Exploring Value Generation in Target Value Design Applying a Value Analysis Model

Abstract

:1. Introduction

2. Background

2.1. Generation and Loss of Value

2.2. Target Value Design (TVD)

2.2.1. Target Costing

2.2.2. TVD Practices and Tools

2.2.3. TVD Measurement

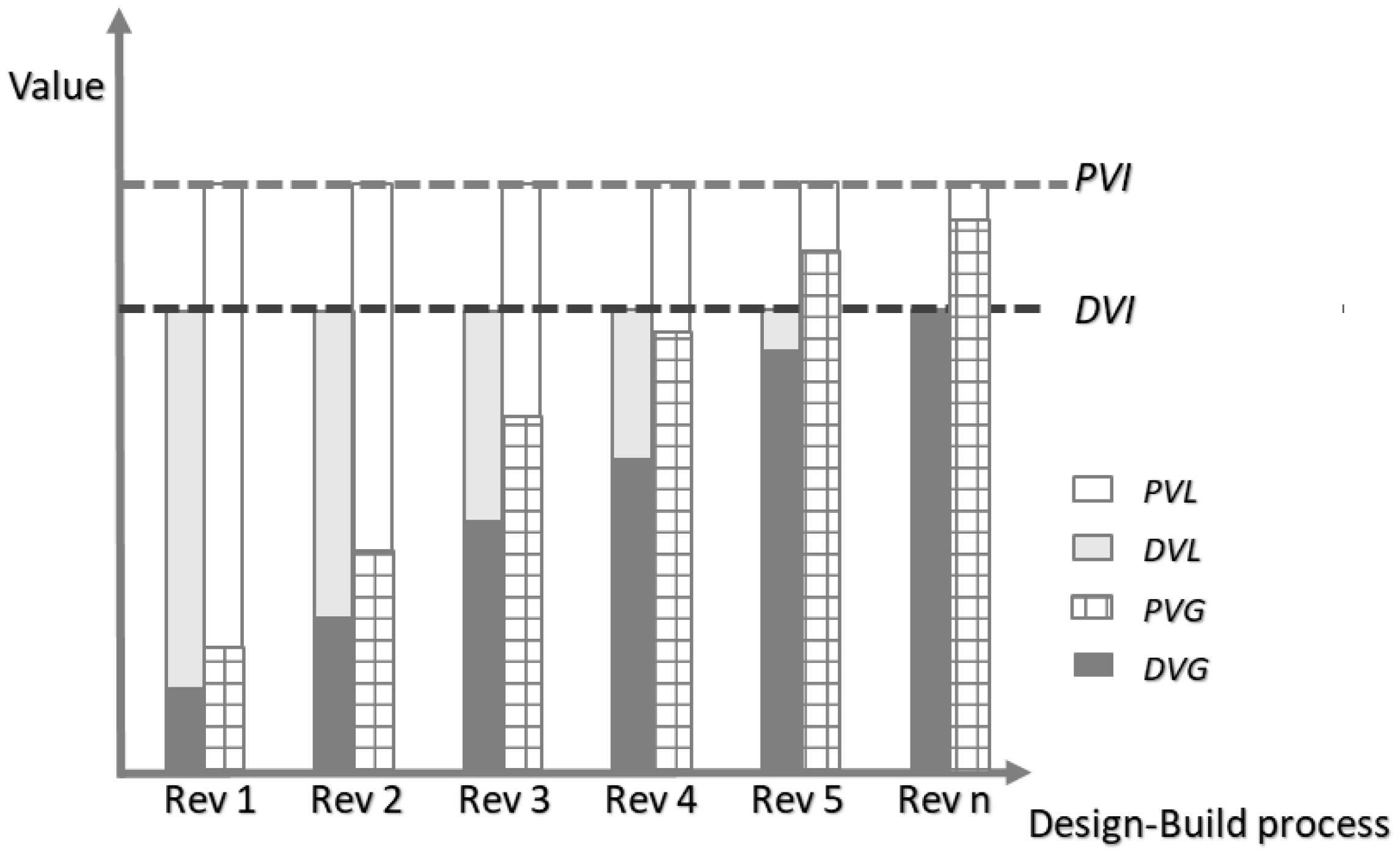

2.3. Value Analysis Model (VAM)

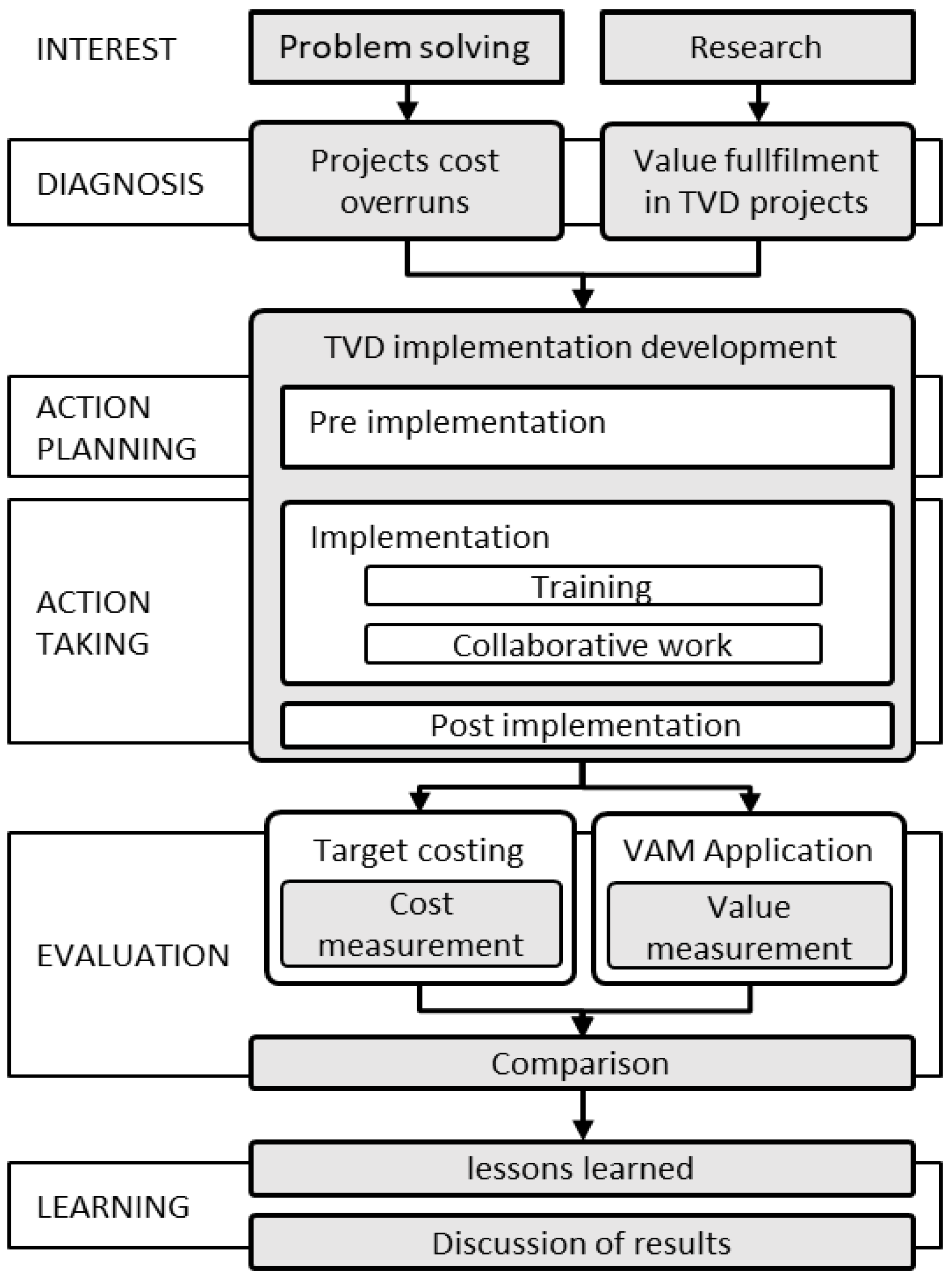

3. Research Approach

3.1. Phase 1: Diagnosis

3.2. Phase 2: Action Planning

TVD Pre-Implementation

- Pilot project selection

- Participants selection

- Preliminary considerations

- Data collection planning

- TVD practices and tools selection

- Cost measurement in pre-implementation

- Value measurement in pre-implementation

- Value Review 0

3.3. Phase 3: Action Taking

3.3.1. TVD Implementation

- Training

- Collaborative work

3.3.2. TVD Post-Implementation

3.4. Phase 4: Evaluation

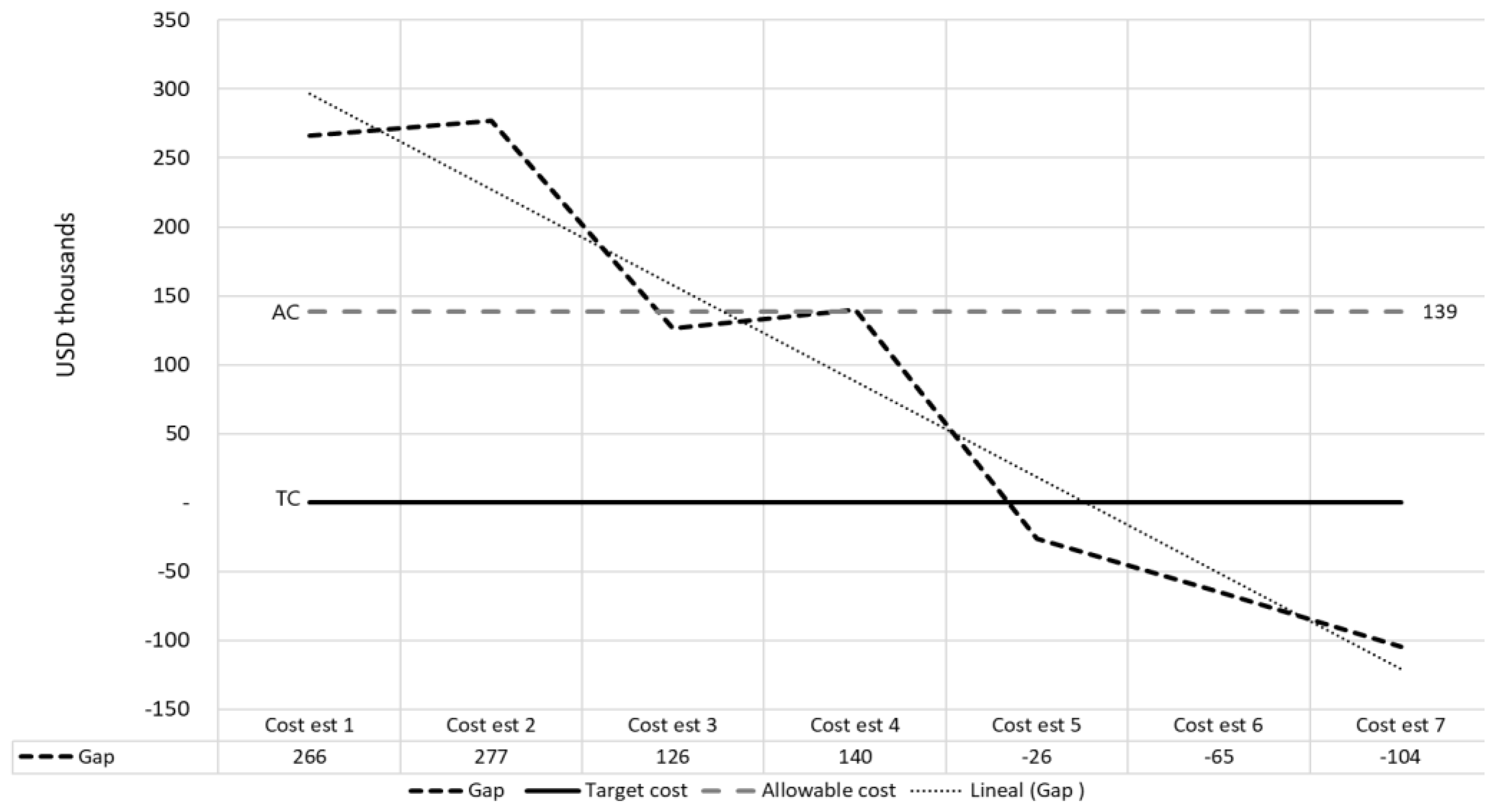

3.4.1. Cost Measurement

- Preliminary Cost Indexes

- Cost Evolution

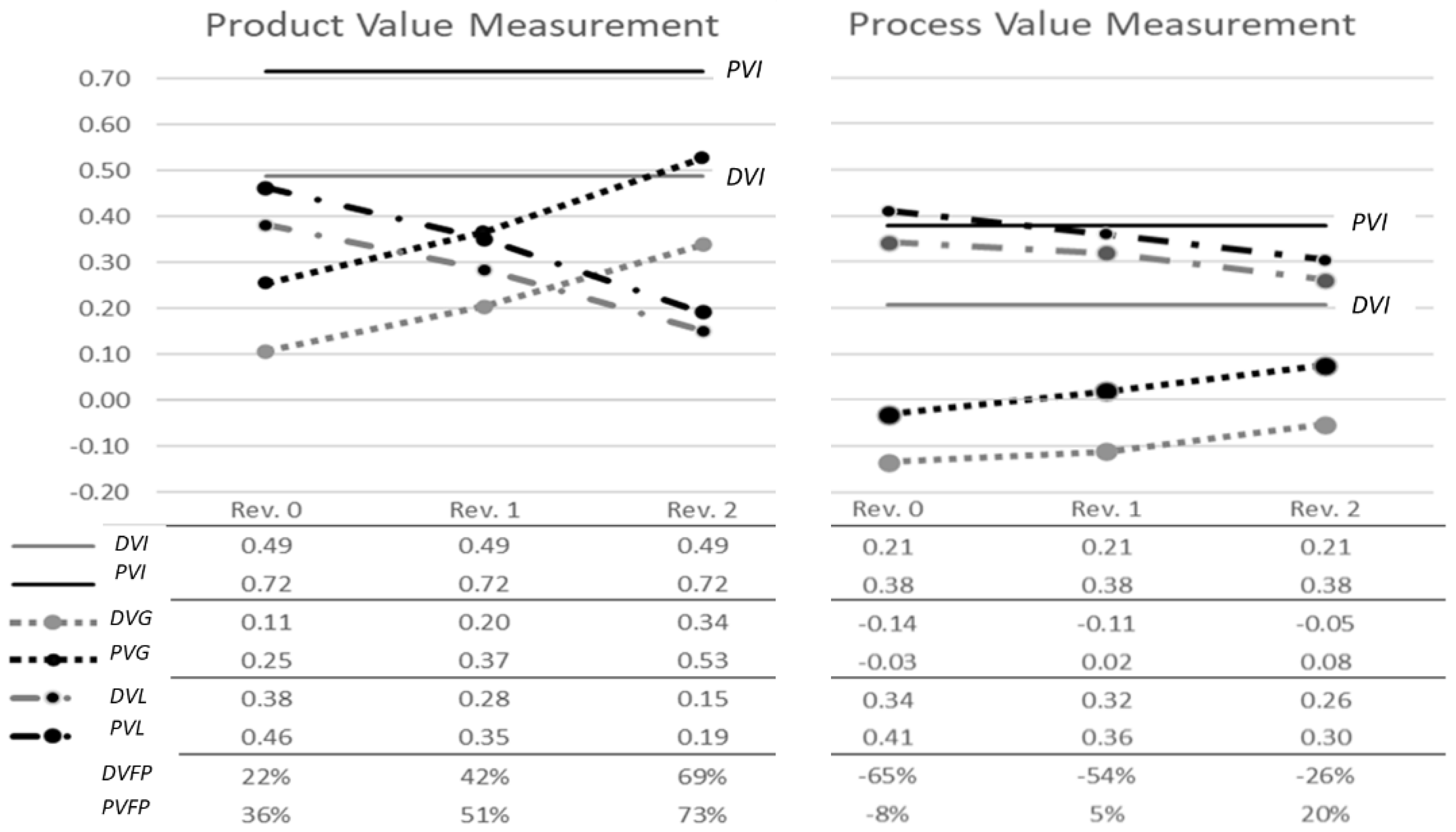

3.4.2. Value Measurement

- Preliminary Value Indexes

- Value Evolution

3.4.3. Comparison between Value and Cost Evolution

3.5. Phase 5: Learning

4. Discussion

5. Conclusions

Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Conditions of Satisfaction (CoS) | Process Attributes | OW | DE | BU | PR | %Ideal | %R0 | %R1 | %R2 |

|---|---|---|---|---|---|---|---|---|---|

| Information flow/communications | Low response time to information requests | O | A | M | M | 100% | 63% | 69% | 88% |

| Low response time to requests for modifications | O | O | M | M | 100% | 53% | 61% | 67% | |

| Clarity in requests for information and solutions | M | M | M | M | 100% | 66% | 67% | 83% | |

| Clarity in the background and requirements of the clients | M | M | O | M | 100% | 64% | 78% | 83% | |

| Formality in the documentation of failures, problems and modifications | M | O | M | M | 100% | 68% | 72% | 83% | |

| Important information visible and available to all involved in the design | M | M | O | M | 100% | 64% | 89% | 75% | |

| Times and costs | Commitment to meeting deadlines | M | M | M | M | 100% | 59% | 45% | 83% |

