Effects of Various Pseudomonas Bacteria Concentrations on the Strength and Durability Characteristics of Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cement, Sand, Aggregate, and Water

2.2. Pseudomonas Bacteria

2.3. Culturing Process of Bacteria

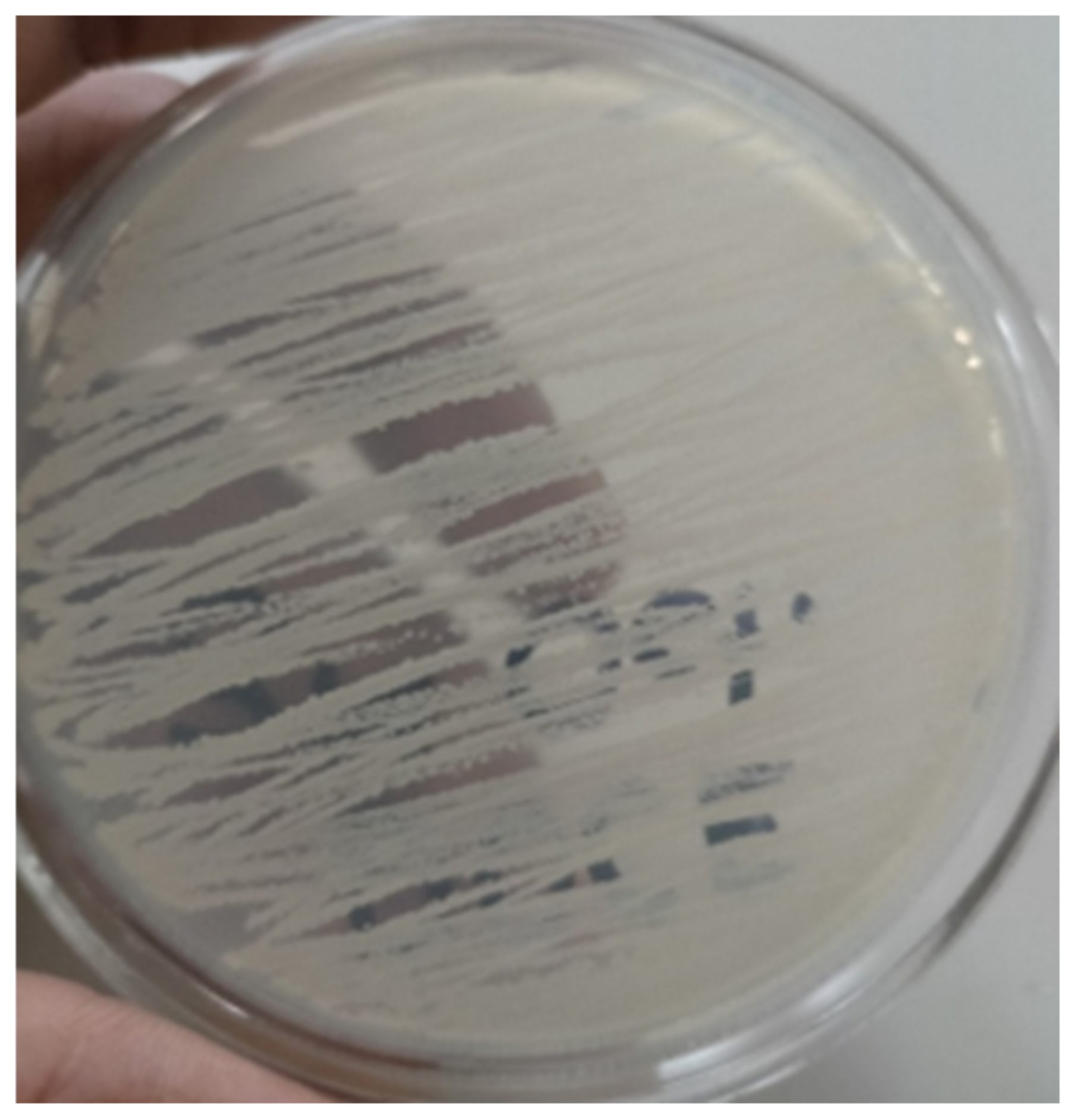

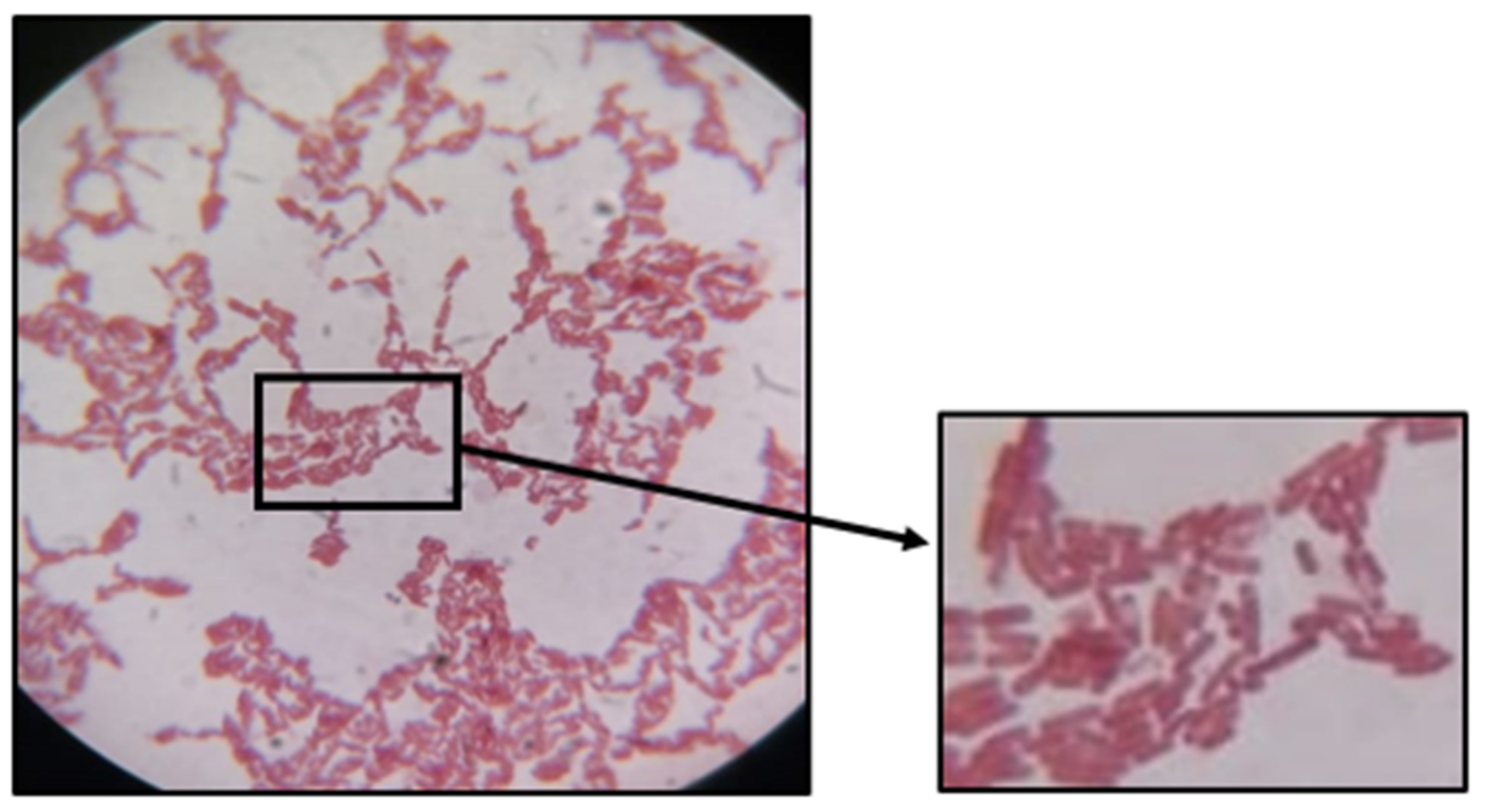

Gram Staining

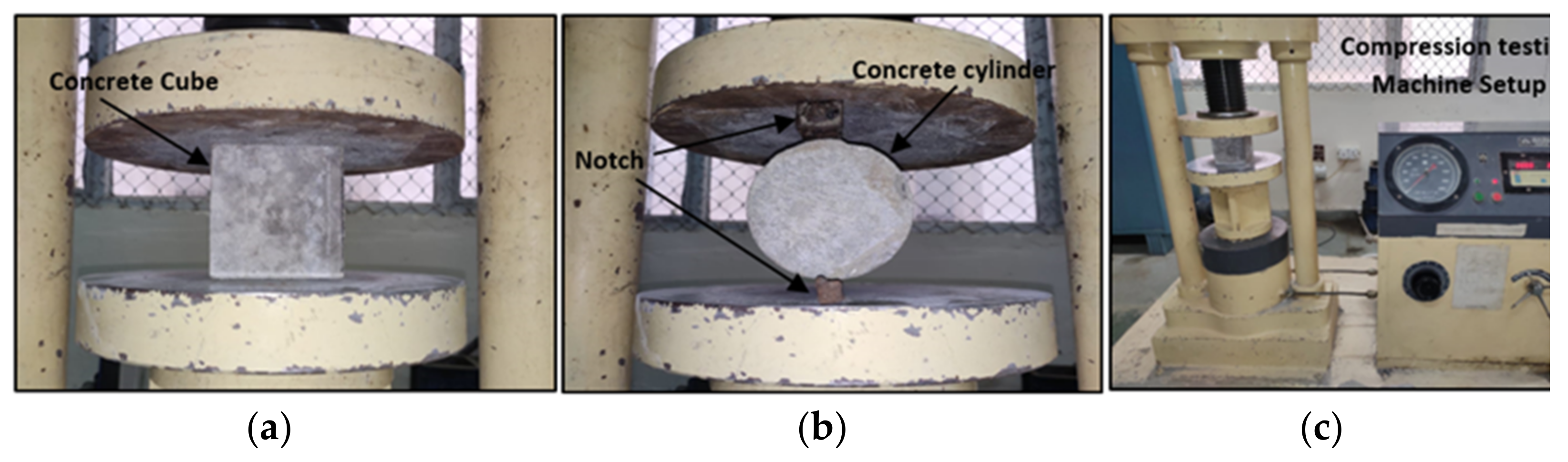

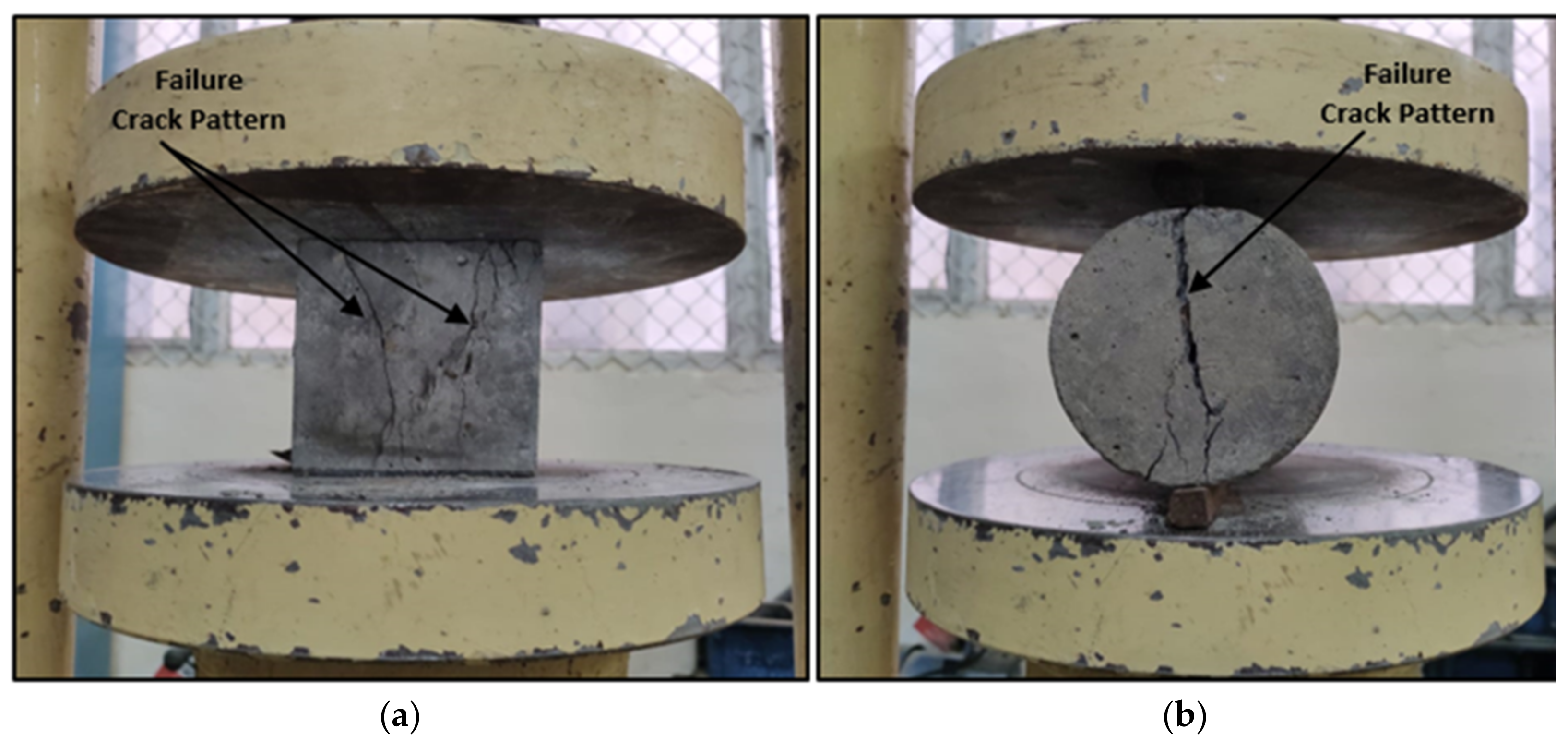

2.4. Compressive Strength

