Toughness, Reinforcing Mechanism, and Durability of Hybrid Steel Fiber Reinforced Sulfoaluminate Cement Composites

Abstract

:1. Introduction

2. Materials and Methods

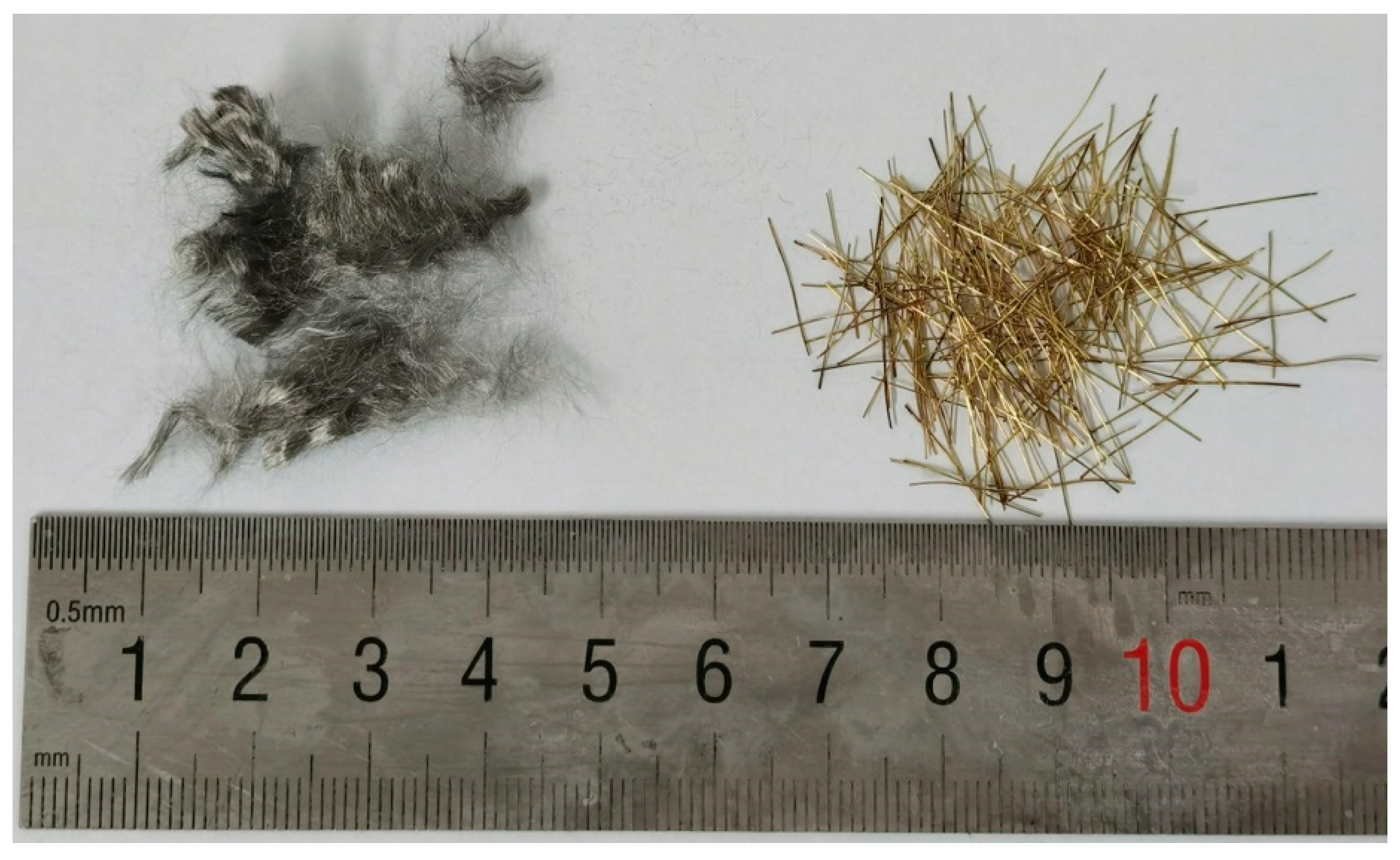

2.1. Materials

2.2. Mix Proportions and Methods

3. Results and Analysis

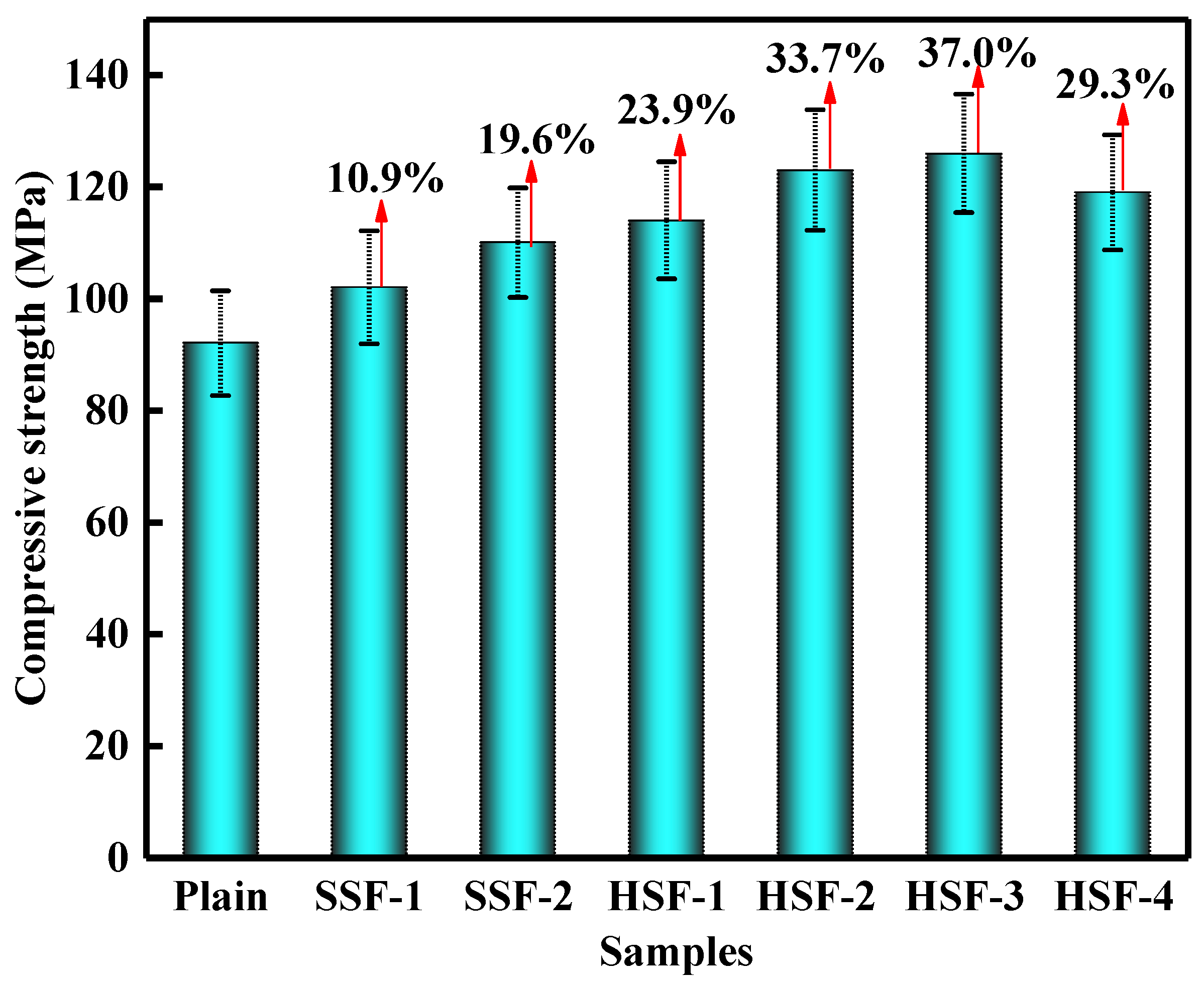

