Ph.D. Thesis, Faculty of Environmental Science and Process Engineering of the Brandenburg Technical University Cottbus, Cottbus, Germany, 2006. [Google Scholar]

- NF P 94-093. Détermination des références de Compactage d’un Matériau—Proctor Normal et Proctor Modifié. 1999. Available online: https://pdfslide.net/documents/nf-p-94-093-proctor-99.html (accessed on 2 September 2021).

- Preethi, R.K.; Venkatarama Reddy, B.V. Experimental investigations on geopolymer stabilised compressed earth products. Constr. Build. Mater. 2020, 257, 119563. [Google Scholar] [CrossRef]

- NF-EN 1936. Méthodes d’Essai des Pierres Naturelles—Détermination des Masses Volumiques Réelle et Apparente et des Porosités Ouvertes et Totale. Available online: https://www.boutique.afnor.org/fr-fr/norme/nf-en-1936/methodes-dessai-pour-pierres-naturelles-determination-des-masses-volumiques/fa041094/49522 (accessed on 13 November 2021).

- Jaditager, M. Sedimentation and Consolidation Behaviour of Fly Ash-Based Geopolymer Stabilised Dredged Mud. Ph.D. Thesis, James Cook University, Douglas, Australia, 2018. [Google Scholar] [CrossRef]

- Adam, A.A.; Horianto, X.X.X. The Effect of Temperature and Duration of Curing on the Strength of Fly Ash Based Geopolymer Mortar. Procedia Eng. 2014, 95, 410–414. [Google Scholar] [CrossRef] [Green Version]

- Firdous, R.; Stephan, D.; Djobo, J.N.Y. Natural pozzolan based geopolymers: A review on mechanical, microstructural and durability characteristics. Constr. Build. Mater. 2018, 190, 1251–1263. [Google Scholar] [CrossRef]

- Touré, P.M.; Sambou, V.; Faye, M.; Thiam, A.; Adj, M.; Azilinon, D. Mechanical and hygrothermal properties of compressed stabilized earth bricks (CSEB). J. Build. Eng. 2017, 13, 266–271. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Jia, L.T.; Mei, H.; Cui, Q.; Zhang, P.G.; Sun, Z.M. Fabrication, microstructure and properties of bricks fired from lake sediment, cinder and sewage sludge. Constr. Build. Mater. 2016, 121, 154–160. [Google Scholar] [CrossRef]

- Yoobanpot, N.; Jamsawang, P.; Poorahong, H.; Jongpradist, P.; Likitlersuang, S. Multiscale laboratory investigation of the mechanical and microstructural properties of dredged sediments stabilized with cement and fly ash. Eng. Geol. 2020, 267, 105491. [Google Scholar] [CrossRef]

- Islam, M.S.; Elahi, T.E.; Shahriar, A.R.; Mumtaz, N. Effectiveness of fly ash and cement for compressed stabilized earth block construction. Constr. Build. Mater. 2020, 255, 119392. [Google Scholar] [CrossRef]

- Saidi, M.; Cherif, A.S.; Zeghmati, B.; Sediki, E. Stabilization effects on the thermal conductivity and sorption behavior of earth bricks. Constr. Build. Mater. 2018, 167, 566–577. [Google Scholar] [CrossRef]

- Meukam, P.; Noumowe, A.; Jannot, Y.; Duval, R. Caractérisation thermophysique et mécanique de briques de terre stabilisées en vue de l’isolation thermique de bâtiment. Mat. Struct. 2003, 36, 453–460. [Google Scholar] [CrossRef]

- Mansour, M.B.; Jelidi, A.; Cherif, A.S.; Jabrallah, S.B. Optimizing thermal and mechanical performance of compressed earth blocks (CEB). Constr. Build. Mater. 2016, 104, 44–51. [Google Scholar] [CrossRef]

- Gencel, O.; Kazmi, S.M.S.; Munir, M.J.; Sutcu, M.; Erdogmus, E.; Yaras, A. Feasibility of using clay-free bricks manufactured from water treatment sludge, glass, and marble wastes: An exploratory study. Constr. Build. Mater. 2021, 298, 123843. [Google Scholar] [CrossRef]

- Gueffaf, N.; Rabehi, B.; Boumchedda, K. Recycling Dam Sediments for the Elaboration of Stabilized Blocks. Int. J. Eng. Res. Afr. 2020, 50, 131–144. [Google Scholar] [CrossRef]

- Réglementation Environnementale RE2020. Available online: https://www.ecologie.gouv.fr/reglementation-environnementale-re2020 (accessed on 17 November 2021).