| Knowledge of budget availability by all those involved in the design | M | M | M | M | 100% | 43% | 75% | 75% | |

| Incorporate cost changes simultaneously with design modifications | R | O | M | M | 100% | 44% | 58% | 50% | |

| Tools and technology | Use of BIM-VDC technology between design and construction | A | A | A | A | 0–100 | 46% | 78% | 78% |

| Using BIM for specialty coordination | A | A | A | A | 0–100 | 54% | 90% | 90% | |

| Technological means with adequate capacity (software, hardware and netware) | M | M | M | M | 100% | 63% | 65% | 75% | |

| To manage several parallel design options | M | I | I | M | 100% | 46% | 72% | 42% | |

| Constructability | Inclusion of standardization within the process | O | I | M | M | 100% | 63% | 60% | 67% |

| Inclusion of industrialization within the process | O | A | M | M | 100% | 75% | 90% | 75% | |

| Inclusion of innovation within the process | O | A | A | O | 100% | 75% | 73% | 67% | |

| Integration | Multidisciplinary contribution to decision-making | M | O | I | M | 100% | 81% | 83% | 75% |

| Early integration of construction professionals | M | M | A | M | 100% | 72% | 86% | 67% | |

| Objectives aligned toward full optimization | M | O | I | M | 100% | 64% | 68% | 75% | |

| Multidisciplinary planning and collaborative design | M | O | O | M | 100% | 75% | 73% | 75% | |

| Long-term relationship with suppliers | M | I | I | M | 100% | 79% | 67% | 75% | |

| Shared risks and rewards | M | M | M | M | 100% | 46% | 53% | 75% | |

| Corporative environment | Good communication and good working environment | M | M | O | M | 100% | 84% | 63% | 92% |

| Low staff turnover | A | I | I | A | 0–100 | 64% | 78% | 67% | |

| Deliverables | Generate ready-to-build deliverables (buildable drawings) | M | M | M | M | 100% | 72% | 42% | 67% |

| Generate clear deliverables, no modifications in execution | O | A | A | O | 100% | 54% | 58% | 67% | |

| Use of standard format for orderly information | A | I | A | A | 0–100 | 67% | 67% | 67% | |

| Generate metric and quantity information | O | M | I | M | 100% | 47% | 40% | 67% | |

