Integrated Building Maintenance and Safety Framework: Educational and Public Facilities Case Study

Abstract

:1. Introduction

- Definition of the risk factors, according to the facility components, performance and users;

- Development of a methodology for the assessment of the safety risks in educational and public facilities;

- Assessment of the maintenance and safety performances in educational and public facilities;

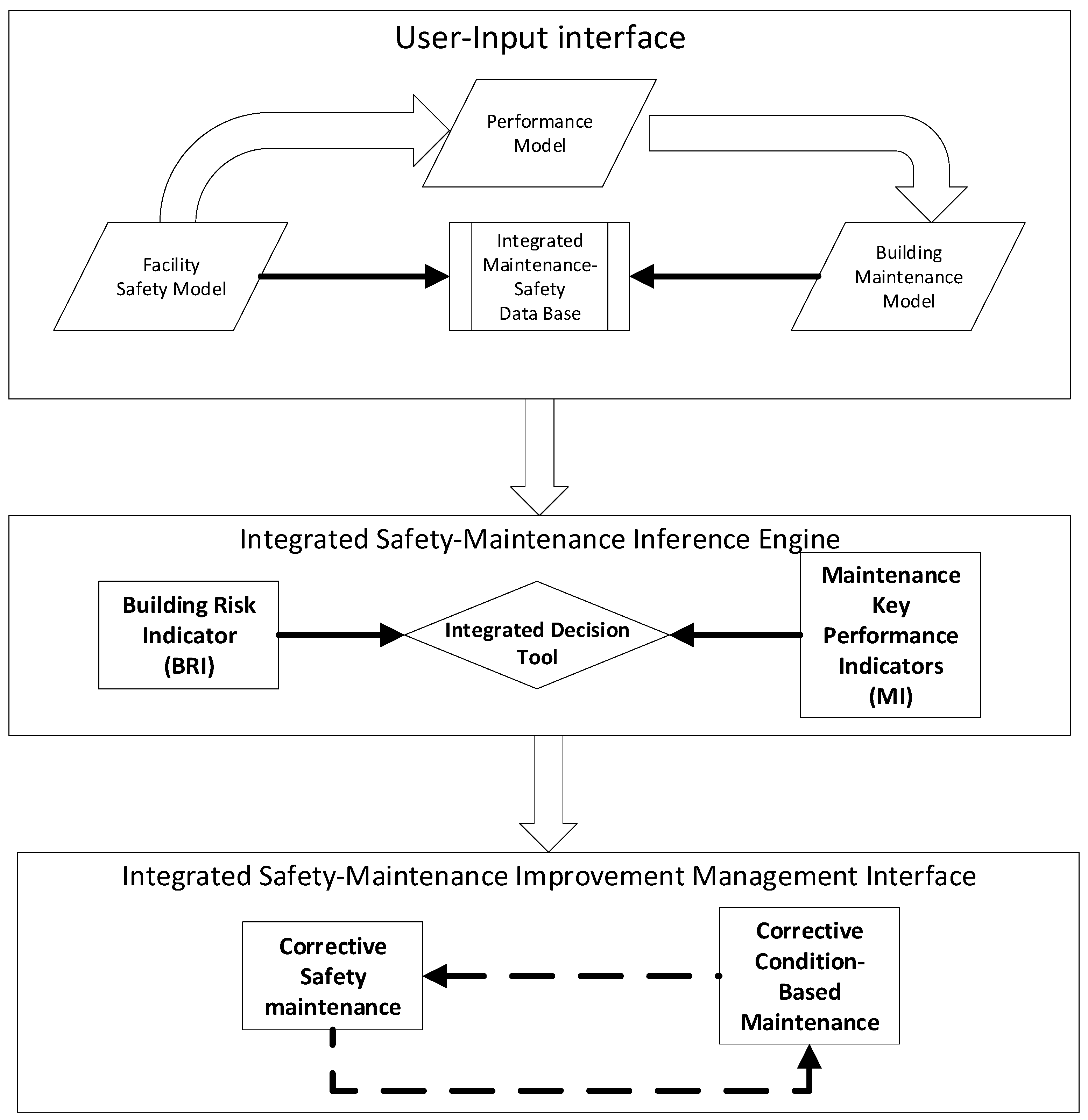

- Development of an Integrated Safety–Maintenance management framework;

- Implementation of the framework and validation of the research hypotheses;

- Recommendations for further research and concluding remarks.