3.1. Compressive Strength

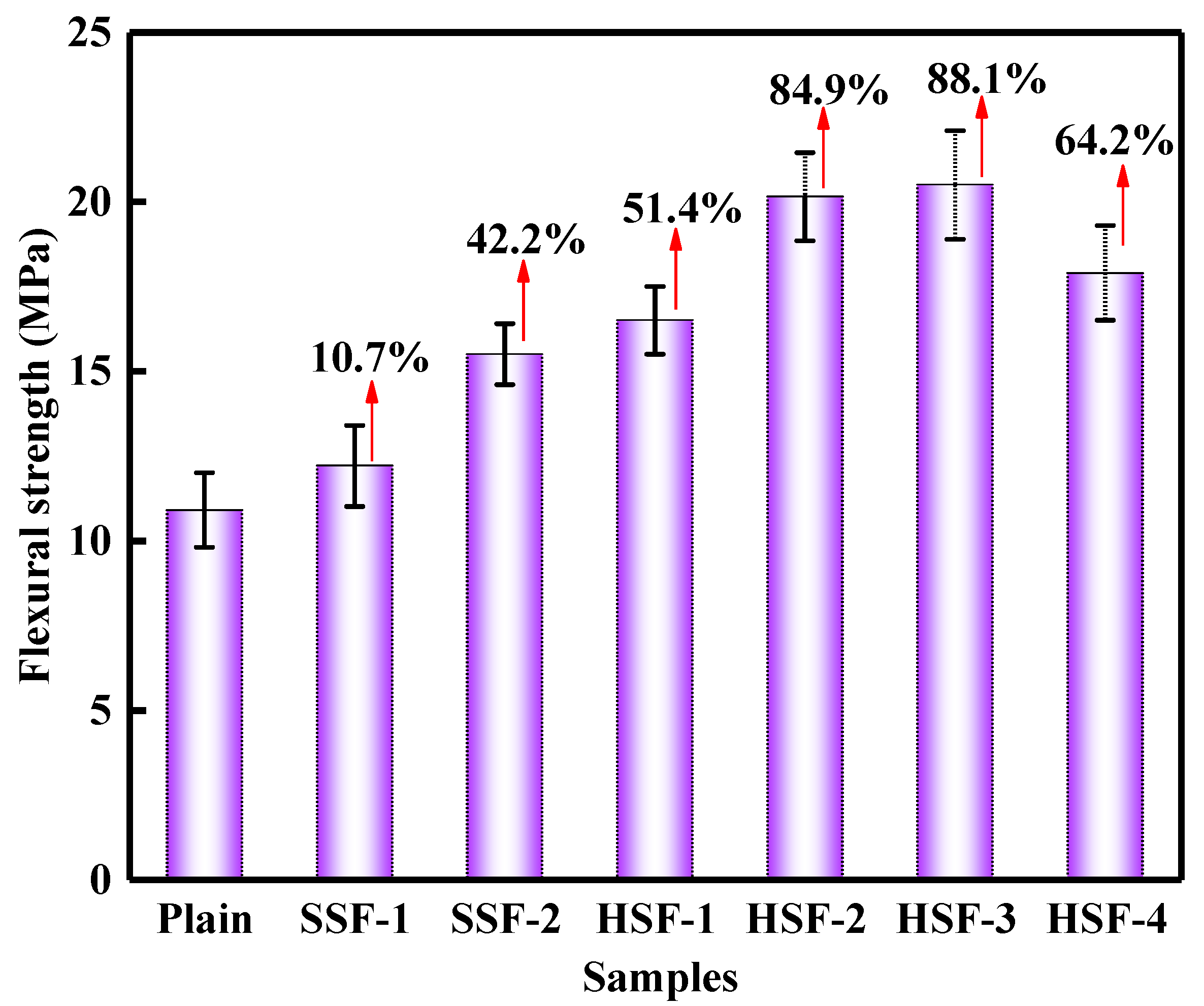

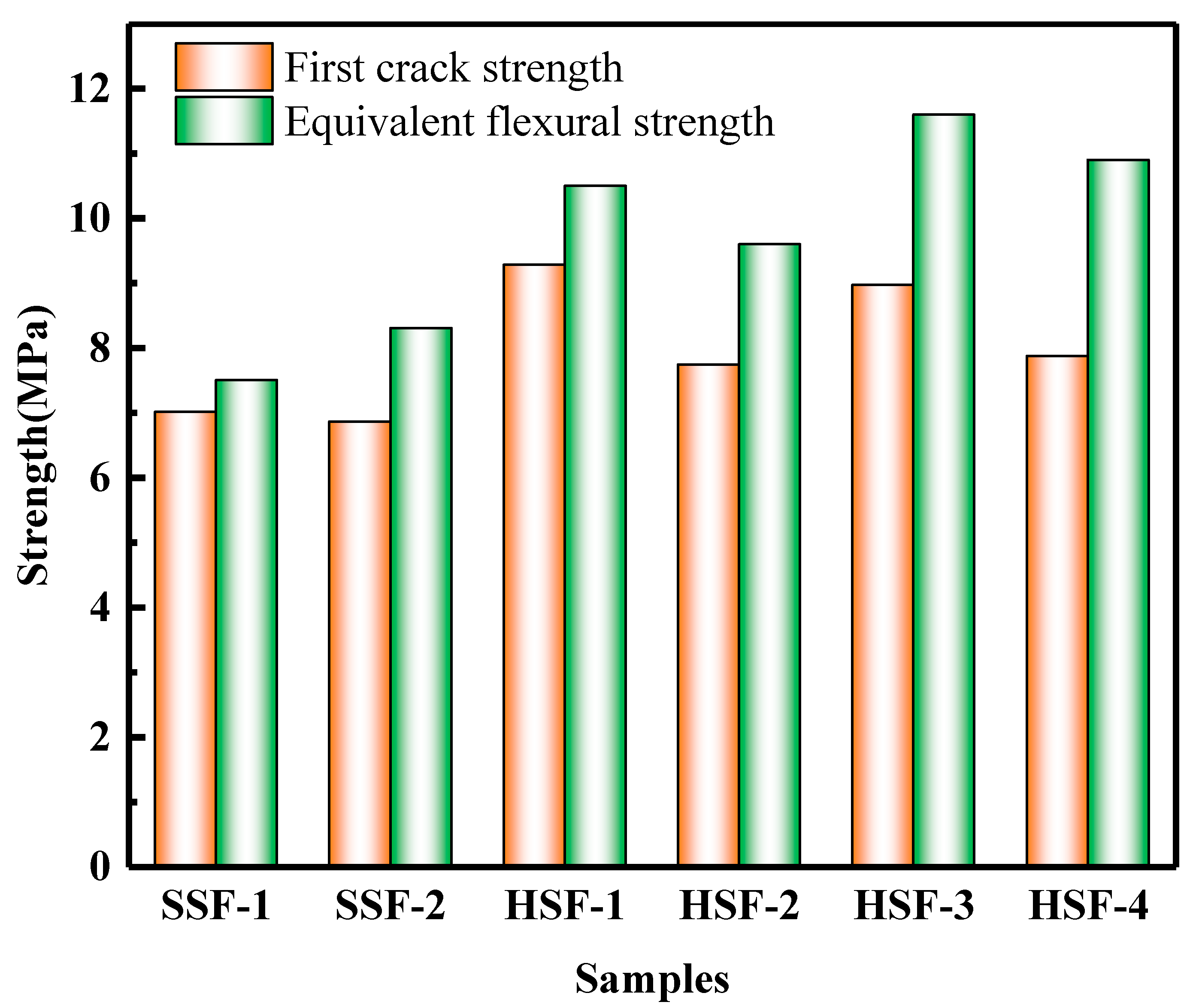

3.2. Flexural Strength

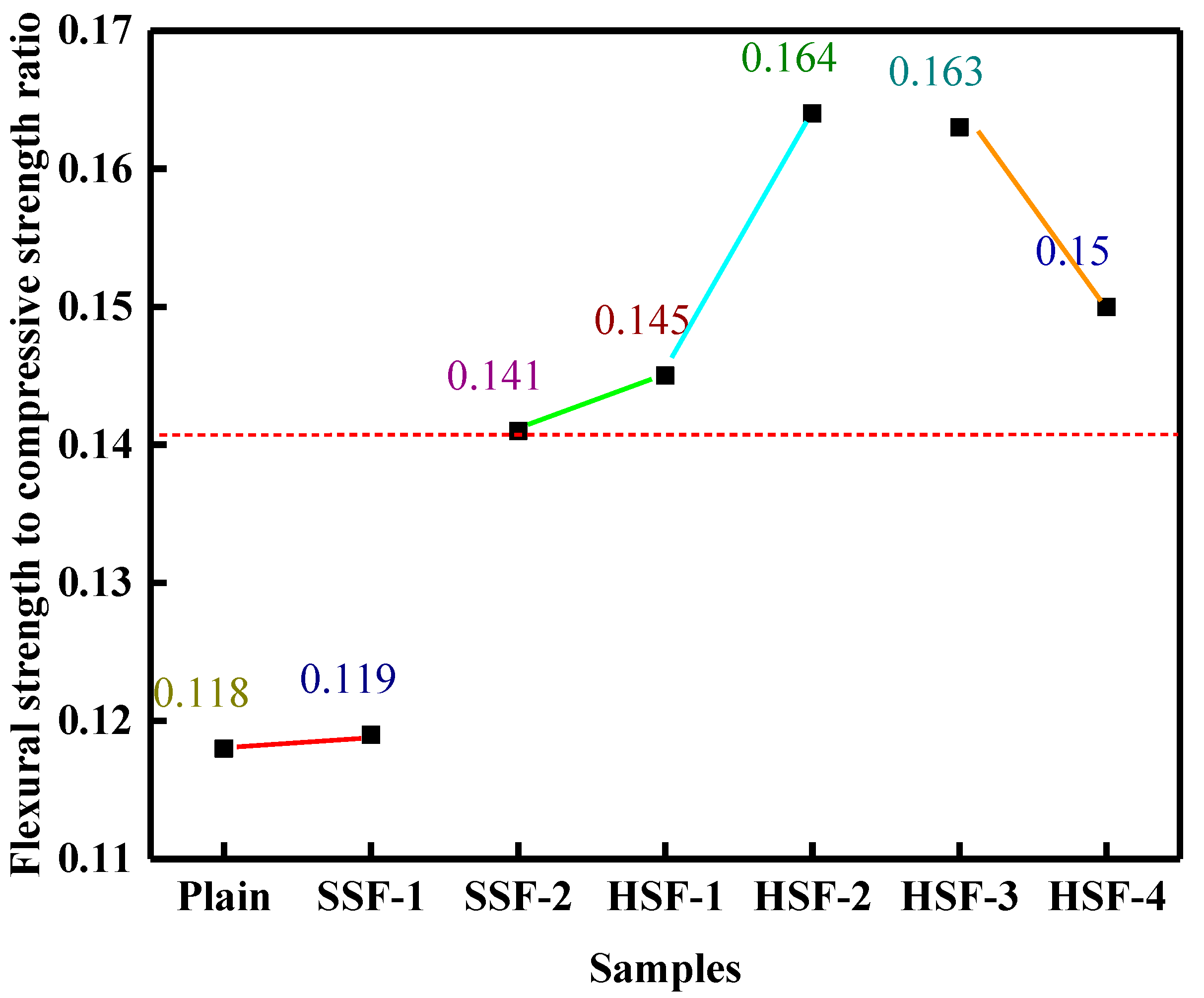

3.3. Flexural Strength to Compressive Strength Ratio

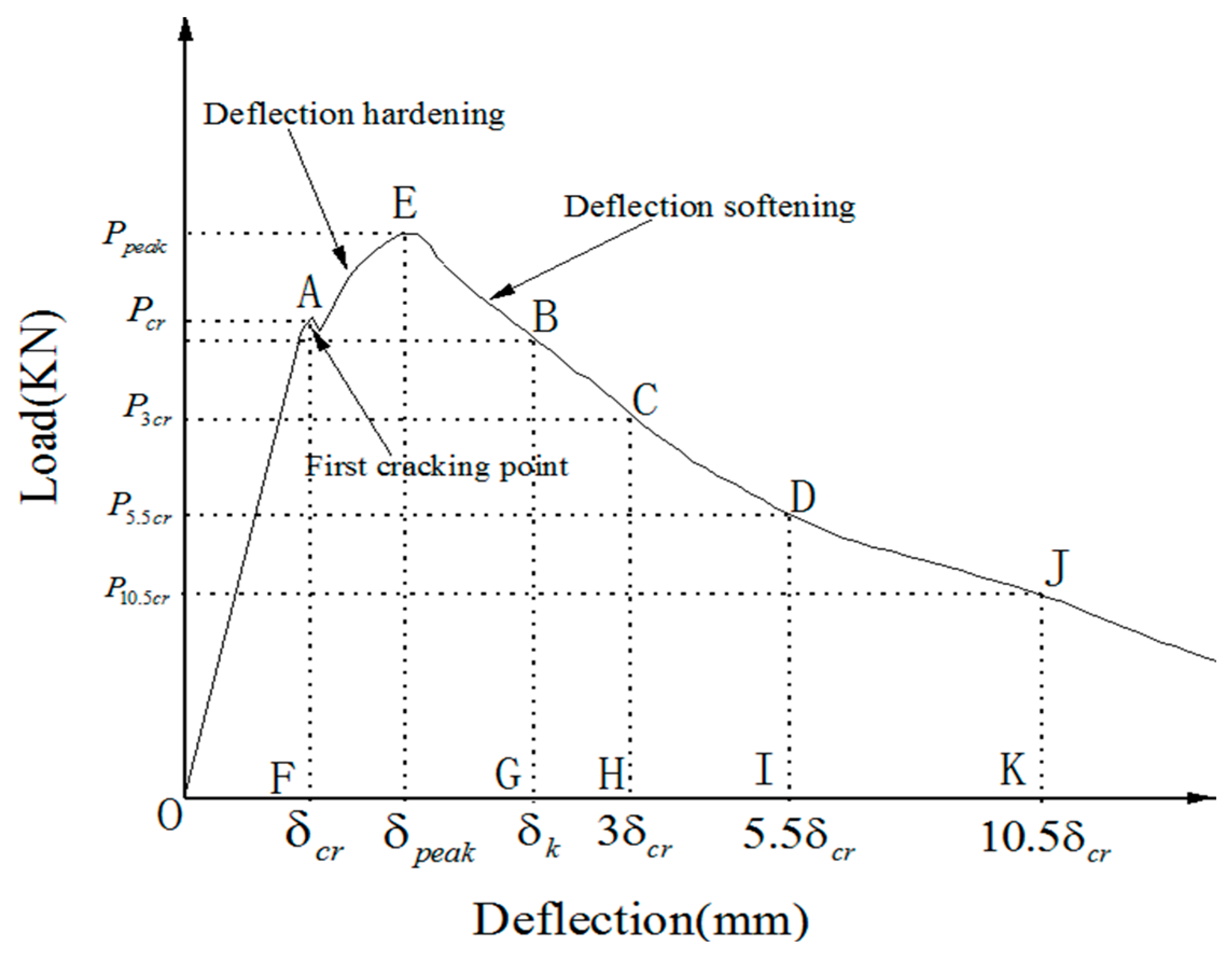

3.4. Toughness