| Project with all necessary specifications and information | M | M | M | M | 100% | 54% | 55% | 67% | |

| Deliverable without inconsistencies between specialties | M | M | M | M | 100% | 64% | 63% | 67% |

Appendix B

| Conditions of Satisfaction (CoS) | Product Attributes | OW | DE | BU | PR | %Ideal | %R0 | %R1 | %R2 |

|---|---|---|---|---|---|---|---|---|---|

| Home comfort | Functional | O | O | M | M | 100% | 38% | 63% | 92% |

| Finance and investment | Good Location | O | A | A | O | 100% | 63% | 63% | 92% |

| Low cost variability | O | I | I | O | 100% | 59% | 69% | 83% | |

| Good cost/quality ratio | O | O | O | O | 100% | 57% | 88% | 83% | |

| Good cost/square meters | O | I | M | M | 100% | 66% | 75% | 92% | |

| Sellable/competitive design | O | O | A | O | 100% | 69% | 84% | 83% | |

| Profitable product | O | A | I | O | 100% | 69% | 75% | 75% | |

| To maintain its value over time | O | O | I | O | 100% | 59% | 88% | 67% | |

| Performance | Compliant with regulations | O | M | O | M | 100% | 53% | 72% | 100% |

| Meets the customer’s requirements | O | A | I | O | 100% | 69% | 72% | 92% | |

| Product stable during earthquakes and other events | O | M | O | M | 100% | 69% | 69% | 83% | |

| Easy to build | O | I | O | O | 100% | 84% | 81% | 92% | |

| High percentage of repetitive elements | A | O | O | O | 100% | 81% | 72% | 83% | |

| Durable materials | O | A | M | M | 100% | 84% | 84% | 83% | |

| Materials available on the market | O | A | I | O | 100% | 66% | 78% | 83% | |

| Easy-to-install materials | O | I | A | O | 100% | 91% | 75% | 75% | |

| No reclaims | O | O | M | M | 100% | 75% | 56% | 100% | |

| Image | Aesthetic | O | M | I | M | 100% | 63% | 94% | 88% |

| Differentiating image | A | A | I | A | 0–100 | 53% | 75% | 75% | |

| Innovation and technology | Innovative | A | M | O | M | 100% | 81% | 66% | 75% |

| Presenting cutting-edge technology | A | A | I | A | 0–100 | 53% | 63% | 75% | |

| Health and sustainability | To improve the quality of life of the community | O | A | M | M | 100% | 46% | 75% | 92% |

| To improve the customer’s quality of life | O | A | O | O | 100% | 59% | 59% | 83% | |

