Axial Load Enhancement of Lightweight Aggregate Concrete (LAC) Using Environmentally Sustainable Composites

Abstract

:1. Introduction

2. Experimental Program

2.1. Test Matrix

2.2. Material Properties

2.3. Specimen Details

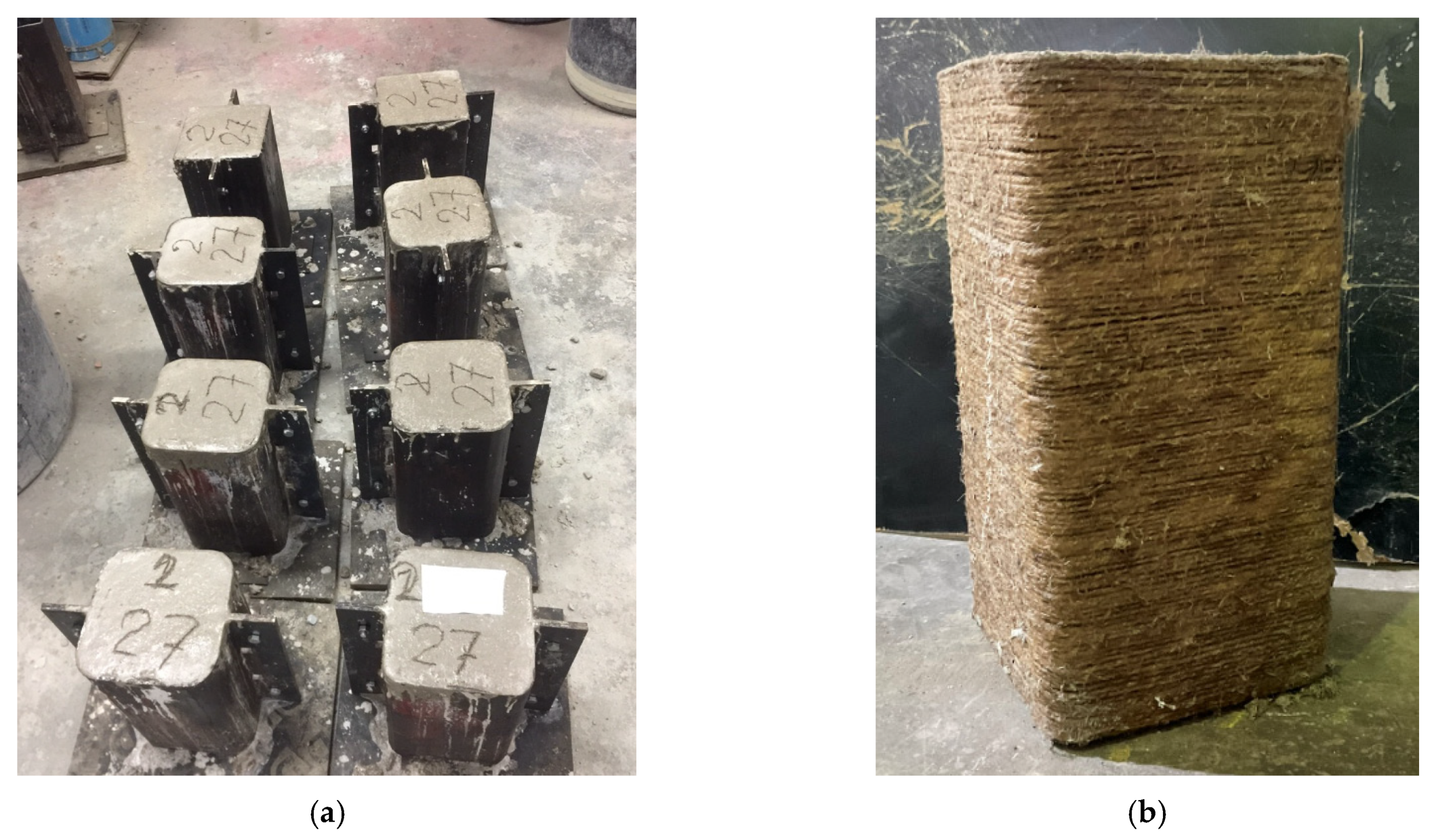

2.4. Construction and Strengthening of the Specimens

