1. Introduction

A truss is a two or three-dimensional structure that is composed of linear members connected at nodes to sustain loads [

1]. Truss layout design aims to find the optimal structural layout considering node locations, connection topology between nodes, and cross-sectional areas of bars [

2]. When considering all three aspects simultaneously, numerous design variables and truss layouts are possible. This makes the design of truss layouts challenging. The design process is often represented as a black-box combinational optimization problem, which meets certain criteria, including the material strength, the displacement allowance, the stability of structural members, and other specifications according to different design codes [

3]. These constraints are often related to structural performance and require the calculation and analysis of the structural stiffness matrix, which may lead to optimization problems such as non-convexity and non-differentiability [

4]. Under such circumstances, how high-level skills can be employed in the automatic design process of complex layout tasks has become a hot and challenging research topic in structural optimization in recent decades [

4,

5,

6]. Many previous studies adopted heuristic search methods to find an approximate global optimal solution, such as a genetic algorithm [

7,

8,

9,

10,

11], simulated annealing algorithm [

12,

13], harmony search algorithm [

14], particle swarm optimizer [

15,

16], and so on. However, most metaheuristic algorithms in truss layout problems do not estimate objective functions and apply multiple static searching policies [

17], which results in user intervention for appropriate parameter settings.

Reinforcement Learning [

17] (RL) is one major kind of machine learning method that deals with the problems interacting between the agent and the environment. An RL algorithm aims to train an agent learning dynamic policies from exploring the environment to maximize the cumulative reward [

17]. The training of an agent can be regarded as a trial-and-error process, and the agent gradually learns how to behave better based on the rewards it receives. Monte Carlo Tree Search (MCTS) [

18] is a well-known search method to solve RL problems, especially when the reward is received after the final step, which has shown exceptional performance in board games and video games [

19]. Alongside AlphaGo [

20] and its successors [

21,

22] in 2016, MCTS-based agents made history by being the first program to beat a professional Go player. It is a landmark event in artificial intelligence that a machine can surpass the vast majority of people in such complex intellectual activity, in which the size of the solution space in Go is as high as 3

361. The success of MCTS in board games has encouraged researchers to apply it in other scientific fields. Therefore, MCTS has been successfully implemented in video-games [

23,

24], protein folding problems [

25], materials design and discovery [

26,

27], mixed-integer planning [

28,

29], and artificial general intelligence for games [

30]. However, there exists still only a small number of engineering applications related to MCTS [

31,

32]. To the best of the authors’ knowledge, no such research has yet applied MCTS in truss layout design problems.

The truss layout design problem is similar to the decision problem of computer Go [

19]. On the one hand, the truss layout (the board) is composed of the nodes and edges of the truss (the locations of the Go pieces), and each decision affects the final result in both problems. On the other hand, the final result evaluation can be obtained only after all decisions are made, such as structural weight and winning or losing the game Go. MCTS is a classical approach to solving a Markov Decision Process (MDP) [

33] with the evaluation performed at the end of MDP. Therefore, the truss layout design problem may benefit from MCTS by splitting the design process into an MDP, which can provide an environment to give feedback to the current layout.

The main components of an MDP are state, action, transition function, and reward. For the design process of a truss structure, the state refers to the description of the current truss layout. The action contains three sequential types, that is, adding nodes, adding bars, and selecting cross-sectional areas of the bars. For each state, a set of sequential actions are used to describe an available process to reach this state. After taking an action based on the current state, the transition function indicates the probability distribution of the next state. The reward means the evaluation of the action. Based on such an MDP, the truss layouts can be generated by a sequence of actions, which is a basic and simple strategy to expand the solution space and make it more possible to search for innovative solutions. For the truss design process, it is difficult to calculate the reward of an intermediate state if the truss structure is geometrically unstable. Only the layout of a truss structure is determined through a sequence of actions in the terminal state. A reward is then assigned to the generated truss layout, which implies that the reward is always received until the terminal state is reached.