2.5. Split Tensile Strength

2.6. Acid Attack and Sulphate Attack

3. Discussion of Test Results

3.1. Effect of Bacterial Solution on Compressive Strength and Split Tensile Strength

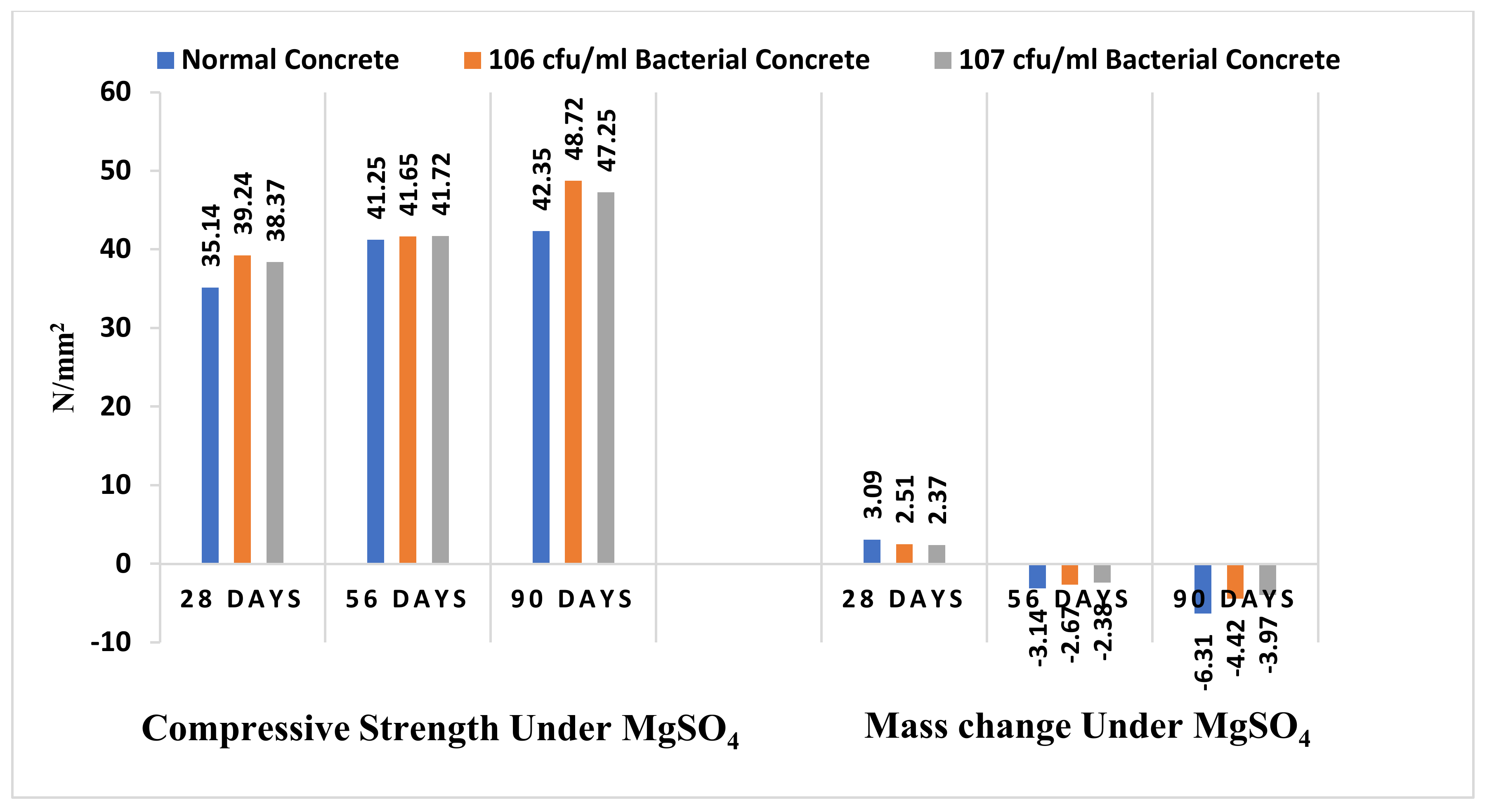

3.2. Effect of H2SO4 and MgSO4 Attack on Pseudomonas Bacterial Concrete

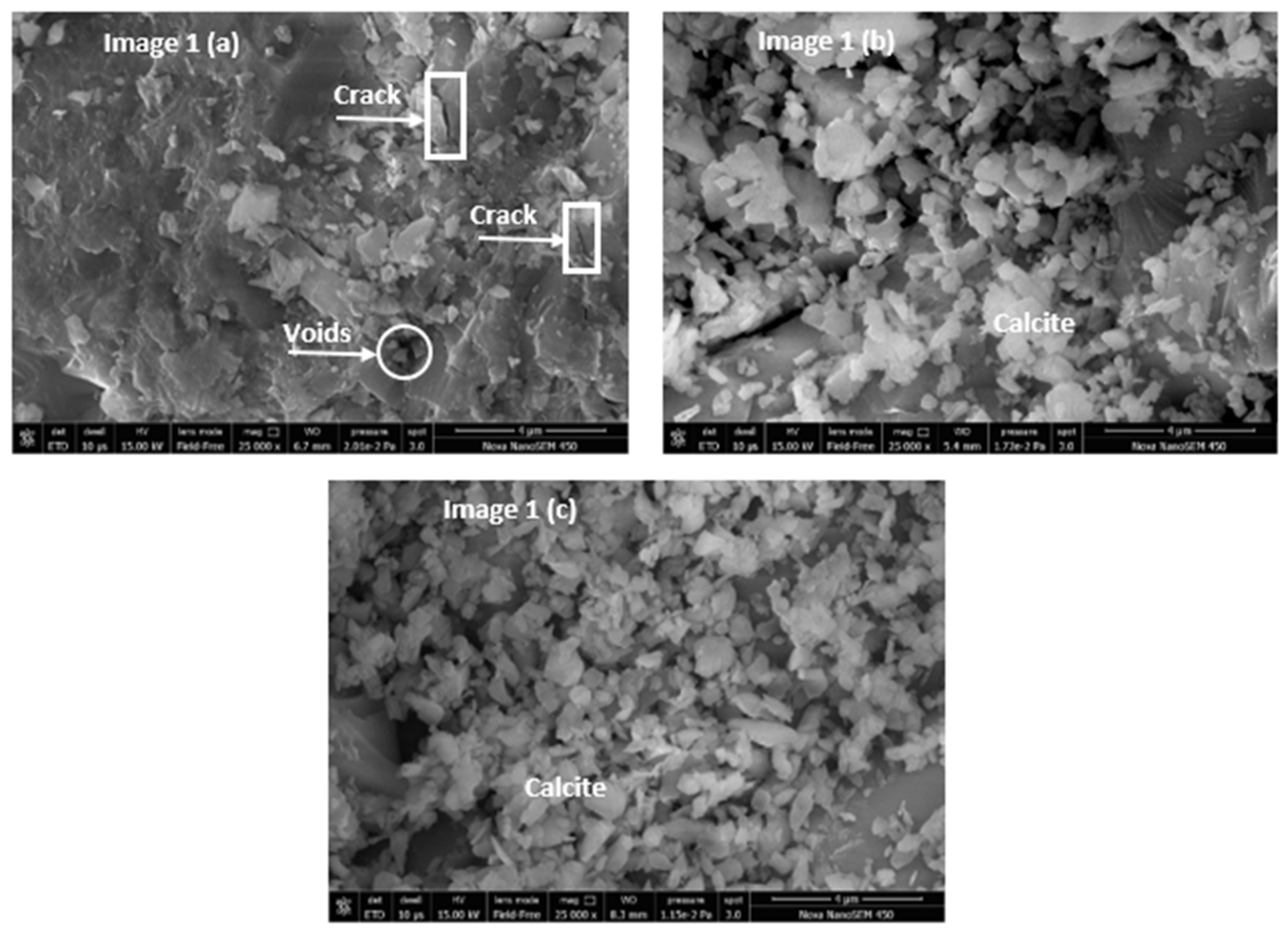

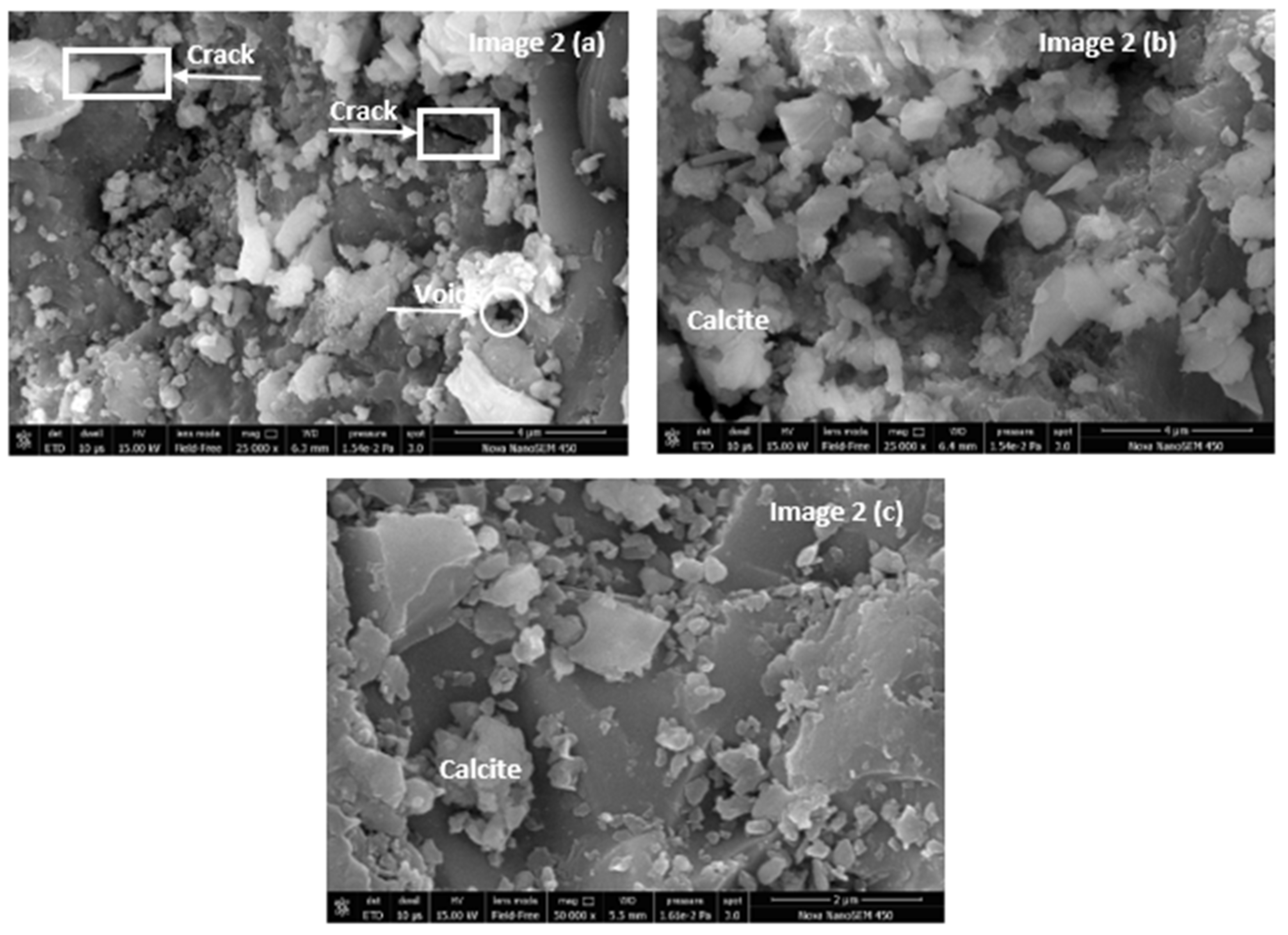

3.3. Scanning Electronic Microscopy (SEM)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, H.J.; Eom, H.J.; Park, C.; Jung, J.; Shin, B.; Kim, W.; Chung, N.; Choi, I.