Cementitious Insulated Drywall Panels Reinforced with Kraft-Paper Honeycomb Structures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

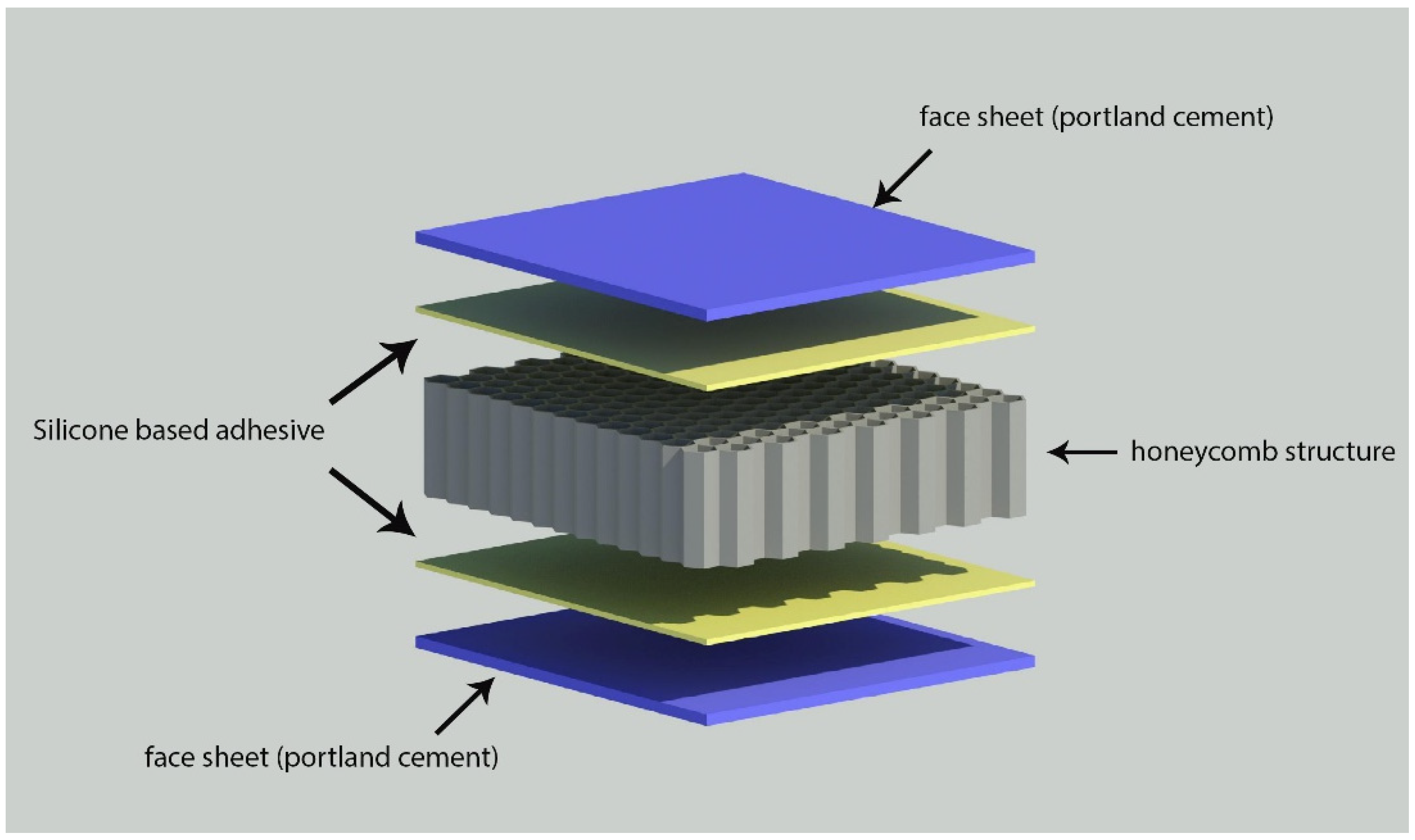

2.2. Sample Preparation

2.3. Flexural Analysis

2.4. Thermal Analysis

2.5. Density Measurement

2.6. Water Vapour Transmission

3. Results

3.1. Flexural Analysis

3.2. Thermal Analysis

3.3. Density Measurement

3.4. Water Vapour Transmission

4. Conclusions

- The incorporation of flax fibres into the Portland Cement mixtures increases samples’ stiffness and prolongs the early stage cracking of non-flax-fibre specimens. These significant enhancements are because of the unique properties of flax fibres in resisting greater bending and fracture forces than the brittle Portland Cement mixtures. Particularly, the 19.05 mm kraft-paper honeycomb structure has approximately 41% higher flexural performance than the kraft-paper honeycomb sandwich panel with a thickness of 10.16 mm. As both the sandwich thickness and core thickness factors influence the maximal strength, the sample with a thicker core tolerated higher loads better than a thin sample. In addition, increasing the core thickness resulted in higher stiffness and resistance against bending loads due to the higher moment of inertia.