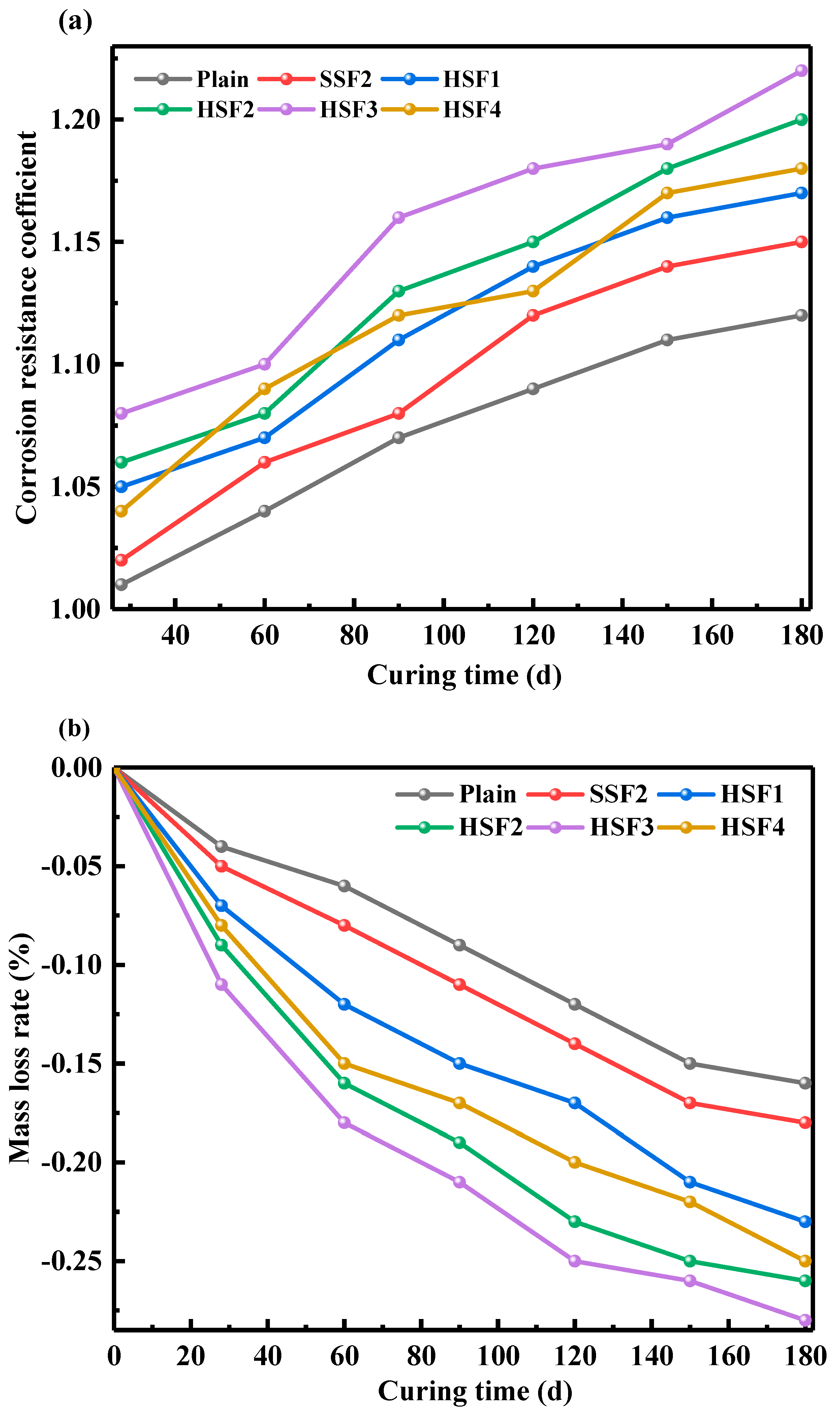

3.5. Resistance to Sulfate Erosion

- 1.

- Corrosion resistant coefficient:

- 2.

- Mass-loss rate:

4. Conclusions

- Adding MSF and HSF can significantly improve concrete’s compressive and flexural strength compared with the Plain group.

- Compared with the Plain group, the compressive strength of SSF1 (1% MSF) and SSF2 (1.5% MSF) increased by 10.9%, 19.6%, and the compressive strength of HSF1 (0.1% mSF, 1.4% MSF), HSF2 (0.2% mSF, 1.3% MSF), HSF3 (0.3% mSF, 1.2% MSF), HSF4 (0.5% mSF, 1.0% MSF) increased by 23.9%, 33.7%, 37.0%, 29.3%, respectively.

- Compared with the Plain group, the flexural strength of HSF1, HSF2, HSF3, HSF4 groups increased by 51.4%, 84.9%, 88.1%, and 64.2%.

- Compared with the SSF group, the HSF group has higher initial crack strength and equivalent flexural strength, toughness index, and toughness ratio. Hybrid fibers have a higher synergistic effect.