-G.; Park, W. Calcium carbonate precipitation by Bacillus and Sporosarcina strains isolated from concrete and analysis of the bacterial community of concrete. J. Microbiol. Biotechnol. 2015, 26, 540–548. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shukla, A.; Gupta, N.; Kishore, K. Experimental investigation on the effect of steel fiber embedded in marble dust based concrete. Mater. Today Proc. 2020, 26, 2938–2945. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kim, H.J.; Park, W. Non-ureolytic calcium carbonate precipitation by Lysinibacillus sp. YS11 isolated from the rhizosphere of Miscanthus sacchariflorus. J. Microbiol. 2017, 55, 440–447. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, M.; Adak, D.; Tamang, A.; Chattopadhyay, B.; Mandal, S. Genetically-enriched microbe-facilitated self-healing concrete—A sustainable material for a new generation of construction technology. RSC Adv. 2015, 5, 105363–105371. [Google Scholar] [CrossRef]

- Talaiekhozan, A.; Fulazzaky, M.A.; Keyvanfar, A.; Andalib, R.; Zaimi, M.; Majid, A. Identification of gaps to conduct a study on biological self-healing concrete. J. Environ. Treat. Tech. 2013, 1, 62–68. [Google Scholar]

- Ahdash, A.I.S. Zeolite/Polyaniline Based Self-Healing and Silicon Oxide Coatings for Microbially Induced Corrosion Inhibition. Ph.D. Thesis, Universiti Teknologi Malaysia, Skudai, Malaysia, 2016. [Google Scholar]

- Manikandan, A.T.; Padmavathi, A. An experimental investigation on improvement of concrete serviceability by using bacterial mineral precipitation. Int. J. Res. Sci. Innov. 2015, 2, 46–49. [Google Scholar]

- Erşan, Y.Ç; Hernandez-Sanabria, E.; Boon, N.; de Belie, N. Enhanced crack closure performance of microbial mortar through nitrate reduction. Cem. Concr. Compos. 2016, 70, 159–170. [Google Scholar] [CrossRef]