| Sustainable/energy efficient | A | M | I | M | 100% | 46% | 72% | 92% |

Appendix C

| Training Plan | Action Plan | Practices | Tools |

|---|---|---|---|

| TVD introduction workshop | Review of difficulties in incorporating them into the company Senior management meeting to determine target cost and allowable cost Project cost visibility Efforts to achieve the target cost Committee creation and work (cluster work) Difficult to implement Big Room in the company All committee meetings (big group = Big Room meeting) Auditing meetings Challenging to incorporate set-based design The target cost and the budget are broken down and tracked within clusters Visibility of project objectives Establishment of value attributes by clients Establishment of satisfaction conditions | 1–9. TVD Nine Foundational Practices 1. Engage deeply with the client to establish the target value. 7. Work in small and diverse groups 8. Work in a Big Room 9. Conduct retrospectives throughout the process 10. Cross-functional teams 15. Sub targets cost by teams 19. Projects are single-purpose networks of commitments 22. All team members understand the business case and stakeholder values 23. Set targets for values and conditions of satisfaction 33. Promote transparent communication | 1. Target costing 6. Formal retrospectives 7. Plus and delta activity 8. Big group meetings and Short codesign sessions 13. Pareto analysis by committee 18. Set-based design 19. TVD update charts |

| Constructability workshop | Inclusion of industrialization, standardization, prefabrication Design solutions are developed with cost, schedule, and constructability as design criteria Constructability improvement proposals Committee meetings Workshop attendance | 5. Concurrently design the product and the process in design sets 12. Balance designer and constructor (team members) interests 13. Early integration of designers and builders 17. Intentionally build relationships on projects 18. Optimize the whole project 21. Design solutions are developed with constructability as design criteria | 3. Functional analysis/Value engineering 20. Standardization |

| CBA workshop | Committee meetings Collaborative process | 16. Best value instead of lowest first cost | 17. CBA decision-making |

| Innovation workshop and A3 thinking workshop | Plus/delta activity Design thinking + kaizen event Lessons learned review | 2. Lead the design effort for learning and innovation. 27.Continuity of staff to retain the knowledge 28. Capture of lessons learned, 29. Lean set of tools to eliminate process waste 35. Encourages the discussion of problems and solutions 36. Prioritizes continuous but durable improvements over time instead of more radical improvements | 10. PDCA; 12. 5-Why™; 16. A3 report; 21. One-page improvement reports 25. Visual management tools 27. Prototyping 31. Design thinking 32. Kaizen event |

| IPD workshop | Balance owners, users, designers and builders’ interests Review of value attributes by customer Aligning team member interests Collaborative actions to achieve target cost Continuous estimating To expand the use of BIM Committee meetings Align project ends, means, and constraints. Achievement search of subtarget cost aiming at the target cost fulfilment Design solutions are developed with cost, schedule, and constructability as design criteria The company uses Last planner system ® in building stages Industry–academy alliance for research in linguistic action | 3. Design to a detailed estimate. 4. Collaboratively plan and replan the project. 6. Design and detail in the sequence of the customer who will use it 11. Long term relationships with suppliers. 14. Early incorporation of main suppliers and contractors 17. Intentionally build relationships on projects 18. Optimize the whole project Projects are single-purpose networks of commitments | 4. Last Planner System® 8. Big group meetings and Short codesign sessions 19. TVD update charts |

| BIM workshop | Collaborative actions to achieve target cost Continuous estimating To expand the use of BIM Committee meetings | 3. Design to a detailed estimate 4. Collaboratively plan and replan the project | 2. nD model (3D, 4D…) 15. Building Information Model (BIM), 19. TVD update charts |

References

- P2SL Project Production Systems Laboratory. Available online: http://p2sl.berkeley.edu/research/initiatives/target-value-design/ (accessed on 23 February 2022).

- Ballard, G. Target Value Design. In Proceedings of the International Design Conference, Dubrovnik, Croatia, 21–24 May 2012; pp. 11–22. [Google Scholar]

- Rybkowski, Z. The Application of Root Cause Analysis and Target Value Design to Evidence-Based Design in the Capital Planning of Healthcare Facilities. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2009. [Google Scholar]

- Ballard, G. Target Value Design: Current Benchmark (1.0). Lean Constr. J. 2011, 79–84, ISSN 1555-1369. Available online: http://p2sl.berkeley.edu/wp-content/uploads/2016/03/Ballard-2011-Target-Value-Design-Current-Benchmark-1.0-LCJ_11_009.pdf (accessed on 6 May 2022).

- Nanda, U.; Rybkowski, Z.K.; Pati, S.; Nejati, A. A Value Analysis of Lean Processes in Target Value Design and Integrated Project Delivery: Stakeholder Perception. Health Environ. Res. Des. J. 2017, 10, 99–115. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, M.-A.; Pellicer, E.; Soler-Severino, M. Target Value Design: A Different Way of Approaching the Constructive Process in Spain. J. Mod. Proj. Manag. 2018, 5, 1–17. [Google Scholar]

- Paik, J.; Miller, V.; Mollaoglu, S.; Aaron Sun, W. Interorganizational Projects: Reexamining Innovation Implementation via IPD Cases. J. Manag. Eng. 2017, 33, 04017017. [Google Scholar] [CrossRef]

- Miron, L.; Kaushik, A.; Koskela, L. Target Value Design: The Challenge of Value Generation. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 15 October 2015; pp. 815–825. [Google Scholar]

- Pennanen, A.; Ballard, G.; Haahtela, Y. Designing to Targets in a Target Costing Process. In Proceedings of the 18th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012; Technion: Haifa, Israel, 2010; pp. 161–170. [Google Scholar]

- Fruchter, R.; Grey, F.; Badasyan, N.; Russell-Smith, S.; Castillo, F. Integrated Target Value Approach Engaging Project Teams in an Iterative Process of Exploration and Decision Making to Provide Clients with the Highest Value. In Proceedings of the 2015 International Workshop on Computing in Civil Engineering, Austin, TX, USA, 21–23 June 2015; pp. 313–321. [Google Scholar] [CrossRef]

- Silveira, S.S.; Da C. L. Alves, T. Target Value Design Inspired Practices to Deliver Sustainable Buildings. Buildings 2018, 8, 116. [Google Scholar] [CrossRef] [Green Version]

- Pöyhönen, P.; Sivunen, M.; Kajander, J.K. Developing a Project Delivery System for Construction Project—A Case Study. Procedia Eng. 2017, 196, 520–526. [Google Scholar] [CrossRef]

- Lee, H.W.; Ballard, G.; Tommelein, I.D. Developing a Target Value Design Protocol for Commercial Energy Retrofits—Part 1. In Proceedings of the Construction Research Congress, West Lafayette, IN, USA, 21–23 May 2012; pp. 1710–1719. [Google Scholar]

- Russell-Smith, S.V.; Lepech, M.D. Cradle-to-Gate Sustainable Target Value Design: Integrating Life Cycle Assessment and Construction Management for Buildings. J. Clean. Prod. 2015, 100, 107–115. [Google Scholar] [CrossRef]

- Zimina, D.; Ballard, G.; Pasquire, C. Target Value Design: Using Collaboration and a Lean Approach to Reduce Construction Cost. Constr. Manag. Econ. 2012, 30, 383–398. [Google Scholar] [CrossRef]

- Elghaish, F.; Abrishami, S.; Hosseini, M.R.; Abu-Samra, S. Revolutionising Cost Structure for Integrated Project Delivery: A BIM-Based Solution. Eng. Constr. Archit. Manag. 2020. [CrossRef]

- De Melo, R.S.S.; Do, D.; Tillmann, P.; Ballard, G.; Granja, A.D. Target Value Design in the Public Sector: Evidence from a Hospital Project in San Francisco, CA. Archit. Eng. Des. Manag. 2016, 12, 125–137. [Google Scholar] [CrossRef]

- Nanda, U.; Sipra, P.; Rybkowski, Z.; Ai, D.; Kalyanaraman, N.; Nejati, A. The Value Analysis of Lean Processes in Target Value Design and Integrated Project Delivery; Technical Report. CADRE/Texas A&M University: Aggieland, TX, USA, 2014; Available online: https://foundationhealthenvironmentsresearch.org/wp-content/uploads/2020/01/2013_Report_NandaPati.pdf (accessed on 6 May 2022).