This paper presents an algorithm named AlphaTruss, a novel two-stage reinforcement learning algorithm for optimal truss layout design, which is trained in the MDP environment to give the optimal decision in the design process. AlphaTruss solves the MDP of the truss layout design, finding the optimal sequence of actions by using MCTS with modified upper confidence bound without complex parameter tuning. During the first stage, the design task is modeled as a sequence generation problem in discrete action space to have an approximate optimal layout. In the second stage, AlphaTruss can refine the layout obtained from Stage 1 to get a better solution, where the action only corresponds to node locations and cross-sectional areas of bars, without changing the topology of the truss.

In the following part,

Section 2 provides a theoretical background for the methodology on how AlphaTruss algorithm applies MCTS to solve the MDP in the layout design of a truss structure.

Section 3 describes four examples of structural layout design considering the material strength, the displacement allowance, the stability of structural members and showing the high performance in comparison with the existing results from the literature. Two analyses and discussions of the MCTS algorithm are presented in

Section 4.

Section 5 gives several conclusions.

2. Problem and Methodology

2.1. Problem Statement

The truss layout design can be regarded as a black-box problem of combinational optimization, which aims to find the optimal layout by considering node locations, connection topology between nodes, and cross-sectional areas of the bars. A truss layout can be characterized by a set of nodes and bars, denoted as a tuple

, where

represents the set of nodes,

represents the set of bars and

Ω is the design domain. Each node

is a point in Euclidean space (

), and each bar

is defined as a tuple

, where

,

is the cross-sectional area of the bar and

is the material density. The design objective is to minimize the total weight of the truss generated under various constraints. This design problem can be formally expressed in Equation (1):

subject to:

The constraint

represents the constraint in the cross-sectional area, which implies that the cross-sectional area

should fall within the area interval

The constraint

denotes the strength constraint, where

represents the Mises stress of the bar, and

and

are the maximum allowed compression and tension stresses of the materials. The constraint

represents the Euler buckling constraint, where

is the set of all bars in compression.

is calculated using Euler’s critical load

given in Equations (2) and (3), where

is the moment of inertia of the section and

represents the length coefficient. For simplicity, the section of all bars is assumed as solid circles, and the length coefficient

is 1.0 assuming a pin connection. The constraint

denotes the stiffness constraint, where

is the maximum displacement in all directions of the

th node. This constraint implies that the displacements at all nodes should not exceed

in all directions.

The last constraint

implies that any two bars should not intersect with each other. If two bars share one common point at their end, it should not be considered as an intersection. A major omission in the traditional optimization model based on the ground structure method [

34] is that the intersection of coplanar bars is allowed. This means that two coplanar solid bars can pass through each other without generating a new node and with no structural effect. However, such intersection of the bars is unusual. Therefore, it is reasonable to avoid such intersection of the bars and consider it as a constraint during the adding-bar steps.