2.5. Test Setup and Instrumentation

3. Experimental Results

3.1. Ultimate Failure Modes

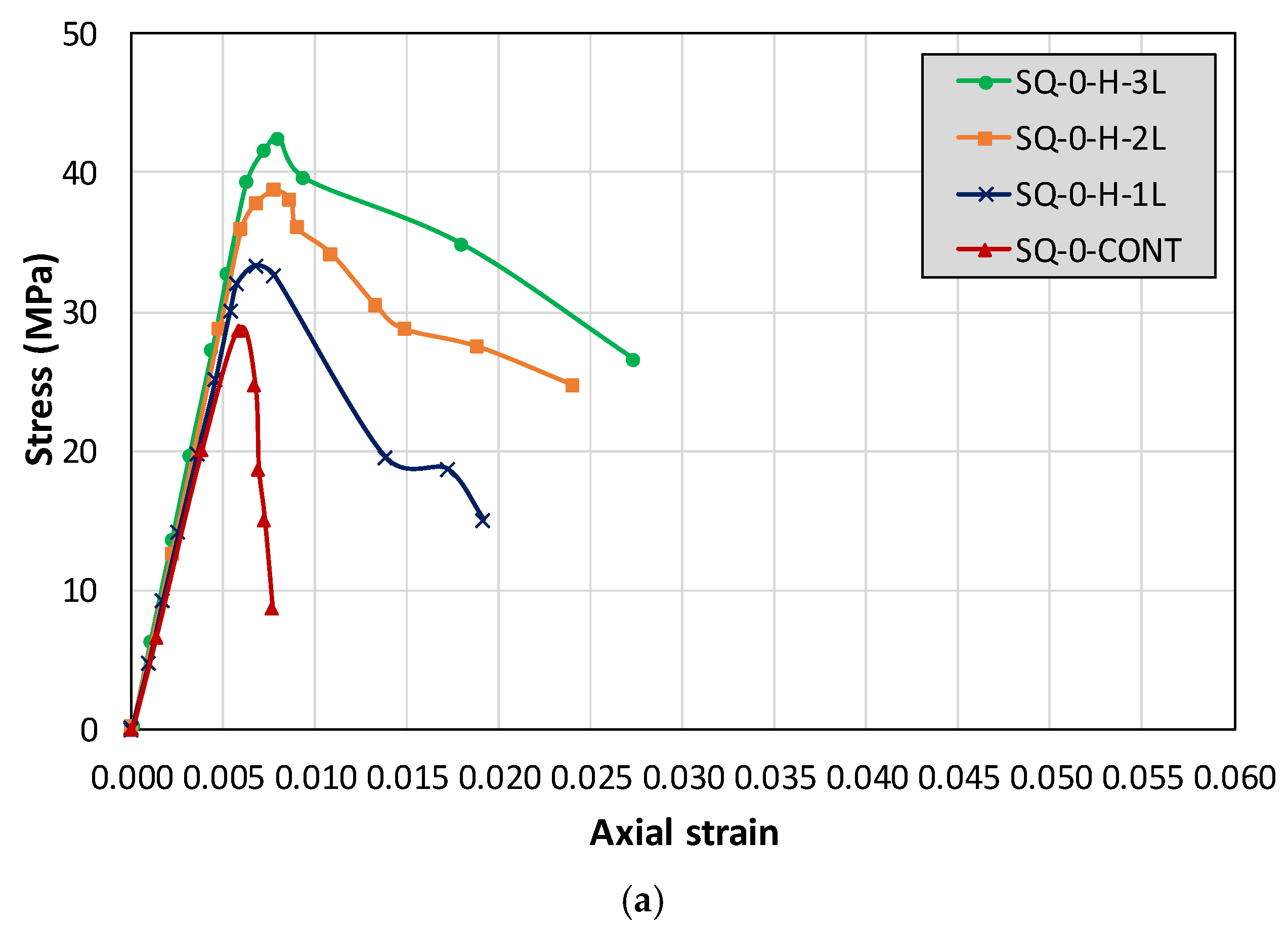

3.2. Compressive Stress–Strain Relationship

3.3. Ultimate Stress and Strain Values

3.4. Effect of the Quantity of Lightweight Aggregates

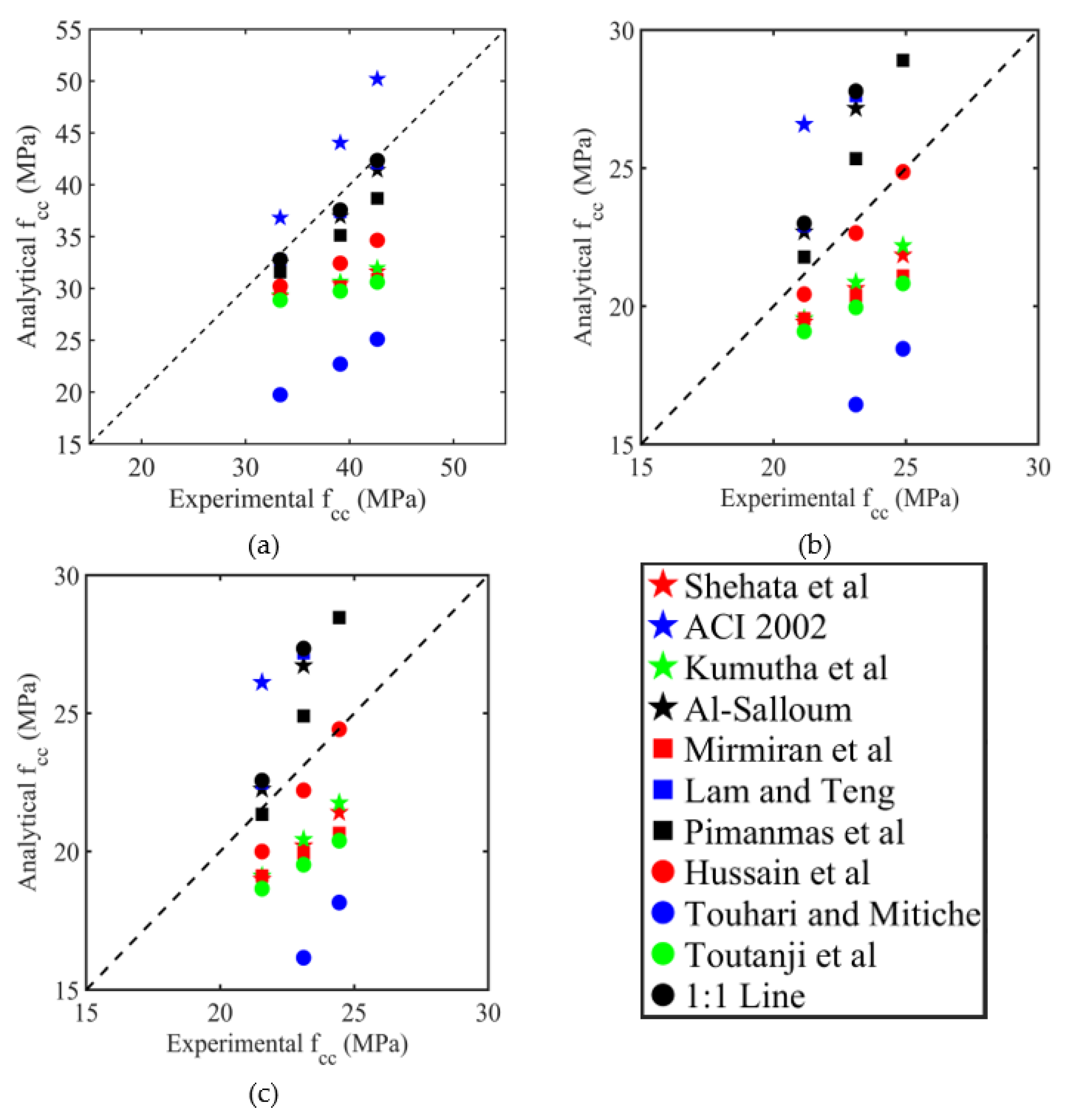

3.5. Analytical Investigations

4. Conclusions

- Concrete constructed with lightweight aggregates exhibited lower ultimate compressive strength and strain as compared to normal aggregate concrete. Specimens confined with hemp fiber ropes and constructed with lightweight aggregate concrete demonstrated a substantial increase in peak compressive strength and corresponding strain.