2. Literature Review

2.1. Risk Factors

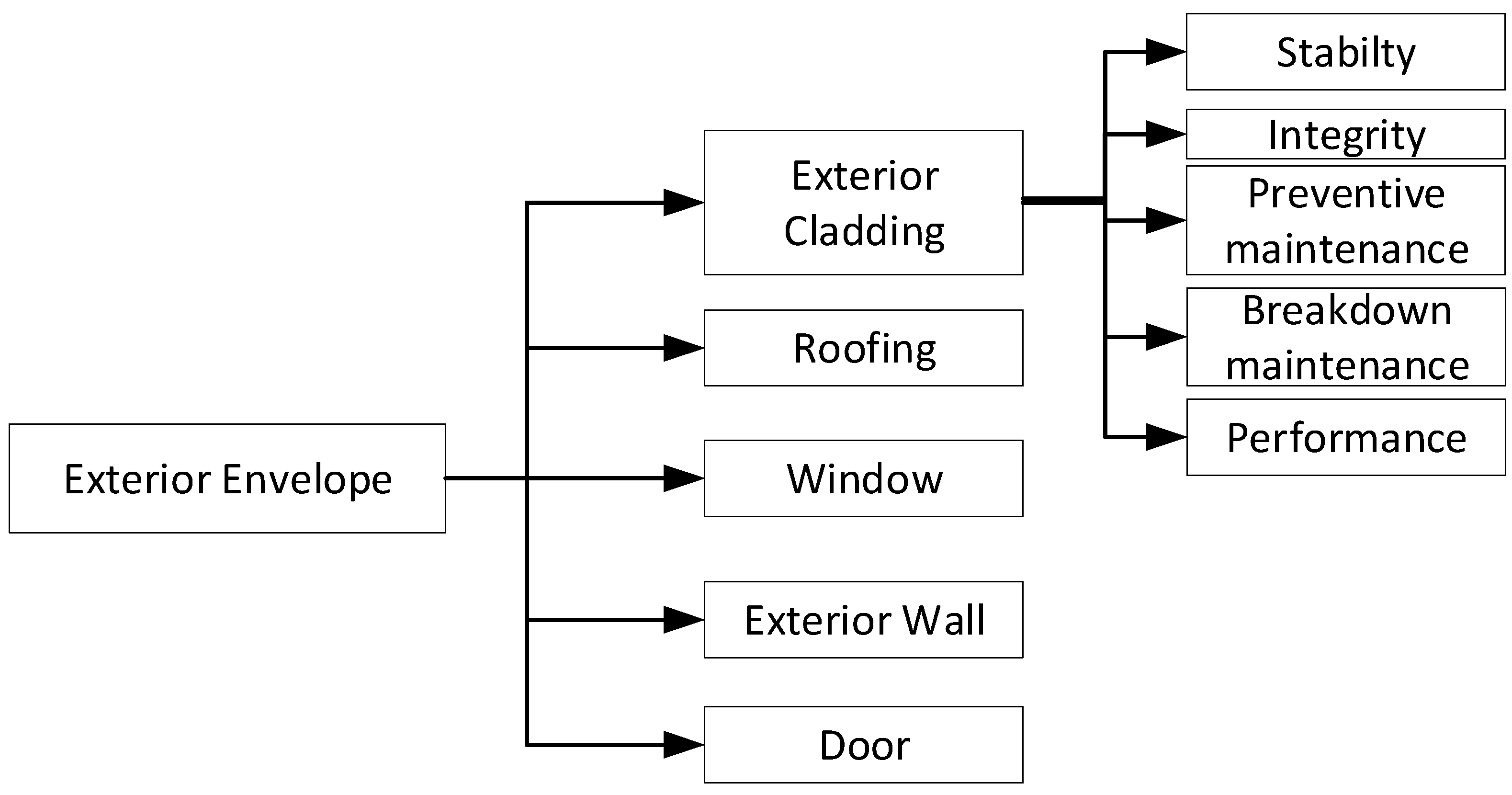

2.2. Maintenance

2.3. Safety Indicators

- A correlation exists between the maintenance performance of the educational facility and its safety, i.e., the higher the maintenance performance of the facility, the higher the safety of the facility is.

- There exists a correlation between the density of occupants (occupancy) and the performance and safety of educational and public facilities.

3. Integrated Risk-Informed Safety–Maintenance Framework

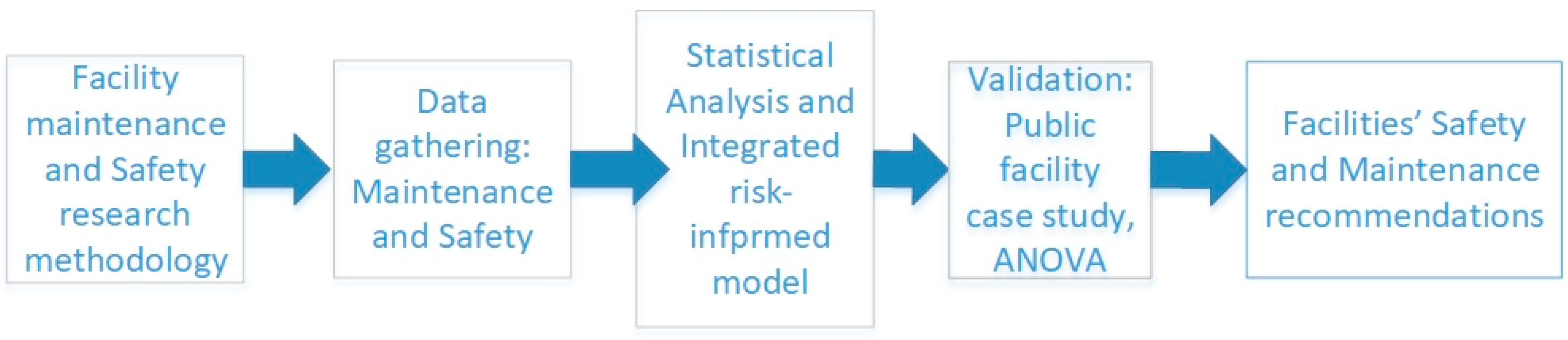

4. Research Method

- Field survey of 24 educational institutions facilities, with at least 200 students each carried out by the researchers. The survey examined the maintenance activities according to: (1) breakdown maintenance, (2) routine maintenance (performance based) and (3) preventive maintenance [46,47]. The institutions were sampled according to their size, data was gathered by a trained surveyor and the information was collected from the city database and from the site survey. The data collected included: floor area (sq.m.), number of students, density of students (students/sq.m.), BRI score and MI score.

- Gathering of the data of safety hazards in the institutions in all disciplines of the buildings’ systems; the data was gathered through interviews with the facilities’ maintenance managers using the BRI (Building Risk Indicator) described below;

- Assessment of the maintenance performance and safety of the facilities using a 25-point rating scale of the severity and probability of failures; assessments were carried out by the researchers through walk out and detailed site surveys in the facilities;

- Case study and validation of the proposed framework in a public facility using the safety (BRI) and maintenance performance (MI—Maintenance Indicator) models.