- Zhang, L.; El-Gohary, N.M. Human-Centered Value Analysis: Building-Value Aggregation Based on Human Values and Building-System Integration. J. Constr. Eng. Manag. 2017, 143, 04017040. [Google Scholar] [CrossRef]

- Giménez, Z.; Mourgues, C.; Alarcón, L.; Mesa, H.; Pellicer, E. Value Analysis Model to Support the Building Design Process. Sustainability 2020, 12, 4224. [Google Scholar] [CrossRef]

- Kelly, J.; Male, S.; Graham, D. Value Management of Construction Projects, 2nd ed.; Blackwell Science, Inc.: Malden, MA, USA, 2014; ISBN 9781119007258. [Google Scholar]

- Novak, V. Managing Sustainability Value in Design: A Systems Approach in Environmental Design and Planning. Ph.D. Thesis, Faculty of the Virginia Polytechnic Institute and State University, Blacksburg, VI, USA, 2012. [Google Scholar]

- Bahadorestani, A.; Karlsen, J.T.; Farimani, N.M. Novel Approach to Satisfying Stakeholders in Megaprojects: Balancing Mutual Values. J. Manag. Eng. 2020, 36, 04019047. [Google Scholar] [CrossRef]

- Saxon, R. Be Valuable. In Report of Value Task Group; Constructing Excellence: London, UK, 2005. [Google Scholar]

- Salvatierra, J.; Pasquire, C.; Miron, L. Exploring Value Concept through the IGLC Community: Nineteen Years of Experience. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Womack, J.; Jones, D. Lean Thinking; Simon and Schuster: New York, NY, USA, 2012; ISBN 978-84-9875-199-4. Available online: www.planetadelibros.com (accessed on 1 May 2022).

- Macomber, H.; Howell, G.; Barberio, J. Target-Value Design: Nine Foundational Practices for Delivering Surprising Client Value; Lean Project Consulting, Inc.: Minneapolis, MN, USA, 2007; Available online: https://leanconstruction.org/uploads/wp/media/learning_laboratory/Target_Value_Design/Target%20Value%20Design%20%5bLPC%5d.pdf. (accessed on 1 May 2022).

- Bølviken, T.; Rooke, J.; Koskela, L. The Wastes of Production in Construction—A TFV Based Taxonomy. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 811–822. [Google Scholar]

- Rybkowski, Z.; Shepley, M.; Ballard, G. Target Value Design: Applications to Newborn Intensive Care Units. Health Environ. Res. Des. J. 2012, 5, 5–23. [Google Scholar] [CrossRef] [PubMed]

- Eskerod, P.; Ang, K. Stakeholder Value Constructs in Megaprojects: A Long-Term Assessment Case Study. Proj. Manag. J. 2017, 48, 60–75. [Google Scholar] [CrossRef]

- Borgianni, Y. Verifying Dynamic Kano’s Model to Support New Product/Service Development. J. Ind. Eng. Manag. 2018, 11, 569–587. [Google Scholar] [CrossRef]

- Chong, Y.T.; Chen, C. Customer Needs as Moving Targets of Product Development: A Review. Int. J. Adv. Manuf. Technol. 2010, 48, 395–406. [Google Scholar] [CrossRef]

- Bolar, A.; Tesfamariam, S.; Sadiq, R. Framework for Prioritizing Infrastructure User Expectations Using Quality Function Deployment (QFD). Int. J. Sustain. Built Environ. 2017, 6, 16–29. [Google Scholar] [CrossRef]

- Drevland, F.; Lohne, J.; Klakegg, O.J. Defining an Ill-Defined Concept-Nine Tenets on the Nature of Value. Lean Constr. J. 2018, 31–46. Available online: www.leanconstructionjournal.org (accessed on 1 June 2022).

- Zhang, Y.; Tzortzopoulos, P.; Kagioglou, M. Evidence-Based Design in Healthcare: A Lean Perspective with an Emphasis on Value Generation. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 20–22 July 2016; pp. 53–62. [Google Scholar]

- AFNOR. French Standard NF EN 12973; Association Francaise de Normalisation: Paris, France, 2000; ISBN 2008012425. [Google Scholar]

- Rischmoller, L.; Alarcón, L.; Koskela, L. Improving Value Generation in the Design Process of Industrial Projects Using CAVT. J. Manag. Eng. 2006. [CrossRef]

- Tauriainen, M.; Marttinen, P.; Dave, B.; Koskela, L. The Effects of BIM and Lean Construction on Design Management Practices. Procedia Eng. 2016, 164, 567–574. [Google Scholar] [CrossRef]

- Gunby, M.; Damnjanovic, I.; Anderson, S.; Joyce, J.; Nuccio, J. Identifying, Communicating, and Responding to Project Value Interests. J. Manag. Eng. 2013, 29, 50–59. [Google Scholar] [CrossRef]

- Haddadi, A.; Johansen, A.; Andersen, B. A Conceptual Framework to Enhance Value Creation in Construction Projects. Procedia Comput. Sci. 2016, 100, 565–573. [Google Scholar] [CrossRef] [Green Version]

- Volkova, T.; Jākobsone, I. Design Thinking as a Business Tool to Ensure Continuous Value Generation. Intellect. Econ. 2016. [CrossRef] [Green Version]

- Kowaltowski, D.; Granja, A. The Concept of Desired Value as a Stimulus for Change in Social Housing in Brazil. Habitat Int. 2011, 35, 435–446. [Google Scholar] [CrossRef]

- Huang, J. Application of Kano Model in Requirements Analysis of Y Company’s Consulting Project. Am. J. Ind. Bus. Manag. 2017, 7, 910–918. [Google Scholar] [CrossRef] [Green Version]

- Díaz, H. Optimización Multidisciplinaria de Diseño Mediante El Uso de Herramientas PIDO y BIM Como Soporte a La Metodología Target Value Design En Proyectos de Vivienda. Ph.D. Thesis, Pontificia Universidad Catolica de Chile, Santiago, Chile, 2017. [Google Scholar]

- Lin, G.; Shen, Q. Measuring the Performance of Value Management Studies in Construction: Critical Review. J. Manag. Eng. 2007, 23, 2–9. [Google Scholar] [CrossRef]

- Koskela, L. An Exploration towards a Production Theory and Its Application to Construction. Ph.D. Thesis, Helsinki University of Technology, Espoo, Finland, 2000. [Google Scholar]

- Nicolini, D.; Tomkins, C.; Holti, R.; Oldman, A.; Smalley, M. Can Target Costing and Whole Life Costing Be Applied in the Construction Industry?: Evidence from Two Case Studies. Br. J. Manag. 2000, 11, 303–324. [Google Scholar] [CrossRef]

- Ballard, G.; Reiser, P. The St. Olaf College Fieldhouse Project: A Case Study in Designing to Target Cost. In Proceedings of the 12th Annual Conference of the International Group for Lean Construction, Helsingør, Denmark, 3–5 August 2004; pp. 1–9. [Google Scholar]