- Wang, J.Y.; De Belie, N.; Verstraete, W. Diatomaceous earth as a protective vehicle for bacteria applied for self-healing concrete. J. Ind. Microbiol. Biotechnol. 2012, 39, 567–577. [Google Scholar] [CrossRef] [PubMed]

- Erşan, Y.Ç.; Boon, N.; Belie, N.D. Microbial self-healing concrete: Denitrification as an enhanced and environment-friendly approach. In Proceedings of the 5th International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015. [Google Scholar]

- Chattopadhyay, B. Genetically-enriched microbe-facilitated self-healing nano-concrete. In Smart Nanoconcretes and Cement-Based Materials: Properties, Modelling and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Alazhari, M.; Sharma, T.; Heath, A.; Cooper, R.; Paine, K. Application of expanded perlite encapsulated bacteria and growth media for self-healing concrete. Constr. Build. Mater. 2018, 160, 610–619. [Google Scholar] [CrossRef]

- De Belie, N.; Wang, J. Bacteria-based repair and self-healing of concrete. J. Sustain. Cem.-Based Mater. 2015, 5, 35–56. [Google Scholar] [CrossRef]

- Schreiberová, H.; Kohoutková, A.; Bílý, P.; Ryparová, P. Bio-based self-healing concrete: A review. In Proceedings of the 12th Fib International PhD Symposium in Civil Engineering, Prague, Czech Republic, 29–31 August 2018; pp. 1169–1176. [Google Scholar]

- Sharma, P. A study on self-healing mechanism of microcracks in concrete structures using bacillus bacteria. Int. J. Sci. Res. Sci. Eng. Technol. 2016, 2, 6–13. [Google Scholar]

- Santos, R.P.; Ramos, T.M.; Borges, B.M.; Hollanda, L.M.; Lima, Á.S.; Soares, C.M.F.; Souza, R.L. A selected bacterial strain for the self-healing process in cementitious specimens without cell immobilization steps. Bioprocess Biosyst. Eng. 2021, 44, 195–208. [Google Scholar] [CrossRef] [PubMed]

- Sharma, N.; Sharma, P. Effect of hydrophobic agent in cement and concrete: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1116, 012175. [Google Scholar] [CrossRef]

- Parashar, A.K.; Gupta, A. Investigation of the effect of bagasse ash, hooked steel fibers and glass fibers on the mechanical properties of concrete. Mater. Today Proc. 2021, 44, 801–807. [Google Scholar] [CrossRef]

- Shaheen, N.; Khushnood, R.A.; Khaliq, W.; Murtaza, H.; Iqbal, R.; Khan, M.H. Synthesis and characterization of bio-immobilized nano/micro inert and reactive additives for feasibility investigation in self-healing concrete. Constr. Build. Mater. 2019, 226, 492–506. [Google Scholar] [CrossRef]

- De Belie, N. Application of bacteria in concrete: A critical evaluation of the current status. RILEM Tech. Lett. 2016, 1, 56. [Google Scholar] [CrossRef] [Green Version]

- Souradeep, G.; Kua, H.W. Encapsulation technology and techniques in self-healing concrete. J. Mater. Civ. Eng. 2016, 28, 04016165. [Google Scholar] [CrossRef]

- Erşan, Y.Ç. Self-healing performance of biogranule containing microbial self-healing concrete under intermittent wet/dry cycles. J. Polytech. 2020, 24, 323–332. [Google Scholar] [CrossRef]

- Jakubovskis, R.; Jankutė, A.; Urbonavičius, J.; Gribniak, V. Analysis of mechanical performance and durability of self-healing biological concrete. Constr. Build. Mater. 2020, 260, 119822. [Google Scholar] [CrossRef]

- Mohammed, H.; Ortoneda-Pedrola, M.; Nakouti, I.; Bras, A. Experimental characterisation of non-encapsulated bio-based concrete with self-healing capacity. Constr. Build. Mater. 2020, 256, 119411. [Google Scholar] [CrossRef]

- Shukla, A.; Gupta, N. Study on the efficacy of natural pozzolans in cement mortar. In Calcined Clays for Sustainable Concrete; Springer: Berlin/Heidelberg, Germany, 2020; pp. 469–480. [Google Scholar] [CrossRef]

- Gupta, N.; Gupta, A.; Saxena, K.K.; Shukla, A.; Goyal, S.K. Mechanical and durability properties of geopolymer concrete composite at varying superplasticizer dosage. Mater. Today Proc. 2021, 44, 12–16. [Google Scholar] [CrossRef]

- Jena, S.; Panda, K.C. Effect of bacteria on the properties of concrete—A review. In Proceedings of the UKIERI Concrete Congress: Concrete: The Global Builder, Jalandhar, India, 5–8 March 2019. [Google Scholar]