5. Results

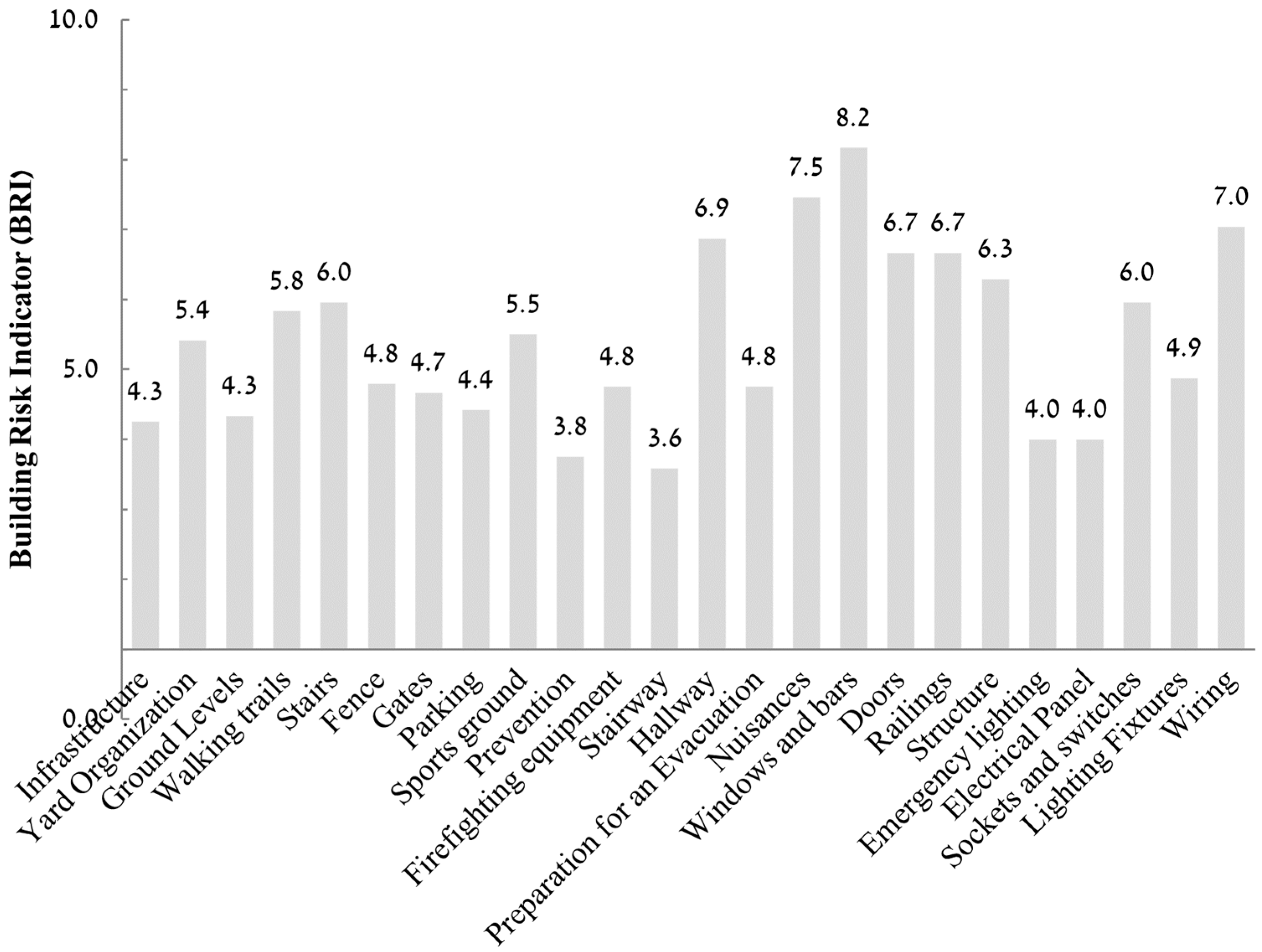

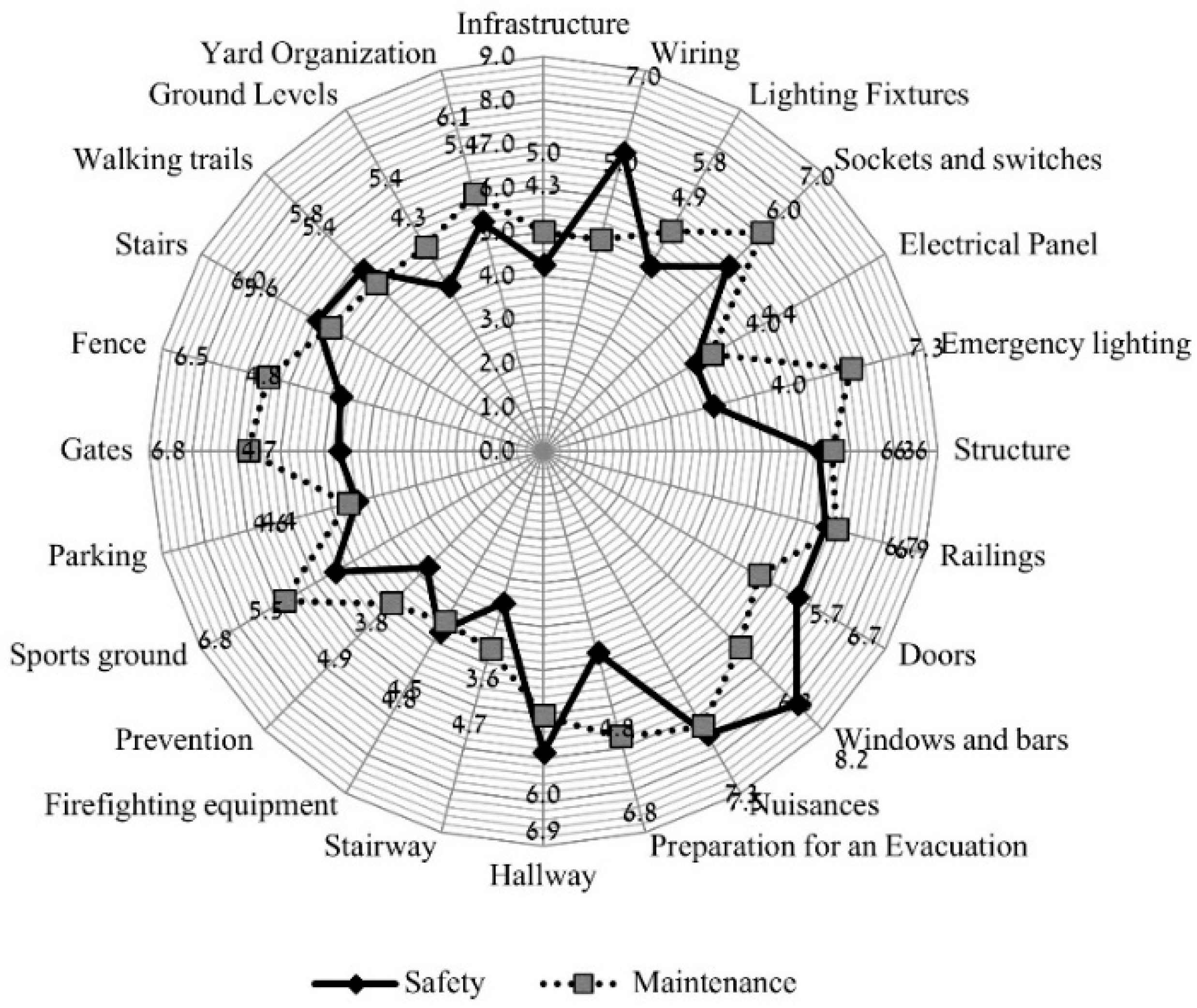

5.1. Safety

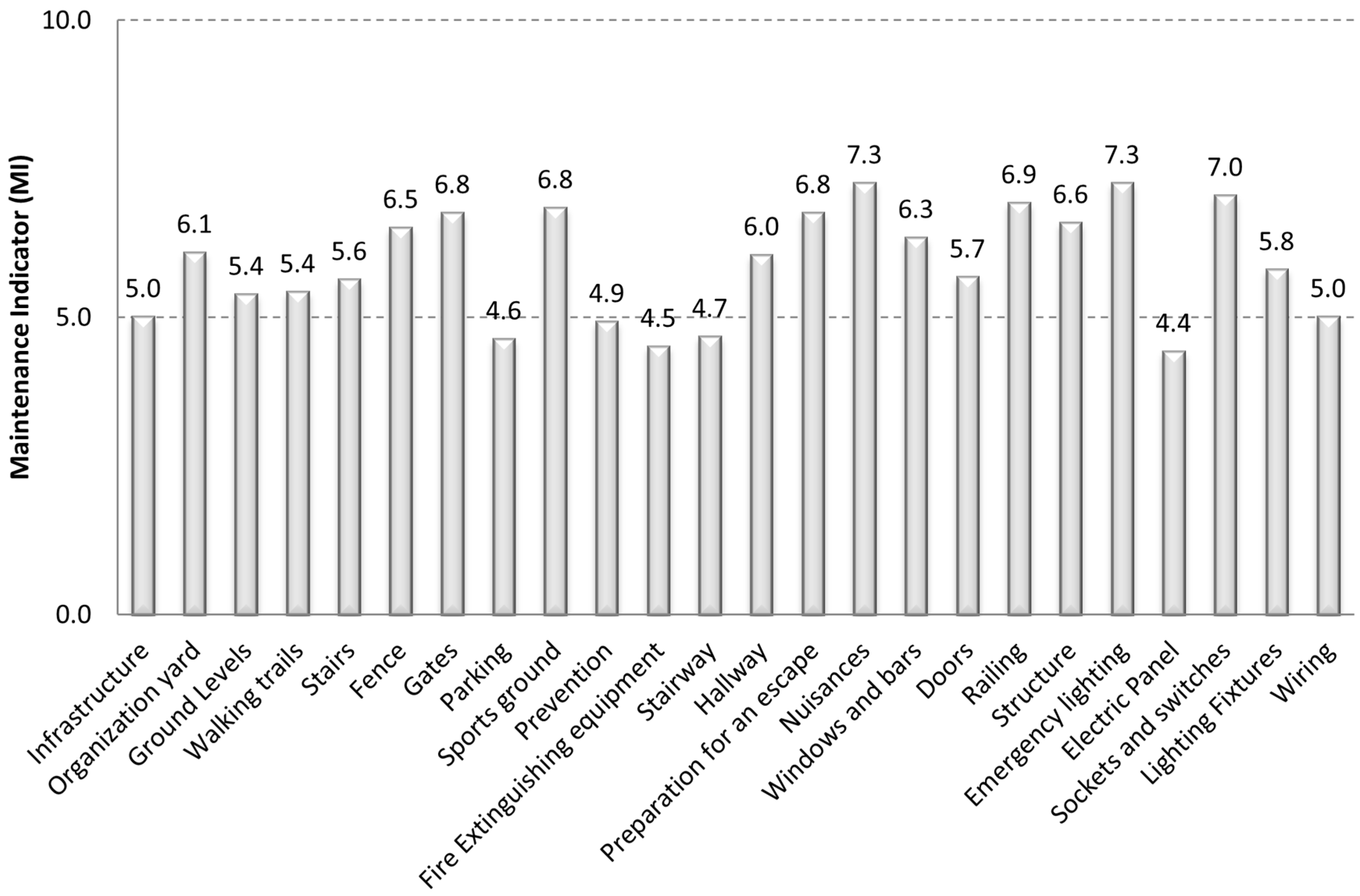

5.2. Maintenance

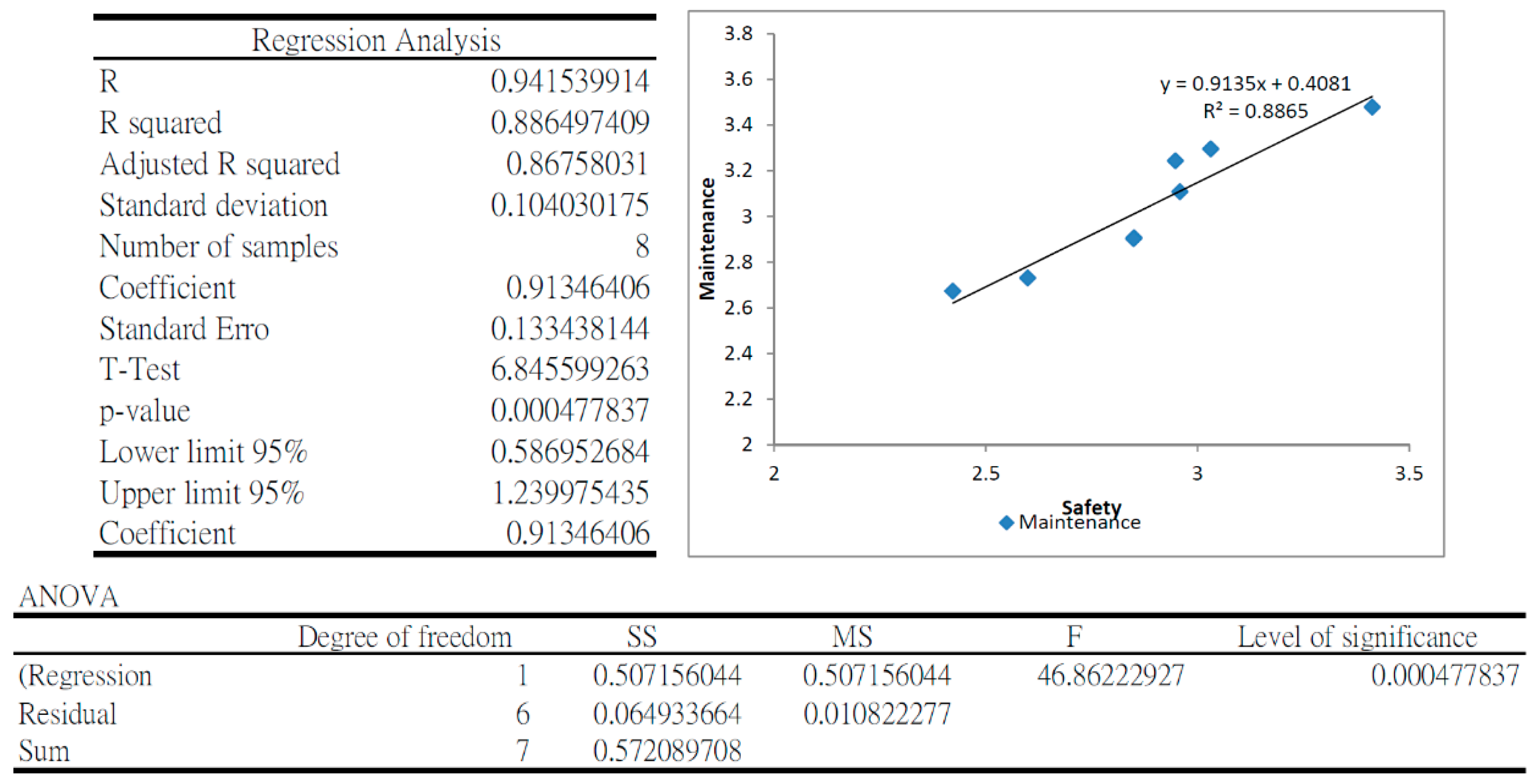

5.3. Synergy between Maintenance and Safety

5.4. Case-Study—Public Building Integrated Maintenance and Safety

6. Discussion

7. Conclusions

- Safety performance in educational institutions was found to be highly dependent on the variance in maintenance performance; this conclusion was deduced from the high Pearson coefficient between the Building Risk Indicator and the Maintenance Indicator;

- It was found that maintenance activities strongly affect the safety of electric system components (electric panels, lighting, end-fixtures and switches); infrastructures (parking lots, sports facilities, walking trails, and yard organization), fire protection and structural components (stairways, walls, roofs and columns). This conclusion deduced from the partial Pearson coefficients of the facilities’ systems between the safety and the maintenance performance for these systems;

- The study indicates that systematic maintenance of the critical facilities’ components such as electric system components, structural components, fire protection and infrastructures implemented with robust, integrated safety–maintenance procedures. This conclusion stems from the inherent dependency between these systems safety and maintenance performance as depicted by the Pearson coefficients discussed above.

