Experimental Investigations on Heat Transfer Characteristics of Direct Contact Liquid Cooling for CPU

Abstract

:1. Introduction

2. Materials and Methods

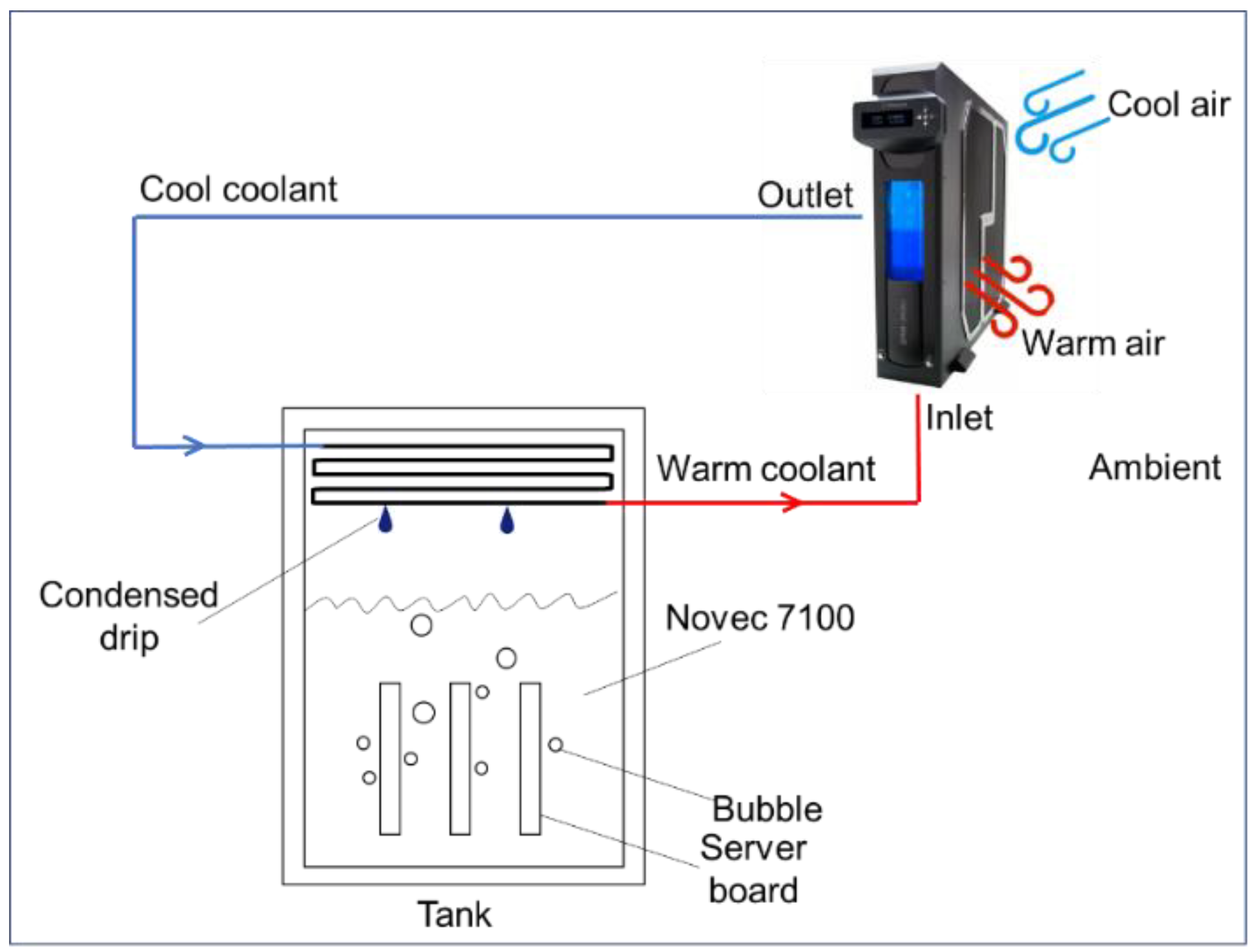

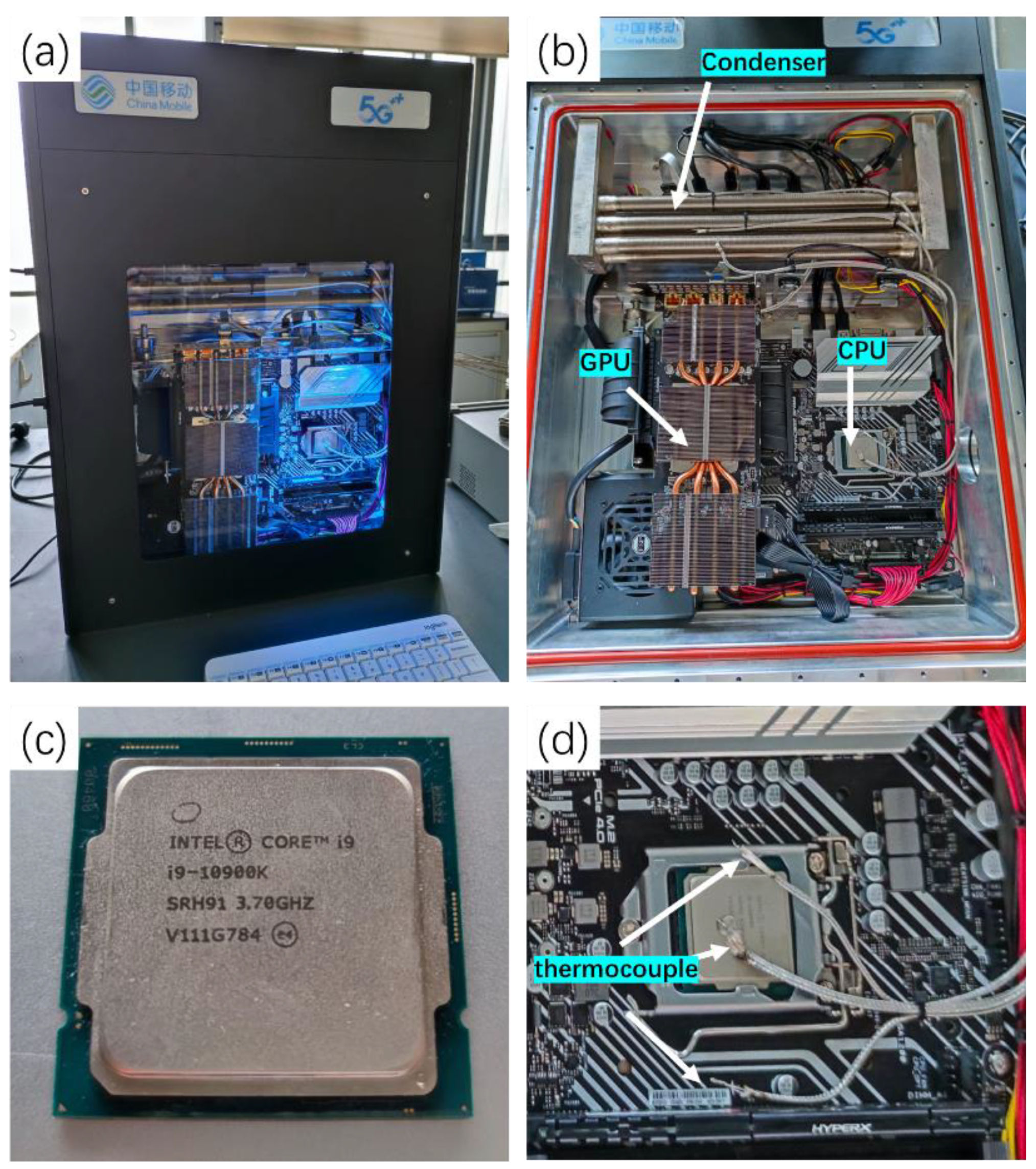

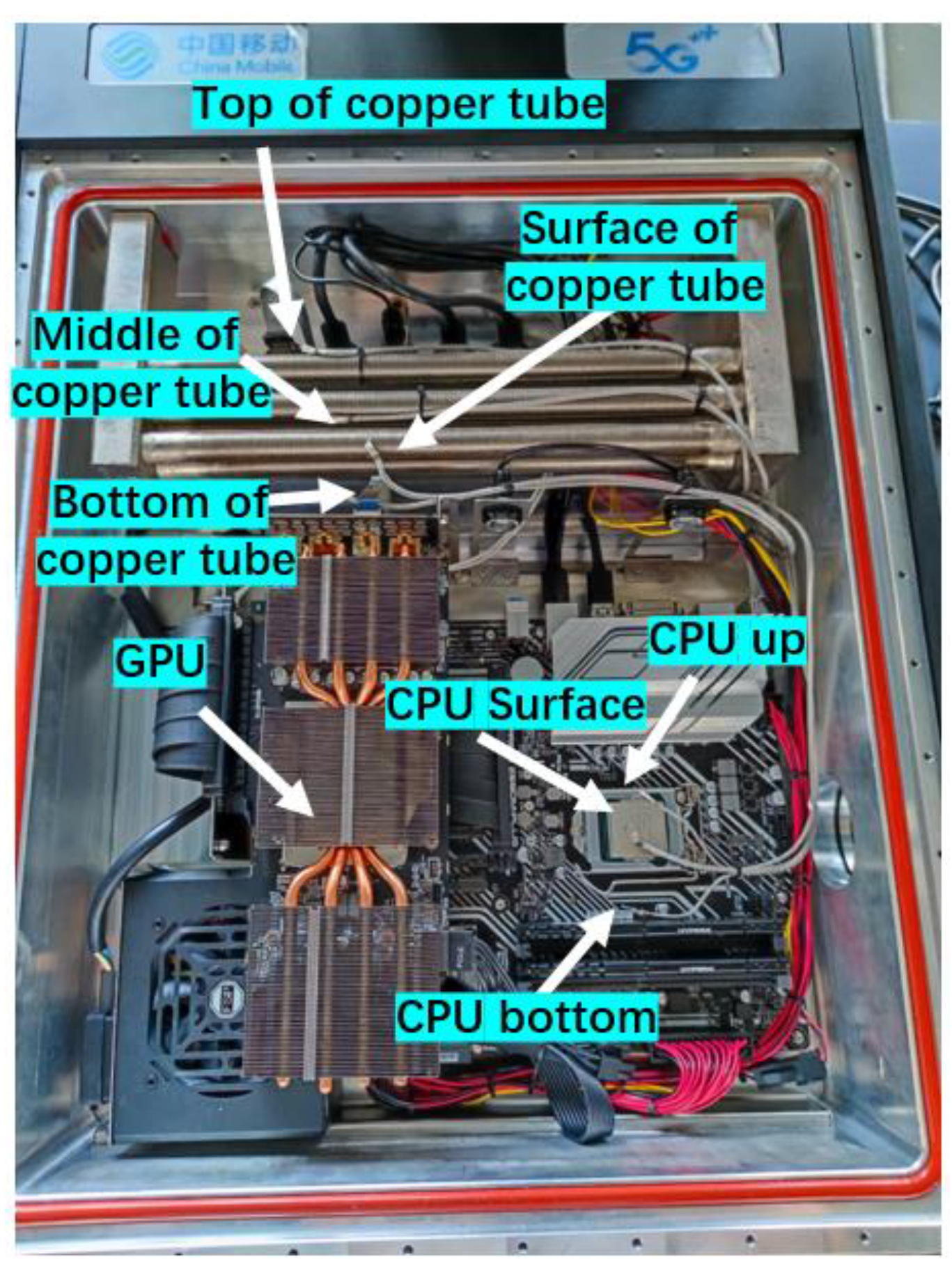

2.1. Structure of System

2.2. Experimental Study

3. Results and Discussion

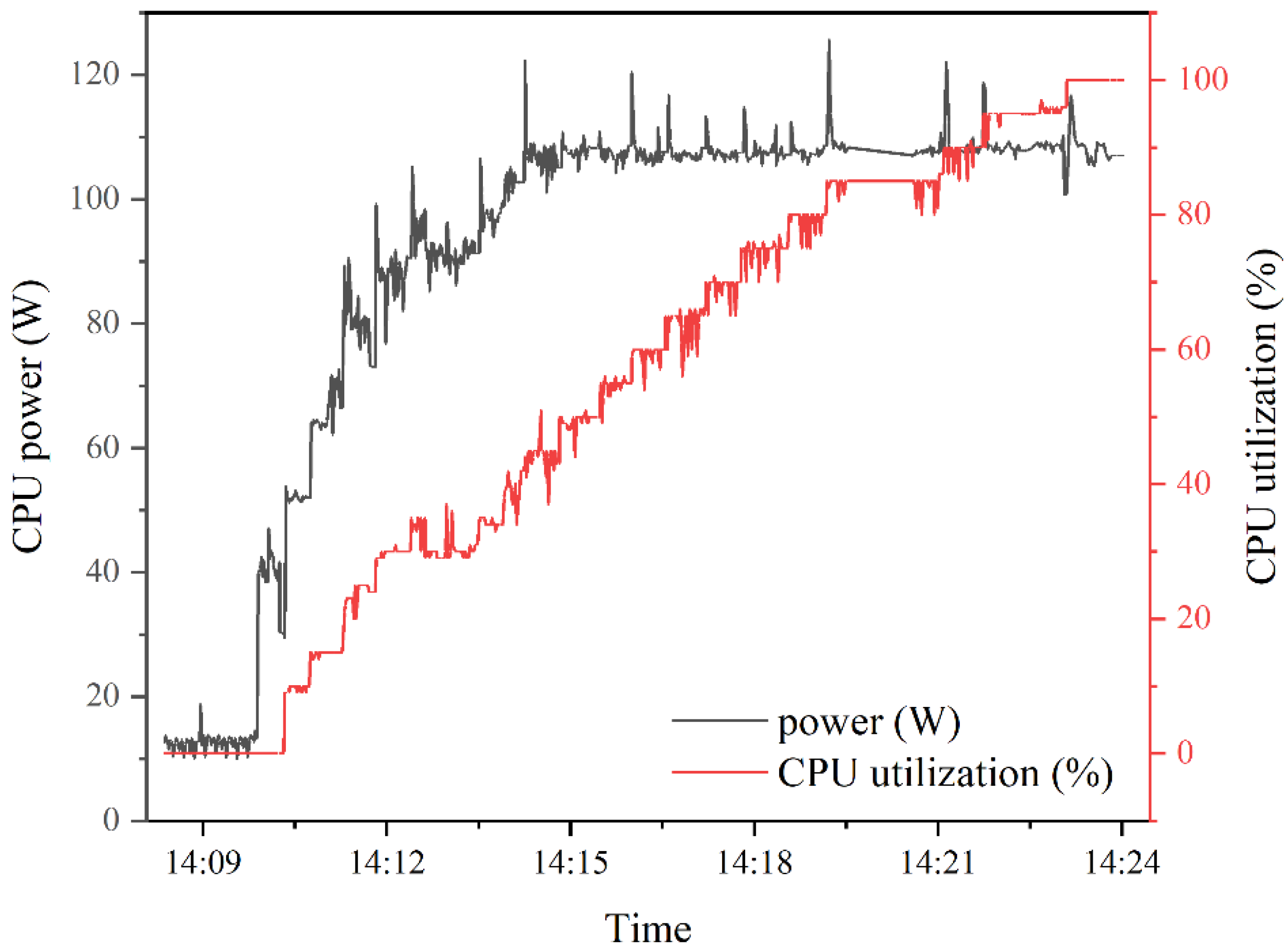

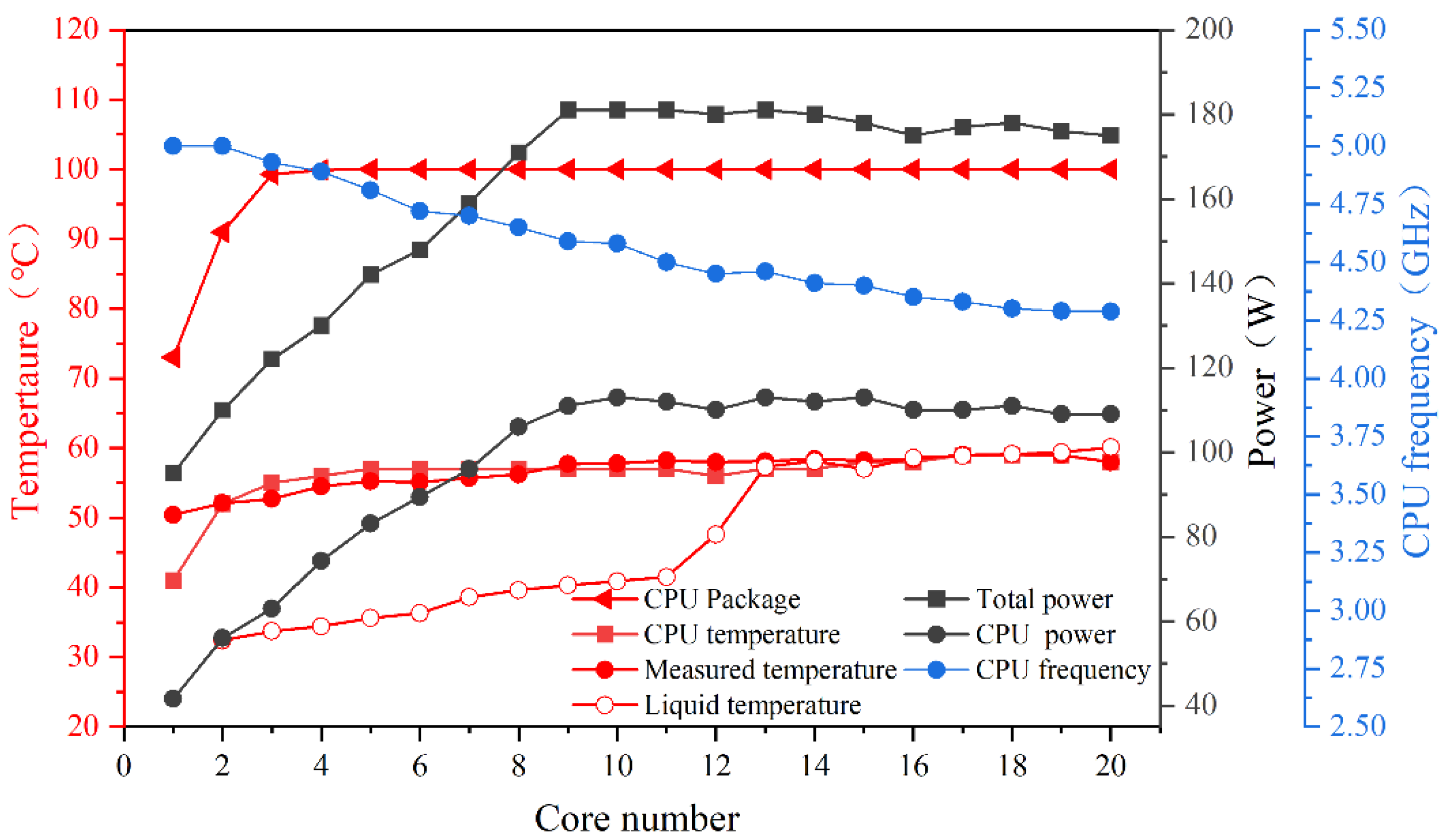