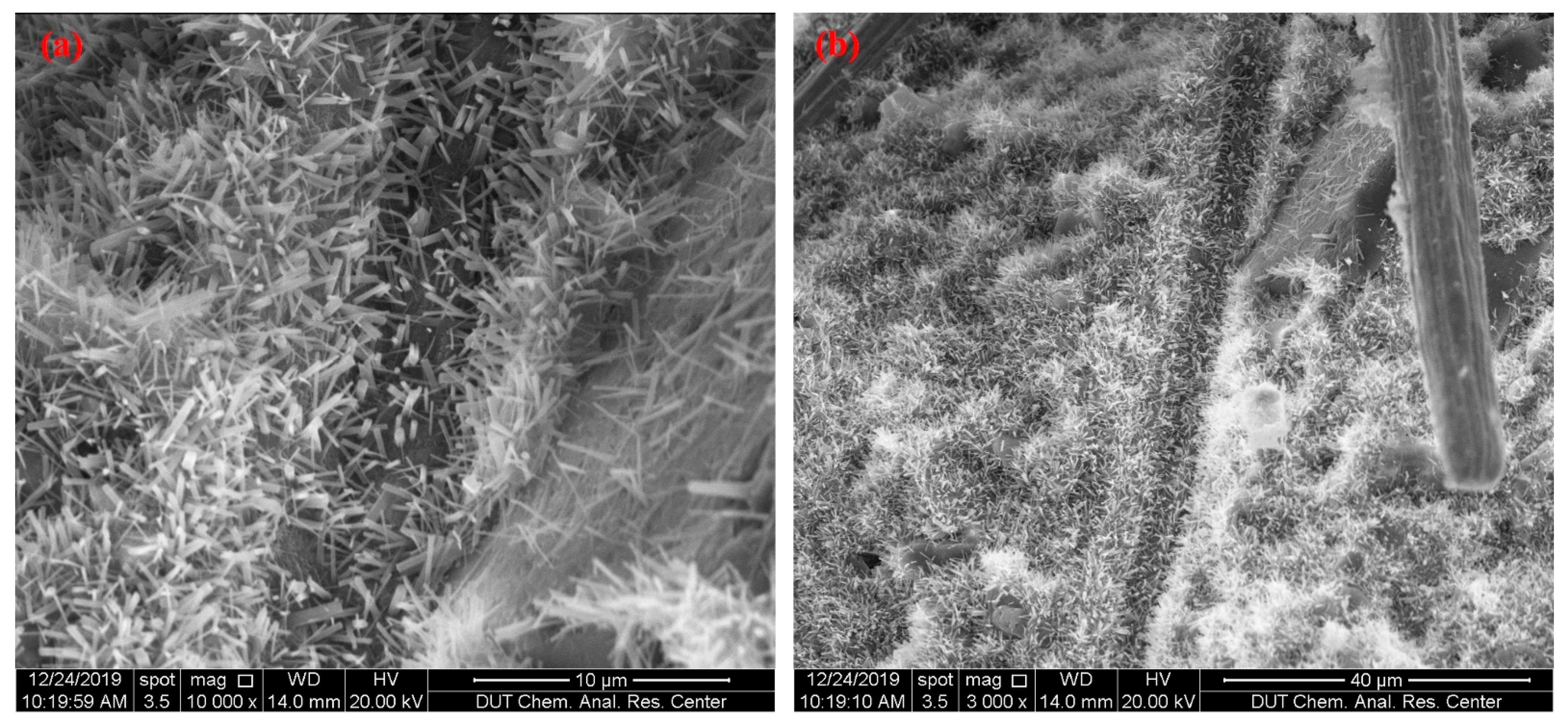

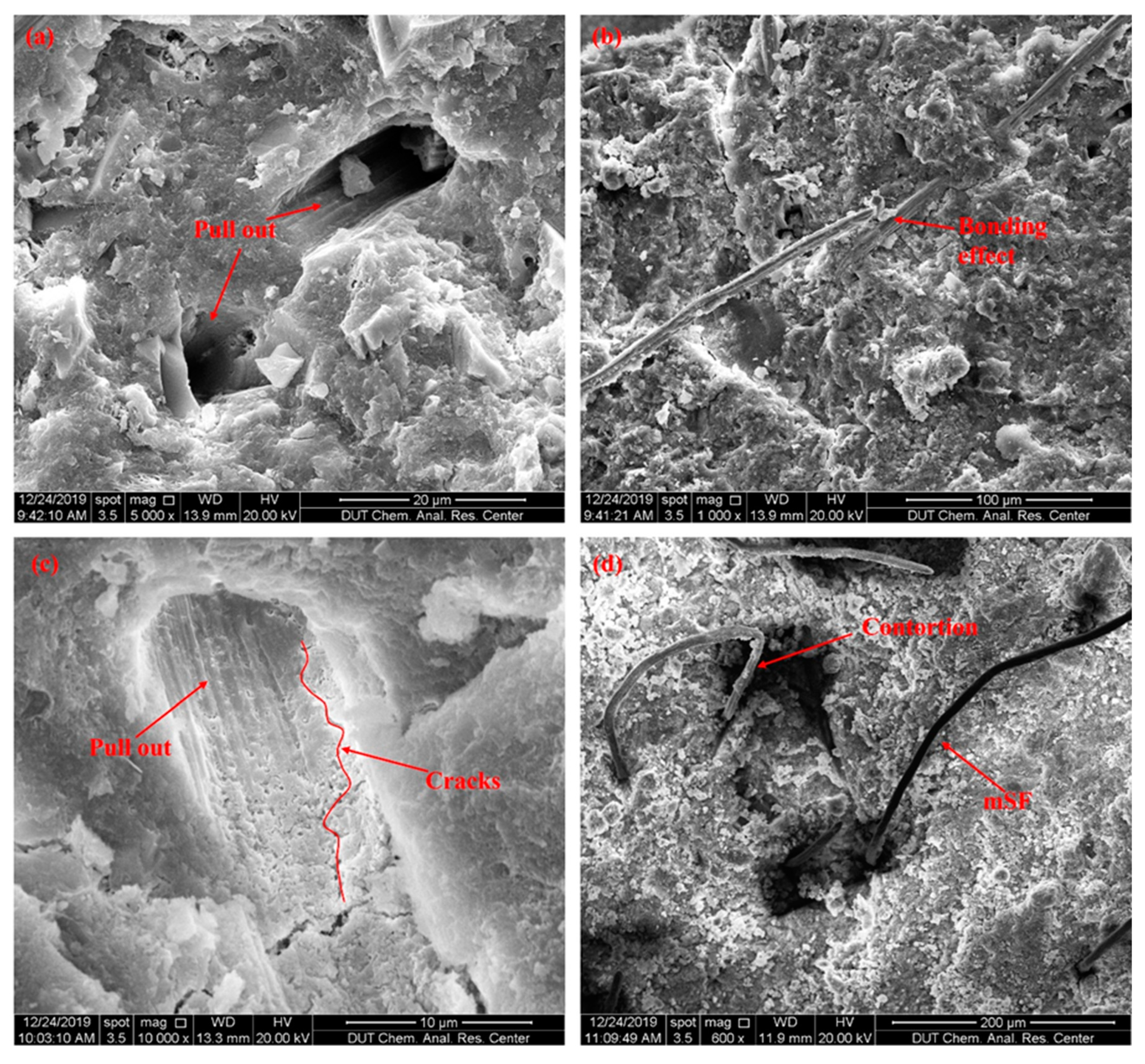

- The mechanism of multi-scale reinforcement of hybrid steel fibers enhances sulfoaluminate cement-based composites: mSF bridges micro-cracks, MSF bridges macro-cracks, and two different scales of steel fibers, through filling, bridging, anchoring, pulling off, and pulling out, improve the toughness of composite materials.

- The mechanism of sulfate corrosion resistance of sulfoaluminate cement-based composites was obtained. SO42− entered the matrix and reacted and formed AFt, filling the matrix’s pores. The whole process is similar to the self-healing process of concrete.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Fu, C.; Ye, H.; Wang, K.; Zhu, K.; He, C. Evolution of mechanical properties of steel fiber-reinforced rubberized concrete (FR-RC). Compos. Part B Eng. 2019, 160, 158–166. [Google Scholar] [CrossRef]

- Cui, K.; Liang, K.; Chang, J.; Lau, D. Investigation of the macro performance, mechanism, and durability of multiscale steel fiber reinforced low-carbon ecological UHPC. Constr. Build. Mater. 2022, 327, 126921. [Google Scholar] [CrossRef]

- Bencardino, F.; Rizzuti, L.; Spadea, G.; Swamy, R.N. Experimental evaluation of fiber reinforced concrete fracture properties. Compos. Part B Eng. 2010, 41, 17–24. [Google Scholar] [CrossRef]

- Lee, J. Influence of concrete strength combined with fiber content in the residual flexural strengths of fiber reinforced concrete. Compos. Struct. 2017, 168, 216–225. [Google Scholar] [CrossRef]

- Sirijaroonchai, K.; El-Tawil, S.; Parra-Montesinos, G. Behavior of high performance fiber reinforced cement composites under multi-axial compressive loading. Cem. Concr. Compos. 2010, 32, 62–72. [Google Scholar] [CrossRef]

- Kazemi, M.T.; Golsorkhtabar, H.; Beygi, M.H.A.; Gholamitabar, M. Fracture properties of steel fiber reinforced high strength concrete using work of fracture and size effect methods. Constr. Build. Mater. 2017, 142, 482–489. [Google Scholar] [CrossRef]

- Cui, K.; Chang, J.; Feo, L.; Chow, C.L.; Lau, D. Developments and Applications of Carbon Nanotube Reinforced Cement-Based Composites as Functional Building Materials. Front. Mater. 2022, 9, 146. [Google Scholar] [CrossRef]