- Tommelein, I.; Ballard, G. Target Value Design. Introduction, Framework and Current Benchmark; UC Berkeley: Arlington, TX, USA, 2016; Volume 1.7, ISBN 978-0-692-68625-6. [Google Scholar]

- Palaneeswaran, E.; Kumaraswamy, M.; Xue Qing, Z. Focusing on Best Value from a Source Selection Perspective. Aust. J. Constr. Econ. Build. 2004, 4, 21–34. [Google Scholar]

- Wang, B. The Future of Manufacturing: A New Perspective. Engineering 2018, 4, 722–728. [Google Scholar] [CrossRef]

- Ballard, G. Rethinking Project Definition in Terms of Target Costing. In Proceedings of the 14th Annual Conference of the International Group for Lean Construction, Santiago, Chile, 25–27 July 2006; pp. 77–89. [Google Scholar]

- Ballard, G.; Rybkowski, Z. Overcoming the Hurdle of First Cost: Action Research in Target Costing. In Proceedings of the Construction Research Congress, Seattle, WA, USA, 5–7 April 2009; pp. 1038–1047. [Google Scholar]

- Love, P.E.D.; Ika, L.A. Making Sense of Hospital Project (Mis)Performance: Over Budget, Late, Time and Time Again—Why? And What Can Be Done about It? Engineering 2022, 12, 184–202. [Google Scholar] [CrossRef]

- Ballard, G. Target Value Delivery. In Lean Construction Core Concepts and New Frontiers; Tzortzopoulos, P., Kagioglou, M., Koskela, L., Eds.; Routledge: London, UK, 2020; pp. 149–161. [Google Scholar]

- AIA. Integrated Project Delivery: A Guide. Report. Version 1. The American Institute of Architects; California Council National: CA, USA, 2007; Available online: https://info.aia.org/siteobjects/files/ipd_guide_2007.pdf (accessed on 1 June 2022).

- Czmoch, I.; Pękala, A. Traditional Design versus BIM Based Design. Procedia Eng. 2014, 91, 210–215. [Google Scholar] [CrossRef]

- Jacomit, A.; Granja, A.; Picchi, F. Target Costing Research Analysis: Reflections for Construction Industry Implementation. In Proceedings of the 16th Annual Conference of the International Group for Lean Construction, Manchester, UK, 16–18 July 2008; pp. 601–612. [Google Scholar]

- Alwisy, A.; Bouferguene, A.; Al-Hussein, M. Framework for Target Cost Modelling in Construction Projects. Int. J. Constr. Manag. 2020, 20, 89–104. [Google Scholar] [CrossRef]

- Alves, T.D.C.; Lichtig, W.; Rybkowski, Z.K. Implementing Target Value Design: Tools and Techniques to Manage the Process. Health Environ. Res. Des. J. 2017, 10, 18–29. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Dong, N.; Rischmoller, L. Design Thinking in Action: A DPR Case Study to Develop a Sustainable Digital Solution for Labor Resource Management. In Proceedings of the 28th Annual Conference of the International Group for Lean Construction, Berkeley, CA, USA, 6–12 July 2020; pp. 25–36. [Google Scholar]

- Herrera, R.F.; Mourgues, C.; Alarcón, L.F.; Pellicer, E. Analyzing the Association between Lean Design Management Practices and BIM Uses in the Design of Construction Projects. J. Constr. Eng. Manag. 2021, 147, 04021010. [Google Scholar] [CrossRef]

- O’Connor, R.; Swain, B. Implementing Lean in Construction: Lean Tools and Techniques—An Introduction; Construction Industry Research and Information Association (CIRIA): London, UK, 2013. [Google Scholar]

- Bloom, N.; van Reenen, J. Measuring and Explaining Management Practices Acroos Firms and Countries. Q. J. Econ. 2007, 122, 1351–1408. [Google Scholar] [CrossRef]

- Macomber, H. Putting the Five Big Ideas to Work; Lean Project Consulting, Inc.: Minneapolis, MN, USA, 2010; Available online: https://www.cca-acc.com/wp-content/uploads/2021/08/Five-Big-Ideas.pdf (accessed on 1 June 2022).

- Lee, H. Application of Target Value Design to Energy Efficiency Investments. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2012. [Google Scholar]

- Oliveros, B.; Granja, A.; Dionisio, S. An Initial Evaluation of a Method for Adopting Kaizen Events in the Construction. Rev. Ing. Construcción RIC 2018, 33, 173–182. [Google Scholar]

- Talebnia, G.; Baghiyan, F.; Baghiyan, Z.; Moussavi, F.; Abadi, N. Target Costing, the Linkages Between Target Costing and Value Engineering and Expected Profit and Kaizen. Int. J. Eng. Manag. 2017, 1, 11–15. [Google Scholar] [CrossRef]

- Jørgensen, B. Designing to Target Cost: One Approach to Design/Construction Integration. In Architectural Management: Designing Value; DTU/CIB; Anker Engelunds Vej 1 Building 101A 2800 Kgs: Lyngby, Denmark, 2005; pp. 311–319. ISBN 897877190-0. [Google Scholar]

- Marius, L.; Paulos, A.W.; Ola, L. Early Contractor Involvement in the Valdres Project Delivery Model. Procedia Comput. Sci. 2022, 196, 1028–1035. [Google Scholar] [CrossRef]

- Oliva, C.A.; Granja, A.D.; Bridi, M.E.; Soliman-Junior, J.; Ayo-Adejuyigbe, M.; Tzortzopoulos, P. Strengthening Target Value Design Benefits in the Real Estate Market through Living Labs. In Proceedings of the 29th Annual Conference of the International Group for Lean Construction, Lima, Peru, 14–17 July 2021; pp. 634–643. Available online: https://www.researchgate.net/profile/Ariovaldo-Granja/publication/353496813_Strengthening_Target_Value_Design_TVD_benefits_in_real_estate_market_through_living_labs/links/61009ad21e95fe241a918c80/Strengthening-Target-Value-Design-TVD-benefits-in-real-estate-market-through-living-labs.pdf (accessed on 1 June 2022).

- Engebø, A.; Torp, O.; Lædre, O. Development of Target Cost for a high-performance building. In Proceedings of the 29th Annual Conference of the International Group for Lean Construction, Lima, Peru, 14–17 July 2021; pp. 3–12. Available online: https://iglc.net/Papers/Details/1856 (accessed on 1 June 2022). [CrossRef]

- Gutiérrez Lazarte, F.M. Influence of Integrated Teams and Co-Location to Achieve the Target Cost in Building Projects. In Proceedings of the IGLC 28—28th Annual Conference of the International Group for Lean Construction 2020, Berkeley, CA, USA, 6–10 July 2020; The International Group for Lean Construction: Edmonton, Canada, 2020; pp. 709–720. [Google Scholar] [CrossRef]

- Musa, M.; Pasquire, C. Target Value Delivery in Bid Process. In Proceedings of the IGLC 28—28th Annual Conference of the International Group for Lean Construction 2020, Berkeley, CA, USA, 6–10 July 2020; The International Group for Lean Construction: Edmonton, Canada, 2020; pp. 697–708. [Google Scholar] [CrossRef]

- Meijon Morêda Neto, H.; Bastos Costa, D.; Coelho Ravazzano, T. Recommendations for Target Value Design Implementation for Real Estate Development in Brazil. Archit. Eng. Des. Manag. 2019, 15, 48–65. [Google Scholar] [CrossRef]

- Denerolle, S. The Application of Target Value Design to the Design Phase of 3 Hospital Projects; Technical Report; DPR Construction/University of California: Berkeley, CA, USA, 2013; Available online: http://p2sl.berkeley.edu/wp-content/uploads/2016/03/Denerolle-2011-Application-of-TVD-to-the-Design-Phase-of-3-Hospital-Projects.pdf (accessed on 1 June 2022).