- Specimens constructed with lightweight aggregate concrete and externally confined with hemp fiber ropes exhibited a flat plateau in their post peak compressive stress–strain response. This suggests that significant axial compressive ductility was imparted by the hemp ropes to the lightweight aggregate concrete, which is a vital desired characteristic of concrete that is subjected to dynamic loadings.

- Natural coarse aggregates were replaced in the amount of 50% and 100% in group 2 and 3 specimens, respectively. Hemp fiber wraps resulted in an approximately similar gain in ultimate compressive strength and strain in both the groups. In terms of axial ductility, specimens constructed with 100% lightweight aggregates showed higher ductility compared to those constructed with 50% lightweight aggregates. This indicates that the efficacy of hemp fiber ropes in terms of imparting axial ductility improved as the amount of lightweight aggregates increased.

- Several ultimate compressive models were assessed in this study to predict hemp rope-confined specimens’ compressive strengths. It was found that the model of Hussain et al. agreed well with the experimental results. Therefore, for design and analysis purposes of hemp rope-confined concrete, the model of Hussain et al. is recommended to predict the ultimate compressive strength of lightweight aggregate concrete.

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Kucharczyková, B.; Keršner, Z.; Pospíchal, O.; Misák, P.; Vymazal, T. Influence of Freeze–Thaw Cycles on Fracture Parameters Values of Lightweight Concrete. Procedia Eng. 2010, 2, 959–966. [Google Scholar] [CrossRef]

- Dabbagh, H.; Delshad, M.; Amoorezaei, K. Design-Oriented Stress-Strain Model for FRP-Confined Lightweight Aggregate Concrete. KSCE J. Civ. Eng. 2021, 25, 219–234. [Google Scholar] [CrossRef]

- Lo, T.Y.; Tang, W.C.; Cui, H.Z. The Effects of Aggregate Properties on Lightweight Concrete. Build. Environ. 2007, 42, 3025–3029. [Google Scholar] [CrossRef]

- Miller, N.M.; Tehrani, F.M. Mechanical Properties of Rubberized Lightweight Aggregate Concrete. Constr. Build. Mater. 2017, 147, 264–271. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, K.; Cui, N.; Cheng, X.; Ren, K.; Hou, P.; Feng, L.; Zhou, Z.; Xie, N. Green and Durable Lightweight Aggregate Concrete: The Role of Waste and Recycled Materials. Materials 2020, 13, 3041. [Google Scholar] [CrossRef] [PubMed]

- Mo, K.H.; Ling, T.C.; Alengaram, U.J.; Yap, S.P.; Yuen, C.W. Overview of Supplementary Cementitious Materials Usage in Lightweight Aggregate Concrete. Constr. Build. Mater. 2017, 139, 403–418. [Google Scholar] [CrossRef]

- Wu, T.; Yang, X.; Wei, H.; Liu, X. Mechanical Properties and Microstructure of Lightweight Aggregate Concrete with and without Fibers. Constr. Build. Mater. 2019, 199, 526–539. [Google Scholar] [CrossRef]

- Lim, J.C.; Ozbakkaloglu, T. Stress–Strain Model for Normal- and Light-Weight Concretes under Uniaxial and Triaxial Compression. Constr. Build. Mater. 2014, 71, 492–509. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, X.; Xing, F.; Cui, H.; Sui, L. Axial Compressive Behavior of FRP-Confined Lightweight Aggregate Concrete: An Experimental Study and Stress-Strain Relation Model. Constr. Build. Mater. 2016, 119, 1–15. [Google Scholar] [CrossRef]

- Wang, H.T.; Wang, L.C. Experimental Study on Static and Dynamic Mechanical Properties of Steel Fiber Reinforced Lightweight Aggregate Concrete. Constr. Build. Mater. 2013, 38, 1146–1151. [Google Scholar] [CrossRef]

- Haque, M.N.; Al-Khaiat, H.; Kayali, O. Strength and Durability of Lightweight Concrete. Cem. Concr. Compos. 2004, 26, 307–314. [Google Scholar] [CrossRef]