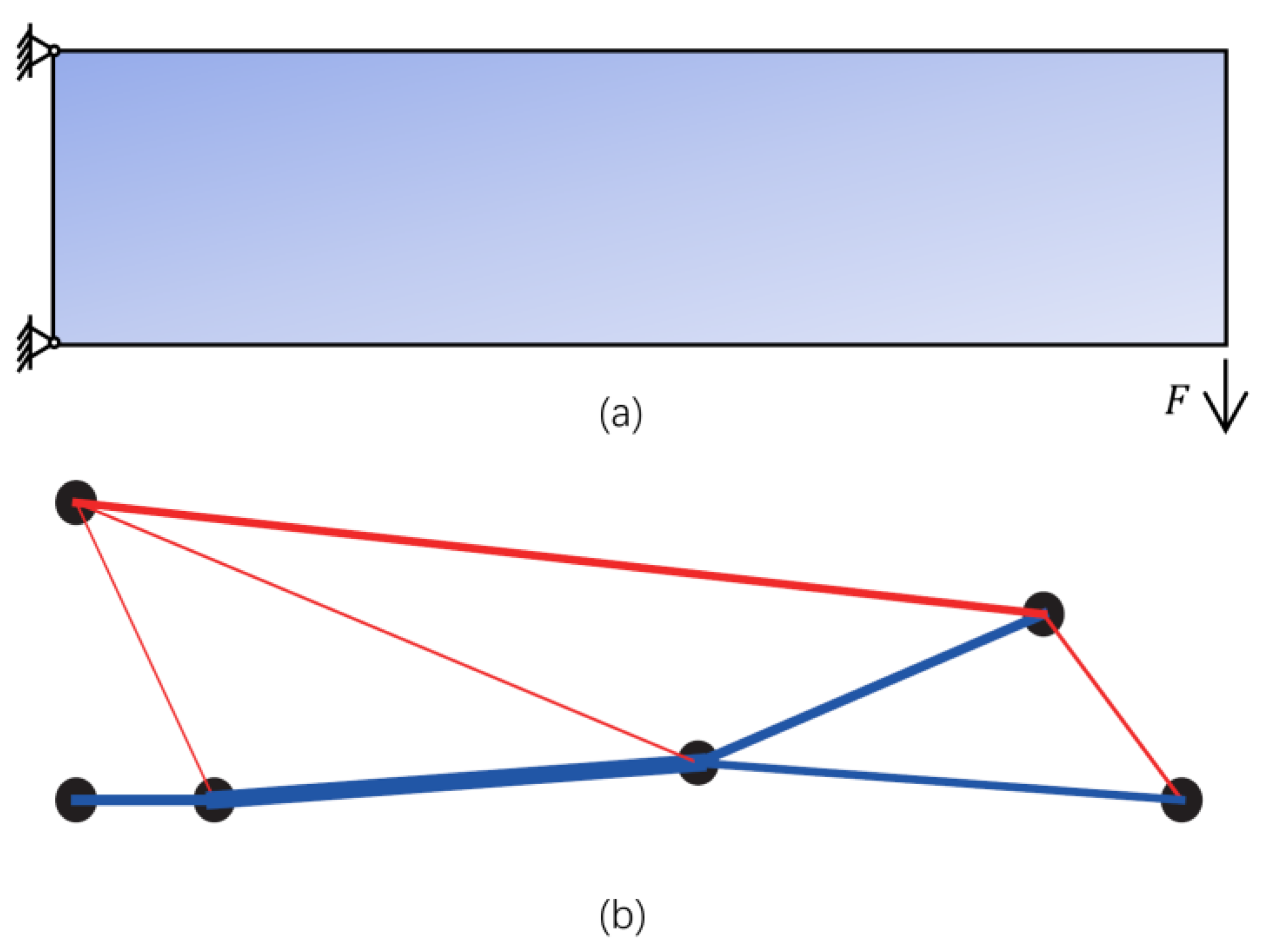

For a specific truss design task, the initial design information and basic design settings are clarified at first. The initial design information includes the positions of the supports, loads, and other fixed nodes defined by users. The basic design settings consist of material data, design domain, and other information required in the design process since the design is constrained by many design metrics. For example,

Figure 1 shows a typical truss layout design case for generating a cantilever truss, given the initial design information, such as material properties, load and support conditions (

Figure 1a). The task is to find the lightest truss taking stress, displacement, and buckling constraints into account.

Figure 1b illustrates a layout solution that will be used in the experiment part (

Section 3.1).

2.2. Monte Carlo Tree Search in AlphaTruss

Monte Carlo Tree Search (MCTS) is an iterative, guided, random best-first tree search method that systemically searches a space of candidates to obtain an optimal solution in decision-making problems. Given an MDP

, where

is the set of state

,

is the set of action

,

is a transition function, and

is the reward function for a terminal state. MCTS aims to find an optimal action

for a given initial state

in the MDP model.

Figure 2 explains in detail how MCTS is introduced to solve an MDP model with the reward obtained in the final state.

The MCTS method begins with a search tree having only an initial root node built from the given state

. Subsequently, an iterative analysis is performed, expanding the search tree until the search time is terminated. Each iteration consists of four steps [

18]: selection, expansion, simulation, and backpropagation.

Selection: First, starting with , the algorithm continuously selects actions a according to a strategy of the action selection and transfers them to new states by function until reaching a new state , which does not yet exist in the search tree.

Expansion: The algorithm subsequently expands in the search tree base on the selection strategy in selection.

Simulation: To simulate , the algorithm follows the Monte Carlo method by randomly taking actions through the function until arriving at a terminal state and receiving a reward from .

Backpropagation: Finally, is used to update information from the new leaf back to the root.