3.1. CPU Direct Contact Boiling Heat Exchange

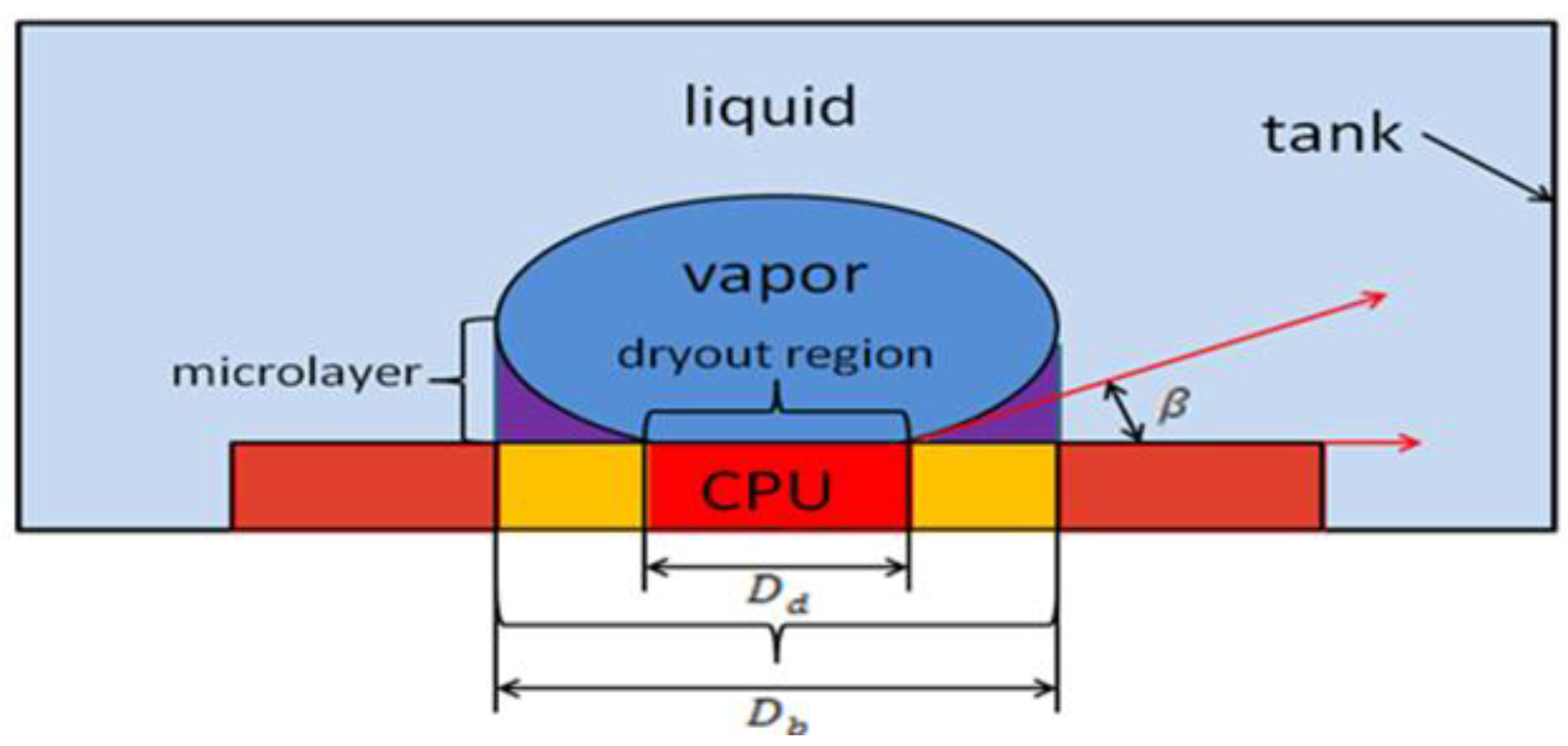

3.2. HTC Correlation Equation of Boiling Heat Transfer Considering Surface Characteristics

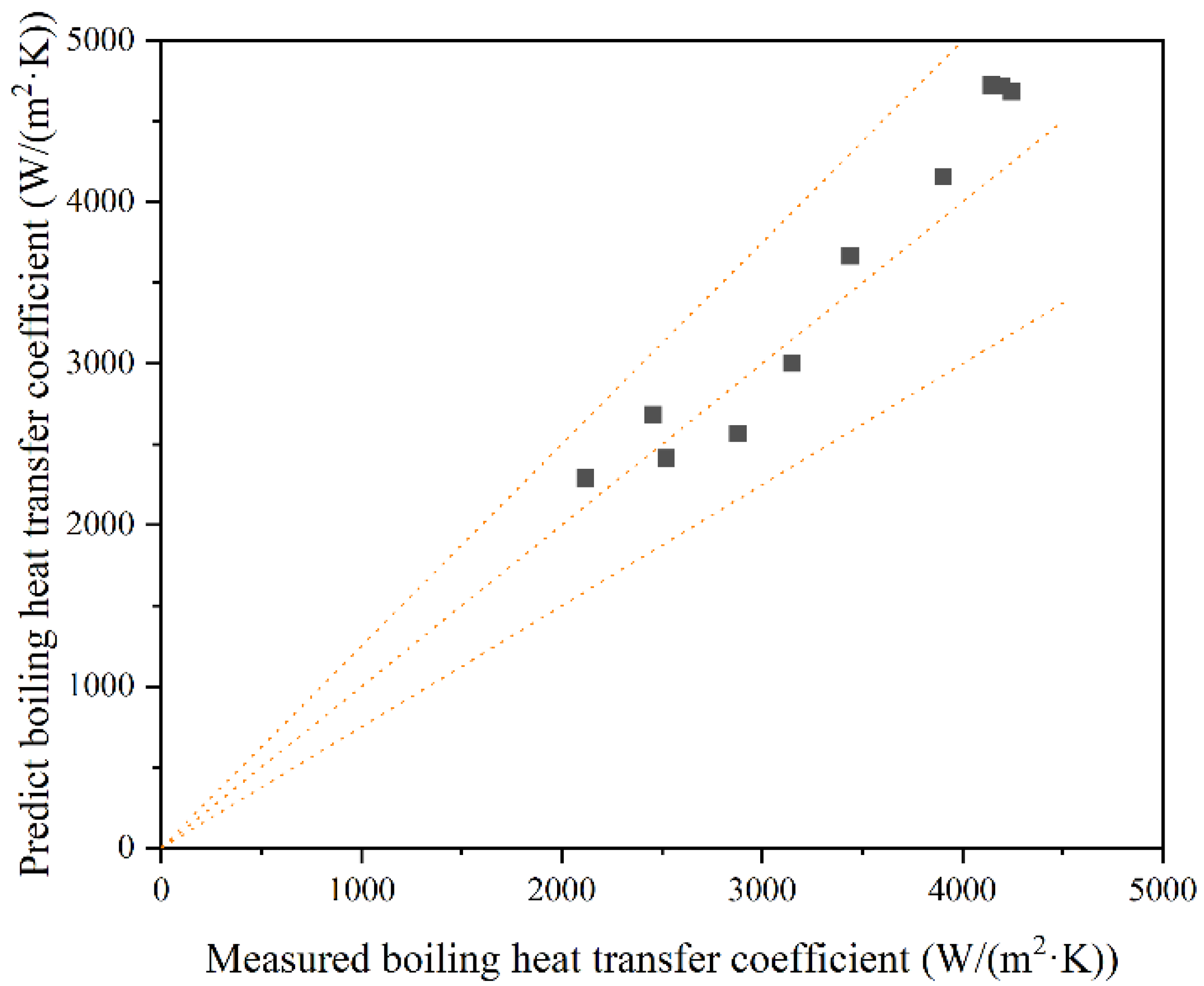

3.3. Comparison of HTC Boiling Heat Transfer Correlation Equations

3.4. pPUE of the System

4. Conclusions

- The pPUE of this system ranged from 1.035 to 1.037; the cooling system operated within the desired high-efficiency range, and the average value was 1.036. This value is relatively smaller than that of typical air-cooled systems in data centers. The proposed CPU-immersion two-phase cooling system was, therefore, found to be more energy efficient. It can significantly reduce the energy consumption of data centers while conducting the heat dissipation of high-density CPUs. In addition, the outlet coolant temperature can be considerably high, which allows the supply of high-quality waste heat to be further used to enhance the efficiency of the entire system.

- The direct contact boiling heat exchange at the CPU was studied for CPU heat dissipation. Studies have shown that direct contact heat dissipation is suitable for supercomputer server CPU heat dissipation with low heat flux density; for high-density CPU heat dissipation, it is easy to reach the maximum temperature limit of the CPU, thereby reducing the frequency of the CPU (evidenced as a drop of 14.2% in this study).

- We proposed a qw-ΔTsat-like boiling curve for the heat transfer at the surface of the CPU, and the direct contact heat transfer boiling curve of the CPU differed from the conventional boiling curve. The frequency of the CPU decreased due to the influence of temperature, and the increase in CPU power results in a decrease in superheat, which once again demonstrates the impact of the dynamic adjustment of the CPU on the boiling heat transfer.