- Rico, S.; Farshidpour, R.; Tehrani, F.M. State-of-the-Art Report on Fiber-Reinforced Lightweight Aggregate Concrete Masonry. Adv. Civ. Eng. 2017, 2017, 8078346. [Google Scholar] [CrossRef] [Green Version]

- Deifalla, A.; Awad, A.; Seleem, H.; Abdelrahman, A. Investigating the Behavior of Lightweight Foamed Concrete T-Beams under Torsion, Shear, and Flexure. Eng. Struct. 2020, 219, 110741. [Google Scholar] [CrossRef]

- Deifalla, A.; Awad, A.; Seleem, H.; Abdelrahman, A. Experimental and Numerical Investigation of the Behavior of LWFC L-Girders under Combined Torsion. Structures 2020, 26, 362–377. [Google Scholar] [CrossRef]

- Yang, X.; Wu, T.; Liu, X. Stress–Strain Model for Lightweight Aggregate Concrete Reinforced with Carbon–Polypropylene Hybrid Fibers. Polymers 2022, 14, 1675. [Google Scholar] [CrossRef] [PubMed]

- Wenchen, M. Behavior of Aged Reinforced Concrete Columns Under High Sustained Concentric and Eccentric Loads. Ph.D. Thesis, University of Nevada, Las Vegas, NV, USA, 2021. [Google Scholar]

- Wenchen, M. Simulate Initiation and Formation of Cracks and Potholes. Master’s Thesis, Northeastern University, Boston, MA, USA, 2016. [Google Scholar]

- Wei, H.; Wu, T.; Liu, X.; Zhang, R. Investigation of Stress-Strain Relationship for Confined Lightweight Aggregate Concrete. Constr. Build. Mater. 2020, 256, 119432. [Google Scholar] [CrossRef]

- Khaloo, A.R.; El-Dash, K.M.; Ahmad, S.H. Model for Lightweight Concrete Columns Confined by Either Single Hoops or Interlocking Double Spirals. Struct. J. 1999, 96, 883–890. [Google Scholar] [CrossRef]

- Han, Q.; Yuan, W.; Bai, Y.; Du, X. Compressive Behavior of Large Rupture Strain (LRS) FRP-Confined Square Concrete Columns: Experimental Study and Model Evaluation. Mater. Struct. 2020, 53, 99. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, X.; Mo, Z.; Chouw, N.; Li, Z.; Xu, Z.D. A Comparative Study of Impact Behaviour between Natural Flax and Glass FRP Confined Concrete Composites. Constr. Build. Mater. 2020, 241, 117997. [Google Scholar] [CrossRef]

- Wang, W.; Sheikh, M.N.; Al-Baali, A.Q.; Hadi, M.N.S. Compressive Behaviour of Partially FRP Confined Concrete: Experimental Observations and Assessment of the Stress-Strain Models. Constr. Build. Mater. 2018, 192, 785–797. [Google Scholar] [CrossRef] [Green Version]

- Pimanmas, A.; Saleem, S. Dilation Characteristics of PET FRP–Confined Concrete. J. Compos. Constr. 2018, 22, 04018006. [Google Scholar] [CrossRef]

- Feng, C.; Yu, F.; Fang, Y. Mechanical Behavior of PVC Tube Confined Concrete and PVC-FRP Confined Concrete: A Review. Structures 2021, 31, 613–635. [Google Scholar] [CrossRef]

- Jiangfeng, D.; Shucheng, Y.; Qingyuan, W.; Wenyu, Z.; Jiangfeng, D.; Shucheng, Y.; Qingyuan, W.; Wenyu, Z. Flexural Behavior of RC Beams Made with Recycled Aggregate Concrete and Strengthened by CFRP Sheets. J. Build. Struct. 2019, 40, 71–78. [Google Scholar] [CrossRef]

- Liang, J.; Lin, S.; Ahmed, M. Axial Behavior of Carbon Fiber-Reinforced Polymer–Confined Recycled Aggregate Concrete-Filled Steel Tube Slender Square Columns. Adv. Struct. Eng. 2021, 24, 3507–3518. [Google Scholar] [CrossRef]