The most common selection strategy for MCTS is the upper confidence bounds [

18]. This strategy is applied by using the Chernoff–Hoeffding bounds calculated by Equation (4):

where

is the average reward from action

and

is the number of actions

that have been applied.

implies the total number of simulations so far. The reward term

is used to encourage the exploitation of actions with higher reward, while the term

is employed to encourage the exploration of actions that are less-visited.

is a heuristic parameter that is empirically set. Usually,

is set as a positive constant, keeping

when

initially. This is a standard technique for the application of MCTS [

19]. In this study, the value of parameter

is fine-tuned in order to adjust the search width according to different experimental environments.

The MCTS method with the upper confidence bounds is generally called Upper Confidence bounds applied to Trees (UCT). To apply a UCT search to the truss layout design problem, the key step is to formulate the problem to an MDP (

Figure 2a). In the MDP of truss layout design, a state

represents the current structural layout and could be denoted by a tuple

, where

and

are the node and bar set of the structure. A structural layout and a tuple

can be mapped to each other. Three different types of actions exist in the action set, i.e., adding a node, adding a bar, and selecting a cross-sectional area (

Figure 2b). After taking an action, either set

or set

would change depending on the consequence of the undertaken action. Accordingly, the transition function is defined as the variation of the tuple

. The reward is the most important part of MCTS, which guides the AlphaTruss algorithm in the right searching direction towards a better solution. In this paper, the reward function is designed to evaluate the action by AlphaTruss, which is based on the theory of structural geometric stability and the results from the structural simulator of Opensees [

35]. The details in the reward function are given in the pseudo-code Algorithm 1.

First, whether the structure

forms a geometric stable structure or not is to be checked. The function

IsStructure is used to conduct this checking task in two steps: evaluation of the Maxwell criterion [

36] to calculate the degrees of freedom of

, and evaluation of the positive definiteness of the stiffness matrix [

37] of the structure

if the degree of freedom is not larger than 0. If the structure

is not geometrically stable defined by the function

IsStructure, a negative reward of -1 is assigned as a punishment. Otherwise, the function goes through all constraints and checks if the structure

satisfies them. If this is not the case, the function receives only a reward of 0. If the structure

passes through all the constraints, the function receives a positive reward. Furthermore, the better the objective, the higher reward. Note that the geometric stability is ensured by the

IsStructure function. Therefore, it is not included in the constraints part of Equation (1). To check the above-mentioned constraints, the Python package OpenSeesPy [

38] is used to conduct all the structural performance calculations, including the constraints

and

. It is assumed that all truss bars are straight, not curved, and all truss nodes are perfectly hinged.

| Algorithm 1 Reward Function for Evaluation |

| | Input: Node Set , Bar Set

Output: Reward of Structure |

| 1: | Function//return current action set |

| 2: | If then |

| 3: | For every constraint do |

| 4: | If does not pass then |

| 5: | Return 0 |

| 6: | End For |

| 7: | objective of |

| 8: | Return |

| 9: | Return -1 |

| 10: | |

| 11: | Function//check the geometry stability |

| 12: | dimension of |

| 13: | restricted number of degrees of freedom at support nodes of |

| 14: | |

| 15: | If then |

| 16: | stiffness matrix of |

| 17: | If then |

| 18: | Return True |

| 19: | Return False |

In pseudo-code, represents the reward function. For this minimum weight truss design problem, the reward function is defined as , where is a positive constant to keep the positive rewards matching the negative reward in the same order of magnitude. Based on this MCTS mechanism, the AlphaTruss algorithm adopts a two-stage strategy to find the optimal truss layout, which is introduced in the following two sections.