- Due to flax fibres’ lower thermal conductivity and better thermal insulation properties, all flax-fibre-reinforced panels exhibited lower thermal conductivity than the gypsum-based drywall. However, the thermal conductivity of showed a greater reduction, e.g., by 42%, compared to the gypsum board. The thermal analysis results confirmed that the samples’ air volume increased by raising the thickness of the sample. Therefore, effectively decreased the coefficient of thermal conductivity compared to in different temperatures and is more resistant against a heat flow due to its higher embodied porosity. The results indicated that the thermal conductivity of as a function of temperature, ranging from −10 to 80 °C, is relatively 5.4% higher than the thermal conductivity of

- The density measurements carried out on kraft-paper honeycomb sandwich panels showed a reduction in density by adding flax fibres to the cementitious boards. In addition, for equal fibre content, the density of the sample with a thick honeycomb core is approximately 24% lower than that of This remains possible due to the highest average volume and larger void volume in samples compared to the specimens with a thicker core.

- The water vapour transmission and permeance analysis indicated that samples with a core thickness of 19.05 mm had lower values, with the amounts of 8.88 g/h·m2 and 1.291 perms, respectively, in comparison to the . sample. In effect, as the kraft-paper honeycomb is a closed-cell structure, the diffusion mechanism mainly affects the rate of water vapour transmission. Therefore, samples with thick cores exhibited a greater decrease in the amount of water vapour diffusion and permeance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gencel, O.; del Coz Diaz, J.J.; Sutcu, M.; Koksal, F.; Álvarez Rabanal, F.P.; Martínez-Barrera, G. A novel lightweight gypsum composite with diatomite and polypropylene fibers. Constr. Build. Mater. 2016, 113, 732–740. [Google Scholar] [CrossRef]

- Eve, S.; Gomina, M.; Gmouh, A.; Samdi, A.; Moussa, R.; Orange, G. Microstructural and mechanical behaviour of polyamide fibre-reinforced plaster composites. J. Eur. Ceram. Soc. 2002, 22, 2269–2275. [Google Scholar] [CrossRef]

- Ghazi Wakili, K.; Hugi, E.; Wullschleger, L.; Frank, T.H. Gypsum Board in Fire—Modeling and Experimental Validation. J. Fire Sci. 2007, 25, 267–282. [Google Scholar] [CrossRef]

- Norgaard, J.; Othuman Mydin, M.A. Drywall Thermal Properties Exposed to High Temperatures and Fire Condition. J. Teknol. Sci. Eng. 2013, 62, 63–68. [Google Scholar] [CrossRef]

- Andersen, B.; Frisvad, J.C.; Sondergaard, I.; Rasmussen, I.S.; Larsen, L.S. Associations between fungal species and water-damaged building materials. Appl. Environ. Microbiol. 2011, 77, 4180–4188. [Google Scholar] [CrossRef] [PubMed]

- Kazemian, N. Environmental Factors Influencing Fungal Growth on Gypsum Boards and their Biodegradation: A University Campus Case Study. Univ. Br. Columbia 2014, 14, e0220556. [Google Scholar] [CrossRef]

- Gandage, A.S.; Rao, V.R.V.; Sivakumar, M.V.N.; Vasan, A.; Venu, M.; Yaswanth, A.B. Effect of Perlite on Thermal Conductivity of Self Compacting Concrete. Procedia-Soc. Behav. Sci. 2013, 104, 188–197. [Google Scholar] [CrossRef]

- Koksal, F.; Gencel, O.; Kaya, M. Combined effect of silica fume and expanded vermiculite on properties of lightweight mortars at ambient and elevated temperatures. Constr. Build. Mater. 2015, 88, 175–187. [Google Scholar] [CrossRef]