- Through research on the theoretical relationship of boiling heat transfer, we derived an improved theoretical equation for boiling heat transfer which was in good agreement with the measured values, with the difference between the measured and predicted values being 8.72%. The proposed HTC equation does not need to query the value of the index n corresponding to the selected liquid or the heating surface combination coefficients Csf and Pr.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| PUE | Power usage effectiveness |

| pPUE | Partial power usage effectiveness |

| COP | Coefficient performance |

| ICT | Information communication technology |

| t | Temperature (K) |

| DC | Data center |

| IT | Internet technology |

| AC | Air conditioning |

| HTC/h | Heat transfer coefficient |

| CHF | Critical heat flux |

| Cs | Comprehensive influence parameter |

| Pr | Prandtl number |

| θ | Solid–liquid contact angle |

| Ra | Surface roughness |

| γ | Surface material influence parameter |

| Wserver | Power of server (W) |

| Wtotal | Power total cooling (W) |

| tpackage | Temperature of the die |

| q | Heat exchange/power (W) |

| λ | Thermal conductivity |

| d | Thickness (m) |

| μ | Dynamic viscosity (Pa s) |

| μi | Velocity component in the xi direction (m/s) |

| μj | Velocity component in the xj direction (m/s) |

| μturb | Turbulent viscosity (Pa s) |

| ρ | Density (kg/m3) |

| m | Mass flow (kg/s) |

| σ | Surface tension (N/m) |

| σc | Condensation coefficient |

| σe | Evaporation coefficient |

| k | Turbulent kinetic energy (m2/s2) |

| tboiling | Boiling point |

| 0 | Status at reference temperature |

| l | Fluid state |

| g | Vapor state |

| P | Power |

| u | Uncertainty |

Appendix A

| Temperature | Density | Viscosity | Dynamic Viscosity (kg/m s) | Kinematic Viscosity | Specific Heat | Thermal Conductivity | Saturated |

|---|---|---|---|---|---|---|---|

| Vapor | |||||||

| (°C) | (kg/m3) | (m2/s) | (m2)/s) | (J/kg K) | (W/m K) | Pressure (Pa) | |

| 0 | 1582.91 | 5.28 × 10−7 | 0.0008 | 0.835 | 1133 | 0.0737 | 8815.499 |

| 10 | 1555.99 | 4.6 × 10−7 | 0.0007 | 0.715 | 1153 | 0.0717 | 14,091.42 |

| 20 | 1529.07 | 4.05 × 10−7 | 0.0006 | 0.619 | 1173 | 0.0698 | 21,815.44 |

| 30 | 1502.15 | 3.61 × 10−7 | 0.0005 | 0.542 | 1193 | 0.0678 | 32,813.30 |

| 40 | 1475.23 | 3.24 × 10−7 | 0.0004 | 0.478 | 1213 | 0.0658 | 48,085.29 |

| 50 | 1448.31 | 2.94 × 10−7 | 0.0004 | 0.426 | 1233 | 0.0639 | 68,818.07 |

| 60 | 1421.39 | 2.69 × 10−7 | 0.0003 | 0.383 | 1253 | 0.0619 | 96,393.02 |

| 70 | 1394.47 | 2.49 × 10−7 | 0.0003 | 0.346 | 1273 | 0.06 | 132,391.102 |

References

- Król, A. The Application of the Artificial Intelligence Methods for Planning of the Development of the Transportation Network. Transp. Res. Procedia 2016, 14, 4532–4541. [Google Scholar] [CrossRef] [Green Version]

- Bae, J.S.; Yong, S.C.; Kim, J.S.; Min, Y.C. Architecture and performance evaluation of MmWave based 5G mobile communication system. In Proceedings of the 2014 International Conference on Information and Communication Technology Convergence (ICTC), Busan, Korea, 22–24 October 2014. [Google Scholar]

- Fei, T.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar]

- Malik, P.; Pathania, M.; Rathaur, V.K. Overview of artificial intelligence in medicine. J. Fam. Med. Prim. Care 2019, 8, 2328. [Google Scholar]

- Yang, Y.B. The Application Research of Data Mining Technique in Education. Comput. Sci. 2006, 33, 284–286. [Google Scholar]

- Meng, X.; Zhou, J.; Zhang, X.; Luo, Z.; Gan, T. Optimization of the thermal environment of a small-scale data center in China. Energy 2020, 196, 117080. [Google Scholar] [CrossRef]

- Petrovi, S.; Colangelo, A.; Balyk, O.; Delmastro, C.; Karlsson, K. The role of data centres in the future Danish energy system. Energy 2020, 194, 116928. [Google Scholar] [CrossRef]

- Weissberger, A. Synergy Research Group: Hyperscale Data Center Count >500 as of 3Q-2019. Available online: https://techblog.comsoc.org/2019/10/19/synergy-research-group-hyperscale-data-center-count-500-as-of-3q-2019/ (accessed on 19 October 2019).

- Andrae, A.S.G. Total Consumer Power Consumption Forecast. Available online: https://10times.com/nordic-digital-business-summit (accessed on 1 October 2017).

- Chen, M.; Gao, C.; Song, M.; Chen, S.; Liu, Q. Internet data centers participating in demand response: A comprehensive review. Renew. Sustain. Energy Rev. 2020, 117, 109466. [Google Scholar] [CrossRef]

- Li, J.; Jurasz, J.; Li, H.; Tao, W.Q.; Duan, Y.; Yan, J. A new indicator for a fair comparison on the energy performance of data centers. Appl. Energy 2020, 276, 115497. [Google Scholar] [CrossRef]

- Lei, N.; Masanet, E. Statistical analysis for predicting location-specific data center PUE and its improvement potential. Energy 2020, 201, 117556. [Google Scholar] [CrossRef]

- Greenpeace. Potential Analysis on Energy Consumption of Data Centers and Renewable Energy in China 2019. Available online: https://www.greenpeace.org.cn/china-data-center-electricity-consumption-and-renewable-energy/ (accessed on 9 September 2019).