2.3. Stage I in AlphaTruss for Form-Finding

Stage I in AlphaTruss aims to find an action sequence to form an optimal layout, which will be refined in stage II. In stage I, the design domain of the node locations and cross-sectional areas of the bars are uniformly discretized. The main process of Stage I in AlphaTruss is explained through the pseudo-code Algorithm 2.

| Algorithm 2 AlphaTruss Stage I |

| | Input: Node Set , Bar Set , Allowed Area Interval , Number of Nodes , Design Domain

Output: Generated Node Set , Generated Bar Set |

| 1: | discretized |

| 2: | all allowed bars |

| 3: | discretized |

| 4: | Whiledo |

| 5: | |

| 6: | //modify by taking action |

| 7: | End While |

| 8: | |

| 9: | Return |

| 10: | |

| 11: | Function//return current action set |

| 12: | If then |

| 13: | Return |

| 14: | If then |

| 15: | Return

|

| 16: | index of the first unmodified bar |

| 17: | If exists then |

| 18: | Return

|

| 19: | Return |

| 20: | |

| 21: | Function//find an optimal action for |

| 22: | While there is time left do |

| 23: |

|

| 24: | While is in search tree and do |

| 25: |

|

| 26: |

|

| 27: | |

| 28: | End While |

| 29: | If is not in search tree, then |

| 30: |

|

| 31: | |

| 32: | While do |

| 33: | |

| 34: | End While |

| 35: |

|

| 36: | While do |

| 37: | Use to update of |

| 38: |

|

| 39: | End While |

| 40: | End While |

| 41: | Return |

In stage I, the AlphaTruss algorithm discretizes at first uniformly the design domain (line 1) and the range of the cross-sectional area (line 3) by choosing a certain number of samples from the continuous space.

The available actions vary in different states. The actions are determined by the function ActionSet, which returns an available action set for the current state following the three-step process of truss generation. The first step is to add new structural nodes in the discretized design domain (line 13). The candidate nodes are chosen from the discretized node set. If a sufficient number of nodes have been already added to the node set (line 12), i.e., the number of nodes is equal to , the process moves to the second step, that is, adding bars between the nodes (line 15). The adding-bar step ends when a positive reward is received (line 14), i.e., the structure passes all the constraints. To achieve this condition efficiently, the cross-sectional areas of newly added bars are set to the maximum allowed value for more easily fulfilling constraints. The final step is to select the area of each bar according to the adding order of bars (lines 16–18). The area is chosen from the set of the discretized cross-sectional areas. Upon completion, the function ActionSet returns an empty set (line 19), which also indicates that the current state is a terminal one.

After clarifying the action-taking process, the main algorithm (lines 4–7) calls the function UCTSearch to find the optimal action for the current state . This state is updated to a new state by applying the optimal action. Then UCTSearch is repeatedly conducted until the terminal state is reached.

The function

UCTSearch constitutes the main part of the AlphaTruss in stage I, which follows the four-step repetition described in

Figure 2 (

Section 2.2). In each iteration, the

UCTSearch function selects initially the path to a new leaf node (line 24) using the upper confidence bound formula (line 26). Usually, the evaluation of an action

is conducted using the average reward [

18]. Since the positive reward is rather sparse and the aim is to find the optimal layout, Equation (5) is used here to estimate

by increasing the proportion of the best solution in the evaluation of

, which combines the average (

and best (

rewards using a parameter

. In this study, this parameter is fine-tuned to 0.4. Thus, the final upper confidence bounds used in AlphaTruss can be represented as Equation (6).

Subsequently, the algorithm expands the search tree (line 30) and conducts a simulation using the Monte Carlo method (lines 32–34). The pseudo-code in line 33 represents randomly selected samples from . At the end of an iteration, the algorithm uses the received reward (line 35) to update the information from the new leaf to the root (lines 34–37) by maintaining , , . Finally, the UCTSearch function uses to estimate each candidate action, and it returns the action with the largest .

It is known that MCTS is able to give a better MDP decision through more searching time. However, the efficiency of AlphaTruss is also an important issue. Instead of setting the running time for function

UCTSearch, the loops are run in AlphaTruss for a certain number of iterations, which is determined by Equation (7):

The variable is the number of actions taken. Starting from , is increased by after every call of the function UCTSearch. For the experiments in this study, the maximum number of iterations in stage I does not exceed and these experiments share the same iteration function in stage I as shown in Equation (7).

2.4. Stage II in AlphaTruss for Refinement

When generating a free-form truss layout, the locations of the nodes and the cross-sectional area of the bars are generally continuous. Stage I in AlphaTruss manages these continuous variables by uniformly discretizing these variables. However, this discretization policy restricts the continuous variables from finding a better solution, and the layout obtained in stage I loses its accuracy to a certain degree. To loosen this restriction, Stage II in AlphaTruss is proposed to refine the continuous variables by using a process that is similar to the process in Algorithm 2 (

Section 2.3).