- Réglementation Thermique RT2012. Available online: https://www.ecologie.gouv.fr/reglementation-thermique-rt2012 (accessed on 17 November 2021).

- Mimboe, A.G.; Abo, M.T.; Djobo, J.N.Y.; Tome, S.; Kaze, R.C.; Deutou, J.G.N. Lateritic soil based-compressed earth bricks stabilized with phosphate binder. J. Build. Eng. 2020, 31, 101465. [Google Scholar] [CrossRef]

| Characterization | Sediment | Standard Used |

|---|---|---|

| Clay (<2 µm) | 1.80 | |

| Silt (2–63 µm) | 30.57 | NF ISO 13320-1 |

| Sand (>63 µm) | 67.41 | |

| Liquid limit Wl (%) | 63.54 | |

| Plastic limit Wp (%) | 49.13 | NF P94-051 |

| Plasticity index Ip (%) | 14.41 | |

| Methylene blue value (VBS) | 1.3 g/100 g | NF P94-068 |

| Density Gs (g/cm3) | 2.39 | NF EN 1097-7 |

| LOI (450 °C) (%) | 13.82 | XP P94-047 |

| Water content (%) | 22.34 | NF P94-050 |

| Oxide Content (%) | Sediment |

|---|---|

| SiO2 | 51.9 |

| Al2O3 | 11.1 |

| CaO | 13.3 |

| Fe2O3 | 4.7 |

| Na2O | 0.6 |

| K2O | 3.8 |

| MgO | 1.6 |

| TiO2 | 0.5 |

| Characterization | Fly Ash |

|---|---|

| Specific Gravity g/cm2 | 2300–5000 |

| Major minerals | Quartz (SiO2) |

| Maghemite (Υ-Fe2O3) | |

| Mullite (Al6O13Si2) | |

| SiO2 (50%) + Al2O3 (20%) + Fe2O3 (8%) | 78% |

| Materials | CEB0FA | CEB10FA | CEB20FA | CEB30FA | CEB40FA | CEB50FA |

|---|---|---|---|---|---|---|

| Sediment (%) | 100 | 90 | 80 | 70 | 60 | 50 |

| Fly ash (%) | 0 | 10 | 20 | 30 | 40 | 50 |

| Water */dry material (%) | 0.1409 | 0.1855 | 0.2187 | 0.1993 | 0.207 | 0.1884 |

| NaOH concentration (Mol/L) | 8 | 8 | 8 | 8 | 8 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brahim, M.; Ndiaye, K.; Aggoun, S.; Maherzi, W. Valorization of Dredged Sediments in Manufacturing Compressed Earth Blocks Stabilized by Alkali-Activated Fly Ash Binder. Buildings 2022, 12, 419. https://doi.org/10.3390/buildings12040419

Brahim M, Ndiaye K, Aggoun S, Maherzi W. Valorization of Dredged Sediments in Manufacturing Compressed Earth Blocks Stabilized by Alkali-Activated Fly Ash Binder. Buildings. 2022; 12(4):419. https://doi.org/10.3390/buildings12040419

Chicago/Turabian StyleBrahim, Mohamedou, Khadim Ndiaye, Salima Aggoun, and Walid Maherzi. 2022. "Valorization of Dredged Sediments in Manufacturing Compressed Earth Blocks Stabilized by Alkali-Activated Fly Ash Binder" Buildings 12, no. 4: 419. https://doi.org/10.3390/buildings12040419

APA StyleBrahim, M., Ndiaye, K., Aggoun, S., & Maherzi, W. (2022). Valorization of Dredged Sediments in Manufacturing Compressed Earth Blocks Stabilized by Alkali-Activated Fly Ash Binder. Buildings, 12(4), 419. https://doi.org/10.3390/buildings12040419