- Annual safety audits of the systems seem to be insufficient in light of the study findings, higher frequencies of maintenance, and safety audits with intervals of between 3 and 6 months are suggested. This conclusion drawn from the marginal performance of maintenance indicator (MI) and safety (BRI) in the sample population, which accomplished in annual safety and performance audits regime.

- An integrated safety–maintenance performance framework was introduced for synergetic safety–maintenance monitoring, control and management. The framework proposes a cycle loop of safety–maintenance–performance of facilities as a key tool for advanced and effective maintenance and safety management with intervals between 3 and 6 months in public facilities.

- The framework was validated in a case study of public facility along a period of 11 years. The time history of maintenance performance and safety shows a high level of fitness (R2 = 0.8865 p < 0.05). The latter finding supports the practical implication of the framework for facility management applications.

- This research findings stresses that integrated safety and maintenance should be implemented as a unified and integrated procedure and that this procedure will enhance advanced maintenance performance and safety.

8. Limitations of the Research

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Static and Dynamic Nuisance Maintenance and Safety Grading Criteria

| 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|

| Cladding is complete and undamaged. No cladding elements have fallen off. Some capillary cracking may be present. | Capillary cracks have developed on portions of the cladding. Single cladding elements have fallen off. | Cracks 0.5 mm wide cover less than 5% of the total cladding area. Up to 3 % of cladding elements have fallen off | Cracks wider than 1 mm have developed on 5% or more of the cladding area. Portions of stone cladding have fallen off. | Significant portions of the cladding have peeled or fallen off. Cracks wider than 5 mm have developed |

| 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|

| Interior Claddings: Complete, stable, no signs of erosion, degradation, No mechanical deflections, cladding is planar Exterior cladding: Cladding is complete, no minor cracking, no mechanical deformations exterior element properly fixed to claddings. | No erosions, but minor sporadic cracks or spalling in interior cladding, Exterior cladding: Cladding is complete, nor fractures, minor cracks and spalling. | Detachment of up to 3% of cladding, erosion and deterioration of cladding due to intensive use. Fixtures attached to cladding are loosely fixed. | Exterior cladding cracking of up to 5 mm. development of spalling and detachments. Fixtured detached from cladding. | Significant part of cladding have peeled or fallen off. Significant spalling, cladding detached. Cracks wider than 5 mm have developed. Cladding is unstable. |