- Jin, C.; Bai, X.; Yang, C.; Mao, W.; Xu, X. A review of power consumption models of servers in data centers. Appl. Energy 2020, 265, 114806. [Google Scholar] [CrossRef]

- Zimmermann, S.; Meijer, I.; Tiwari, K.M.; Paredes, S.; Michel, B.; Poulikakos, D. Aquasar: A hot water cooled data center with direct energy reuse. Energy 2012, 43, 237–245. [Google Scholar] [CrossRef]

- Shao, S.; Liu, H.; Zhang, H.; Tian, C. Experimental investigation on a loop thermosyphon with evaporative condenser for free cooling of data centers. Energy 2019, 185, 829–836. [Google Scholar] [CrossRef]

- Zhang, Q.; Meng, Z.; Hong, X.; Zhan, Y.; Deen, M.J. A survey on data center cooling systems: Technology, power consumption modeling and control strategy optimization. J. Syst. Archit. 2021, 119, 102253. [Google Scholar] [CrossRef]

- ASHRAE. PUE: A Comprehensive Examination of the Metric; ASHRAE: Atlanta, GA, USA, 2012. [Google Scholar]

- Guo, L. Mega-projects for data clusters, promoting five major changes in the computing industry. Commun. World 2022, 18–19. [Google Scholar]

- Shanghai Municipal Commission of economy and informatization. Guidelines for the Construction of Data Center in Shanghai; White Paper: Singapore, 2021; p. 20. [Google Scholar]

- Beghi, A.; Cecchinato, L.; Dalla Mana, G.; Lionello, M.; Rampazzo, M.; Sisti, E. Modelling and control of a free cooling system for Data Centers. Energy Procedia 2017, 140, 447–457. [Google Scholar] [CrossRef]

- Ko, J.S.; Huh, J.H.; Kim, J.C. Improvement of Energy Efficiency and Control Performance of Cooling System Fan Applied to Industry 4.0 Data Center. Electronics 2019, 8, 582. [Google Scholar] [CrossRef] [Green Version]

- Khalaj, A.H.; Halgamuge, S.K. A Review on efficient thermal management of air- and liquid-cooled data centers: From chip to the cooling system. Appl. Energy 2017, 205, 1165–1188. [Google Scholar] [CrossRef]

- Tuma, P.E. The merits of open bath immersion cooling of datacom equipment. In Proceedings of the 2010 26th Annual IEEE Semiconductor Thermal Measurement and Management Symposium (SEMI-THERM), Santa Clara, CA, USA, 21–25 February 2010. [Google Scholar]

- Qiu, L.; Dubey, S.; Choo, F.H.; Duan, F. Recent developments of jet impingement nucleate boiling. Int. J. Heat Mass Transf. 2015, 89, 42–58. [Google Scholar] [CrossRef]

- Robinson, A.J.; Colenbrander, J.; Byrne, G.; Burke, P.; Kempers, R. Passive two-phase cooling of air circuit breakers in data center power distribution systems. Int. J. Electr. Power Energy Syst. 2020, 121, 106138. [Google Scholar] [CrossRef]

- Liu, C.; Yu, H. Evaluation and Optimization of a Two-Phase Liquid-Immersion Cooling System for Data Centers. Energies 2021, 14, 1395. [Google Scholar] [CrossRef]

- Wu, D.; Marcinichen, J.B.; Thome, J.R. Experimental Evaluation of a Controlled Hybrid Two-Phase Multi-Microchannel Cooling and Heat Recovery System Driven by Liquid Pump and Vapor Compressor. Int. J. Refrig. 2013, 36, 375–389. [Google Scholar] [CrossRef]

- Saini, M.; Webb, R.L. Heat rejection limits of air cooled plane fin heat sinks for computer cooling. IEEE Trans. Compon. Packag. Technol. 2003, 26, 71–79. [Google Scholar] [CrossRef]

- Bbk, A.; Cwa, B.; Sfa, B.; Fei, D.A. System-level experimental investigations of the direct immersion cooling data center units with thermodynamic and thermoeconomic assessments. Energy 2020, 217, 119373. [Google Scholar]

- Cheng, C.C.; Chang, P.C.; Li, H.C.; Hsu, F.I. Design of a single-phase immersion cooling system through experimental and numerical analysis. Int. J. Heat Mass Transf. 2020, 160, 120203. [Google Scholar] [CrossRef]

- Zhou, G.; Zhou, J.; Huai, X.; Zhou, F.; Jiang, Y. A two-phase liquid immersion cooling strategy utilizing vapor chamber heat spreader for data center servers. Appl. Therm. Eng. 2022, 210, 118289. [Google Scholar] [CrossRef]

- Chien, L.H.; Chang, C.Y. An experimental study of two-phase multiple jet cooling on finned surfaces using a dielectric fluid. Appl. Therm. Eng. 2011, 31, 1983–1993. [Google Scholar] [CrossRef]

- Kanbur, B.B.; Wu, C.; Fan, S.; Tong, W.; Duan, F. Two-phase liquid-immersion data center cooling system: Experimental performance and thermoeconomic analysis. Int. J. Refrig. 2020, 118, 290–301. [Google Scholar] [CrossRef]

- Kanbur, B.B.; Wu, C.; Duan, F. Combined heat and power generation via hybrid data center cooling-polymer electrolyte membrane fuel cell system. Int. J. Energy Res. 2020, 44, 4759–4772. [Google Scholar] [CrossRef]

- Kanbur, B.B.; Wu, C.; Duan, F. Multi-criteria thermoeconomic and thermodynamic assessments of the desalination-integrated two-phase liquid-immersion data center cooling system. Int. J. Energy Res. 2020, 44, 10453–10470. [Google Scholar] [CrossRef]