- Laurent, J.; Leicht, R.M. Practices for Designing Cross-Functional Teams for Integrated Project Delivery. J. Constr. Eng. Manag. 2019, 145, 1–11. [Google Scholar] [CrossRef]

- Brioso, X. Integrating ISO 21500 Guidance on Project Management, Lean Construction and PMBOK. Procedia Eng. 2015, 123, 76–84. [Google Scholar] [CrossRef]

- Lichtig, W. Sutter Health Integrated Agreement for Lean Project Delivery between Owner, Architect & CM/GC. 2008. Available online: https://leanconstruction.org/uploads/wp/media/docs/lcj/V2_N1/LCJ_05_008.pdf (accessed on 1 June 2022).

- Alwisy, A.; Bouferguene, A.; Al-Hussein, M. Factor-Based Target Cost Modelling for Construction Projects. Can. J. Civ. Eng. 2018, 45, 393–406. [Google Scholar] [CrossRef]

- Robert, G.; Granja, A. Target and Kaizen Costing Implementation in Construction. In Proceedings of the 14th Annual Conference of the International Group for Lean Construction, Santiago, Chile, 3–7 July 2006; pp. 91–105. [Google Scholar]

- Forbes, L.H.; Ahmed, S.M. Modern Construction: Lean Project Delivery and Integrated Practices; CRC Press: Boca Raton, FL, USA, 2011; ISBN 978-1-4200-6312-7. [Google Scholar]

- Do, D.; Chen, C.; Ballard, G.; Tommelein, I.D. Target Value Design as a Method for Controlling Project Cost Overruns. In Proceedings of the 22th Conference of the International Group for Lean Construction (IGLC 2014), Oslo, Norway, 25–27 June 2014; Volume 1, pp. 171–181. [Google Scholar]

- Kano, N.; Seraku, N.; Takahashi, F.; Tsuji, S. Attractive Quality Vs. Must Be Quality. J. Jpn. Soc. Qual. Control 1984, 41, 39–48. [Google Scholar]

- Lewin, K. Action Research and Minority Problems. J. Soc. Issues 1946, 2, 34–46. [Google Scholar] [CrossRef]

- Lines, B.C.; Perrenoud, A.J.; Sullivan, K.T.; Kashiwag, D.T.; Pesek, A. Implementing Project Delivery Process Improvements: Identification of Resistance Types and Frequencies. J. Manag. Eng. 2017, 33, 04016031. [Google Scholar] [CrossRef]

- Jørgensen, F.; Boer, H.; Gertsen, F. Jump-Starting Continuous Improvement through Self-Assessment. Int. J. Oper. Prod. Manag. 2003, 23, 1260–1278. [Google Scholar] [CrossRef]

- Powell, W. Organizational Change Models. Futurics 2002, 26, 20–45. [Google Scholar]

- Azhar, S.; Ahmad, I.; Sein, M.K. Action Research as a Proactive Research Method for Construction Engineering and Management. J. Constr. Eng. Manag. 2010, 136, 87–98. [Google Scholar] [CrossRef]

- Mckay, J.; Marshall, P. The Dual Imperatives of Action Research. Inf. Technol. People 2001, 14, 46–59. [Google Scholar] [CrossRef] [Green Version]

- Kuru, M.; Erdem, O.; Calis, G. Sale Price Classification Models for Real Estate Appraisal. J. Constr. 2021, 20, 440–451. [Google Scholar] [CrossRef]

- De Melo, R.S.S.; Granja, A.D. Guidelines for Target Costing Adoption in the Development of Products for the Residential Real Estate Market. Ambiente Construído 2017, 17, 153–165. [Google Scholar] [CrossRef] [Green Version]

- Bustos, O. Factores Latentes En La Desviación de Presupuestos En Proyectos de Arquitectura. Un Análisis Empírico. Doctor Thesis, Universitat Politècnica de València, Valencia, Spain, 2015. [Google Scholar]

- Ballard, G.; Dilsworth, B.; Do, D.; Low, W.; Mobley, J.; Phillips, P.; Reed, D.; Sargent, Z.; Tillmann, P.; Wood, N. How to Make Shared Risk and Reward Sustainable. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 23 July 2015; pp. 257–266. [Google Scholar]

- Cheng, R. Motivation and Means: How and Why IPD and Lean Lead to Success; Research Report; Lean Construction Institute and Integrated Project Delivery Alliance: MI, USA, 2016; Available online: https://conservancy.umn.edu/handle/11299/198897 (accessed on 1 June 2022).

- Barutha, P.J.; Jeong, H.D.; Gransberg, D.D.; Touran, A. Evaluation of the Impact of Collaboration and Integration on Performance of Industrial Projects. J. Manag. Eng. 2021, 37. [Google Scholar] [CrossRef]

- Ruiz, J.; Granja, A.; Kowaltowski, D. Cost Reallocation in Social Housing Projects Considering the Desired Values of End-Users. Built Environ. Proj. Asset Manag. 2014, 4, 352–367. [Google Scholar] [CrossRef]

- Fischer, M.; Ashcraft, H.; Reed, D.; Khanzode, A. Integrated Project Delivery; Wiley: Hoboken, NJ, USA, 2017; ISBN 978-1-118-41538-2. [Google Scholar]

- Zhang, L.; El-Gohary, N.M. Discovering Stakeholder Values for Axiology-Based Sustainability-Oriented Value Analysis of Educational Building Projects. In Proceedings of the Construction Research Congress, Atlanta, GA, USA, 19–21 May 2014; pp. 623–632. [Google Scholar]

- Arroyo, P.; Tommelein, I.D.; Ballard, G. Selecting Globally Sustainable Materials: A Case Study Using Choosing by Advantages. J. Constr. Eng. Manag. 2016, 142, 1–10. [Google Scholar] [CrossRef]

- Kpamma, Z.E.; Adjei-kumi, T.; Ayarkwa, J. An Exploration of the Choosing by Advantages Decision System as a User Engagement Tool in Participatory Design. Archit. Eng. Des. Manag. 2016, 12, 51–66. [Google Scholar] [CrossRef]