References

- Achuthan, K.; Murali, S.S. A comparative study of educational laboratories from cost & learning effectiveness perspective. Adv. Intell. Syst. Comput. 2015, 349, 143–153. [Google Scholar] [CrossRef]

- Al-Hemoud, A.M.; Al-Asfoor, M.M. A Behavior Based Safety Approach at a Kuwait Research Institution. J. Saf. Res. 2006, 37, 201–206. [Google Scholar] [CrossRef]

- Lau, E.; Hou, H.C.; Lai, J.H.; Edwards, D.; Chileshe, N. User-centric analytic approach to evaluate the performance of sports facilities: A study of swimming pools. J. Build. Eng. 2021, 44, 102951. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Fang, Y.C.; Chiu, Y.F.; Wu, Y.W.; Lin, T.C. Design and Maintenance Information Integration for Concrete Bridge Assessment and Disaster Prevention. J. Perform. Constr. Facil. ASCE 2021, 35, 04021015. [Google Scholar] [CrossRef]

- Okoro, C.S.; Nkambule, M.; Kruger, A. The state of restroom facilities as a measure of cleaning service quality in an educational institution. J. Corp. Real Estate 2020, 23, 55–68. [Google Scholar] [CrossRef]

- Miraglia, S. A data-driven probabilistic model for well integrity management: Case study and model calibration for the Danish sector of North Sea. J. Struct. Integr. Maint. 2020, 5, 142–153. [Google Scholar] [CrossRef]

- Salaheldin, M.H.; Hassanain, M.A.; Hamida, M.B.; Ibrahim, A.M. A code-compliance assessment tool for fire prevention measures in educational facilities. Int. J. Emerg. Serv. 2021, 10, 412–426. [Google Scholar] [CrossRef]

- Heinrich, H.W. Industrial Accident Prevention: A Scientific Approach; McGraw Hill: New York, NY, USA, 1941. [Google Scholar]

- DePasquale, J.P.; Geller, E.S. Critical success factors for behavior-based safety: A study of twenty industry-wide applications. J. Saf. Res. 1999, 30, 237–249. [Google Scholar] [CrossRef]

- Addington, L.A. Cops and cameras: Public school security as a policy response to Columbine. Am. Behav. Sci. 2009, 52, 1426–1446. [Google Scholar] [CrossRef]

- Schreck, C.J.; Miller, J.M. Sources of fear of crime at school. J. Sch. Violence 2003, 2, 57–79. [Google Scholar] [CrossRef]

- Schreck, C.J.; Miller, J.M.; Gibson, C. Trouble in the school yard: A study of the risk factors of victimization at school. Crime Delinq. 2003, 49, 460–484. [Google Scholar] [CrossRef]

- Sabatino, S.; Frangopol, D.M.; Dong, Y. Life cycle utility-informed maintenance planning based on lifetime functions: Optimum balancing of cost, failure consequences, and performance benefit. Struct. Infrastruct. Eng. 2015, 12, 830–847. [Google Scholar] [CrossRef]

- Lai, J.H.K.; Yik, F.W.H. An analytical method to evaluate facility management services for residential buildings. Build. Environ. 2011, 46, 165–175. [Google Scholar] [CrossRef]

- Olanrewaju, A.L.; Khamidi, M.F.; Idrus, A. Quantitative analysis of defects in Malaysian university buildings: Providers, Perspective. J. Retail. Leis. Prop. 2010, 9, 137–149. [Google Scholar] [CrossRef]

- Hobbs, A.; Williamson, A. Aircraft Maintenance Safety Survey: Results; AR-2007-053; Australian Transport Safety Bureau: Canberra, Australia, 2000.

- Farrington-Darby, T.; Pickup, L.; Wilson, J.R. Safety culture in railway maintenance. Saf. Sci. 2005, 43, 39–60. [Google Scholar] [CrossRef]

- Hollnagel, E. Safety Management—Looking Back or Looking Forward, Resilience Engineering Perspectives; CRC Press: Aldershot, UK, 2008. [Google Scholar]

- Shohet, I.M. Key Performance Indicators for Strategic healthcare facilities maintenance. J. Constr. Eng. Manag. ASCE 2006, 132, 345–352. [Google Scholar] [CrossRef]

- Aven, T. Foundations of Risk Analysis. A Knowledge and Decision-Oriented Approach; John Wiley and Sons, Ltd.: Chichester, UK, 2003. [Google Scholar]

- Hollnagel, E. Risk + barriers = safety? Saf. Sci. 2008, 46, 221–229. [Google Scholar] [CrossRef]

- Straub, D.; Faber, M.H. Systems effects in generic risk based inspection planning. J. Offshore Mech. Arct. Eng. ASME 2004, 126, 265–271. [Google Scholar] [CrossRef] [Green Version]

- Khalil, N.; Kamaruzzaman, S.N.; Baharum, M.R. Ranking the indicators of building performance and the users’ risk via Analytical Hierarchy Process (AHP): Case of Malaysia. Ecol. Indic. 2016, 71, 567–576. [Google Scholar] [CrossRef]

- Khan, F.I.; Sadiq, R.; Haddara, M. Risk-based inspection and maintenance (RBIM) multi-attribute decision making with aggregate risk analysis. Process Saf. Environ. Prot. 2004, 82, 398–411. [Google Scholar] [CrossRef]

- Backlund, F.; Hannu, J. Can we make maintenance decisions on risk analysis results? J. Qual. Maint. Eng. 2000, 8, 77–91. [Google Scholar] [CrossRef]

- Khan, F.I.; Haddara, M.R. Risk-based maintenance (RBM): A quantitative approach for maintenance/inspection scheduling and planning. J. Loss Prev. Process Ind. 2003, 16, 561–573. [Google Scholar] [CrossRef]