- Cui, K.; Lau, D.; Zhang, Y.; Chang, J. Mechanical properties and mechanism of nano-CaCO3 enhanced sulphoaluminate cement-based reactive powder concrete. Constr. Build Mater. 2021, 309, 125099. [Google Scholar] [CrossRef]

- Du, Y.; Yang, J.; Skariah Thomas, B.; Li, L.; Li, H.; Mohamed Shaban, W.; Wai, T. Influence of hybrid graphene oxide/carbon nanotubes on the mechanical properties and microstructure of magnesium potassium phosphate cement paste. Constr. Build. Mater. 2020, 260, 120449. [Google Scholar] [CrossRef]

- Mansouri Sarvandani, M.; Mahdikhani, M.; Aghabarati, H.; Haghparast Fatmehsari, M. Effect of functionalized multi-walled carbon nanotubes on mechanical properties and durability of cement mortars. J. Build. Eng. 2021, 41, 102407. [Google Scholar] [CrossRef]

- Jung, M.; Lee, Y.; Hong, S.; Moon, J. Carbon nanotubes (CNTs) in ultra-high performance concrete (UHPC): Dispersion, mechanical properties, and electromagnetic interference (EMI) shielding effectiveness (SE). Cem. Concr. Res. 2020, 131, 106017. [Google Scholar] [CrossRef]

- Cui, K.; Chang, J. Hydration, reinforcing mechanism, and macro performance of multi-layer graphene-modified cement composites. J. Build. Eng. 2022, 57, 104880. [Google Scholar] [CrossRef]

- Cui, K.; Chang, J.; Sabri, M.M.S.; Huang, J. Influence of Graphene Nanoplates on Dispersion, Hydration Behavior of Sulfoaluminate Cement Composites. Materials 2022, 15, 5357. [Google Scholar] [CrossRef]

- Cui, K.; Chang, J.; Sabri, M.M.S.; Huang, J. Study of Dispersion, Hydration, and Microstructure of Graphene Nanoplates-Modified Sulfoaluminate Cement Paste. Nanomaterials 2022, 12, 2708. [Google Scholar] [CrossRef]

- Matalkah, F.; Soroushian, P. Graphene nanoplatelet for enhancement the mechanical properties and durability characteristics of alkali activated binder. Constr. Build. Mater. 2020, 249, 118773. [Google Scholar] [CrossRef]

- Gong, P.; Zhang, C.; Wu, Z.; Zhang, G.; Mei, K.; Gao, Q.; Cheng, X. Study on the effect of CaCO3 whiskers on carbonized self-healing cracks of cement paste: Application in CCUS cementing. Constr. Build. Mater. 2022, 321, 126368. [Google Scholar] [CrossRef]