- Kang, Y.; Chang, S.J.; Kim, S. Hygrothermal behavior evaluation of walls improving heat and moisture performance on gypsum boards by adding porous materials. Energy Build. 2018, 165, 431–439. [Google Scholar] [CrossRef]

- Serhat Başpınar, M.; Kahraman, E. Modifications in the properties of gypsum construction element via addition of expanded macroporous silica granules. Constr. Build. Mater. 2011, 25, 3327–3333. [Google Scholar] [CrossRef]

- Maskell, D.; Church, M.; Thomson, A.; Walker, P.; Robinson, T. An Alternative to Gypsum Plasterboard. In Proceedings of the 8th International Conference on Structural Engineering and Construction Management 2017, Kandy, Sri Lanka, 7–10 December 2017; pp. 93–99. [Google Scholar]

- Triantafillou, T.C.; Gibson, L.J. Failure mode maps for foam core sandwich beams. Mater. Sci. Eng. 1987, 95, 37–53. [Google Scholar] [CrossRef]

- Shir Mohammadi, M.; Nairn, J.A. Balsa sandwich composite fracture study: Comparison of laminated to solid balsa core materials and debonding from thick balsa core materials. Compos. Part B Eng. 2017, 122, 165–172. [Google Scholar] [CrossRef]

- Banerjee, S.; Bhattacharyya, D. Optimal design of sandwich panels made of wood veneer hollow cores. Compos. Sci. Technol. 2011, 71, 425–432. [Google Scholar] [CrossRef]

- Cooke, G. Fire safety considerations in the design of structural sandwich panels. Build. Res. Establ. 1987, 4, 540–543. [Google Scholar]

- Cooke, G. Stability of lightweight structural sandwich panels exposed to fire. Struct. Fire 2004, 28, 299–308. [Google Scholar] [CrossRef]

- Coutts, R.S.P. Flax fibres as a reinforcement in cement mortars. Int. J. Cem. Compos. Light. Concr. 1983, 5, 257–262. [Google Scholar] [CrossRef]

- Tricel, Honeycomb Cores Since 1982, Tricel Honeycomb Corperation. 2021. Available online: https://www.tricelcorp.com/ (accessed on 6 May 2021).

- Ahmad, J.; Majdi, A.; Al-Fakih, A.; Deifalla, A.F.; Althoey, F.; El Ouni, M.H.; El-Shorbagy, M.A. Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art Review. Materials 2022, 15, 3601. [Google Scholar] [CrossRef]

- Majstorović, F.; Sebera, V.; Mrak, M.; Dolenec, S.; Wolf, M.; Marrot, L. Impact of metakaolin on mechanical performance of flax textile-reinforced cement-based composites. Cem. Concr. Compos. 2022, 126, 104367. [Google Scholar] [CrossRef]

- ASTM C305-14; Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. ASTM Int.: West Conshohocken, PA, USA, 2014.

- Moudood, A.; Rahman, A.; Ochsner, A.; Islam, M.; Francucci, G. Flax fiber and its composites: An overview of water and moisture absorption impact on their performance. J. Reinf. Plast. Compos. 2018, 38, 2019. [Google Scholar] [CrossRef]

- ASTM C393/C393M-20; Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure. ASTM Int.: West Conshohocken, PA, USA, 2020.

- Hahn, M.H.; Robinson, H.E.; Flynn, D.R. Robinson Line-Heat-Source Guarded Hot Plate Apparatus. In Heat Transmission Measurements in Thermal Insulations; Tye, R.P., Ed.; ASTM International: West Conshohocken, PA, USA, 1974; pp. 167–192. ISBN 978-0-8031-4638-9. [Google Scholar]

- Bomberg, M.; Solvason, K.R. Discussion of Heat Flow Meter Apparatus and Transfer Standards Used for Error Analysis. In Guarded Hot Plate and Heat Flow Meter Methodology; Shirtliffe, C.J., Tye, R.P., Eds.; ASTM International: West Conshohocken, PA, USA, 1985; pp. 140–153. ISBN 978-0-8031-4944-1. [Google Scholar]

- ASTM C518-17; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. ASTM Int.: West Conshohocken, PA, USA, 2017.

- TA Instruments. TA Instruments Fox 600. Available online: https://www.tainstruments.com/fox-600/ (accessed on 6 May 2012).

- Girardi, G. Measurement of Thermal Conductivity of Smaller Thermal Insulation Specimens Using Standard Heat Flow Meter Apparatus; Carleton University: Ottawa, ON, Canda, 2013. [Google Scholar]

- ASTM C271; Standard Test Method for Density of Sandwich Core Materials. ASTM Int.: West Conshohocken, PA, USA, 2000.