- De Silva, N.; Malik, R. Maintainability risks of condominiums in Sri Lanka. J. Financ. Manag. Prop. Constr. 2010, 15, 41–60. [Google Scholar] [CrossRef]

- Ruparathna, R.; Hewage, K.; Sadiq, R. Multi-period maintenance planning for public buildings: A risk based approach for climate conscious operation. J. Clean. Prod. 2018, 170, 1338–1353. [Google Scholar] [CrossRef]

- Chiu, C.K.; Chien, W.Y.; Noguchi, T. Risk-based life-cycle maintenance strategies for corroded reinforced concrete buildings located in the region with high seismic hazard. Struct. Infrastruct. Eng. 2012, 8, 1108–1122. [Google Scholar] [CrossRef]

- Wu, Y.; Maravelias, C.T.; Wenzel, M.J.; ElBsat, M.N.; Turney, R.T. Predictive maintenance scheduling optimization of building heating, ventilation, and air conditioning systems. Energy Build. 2021, 231, 110487. [Google Scholar] [CrossRef]

- Duan, C.; Li, Z.; Liu, F. Condition-based maintenance for ship pumps subject to competing risks under stochastic maintenance quality. Ocean. Eng. 2020, 218, 108180. [Google Scholar] [CrossRef]

- Kim, S.; Ge, B.; Frangopol, D.M. Optimum Target Reliability Determination for Efficient Service Life Management of Bridge Networks. J. Bridge Eng. ASCE 2020, 25, 04020087. [Google Scholar] [CrossRef]

- Akanmu, A.A.; Olayiwola, J.; Olatunji, O.A. Automated checking of building component accessibility for maintenance. Autom. Constr. 2020, 114, 103196. [Google Scholar] [CrossRef]

- Park, C.H.; Lim, H. A parametric approach to integer linear fractional programming: Newton’s and Hybrid-Newton methods for an optimal road maintenance problem. Eur. J. Oper. Res. 2014, 289, 1030–1039. [Google Scholar] [CrossRef]

- Chen, W.; Chen, K.; Cheng, J.C.; Wang, Q.; Gan, V.J. BIM-based framework for automatic scheduling of facility maintenance work orders. Autom. Constr. 2018, 91, 15–30. [Google Scholar] [CrossRef]

- Chen, C.; Tang, L. BIM-based integrated management workflow design for schedule and cost planning of building fabric maintenance. Autom. Constr. 2019, 107, 102944. [Google Scholar] [CrossRef]

- Saqib, M.; Farooqui, R.U.; Lodi, S.H. Assessment of critical success factors for construction projects in Pakistan. In Proceedings of the First International Conference on Construction in Developing Countries, Karachi, Pakistan, 4–5 August 2008; pp. 392–404. [Google Scholar]

- Au-Yong, C.P. Maintenance priority in high-rise housings: Practitioners’ perspective versus actual practice. J. Eng. Res. 2019, 7, 167–177. [Google Scholar] [CrossRef]

- Au-Yong, C.P.; Chua, S.J.L.; Ali, A.S.; Tucker, M. Optimising maintenance cost by prioritising maintenance of facilities services in residential buildings. Eng. Constr. Archit. Manag. 2019, 26, 1593–1607. [Google Scholar] [CrossRef]

- Ho, D.C.W.; Chau, K.W.; Cheung, A.K.C.; Yau, Y.; Wong, S.K.; Leung, H.F.; Lau, S.S.Y.; Wong, W.S. A survey of the health and safety conditions of apartment buildings in Hong Kong. Build. Environ. 2008, 43, 764–775. [Google Scholar] [CrossRef]

- Hopkins, A. Thinking about process safety indicators. Saf. Sci. 2009, 47, 460–465. [Google Scholar] [CrossRef]

- Harms-Ringdahl, L. Dimensions in safety indicators. Saf. Sci. 2009, 47, 481–482. [Google Scholar] [CrossRef]

- Ryczyński, J.; Saska, P.; Surowiecki, A.; Ksiądzyna, K. Selected safety issues in designing engineering structures. Sci. J. Mil. Univ. Land Forces 2020, 195, 135–153. [Google Scholar] [CrossRef]

- Lu, Y.; Gong, P.; Tang, Y.; Sun, S.; Li, Q. BIM-integrated construction safety risk assessment at the design stage of building projects. Autom. Constr. 2021, 124, 103553. [Google Scholar] [CrossRef]

- ISO/DIS 45001:2016; Occupational Health and Safety Management Systems: Requirements with Guidance for Use. ISO: Geneva, Switzerland, 2016.

- Shohet, I.M. Building evaluation methodology for setting priorities in hospital buildings. Constr. Manag. Econ. 2003, 21, 681–692. [Google Scholar] [CrossRef]

- Shohet, I.M.; Lavy-Leibovich, S.; Bar-On, D. Integrated maintenance monitoring of hospital buildings. Constr. Manag. Econ. 2003, 21, 219–228. [Google Scholar] [CrossRef]

- Ni, H.; Chen, A.; Chen, N. Some extensions on risk matrix approach. Saf. Sci. 2010, 48, 1269–1278. [Google Scholar] [CrossRef]

- Ministry of Education. Director General Guidelines Paper 5-52: Safety and Security in Educational Institutions. State of Israel. 2013. Available online: http://cms.education.gov.il/EducationCMS/Applications/Mankal/EtsMedorim/5/5-1/HoraotKeva/K-2013-6-1-5-1-52.htm (accessed on 13 April 2019).