- Khalid, R.; Wemhoff, A.P.; Joshi, Y. Energy and exergy analysis of modular data centers. IEEE Trans. Compon. Pack. Manuf. Technol. 2017, 7, 1440–1452. [Google Scholar] [CrossRef]

- Kawaguchi, K.; Terao, T.; Kobayashi, K. Cooling Unit for Computer Chip by using Boiling Heat Transfer. Trans. Jpn. Soc. Refrig. Air Cond. Eng. 2012, 21, 309–317. [Google Scholar]

- El-Genk, M.S. Immersion cooling nucleate boiling of high power computer chips. Energy Convers. Manag. 2012, 53, 205–218. [Google Scholar] [CrossRef]

- Nemati, H. A General Equation Based on Entropy Generation Minimization to Optimize Plate Fin Heat Sink. Eng. J. 2018, 22, 159–174. [Google Scholar] [CrossRef]

- Shahsavar, A.; Jafari, M.; Sardari, P.T.; Toghraie, D. Hydrothermal and entropy generation specifications of a hybrid ferronanofluid in microchannel heat sink embedded in CPUs. Chin. J. Chem. Eng. 2020, 32, 27–38. [Google Scholar] [CrossRef]

- Jing, Z. Numerical Simulation on Critical Heat Flux of Flow Boiling Heat Transfer in Microchannel with V-typed Grooves. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2017. [Google Scholar]

- Lu, Z. Influence of Near Wall Bubble Dynamics on the Heat Transfer during Nucleate Pool Boiling. Master’s Thesis, Tsinghua University, Beijing, China, 2008. [Google Scholar]

- Yuanyang, L. Experimental and Theoretical Study of the Heat Transfer Characteristic of Pool Boiling and Jet Impingement Boiling on the Modification Surface. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2014. [Google Scholar]

- Rohsenow, W.M. A Method of Correlating Heat Transfer Data for Surface Boiling Liquids; MIT Division of Industrial Cooporation: Cambridge, MA, USA, 1951. [Google Scholar]

- Nam, Y.; Wu, J.; Warrier, G.; Ju, Y.S. Experimental and Numerical Study of Single Bubble Dynamics on a Hydrophobic Surface. J. Heat Transf. 2009, 131, 315–320. [Google Scholar] [CrossRef]

- Bourdon, B.; Bertrand, E.; Di Marco, P.; Marengo, M.; Rioboo, R.; De Coninck, J. Wettability influence on the onset temperature of pool boiling: Experimental evidence onto ultra-smooth surfaces. Adv. Colloid Interface Sci. 2015, 221, 34–40. [Google Scholar] [CrossRef]

- Surtaev, A.S.; Serdyukov, V.S.; Safonov, A.I. Enhancement of boiling heat transfer on hydrophobic fluoropolymer coatings. Interfacial Phenom. Heat Transf. 2019, 6, 269–276. [Google Scholar] [CrossRef]

- Stephan, K.; Abdelsalam, M. Heat-transfer correlations for natural convection boiling. Int. J. Heat Mass Transf. 1980, 23, 73–87. [Google Scholar] [CrossRef]

- Shiraishi, M.; Kikuchi, K.; Yamanishi, T. Investigation of heat transfer characteristics of a two-phase closed thermosyphon. J. Heat Recovery Syst. 1981, 1, 287–297. [Google Scholar] [CrossRef]

- Cooper, M.G. Saturation Nucleate Pool Boiling—A Simple Correlation; Oxford University: Oxford, UK, 1984. [Google Scholar]

- Kutateladze, S.S. Heat Transfer in Condensation and Boiling; Technical Report; State Scientific and Technical Publishers of Literature on Machinery, 1952. [Google Scholar]

- ISO/IEC 30134-2:2016; Information Technology-Data Centres-Key Performance Indicators-Part 2: Power Usage Effectiveness (PUE). ISO/IEC: Geneva, Switzerland, 2016.

| Surface | θ (°) | Ra (μm) | γ | r | Cs |

|---|---|---|---|---|---|

| Pure copper surface | 10 | 0.135 | 12 | 1.04 | 0.171 |

| Power Density | Measured | Predict | Error | |

|---|---|---|---|---|

| W/m2 | W/(m2 K) | W/(m2 K) | ||

| 1 | 62,222 | 2456 | 2683 | −9.2% |

| 2 | 70,000 | 2118 | 2290 | −8.1% |

| 3 | 82,555 | 2523 | 2414 | 4.3% |

| 4 | 92,333 | 2878 | 2566 | 10.8% |

| 5 | 99,333 | 3148 | 3002 | 4.6% |

| 6 | 106,666 | 3440 | 3666 | −6.6% |

| 7 | 117,777 | 3904 | 4158 | −6.5% |

| 8 | 123,333 | 4145 | 4726 | −14.0% |

| 9 | 125,555 | 4244 | 4685 | −10.4% |

| 10 | 124,444 | 4194 | 4723 | −12.6% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Yu, H. Experimental Investigations on Heat Transfer Characteristics of Direct Contact Liquid Cooling for CPU. Buildings 2022, 12, 913. https://doi.org/10.3390/buildings12070913

Liu C, Yu H. Experimental Investigations on Heat Transfer Characteristics of Direct Contact Liquid Cooling for CPU. Buildings. 2022; 12(7):913. https://doi.org/10.3390/buildings12070913

Chicago/Turabian StyleLiu, Cheng, and Hang Yu. 2022. "Experimental Investigations on Heat Transfer Characteristics of Direct Contact Liquid Cooling for CPU" Buildings 12, no. 7: 913. https://doi.org/10.3390/buildings12070913

APA StyleLiu, C., & Yu, H. (2022). Experimental Investigations on Heat Transfer Characteristics of Direct Contact Liquid Cooling for CPU. Buildings, 12(7), 913. https://doi.org/10.3390/buildings12070913