- Jayaprakash, J. In Advances in Construction Materials and system. In Proceedings of the International Conference (ICACMS), Chennai, India, 3–8 September 2017. [Google Scholar]

- Lee, Y.S.; Park, W. Current challenges and future directions for bacterial self-healing concrete. Appl. Microbiol. Biotechnol. 2018, 102, 3059–3070. [Google Scholar] [CrossRef] [PubMed]

- Joshi, S.; Goyal, S.; Mukherjee, A.; Reddy, M.S. Microbial healing of cracks in concrete: A review. J. Ind. Microbiol. Biotechnol. 2017, 44, 1511–1525. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.G.; Rathi, C.; Kapur, S. Biologically induced self healing concrete: A futuristic solution for crack repair. Int. J. Appl. Sci. Biotechnol. 2013, 1, 85–89. [Google Scholar] [CrossRef] [Green Version]

- Ryu, Y.; Lee, K.-E.; Cha, I.-T.; Park, W. Optimization of bacterial sporulation using economic nutrient for self-healing concrete. J. Microbiol. 2020, 58, 288–296. [Google Scholar] [CrossRef] [PubMed]

- Kiranmaye, B.R.; Dutta, J.R.; Kar, A.; Parimi, C.; Raju, S. Optimization of culture parameters of Pseudomonas alcaligenes for crack healing in concrete. Mater. Today Proc. 2019, 28, 713–716. [Google Scholar] [CrossRef]

- Erşan, Y.C.; Akın, Y. Optimizing nutrient content of microbial self-healing concrete. In Life-Cycle Analysis and Assessment in Civil Engineering: Towards an Integrated Vision—Proceedings of the 6th International Symposium on Life-Cycle Civil Engineering, IALCCE 2018, Ghent, Belgium, 28–31 October 2018; CRC Press: Boca Raton, FL, USA, 2018; pp. 2241–2246. [Google Scholar]

- Nonakaran, S.H.; Pazhouhandeh, M.; Keyvani, A.; Abdollahipour, F.Z.; Shirzad, A. Isolation and identification of Pseudomonas azotoformans for induced calcite precipitation. World J. Microbiol. Biotechnol. 2015, 31, 1993–2001. [Google Scholar] [CrossRef]

- Parashar, A.K.; Gupta, A. Effects of the concentration of various bacillus family bacteria on the strength and durability properties of concrete: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1116, 012162. [Google Scholar] [CrossRef]

- Parashar, A.K.; Gupta, A. Experimental study of the effect of bacillus megaterium bacteria on cement concrete. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1116, 012168. [Google Scholar] [CrossRef]

- IS 516; Method of Tests for Strength of Concrete. Bureau of Indian Standards: New Dehli, India, 2018. [CrossRef]

- Paknahad, A.; Kucko, N.W.; Leeuwenburgh, S.C.; Sluys, L.J. Experimental and numerical analysis on bending and tensile failure behavior of calcium phosphate cements. J. Mech. Behav. Biomed. Mater. 2020, 103, 103565. [Google Scholar] [CrossRef]

- Paknahad, A.; Goudarzi, M.; Kucko, N.W.; Leeuwenburgh, S.C.G.; Sluys, L.J. Calcium phosphate cement reinforced with poly (vinyl alcohol) fibers: An experimental and numerical failure analysis. Acta Biomater. 2021, 119, 458–471. [Google Scholar] [CrossRef] [PubMed]

- Erşan, Y.Ç; Verbruggen, H.; De Graeve, I.; Verstraete, W.; De Belie, N.; Boon, N. Nitrate reducing CaCO3 precipitating bacteria survive in mortar and inhibit steel corrosion. Cem. Concr. Res. 2016, 83, 19–30. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shukla, A.; Gupta, N.; Dixit, S.; Ivanovich Vatin, N.; Gupta, M.; Saxena, K.K.; Prakash, C. Effects of Various Pseudomonas Bacteria Concentrations on the Strength and Durability Characteristics of Concrete. Buildings 2022, 12, 993. https://doi.org/10.3390/buildings12070993

Shukla A, Gupta N, Dixit S, Ivanovich Vatin N, Gupta M, Saxena KK, Prakash C. Effects of Various Pseudomonas Bacteria Concentrations on the Strength and Durability Characteristics of Concrete. Buildings. 2022; 12(7):993. https://doi.org/10.3390/buildings12070993

Chicago/Turabian StyleShukla, Ashish, Nakul Gupta, Saurav Dixit, Nikolai Ivanovich Vatin, Manish Gupta, Kuldeep Kumar Saxena, and Chander Prakash. 2022. "Effects of Various Pseudomonas Bacteria Concentrations on the Strength and Durability Characteristics of Concrete" Buildings 12, no. 7: 993. https://doi.org/10.3390/buildings12070993