- Chen, G.M.; Zhang, J.J.; Jiang, T.; Lin, C.J.; He, Y.H. Compressive Behavior of CFRP-Confined Recycled Aggregate Concrete in Different-Sized Circular Sections. J. Compos. Constr. 2018, 22, 04018021. [Google Scholar] [CrossRef]

- Li, P.; Zhao, Y.; Long, X.; Zhou, Y.; Chen, Z. Ductility Evaluation of Damaged Recycled Aggregate Concrete Columns Repaired with Carbon Fiber-Reinforced Polymer and Large Rupture Strain FRP. Front. Mater. 2020, 7, 346. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Z. Evaluation of FRP and Hybrid FRP Cables for Super Long-Span Cable-Stayed Bridges. Compos. Struct. 2010, 92, 2582–2590. [Google Scholar] [CrossRef]

- Chaiyasarn, K.; Hussain, Q.; Joyklad, P.; Rodsin, K. New Hybrid Basalt/E-Glass FRP Jacketing for Enhanced Confinement of Recycled Aggregate Concrete with Clay Brick Aggregate. Case Stud. Constr. Mater. 2021, 14, e00507. [Google Scholar] [CrossRef]

- Tarvainen, K.; Jolanki, R.; Forsman-Grönholm, L.; Estlander, T.; Pfäffli, P.; Juntunen, J.; Kanerva, L. Exposure, Skin Protection and Occupational Skin Diseases in the Glass-Fibre-Reinforced Plastics Industry. Contact Dermat. 1993, 29, 119–127. [Google Scholar] [CrossRef]

- Tarvainen, K.; Jolanki, R.; Estlander, T. Occupational Contact Allergy to Unsaturated Polyester Resin Cements. Contact Dermat. 1993, 28, 220–224. [Google Scholar] [CrossRef]

- Minamoto, K.; Nagano, M.; Inaoka, T.; Kitano, T.; Ushijima, K.; Fukuda, Y.; Futatsuka, M. Skin Problems among Fiber-Glass Reinforced Plastics Factory Workers in Japan. Ind. Health 2002, 40, 42–50. [Google Scholar] [CrossRef] [PubMed]

- Yinh, S.; Hussain, Q.; Joyklad, P.; Chaimahawan, P.; Rattanapitikon, W.; Limkatanyu, S.; Pimanmas, A. Strengthening Effect of Natural Fiber Reinforced Polymer Composites (NFRP) on Concrete. Case Stud. Constr. Mater. 2021, 15, e00653. [Google Scholar] [CrossRef]

- Yooprasertchai, E.; Wiwatrojanagul, P.; Pimanmas, A. A Use of Natural Sisal and Jute Fiber Composites for Seismic Retrofitting of Nonductile Rectangular Reinforced Concrete Columns. J. Build. Eng. 2022, 52, 104521. [Google Scholar] [CrossRef]

- Jirawattanasomkul, T.; Likitlersuang, S.; Wuttiwannasak, N.; Ueda, T.; Zhang, D.; Shono, M. Structural Behaviour of Pre-Damaged Reinforced Concrete Beams Strengthened with Natural Fibre Reinforced Polymer Composites. Compos. Struct. 2020, 244, 112309. [Google Scholar] [CrossRef]

- Sen, T.; Jagannatha Reddy, H.N. Efficacy of Bio Derived Jute FRP Composite Based Technique for Shear Strength Retrofitting of Reinforced Concrete Beams and Its Comparative Analysis with Carbon and Glass FRP Shear Retrofitting Schemes. Sustain. Cities Soc. 2014, 13, 105–124. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.W.; Ye, L. Sisal Fibre and Its Composites: A Review of Recent Developments. Compos. Sci. Technol. 2000, 60, 2037–2055. [Google Scholar] [CrossRef]

- Hussain, Q.; Ruangrassamee, A.; Tangtermsirikul, S.; Joyklad, P. Behavior of Concrete Confined with Epoxy Bonded Fiber Ropes under Axial Load. Constr. Build. Mater. 2020, 263, 120093. [Google Scholar] [CrossRef]

- Fragoudakis, R.; Gallagher, J.A.; Kim, V. A Computational Analysis of the Energy Harvested by Gfrp and Nfrp Laminated Beams Under Cyclic Loading. Procedia Eng. 2017, 200, 221–228. [Google Scholar] [CrossRef]