- Mesa, H.A.; Molenaar, K.R.; Alarcón, L.F. Comparative Analysis between Integrated Project Delivery and Lean Project Delivery. Int. J. Proj. Manag. 2019, 37, 395–409. [Google Scholar] [CrossRef]

| Practices Related to TVD | Tools Related to TVD Practices | ||

|---|---|---|---|

| 1 | Engage deeply with the client to establish the target value [27] | 1 | Target costing [5,9,15,48,68,69] |

| 2 | Lead the design effort for learning and innovation [27]. | 2 | nD model (3D, 4D…) [16,48,60] |

| 3 | Design of a detailed estimate [27,66]. | 3 | Functional analysis/value engineering [15,48] |

| 4 | Collaboratively plan and replan the project [15,27,70,71,72,73,74] | 4 | Last Planner System ® [5,11,15,17,48,60,75] |

| 5 | Concurrently design the product and the process in design sets [27,48]. | 5 | Integrated product/cost model [48] |

| 6 | Design and detail in the sequence of the customer who will use it [15,27,48,55]. | 6 | Formal retrospectives [27] |

| 7 | Work in small and diverse groups [27]. | 7 | Plus and delta activity [27] |

| 8 | Work in a Big Room [27]. | 8 | Short codesign sessions and Big Room meetings [5,15,27,73,75] |

| 9 | Conduct retrospectives throughout the process [27]. | 9 | Design–build contract [48] |

| 10 | Cross-functional teams [17,48,74,76]. | 10 | Plan Do Check Act (PDCA) [15,65] |

| 11 | Long-term relationships with suppliers [48] | 11 | 5-minute meetings [65] |

| 12 | Balance designer and constructor (team members) interests [48] | 12 | 5-Why™ [65] |

| 13 | Early integration of designers and builders [48,55,70,72,77] | 13 | Pareto analysis [65] |

| 14 | Early incorporation of main suppliers and contractors [15,48,76,78]. | 14 | Relational contract [4,60,79]. |

| 15 | Sub targets cost by teams [48,66] | 15 | Building Information Model (BIM) [4,5,11,15,17,75,76] |

| 16 | Best value instead of the lowest first cost [11,17,48,55,73,74] | 16 | A3 thinking [4] |

| 17 | Intentionally build relationships on projects [65] | 17 | Choosing by advantages (CBA) decision making [4,15] |

| 18 | Optimize the whole project [65] | 18 | Set-based design [4] |

| 19 | Projects are single-purpose networks of commitments [65]. | 19 | TVD update charts [66] |

| 20 | Involve all key stakeholders in feasibility study [4]. | 20 | Standardization [15,17,76,80] |

| 21 | Design solutions are developed with cost, schedule, and constructability as design criteria [4]. | 21 | One-page improvement reports [11,60] |

| 22 | All team members understand the business case and stakeholder values [4] | 22 | 3P (production preparation process)/mockups [11,60] |

| 23 | Set targets for values and conditions of satisfaction [66] | 23 | Virtual meetings [11,60] |

| 24 | A cross-disciplinary “validation study” [66] | 24 | Charrette meeting [11,60] |

| 25 | Aligned goals and share risks and rewards [4] | 25 | Visual management tools [11,60] |

| 26 | Rapid estimating [66] | 26 | Value stream mapping [11,60] |

| 27 | Continuity of staff to retain the knowledge [15], | 27 | Prototyping [11,60] |

| 28 | Capture of lessons learned [11,15,60] | 28 | Gemba walks (site tours) [11,60] |

| 29 | Lean set of tools to eliminate process waste [15] | 29 | Focus groups [11,60] |

| 30 | “three musketeers” attitude. “All for one, one for all” thinking [15] | 30 | Innovation workbooks [11,60]. |

| 31 | Monetary and nonmonetary motivation [15] | 31 | Design thinking [61] |

| 32 | Support continuous tracking of issues and indicators [11,60] | 32 | Kaizen/continuous improvement/ kaizen event [11,15,17,60,67,78] |

| 33 | Promote transparent communication [11,60] | ||

| 34 | Searching for and developing innovative solutions with the users [55,61,71,72,73] | ||

| 35 | Encourages the discussion of problems and solutions [67] | ||

| 36 | Prioritizes continuous but durable improvements over time instead of more radical improvements [67]. | ||

| Focus or Benefits | Measured (Explicit) | Not Measured (Implicit) |

|---|---|---|

| Cost | [2,14,15,16,17,18,29,48,53,55,59,66,76,80,81,82,83] | [9,11,47] |

| Schedule | [2,14,18,48,55] | [11,76] |

| Value | Importance degree of value items [81]; reduction in design document drafting time [82]; energy savings [66]; 30% space reduction [15]; safety and quality metrics [18,55]; people metrics [55]; sustainable target values (STV) [14]; value perceived by different groups of stakeholders: 1 to 5 scale [5]; value ranking analysis of key construction factors [59,80]. | Functionality, durability/maintainability, and buildability requirements [47]; relocate the building from its initial location, quality of the facility produced [48]; design innovations, increased efficiency [53]; quality [9]; maximum long-term value for the customer, appropriate acoustics and lighting, flexibility, privacy for families and staff interaction [29] quality, performance [76]; benefits perceived, aesthetics, lighting, larger helipad… [18]; significant value for the project [12] performance, sustainability, value [11]; improvements in the design–build process [77]. |

| Acronym | Meaning |

|---|---|

| TVD | Target value design |

| IC | Initial cost |

| TC | Target cost |

| AC | Allowable cost |

| VAM | Value analysis model |

| DVI | Desired value index |

| DVG | Desired value generated |

| DVL | Desired value loss |

| DVFP | Desired value fulfillment percentage |

| PVI | Potential value index |

| PVG | Potential value generated |

| PVL | Potential value loss |

| PVFP | Potential value fulfillment percentage |

| W | Weighting factor |

| M | Must-be attributes |

| O | One-dimensional attributes |

| R | Reverse attributes |

| A | Attractive attributes |

| I | Indifferent attributes |

| Cost Measurement | Value Measurement | |

|---|---|---|

| TVD Pre-implementation |

|

|

| TVD implementation |

|

|

| TVD Post-implementation |

|

|

| Attributes | Value | |

|---|---|---|

| Present | Absent | |

| M | 0 * | −1 |

| O | +1 * | −1 |

| R | −1 | +1 * |

| A | +1 | 0 * |

| I | 0 | 0 |

| Committee | Participation in Total Budget (%) | TC-IC Gap (Thousands USD) | Cost Reduction Achieved (Thousands USD) | Cost Reduction Achieved (% of Gap) |

|---|---|---|---|---|

| Structure and urban development | 28.60% | 75.6 | 165.72 | 219% |

| Finishes | 38.80% | 102.5 | 27.25 | 27% |

| MEP | 19.70% | 52.1 | 150.56 | 289% |

| Logistics | 13.00% | 34.3 | 25.21 | 73% |

| Total | 100.00% | 265.64 | 368.74 | 139% |

| Product | Process | |||||||

|---|---|---|---|---|---|---|---|---|

| Customer | Total Project | Customer | Total Project | |||||

| Owner | Designers | Builders | Owner | Designers | Builders | |||

| W | 41.6% | 27.6% | 30.8% | 100% | 41.6% | 27.6% | 30.8% | 100% |

| DVI | 0.79 | 0.25 | 0.29 | 0.49 | 0.27 | 0.20 | 0.13 | 0.21 |

| PVI | 1.00 | 0.63 | 0.42 | 0.72 | 0.40 | 0.40 | 0.33 | 0.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giménez, Z.; Mourgues, C.; Alarcón, L.F.; Mesa, H. Exploring Value Generation in Target Value Design Applying a Value Analysis Model. Buildings 2022, 12, 922. https://doi.org/10.3390/buildings12070922

Giménez Z, Mourgues C, Alarcón LF, Mesa H. Exploring Value Generation in Target Value Design Applying a Value Analysis Model. Buildings. 2022; 12(7):922. https://doi.org/10.3390/buildings12070922

Chicago/Turabian StyleGiménez, Zulay, Claudio Mourgues, Luis F. Alarcón, and Harrison Mesa. 2022. "Exploring Value Generation in Target Value Design Applying a Value Analysis Model" Buildings 12, no. 7: 922. https://doi.org/10.3390/buildings12070922

APA StyleGiménez, Z., Mourgues, C., Alarcón, L. F., & Mesa, H. (2022). Exploring Value Generation in Target Value Design Applying a Value Analysis Model. Buildings, 12(7), 922. https://doi.org/10.3390/buildings12070922