- Togkalidou, T.; Karoglou, M.; Bakolas, A.; Giakoumaki, A.; Moropoulou, A. Correlation of Water Vapor Permeability with Microstructure Characteristics of Building Materials Using Robust Chemometrics. Transp. Porous Media 2013, 99, 273–295. [Google Scholar] [CrossRef]

- ASTM E96-93; Standard Test Methods for Water Vapor Transmission of Materials. ASTM Int.: West Conshohocken, PA, USA, 1993.

- ASTM E96/E96M-16; Standard Test Methods for Water Vapor Transmission of Materials. ASTM Int.: West Conshohocken, PA, USA, 2016.

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Gypsum Association. Gypsum Board Typical Mechanical and Physical Properties. 2019. Available online: https://inspectapedia.com/interiors/Gypsum-Board-Properties-Gypsum-Association.pdf (accessed on 20 February 2022).

- Lertwattanaruk, P.; Suntijitto, A. Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- Quintaliani, C.; Merli, F.; Fiorini, C.V.; Corradi, M.; Speranzini, E.; Buratti, C. Vegetal Fiber Additives in Mortars: Experimental Characterization of Thermal and Acoustic Properties. Sustainability 2022, 14, 1260. [Google Scholar] [CrossRef]

- Spray Polyurethane Foam Alliance. Moisture Vapor Transmision; Technical Committee. 1994. Available online: https://www.sprayfoamofmaine.com/pdf/MoistureVapor.pdf (accessed on 12 March 2022).

- Jones, D.; Brischke, C. Wood as bio-based building material. In Performance of Bio-based Building Materials; Woodhead Publishing: Sawston, UK, 2017; Chapter 2; pp. 21–96. [Google Scholar]

| Compound | Formula | % by Weight |

|---|---|---|

| Tricalcium silicate | C3S | 55% |

| Dicalcium silicate | C2S | 19% |

| Tricalcium aluminate | C3A | 10% |

| Tetracalcium aluminoferrite | C4AF | 7% |

| Name | Mix Design | Kraft-Paper Honeycomb Thickness (mm) | Flax Fibre (%) |

|---|---|---|---|

| Standard Portland Cement | 10.16 | - | |

| Standard Portland Cement | 19.05 | - | |

| Flax-reinforced Portland Cement | 10.16 | 1 | |

| Flax-reinforced Portland Cement | 19.05 | 1 |

| Sample | Average Strength (MPa) | Standard Deviation (MPa) |

|---|---|---|

| 0.87 | 0.40 | |

| 1.02 | 0.31 | |

| 1.55 | 0.13 | |

| 2.11 | 0.14 | |

| 1.8 | 0.45 |

| Sample | Average Volume (mm3) | Average Density (g/cm3) | Standard Deviation (g/cm3) |

|---|---|---|---|

| 178,360 | 0.99 | 0.085 | |

| 251,400 | 0.76 | 0.069 | |

| 250,000 | 0.89 | 0.068 | |

| 270,500 | 0.67 | 0.051 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahbazi, S.; Singer, N.; Majeed, M.; Kavgic, M.; Foruzanmehr, R. Cementitious Insulated Drywall Panels Reinforced with Kraft-Paper Honeycomb Structures. Buildings 2022, 12, 1261. https://doi.org/10.3390/buildings12081261

Shahbazi S, Singer N, Majeed M, Kavgic M, Foruzanmehr R. Cementitious Insulated Drywall Panels Reinforced with Kraft-Paper Honeycomb Structures. Buildings. 2022; 12(8):1261. https://doi.org/10.3390/buildings12081261

Chicago/Turabian StyleShahbazi, Sepideh, Nicholas Singer, Muslim Majeed, Miroslava Kavgic, and Reza Foruzanmehr. 2022. "Cementitious Insulated Drywall Panels Reinforced with Kraft-Paper Honeycomb Structures" Buildings 12, no. 8: 1261. https://doi.org/10.3390/buildings12081261

APA StyleShahbazi, S., Singer, N., Majeed, M., Kavgic, M., & Foruzanmehr, R. (2022). Cementitious Insulated Drywall Panels Reinforced with Kraft-Paper Honeycomb Structures. Buildings, 12(8), 1261. https://doi.org/10.3390/buildings12081261