- Li, M.; Yang, Y.; Liu, M.; Guo, X.; Zhou, S. Hybrid effect of calcium carbonate whisker and carbon fiber on the mechanical properties and microstructure of oil well cement. Constr. Build. Mater. 2015, 93, 995–1002. [Google Scholar] [CrossRef]

- Kim, G.M.; Yang, B.J.; Yoon, H.N.; Lee, H.K. Synergistic effects of carbon nanotubes and carbon fibers on heat generation and electrical characteristics of cementitious composites. Carbon 2018, 134, 283–292. [Google Scholar] [CrossRef]

- Stynoski, P.; Mondal, P.; Marsh, C. Effects of silica additives on fracture properties of carbon nanotube and carbon fiber reinforced Portland cement mortar. Cem. Concr. Compos. 2015, 55, 232–240. [Google Scholar] [CrossRef]

- Zhou, A.; Qiu, Q.; Chow, C.L.; Lau, D. Interfacial performance of aramid, basalt and carbon fiber reinforced polymer bonded concrete exposed to high temperature. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105802. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Abbass, W.; Khan, M.I.; Mourad, S. Evaluation of mechanical properties of steel fiber reinforced concrete with different strengths of concrete. Constr. Build. Mater. 2018, 168, 556–569. [Google Scholar] [CrossRef]

- Mohod, A.V.; Gogate, P.R. Ultrasonic degradation of polymers: Effect of operating parameters and intensification using additives for carboxymethyl cellulose (CMC) and polyvinyl alcohol (PVA). Ultrason. Sonochem. 2011, 18, 727–734. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Qin, J.; Qian, J.; Li, Z.; You, C.; Dai, X.; Yue, Y.; Fan, Y. Mechanical properties of basalt fiber reinforced magnesium phosphate cement composites. Constr. Build. Mater. 2018, 188, 946–955. [Google Scholar] [CrossRef]

- Yu, S.; Bale, H.; Park, S.; Hwang, J.Y.; Hong, S.H. Anisotropic microstructure dependent mechanical behavior of 3D-printed basalt fiber-reinforced thermoplastic composites. Compos. Part B Eng. 2021, 224, 109184. [Google Scholar] [CrossRef]

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Constr. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- Huang, L.; Xu, L.; Chi, Y.; Xu, H. Experimental investigation on the seismic performance of steel–polypropylene hybrid fiber reinforced concrete columns. Constr. Build. Mater. 2015, 87, 16–27. [Google Scholar] [CrossRef]

- Banthia, N.; Majdzadeh, F.; Wu, J.; Bindiganavile, V. Fiber synergy in Hybrid Fiber Reinforced Concrete (HyFRC) in flexure and direct shear. Cem. Concr. Compos. 2014, 48, 91–97. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C. How do fiber shape and matrix composition affect fiber pullout behavior and flexural properties of UHPC? Cem. Concr. Compos. 2018, 90, 193–201. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L. Flexural performance and evaluation method of steel fiber reinforced recycled coarse aggregate concrete. Constr. Build. Mater. 2018, 159, 126–136. [Google Scholar] [CrossRef]

- Chang, J.; Cui, K.; Zhang, Y. Effect of hybrid steel fibers on the mechanical performances and microstructure of sulphoaluminate cement-based reactive powder concrete. Constr. Build. Mater. 2020, 261, 120502. [Google Scholar] [CrossRef]

| Type | Fe2O3 | Al2O3 | CaO | SO3 | MgO | SiO2 | TiO2 |

|---|---|---|---|---|---|---|---|

| SAC | 2.15 | 16.34 | 46.08 | 12.45 | 2.52 | 19.15 | 1.31 |

| SF | 0.64 | 0.71 | 0.11 | 0.15 | 0.13 | 94.36 | -- |

| Group | w/b | Cement | Silica Fume | Water | Sand | mSF (%) | MSF (%) | SP |

|---|---|---|---|---|---|---|---|---|

| Plain | 0.34 | 1 | 0.15 | 0.391 | 1.1 | 0 | 0 | 2% |

| SSF-1 | 0.34 | 1 | 0.15 | 0.391 | 1.1 | 0 | 1% | 2% |

| SSF-2 | 0.34 | 1 | 0.15 | 0.391 | 1.1 | 0 | 1.5% | 2% |

| HSF-1 | 0.34 | 1 | 0.15 | 0.391 | 1.1 | 0.1% | 1.4% | 2% |

| HSF-2 | 0.34 | 1 | 0.15 | 0.391 | 1.1 | 0.2% | 1.3% | 2% |

| HSF-3 | 0.34 | 1 | 0.15 | 0.391 | 1.1 | 0.3% | 1.2% | 2% |

| HSF-4 | 0.34 | 1 | 0.15 | 0.391 | 1.1 | 0.5% | 1.0% | 2% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, K.; Chang, J.; Sabri, M.M.S.; Huang, J. Toughness, Reinforcing Mechanism, and Durability of Hybrid Steel Fiber Reinforced Sulfoaluminate Cement Composites. Buildings 2022, 12, 1243. https://doi.org/10.3390/buildings12081243

Cui K, Chang J, Sabri MMS, Huang J. Toughness, Reinforcing Mechanism, and Durability of Hybrid Steel Fiber Reinforced Sulfoaluminate Cement Composites. Buildings. 2022; 12(8):1243. https://doi.org/10.3390/buildings12081243

Chicago/Turabian StyleCui, Kai, Jun Chang, Mohanad Muayad Sabri Sabri, and Jiandong Huang. 2022. "Toughness, Reinforcing Mechanism, and Durability of Hybrid Steel Fiber Reinforced Sulfoaluminate Cement Composites" Buildings 12, no. 8: 1243. https://doi.org/10.3390/buildings12081243

APA StyleCui, K., Chang, J., Sabri, M. M. S., & Huang, J. (2022). Toughness, Reinforcing Mechanism, and Durability of Hybrid Steel Fiber Reinforced Sulfoaluminate Cement Composites. Buildings, 12(8), 1243. https://doi.org/10.3390/buildings12081243