- Shohet, I.M.; Nobili, L. Performance-Based Maintenance of Public Facilities: Principles and Implementation in Courthouses. J. Perform. Constr. Facil. ASCE 2016, 30, 04015086. [Google Scholar] [CrossRef] [Green Version]

- Shohet, I.M.; Nobili, L. Enterprise Resource Planning System for Performance-Based Maintenance of Healthcare Clinics. Autom. Constr. 2016, 65, 33–41. [Google Scholar] [CrossRef]

- Frangopol, D.M.; Dong, Y.; Sabatino, S. Bridge life-cycle performance and cost: Analysis, prediction, optimisation and decision-making. Struct. Infrastruct. Eng. 2017, 13, 1239–1257. [Google Scholar] [CrossRef]

- Arunraj, N.S.; Maiti, J. Risk-based maintenance techniques and applications. J. Hazard. Mater. 2007, 142, 653–661. [Google Scholar] [CrossRef]

- Geng, J.; Zhou, D.; Lv, C.; Wang, Z.L. A modeling approach for maintenance safety evaluation in a virtual maintenance environment. Comput.-Aided Des. 2013, 45, 937–949. [Google Scholar] [CrossRef]

| Parameter | Definition | Cross-Comparative Definition |

|---|---|---|

| Safety | All preventive measures aimed at ensuring user well-being and facility-designated use. | Hollnagel [18] indicated that safety is accomplished through the prevention of hazards, unsafe events and the consequences of structural failures. |

| Maintenance | Activities carried out to maintain the durability and performance of the building in accordance with its designated use. | Three aspects of key facility maintenance: (1) actual service condition of the system, (2) failures affecting the service condition provided by the system and (3) actual preventive activities carried out to maintain acceptable designated service condition [19]. |

| Risk | The probability and severity of an undesired event. | Aven [20] stated that the capability to express risk quantitatively and compare alternative mitigation strategies is at the heart of risk management. |

| Building performance | The concept in which the functions of buildings are defined by their outcomes rather than by prescription. Performance is determined by a building’s success in achieving user satisfaction and meeting designated performance criteria. | The evaluation of the overall service condition of the building or of the building portfolio, according to the performance criteria of its components and systems defined by its designated use and current standards [19]. |

| Acceptable risk | The level of risk deemed acceptable for an organization. | Hollnagel [21] stated that risk and safety are conceptually and practically linked—with higher safety meaning lower risk—and that the most effective way to achieve safety is through proactive mitigation actions. |

| Probability | Rare 1 0–10% | Low 2 11–40% | Moderate 3 41–60% | High 4 61–90% | Frequent 5 91–100% | |

|---|---|---|---|---|---|---|

| Severity | ||||||

| Critical 5 | 5 | 10 | 15 | 20 | 25 | |

| Severe 4 | 4 | 8 | 12 | 16 | 20 | |

| Moderate 3 | 3 | 6 | 9 | 12 | 15 | |

| Minor 2 | 2 | 4 | 6 | 8 | 10 | |

| Negligible 1 | 1 | 2 | 3 | 4 | 5 | |

| Legend | High Risk Moderate Risk Low Risk | |||||

| Probability | Rare 1 0–10% | Low 2 11–40% | Moderate 3 41–60% | High 4 61–90% | Frequent 5 91–100% | |

|---|---|---|---|---|---|---|

| Severity | ||||||

| Critical 5 | 5 | 10 | 15 | 20 | 25 | |

| Severe 4 | 4 | 8 | 12 | 16 | 20 | |

| Moderate 3 | 3 | 6 | 9 | 12 | 15 | |

| Minor 2 | 2 | 4 | 6 | 8 | 10 | |

| Negligible 1 | 1 | 2 | 3 | 4 | 5 | |

| Legend | High Risk Moderate Risk Low Risk | |||||

| Variable | Total | Mean |

|---|---|---|

| Floor area (sq.m.) | 98,270 | 4095 |

| Number of students | 14,381 | 599 |

| Density (Number of students/100 sq.m.) | - | 15.94 |

| Mean Maintenance score (MI) | - | 5.88 |

| Mean Safety Score (BRI) | - | 5.42 |

| Component | % of Explained Variance | ||

|---|---|---|---|

| Infrastructures | 0.310 | 0.10 | 9.61 |

| Yard organization | 0.603 | 0.36 | 36.36 |

| Ground leveling | 0.422 | 0.18 | 17.81 |

| Walking Trails | 0.649 | 0.42 | 42.12 |

| Stairs | 0.114 | 0.01 | 1.30 |

| Fence | 0.538 | 0.29 | 28.94 |

| Gates | 0.318 | 0.10 | 10.11 |

| Parking | 0.886 | 0.78 | 78.50 |

| Sports Facilities | 0.702 | 0.49 | 49.28 |

| Prevention | 0.331 | 0.11 | 10.96 |

| Fire Protection | 0.697 | 0.49 | 48.58 |

| Stairways | 0.734 | 0.54 | 53.88 |

| Hallways | 0.444 | 0.20 | 19.71 |

| Escape Preparation | 0.576 | 0.33 | 33.18 |

| Nuisance | 0.056 | 0.00 | 0.31 |

| Windows and Bars | 0.117 | 0.01 | 1.37 |

| Doors | 0.426 | 0.18 | 18.15 |

| Railing | 0.475 | 0.23 | 22.56 |

| Structure | 0.666 | 0.44 | 44.36 |

| Emergency Lighting | 1 | 1 | 100 |

| Electric Panels | 1 | 1 | 100 |

| Electric Fixtures and Switches | 0.952 | 0.91 | 90.63 |

| Lighting fixtures | 0.334 | 0.11 | 11.16 |

| Wirings | 0.291 | 0.08 | 8.47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.-C.; Almassy, R.; Wei, H.-H.; Shohet, I.M. Integrated Building Maintenance and Safety Framework: Educational and Public Facilities Case Study. Buildings 2022, 12, 770. https://doi.org/10.3390/buildings12060770

Wang K-C, Almassy R, Wei H-H, Shohet IM. Integrated Building Maintenance and Safety Framework: Educational and Public Facilities Case Study. Buildings. 2022; 12(6):770. https://doi.org/10.3390/buildings12060770

Chicago/Turabian StyleWang, Kun-Chi, Reut Almassy, Hsi-Hsien Wei, and Igal M. Shohet. 2022. "Integrated Building Maintenance and Safety Framework: Educational and Public Facilities Case Study" Buildings 12, no. 6: 770. https://doi.org/10.3390/buildings12060770