- Ramadan, R.; Saad, G.; Awwad, E.; Khatib, H.; Mabsout, M. Short-Term Durability of Hemp Fibers. Procedia Eng. 2017, 200, 120–127. [Google Scholar] [CrossRef]

- Ghalieh, L.; Awwad, E.; Saad, G.; Khatib, H.; Mabsout, M. Concrete Columns Wrapped with Hemp Fiber Reinforced Polymer—An Experimental Study. Procedia Eng. 2017, 200, 440–447. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-Oriented Stress-Strain Model for FRP-Confined Concrete in Rectangular Columns. J. Reinf. Plast. Compos. 2016, 22, 1149–1186. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H. Compressive Behavior of Concrete Confined by Carbon Fiber Composite Jackets. J. Mater. Civ. Eng. 2000, 12, 139–146. [Google Scholar] [CrossRef]

- Rochette, P.; Labossière, P. Axial Testing of Rectangular Column Models Confined with Composites. J. Compos. Constr. 2000, 4, 129–136. [Google Scholar] [CrossRef]

- Hussain, Q.; Ruangrassamee, A.; Tangtermsirikul, S.; Joyklad, P.; Wijeyewickrema, A.C. Low-Cost Fiber Rope Reinforced Polymer (FRRP) Confinement of Square Columns with Different Corner Radii. Buildings 2021, 11, 355. [Google Scholar] [CrossRef]

- Soudki, K.; Alkhrdaji, T. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures (ACI 440.2R-02). In Proceedings of the Structures Congress 2005, New York, NY, USA, 20–24 April 2005; pp. 1–8. [Google Scholar] [CrossRef] [Green Version]

- Shehata, I.A.E.M.; Carneiro, L.A.V.; Shehata, L.C.D. Strength of Short Concrete Columns Confined with CFRP Sheets. Mater. Struct. 2002, 35, 50–58. [Google Scholar] [CrossRef]

- Kumutha, R.; Vaidyanathan, R.; Palanichamy, M.S. Behaviour of Reinforced Concrete Rectangular Columns Strengthened Using GFRP. Cem. Concr. Compos. 2007, 29, 609–615. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A. Influence of Edge Sharpness on the Strength of Square Concrete Columns Confined with FRP Composite Laminates. Compos. Part B Eng. 2007, 38, 640–650. [Google Scholar] [CrossRef]

- Mirmiran, A.; Shahawy, M.; Samaan, M.; El Echary, H.; Mastrapa, J.C.; Pico, O. Effect of Column Parameters on FRP-Confined Concrete. J. Compos. Constr. 1998, 2, 175–185. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Strength Models for Fiber-Reinforced Plastic-Confined Concrete. J. Struct. Eng. 2002, 128, 612–623. [Google Scholar] [CrossRef]

- Pimanmas, A.; Hussain, Q.; Panyasirikhunawut, A.; Rattanapitikon, W. Axial Strength and Deformability of Concrete Confined with Natural Fibre-Reinforced Polymers. Mag. Concr. Res. 2018, 71, 55–70. [Google Scholar] [CrossRef]

- Touhari, M.; Mitiche, R.K. Strength Model of FRP Confined Concrete Columns Based on Analytical Analysis and Experimental Test. Int. J. Struct. Integr. 2020, 11, 82–106. [Google Scholar] [CrossRef]

- Toutanji, H.; Han, M.; Matthys, S. Axial Load Behavior of Rectangular Concrete Columns Confined with FRP Composites. In Proceedings of the 8th International Symposium on fiber-Reinforced Polymer Reinforcement for Concrete Structures FRPRCS-8, Patras, Greece, 16–18 July 2007. [Google Scholar]

- Thermou, G.E.; Hajirasouliha, I. Design-Oriented Models for Concrete Columns Confined by Steel-Reinforced Grout Jackets. Constr. Build. Mater. 2018, 178, 313–326. [Google Scholar] [CrossRef] [Green Version]