Stage II includes two types of action sets: adjusting node locations and adjusting the cross-sectional area of the bar. It requires the layout generated in stage I as an initial layout. Preserving the same topological relations, the node locations and cross-sectional area of the bar are adjusted to improve the layout design. The reward function and constraints are consistent with stage I in AlphaTruss except for the action set.

The first action type is to adjust the position of nodes that are newly added in stage I. The neighborhoods of the nodes are subdivided into several node sets (denoted as neighborhood node sets). Then, new positions of the nodes are chosen from these neighborhood node sets. Similarly, the second action type is to adjust the cross-sectional area of each bar from the input layout, finding the optimal adjustment from each neighborhood area set. Since the connection topology between nodes has already been obtained in stage I, the maximum number of iterations used in stage II is set as half of the one used in stage I for saving the computational budget.

In order to better illustrate this local discretization policy in stage II,

Figure 3 shows an example for the generation of the neighborhood node set. The blue dotted lines represent the original truss layout requiring refinement, and the nodes shaded by the blue squares imply that these nodes require position adjustment. The initial truss layout is obtained in stage I of AlphaTruss, where the design domain is uniformly discretized into a 17 × 9 grid distribution. Stage II of AlphaTruss locally adjusts the locations of existing nodes, and the amplitude of each adjustment should not exceed the shaded area of the blue square in

Figure 3a, denoted as

, where

is the step size of the discretization in stage I.

Figure 3b shows the newly generated neighborhood node set. A 9 × 9 local subdivision grid pattern is generated in the neighborhood of the considered node. These small neighborhoods make up the candidate node set for each node in the original layout that needs adjustment. For the cross-sectional area, the interval

is divided into 50 pieces to form a candidate set of the cross-sectional area with 51 entries, where

is the step size of the cross-sectional area discretizing in stage I.

Stage II for refinement of AlphaTruss is run for multiple rounds. The refinement process is carried out for at least 10 rounds. After that, the algorithm continues running until either generating a structure with a higher weight than the previous round or reaching 25 rounds. To achieve a better convergence rate, are used after each round in stage II.

It is worth mentioning that, in this two-stage algorithm, the solution generated by stage I, which is the best one of the ten repeated independent runs in stage I, will be used as the input topology to stage II. The second stage can carry out an effective neighbor-hood search to improve the truss layout based on the topology obtained in stage I.

5. Conclusions

This study formulates the problem of truss layout design into a Markov Decision Process (MDP) model and proposes a two-stage design algorithm named AlphaTruss, which can be used to search the optimal truss layout using the reinforcement learning technique, Monte Carlo Tree Search (MCTS). This MDP model contains three kinds of action sets: adding nodes, adding bars, and selecting sectional areas. Then, any truss layout in the solution space can be realized through these three action sets. In the first stage, AlphaTruss selects the optimal sequential actions in a three-step process of truss generation, expanding the solution space and providing a high likelihood of obtaining superior solutions in terms of size, shape, and topology. In the second stage, AlphaTruss refines the layout obtained in the first stage, aiming to improve the loss of optimization performance due to the discrete strategy of continuous variables in terms of size and shape. The reward function of the MDP can efficiently guide the AlphaTruss in the right searching direction based on knowledge and experience in structural engineering, such as geometric stability and structural performance. Compared with existing results from the literature, it is shown that AlphaTruss exhibits better performance in finding the truss layout with the minimum weight under stress, displacement, and buckling constraints in the 2D benchmark problem of a cantilever truss structure, simultaneously considering size, shape and topology optimization. AlphaTruss also has a strong generality to be applied, e.g., the traditional ten-bar for size and topology level or the structural layout design under multiple load cases.

Although AlphaTruss can be used to search optimal solutions for layout problems where size, shape, and topology optimization are simultaneously considered, the total number of nodes cannot be too large due to a limited computational budget. Otherwise, the discrete strategy for continuous variables such as node locations may make the solution space too large to search in large-scale problems. Next, the authors will study how to apply the AlphaTruss decision algorithm to practical engineering and large-scale problems in future research.