- Deifalla, A. Strength and Ductility of Lightweight Reinforced Concrete Slabs under Punching Shear. Structures 2020, 27, 2329–2345. [Google Scholar] [CrossRef]

| Group | Specimen | Amount of Lightweight Aggregate (%) | Number of Layers of Hemp FRP | Number of Specimens |

|---|---|---|---|---|

| 1 | SQ-0-CONT | 0 | 0 | 2 |

| SQ-0-H-1L | 0 | 1 | 2 | |

| SQ-0-H-2L | 0 | 2 | 2 | |

| SQ-0-H-3L | 0 | 3 | 2 | |

| 2 | SQ-50-CONT | 50 | 0 | 2 |

| SQ-50-H-1L | 50 | 1 | 2 | |

| SQ-50-H-2L | 50 | 2 | 2 | |

| SQ-50-H-3L | 50 | 3 | 2 | |

| 3 | SQ-100-CONT | 100 | 0 | 2 |

| SQ-100-H-1L | 100 | 1 | 2 | |

| SQ-100-H-2L | 100 | 2 | 2 | |

| SQ-100-H-3L | 100 | 3 | 2 |

| Quantity | G-1 | G-2 | G-3 |

|---|---|---|---|

| Cement | 600 | 600 | 600 |

| Fine aggregates | 600 | 600 | 600 |

| Natural coarse aggregates | 900 | 450 | 0.0 |

| Lightweight aggregates | 0.0 | 450 | 900 |

| Water | 300 | 300 | 300 |

| Group | Specimen | Ultimate Stress (MPa) | Increase in Ultimate Stress (%) | Strain at Ultimate Stress | Increase in (%) |

|---|---|---|---|---|---|

| 1 | SQ-0-CONT | 28.00 | - | 0.0058 | - |

| SQ-0-H-1L | 33.33 | 19 | 0.0068 | 16 | |

| SQ-0-H-2L | 39.11 | 40 | 0.0078 | 33 | |

| SQ-0-H-3L | 42.67 | 52 | 0.0080 | 37 | |

| 2 | SQ-50-CONT | 18.22 | - | 0.0055 | - |

| SQ-50-H-1L | 21.16 | 16 | 0.0076 | 37 | |

| SQ-50-H-2L | 23.11 | 27 | 0.0086 | 55 | |

| SQ-50-H-3L | 24.89 | 37 | 0.0251 | 355 | |

| 3 | SQ-100-CONT | 17.78 | - | 0.0049 | - |

| SQ-100-H-1L | 21.56 | 21 | 0.0061 | 23 | |

| SQ-100-H-2L | 23.11 | 30 | 0.0068 | 38 | |

| SQ-100-H-3L | 24.44 | 38 | 0.0082 | 65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suparp, S.; Ali, N.; Al Zand, A.W.; Chaiyasarn, K.; Rashid, M.U.; Yooprasertchai, E.; Hussain, Q.; Joyklad, P. Axial Load Enhancement of Lightweight Aggregate Concrete (LAC) Using Environmentally Sustainable Composites. Buildings 2022, 12, 851. https://doi.org/10.3390/buildings12060851

Suparp S, Ali N, Al Zand AW, Chaiyasarn K, Rashid MU, Yooprasertchai E, Hussain Q, Joyklad P. Axial Load Enhancement of Lightweight Aggregate Concrete (LAC) Using Environmentally Sustainable Composites. Buildings. 2022; 12(6):851. https://doi.org/10.3390/buildings12060851

Chicago/Turabian StyleSuparp, Suniti, Nazam Ali, Ahmed W. Al Zand, Krisada Chaiyasarn, Muhammad Usman Rashid, Ekkachai Yooprasertchai, Qudeer Hussain, and Panuwat Joyklad. 2022. "Axial Load Enhancement of Lightweight Aggregate Concrete (LAC) Using Environmentally Sustainable Composites" Buildings 12, no. 6: 851. https://doi.org/10.3390/buildings12060851

APA StyleSuparp, S., Ali, N., Al Zand, A. W., Chaiyasarn, K., Rashid, M. U., Yooprasertchai, E., Hussain, Q., & Joyklad, P. (2022). Axial Load Enhancement of Lightweight Aggregate Concrete (LAC) Using Environmentally Sustainable Composites. Buildings, 12(6), 851. https://doi.org/10.3390/buildings12060851